i

Contents

Network Viedo Recorder

User Manual

The manual is applied to the following model:

Model No: NRM 301

Note: The manual is subject to change without notic

v

Contents

Regulatory Compliance Statements

This section provides the FCC compliance statement for Class B devices and

describes how to keep the system CE compliant.

Declaration of Conformity

FCC

This equipment has been tested and veried to comply with the limits for

a Class B digital device, pursuant to Part 15 of FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference

to radio communications. Operation of this equipment in a residential area

(domestic environment) is likely to cause harmful interference, in which

case the user will be required to correct the interference (take adequate

measures) at their own expense.

CE

The product(s) described in this manual complies with all applicable

European Union (CE) directives if it has a CE marking. For computer systems

to remain CE compliant, only CE-compliant parts may be used. Maintaining

CE compliance also requires proper cable and cabling techniques.

Copyright

This publication, including all photographs, illustrations and software, is

protected under international copyright laws, with all rights reserved. No

part of this manual may be reproduced, copied, translated or transmitted

in any form or by any means without the prior written consent from

Divio Tec International Co., Ltd.

Disclaimer

The information in this document is subject to change without prior notice

and does not represent commitment from Divio Tec International Co., Ltd.

However, users may update their knowledge of any product in use by constantly

checking its manual posted on our website: http://www.Divio Tec.com. Divio Tec

shall not be liable for direct, indirect, special, incidental, or consequential

damages arising out of the use of any product, nor for any infringements

upon the rights of third parties, which may result from such use. Any implied

warranties of merchantability or tness for any particular purpose is also

disclaimed.

Acknowledgements

NRM301 is a trademark of Divio Tec International Co., Ltd. All other product

names mentioned herein are registered trademarks of their respective owners.

Preface

vi

Contents

RoHS Compliance

Divio Tec RoHS Environmental Policy and

Status Update

Divio Tec is a global citizen for building the digital

infrastructure. We are committed to providing green

products and services, which are compliant with

European Union RoHS (Restriction on Use of Hazardous Substance in

Electronic Equipment) directive 2011/65/EU, to be your trusted green partner

and to protect our environment.

RoHS restricts the use of Lead (Pb) < 0.1% or 1,000ppm, Mercury (Hg)

< 0.1% or 1,000ppm, Cadmium (Cd) < 0.01% or 100ppm, Hexavalent

Chromium (Cr6+) < 0.1% or 1,000ppm, Polybrominated biphenyls (PBB) <

0.1% or 1,000ppm, and Polybrominated diphenyl Ethers (PBDE) < 0.1% or

1,000ppm.

In order to meet the RoHS compliant directives, Divio Tec has established an

engineering and manufacturing task force in to implement the introduction

of green products. The task force will ensure that we follow the standard Divio

Tec development procedure and that all the new RoHS components and new

manufacturing processes maintain the highest industry quality levels for

which Divio Tec are renowned.

How to recognize Divio Tec RoHS Products?

For existing products where there are non-RoHS and RoHS versions, the

sux “(LF)” will be added to the compliant product name.

All new product models launched after January 2013 will be RoHS compliant.

They will use the usual Divio Tec naming convention.

vii

Contents

Warnings

Read and adhere to all warnings, cautions, and notices in this guide and

the documentation supplied with the chassis, power supply, and accessory

modules. If the instructions for the chassis and power supply are inconsistent

with these instructions or the instructions for accessory modules, contact

the supplier to nd out how you can ensure that your computer meets

safety and regulatory requirements.

Cautions

Electrostatic discharge (ESD) can damage system components. Do the

described procedures only at an ESD workstation. If no such station is

available, you can provide some ESD protection by wearing an antistatic

wrist strap and attaching it to a metal part of the computer chassis.

Safety Information

Before installing and using the device, note the following precautions:

▪ Read all instructions carefully.

▪ Do not place the unit on an unstable surface, cart, or stand.

▪ Follow all warnings and cautions in this manual.

▪ When replacing parts, ensure that your service technician uses parts

specied by the manufacturer.

▪ Avoid using the system near water, in direct sunlight, or near a heating

device.

▪ The load of the system unit does not solely rely for support from the

rackmounts located on the sides. Firm support from the bottom is highly

necessary in order to provide balance stability.

▪ The computer is provided with a battery-powered real-time clock circuit.

There is a danger of explosion if battery is incorrectly replaced. Replace

only with the same or equivalent type recommended by the manufacturer.

Discard used batteries according to the manufacturer’s instructions.

Installation Recommendations

Ensure you have a stable, clean working environment. Dust and dirt can

get into components and cause a malfunction. Use containers to keep

small components separated.

Adequate lighting and proper tools can prevent you from accidentally

damaging the internal components. Most of the procedures that follow

require only a few simple tools, including the following:

• A Philips screwdriver

• A at-tipped screwdriver

• A grounding strap

• An anti-static pad

Using your ngers can disconnect most of the connections. It is recommended that you do not use needlenose pliers to disconnect connections

as these can damage the soft metal or plastic parts of the connectors.

viii

Contents

Safety Precautions

▪ Read these safety instructions carefully.

▪ Keep this User Manual for later reference.

▪ Disconnect this equipment from any AC outlet before cleaning. Use a

damp cloth. Do not use liquid or spray detergents for cleaning.

▪ For plug-in equipment, the power outlet socket must be located near the

equipment and must be easily accessible.

▪ Keep this equipment away from humidity.

▪ Put this equipment on a stable surface during installation. Dropping it or

letting it fall may cause damage.

▪ Do not leave this equipment in either an unconditioned environment or

in a above 40

o

C storage temperature as this may damage the equipment.

▪ The openings on the enclosure are for air convection to protect the

equipment from overheating. DO NOT COVER THE OPENINGS.

▪ Make sure the voltage of the power source is correct before connecting

the equipment to the power outlet.

▪ Place the power cord in a way so that people will not step on it. Do not

place anything on top of the power cord. Use a power cord that has been

approved for use with the product and that it matches the voltage and

current marked on the product’s electrical range label. The voltage and

current rating of the cord must be greater than the voltage and current

rating marked on the product.

▪ All cautions and warnings on the equipment should be noted.

▪ If the equipment is not used for a long time, disconnect it from the power

source to avoid damage by transient overvoltage.

▪ Never pour any liquid into an opening. This may cause re or electrical

shock.

▪ Never open the equipment. For safety reasons, the equipment should be

opened only by qualied service personnel.

▪ If one of the following situations arises, get the equipment checked by

service personnel:

a. The power cord or plug is damaged.

b. Liquid has penetrated into the equipment.

c. The equipment has been exposed to moisture.

d. The equipment does not work well, or you cannot get it to work

according to the user’s manual.

e. The equipment has been dropped and damaged.

f. The equipment has obvious signs of breakage.

▪ Do not place heavy objects on the equipment.

▪ The unit uses a three-wire ground cable which is equipped with a third

pin to ground the unit and prevent electric shock. Do not defeat the

purpose of this pin. If your outlet does not support this kind of plug,

contact your electrician to replace your obsolete outlet.

▪ CAUTION: DANGER OF EXPLOSION IF BATTERY IS INCORRECTLY

REPLACED. REPLACE ONLY WITH THE SAME OR EQUIVALENT TYPE

RECOMMENDED BY THE MANUFACTURER. DISCARD USED BATTERIES

ACCORDING TO THE MANUFACTURER’S INSTRUCTIONS.

▪ The computer is provided with CD drives that comply with the appropriate

safety standards including IEC 60825.

ix

Contents

Conventions Used in this Manual

Warning:

Information about certain situations, which if not observed,

can cause personal injury. This will prevent injury to yourself

when performing a task.

CAUTION!

CAUTION!CAUTION!

Caution:

Information to avoid damaging components or losing data.

Note:

Provides additional information to complete a task easily.

Technical Support and Assistance

1. For the most updated information of Divio Tec products, visit Divio Tec’s

website at www.Divio Tec.com.

2. For technical issues that require contacting our technical support team or

sales representative, please have the following information ready before

calling:

– Product name and serial number

– Detailed information of the peripheral devices

– Detailed information of the installed software (operating system,

version, application software, etc.)

– A complete description of the problem

– The exact wordings of the error messages

Warning!

1. Handling the unit: carry the unit with both hands and handle it with care.

2. Maintenance: to keep the unit clean, use only approved cleaning products

or clean with a dry cloth.

