Page 1

Operating Instructions XWA11V

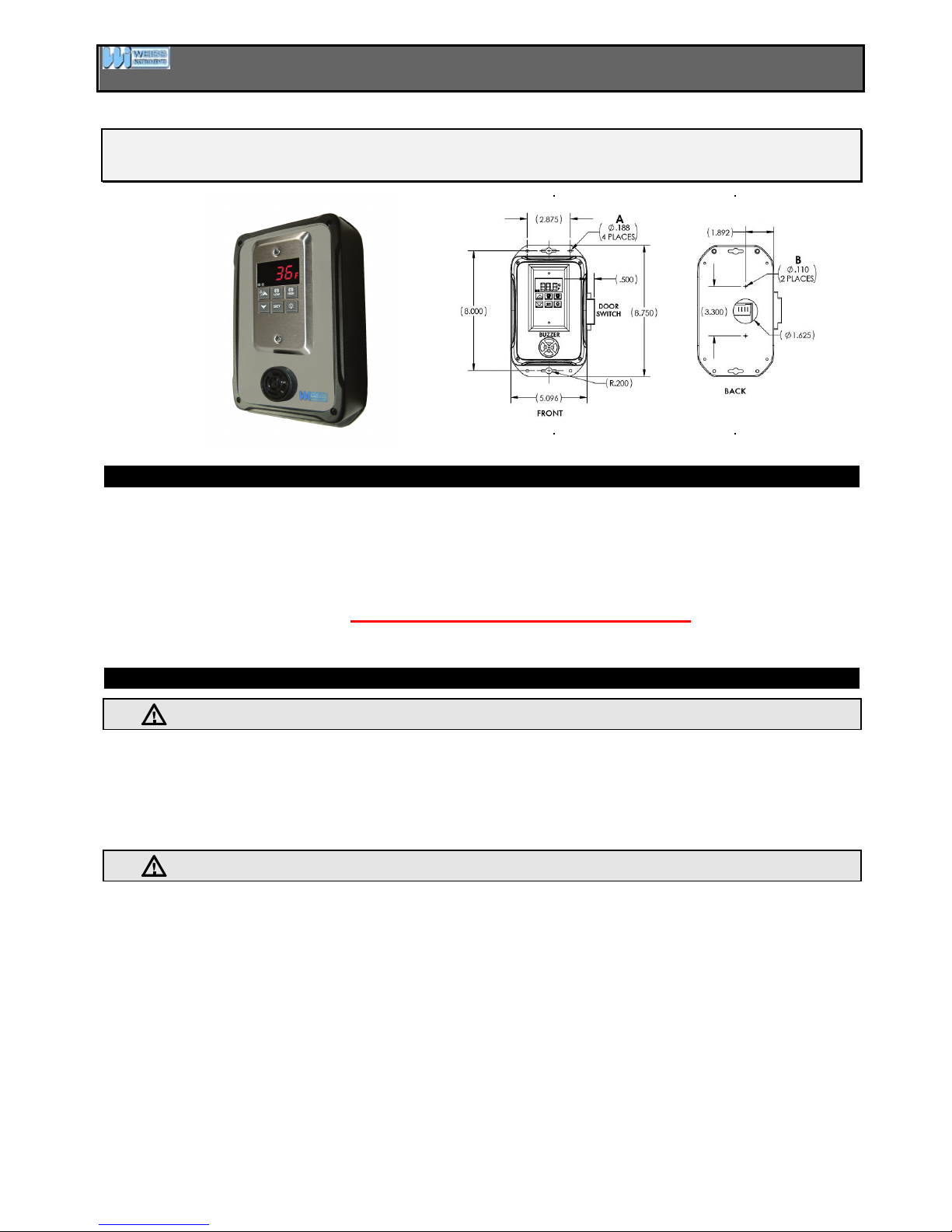

dIXELV8.8-KIT

XWA11V-KIT

Walk-In Temp / Door /Alarm / Light Module with Mounting Box and Wiring

1. GENERAL DESCRIPTION

Model XWA11V-KIT, 100x64 mm format, is a microprocessor based light and alarm management controller, suitable for

temperature monitoring in a walk-in cooler or freezer. It is provided with two (2) relay outputs that supply 120 Volts to

control lights and signal an alarm. It is also provided with one (1) NTC probe input for temperature measurement. To

ease installation on existing walk-in coolers the unit has been installed in a VBOX pre-wired with an outboard buzzer,

magnetic door switch (MDS), a 9V battery harness, a pigtail harness for the unit power and the light. There is also a five

pin port that allows the user to program the parameter list with a “Hot Key”.

