Page 1

Lighting Systems

Owners Manual

Read this manual, in its entirety, before using your light. Failure

to follow the instructions it gives, or to heed the warnings it

provides, can lead to serious personal injury or death.

117 West Washington Street • Lake City, FL 32055 • USA

Phone (386) 752-1087 • Fax (386) 755-0613

www.diverite.com

Page 2

Light System Owner’s Manual Page 2

Dive Rite Lighting System Limited Warranty

➤ Dive Rite will — at its sole discretion — repair or replace dive light components proved to

be damaged by faulty manufacture or material, at no cost, for a period of up to one year (365

days) from the date of purchase.

➤ Canister bodies and the metal portions of light heads are warranted for the life of the product.

➤ Batteries are warranted against defects in manufacture or material for 90 days from date of

purchase. This warranty does not cover loss of battery “burn time”—a condition that results

almost exclusively from mis-use or abuse. Users must read and study the rated “burn time”

information appearing in this manual. Failure to do so can easily result in expensive damage not

covered under warranty.

➤ Attempting the charge damaged batteries can further result in damage to chargers. This is

not covered under warranty — nor is damage to chargers caused by nonstandard alternating

current voltages or cycle rates. Chargers returned under warranty must be accompanied by the

battery(s) they were being used to charge. If the battery(s) are determined to be the cause of

charger damage, no warranty coverage will be provided.

➤ The warranty also specifi cally excludes bulbs, lenses, fuses, O-rings or other conditions resulting

from misuse, negligence, failure to properly lubricate O-rings, alteration, accident or unauthorized repair.

➤ This warranty applies only to the original retail purchaser. It does not cover commercial or

rental use, nor does it extend to units purchased from other than an authorized Dive Rite dealer

or Tekreational Dive Center.

➤ To make a claim under this warranty, the owner must have either completed and returned

the warranty registration card at the time of purchase, or registered his/her warranty using

Dive Rite’s website (www.diverite.com). He or she must then return the damaged items to Dive

Rite, along with a copy of the original purchase invoice or receipt. No warranty service will be

performed for other than registered owners.

➤ This warranty becomes void if dive light components are damaged by anything other than

normal recreational diving use, of if they have been serviced or repaired by other than

authorized Dive Rite dealers.

➤ Repairs made under this warranty will not extend the warranty period.

➤ All further claims, especially for damage after diving accidents, are excluded from coverage

under this warranty.

➤ Lamartek, Inc., dba Dive Rite, has no obligation to honor any extension of this warranty.

All Dive Rite light systems are pressure tested at the factory prior to delivery. When light systems

are returned to Dive Rite for warranty service, the fi rst thing we do is assemble the light precisely

as outlined in this manual, including proper lubrication and installation of O-rings. We then

pressure test the light, just as we did when new. If the light passes this second pressure test, we

have to assume that any reported fl ooding must have resulted from failure to properly assemble

and/or maintain the light as outlined in this manual — in which case no warranty coverage is

provided.

© 1997-2001, Lamartek, Inc., dba Dive Rite • All Rights Reserved Version Date: 01.06.11

Page 3

Light System Owner’s Manual Page 3

Table of Contents

Light Systems Overview............................................................4

High-Intensity Discharge (HID) Light Heads..........................................................5

Quartz-Halogen Light Heads ...................................................................................7

Battery Canisters ......................................................................................................9

Batteries .................................................................................................................15

Switch Mechanisms................................................................................................17

Light System Packages............................................................................................18

Light System Accessories ........................................................................................19

Using Your Light System..........................................................21

Transporting Your Light System .............................................................................22

Charging Your Light System...................................................................................23

Assembling Your Light System ...............................................................................25

Testing Light Operation.........................................................................................31

Mounting Your Light System .................................................................................32

Maintaining Your Light System................................................36

Post-Dive Maintenance and Care ...........................................................................37

Changing Actuators................................................................................................37

Changing or Replacing Bulbs.................................................................................38

Making Batteries Last.............................................................................................44

Dealing with Flooding or Other Damage...............................................................46

Page 4

Light System Owner’s Manual Page 4

Before You Start…

This information has been developed for your safety. Please read and understand this

manual completely before using your Dive Rite light system.