3. CompactFlash: Turn o the unit’s power before inserting or removing a

CompactFlash storage card.

x

Contents

contents

Preface

Copyright ............................................................................................................................... v

Disclaimer .............................................................................................................................. v

Acknowledgements ........................................................................................................... v

Regulatory Compliance Statements ............................................................................. v

Declaration of Conformity ................................................................................................ v

RoHS Compliance ................................................................................................................ vi

Technical Support and Assistance.................................................................................ix

Conventions Used in this Manual .................................................................................. ix

Chapter 1: Product Introduction

Physical Features ..................................................................................................................1

Front View ...........................................................................................................................1

Rear View ............................................................................................................................ 1

Overview ................................................................................................................................. 2

Key Features ........................................................................................................................... 2

Hardware Specications .................................................................................................... 3

Connector Numbering ....................................................................................................... 5

Chapter 2: External Connectors Pinout Description

Event Button ...................................................................................................................... 6

LED Indicators (HDD, WWAN, Power & WLAN) ......................................................6

USB 3.0 Port ....................................................................................................................... 7

Reset ..................................................................................................................................... 7

SIM1 and SIM2 Sockets .................................................................................................. 8

CFast ..................................................................................................................................... 8

Line-out2 ............................................................................................................................ 9

Mic2 ...................................................................................................................................... 9

Line-out1 .......................................................................................................................... 10

Mic1 ....................................................................................................................................10

LAN1 and LAN2 Ports ...................................................................................................11

VGA .....................................................................................................................................11

USB 2.0 Ports....................................................................................................................12

GPIO/CAN/OBDII ............................................................................................................12

DisplayPort .......................................................................................................................13

DC Output ........................................................................................................................13

DC Input 9V-36V .............................................................................................................14

COM3 (RS422/485) ........................................................................................................14

COM2 RS-232 (RI/5V/12V Selectable) .....................................................................15

COM1 RS-232 (RI/5V/12V Selectable) .....................................................................15

MCU-DIO ...........................................................................................................................16

Chapter 3: Jumpers and Switches

Before You Begin ................................................................................................................17

Precautions ..........................................................................................................................17

Jumper Settings ..................................................................................................................18

DIP Switch Settings ............................................................................................................20

RTC Clear Selection .......................................................................................................20

GPIO Pull-High Setup ...................................................................................................20

COM1 RI/Power Select .................................................................................................21

xi

Contents

COM2 RI/Power Select .................................................................................................21

MiniCard (CN26) Power Selection ............................................................................22

WWAN Module Selection Table

(For Wake-Up & Voice Functions on Mini-PCIe CN26) ......................................23

Input Voltage Setup Selection ..................................................................................24

RTC Battery Connector.................................................................................................25

Debug 80 Port Connector ..........................................................................................25

COM Port Connecter (COM1 RS-232) ......................................................................26

COM Port Connecter (COM2 RS-232) ......................................................................26

COM Port Connecter (COM3 - RS422/485)............................................................27

MCU-DIO Connector .....................................................................................................27

Reset Button (Reserved) ..............................................................................................28

Power Button Connector (Reserved) ......................................................................28

SATA HDD Connector ...................................................................................................29

OBDII Module Connector ...........................................................................................29

Debug Port .......................................................................................................................30

GAL Download Port ......................................................................................................30

GPS Connector ................................................................................................................31

Internal WWAN SIM Card Socket (SIM 3) For CN27 ............................................31

MCU Download Port .....................................................................................................32

Mini-PCIe (USB + PCIe) .................................................................................................33

Mini-PCIe (USB + PCIe) .................................................................................................34

Mini-PCIe (USB) ...............................................................................................................35

Mini-PCIe (USB) ...............................................................................................................36

Chapter 4: System Setup

Removing the Chassis Cover .........................................................................................37

Installing a SSD/HDD Drive .............................................................................................38

Installing a WLAN Module (Half Mini-PCIe) ...............................................................40

Installing a WWAN Module .............................................................................................40

Installing a SO-DIMM ........................................................................................................41

Installing a OBDII Module ................................................................................................42

Appendix A: Software Demo Utility for I/O Ports of

Function Control

Menu Screen ....................................................................................................................43

1.1 Status .........................................................................................................................44

1.2 Input Voltage ...........................................................................................................44

1.3 Output Power ..........................................................................................................45

1.4 GPIO Setting ............................................................................................................45

1.5 MCU GPIO Setting .................................................................................................46

1.6 WDT Setting .............................................................................................................46

1.7 WWAN Module ......................................................................................................47

1.8 Selection of RS-422 or RS-485 for COM3 .......................................................47

1.9 Power O Delay Time ..........................................................................................47

1.10 Wake Up Function ..............................................................................................48

1.11 CAN Bus Setting .................................................................................................48

1.12 Interface Power ..................................................................................................49

1.13 Mini-PCIe Power .................................................................................................49

Appendix B: Using the GPS Feature

Setup and Using GPS Information ...............................................................................50

Appendix C: Signal Connection of DI/DO

GPIO Pinout Description ..................................................................................................54

SW2 Setting ..........................................................................................................................54

Digital Input .........................................................................................................................55

Digital Output ......................................................................................................................56

Appendix D: Signal Connection of MCU DI/DO and

Event Button

xii

Contents

MCU-DIO Pinout Description .........................................................................................57

Digital Input .........................................................................................................................57

Digital Output ......................................................................................................................58

Event Button ........................................................................................................................58

Pre-Alarm Function by Event Button, MCU-DI and MCU-DO .............................60

Setting up Pre-Alarm function ..................................................................................60

Activating Pre-Alarm function ..................................................................................61

Deactivating Pre-Alarm function .............................................................................61

Activating Pre-Alarm Function .....................................................................................62

(For Event Button) ..........................................................................................................62

(For MCU-DI2) ..................................................................................................................62

Deactivating Pre-Alarm Function ................................................................................63

(For Event Button) ..........................................................................................................63

(For MCU-DI2) ..................................................................................................................63

Appendix E: Vehicle Power Management Setup

External Power Output Setting .....................................................................................64

Startup and Shutdown Voltage Setting .....................................................................64

Power-on Delay Setting ...................................................................................................66

Power-o Delay Setting ...................................................................................................68

Appendix F: OBDII Module Setup and Command

OBDII Module.......................................................................................................................70

VIOX-CAN01 Setup.............................................................................................................70

AT Command Summary ................................................................................................... 71

Simple Data Protocol: (ASCII CODE) .............................................................................72

Simple Data Protocol: (HEX CODE) ...............................................................................73

J1939 Raw Data Protocol (HEX CODE) ........................................................................74

J1708 Raw Data Protocol (HEX CODE) ........................................................................74

J1939 Packaged Messages Protocol ............................................................................75

J1708 Packaged Messages Protocol ............................................................................83

J1708 Command Example ..............................................................................................87

Appendix G: Pin Definition for GPS Dead Reckoning

Module -- VIOB-GPS-DR02

S2532DR Overview ............................................................................................................88

Technical Specications ...................................................................................................88

Appendix H: Power Consumption.........................91

1

Contents

chaPter 1: Product IntroductIon

Physical Features

Front View

SSD/HDD

CFast LINE OUT2 Mic1

MIC2

SIM1 / SIM2

slot cover

Event

button

LED

indicators

COM1COM2COM3 MCU-DIOLine-out 1 GPS antenna hole

VGA

USB 2.0

GPIO/CAN/OBDII

DisplayPort

DC OUT

DC IN

9V-36V

LAN2 LAN1

USB 3.0

Reset

Antenna holes

Rear View

2

Contents

Overview

NRM301, based on Intel® Core™ quad core processor E3845 (1.91GHz), is

specically designed for the harsh in-vehicle environment. It allows NRM301

to comply with stringent MIL-STD-810G military standard in rugged, fanless

and compact mechanism. NRM301 provides complete communication

capability between automotive and computer with build-in CAN BUS 2.0B

interface. Optional OBDII interface (J1939/J1708) is also available for vehicle

diagnostics. NRM301 features rich PAN, WLAN and WWAN wireless connectivity.

With three SIM cards support, NRM301 allows three SIM cards backup each

other for a better connectivity quality by software. In addition, three SIM

cards and dual WWAN modules architecture can increase the bandwidth for

a faster data transmission speed. Not only data transmission, NRM301 also

supports two-way voice communication. Equipped with intelligent power

management, NRM301 can be waked on by ignition, RTC timer or SMS

message remotely. By integrating the variety of I/O ports and 4x Mini-PCIe

sockets expansibility, NRM301 keeps the exibility to meet the demand for

dierent telematics applications, such as infotainment, eet management,

dispatching system and video surveillance.

Key Features

• Intel® Atom™ processor quad core E3845, 1.91GHz

• Three SIM cards + dual WWAN modules support

• Built-in U-blox UBX-G6010 GPS, optional Dead Reckoning support

• Built-in CAN Bus 2.0B. Optional OBDII function (SAE J1939/J1708)

• Wake on RTC/SMS via WWAN module

• Compliant with MIL-STD-810G

• 4x Mini-PCIe socket expansion

• Programmable 8x GPIO

• Voice communication via WWAN module

3

Contents

Hardware Specifications

CPU

▪ Intel® Atom™ processor quad core E3845, 1.91GHz

Memory

▪ 1x 204-pin DDR3L SO -DIMM socket support 1066MHz/1333MHz up to 8GB.

Default 4GB

Storage

▪ 1x 2.5” SSD/HDD SATA 2.0

(externally accessible, optional lockable storage available)

▪ 1x CFast (externally accessible)

Expansion

▪ 1x full size Mini-PCIe socket (USB 2.0)

▪ 1x full size Mini-PCIe socket (USB 2.0)

▪ 1x full size Mini-PCIe socket (USB 2.0 + PCIe)

▪ 1x half size Mini-PCIe socket (USB 2.0 + PCIe)

Function

▪ 1x default U-blox UBX-G6010 GPS module (50-channel and Galileo) or

optional modules with Dead Reckoning or GLONASS support

▪ Built-in G-sensor

I/O Interface-Front

▪ 4x LED for power, storage, WWAN, WLAN

▪ 2x externally accessible SIM card socket (selectable)

▪ 1x phone jack 3.5mm for 1x Mic-I n

▪ 1x phone jack 3.5mm for 1x Line -Out

▪ 1x externally accessible 2.5” SATA 2.0 SSD/HDD tray

▪ 1x externally accessible CFast card socket with cover

▪ 1x event button (trigger type)

▪ 1x reset button

▪ 1x type A USB 3.0 compliant host, suppor ting system boot up

▪ 4x antenna hole for WWAN/WLAN/BT

I/O Interface-Rear

▪ 1x 9~36VDC input with ignition and 19W typical power consumption

▪ 2x type A USB 2.0 compliant host, supporting system boot up

▪ 2x RJ45 10/100/1000 Fast Ethernet with LED

▪ 1x phone jack 3.5mm for 1x Mic-In

▪ 1x phone jack 3.5mm for 1x Line-Out

▪ 1x DB-15 VGA, resolution up to 2560 x 1600 @60Hz

▪ 1x DP port, resolution up to 2560 x 1600 @60H

▪ 1x antenna hole for GPS

▪ 2x DB-9 RS-232 (RI/5V/12V selectable)