Note: The default settings are listed in the back of this manual. They are set for Coolers (Medium

Temp). For Freezers (Low Temp) you MUST Change the ALL and ALU settings.

We have responded to many requests to make a change in the way the light key operates. It now

overrides the Digital Input to allow a manual OFF prior to the “Lht” being exhausted.

See Section 4.0

2. GENERAL WARNINGS

2.1 PLEASE READ BEFORE USING THIS PRODUCT

This manu

reference.

The instrument shall not be used for purposes different from those described hereunder. It cannot be used

as a safety device.

Check the applicatio n limits before proceeding

2.2 SAFETY PRECAUTIONS **READ ME FIRST!**

Check if the supply voltage is correct before connecting the instrument.

Do not expose the back of the instrument to w ater or moisture: use the controll er only within the operating limits

avoiding sudden temperature changes with high atmospheric humidity to prevent the form ation of condensation.

Be sure to seal any J-Box with RTV sealant to prevent cold and moisture intrusion.

Warning: disconnect all electrical connections before performing any maintenance operation.

Fit the probe where it is not damaged by the end-user. The instrument must not be opened.

In case of failure or faulty operation send the instrument back to the distributor (see address) with a detailed

description of the fault.

Consider the maximum current that can be applied to each relay (see Technic al Data).

Ensure that the wires for probes, loads and the power supply are separated and far enough from each other,

without crossing or intertwining or you may get bad temp readings.

The box supplied is not suitable for exterior use. If a water tight box is required co ntact the distributor.

al is part of the product and should be kept close to the instrument for easy and quick

.

(UL SPEC 0873)

Weiss Instruments,LLC. 905 Waverly Ave. Holtsville , NY 11742 631-207-1200 www.weissinstruments.com

