Page 1

USER MANUAL

USER MANUAL

USER MANUALUSER MANUAL

March 2018 – Rev A

Page 2

www.diverite.com

This is the user manual for the Dive Rite O2ptima eCCR rebreather.

This user manual is proprietary and copyright Lamartek, Inc. 2018. It may not be reproduced, changed,

or distributed without authorization from Lamartek, Inc.

All information contained in this manual has been carefully reviewed and is believed to be accurate,

however it is subject to change. Rebreather technology is constantly and rapidly evolving. Please check

www.diverite.com to ensure that you have the latest version of this manual.

Companies and/or product names cited in the manual are trademarks belonging to their respective

companies.

The O2ptima is manufactured in the USA by:

Lamartek, inc. dba Dive Rite

175 NW Washington Street

Lake City, FL, 32055 USA

Phone (386) 752-1087

www.diverite.com

March 2018 © Lamartek, Inc. dba Dive Rite 2

Page 3

www.diverite.com

General Safety Statements and Warnings

DO NOT use the O2ptima without successfully completing an O2ptima

specific training program.

DO NOT use the O2ptima without reading and understanding this manual

in its entirety.

Reading this user manual DOES NOT replace unit specific training. This

manual does not provide directions for diving with closed circuit rebreather

equipment. This manual is only intended to be a guide for the proper

maintenance, setup, operation, and basic service of the O2ptima

rebreather.

As with any piece of equipment, this rebreather will eventually fail. Even

careful maintenance, assembly, and testing will not prevent this from

happening. It is possible that any part of this unit may fail at any time.

Because of this, it is essential that a separate, independent bailout system

be taken by the diver on every dive. The bailout system must be configured

to allow safe termination of the dive and return to the surface in the event

of a malfunction at any point during the dive.

All components of the rebreather must be in good working order and be

carefully maintained, assembled, and tested to reduce the risk of failure.

Participation in rebreather diving can result in serious injury or death.

These risks can be reduced, but never eliminated.

Knowledge and training are the best tools for avoiding accidents.

Rebreather diving is a physically as well as mentally demanding activity.

If you do not have adequate training, equipment, physical conditioning, and

proper mind-set, do not get in the water.

As the diver, YOU have the final responsibility for your own actions and

safety while using this rebreather.

March 2018 © Lamartek, Inc. dba Dive Rite 3

Page 4

www.diverite.com

Table of Contents

General Safety Statements and Warnings .................................................................................................. 3

Introduction .................................................................................................................................................. 7

Design Philosophy ........................................................................................................................................ 7

System Overview .......................................................................................................................................... 8

The Breathing Loop ...................................................................................................................................... 9

Component Features & Functions ............................................................................................................. 10

Counter Lungs ................................................................................................................................ 10

Breathing Hoses & Fittings ............................................................................................................. 10

Divesoft BOV + ADV + MAVs .......................................................................................................... 10

Overpressure/Dump Valve ............................................................................................................ 11

Scrubber Canister ........................................................................................................................... 12

Scrubber End Cap & Water Trap .................................................................................................... 12

Electronics Head ............................................................................................................................ 12

Oxygen Sensors .............................................................................................................................. 13

Controller ....................................................................................................................................... 14

Electronics/Battery Canisters......................................................................................................... 14

HUD ................................................................................................................................................ 15

Regulators, Hoses, & Gauges ......................................................................................................... 15

Cylinders & Valves .......................................................................................................................... 16

Stand .............................................................................................................................................. 16

Cover .............................................................................................................................................. 17

Harness .......................................................................................................................................... 17

Air Cell ............................................................................................................................................ 17

Micropore ExtendAir Cartridge Overview ................................................................................................. 19

Assembling the O2ptima ............................................................................................................................ 21

Importance of Checklists................................................................................................................ 21

Gas Analyzation .............................................................................................................................. 21

Installing the Cylinders and Regulators ......................................................................................... 21

How to Install a Micropore ExtendAir Cartridge ............................................................................ 22

March 2018 © Lamartek, Inc. dba Dive Rite 4

Page 5

www.diverite.com

How to Pack the Scrubber ............................................................................................................. 23

Installing the Scrubber Assembly ................................................................................................... 26

Installing the Electronics Head ....................................................................................................... 27

Installing the Scrubber End Cap & Water Trap .............................................................................. 28

Mounting the Electronics/Battery Canisters ................................................................................. 30

Installing the Air Cell & Harness ..................................................................................................... 31

Installing the Cover ........................................................................................................................ 33

Installing the Loop Hoses ............................................................................................................... 33

Basic Operation & Use ............................................................................................................................... 35

Harness Adjustment ....................................................................................................................... 35

Adding Trim Weights ..................................................................................................................... 35

Oxygen Sensor Calibration ............................................................................................................. 35

BOV Operation ............................................................................................................................... 36

Breathing on the Loop ................................................................................................................... 37

Electronic vs Manual Operation .................................................................................................... 37

Diluent Injection............................................................................................................................. 38

Servicing, Maintenance, & Cleaning .......................................................................................................... 38

Post Dive Procedures & Cleaning ................................................................................................... 38

Oxygen Sensor Care ....................................................................................................................... 39

Oxygen Sensor Replacement ......................................................................................................... 41

Battery Replacement ..................................................................................................................... 43

Battery Recommendations ............................................................................................................ 44

Storage ........................................................................................................................................... 44

Annual Service ............................................................................................................................... 45

Recommended Care Products ....................................................................................................... 45

Technical Specifications ............................................................................................................................. 45

Revisions & Changes in Documentation .................................................................................................... 46

Appendix I: Checklists ............................................................................................................................... 47

Assembly Guide Checklist .............................................................................................................. 48

Survival Checklist ........................................................................................................................... 49

March 2018 © Lamartek, Inc. dba Dive Rite 5

Page 6

www.diverite.com

Pre-flight Checklist ......................................................................................................................... 49

Post Dive Checklist ......................................................................................................................... 50

Appendix II: Galvanic Oxygen Sensors Applied to Closed Circuit Rebreathers

by Analytical Industries, Inc. .............................................................................................................. 51

March 2018 © Lamartek, Inc. dba Dive Rite 6

Page 7

www.diverite.com

Introduction

Congratulations on your purchase of the O2ptima rebreather! First produced in late 2005, the O2ptima

has been a leader in the rebreather market for over a decade. During that time it has been used for

cutting edge exploration and world class expeditions all over the planet. Dive Rite has made a strong

commitment to ensuring that it is one of the most reliable, capable, and high performing rebreathers on

the market. The O2ptima design continues to evolve as refinements are made and new technology

becomes available. We are certain that this unit will provide you with many unforgettable hours

exploring your underwater world.

Design Philosophy

The design parameters for the O2ptima were simple:

Keep the breathing loop as short as possible

Use proven, state of the art electronics

Be fully compatible with the Micropore ExtendAir cartridge

Maintain a rugged and durable package in the smallest profile possible

These parameters were originally chosen in order to produce a rebreather ideally suited to underwater

cave exploration. The unique challenges of the cave environment demanded a unit that was as safe and

reliable as possible while maintaining a minimal profile. The end result was a rebreather that is not only

highly suitable for cave diving, but also any other type of technical diving where a direct ascent to the

surface is not always possible.

By utilizing a horizontally mounted scrubber canister behind the divers head, the breathing loop was

kept as short as possible. This helps to create the lowest possible work of breathing and allows the use

of smaller diameter loop hoses. This in turn increases comfort and reduces diver fatigue. Mounting the

scrubber canister at the highest point of the loop has the additional advantage of reducing the likelihood

of water entering the scrubber. This, combined with the use of the Micropore ExtendAir cartridge,

greatly reduces the possibility of a “caustic cocktail.”

The O2ptima now utilizes Shearwater electronics for their proven and unparalleled reliability and

functionality.

At Dive Rite, we understand that one size does not fit all, so in addition to the standard O2ptima

features there are a number of options to ensure a proper fit for any diver and mission. Contact Dive

Rite or visit www.diverite.com for more details.