▪ 1x DB-9 RS-422/485

▪ 1x DB-9 for CAN 2.0B (optional CAN Bus 2.0B Mini-PCIe card),

2x MCU-DI and 2x MCU-DO

▪ 1x 16-pin terminal block

- 1x CAN Bus 2.0B (on board)

- 1x optional OBDII module (SAE J1939 or J1708)

- 8x GPIO (Programmable or optional isolation)

Digital Input (internal type): 5VDC TTL (default)

Digital Input (source type): 3~12VDC

Digital Output (sink type): 5VDC TTL (default), max current: 20mA

Digital Output (source type): 3~24VDC, max current: 150mA

▪ 1x 12VDC output (2A), SM Bus

Power Management

▪ Selectable boot-up & shut-down voltage for low power protection by

software

▪ Setting 8-level power on/o delay time by software

▪ Status of ignition and low voltage can be detected by software

▪ Support S3/S4 suspend mode

4

Contents

Operating System

▪ Windows 8, WES8

▪ Windows 7, WES8

▪ Fedora

Dimensions

▪ 260 mm (W) x 176 mm (D) x 50 mm (H) (10.24” x 6.93” x 1.97”)

▪ Weight : 2.1kg

Environment

▪ Operating temperatures: -30°C to 70°C (w/industrial SSD) with air ow

-20°C to 50°C (w/commercial HDD) with air ow

▪ Storage temperatures: -35°C to 85°C

▪ Relative humidity: 10% to 90% (non-condensing)

▪ Vibration (random):

1g@5~500 Hz (in operation, HDD), 2g@5~500 Hz (in operation, SSD)

▪ Vibration (SSD/HDD):

Operating: MIL-STD-810G, Method 514.6, Category 4, common carrier

US highway truck vibration exposure

Storage: MIL-STD-810G, Method 514.6, Category 24, minimum

integrity test

▪ Shock (SSD/HDD):

Operating: MIL-STD-810G, Method 516.6, Procedure I, functional

shock=20g

▪ Non-operating: MIL-STD-810G, Method 516.6, Procedure V, crash

hazard shock test=75g

Certifications

▪ CE approval

▪ FCC Class B

▪ E13 Mark

5

Contents

Connector Numbering

The following diagrams indicate the numbers of the connectors. Use these

numbers to locate the connectors’ respective pinout assignments on chapter

2 of the manual.

6

Contents

chaPter 2: external connectors PInout descrIPtIon

Event Button

Connector Number: 1

LED Indicators (HDD, WWAN, Power & WLAN)

Connector Number: 2

LED LED Behavior

HDD Light On: HDD/SSD Active

PWR

Light On: Power On

Light O: Power O

WWA N Blinking: Active

WLAN Blinking: Active

HDD

PWR

WWA N

WLAN

Pin Definition

1 Event Input

2 GND

21

7

Contents

USB 3.0 Port

Connector Number: 3

Pin Definition Pin Definition

1 5V 2 USB_N

3 USB_P 4 GND

5 USB3_RXN 6 USB3_RXP

7 GND 8 USB3_TXN

9 USB3_TXP

4

1

95

Reset

Connector Number: 4

Pin Definition

1 GND

2 RESET

1 2

8

Contents

SIM1 and SIM2 Sockets

Connector Number: 5

Pin Definition Pin Definition

C1 UIM1_PWR2 C5 GND

C2 UIM1_RST2 C6 NC

C3 UIM1_CLK2 C7 UIM1_DAT2

C3

C2

C1

C7

C6

C5

CFast

Connector Number: 6

S7 P17P1S1

Pin Definition Pin Definition

S1 GND PC6 NC

S2 SATA_TX1+ PC7 GND

S3 SATA_TX1- PC8 CFAST_LED1_C

S4 GND PC9 CFAST_LED2_C

S5 SATA_RX1- PC10 NC

S6 SATA_RX1+ PC11 NC

S7 GND PC12 NC

PC1 CFAST_CDI PC13 VCC3

PC2 GND PC14 VCC3

PC3 NC PC15 GND

PC4 NC PC16 GND

PC5 NC PC17 CFAST_CDO

9

Contents

Mic2

Connector Number: 8

Line-out2

Connector Number: 7

Pin Definition Pin Definition

1 Headphone (mono) 2 Detect

3 NC 4 Headphone (mono)

5 GND 6 GND

Pin Definition Pin Definition

1 NC 2 Detect

3 NC 4

Mic-In (Right Channel) to

WWAN module

5 GND 6 GND

10

Contents

Mic1

Connector Number: 10

Line-out1

Connector Number: 9

Pin Definition Pin Definition

22 Left Channel 23 GND

24 Detect 25 Right Channel

Pin Definition Pin Definition

1 GND 2 Mic-In (Left Channel)

3 GND 4 Detect

5 NC 6

11

Contents

LAN1 and LAN2 Ports

Connector Number: 11

Pin Definition Pin Definition

1 MDI0P 2 MDI0N

3 MDI1P 4 MDI2P

5 MDI2N 6 MDI1N

7 MDI3P 8 MDI3N

9 LED1- 10 LED1+

11 LED2- 12 LED2+

1 8

VGA

Connector Number: 12

Pin Definition Pin Definition

1 VGA_RED 2 VGA_GREEN

3 VGA_BLUE 4 VGA_GND

5 VGA_GND 6 VGA_GND

7 VGA_GND 8 VGA_GND

9 VGA +5V 10 VGA_GND

11 VGA_GND 12 VGA_DATA

13 VGA_HS 14 VGA_VS

15 VGA_CLK

5 1

15 11

12

Contents

USB 2.0 Ports

Connector Number: 13

GPIO/CAN/OBDII

Connector Number: 14

Pin Definition Pin Definition

1 VCC 2 DATA13 DATA1+ 4 GND

Pin Definition Pin Definition

5 VCC 6 D ATA7 DATA + 8 GND

4

8

1

5

USB1

USB2

USB1 Pin Connector Definition

USB2 Pin Connector Definition

Pin Definition Pin Definition

1 CAN_H_SJA1000 9 GPIO1 (Default: GPI1)

2 CAN_L_SJA1000 10 GPIO2 (Default: GPI2)

3 CAN_1939_L 11 GPIO3 (Default: GPI3)

4 CAN_1939_H 12 GPIO4 (Default: GPI4)

5 CAN_1708_L 13 GPIO5 (Default: GPO1)

6 CAN_1708_H 14 GPIO6 (Default: GPO2)

7 GND 15 GPIO7 (Default: GPO3)

8 GND 16 GPIO8 (Default: GPO4)

GPIO can be programmed by S/W.

Please refer to the source code in utility.

1 8GPIO

CAN GNDOBDII

Pin 9

Pin 1 Pin 8

Pin 16

13

Contents

DisplayPort

Connector Number: 15

DC Output

Connector Number: 16

Pin Definition Pin Definition

1 DP0_DATA0_P 2 GND

3 DP0_DATA0_N 4 DP0_DATA1_P

5 GND 6 DP0_DATA1_N

7 DP0_DATA2_P 8 GND

9 DP0_DATA2_N 10 DP0_DATA3_P

11 GND 12 DP0_DATA3_N

13 CONFIG1 14 CONFIG2

15 DPC0_AUXP_C 16 GND

17 DPC0_AUXN_C 18 HPD

19 RETURN 20 DP0_PWR

1

1 3

4 6

19

20 2

Pin Definition Pin Definition

1

Voltage from Car Battery

(2A)

2 12VDC Out (2A)

3 SMB_CLK(For VTK61B) 4 GND

5 GND 6 SMB_DAT(For VTK61B)

14

Contents

DC Input 9V-36V

Connector Number: 17

COM3 (RS422/485)

Connector Number: 18

Pin Definition

1 GND_IN

2 V_IN

3 IGNITION

Pin Definition Pin Definition

1 NC 2 RS485_-/RS422_RX3 RS485_+/RS422_RX+ 4 NC

5 GND 6 NC

7 RS422_TX- 8 RS422_TX+

9 NC 10 NC

1

3

I+-

1 5

6 9

15

Contents

COM2 RS-232 (RI/5V/12V Selectable)

Connector Number: 19

COM1 RS-232 (RI/5V/12V Selectable)

Connector Number: 20

Pin Definition Pin Definition

1 DCD_2 2 RXD_2

3 TXD_2 4 DTR_2

5 GND 6 DSR_2

7 RTS_2 8 CTS_2

9 RI/PW 10 NC

Pin Definition Pin Definition

1 DCD_1 2 RXD_1

3 TXD_1 4 DTR_1

5 GND 6 DSR_1

7 RTS_1 8 CTS_1

9 RI/PW 10 NC

1 5

6 9

1 5

6 9

16

Contents

MCU-DIO

Connector Number: 21

1 5

6 9

Pin Definition Pin Definition

1 NC 2 NC

3 MCU-DI1 4 MCU-DI2

5 GND 6 NC

7 NC 8 MCU-DO1

9 MCU-DO2

17

Contents

chaPter 3: JumPers and swItches

This chapter describes how to set the jumpers on the NRM301 motherboard.

Before You Begin

▪ Ensure you have a stable, clean working environment. Dust and dirt can

get into components and cause a malfunction. Use containers to keep

small components separated.

▪ Adequate lighting and proper tools can prevent you from accidentally

damaging the internal components. Most of the procedures that follow

require only a few simple tools, including the following:

– A Philips screwdriver

– A at-tipped screwdriver

– A set of jewelers screwdrivers

– A grounding strap

– An anti-static pad

▪ Using your ngers can disconnect most of the connections. It is

recommended that you do not use needle-nosed pliers to disconnect

connections as these can damage the soft metal or plastic parts of the

connectors.

▪ Before working on internal components, make sure that the power is o.