1

Page 2

Operating Instructions XWA11V

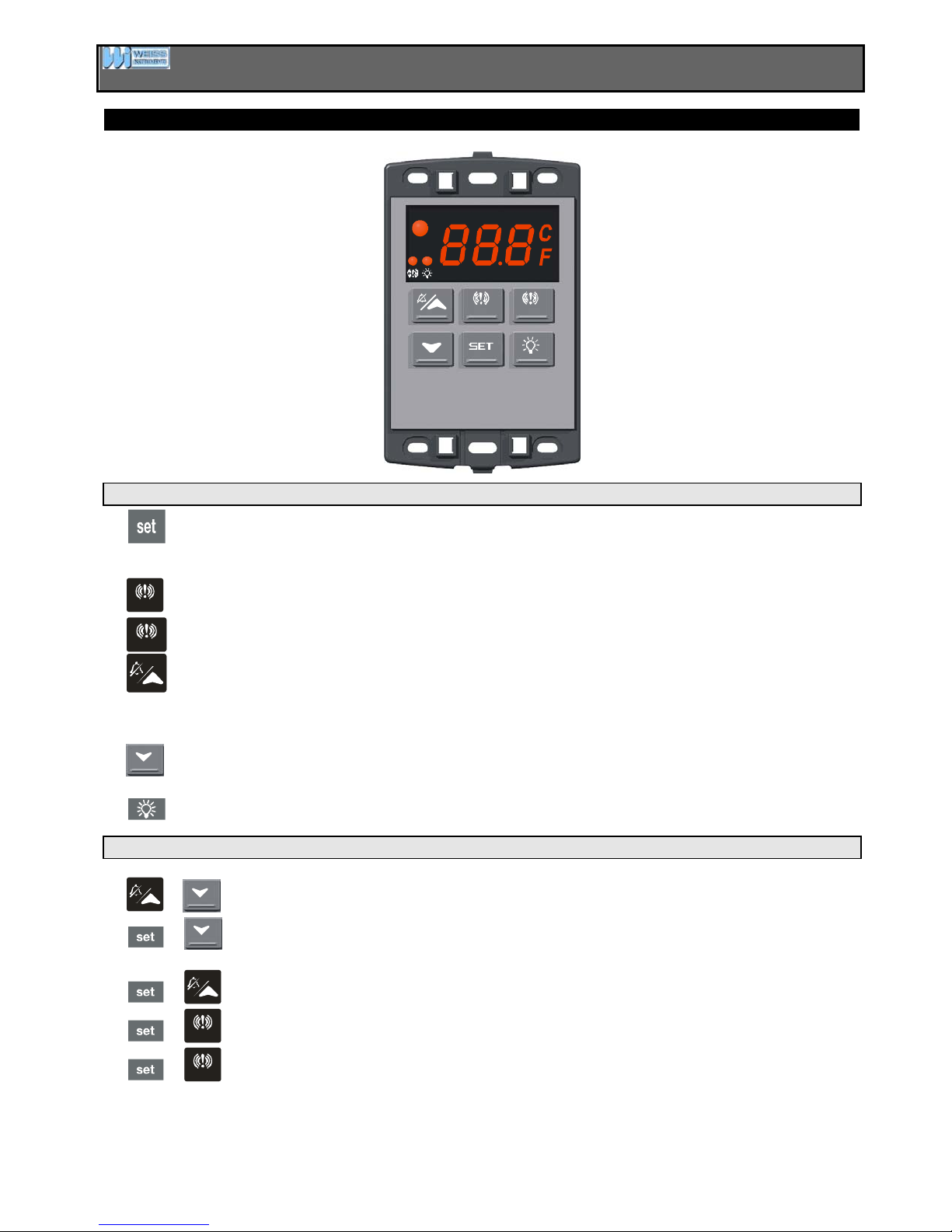

3. INTERFACE

LO W HI G H

3.1 KEY FRONT PANEL OPERATION

In Progra

Press and hold this key for more than 5 seconds to turn the controller OFF. (onF=y)

Press and hold this key for more than 1 second to turn the controller back ON.

mming Mode press to select a parameter or to confirm an operation.

dIXELV8.8-KIT

HIGH

Press to se

Press to se

LOW

In Progra

e the HIGH Temp ALARM (ALU parameter)

e the LOW Temp ALARM (ALL parameter)

mming Mode press to browse parameter codes.

Press to increase the displayed value.

Press to mute the buzzer (+ relay) when an ALARM is happening.

Hot key programming: with the instrument on, insert the hot key and then press

the UP button.

In Progra

mming Mode press to browse parameter codes.

Press to decreases the displayed value.

Switch O

N and OFF the light of the cold room

3.2 KEY COMBINATIONS: PRESS SIMULTANEOUSLY

+

+

+

HIGH

+

LOW

+

To lock and unlock the Keyboard.

To enter the

To exit the Progra

To enter a n

To enter a n

Programming

Mode.

mming Mode.

ew value for the HIGH Temp ALARM (ALU).

ew value for the LOW Temp ALARM (ALL

).

Weiss Instruments, LLC. 905 Waverly Ave. Holtsville , NY 11742 631-207-1200 www.weissinstruments.com