March 2018 © Lamartek, Inc. dba Dive Rite 7

Page 8

www.diverite.com

System Overview

The O2ptima is an electronically controlled, constant PPO2, fully closed circuit rebreather (eCCR). It has

built-in decompression calculation and mixed gas capabilities. The following features come standard on

the unit:

Back mounted counterlungs with 6.5 Liter loop volume

Redundant Shearwater DiveCAN electronics including heads-up display (HUD) and Petrel 2

controller

Dual use scrubber canister design that can be used with Micropore ExtendAir cartridges or

packed with loose CO2 absorbent

Divesoft BOV + ADV + MAVs standard (all-in-one Bail Out Valve with Automatic Diluent Valve

and Manual Add Valves for O2 and diluent) DSV optional

Dual water traps

Regulators and hoses

(4) AI R22 Oxygen Sensors

CCR XT air cell utilizing abrasion resistant SuperFabric

Kydex cover for abrasion protection

Stainless Steel and StarBoard frame and stand

AL 20 oxygen and diluent cylinders with valves

Dive Rite TransPac Harness (Transplate harness optional)

March 2018 © Lamartek, Inc. dba Dive Rite 8

Page 9

www.diverite.com

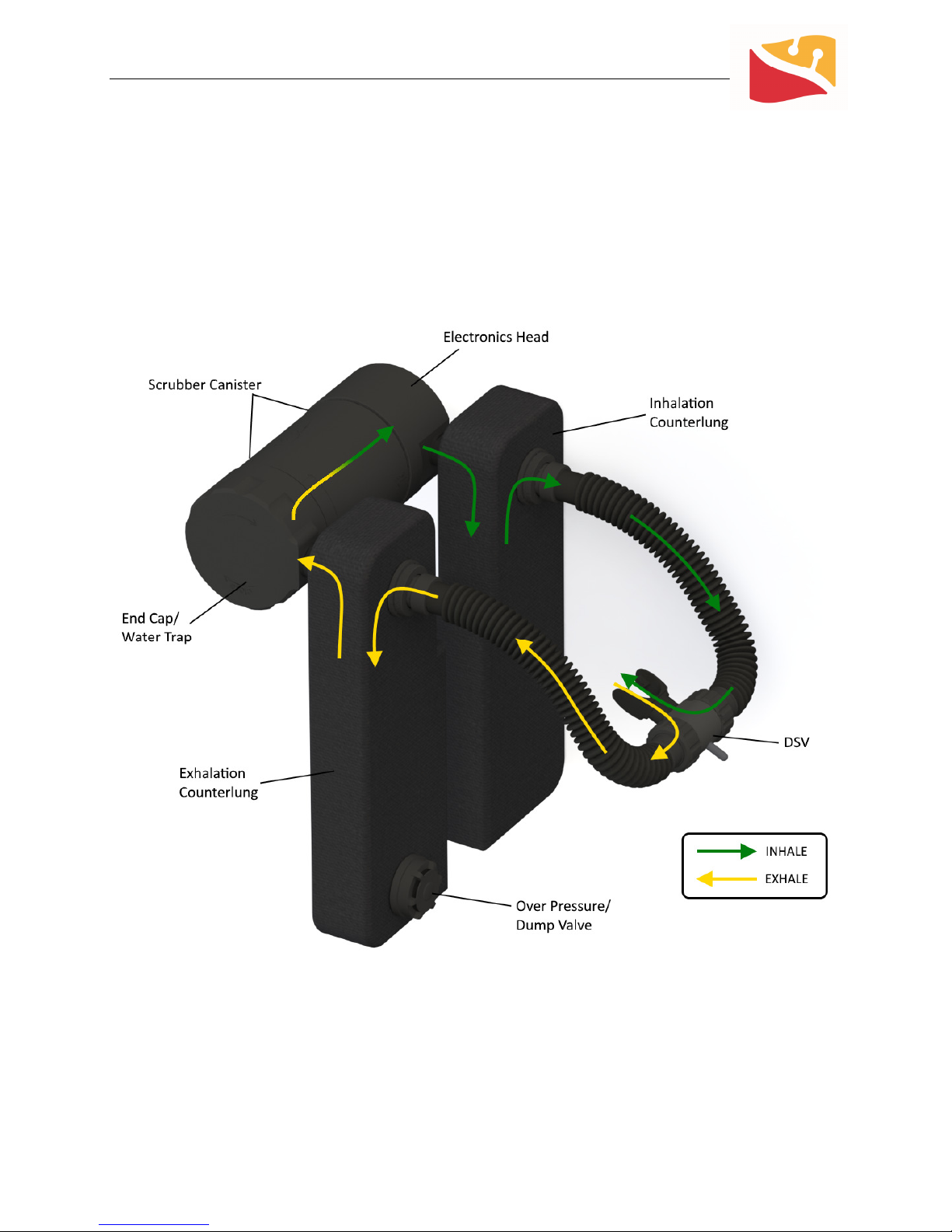

The Breathing Loop

The O2ptima incorporates a back mounted, dual counterlung design. The breathing loop consists of the

BOV or DSV, breathing hoses and hose fittings, inhalation and exhalation counterlungs, scrubber

canister, canister end cap, and electronics head. Gas flows in a clockwise direction—from the left

shoulder—to the diver—to the right shoulder.

March 2018 © Lamartek, Inc. dba Dive Rite 9

Page 10

www.diverite.com

Component Features and Functions

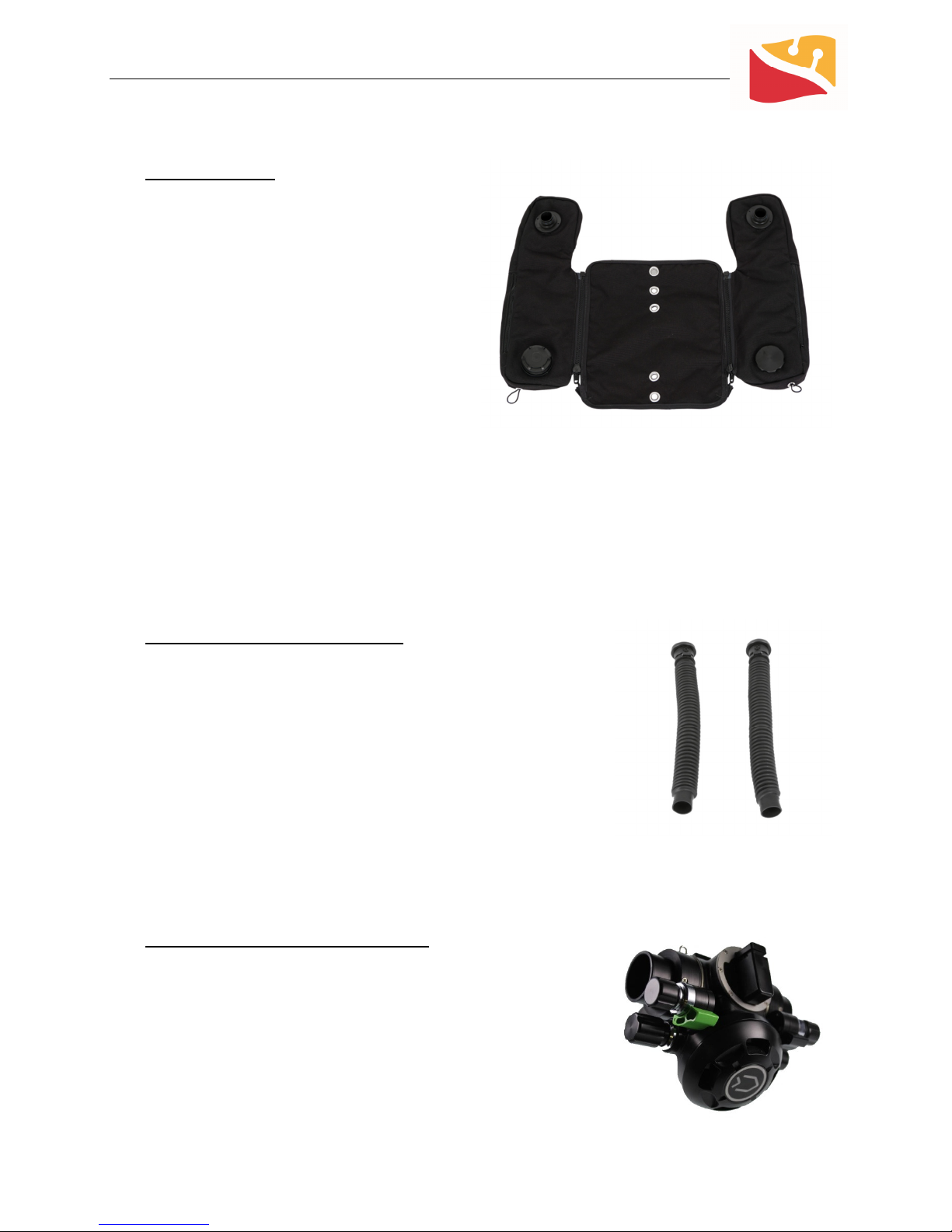

Counterlungs

The O2ptima uses two detachable back mounted

counterlungs. The counterlung position keeps

them as close to the diver’s lung centroid as

possible providing excellent breathing

characteristics in a variety of diver positions. They

are adjustable for optimal positioning and easily

unzip from the center panel to remove for cleaning

and inspection.

The counterlungs consist of an abrasion resistant

outer bag and a removable welded polyurethane

inner bladder. The bladder is accessible through a

zipper on the side of each counterlung.

The back side of the counterlungs attach directly to the scrubber canister. The breathing loop hoses

attach to the front of the counterlungs using threaded connections.

The exhalation counterlung has an overpressure/dump valve located at the bottom of the lung. An

internal water trap is located in the bottom of the exhalation counterlung to make de-watering the loop

easy.