Ground yourself before touching any internal components, by touching

a metal object. Static electricity can damage many of the electronic

components. Humid environment tend to have less static electricity than

dry environments. A grounding strap is warranted whenever danger of

static electricity exists.

Precautions

Computer components and electronic circuit boards can be damaged by

discharges of static electricity. Working on the computers that are still

connected to a power supply can be extremely dangerous.

Follow the guidelines below to avoid damage to your computer or yourself:

▪ Always disconnect the unit from the power outlet whenever you are

working inside the case.

▪ If possible, wear a grounded wrist strap when you are working inside the

computer case. Alternatively, discharge any static electricity by touching

the bare metal chassis of the unit case, or the bare metal body of any

other grounded appliance.

▪ Hold electronic circuit boards by the edges only. Do not touch the

components on the board unless it is necessary to do so. Don’t ex or

stress the circuit board.

▪ Leave all components inside the static-proof packaging that they shipped

with until they are ready for installation.

▪ Use correct screws and do not over tighten screws.

18

Contents

Jumper Settings

A jumper is the simplest kind of electric switch. It consists of two metal

pins and a cap. When setting the jumpers, ensure that the jumper caps are

placed on the correct pins. When the jumper cap is placed on both pins, the

jumper is short. If you remove the jumper cap, or place the jumper cap on

just one pin, the jumper is open.

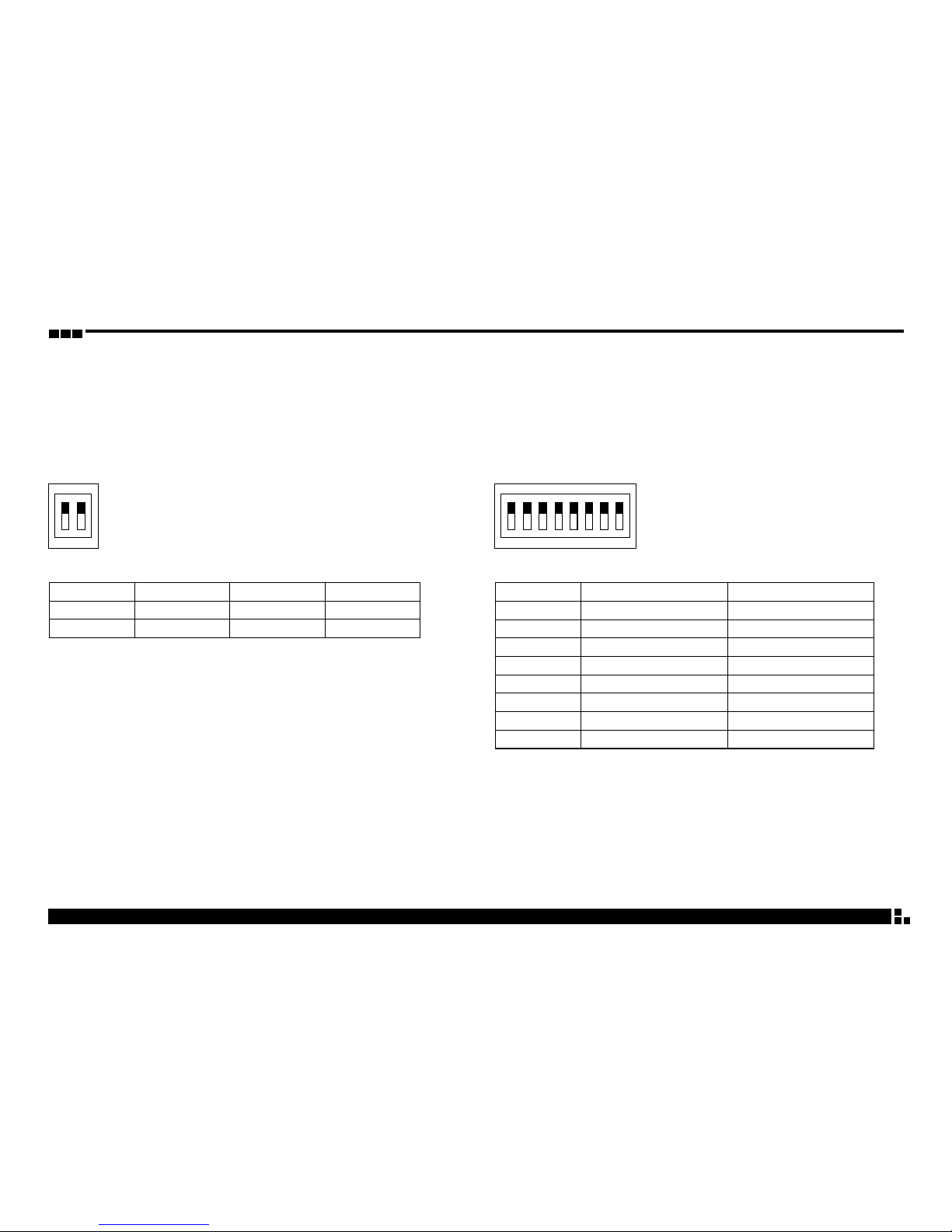

Refer to the illustrations below for examples of what the 2-pin and 3-pin

jumpers look like when they are short (on) and open (o).

Two-Pin Jumpers: Open (Left) and Short (Right)

Three-Pin Jumpers: Pins 1 and 2 are Short

1

2

3

1

2

3

19

Contents

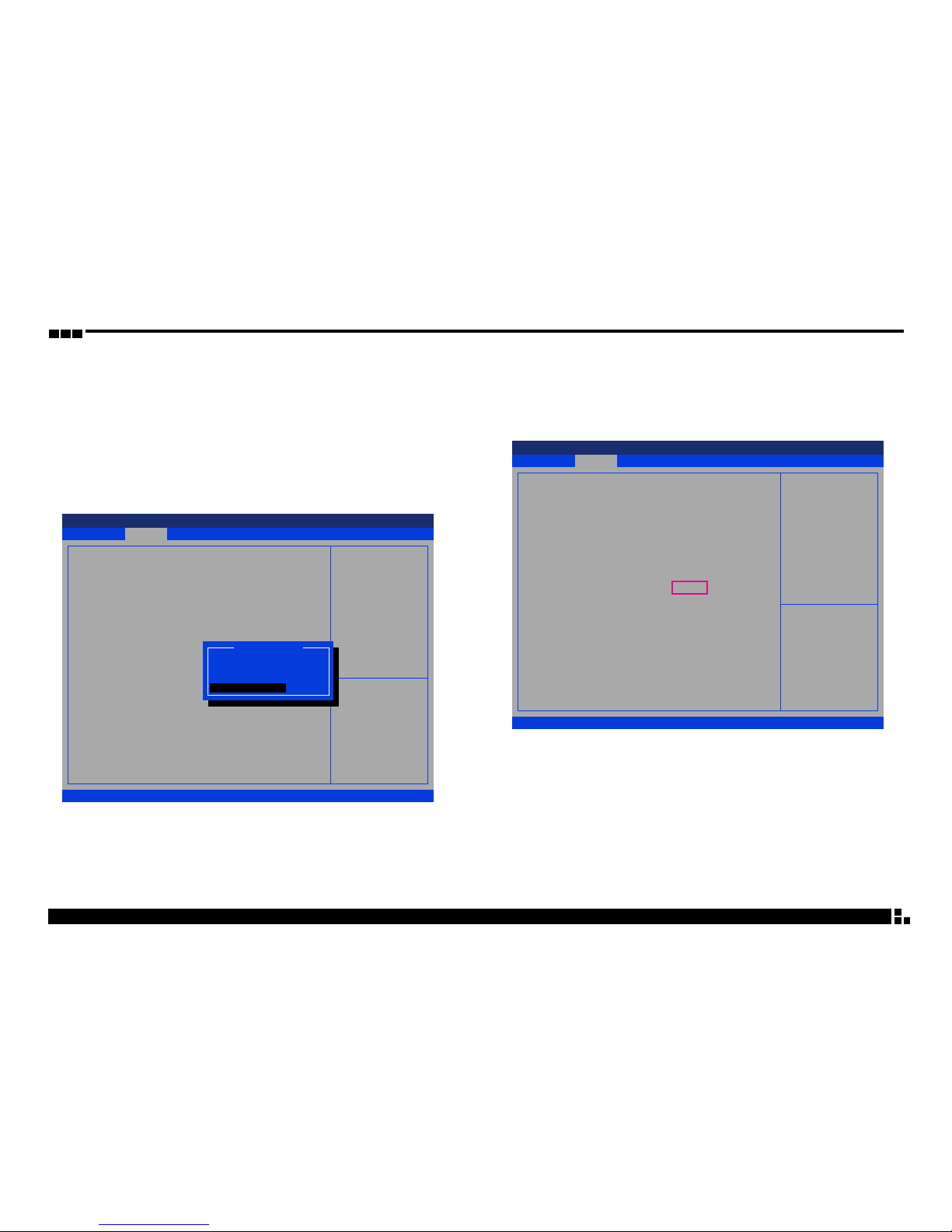

NRM301 Connector Specification & Jumper Setting

NRM301 carrier board placement

The gure below is the carrier board used in the NRM301 system. It shows the locations of the jumpers and connectors.