2

Page 3

Operating Instructions XWA11V

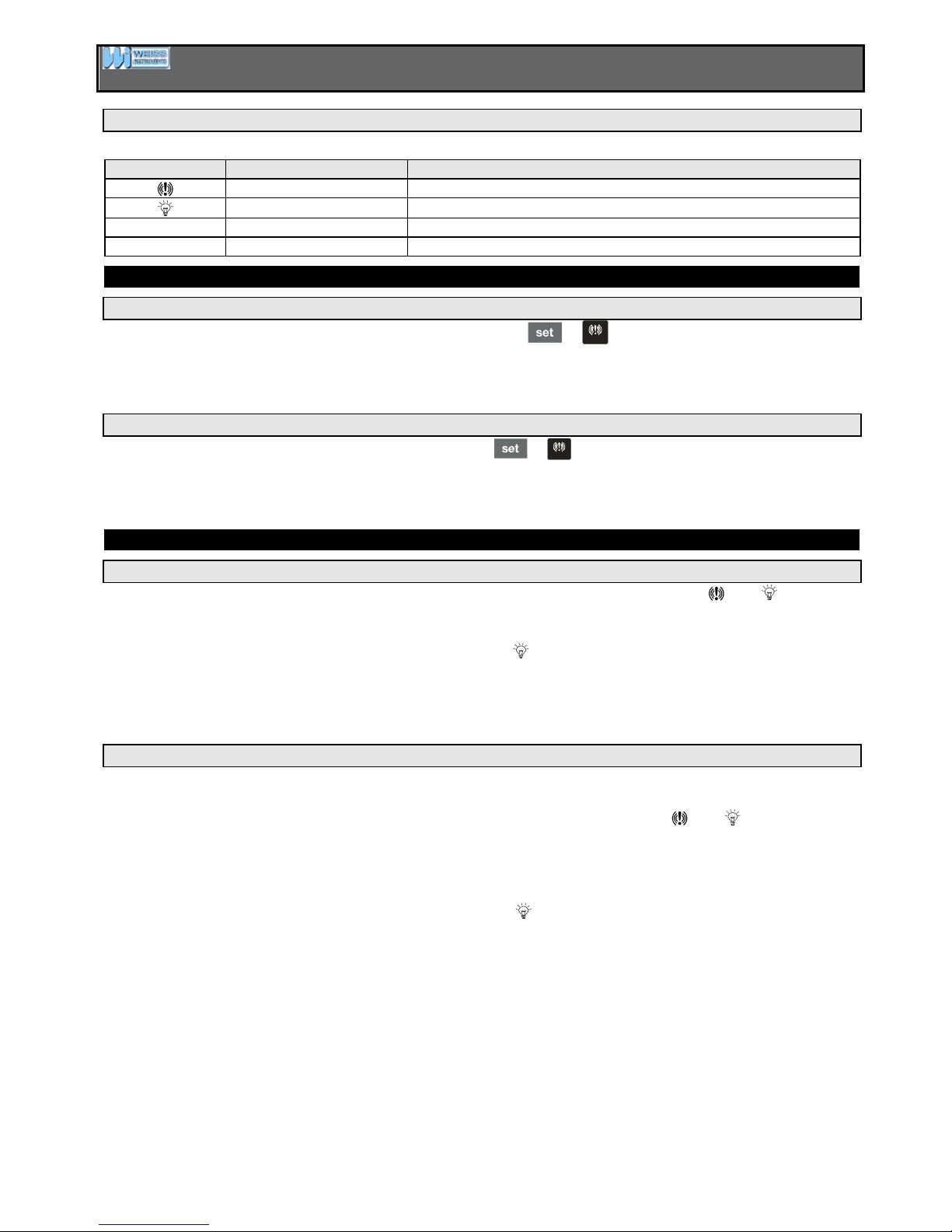

3.3 USE OF LEDS

Each LED function is described in the following table:

LED MODE Function

N

O

ON

ARM signalin

AL

The light is on

°C ON Celsius operation

°F ON Fahrenheit operation

4. TEMP ALARMS SETTING

4.1 HOW TO SET THE MIN TEMPERATURE ALARM

To modify the minimum (LOW) Temp ALARM: hold the

the minimum Temp alarm is displayed.

Change the value using the UP and DOWN keys.

Press

the SET key to confirm the new value an

4.2 HOW TO SET THE MAX TEMPERATURE ALARM

To modify the max (HIGH) Temp ALARM: hold the +

max Temp alarm is displa

Change the value using the UP and DOWN keys.

Press

the SET key to confirm the new value an

yed.

d exit.

d exit.

dIXELV8.8-KIT

g

LOW

keys pressed for 3 seconds until

+

HIGH

keys pressed for 3 seconds until the

5. PROGRAMMING

5.1 HOW TO CHANGE A PARAMETER VALUE MAIN MENU

1. Enter the Programming Mode by pressing the SET and DOWN key for 3 seconds ( and will start

blinking).

Select the required parameter. By using the UP or DOWN

2.

3.

Press the “SET” key to display its value (now only the

4. Use

Press

“UP” or “DOWN” to change its valu

“SET” to store the new value and move to the following parameter.

e.

To exit: Press SET + UP or wait 15 seconds without pressing a ke

NOTE: the se

t value is stored even when the procedure is exited, by waiting the time-out to expire.