This manual contains important safety and maintenance infor-

mation. Read this manual thoroughly and become familiar with

all of your scuba equipment before diving.

Important information regarding the use or maintenance of your dive light is

designated, throughout this manual, by the Important symbol appearing above. This

manual also uses several signal words to designate hazards with various levels of

seriousness. These are:

Indicates a potentially hazardous situation which, if not

avoided, could result in damage to or loss of equipment, serious

personal injury or death.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury, or equipment

damage. It may also be used to alert against unsafe practices.

Light Systems Overview

Dive Rite light system components enable users to choose from:

➤ Three different High-Intensity Discharge (HID) light heads and four different

quartz-halogen light heads.

➤ Five different battery canister confi gurations.

➤ Two different switching mechanisms.

➤ A variety of accessories and bulbs in several different wattages.

Page 5

Light System Owner’s Manual Page 5

High-Intensity Discharge (HID) Light Heads

Dive Rite’s HID light heads enable divers to carry with them a compact, selfcontained underwater light system that is capable of providing a level of illumination

previously available only from lights using surface-supplied power. Among their key

features:

➤ To the eye, a 10-watt HID bulb’s outputs is comparable to that of a 50-watt

quartz-halogen bulb. How can this be? Due, in part, to a substantial difference in

color temperature, the perceived output and penetrating power of an HID light is

noticeably greater. Also, just as a fl uorescent bulb consumes only a fraction of the

wattage that a comparable incandescent bulb does, the HID bulb consumes but a

tiny fraction of the power a comparable quartz-halogen bulb demands.

➤ Because it requires just a fraction of the wattage a comparable quartz-halogen bulb

would, HID light system burn times are substantially longer. With a new, singlesection MLS battery pack, the recommended maximum burn time for a Compact

HID light is 300 minutes — roughly four times greater than it would be for a

50-watt quartz-halogen bulb.

➤ An HID’s light output has a color temperature of 6,000–6,500 degrees Kelvin.

This is substantially higher (and whiter) than the typical quartz-halogen light’s

color temperature of 3,000 degrees Kelvin. In fact, it is essentially the same color

temperature as the sun. As a result, an HID light is a much better choice for

underwater video — and nearly any other underwater activity.

➤ Quartz halogen bulbs normally yellow in color and/or decrease in brightness as

battery voltage drops. In contrast, an HID Light’s system circuitry helps keep

light output constant. In fact, an HID light is capable of drawing battery packs

down past recommended voltage levels, without any noticeable decrease in output.

For this reason, it is important users keep light use well within recommended

“burn” times.

Available Models Dive Rite HID light heads are available in three different models.

➤ 10-Watt Compact HID The compact HIS light head looks like a slightly thicker

(but signifi cantly shorter) version of our standard MR11, quartz-halogen light

head. The head contains not only the bulb, but the ultra-small ballast assembly

as well (there is no external “ballast box,” as is necessary on the 17- and 18-watt

models). So small and so light is this head that we do not even use a standard

or “Ergo” hand mount with it. Instead, a simple elastic band that slides over two

fi ngers enables the head to rest comfortably on the back of your hand.

➤ 18-Watt H1 HID This version uses the same test-tube style lens as the regular H1,

and accepts special versions of the compact H1 refl ector or the larger Lumedyne

video refl ector (item number 6270HID). The standard hand mount for the H1-

Page 6

Light System Owner’s Manual Page 6

style HID light head is Dive Rite’s 6126E “Ergo” mount, which attaches directly to

the refl ector collar. (A standard hand mount can also be attached to the H1 HID

light head’s ballast box, either by special order, or as an after-market item.)

Figure 1 Compact, H1- and MR11-style HID light heads.

➤ 17-Watt MR11 HID The front half of this light head is almost indistinguishable

from its quartz-halogen cousin. The hand mount for the MR11 HID light head is

Dive Rite’s 6126 standard hand mount; this attaches directly to the ballast box.

What Make HID Bulbs Different Among the things that distinguish HID bulbs

from incandescent models is that they have no fi lament. Like a fl uorescent bulb, the

HID creates illumination by creating an arc between poles. The result is an extremely

bright and powerful beam.