Breathing Hoses & Fittings

The hose diameter and lengths have been specifically chosen to

provide the best balance of comfort and low work of breathing. The

hose lengths are some of the shortest in the industry due to the

location of the behind-the-head scrubber canister. This not only keeps

the work of breathing low, but also reduces drag and uncomfortable

vibrations occasionally encountered with excessive hose lengths when

scootering or swimming against strong flow.

The hoses have threaded fittings attached to the counterlung ends.

Each fitting utilizes a double O-ring seal to help ensure loop integrity. The hoses are 15 inches in length

standard. Other sizes are available for improved fit on smaller divers.

Divesoft BOV + ADV + MAVs

The Divesoft BOV (Bail Out Valve) comes standard on the O2ptima.

(The Dive Rite DSV is optional.) The BOV features an integrated ADV

(Automatic Diluent Valve) and manual oxygen and diluent addition

valves.

The BOV and ADV functions are controlled by the knob on the front

of the BOV. With the knob turned horizontally, the BOV is in closedcircuit mode and you are breathing “on the loop”. Bailing out is

March 2018 © Lamartek, Inc. dba Dive Rite 10

Page 11

www.diverite.com

accomplished by turning the knob 90 degrees so that is vertical. This closes the loop and activates opencircuit mode using the integrated 2nd stage. The BOV is plumbed to the onboard diluent tank. Because of

the small size of the tank, the BOV does not eliminate the need for a separate, independent bailout

system.

The integrated ADV can be activated or deactivated by pressing the button on the knob and rotating the

knob 180 degrees. The ADV only functions in closed circuit mode and does not affect open circuit

operation, i.e. when the knob is vertical the open circuit function is the same even if it is turned 180

degrees.

The ADV uses a built in demand valve that is activated by negative loop pressure against a diaphragm in

the same manner as a standard second stage regulator. The ADV design feeds diluent gas directly to the

BOV. This provides a fast, hands-free method of receiving a known breathable gas as well as supplying

additional gas to increase loop volume.

The BOV should be turned to open circuit mode (vertically) when on the surface or during a bailout

procedure to prevent water from entering the loop.

The integrated Manual Addition Valves (MAVs) are located on the front of the BOV. The green button on

the right side of the diver’s mouth is the oxygen addition button, and the black button on the diver’s left

is the diluent addition button. Low pressure supply hoses are attached to the threaded fittings located

next to each button.

Manual diluent addition is injected just upstream of the BOV to provide an immediate known breathable

gas mix. Manual oxygen addition is injected downstream of the BOV so that it must travel through the

loop before being inhaled. This prevents oxygen spikes to the diver and ensures that the gas mixture is

homogenous before traveling over the oxygen sensors and being inhaled.

The BOV uses a snap ring system to attach the hose fittings to the BOV body. To remove the fittings for

cleaning or inspection of the mushroom valves, simply remove the wire snap ring from its locking groove

and gently pull the fitting away from the body. Pull straight out and avoid twisting the fittings.

If the BOV is unused for a period of time, the knob may become difficult to turn. This is normal and is

due to the lubricant taking a set. Turning the knob back and forth several times before the dive will

redistribute the lubricant and ensure that the knob is smooth and easy to turn.

Overpressure/Dump Valve

The O2ptima uses a special loop overpressure valve (OPV) located on

the front side of the exhalation (right) counterlung. A specific spring is

used to optimize the cracking pressure for rebreather counterlung use.

Do not replace with a standard drysuit exhaust valve as they can have a

much higher cracking pressure which can lead to lung overexpansion

injuries.

This valve will normally be operated in the open position (turned fully counter-clockwise). Divers with a

large tidal volume may find that they need to close the OPV slightly in order to maintain proper loop

volume. The valve can also be manually opened by pressing on the valve. The valve is screwed into a

welded flange on the counterlung inner bladder.

March 2018 © Lamartek, Inc. dba Dive Rite 11

Page 12

www.diverite.com

During an ascent, the gas in the loop will expand, increasing buoyancy and slightly increasing the

breathing effort. Even though the maximum volume in the O2ptima’s breathing loop is relatively small,

it is important to set the OPV properly so that buoyancy shifts will be kept to a minimum without any

diver action.

Scrubber Canister

The scrubber canister contains the scrubbing media that removes CO2 from

the breathing loop. The O2ptima uses an axial style scrubber canister and can

be used with either Micropore ExtendAir cartridges or loose packable CO2

absorbent.

Assembly is slightly different depending on which scrubber media is used. The

wave spring and top plate with screen are not used when using an Extendair

cartridge. The finger nut is reversible. It is used in one direction when packing

loose CO2 absorbent and is flipped over when using Extendair cartridges. See

the How to Pack the Scrubber section for more information on properly

seting up the scrubber canister.

Scrubber End Cap & Water Trap

The scrubber end cap contains a snap-in water trap in the shape of a

cone. This shape prevents excess water from entering the scrubber

canister regardless of the diver’s position in the water.

The shape of the cone also assists in mixing the exhaled gas with

added oxygen into a homogenous blend. The result is even gas flow

through the scrubber canister and accurate readings by the oxygen

sensors.

The end cap has an O-ring and a flat seal that seals against the scrubber canister and an additional Oring that seals the water trap. These O-rings and seal require cleaning and maintenance and should be

replaced on an annual schedule at a minimum.

The end cap attaches to the scrubber body by aligning the marks on the cap and body, pressing the cap

into place, and the turning the cap clockwise until the mark is aligned with the “locked” position

marking.

Electronics Head

The electronics head contains the solenoid, oxygen sensors (4),

sensor disk, sensor wiring harness, and oxygen injection premix

tube. These components are responsible for analyzing the oxygen

content of the breathing gas and injecting oxygen as needed.

The controller (Shearwater DiveCan system) interprets the

readings from the oxygen sensors and makes decisions on when to

add oxygen via the solenoid.

March 2018 © Lamartek, Inc. dba Dive Rite 12

Page 13

www.diverite.com

The injected oxygen travels through the premix tube to the exhalation side of the scrubber canister

where it is blended with the loop gas before going through the scrubber material. This reduces O2

“spikes” by ensuring that the gas mixture is homogenous before passing over the oxygen sensors.

Oxygen Sensors

The O2ptima uses four oxygen sensors. These sensors are threaded into

the sensor disk mounted inside the electronics head. Dive Rite uses

Analytical Industries, Inc. type R22D sensors.

Oxygen sensors have a finite life. They are a consumable item and must be

replaced at regular intervals. They are typically replaced during the annual

service, but may need to be replaced prior to this.

The sensor labeling includes a “Sell by” date of 4 months after

manufacture and a “Do not use after” date of 16 months after

manufacture. Sensors must not be used after this date even if they appear

to still be functioning correctly.

Four sensors are used to provide redundancy and the ability to cross check their values against each

other to determine if a sensor is not reading correctly. Sensors 1 and 2 are shared between the

controller and the HUD. Sensor 3C is only connected to the controller, and sensor 3H is only connected

to the HUD. By comparing sensor readings between the HUD and the controller it is easy to determine if

a sensor is not reading correctly.

If sensor values 1, 2, and 3C do not agree, the controller automatically uses a voting logic to make an

educated guess of which sensor is not reading correctly. Having an independent “4th sensor” display on

the HUD allows the diver to independently verify the controller’s voting logic.

Beginning in Q1 of 2018 Dive Rite will begin shipping all new rebreather units with digital O2 cells. These

new sensors from Analytical Industries operate as traditional analog sensors but provide several benefits

including:

Automatic warning for use of sensors past expiry date

Advanced notification for sensor ordering/replacement

Monitors for early sensor failure by recording and observing calibration results

All Dive Rite rebreathers produced after September 2017 are compatible with the new digital sensors.

For more information on oxygen sensors, see the Oxygen Sensor Care section and also Appendix II:

Galvanic Oxygen Sensors Applied to Closed Circuit Rebreathers by Analytical Industries, Inc.

March 2018 © Lamartek, Inc. dba Dive Rite 13

Page 14

www.diverite.com

Controller

Dive Rite has chosen to use Shearwater electronics to control

and monitor the O2ptima. The controller is a DiveCAN Petrel 2

handset. The controller allows diver control of the PPO2

setpoint and PPO2 monitoring of oxygen sensors 1, 2, and 3C.

It also functions as a full featured dive computer displaying

depth, dive time, decompression information, and other

important dive information.

It is recommended to use a second standalone dive computer

with decompression information as a backup in addition to the

controller.

For detailed information on the DiveCAN Petrel controller, please see the Shearwater Petrel DiveCAN

Rebreather Controller Model Operations Manual.

Electronics/Battery Canisters

There are two external electronics & battery canisters on the O2ptima.

They are mounted behind the air cell in elastic sleeves on each side of

the tanks.