5.2 THE HIDDEN MENU (PR2)

The hidden menu includes all the parameters of the instrument.

5.2.1 HOW TO ENTER THE HIDDEN MENU (PR2)

Enter the Programming Mode by pressing the Set + down key for 3seconds (

1.

When a parameter is displayed, release and re-press the SET + down for more than 7seco

2.

3. The

4. Select the re

5.

6. Use

7. Press

Pr2 label will be displayed immediately followed from the HY parameter. NOW YOU ARE IN THE

HID

DEN MENU.

quired parameter as above

Press the “SET” key to display its value (Now only the

“UP” or “down” to change its value.

“SET” to store the new value and move to the following parameter.

To exit: Press SET + up or wait 15seconds without pressing a key.

NOTE: the set value is stored even when the procedure is exited by waiting the time-out to expire.

5.2.2 HOW TO MOVE A PARAMETER FROM THE HIDDEN MENU TO THE FIRST LEVEL AND

VICEVERSA

Each parameter present in the HIDDEN MENU can be removed or put into “THE FIRST LEVEL” (user

level) by pressing “SET + down”.

In HIDDEN MENU when a parameter is present in First Level the decimal point LED is on.

KEY

LED is blinking).

y.

LED is blinking).

and

starts blinking).

nds.

Weiss Instruments, LLC. 905 Waverly Ave. Holtsville , NY 11742 631-207-1200 www.weissinstruments.com

3

Page 4

Operating Instructions XWA11V

5.3 HOW TO LOCK THE KEYBOARD

dIXELV8.8-KIT

1. Keep the UP and DOWN key

The “POF” message will be displayed and the keyboard will be locked

2.

only to see th

3. If a key is presse

5.4 TO UNLOCK THE KEYBOARD

Keep the UP and DOWN keys pressed together for more than 3seconds. The “PON” message is displayed

e Set Point or the MAX o MIN Temp stored

d more than 3seconds the “POF” message will be displayed.

s pressed for more than 3 second

s.

. At this point it will be possible

6. LIGHT MANAGEMENT

6.1 TIMED REGULATION: I1L = Y

With i1L = y the light remains on at least for the LHt parameter.

The LHt timer is re-initialized every time the light button is pushed or the door is opened.

With LHt=0 the light remains on until the light button is pushed again or when the door is closed.

The light is switched on every time one of the following conditions happens:

the door is open (i1F = dor)*DOOR SWITCH PRESENT

the presence sensor is activated (i2F = LHt)*OCCUPANCY SENSO

the light button is pushed

The light is switched off when all the following conditions happen:

the LHt time

the door is closed (i1F = dor)*DOOR SWITCH PRE

the presence sensor is de-activated (i2F = LHt)*OCCUPANCY SENSOR PR

Light button regulation: i1L

r is exhausted

SENT

= n

R PRESENT

ESENT

FLH (opera

end of the LHt time as a warning that the lights are about to turn off. (This should only be used for

incandescent or LED lighting only!)

6.2 MANUAL OVERRIDE VIA LIGHT BUTTON OF XWA11V VERSION: 8.8 OR HIGHER ONLY

With the intorduction of V8.8 it is now possible to overrided the light on time with a press of the light button on

the face of the XWA11V. Regardless of mode in which the light had been turned on the Light button will always

overide a door switch activation or occupancy sensor input.

mode) The lights will flash (for 2 minutes) every 20 seconds for the FLH time (0-5 min) before the

7. INSTALLATION AND MOUNTING

7.1 MOUNTING OF XWA11V

The XWA11V must be mounted on a vertical

panel using the VBOX wall mount box. The

back of the box has two screw mounting

holes and a larger hole for the electrical

connections to pass through.

The Temp range allowed for correct

operation is 32 – 140°F. Avoid installation in

places subject to strong vibrations, corrosive

gases, excessive dirt or humidity. The same

recommendations apply to probes.

The Door Switch Magnet should be

mounted no more than ¾” of an inch from

the switch.