The HID is designed for underwater use only. Water not only

provides the necessary cooling medium, it acts as a natural

ultraviolet (UV) fi lter. Still, users should avoid looking directly

at the bulb, even though it is under water.

Expected bulb life is 1,100 hours — provided you don’t drop it. The HID bulb is

somewhat more impact resistant than most quartz-halogen bulbs, in that there is

no fi lament to break. It is not bulletproof, however. You should not, for example,

repeatedly turn the light on and off.

Page 7

Light System Owner’s Manual Page 7

Once activated, you should give the bulb at least four minutes

to warm up to operating temperature before turning it off.

Failure to do so will damage the bulb and is not covered under

warranty. Tr eat the bulb with care, always keeping in mind that

it is among the most expensive components in the system and

fi nancially painful to replace.

Ballast Incorporated into each HID light head is a self-contained ballast assembly.

The HID ballast fulfi lls two important functions. At start-up, the it converts the

battery pack’s normal 12-volt output to the substantially higher voltage (6,000 volts!)

needed to create an arc in the HID bulb.

Following start-up, the ballast continues to function as a converter, providing

the somewhat higher voltage necessary to maintain the arc. In so doing, it maximizes

battery output, resulting in the light’s unusually long burn times.

The HID ballast box contains no user-serviceable parts. Opening

the ballast box voids all warranty coverage.

Quartz-Halogen Light Heads

Although quartz-halogen lights are not as energy effi cient as HID lights (and do

not offer the HID lights’ exceptional burn times), they do have the advantage of

costing substantially less. This makes them a good choice when initial purchase price

is a consideration.

Four different quartz-halogen light heads are available for Dive Rite light

systems. These light heads all have a military specifi cation (mil-spec) coating that

enables them to stand up to the rigors of saltwater diving. Here is a description

of each light head.