The canister on the (diver’s) left side of the unit contains the SOLO

(SOLenoid and Oxygen) electronics board and battery. The battery is a

standard 9 volt battery that powers the SOLO board as well as the

oxygen solenoid. The Petrel 2 controller handset has its own internal

battery and does not rely on the 9 volt.

The canister on the (diver’s) right side of the unit contains the OBOE

(Oxygen BOard Electronics) board and battery. The OBOE board

controls the HUD. The battery is a standard AA type. This battery only

powers the OBOE board and HUD.

By locating the batteries in these external compartments, they are completely isolated from the head

and the breathing loop. This is important because as batteries age or are damaged they can release toxic

chemicals. Obviously this is not something you want to have in your breathing gas.

The batteries are accessed via a threaded cap on the end of each canister. The caps are double O-ring

sealed to ensure water integrity. These O-rings must be inspected and maintained when the canisters

are opened to reduce the chance of flooding. See the Battery Replacement section for additional

information.

The electronics canisters connect to the controller and HUD using wet pluggable, waterproof

connectors. Regular lubrication of the inside of these connectors with a light coating of silicone grease

such as Molykote 111 will increase their usable life.

March 2018 © Lamartek, Inc. dba Dive Rite 14

Page 15

www.diverite.com

HUD

The O2ptima includes a Shearwater HUD (Heads-Up

Display). The HUD displays the PPO2 readings of oxygen

sensors 1, 2, and 3H. These values are displayed using

three columns of LEDs. Each column represents a different

sensor. The colored LEDs flash using a modified Smither’s

code to convey the PPO2 values. A “color blind” mode is

also available. The HUD can be setup for right or left eye operation. The HUD can be turned on manually

by pressing the button on the end of the housing. There are also wet contacts which automatically turn

the unit on in case it was not turned on prior to the dive.

Your life depends on always knowing the PPO2 in the breathing loop while diving a rebreather. Do not

make assumptions about how the HUD displays PPO2 values. Previous versions of the HUD used

different blink patterns. Refer to the latest Shearwater HUD User Manual for a detailed description of

the HUD blink pattern and operation.

The Shearwater NERD (Near Eye Remote Display) is also available as an option.

(https://www.shearwater.com/products/nerd/) The NERD replaces the standard HUD providing a

numerical readout of the 3 sensor PPO2 values and also serving as a backup computer with fully

redundant decompression and dive information.

Regulators, Hoses, & Gauges

Dive Rite first stages with DIN connectors are used for both

diluent and oxygen supply. First stage intermediate pressure

(IP) is set to 85 psi for the oxygen regulator and 140 psi for

the diluent regulator. The oxygen regulator IP must be set no

higher than 85psi due to the maximum rated pressure of the

solenoid.

Each regulator is connected to a manifold which supplies gas

to the rest of the rebreather. Over-pressurization valves

(OPVs) are installed in the manifolds for safety. Because there are no second stages installed there is no

way for excess pressure to be released. The over-pressurization valve must be in place in the event of a

first stage high pressure seat failure to prevent high pressure gas from reaching all of the downstream

components.

An OPV that is releasing pressure indicates a malfunction and the dive should be terminated

immediately. The OPV should be inspected for bubbling during the S-drill at the beginning of the dive.

The first stages need to be serviced annually by an Authorized Dive Rite service center or directly by Dive

Rite. Call Dive Rite directly (1-800-495-1046) or email support@diverite.com to schedule service.

Braided nylon Airflex LP hoses are used for gas supply throughout the O2ptima. Green hoses designate

oxygen, and black hoses designate diluent. Airflex hoses are flexible, yet tough. The hose lengths are

optimized for streamlined routing.

High quality brass and glass SPGs are included to monitor oxygen and diluent tank pressures. BAR

gauges are used to help simplify gas consumption calculations.

March 2018 © Lamartek, Inc. dba Dive Rite 15

Page 16

www.diverite.com

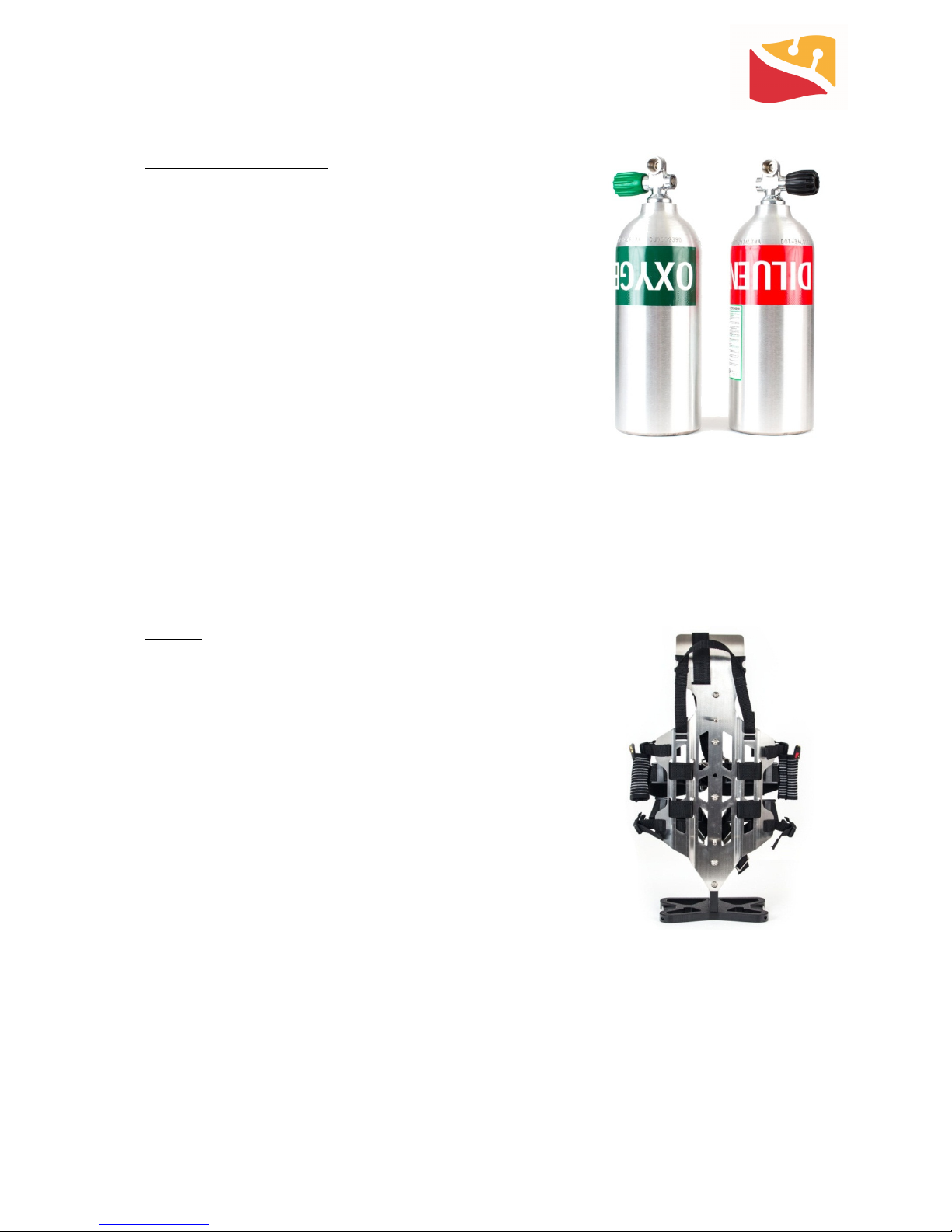

Cylinders & Valves

The O2ptima is supplied with two aluminum 20 cf (3L) cylinders—

one for oxygen and one for diluent. Left and Right hand valves are

included. One of the valve handwheels is green to designate oxygen

use.

The cylinders are held in place with cam straps and Velcro straps. No

additional cylinder mounting hardware is necessary.

The AL20 cylinders are a good compromise between weight and gas

volume. They are an excellent choice for general rebreather diving.

Other recommended cylinders that will work well with the O2ptima

are:

Aluminum 13 cf (2L)

Steel AA LP13 cf (2L)

Steel AA LP15 cf (2L)

Steel AA LP27 cf (4L)

Steel AA HP32 cf (4L)

Divers should select cylinders based on their dive duration, travel logistics, and buoyancy characteristics.

Stand

The O2ptima uses a hybrid stand consisting of a light weight, laser cut

stainless steel backplate attached to a machined StarBoard plastic

brace and foot.

The backplate is contoured to sit close to your back like a set of

doubles. Slots in the plate accommodate cam straps to attach the

cylinders.

StarBoard is a high impact, marine grade polymer. It is very durable

and will flex under a load without breaking. StarBoard also has

excellent buoyancy characteristics. It is very close to neutrally buoyant

in fresh water. The foot is very boat friendly and has integrated

mounting rails for accessories. Hand cut-outs on the bottom of the

foot make it easy to carry and maneuver the unit on land.