J1

JP5

DIMM1

CN6

J9

J8

SW9

J2

JP2

JP3

JP4

J12

SW1

J14

J13

JP6

JP8

CN17

JP7

CN24

SW8

J20

J21

J22

CN25

CN26

CN27

SW6

SW7

J17

SW3

CN20

CN18 CN19

SW4

CN10

CN9CN7

20

Contents

DIP Switch Settings

RTC Clear Selection

Connector location: SW1

Normal(*) Clear ME Clear CMOS

SW1.1 OFF OFF ON

SW1.2 OFF ON OFF

(*) Default

ON OFF

SW2.1 GPIO1 Pull-High 5V Open

SW2.2 GPIO 2 Pull-High 5V Open

SW2.3 GPIO 3 Pull-High 5V Open

SW2.4 GPIO 4 Pull-High 5V Open

SW2.5 GPIO 5 Pull-High 5V Open

SW2.6 GPIO 6 Pull-High 5V Open

SW2.7 GPIO 7 Pull-High 5V Open

SW2.8 GPIO 8 Pull-High 5V Open

GPIO Pull-High Setup

Connector location: SW2

1

O

N

2

1

O

N

2345678

21

Contents

ON OFF

SW3.1 12V NC

SW3.2 5V NC

SW3.3(*) Ring NC

SW3.4 NC NC

(*) Default

COM1 RI/Power Select

Connector location: SW3

1

O

N

234

ON OFF

SW4.1 12V NC

SW4.2 5V NC

SW4.3(*) Ring NC

SW4.4 NC NC

(*) Default

COM2 RI/Power Select

Connector location: SW4

1

O

N

234

22

Contents

MiniCard (CN26) Power Selection

Connector location: SW6

3.3V(*) 3.6V

SW6.1 OFF ON

SW6.2 OFF ON

(*) Default

1

O

N

2

23

Contents

WWAN Module SW8.1 SW8.2 SW8.3 SW8.4

Sierra MC7700 OFF OFF ON OFF

Sierra MC7710 OFF OFF ON OFF

Sierra MC7750 OFF OFF ON OFF

Sierra MC8805 OFF OFF ON OFF

HUAWEI EM820W OFF OFF ON OFF

Sierra MC7355 OFF OFF ON OFF

Telit HE910 OFF OFF ON OFF

CM8000(*) ON OFF OFF ON

Sierra MC8090/MC8092 ON OFF OFF OFF

Sierra MC9090 OFF OFF ON OFF

(*) Default

(Digital voice is selectable in BIOS)

WWAN Module Selection Table (For Wake-Up & Voice Functions on Mini-PCIe CN26)

Connector location: SW8

If SMS/Ring Wake Up function or/and Voice Funciton is/are not needed, the setting on SW8 can be ignored.

1

O

N

234

24

Contents

Input Voltage Setup Selection

Connector location: SW9

12V 24V

9V~36V

(*)

all can start

SW9.1 OFF OFF ON

SW9.2 OFF ON Don’t Care

(*) Default

1

O

N

2

25

Contents

Connectors

RTC Battery Connector

Connector size: 1 x 2 = 2-pin header (1.25mm)

Connector location: J9

Pin Definition

1 GND

2 RTC_BAT

1

2

1

10

Debug 80 Port Connector

Connector size: 1 x 10 = 10-pin header (1.0mm)

Connector location: J13

Pin Definition Pin Definition

1 GND 2 PCIRST#

3 33M_CLK 4 LPC_FRAME#

5 LPC_AD3 6 LPC_AD2

7 LPC_AD1 8 LPC_AD0

9 VCC3 10 VCC3

26

Contents

COM Port Connecter (COM1 RS-232)

Connector size: 2 x 5 = 10-pin header (2.00mm)

Connector location: CN18

COM Port Connecter (COM2 RS-232)

Connector size: 2 x 5 = 10-pin header (2.00mm)

Connector location: CN19

Pin Definition Pin Definition

1 DCD_1 2 RXD_1

3 TXD_1 4 DTR_1

5 GND 6 DSR_1

7 RTS_1 8 CTS_1

9 RI/PW 10 NC

Pin Definition Pin Definition

1 DCD_2 2 RXD_2

3 TXD_2 4 DTR_2

5 GND 6 DSR_2

7 RTS_2 8 CTS_2

9 RI/PW 10 NC

1

2

9

10

1

2

9

10

27

Contents

COM Port Connecter (COM3 - RS422/485)

Connector size: 2 x 5 = 10-pin header (2.00mm)

Connector location: CN20

1

2

9

10

Pin Definition Pin Definition

1 NC 2 RS485_-/RS422_RX-

3 RS485_+/RS422_RX+ 4 NC

5 GND 6 NC

7 RS422_TX- 8 RS422_TX+

9 NC 10 NC

1

10

MCU-DIO Connector

Connector size: 1 x 10 = 10-pin header (1.0mm)

Connector location: CN10

Pin Definition Pin Definition

1 GND 2 SIO_RTS_1

3 SIO_TXD_1 4 SIO_CTS_1

5 SIO_RXD_1 6 GND

7 SIO_CTS_0 8 SIO_RXD_0

9 SIO_RTS_0 10 SIO_TXD_0

28

Contents

Reset Button (Reserved)

Connector size: 1 x 2 = 2-pin header (1.25mm)

Connector location: J17

Pin Definition

1-2 Open NORMAL

1-2 Short RESET#

1

2

Power Button Connector (Reserved)

Connector size: 1 x 2 = 2-pin header (2.5mm)

Connector location: J20

Pin Definition

1 GND

2 PB

1

2

29

Contents

SATA HDD Connector

Connector size: CN7, 1 x 4 = 4-pin header (2.54mm)

CN9 1 x 7 = 7-pin header (1.27mm)

Connector location: CN7 & CN9

Pin Definition Pin Definition

1 VCC12 2 GND

3 GND 4 VCC5

Pin Definition Pin Definition

1 GND 2 SATA_TXP0

3 SATA_TXN0 4 GND

5 SATA_RXN0 6 SATA_RXP0

7 GND

CN7

CN9

14

1 7

19

21

0

OBDII Module Connector

Connector size: 2 x 5 = 10-pin header (2.0mm)

Connector location: JP8 & JP7

Pin Definition Pin Definition

1 CAN_M_H 2 C1708_1_H

3 CAN_M_L 4 C1708_1_L

5 GND 6 GND

7 NC 8 NC

9 NC 10 NC

Pin Definition Pin Definition

1 TXD 2 RXD

3 CAN_DI1 4 CAN_DO1

5 GND 6 GND

7 NC 8 NC

9 CAN_M_VCC5 10 NC

JP8

JP7

30

Contents

13

Debug Port

Connector size: 1 x 3 = 3-pin header (2.54mm)

Connector location: JP2

Pin Definition

1 TX

2 RX

3 GND

GAL Download Port

Connector size: 1 x 6 = 6-pin header (2.54mm)

Connector location: JP4

Pin Definition Pin Definition

1 VCC3 2 GND

3 TCK 4 TDO

5 TDI 6 TMS

16

31

Contents

6 1

GPS Connector

Connector size: 1 x 6 = 6-pin header (1.0mm)

Connector location: J12

Pin Definition Pin Definition

1 GPS_BAT 2 GPS_LED#

3 GPS_TX 4 GPS_RX

5 GND 6 VCC3_GPS

Internal WWAN SIM Card Socket (SIM 3) For CN27

Connector location: CN24

Pin Definition Pin Definition

C1 SIM PWR C5 GND

C2 SIM RST C6 NC

C3 SIM CLK C7 SIM DAT

C3

C2

C1

C7

C6

C5

32

Contents

MCU Download Port

Connector size: 1 x 5 = 5-pin header (2.54mm)

Connector location: JP3

Pin Definition Pin Definition

1 V3.3ALW 2 C2D

3 MRST 4 C2CK

5 GND

15

33

Contents

Mini-PCIe (USB + PCIe)

Connector location: CN17

12

51 52

Pin Definition Pin Definition

1 WAKE# 2 +V3.3A_MINI1

3 NC 4 GND

5 NC 6 +V1.5S_MINI1

7 CLK_REQ# 8 NC

9 GND 10 NC

11 PCIE_CLK# 12 NC

13 PCIE_CLK 14 NC

15 GND 16 NC

17 NC 18 GND

19 NC 20 WLAN_DIS#

21 GND 22 RESET#

23 PCIE_RX_N 24 +V3.3A_MINI1

25 PCIE_RX_P 26 GND

Pin Definition Pin Definition

27 GND 28 +V1.5S_MINI1

29 GND 30 SMBCLK

31 PCIE_TX_N 32 SMBDAT

33 PCIE_TX_P 34 GND

35 GND 36 USB37 GND 38 USB+

39 +V3.3A_MINI1 40 GND

41 +V3.3A_MINI1 42 NC

43 GND 44 WLAN_LED#

45 NC 46 NC

47 NC 48 +V1.5S_MINI1

49 NC 50 GND

51 BT_EN 52 +V3.3A_MINI1

34

Contents

Mini-PCIe (USB + PCIe)

Connector location: CN25

1 2

51 52

Pin Definition Pin Definition

1 WAKE# 2 +V3.3_MINI_3

3 NC 4 GND

5 NC 6 +V1.5S_MINI_3

7 CLKREQ 8 NC

9 GND 10 NC

11 REFCLK- 12 NC

13 REFCLK+ 14 NC

15 GND 16 NC

17 NC 18 GND

19 NC 20 MINICARD3_DIS#

21 GND 22 WLAN_RESET#

23 PCIE_RX_N 24 +V3.3_MINI_3

25 PCIE_RX_P 26 GND

Pin Definition Pin Definition

27 GND 28 +V1.5S_MINI_3

29 GND 30 SMBCLK

31 PCIE_TX_N 32 SMBDAT

33 PCIE_TX_P 34 GND

35 GND 36 USB_D37 GND 38 USB_D+

39 +V3.3_MINI_3 40 GND

41 +V3.3_MINI_3 42 WWAN_LED#

43 GND 44 NC

45 NC 46 NC

47 NC 48 +V1.5S_MINI_3

49 NC 50 GND

51 CTRL0 52 +V3.3_MINI_3

35

Contents

Mini-PCIe (USB)

Connector location: CN26

SIM Socket: SIM 1 (default)