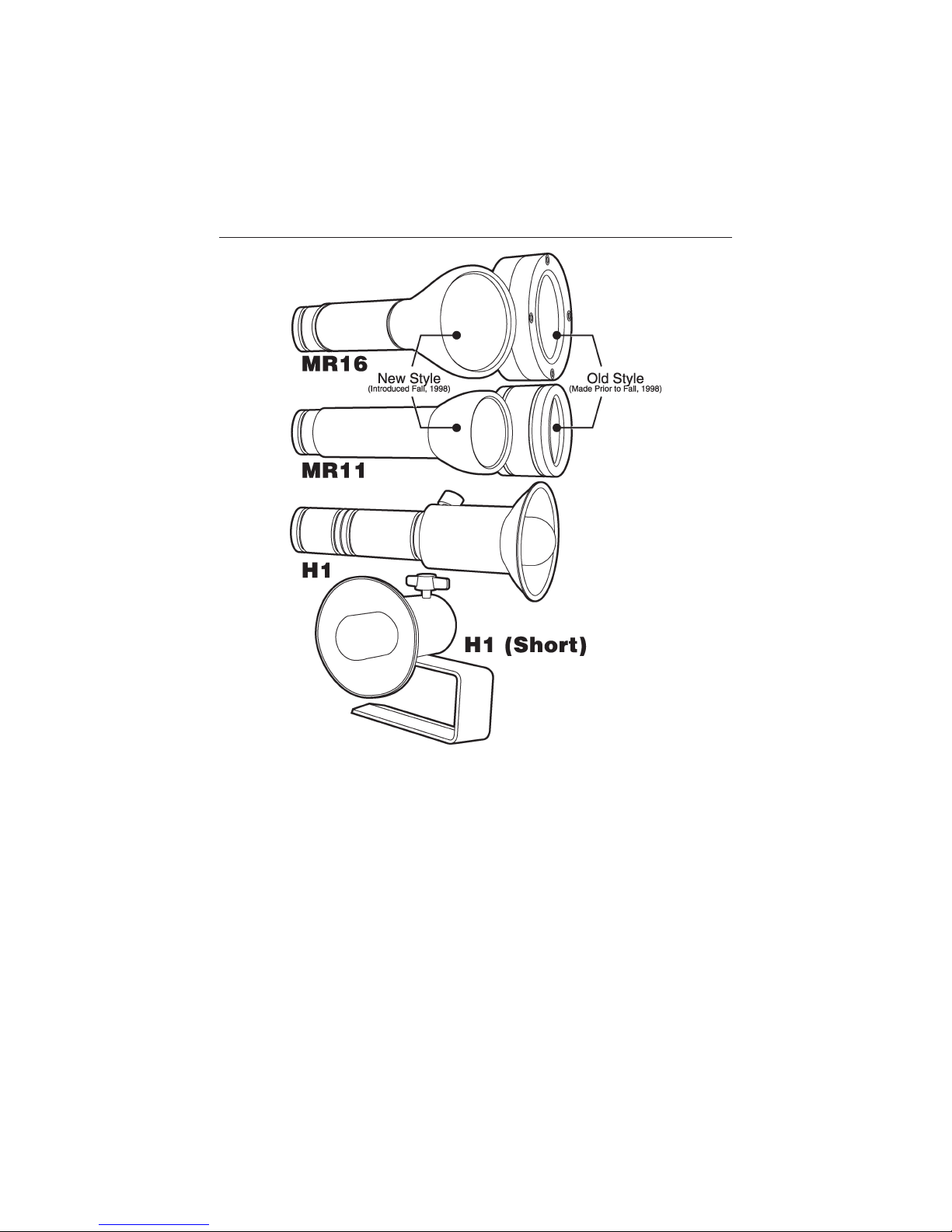

MR16 The MR16 is among the most versatile of Dive Rite light heads. MR16

bulbs provide a combination of moderately wide fl ood pattern coverage, with slightly

more intense spot coverage in the center of the beam. Wide-angle coverage bulbs are

available that provide a softer, more even coverage required for video lighting.

The aluminum casing that houses the MR16 bulb is particularly rugged. It

resists damage from crushing (although the MR16 bulb fi lament can be broken by

the impact that results from accidentally dropping the head on a hard surface). This

casing makes the MR16 head the best choice for operating in environments that are

especially hard on equipment.

Page 8

Light System Owner’s Manual Page 8

Figure 2 Quartz-Halogen light head options.

MR11 The MR11 is a compact version of the MR16. Although its beam pattern

is not as wide or as even as that of the MR16, the MR11 has the advantage of

being much more streamlined. This makes the MR11 an excellent choice for helmetmounted light heads, or light heads that will be used in high-fl ow situations.

H1 The H1 light head is designed primarily for cave diving. A compact, adjustable,

2.75-inch/70 mm refl ector allows the beam pattern to be focused from a moderately

wide fl ood to a highly penetrating pinpoint spot light that is highly suitable for

exploration. Also available is a special video refl ector (item number 6270) that

provides the widest and softest beam possible for underwater cinematography and

video.

H1 “Short” The H1 “Short” light head is an ultra-light, ultra-compact version of the

regular H1 light head, that is less than half as long as its actuator-style brother. It

Page 9

Light System Owner’s Manual Page 9

comes with its own built-in “ergo” hand mount and is a favorite among some of the

world’s most experienced cave divers. The H1 “Shorty” is available in a toggle-switch

confi guration only.