Weiss Instruments,LLC. 905 Waverly Ave. Holtsville , NY 11742 631-207-1200 www.weissinstruments.com

4

Page 5

Operating Instructions XWA11V

dIXELV8.8-KIT

8. ELECTRICAL CONNECTIONS

The instrument is provided with ¼” (.250”) fast-on terminal blocks to connect the digital and analog inputs.

Relay

s and power supply have a Fast-on connection ¼” (.250”). For supply connections use 14

r copper or CU wire only, rated to at least 90°C (194°F). Before connecting cables make sure the po

large

ply complies with the instrument requirements. Separate the probe cables from the power supply an

sup

output po

load

Not

8.1 PROBE CONNECTIONS

The probe shall be mounted with the bulb upwards to prevent damage due to casual liquid infiltration. It is

recommended to place the thermostat probe away from air streams to correctly measure the average room

temperature. The probe can be extended up to 300 ft. Check calibration when running long lengths over

100ft.

8.2 BATTERY BACK-UP

Battery Back-up will automatically power the XWA display in case of a power failure for up to 36 hours.

Display will flash when battery runs low. (Battery not included)

wer connections. Do not exceed the maximum current allowed on each relay and in case of heavie

s use a suitable extern

e: Maximum current allowed for all the loads is 15A.

al relay.

AWG or

wer

d

9. USE OF THE PROGRAMMING “HOT KEY”

The XWA11V units can UPLOAD or DOWNLOAD the parameter list from its own E2 internal memory to the

“H

OT KEY” and vice versa.

r

9.1 TO PROGRAM A HOT KEY FROM THE INSTRUMENT (UPLOAD)

1. Program one controller with the front keypad.

2. When the controller is ON

by flashing “End”

3. Push

4. Turn

9.2 HOW TO PROGRAM AN INSTRUMENT USING A HOT KEY (DOWNLO AD )

1. Turn OFF the instrument.

2. Insert a programmed “Hot Key” into the 5 PIN receptacle and then turn the Controlle

3.

4.

5. Remove

“SET” key and the End will stop flashing.

OFF

the instrument and remove the “Hot Key”, then turn it ON again.

NOTE: the “Er

to restart the upload again or remove the “Hot key” to abort the operatio

Automatically the parameter list of the “Hot Key” is downloaded into the Controller memory, the “doL

messag

After 10 seconds the instrument will restart operation

NOTE the message “Err” is displayed for failed programming. In this case turn th

you want to restart the d

r” message is displayed for failed programming. In this case pu

e is blinking followed a by flashing “End”.

the “Hot Key”.

, insert the “Hot key” and push UP key; the "uPL" message appears followed a

sh again

n.

with the new parameters.

e unit off and then on if

ownload again or remove the “Hot key” to abort the operatio

key if you want

r ON.

n.

10. ALARM SIGNALS

Message Mode Cause Outputs

“P1” Flashing Probe failure Alarm output ON

“PoF” Flashing (3s) Keyboard locked Not changed

“Pon” Flashing (3s) Keyboard un-locked Not changed

“HA” Alternated with temp Maximum temperature alarm Alarm output ON

“LA” Alternated with temp Minimum temperature alarm Alarm output ON

“dA” Alternated with temp Door switch alarm Alarm output ON

“EA” Alternated with temp External alarm Alarm output ON

“PAn” Alternated with temp Serious external alarm Alarm output ON

dEF Alternated with temp Defrost is running Not changed

The alarm message is displayed until the alarm condition is reset.

”

10.1 SILENCING BUZZER

Once the alarm signal is detected the buzzer can be silenced by pressing the (UP) key. (tbA=y)

Weiss Instruments,LLC. 905 Waverly Ave. Holtsville , NY 11742 631-207-1200 www.weissinstruments.com

5

Page 6

Operating Instructions XWA11V

10.2 ALARM RECOVERY

Probe alarms: “P1” (probe1 faulty), they automatically stop 10seconds after the probe restarts normal

operation. Check connections before replacing the probe.

Temperature° alarms “HA” and “LA” automatically stop as soon as the thermometer temperature returns to

normal operating values or when the defrost starts.

Door switch alarm “dA” stops as soon as the door is closed.