The scrubber canister mounts to the top of the backplate using a special rubberized cam strap to grip

the canister and prevent shifting. A StarBoard brace underneath the canister provides additional

stability.

March 2018 © Lamartek, Inc. dba Dive Rite 16

Page 17

www.diverite.com

Cover

A Kydex cover protects the back of the unit from hazardous overhead

environments. It provides hard shell protection for the scrubber

canister, hoses, and cylinders. It also keeps the hoses and cords

tucked in, reducing drag and potential snag points.

The cover attaches with six plastic buckles—two on the top and two

on each side.

Slots at the top and sides of the cover are ideal for adding pockets to

hold additional ballast weight, if necessary.

Holes on the sides of the cover allow optional mounting of Dive Rite’s

QRM receivers for quick and secure attachment of accessories such as

a battery canister or small drysuit inflation bottle.

Custom covers are also available. Contact Dive Rite directly for more

information.

Harness

The O2ptima comes standard with either a TransPac XT or TransPlate XT

harness, but can be used with any standard technical style backplate

with 11 inch bolt-hole centers.

Modeled after a mountaineer’s backpack style harness, the TransPac

incorporates a soft backplate and wrap around hip pads and waist belt

to evenly distribute weight across the hips and back. Ergonomic

shoulder pads and contoured lumbar support pad provide additional

comfort. Shoulder, hip, and crotch strap D-rings provide multiple

locations for attaching accessories. Quick release buckles on the chest

strap and at the bottoms of the shoulder straps make harness removal

fast and easy. TransPacs are available in a full range of sizes and are

easily adjustable to all body types.

The TransPlate harness is a hybrid design for divers who prefer a

traditional metal backplate but want the support of a backpack style harness for better weight

distribution. When used with a 6 pound steel backplate, divers can minimize or remove additional

ballast weight.

Air Cell

The custom designed CCR XT wing comes standard on all O2ptimas. Providing 40 lbs of lift, the CCR XT

wing was designed specifically for use with the O2ptima.

A 360 degree flow-through design allows gas to flow freely as the diver moves in the water. The wide

center section puts the lift to the outside edges of the unit and prevents raising it off the center of the

March 2018 © Lamartek, Inc. dba Dive Rite 17

Page 18

www.diverite.com

diver’s back. The over-the-shoulder inflator hose is located farther

out on the divers shoulder so it will not interfere with loop hoses

and counterlungs.

Abrasion resistant SuperFabric material is used on the back and side

panels of the outerbag. The included adjustable bungee gusset

control system can be used to contain excess material and maintain

a streamlined profile when the wing is not fully inflated. Dual sets of

grommets allow two height position options to fine tune trim.

An optional bailout bladder is available which provides redundant

lift in case of a primary bladder failure.

An optional 10 lb trim pillow can also be installed in the bottom of the wing. The trim pillow helps divers

maintain optimal horizontal trim even when wearing a wet suit or minimal exposure protection. The

bailout bladder and trim pillow can be retrofitted on current CCR XT wings. Contact Dive Rite directly for

these options.

March 2018 © Lamartek, Inc. dba Dive Rite 18

Page 19

www.diverite.com

Micropore ExtendAir Cartridge Overview

(Information from www.microporeinc.com)

ExtendAir® adsorbent technology is a combination of a microporous gas

adsorbent sheet and the geometry in which it is utilized. The adsorbent

material is manufactured with a proprietary process into a microporous

sheet that can be made into different thicknesses and widths, using the same

chemistry as in granular adsorbents.

Sheets of adsorbent material are wrapped around a core to form an

ExtendAir® cartridge. The molded ribs in the

material create channels through which the breathing gases flow. One of

the unique features of an ExtendAir® cartridge is that the breathing

resistance of the adsorbent can be precisely controlled by varying rib

height and spacing. This controlled channeling of the breathing gases

results in a very uniform reaction zone within the adsorbent.

In a granular canister, gases seek the path of least resistance through the bed. The flow pattern can be

very random and will certainly vary from person to person. Learning to load a granular canister requires

instruction to learn the proper technique. Optimal loading of the canister

requires tapping to achieve a uniform bed of granules. This takes time and

can cause dusting of the adsorbent. All of this leads to variations in duration,

wasted adsorbent and the potential for "caustic cocktail".

In contrast to a granular system, ExtendAir® cartridges use channels, molded

in at the factory, that remain constant and controlled by the manufacturing

process. The user simply places the

cartridge into the canister, without any

need for tapping or shaking as the canister

is being loaded. As such, the duration

variability due to irregular granule settling

patterns, as well as variability due to individual loading technique are

completely eliminated. Eliminating this variability will directly

translate into longer minimum duration, and a +/-5% variation in

duration at any test condition (granules can vary up to +/-30%).

An important concept to understand with ExtendAir® cartridge technology is that the gas flow

distribution through the cartridge must be uniform in order for the system to perform optimally. For

example, one way to visualize flow through an ExtendAir® cartridge system is to take a bunch of soda

straws in your hand (50 or so). What would happen if you blew air down through just a group of 5

straws? All of the air would flow down those five straws, and none of the air would flow through the

other 45. The same thing would happen if you blew air into just one side of an ExtendAir® cartridge

canister: all of the air would flow through that side only.

March 2018 © Lamartek, Inc. dba Dive Rite 19

Page 20

www.diverite.com

The end result of this uniform flow is full utilization of the adsorbent in the cartridge.

To achieve full adsorbent utilization, Micropore designs canisters to achieve a +/- 5% flow distribution at

the inlet face of the ExtendAir® cartridge. This is accomplished through various engineering techniques

such as diffusion screens and flow testing of the breathing loop. The result is a system engineered to

perform consistently independent of individual loading

techniques.

The combination of Micropore’s ExtendAir® adsorbent

manufacturing process, along with the parallel flow cartridge

design, turns out to be extremely efficient. As the gas flow rate

increases, Micropore’s ExtendAir® cartridge duration can out last

a granular system by 2 times or more. Installing an ExtendAir®

Cartridge (EAC) is relatively simple, and takes seconds to

perform. The O2 injection tube runs through the center of the

EAC and with the use of a plug any possibility of “CO2

Channeling” is prevented.

March 2018 © Lamartek, Inc. dba Dive Rite 20

Page 21

www.diverite.com

Assembling the O2ptima

This section will explain basic assembly procedures of the O2ptima. Units are delivered partially

assembled. These instructions will serve as a guideline for correct initial assembly and also should

disassembly be necessary for transportation or maintenance.

The Importance of Using Checklists

Many rebreather accidents and fatalities could have been prevented with the use of assembly and predive checklists. There is nothing particularly difficult about assembling a rebreather, however there are

many small yet important steps in the process. A small oversight such as forgetting to re-install an O-ring

can have disastrous consequences.

We are all human and as such are susceptible to distraction and lapses in memory. There is

overwhelming evidence pointing to the efficacy of checklists in preventing errors in complex technical

procedures. It is highly recommended that you use a written or digital checklist for both assembly and

pre-dive checks before every dive. See the Checklists section in this manual for assembly and pre-dive

checklists.

Gas Analyzation

The most important rule of rebreather diving is to always know what gas is in the breathing loop. This

process begins with analyzing the contents of your cylinders.

Sensor calibration is performed assuming a certain percentage of oxygen, however the only way to

know what percentage of oxygen the cylinder actually contains is to analyze it. If the actual percentage

of oxygen in the cylinder is different than what is assumed, it could lead to an incorrect calibration

resulting in a different gas mix in the loop than what is displayed on the HUD and controller. This could

result in oxygen toxicity or errors in decompression calculations.

It is highly recommended that both oxygen and diluent cylinders, along with any bailout cylinders, be

analyzed and the contents labeled on the cylinder prior to assembling the unit.

Installing the Cylinders and Regulators

Begin by installing the filled and analyzed cylinders onto the stand. Lay the stand down and install the

O2 cylinder (note the green handwheel) on the right hand side and the diluent cylinder on the left with

the valves at the bottom, valve openings pointing away from the stand, and valve handwheels pointing

straight out to the sides.

Before tightening the cylinder cam straps, install the first stage regulators on both cylinders. The green

hoses designate the O2 first stage and black hoses designate the diluent first stage. Install the regulators

with the hoses pointing up (See Figure 1).

With the regulators installed, adjust the height of the cylinder so that the first stage rests gently on the

top surface of the foot or slightly above it. Tighten the cam straps and Velcro straps on the cylinders.

Check to make sure that both cylinders are held securely and do not slide.

March 2018 © Lamartek, Inc. dba Dive Rite 21

Page 22

www.diverite.com

Figure

2 - Installing EAC

Route the hoses in between the cylinders as shown in Figure 1.