SIM Socket: SIM 2

1 2

51 52

Pin Definition Pin Definition

1 MINI_MIC_P 2 +V3.3A_MINI_4

3 MINI_MIC_N 4 GND

5 MINI_SPK_PRR 6 NC

7 U_GND 8 UIM_PWR2

9 GND 10 UIM_DAT2

11 VCC_MSM26_DIG 12 UIM_CLK2

13 NC 14 UIM_RST2

15 GND 16 NC

17 NC 18 GND

19 NC 20 3.5G_DIS#

21 GND 22 3.5G_RST#

23 NC 24 +V3.3A_MINI_4

25 NC 26 GND

Pin Definition Pin Definition

27 GND 28 NC

29 GND 30 NC

31 NC 32 SMS_RI_3.5G_R

33 UMTS_RESET#_R 34 GND

35 GND 36 USB37 GND 38 USB+

39 +V3.3A_MINI_4 40 GND

41 +V3.3A_MINI_4 42 3.5G_LED#_R

43 GND 44 NC

45 PCM_CLK 46 NC

47 PCM_RX 48 NC

49 PCM_TX 50 GND

51 PCM_SYNC 52 +V3.3A_MINI_4

36

Contents

Mini-PCIe (USB)

Connector location: CN27

SIM Socket: SIM 2 (default)

SIM Socket: SIM 3

1 2

51 52

Pin Definition Pin Definition

1 NC 2 +V3.3A_MINI_2

3 NC 4 GND

5 NC 6 +V1.5S_MINI_2

7 NC 8 UIM2_PWR2_MINI

9 GND 10 UIM2_DAT2_MINI

11 VCC_MSM26_DIG 12 UIM2_CLK2_MINI

13 NC 14 UIM2_RST2_MINI

15 GND 16 NC

17 NC 18 GND

19 NC 20 3.5G_DIS#

21 GND 22 3.5G_RST#

23 NC 24 +V3.3A_MINI_2

25 NC 26 GND

Pin Definition Pin Definition

27 GND 28 +V1.5S_MINI_2

29 GND 30 NC

31 NC 32 NC

33 UMTS_RESET#_R 34 GND

35 GND 36 USB37 GND 38 USB+

39 +V3.3A_MINI_2 40 GND

41 +V3.3A_MINI_2 42 NC

43 GND 44 PCIE2_LED

45 NC 46 NC

47 NC 48 +V1.5S_MINI_2

49 NC 50 GND

51 NC 52 +V3.3A_MINI_2

37

Contents

chaPter 4: system setuP

Removing the Chassis Cover

Prior to removing the chassis cover, make sure the unit’s power

is o and disconnected from the power sources to prevent

electric shock or system damage.

CAUTION!

CAUTION!CAUTION!

Front View Rear View

1. The screws on the front and the rear are used to secure the cover to the

chassis. Remove these screws and put them in a safe place for later use.

38

Contents

Installing a SSD/HDD Drive

1. Loosen the thumb screws on the SSD/HDD drive bay and slide the drive

bay out.

2. Insert the hard drive into the drive bay with the SATA data and power

connector facing towards the end. Align the hard drive’s mounting holes

with the mounting holes on the drive bay, and use the provided screws

to secure the hard drive in place.

Mounting

screws

Thumb

screws

SATA

data/power

connector

39

Contents

3. Insert the drive bay back in the SSD/HDD slot and tighten the thumb

screws to secure it in place.

40

Contents

Installing a WLAN Module (Half Mini-PCIe)

1. Locate the WLAN Mini PCI Express slot (CN17). Insert the module into

the Mini PCI Express slot at a 45 degrees angle until the gold-plated

connector on the edge of the module completely disappears inside the

slot. Then fasten screws into the mounting holes to secure the module.

Installing a WWAN Module

1. Locate the WWAN Mini PCI Express slot (CN26 & CN27). Insert the module

into the Mini PCI Express slot at a 45 degrees angle until the gold-plated

connector on the edge of the module completely disappears inside the

slot. Then fasten screws into the mounting holes to secure the module.

Mounting

screws

Mounting

screws

41

Contents

Installing a SO-DIMM

1. Push the ejector tabs which are at the ends of the socket outward. Then

insert the module into the socket at an approximately 30 degrees angle.

Apply rm even pressure to each end of the module until it slips down

into the socket. The contact ngers on the edge of the module will

almost completely disappear inside the socket.

Ejector tab

42

Contents

Installing a OBDII Module

1. Locate the OBDII connectors (JP7 and JP8).

JP7 JP8

2. Connect the OBDII module to JP4 and JP3 and secure the OBDII module

with screws.

Mounting

screws

43

Contents

aPPendIx a:

software demo utIlIty for I/o Ports of functIon control

Divio Tec’s software demo utility enables users to test and control dierent I/O port functions on the NRM301. This document shows how to use the utility.

There are also source code les of the utility in the CD. Users can refer to the source codes to develop their applications.

Menu Screen

44

Contents

1.1 Status

1.1.1 Ignition Status

Press the button of Ignition Status, the signal of ignition will be shown.

ON …… Signal of ignition is high.

OFF ….. Signal of ignition is low.

1.1.2 Battery Status

Press the button of Battery Status, the status of battery voltage will be shown.

Low voltage …… Car battery is at low voltage.

OK .......….......... Car battery is not at low voltage.

1.2 Input Voltage

Shows the setting of input voltage in SW8 DIP switch.

If the setting is 12V:

12V is shown

If the setting is 24V:

24V is shown

If the setting is 9V~36V:

9V~36V is shown

45

Contents

1.3 Output Power

1.3.1 External +12V

Enables or disables the output of 12VDC.

1.3.2 Bypass Car Battery Power

Enables or Disables the output of Car Battery Power.

1.4 GPIO Setting

1.4.1 GPIO Select

Denes GPIO port as GPO or GPI.

1.4.2 GPO Set

Selects the GPO ports and makes the output low or high.

1.4.3 GPI Read

Reads the status of GPI.

46

Contents

1.5 MCU GPIO Setting

1.5.1 MCU GPO Set

Selects MCU GPO ports and makes the output low or high.

1.5.2 MCU GPI Status

Shows the status of the MCU GPI.

1.6 WDT Setting

Enables or disables the WDT function. There are 9 selections of time. The

timer of WDT can also be cleared by Clear Timer button.

1.5.3 Event Button Read

Shows the status of Event Button.

Normal: 0 (default)

Triggered: 1

1.5.4 Event Record Clear

Clears the event record in MCU.

47

Contents

1.7 WWAN Module

1.7.1 Mini-PCIe CN27

Selects SIM2 or SIM3 card.

1.7.2 Mini-PCIe CN26

Selects SIM1 or SIM2 card.

1.8 Selection of RS-422 or RS-485 for COM3

Enables or disables the power on delay time function. There are 8 selections

of delay time.

1.9 Power Off Delay Time

Enables or disables the power o delay time function. There are 8 selections

of delay time.

48

Contents

1.10 Wake Up Function

1.10.1 WWAN

Enables or disables the standby power to Mini-PCIe socket (CN23) for wakeup function.

** The wake-up function is triggered by external RING or SMS.

1.10.2 RTC

Enables or disables the RTC wake up function. The timer setting of RTC is

located in BIOS setting.

1.11 CAN Bus Setting

1.11.1 OBDII Module Reset

Reset OBDII module.

1.11.2 OBDII Module Power Reset

Reset the power of OBDII module.

1.11.3 On Board CAN2.0B Data Link Status

Reads the connection status of on board CAN2.0B

49

Contents

1.12 Interface Power

1.12.1 USB No.13

Enables or disables the power to USB ports (No.13) on rear panel.

*In order to make all input devices (such as mouse and keyboard) work

correctly, please do not disable USB No. 13 and No.3 at the same time.

1.12.2 USB No.3

Enables or disables the power to USB ports (No.3) on front panel.

1.12.3 GPS

Enables or disables the power to GPS module.

1.13 Mini-PCIe Power

1.13.1 CN17

Enables or disables the power to USB port on CN17.

1.13.2 CN25

Enables or disables the power to USB port on CN25.

50

Contents

aPPendIx B: usIng the gPs feature

The NRM301 has a built-in u-blox UBX-G6010 GPS receiver module by default.

Global Positioning System (GPS) uses a constellation of 50 medium earth orbit

satellites to transmit and receive microwave signals to determine its current

location.

You need to install the third-party GPS navigation software to take advantage

of the GPS feature.

Setup and Using GPS Information

Users can use the GPSinfo.exe program to verify that the GPS is correctly

congured and working properly. Also, users can use the GPSinfo.exe program to enable WAAS/EGNOS and power saving mode.

1. Go to Device Manager to ensure the device is installed correctly.

Module: DGM-U2525T

Chip:

• Receiver Type:

•50-channel u-blox UBX-G6010 chip

•GALILEO

•GPS L1 C/A code

•SBAS: WAAS, EGNOS, MSAS, GAGAN

• Navigation Update Rate:

•Up to 5 Hz

• Accuracy Position:

•< 2.5 m autonomous

•< 2.0 m SBAS

• Acquisition:

•Cold starts: 26s

•Aided starts: 1s

•Hot starts: 1s

• Sensitivity:

•Tracking: –162 dBm

•Cold starts: –160 dBm

•Hot starts: –148 dBm

AGPS

Supports Assist Now

®

Online and Oine, OMA SUPL compliant.

51

Contents

2. Insert the Installation Disc into CD-Rom drive and execute the “Gpsinfo.

exe” le (the le also saved in C:\Utility\GPS_Utility).

3. Follow the given instructions to complete the installation.

4. When the setup complete, press <Finish>.

5. Once the installation is completed, installation of GPS Information onto

PDA device will be launched automatically. Select <Yes> to continue.

52

Contents

Setup Window Screenshot

Double click GpsInfo_Vista icon from Desktop to start GPS.