External alarms “EAL”, “BAL”, “dEF” stop as soon as the external digital input is disabled.

dIXELV8.8-KIT

11. TECHNICAL DATA

Housing: self extinguishing ABS

Case: face; 100x64 mm (3.94”x2.52”). Depth; 45.5mm

Mounting

Frontal protection: IP65 (CONTROL ONLY) the box is not wa

Conn

Po

wer supply: 120Vac

Power absorption:

Ambient T

Display: 3 digits, red LED, 14.2 mm (.56”) hi

Inputs: 1 NT

Digital inputs: 2 free voltage

Relay outputs: Voltage Supplied Relay Contac

Other output: alarm buzzer

Data storing: on the non-volatile memory (EEPROM).

Measuring and regulation range:

Resolution: 1 °F

Accuracy: ±1 °F

: J-box or wall-mount in suitable enclosure

ections: ¼” (.250”) fast-on for power, ¼” (.250”) fast-on for probes and Digi

10%, optional 230Vac 10% MAX 15A

4VA max.

emperature: 32-131°F (0-55°C)

gh.

C probe

Light: relay SPST 15A, 120Vac;

Alarm: relay SPST 8A, 120Vac

NTC probe: -40 to 110°C (-58 to 230°F)

(1.79”)

ter proof!

tal Inputs

ts

12. CONNECTIONS

wer supply: 120Vac +/- 10% 15A MAX current

Po

Full P/N Ambient Temp / %RH

Date Code

Weiss Instruments,LLC. 905 Waverly Ave. Holtsville , NY 11742 631-207-1200 www.weissinstruments.com

6

Page 7

Operating Instructions XWA11V

dIXELV8.8-KIT

13. AGENCY APPROVALS, LISTINGS AND SUPPORT INFORMATION

Weiss Instrumen

11742 Phone: (631)207-1200 Fax: (631)207-0900

sales@weissinstruments.com www.weissinstruments.com

Weiss Instruments, LLC. 905 Waverly Ave. Holtsville , NY 11742 631-207-1200 www.weissinstruments.com

ts, LLC., 905 Waverly Ave., Holtsville, NY

F

7

Page 8

Operating Instructions XWA11V

V

A

15

0

ALr

A

A

14. DEFAULT PARAMETER MAP

dIXELV8.8-KIT

LABEL DESCRIPTION

ot Thermostat probe calibration 0

CF Temperature measurement unit F

rES Resolution (only for °C) in

UT Display update 60

OnF Off function enabling y

ALU High temperature alarm setting (med temp / low temp)

ALL Low temperature alarm setting (med temp / low temp)

AFH Temperature alarm differential 2

ALd Temperature alarm delay 30

dAo Delay of temperature alarm at start-up 1.3

EdA Alarm delay at the end of defrost 30

dot Delay of temperature alarm after closing the door

LHt Light timer 15

FLH Light Flashing Timer (time before light goes out that it will flash)

doA Open door alarm delay 15

oA1 First relay configuration

oA2 Second relay configuration LHt

AOP Alarm relay polarity CL

i1P Digital input 1 polarity OP

i1L Door switch to turn light ON y

i1F Digital input 1 operating mode dor

i2P Digital input 2 polarity cL

i2F Digital input 2 operating mode PAn

did Time interval/delay for digital input alarm 0

tbA Alarm relay disabling n

PbC Kind of probe ntc

dP1 Real temperature Probe 1 Pr2

rEL FW release Pr2

Ptb Parameter map Pr2

ALUE LEVEL RANGE

50 / 30

30 / -20

Pr2

Pr2

Pr2

Pr2

Pr2

Pr1

Pr1

Pr2

Pr1

Pr2

Pr2

Pr2

Pr1

Pr1

Pr1

Pr2

Pr2

Pr2

Pr2

Pr2

Pr2

Pr2

Pr2

Pr2

Pr2

Pr2

[-21°F to 21°F]

°C - °F

dE - in

0 to 255 (sec.)

n - Y

LL to 302° F

°-58 to ALU

1°F to 45°F

0 - 255 (min.)

0.0 - 24.0 Hrs.

0 - 255 (min.)

0 - 255 (min.)

0 - 255 (min.)

0 - 5 (Min)

0 - 255 (min.)