How to Install a Micropore ExtendAir Cartridge

Figure 1 - Hose Routing

The next step in the build process is to assemble and install the CO2 scrubber canister. The O2pitma can

be used with either the Micropore ExtendAir cartridge or it can be packed with loose granular CO2

absorbent. This section will deal with using the ExtendAir cartridge. If you are using loose granular

absorbent, skip to the next section, How to Pack the Scrubber.

To use an ExtendAir cartridge, begin by inspecting all of the scrubber components. Look for any damage,

dirt, debris, or excess lubrication on the scrubber canister, ExtendAir cartridge, scrubber end cap,

electronics head, bore plug nut, and seals and O-rings. Any damage or contamination can cause a loss of

water integrity and flooding of the breathing loop.

Next, remove the ExtendAir cartridge from its packaging and, using a permanent marker, mark the

installation direction on the side and/or end of the cartridge. If the cartridge is removed between dives

and then later reinstalled, it is critical that the cartridge be reinstalled in the same orientation to prevent

premature CO2 breakthrough (See Figure 2).

March 2018 © Lamartek, Inc. dba Dive Rite 22

Page 23

www.diverite.com

Figure

4 - Screen Installed in Scrubbe

r Canister

Install the cartridge by sliding it all the way into the canister. Next, install the bore plug nut with the

tapered end toward the cartridge. This tapered end will seal against the center bore of the cartridge.

Tighten until snug (See Figure 3). The included wave spring and top plate with screen are not used when

using an ExtendAir cartridge. The canister is now ready to be installed on the unit.

How to Pack the Scrubber

Figure 3 - Bore Plug Installation for EAC

The scrubber canister can be packed with approximately 5 pounds of loose granular CO2 absorbent.

Dive Rite recommends Intersorb 812 or Sofnolime 797 (8-12 mesh) granular absorbent. 408 (4-8 mesh)

is not recommended. It is important to use fresh absorbent for every dive. Granular absorbent should

never be reused.

To pack the scrubber, begin by inspecting all of the scrubber components. Look for any damage, dirt,

debris, or excess lubrication on the scrubber canister, scrubber end cap, electronics head, bore plug nut,

and seals and O-rings. Any damage or contamination can cause a loss of water integrity and flooding of

the breathing loop.

Ensure that the stainless steel screen mesh is correctly seated in the bottom of the scrubber canister

(See Figure 4).

Begin pouring granular absorbent into the canister (See Figure 5).

March 2018 © Lamartek, Inc. dba Dive Rite 23

Page 24

www.diverite.com

Figure 5 - Pouring Scrubber Media

Fill the canister approximately half full and then tap around the outside of the canister to settle and

level the absorbent (See Figure 6).

Figure 6 - Tap to Settle

Continue filling with absorbent until it is approximately ¼ inch from the top of the canister. Again tap

around the outside of the canister to continue settling and compacting the absorbent. If necessary, add

more absorbent to bring the fill level back to ¼” from the top of the canister.

Place the top plate with attached screen on top of the canister with the screen side down. It should be

flush with the inside edge of the canister (See Figure 7). If it is not, add or remove absorbent and relevel

until it is. Note—the wire handle on the top plate is only for removing the plate. It is not a carry handle

for the scrubber.

March 2018 © Lamartek, Inc. dba Dive Rite 24

Page 25

www.diverite.com

Figure 7 - Proper Fill Level

Next, place the wave spring around the stainless steel center tube, on top of the top plate. Finally, orient

the nut with the tapered side up and thread it onto the center tube (*Note that the nut is installed in

one direction when using an EAC and the other direction for a packed scrubber). Make sure that the

spring sits in the small counterbore in the nut. This keeps the spring centered on the top plate (See

Figure 8). Tighten the nut to compress the wave spring against the top plate. Do not overtighten the nut.

Figure 8 – Spring & Nut Orientation

Figure 9 - Nut Tightened

The nut and spring are not intended to apply pressure to “pack” the scrubber. They are only to ensure

an even pressure is held on the top plate after properly packing it.

The canister is packed correctly if shaking the canister does not result in noise being heard from the

absorbent. Any movement of the absorbent can lead to channeling and premature CO2 breakthrough. If

needed, remove the lid and continue tapping the sides of the canister and adding more material as

necessary.

Clean up any excess absorbent dust before installing the scrubber canister. The dust will quickly react

with any exposure to water and can create a caustic solution in the breathing loop.

March 2018 © Lamartek, Inc. dba Dive Rite 25

Page 26

www.diverite.com

Installing the Scrubber Assembly

With the ExtendAir cartridge installed or the scrubber packed, the next step is to install the canister onto

the stand. It should be centered horizontally in the hood scoop with the perforated base side to the left

and the open side to the right.

Rotate the canister to where the “locked” markings are oriented straight forward. This will place the

counterlung fittings in the correct location once the head and end caps are installed (See Figure 10).

Figure 10 - Scrubber Canister Installation

With the canister in place, tighten the cam strap around the canister positioning the cam buckle low and

close to the cylinders to prevent interference with the cover (See Figure 11).

Figure 11 - Cam Buckle Position

March 2018 © Lamartek, Inc. dba Dive Rite 26

Page 27

www.diverite.com

Installing the Electronics Head

Check that the orange electronics head O-rings and flat seal are clean and lubricated. Dive Rite

recommends lubricating these seals with Tribolube 71 grease.

Confirm that the small orange O-ring is in place on the premix tube. The O-ring should be above the

sensor disk. To ensure that it is in the right spot, lay your fingers on the disk and the O-ring should be

above your fingers (See Figure 12). When the canister is installed it will push the O-ring down to seal

against the stainless steel tube in the center of the canister.

Figure 82 - Premix Tube O-Ring

Install the head by inserting the premix tube into the center tube of the body (See Figure 13), aligning

the arrows on the head and body, pushing the head into position, and then rotating clockwise until the

head arrow is aligned with the “LOCKED” position (See Figure 14).

March 2018 © Lamartek, Inc. dba Dive Rite 27

Figure 13 – Installing Electronics Head

Page 28

www.diverite.com

Figure 94 - Locked Position

Attach the LP oxygen injection supply hose to the head by threading it onto the fitting (See Figure 15).

Do not overtighten. This fitting only needs to be finger tight.

Figure 15 - Install Oxygen Supply Hose

Installing the Scrubber End Cap & Water Trap

The cone shaped water trap snaps into the end cap and can be removed for maintenance and cleaning.

There is a large orange O-ring sealing the edge of the water trap (See Figure 16).

Figure 106 - Water Trap Sealing O-ring

March 2018 © Lamartek, Inc. dba Dive Rite 28

Page 29

www.diverite.com

Clean and lightly lubricate this O-ring with Tribolube 71 and then snap the water trap into place. Next,

clean, lubricate and install the large sealing O-ring (See Figure 17).

Figure 17 - Installing Water Trap & Large Sealing O-ring

There is a large orange flat seal that is pressed into the water trap. It is recommended not to remove

this seal unless replacement is necessary as it is difficult to reinstall.

If the flat seal must be removed, reinstall the clean and lightly lubricated seal by pressing into place on

opposite sides and then slowly, working back and forth, flattening it into the groove (See Figure 18).

Figure 118 - Inserting Flat Seal

Figure 19 shows the completed end cap assembly ready for installation.

March 2018 © Lamartek, Inc. dba Dive Rite 29

Figure 19 - Complete End Cap Assembly

Page 30

www.diverite.com

Figure

20 - Locked Position

Installation of the end cap assembly is the same as for the electronics head—align the arrows, press into

place, and rotate the end cap clockwise until the end cap arrow is aligned with the “LOCKED” position

(See Figure 20).

With both the head and the end cap installed, it is possible to pressure test the canister by covering one

of the loop hose fittings with your hand and blowing into the other. No air should escape. If you hear or

feel air leaking, remove the head and lid and confirm that all seals and O-rings are installed and properly

cleaned and lubricated.

Mounting the Electronics/Battery Canisters

The electronics/battery canisters are mounted in elastic sleeves located on the cylinder cam bands. The

solenoid control canister is located on the left side and the HUD control canister is located on the right

side. Carefully route the cables so that they are not pinched or kinked, and then insert the canisters into

the elastic sleeves (See Figure 21).

March 2018 © Lamartek, Inc. dba Dive Rite 30

Figure 21 - Electronics Canister Installed in Sleeve

Page 31

www.diverite.com

Installing the Air Cell, Counterlungs, & Harness

The air cell installs on the front side of the O2ptima. The CCR XT has two grommet positions to allow two

different height adjustments. This can help to fine tune trim by placing the lift higher or lower on your

back.

Install the air cell by placing the grommets over the threaded posts. Next, route the remaining hoses

through the center portion of the air cell with the exception of the manual addition supply hose and the

BC inflator hose which route over the top of the wing as shown in Figure 22.

Figure 122 - Hose Routing Through Wing

The green oxygen hoses will route to the diver’s right side, and the black diluent hoses will route to the

divers left.

Next, install the counterlungs onto the threaded posts as shown in Figure 23 routing the hoses as

shown. Make sure the counterlungs are oriented with the OPV facing forward.