• Scan Com Port” - Scan all available communication port for GPS recep-

tion

• “Cold Start” - Cold start the GPS receiver

• “Power Save” - Check the box to enable/disable the Power Save Mode

(the option is available only when a GPS device is found)

• “Tab Menu” - Switch between Setup and GPSINFO windows

• “Com Port Selection” - Select the appropriate communication port

where GPS receiver is congured (it may be necessary to try several communication ports until the right one is found)

• “Baud Rate Selection” - Select the appropriate transferring rate (Please

set the baud rate at 9600)

• “Start GPS button” - Turn on/o the GPS device

• “ VTG check box” - Some navigation or map software requires to receive

VTG data output for during operation. Check the box to activate the

VTG data output.

Com Port Selection

Baud Rate Selection

Start GPS button

Cold Start

Scan Com Port

Main GPS data

Window

VTG check box

WAAS/EGNOSPower Save

Tab Menu

• “WAAS/EGNOS” - Check the box to activate WAAS/EGNOS in order to

increase the accuracy of positioning

• “Main GPS data Window” - Display data received by GPS device.

GPS Info Window Screenshot

• “Satellite Distribution Map” – Display the position of all connected

Satellites

•A unique number is assigned to each satellite.

•Red circle indicates that the satellite location is known from almanac

information; however, the satellite is not currently being tracked.

•Green circle indicates that the satellite is being tracked; however, it is

not being used in the current position solution.

•Blue circle indicates that is being tracked and is being used in the cur-

rent position.

Satellite

Distribution

Map

Latitude

Satellite Status

Chart

Longitude

Position Accuracy

Horizontal Accuracy

Positioning Status

Speed

Direction

Time

Date

53

Contents

• “Latitude” – User’s current latitude is displayed in N/S degree (North/

South Hemisphere) format

• “Satellite Status Chart” – display the status of each connected satellite

•The number under each bar marks corresponding Satellite, and the

height of each bar represents the strength of the satellite.

•Red bar indicates that the satellite location is known from almanac

information; however, the satellite is not currently being tracked.

•Green solid bar indicates that the satellite is being tracked; however, it

is not being used in the current position solution.

•Blue bar indicates that the tracked and is being used in the current

position.

• “Date” – display the current date in (dd/mm/yy) format.

• “Time” – display the current (UTC) time in (hh:mm:ss) format.

• “Direction” – display the current direction from 000.0° to 359.9°

• “Speed” – Display the current moving speed in km/hour

• “Positioning Status”- Three Modes

1. No Fix

2. 2D Positioning

3. 3D Positioning

• “Horizontal Accuracy” - Range from 0.5 to 99.9, the smaller the better

• “Position Accuracy” - Range from 0.5 to 99.9, the smaller the better

• “Longitude” – Display current longitude in E/W (East/West Hemisphere)

Time (hhmmss)

GPS Information Instructions

1. Make sure that the GPS device is properly inserted.

2. Start GPS Information Software.

3. Choose and select the proper communication port. (It might be neces-

sary to try each available port to nd the right one since the default

communication port varies according to dierent hardware device.)

4. Click “Start GPS button” to activate the GPS receiver.

5. Upon successful connection, GPS output data should be displayed in

“Main GPS data Window”. If no data is observed, make sure the GPS

receiver is working and properly inserted. Otherwise choose another

communication port.

6. Satellite status can be observed in the “GPS Info Window”. Use the

“Tab Menu” to switch between Setup window and GPS info window.

7. Please make sure to de-activate the GPS device before exiting this pro-

gram.

54

Contents

aPPendIx c: sIgnal connectIon of dI/do

GPIO Pinout Description SW2 Setting

GPIO1

GPIO2

GPIO3

GPIO4

GPIO5

GPIO6

GPIO7

GPIO8

VCC5

PO

DIP SW 2X8

PO

SW2

DIP SW 2X8

1

2

3

4

5

6

7

8

14

13

12

11

10

9

15

16

330Ω

GPIO (SW2)

On Pull up VCC5

O Don’t Care

GPIO (SW2)

SW2.1~SW2.8 Pull up VCC5

Default Settings:

1 8

GPIO

CAN GNDOBDII

Pin 9

Pin 1 Pin 8

Pin 16

Pin Definition

9 GPIO1 (Default: GPI1)

10 GPIO2 (Default: GPI2)

11 GPIO3 (Default: GPI3)

12 GPIO4 (Default: GPI4)

13 GPIO5 (Default: GPO1)

14 GPIO6 (Default: GPO2)

15 GPIO7 (Default: GPO3)

16 GPIO8 (Default: GPO4)

GPIO can be programmed by S/W.

Please refer to the source code in utility.

55

Contents

Dry Contact:

Digital Input

CN14 connector for GPI signal (digital signal input)

The CN14 has 4 digital input channels by default.

Wet Contact (default)

The GPI signals have a pull up resistor to 5V internally.

The gure below shows how to connect an external output source to one

of the input channel.

ExternalInternal

GPIO1

GPI5

GPI6

GPIO2

GPIO7

GPI4

GPIO8

GPIO3

GPIO_GND

CN14

9

10

11

12

13

14

15

7

16

VCC5

6115124

13

1K1K

ExternalInternal

GPIO1

GPI5

GPI6

GPIO2

GPIO7

GPI4

GPIO8

GPIO3

GPIO_GND

CN14

9

10

11

12

13

14

15

7

16

Resistor

External power

External

Switch

Port

GPI

Register

ON (Short) GND 0

OFF (Open) OPEN 1

External

Switch

Port

GPI

Register

ON (Short) GND 0

OFF (Open) HIGH 1

56

Contents

Dry Contact

Each channel can accept 3~24Vdc voltage. And it is able to drive 150mA

current for low level.

The SW2 needs to switch to “OFF” state. The GPO signal will no have a pull

up resistor internally when you switch “SW2” to “OFF” state.

The gure below shows how to connect an external input source to one of

the output channel.

Digital Output

CN14 connector for GPO signal (digital signal output)

The CN14 connector has 4 digital output channels by default. The signal

connection of CN14 support two connected methods for output signal type.

The output signal has two states, one is low level (driven to 0V from GPO

signal) other is open (high voltage is provided from external device).

Wet Contact (default)

The SW2 needs to switch to “ON” state. The GPO signal will have a pull up

resistor to 5V internally when you switch “SW2” to “ON” state. The output

signal has two states, one is low level (driven to 0V from GPO signal ) other

is high level (driven to 5V from GPO signal).

The gure below shows how to connect an external input source to one of

the output channel.

GPO

Register

Port

1 HIGH

0 GND

GPO

Register

Port

1 OPEN

0 GND

ExternalInternal

GPIO1

GPO5

GPO6

GPIO2

GPIO7

GPO4

GPIO8

GPIO3

GPIO_GND

CN14

9

10

11

12

13

14

15

7

16

VCC5

6115124

13

ExternalInternal

GPIO1

GPO5

GPO6

GPIO2

GPIO7

GPO4

GPIO8

GPIO3

GPIO_GND

CN14

9

10

11

12

13

14

15

7

16

Resistor

External power

57

Contents

aPPendIx d: sIgnal connectIon of mcu dI/do and event But

-

ton

MCU-DIO Pinout Description Digital Input

The gure below shows how to connect an external output source to one

of the input channel.

1 5

6 9

Pin Definition Pin Definition

1 NC 2 NC

3 MCU-DI1 4 MCU-DI2

5 GND 6 NC

7 NC 8 MCU-DO1

9 MCU-DO2

MCU-DI1

MCU-DI2

MCU-DO1

MCU-DO2

DB9-FEMALE-90-5.08mm

5

9

4

8

3

7

2

6

1

Internal External

External Power

External Resistor

External

Switch

Port

DI

Register

ON (Short) GND 0

OFF (Open) HIGH 1

58

Contents

The gure below shows how to connect an external input source to one of

the output channel.

Digital Output

MCU-DI1

MCU-DI2

MCU-DO1

MCU-DO2

DB9-FEMALE-90-5.08mm

5

9

4

8

3

7

2

6

1

Internal External

External Power

External Resistor

DO

Register

Port

1 OPEN

0 GND

Event Button

21

Pin Definition

1 Event Input

2 GND

59

Contents

(Status: Normal)

*When Pre-Alarm function is enabled.

Internal External

3.3V pull high

Pin

1P

in 2

Internal External

3.3V pull high

Pin

1P

in 2

(Status: Event Occurs)

*When Pre-Alarm function is enabled

60

Contents

Pre-Alarm Function by Event Button,

MCU-DI and MCU-DO

Pre-Alarm function allows NRM301 to monitor the environment and make

reaction, even when NRM301 is turned o.

By monitoring the environment with sensors connected to Event Button and

MCU-DI ports, NRM301 can react to certain situations. For example, events

triggered by external sensors, such as temperature change, instrusion or

vibration, NRM301 can react accordingly by turning on the siren or warning

light, and power on automatically for further action against the event.

Setting up Pre-Alarm function

MCU-DI1 is used to initiate Pre-Alarm function, which is usually connected

to the vehicle’s Central Locking System. As such, the Pre-Alarm function on

NRM301 will be initiated or released based on the locking and unlocking state

of the Central Locking System. For instance, when the Central Locking System

is initiated or released, the Pre-Alarm function on NRM301 will be initiated or

released, respectively.

Step 1: Enable/Disable Pre-Alarm function in BIOS

Select “Enable” or “Disable”to initiate or terminate Pre-Alarm function.

Step 2: Select the trigger threshold level in BIOS

For vehicles with electric central door lock, check the corresponding trigger

type (negative or positive), then connect MCU-DI1 to Central Locking

System in vehicle.

Negative level: < 3.3V

Positive level: > 3.3V

If the Central Locking System is initiated (locking signal is received) by a

negative signal, select “Low” in the trigger threshold level. Once the Central

Locking System is released by a positive signal, the Pre-Alarm function on

NRM301 will be released.