Lr - LHt - OnF

Lr - LHt - OnF

OP - CL

OP - CL

n - Y

EAL - dor - dEr - LHt

OP - CL

EAL - Pan - dFr - LHt

0 - 255 (min.)

n - Y

PtC - ntC

(probe value)

read only

read only

15. PARAMETER LIST

Ot Thermos

thermostat probe.

CF T measurement unit: °C = Celsius; °F = Fahrenheit. When the measurement unit is cha nged the Set

Point and the values of some parameters have to be modified.

rES Resolution (for °C): (in = 1°C; dE = 0.1 °C) allows decimal point display.

Ut Display update: The time delay of the Temperature readout (0 to 255 seconds)

onF Off function enabling: n = off function disabled; y = off function enabled;

ALU High Temp alarm setting: (ALL to 150°C or 302°F); when this temperature is reached and after the

ALd delay time the HA alarm is enabled.

ALL Low Temp alarm setting: (- 50°C or -58°F to ALU) when this temperature is reached and after the

ALd delay time, the LA alarm is enabled.

AFH Temp alarm differential: (0.1 to 25.5°C; 1 to 45°F) differential for temperature alarm Set Point and fan

regulation Set Point, always a positive value

ALd Temp alarm delay: (0 to 255 min) time interval between the detection of an alarm condition and the

corresponding alarm signaling.

dAO Delay of Temp alarm at start-up: (0min to 23hrs, 50min) time interval between the detection of the

temperature alarm condition after the instrument power on and the alarm signaling.

EdA Alarm delay at the end of defrosts: (0 to 255 min) Time interval b etween the detection of the

temperature alarm condition at the end of defrost and the alarm signaling.

dot Delay of Temp alarm after closing the door: (0

condition after closing the door.

tat probe calibration: (-12.0 to12.0°C/ -21 to 21°F) allows to adjust possible offset of the

Weiss Instruments, LLC. 905 Waverly Ave. Holtsville , NY 11742 631-207-1200 www.weissinstruments.com

255 min) Time delay to signal the temperature alarm

8

Page 9

Operating Instructions XWA11V

LHt Light timer: (0-255 min) Amount of time the light will stay on after pressing the light switch on the

keyboard or after the door is closed.

FLH Light Flashing: (0-5 min) The light will “double flash” every 20 seconds during the FLH time period before

turning off after the LHt time. This should only be enabled for use with incandesant or LED lighting!

doA Open door alarm delay:(0-255 min) delay between the detection of the open door condition and its

alarm signaling: the flashing message “dA” is displayed.

oA1 First relay configuration: (14-15): ALr = alarm; LHt = light; onF = on/off relay

oA2 Second relay configuration: (14-16): ALr = alarm; LHt = light; onF = on/off relay

AOP Alarm relay polarity: cL = closing contacts (Relay will close on alarm giving voltage output);

oP = opening contacts (Relay will open on alarm no voltage output).

i1P Digital input 1 polarity (1-2): CL : the digital input is activated by closing the contact;

OP: the digital input is activated by opening the contact

i1L Door switch to turn light ON(1-2): (y / n) To turn the light ON automatically when the door is open. The

light will turn off based on LHt . Keyboard switch must be turned ON first.

i1F Digital input 1 operating mode(1-2): EAL = external alarm; dor = door switch; dFr = A defrost is

running; LHt = keep light ON (signal from occupancy sensor) override LHt.;

i2P Digital input 2 polarity (1-3): CL : the digital input is activated by closing the contact;

OP: the digital input is activated by opening the contact

i2F Digital input 2 operating mode: configure the digital input function:

EAL = External alarm;

PAn =Panic alarm;

dFr = A defrost is running; (need external CT’s)

LHt = Keep light ON (signal from occupancy sensor) overrides LHt.

did Time interval/delay for digital input alarm:(0-255 min.) If I2F=EAL or PAn (external alarms), “did”

parameter defines the time delay between the detection and the successive signaling of the alarm.

tbA Alarm relay & Buzzer disabling: (y ; no)

Pbc Type of probe (PTC, NTC)

dP1 Probe 1 Temperature

rEL Software release for internal use.

Ptb Parameter table code: read only.

dIXELV8.8-KIT

Weiss Instruments, LLC. 905 Waverly Ave. Holtsville , NY 11742 631-207-1200 www.weissinstruments.com

9

Loading...

Loading...