Press the fittings on the back of the counterlungs into the head and end cap fittings and then tighten the

connector rings.

March 2018 © Lamartek, Inc. dba Dive Rite 31

Page 32

www.diverite.com

Figure 23 – Counterlung Installation

The harness or backplate can now be installed. Remove the lumbar pad if necessary to expose the

grommet holes and install the harness over the same threaded posts as the air cell. Add a flat fender

washer on top of each post and then add the wing nuts and tighten firmly by hand (See Figure 24).

Replace the lumbar pad if desired.

It is important to only use the oversized fender washers supplied with the unit—smaller washers do not

distribute the load as well and can cause the metal grommets to be pulled out of the material.

March 2018 © Lamartek, Inc. dba Dive Rite 32

Figure 24 - Harness Installed with Fender Washers

Page 33

www.diverite.com

Installing the Cover

Ensure that all hoses are routed properly and neatly tucked between the cylinders.

The Kydex cover has slots in both sides and the top for accessory weight pockets. If these are desired,

install them before attaching the cover.

The Kydex cover can now be installed. Place the cover into position and use the plastic buckles to clip it

into place.

Figure 25 – Cover Installed

There are two buckles at the top that clip into buckles sewn into the webbing handle at the top of the

stand. There are two additional buckles on each side of the cover that clip into buckles on webbing

straps weaved through the stand.

Once all buckles are clipped, pull the webbing tabs to snug the cover tight against the cylinders. The

cover should not be loose (See Figure 25).

Installing the Loop Hoses

There are two hoses that connect the BOV to the counterlungs to complete the breathing loop. Each

hose has counterlung fittings attached to the end.

Before installing the hoses, lightly lubricate the O-rings and sealing surfaces on the counterlung fittings

with Tribolube 71.

Install the loop hoses by pressing them into place and tightening the threaded rings. (See Figure 26).

March 2018 © Lamartek, Inc. dba Dive Rite 33

Page 34

www.diverite.com

Figure 26 - Installing Loop Hoses

The oxygen and diluent low pressure hoses can now be routed along the loop hoses and connected to

the BOV manual addition valves (See Figure 27). These connections are threaded on and only need to be

hand tight. Install the HUD into the BOV HUD mount to complete the assembly of the unit.

March 2018 © Lamartek, Inc. dba Dive Rite 34

Figure 27 - Installing Manual

Addition Feed Lines

Page 35

www.diverite.com

Basic Operation & Use

WARNING: This manual does NOT cover all information

and procedures required to safely dive the O2ptima

and is NOT a substitute for unit specific training.

Harness Size & Adjustment

Proper harness adjustment begins with selecting the correct size harness. Dive Rite offers Transpac and

Transplate harnesses from XS through XXL. Your T-shirt size is usually a good starting point, but for more

accurate sizing, use the sizing chart available at www.diverite.com or contact Dive Rite directly. We have

the ability to fit a wide variety of body types and sizes.

To properly adjust the harness, refer to the instruction documents that came with your harness. Your

instructor should also help to make sure the harness is properly fitted to you.

Adding Trim Weights

Trim weight or additional ballast weight can be easily added to the O2ptima in several places. There are

slots on either side as well as the top of the Kydex cover that allow the addition of weight pockets. It is

also possible to put weight pockets onto the waist belt of the harness. Your instructor will work with

you to ensure you are properly weighted for safety and proper horizontal trim in the water.

Oxygen Sensor Calibration

Oxygen sensor calibration should be confirmed prior to every dive and recalibrated as needed. Begin by

disconnecting the counterlungs from the scrubber canister. Next insert the supplied calibration caps by

pressing them into the fittings on the electronics head and end cap. The cap with the mushroom exhaust

valve should be inserted into the electronics head fitting, and the cap with the BC fitting inserted into

the end cap fitting.

With the oxygen cylinder valve turned off, disconnect the green oxygen hose from the manual add valve

and connect it to the calibration cap as shown in Figure 28.

March 2018 © Lamartek, Inc. dba Dive Rite 35

Page 36

www.diverite.com

Figure 28 - Calibration Caps

Turn on the Petrel 2 controller and HUD.

While watching the PPO2 values on the controller and HUD, turn on the oxygen cylinder valve in short

bursts a couple of seconds apart. The PPO2 values on all sensors should climb as oxygen is added.

Continue adding oxygen until all sensor values stabilize and do not continue to increase.

Once all values have stabilized at their maximum value, perform the calibration. See the Shearwater

Petrel Dive CAN Rebreather Controller Model Operations Manual and the Shearwater HUD User

Manual respectively for specific calibration instructions.

It is recommended to calibrate using 100% O2 if available, however it is possible to calibrate the

controller using as low as 70% O2 if that is all that is available. If using a calibration gas less than 100%

O2, the calibration FO2 setting will need to be adjusted in the controller first. See the Shearwater Petrel

Dive CAN Rebreather Controller Model Operations Manual for more information on this.

BOV Operation

The purpose of the BOV (Bail Out Valve) is to produce a one way flow of gas through the breathing loop

when in closed circuit mode. This is accomplished through the use of two one-way mushroom valves.

When the diver inhales, the exhale valve closes and the inhale valve opens. When the diver exhales, the

inhale valve closes and the exhale valve opens. It is extremely important that the integrity of the

mushroom valves be maintained.

Any time the diver is not actively breathing on the loop, the BOV should be closed by rotating the knob

on the front to the vertical or open circuit “bail out” position. This closes the breathing loop while still

allowing open circuit breathing from the diluent tank. It is important to do this before removing the

mouthpiece from your mouth while underwater, or on the surface, to prevent water from entering the

breathing loop and flooding the unit. Minor amounts of water in the loop can be dealt with by flushing it

out of the exhalation counterlung OPV (this is a skill you will learn in class), however a major flood will

not be recoverable during the dive and will require bailing out using the onboard BOV or an

independent open circuit system.

If you are switching back to the BOV from a different breathing source while underwater, you will need

to clear the small amount of water in your mouth and the mouthpiece before opening the BOV. Do this

by exhaling through the BOV mouthpiece before turning the knob back to the horizontal or closed circuit

position.

March 2018 © Lamartek, Inc. dba Dive Rite 36

Page 37

www.diverite.com

Breathing on the Loop

The number #1 rule for diving a rebreather is to ALWAYS KNOW YOUR PPO2! This can be monitored

using the HUD and/or the controller. It is important to check both often and confirm that the PPO2

values agree. If you cannot read the PPO2 values or if for any reason you are unsure of the true PPO2 in

the loop you must bail out to an independent, open circuit bailout system.

It is important to remember that YOU are the engine that drives the breathing gas through the loop. You

are using your lungs to push and pull gas through the unit. Proper functioning depends on this constant

flow of gas. Breathing should be slow, deep, and continuous with no pauses. Pausing between breaths

can cause PPO2 spikes because injected O2 does not flow across the sensors without the gas being

“pushed” across them. If the injected O2 does not reach the sensors quickly enough, the controller will

continue to add more O2 to try to maintain the setpoint. This can cause more O2 than necessary to be

injected and lead to a spike once breathing is resumed and all of the injected oxygen hits the sensors at

once.

It is also important to exhale completely to prevent CO2 buildup in your body. Shallow breathing does a

poor job of expelling CO2 and can lead to hypercapnia. Breathing too fast can also be problematic as this

does not allow proper dwell time of the exhaled gas in the scrubber (commonly referred to as “over

breathing” the scrubber). Strive for a slow, steady breathing rhythm.

It is best to maintain a minimal loop volume when diving. This is achieved when a full inhalation does

not quite trigger the ADV. Too much gas in the loop can have a negative effect on breathing effort and

buoyancy control.

Electronic vs Manual Operation

The O2ptima is a fully electronics controlled rebreather (eCCR), but it is also capable of manual

operation (mCCR). When using the O2ptima in eCCR mode, the controller is analyzing the oxygen sensor

values in real time and determining when and how long to fire the oxygen injection solenoid in order to

maintain the user adjustable PPO2 setpoint. When all systems are functioning properly, the diver will

not have to manually add any gas to maintain a breathable loop.

It is important to keep in mind that the rebreather is only a machine. The controller is taking readings

from the oxygen sensors, and making determinations based on those readings. If the values that the

sensors are providing are not accurate, then the end result will not be accurate either. There are a

variety of reasons that the oxygen sensor values may not accurately reflect the actual PPO2 of the gas in

the breathing loop. Some of these reasons can be aging, damaged, or current limited sensors, wiring

harness or electronics issues, water or other contamination on the face of the sensors, and improper

breathing of the diver.

Because of this, it is up to the diver to monitor the HUD and controller, interpret the information

provided, and take action if necessary. All of these issues and the correct responses to take will be

covered by your instructor during class. The most important things to keep in mind are that the

rebreather cannot think for you, and “when in doubt, bail out!”