If Central Locking System is initiated (locking signal is received) by a positive

signal, select “High” in the trigger threshold level. Once Central Locking

System is released by a negative signal, the Pre-Alarm function on NRM301

will be released.

MCU-DI1 & MCU-DI2 (source type): 3~12VDC

MCU-DO1 & MCU-DO2 (source type): 3~24VDC

61

Contents

Activating Pre-Alarm function

Step 1: Setup Pre-Alarm function

Step 2: Connect Event Button to sensor (such as reed switch)

Normally, the status of Event Button is “Short”. Once the status becomes

“Open”, Event Button will be triggered.

Step 3: Connect MCU-DI2 to sensor

Normally, the status of MCU-DI2 is “Low”. Once the status becomes

“High”, MCU-DI2 will be triggered.

Low level: < 3.3V

High level: > 3.3V

Step 4: Connect MCU-DO1 and MCU-DO2 to external relays

Relays can be used to drive external devices (such as siren or warning light).

Each MCU-DO port can wire a relay.

(Normal)

MCU-DO1 & MCU-DO2: OPEN

(Triggered)

MCU-DO1 & MCU-DO2: GND

Step5:FlagAandFlagCwillbecome“1”automatically

Flag A: at I/O Address -- 0x0ED8 bit4

Flag C: at I/O Address -- 0x0ED8 bit5

Deactivating Pre-Alarm function

(For Event Button)

Option 1:

If Central Locking System is initiated by negative signal:

When MCU-DI1 is “High”, Pre-Alarm Function is deactivated.

If Central Locking System is initiated by positive signal:

When MCU-DI1 is “Low”, Pre-Alarm Function is deactivated.

Option 2:

Whiting”1” to the Flag B, Pre-Alarm Function will be deactivated.

Flag B: at I/O Address -- 0x0ED8 bit2

Option 3:

When Ignition signal is “High”, Pre-Alarm Function is deactivated.

(For MCU-DI2)

Option 1:

If Central Locking System is initiated by negative signal:

When MCU-DI1 is “High”, Pre-Alarm Function is deactivated.

If Central Locking System is initiated by positive signal:

When MCU-DI1 is “Low”, Pre-Alarm Function is deactivated.

Option 2:

Whiting”1” to the Flag B, Pre-Alarm Function will be deactivated.

Flag B: at I/O Address -- 0x0ED8 bit2

Option 3:

When Ignition signal is “High”, Pre-Alarm Function is deactivated.

62

Contents

Activating Pre-Alarm Function

(For Event Button) (For MCU-DI2)

Example: When Central Locking System is initiated (locking signal is received)

by negative signal, select “Low” in the trigger threshold level for MCU-DI1.

MCU-DI1

“Low”?

Event Button

“Open”?

MCU-DO1 & MCU-DO2

“OPEN” “GND”

NViS2310 power on

Flag A is “1”

No

No

Yes

Yes

Point A

Start

MCU-DI1

“Low”?

MCU-DI2

“High”?

MCU-DO1 & MCU-DO2

“OPEN” “GND”

NViS2310 power on

Flag C is “1”

No

No

Yes

Yes

Point A

Start

63

Contents

Deactivating Pre-Alarm Function

(For Event Button) (For MCU-DI2)

Example: When Central Locking System is initiated (locking signal is received)

by negative signal, select “Low” in the trigger threshold level for MCU-DI1.

MCU-DI1

“High”?

Flag B

“1”?

Ignition

“High”?

MCU-DO1 & MCU-DO2

“Low” “H igh”

Yes

Yes

Yes

No

No

No

Start

Point A

MCU-DI1

“High”?

Flag B

“1”?

Ignition

“High”?

MCU-DO1 & MCU-DO2

“Low” “H igh”

Yes

Yes

Yes

No

No

No

Start

Point A

64

Contents

aPPendIx e: vehIcle Power management setuP

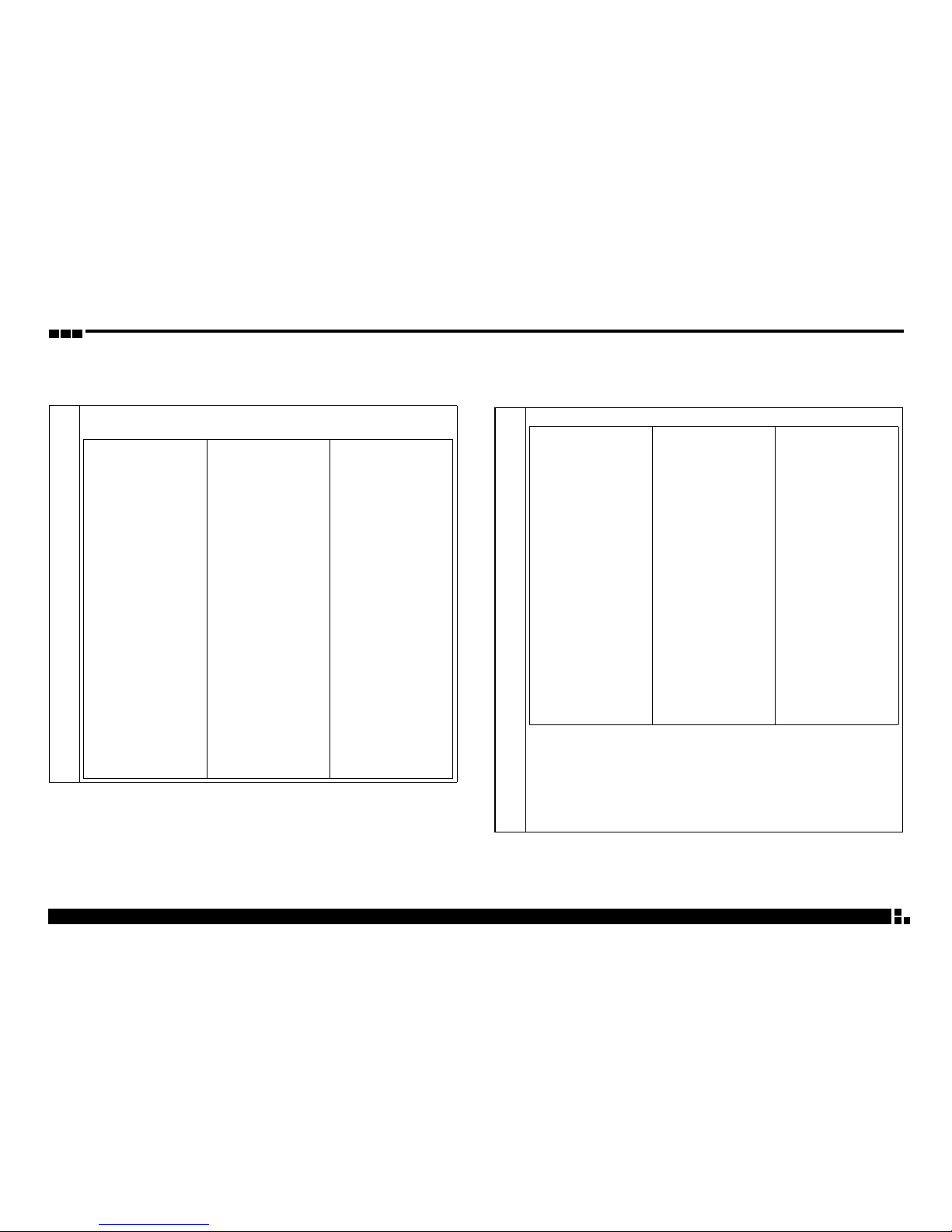

External Power Output Setting

NRM301 series has four modes for external power output setting.

1. External +12V and By Pass Car Battery Turn On Simultaneously

2. External +12V and By Pass Car Battery Turn O Simultaneously

3. External +12V Turn On Only

4. By Pass Car Battery Turn On Only

Advanced

Version 2.14.1219. Copyright (C) 2010 American Megatrends, Inc.

Aptio Setup Utility - Copyright (C) 2010 America Megatrends, Inc.

→←: Select Screen

↑↓: Select Item

Enter: Select

+/-: Change Opt.

F1: General Help

F2: Previous Values

F3: Optimized Defaults

F4: Save & Exit

ESC: Exit

External +12V & By Pass Car

Battery Power Setting

Power Management Conguration

** External +12V & By Pass Car Battery Setting **

External Power

** External +12V & By Pass Car Battery Setting **

Input Voltage

Startup.Shutdown

**Delay Time Setting**

Power On Delay

Power O Delay

[Turn On Both]

9-36V

[(11.5.10.5)/(23,21)]

External Power

Turn On Booth

Turn O Booth

Turn On +12V

Turn On By Pass Car Battery

Startup and Shutdown Voltage Setting

Set the startup voltage to 11.5V or 23V and the shutdown voltage to 10.5V or 21V

If the input voltage is 12V: the startup voltage to 11.5V and the shutdown

voltage to 10.5V.

If the input voltage is 24V: the startup voltage to 23V and the shutdown

voltage to 21V.

Advanced

Version 2.14.1219. Copyright (C) 2010 American Megatrends, Inc.

Aptio Setup Utility - Copyright (C) 2010 America Megatrends, Inc.

→←: Select Screen

↑↓: Select Item

Enter: Select

+/-: Change Opt.

F1: General Help

F2: Previous Values

F3: Optimized Defaults

F4: Save & Exit

ESC: Exit

Startup,Shutdown Setting

Power Management Conguration

** External +12V & By Pass Car Battery Setting **

External Power

** External +12V & By Pass Car Battery Setting **

Input Voltage

Startup.Shutdown

**Delay Time Setting**

Power On Delay

Power O Delay

[Turn On Both]

9-36V

[(11.5.10.5)/(23,21)]