The O2ptima can also be used manually. In this case the diver monitors the PPO2 readings on the HUD

and controller, and manually injects oxygen into the breathing loop by pressing the manual addition

valve on the exhalation counterlung. This gives the diver complete control over the PPO2 in the loop.

March 2018 © Lamartek, Inc. dba Dive Rite 37

Page 38

www.diverite.com

There are several scenarios in which the diver might choose to use manual control such as a solenoid

failure or partial electronics failure.

It is also possible to keep the O2ptima in eCCR mode, but lower the PPO2 setpoint, and then manually

inject oxygen to maintain a higher setpoint. In this way the user is operating the unit manually with the

electronics functioning as a sort of “parachute” in case the diver becomes distracted or is unable to

manually add oxygen.

All of these scenarios and operation modes will be covered in your training class.

Dive Rite recommends diving the O2ptima with a PPO2 setpoint of between 0.7 and 1.2 depending on

the dive. Diving at PPO2s higher than 1.2 can increase the risks of oxygen toxicity.

Diluent Injection

Diluent is injected into the breathing loop in one of two ways—either automatically through the ADV, or

manually by pressing the manual addition valve on the BOV.

The ADV functionality is built into the BOV and uses a demand valve which functions similarly to a

standard 2nd stage. If the counterlungs fully collapse when the diver inhales, the negative pressure on

the ADV diaphragm will cause the valve to open and add diluent. This allows the diver to take a full

breath even if the counterlungs are “bottomed out.” This can be especially useful on descent where the

loop volume is decreasing due to increasing water pressure.

Manually injecting diluent is also an option in case the ADV does not function properly or is turned off.

Manual diluent injection is also used to perform a diluent flush. These skills will be covered in your class.

Servicing, Maintenance, & Cleaning

In order for the O2ptima to continue to perform properly, it must be cleaned and maintained regularly.

Rebreathers require more maintenance and cleaning than standard open circuit SCUBA equipment. For

their own safety, a rebreather diver should be committed to spending the time, effort, and money

required to properly maintain the unit.

Post Dive Procedures and Cleaning

There are several things that should be done as soon as possible after the dive is over.

First, close the BOV and change your set point to 0.19 PPO2 on the controller. This will prevent the unit

from firing the solenoid and wasting oxygen when the unit is not in use.

Next, it is good to check the battery voltages to know if the batteries will need replacing before the next

dive.

Also, note the pressure remaining in the oxygen and diluent cylinders, and the total dive time to

determine scrubber usage.

March 2018 © Lamartek, Inc. dba Dive Rite 38

Page 39

www.diverite.com

The cylinder valves can now be closed and the lines purged by pressing the manual add buttons.

(***Never turn off the cylinder valves before you are out of the water and have removed the

rebreather! ***)

If the unit was dived in salt water, soak it in a freshwater tank if possible and then spray it off thoroughly

with fresh water.

Turn off the controller and HUD to maintain battery life. Make sure the electronics do not come back on

automatically due to the wet switch.

This is all that is needed if the unit will be dived again that day. Otherwise, the breathing loop should be

disassembled and sterilized. It is recommended to do this within 12 hours after diving to prevent the

growth of mold and bacteria in the loop.

Begin the cleaning procedure by disassembling the loop. Remove the BOV, loop hoses, counterlungs,

scrubber end cap, and scrubber canister.

It is not necessary to remove the electronics head from the unit for cleaning. Simply wipe down the

inside of the head with a clean towel and allow it to dry.

Remove the EAC scrubber cartridge or granular media and discard. All of the other pieces of the loop

can now be thoroughly flushed under warm running water paying special attention to the inside of the

exhalation side hose and counterlung.

Next, mix up a solution of Steramine in a bucket according to the directions on the bottle. Submerge all

loop parts except for the electronics head and the counterlungs in the solution for a minimum of 1

minute to sterilize. Do not leave them in the solution for an extended period of time, as over exposure

to the chemicals can damage mushroom valves and seals.

Once sterilized, remove the parts from the solution and thoroughly rinse inside and out with fresh warm

water.

To sterilize the counterlungs use a cup to pour some of the Steramine solution into each counterlung.

Cover the opening and shake the counterlung for 1 minute, then dump and rinse the inside thoroughly

with fresh warm water.

Shake excess water off of all the components and then spread them out on a clean towel to dry. Hang

the counterlungs to dry with the opening pointed downwards.

For reference, see the Post Dive Checklist in the Checklists section.

Oxygen Sensor Care

Oxygen sensors are the Achilles’ heel of all modern rebreathers. Sensors have a finite life span and

should be considered consumable items. They are prone to failure and it is important to know how and

why they can fail.

Oxygen sensors are essentially oxygen powered galvanic fuel cells. They are electrochemical devices that

produce a weak electric current in the presence of oxygen. Over time, the chemicals are slowly

consumed and the sensor becomes increasingly unreliable.

A new sensor will have a linear response to the partial pressure of oxygen throughout the normal

operating range used in rebreather diving. However, as they age, their output becomes increasingly

March 2018 © Lamartek, Inc. dba Dive Rite 39

Page 40

www.diverite.com

non-linear at higher partial pressures of oxygen. This is commonly referred to as “current limiting.” The

problem with this is that a sensor may appear to be acting normally, but display a lower PPO2 than what

is actually in the breathing loop. If the diver (or electronic controller) is using this value to determine

oxygen injection it can quickly lead to a hyperoxic breathing loop.

This is the primary reason for having multiple oxygen sensors. It allows the diver (or controller) to look

at all sensor values simultaneously and easily determine if one is giving a different reading from the rest.

If a discrepancy occurs, the diver has several options available to determine which sensors are reading

correctly and which should be ignored. These procedures will be covered in your training. Any sensors

that are suspected of being current limited must be replaced before diving the unit.

The response time of aging sensors will also slowly increase. If you notice one or more sensors

responding slowly to changes in PPO2 compared to the other sensors, they should be replaced.

Many rebreather fatalities have occurred because of using old sensors. Dive Rite recommends that

sensors be used for no more than 12 months. The clock starts ticking as soon as the sensor is removed

from the original packaging. The 12 month limit is independent of the number of dives on the unit. Even

if the rebreather is stored and unused for a long period of time, the sensors should still be replaced prior

to diving if they have been installed for more than 12 months.

Even unused sensors still in their original packaging have a limited shelf life. Dive Rite uses Analytical

Industries, Inc., sensors which have a “Sell by” date of 4 months after manufacture and a “Do not use

after” date of 16 months after manufacture. Even if the sensor has been in use for less than 12 months

and seems to be working correctly, it should be discarded and replaced once the “Do not use after” date

is reached.

Because of the limited shelf life, it is recommended that you do not keep a large stock of “backup”

sensors. It is much better to purchase fresh sensors as they are needed.

There are different theories about the best replacement schedule for sensors. Many divers opt to

replace all four sensors at once during the annual service every year.

An alternative replacement schedule is to replace one sensor every 3 months. The sensor that is

replaced should either be the oldest of the set, or alternatively the one that is the slowest to respond to

PPO2 changes. This method has the advantage that each sensor will be from a different manufacturing

batch. Although rare, it is possible for an entire batch of sensors to be defective and fail prematurely.

The age of the sensors will also be staggered with this method and will lessen the chance that multiple

sensors will fail at the same time.

Replacing sensors in a timely manner will mitigate a lot of the potential issues, however it is possible for

sensors to fail before their expiration date is reached. Even brand new sensors can fail. It is always best

to keep a close eye on your HUD and controller for any discrepancies and replace any suspect sensors

immediately.

Sensors should not be removed from the unit for storage in between dives. This practice is unnecessary

and can lead to damaged sensors and increased wear and tear on the wiring harness.

Sensors should never be frozen, vacuum sealed, or stored in inert gas or desiccant in an attempt to

increase their life span. Any of these practices will likely damage the sensor. Sensors, along with the rest

of the rebreather, are best stored in a cool (but not freezing), dry location out of direct sunlight.

For more information on oxygen sensors see Appendix II: Galvanic Oxygen Sensors Applied to Closed

Circuit Rebreathers by Analytical Industries, Inc. and Analytical Industries, Inc. (www.aii1.com)

March 2018 © Lamartek, Inc. dba Dive Rite 40

Page 41

www.diverite.com

Oxygen Sensor Replacement

To replace a sensor, remove the screw holding the sensor plate in place (See Figure 29).

Figure 29 - Sensor Plate Screw

Lift the sensor plate and carefully unplug the sensor to be replaced at the back of the sensor. Lift the

connector tab to remove—do not pull on the wires (See Figure 30).

Figure 30 – Oxygen Sensor Wiring Harness

The sensors are threaded into the sensor plate. Remove the sensor by turning it counterclockwise (See

Figure 31).

March 2018 © Lamartek, Inc. dba Dive Rite 41

Page 42

www.diverite.com

Figure 31 - Sensor Removal