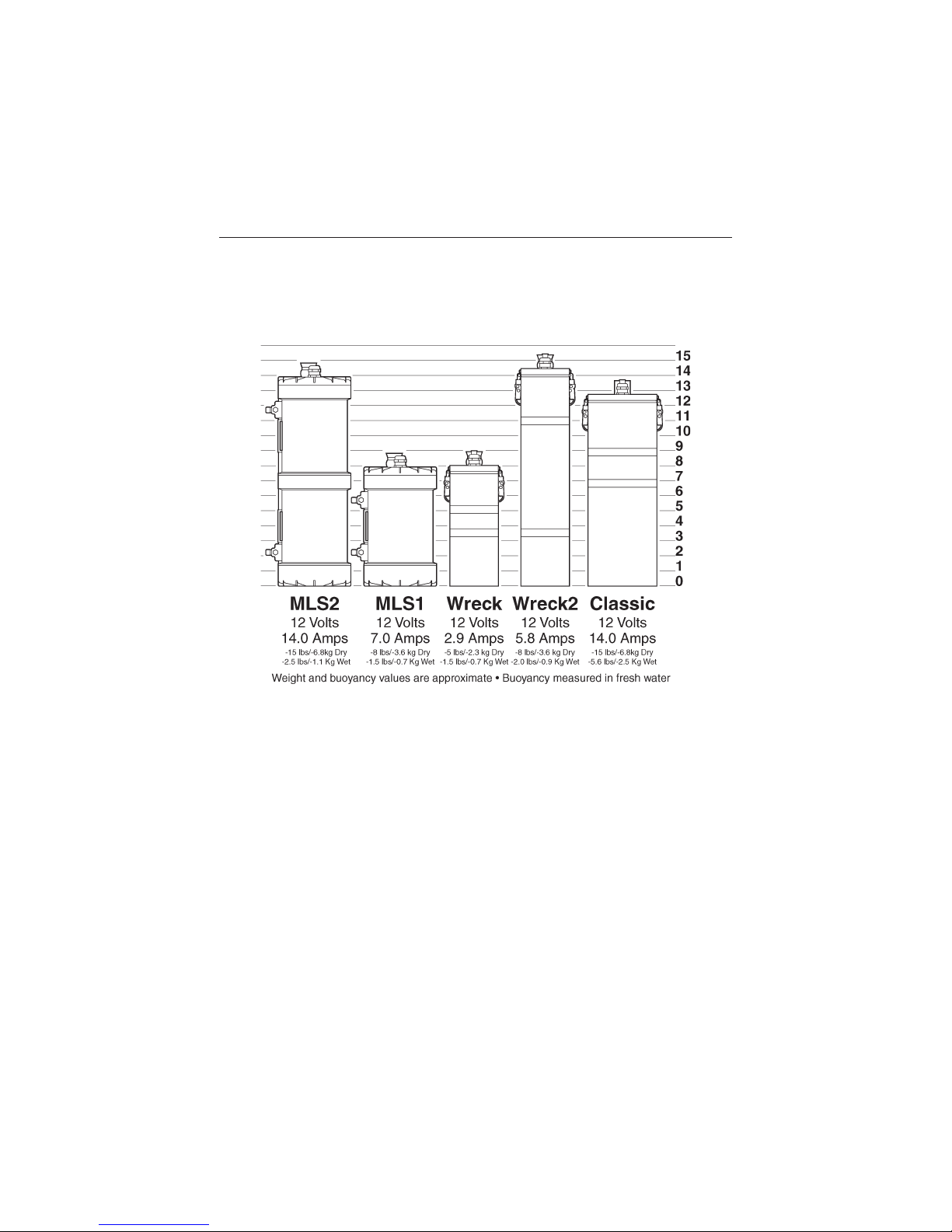

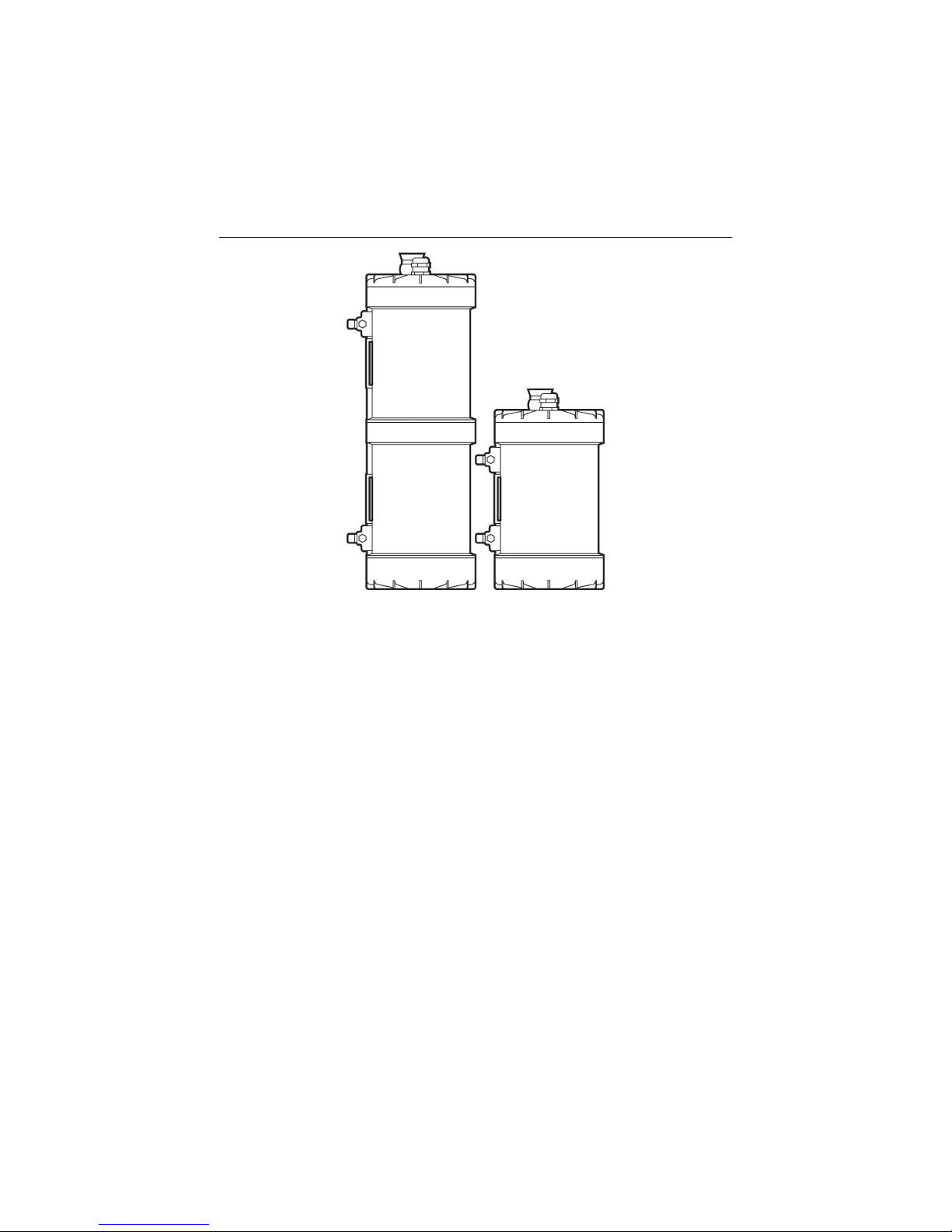

Figure 3: Dive Rite light system battery canisters.

Battery Canisters

Battery canisters house the power supply for each Dive Rite light system. Dive Rite

battery canisters fall into one of two types:

➤ MLS Canisters These house the power supplies for Dive Rite’s top-of-the line MLS1

and MLS2 light systems. No other Dive Rite lights offer as wide a choice of light

heads, or provide as many mounting options.

➤ PVC Canisters Dive Rite PVC canisters help meet special needs. For example, the

Wreck and Wreck2 lights provide a cost-effective alternative to bulky, hand-held

lights. The Classic Light satisfi es the needs of divers seeking a more traditional

exploration light.

Page 10

Light System Owner’s Manual Page 10

Figure 4 MLS2 (left) and MLS1 battery canisters.

MLS Battery Canisters MLS battery canister and pack combinations include:

➤ MLS2 These canisters use a battery pack containing two 12-volt/7-amp batteries,

wired in parallel to provide 12-volts at 14 amperes. In this confi guration, they can

power quartz-halogen bulbs ranging from 20 to 100 watts, for from 420 to 60

minutes, depending on bulb size.

➤ MLS1 With its compact size and diminutive profi le, the MLS1 is well-suited to

applications in which battery size and weight is a consideration. Its single 12-volt/7amp battery pack can power Compact, H1- or MR11-style HID light heads,

providing up to 300 minutes of rated “burn” time. A 50-watt bulb is standard

on quartz-halogen MLS1 lights; however, a 35-watt bulb is recommended if users

desire more than an hour of “burn” time.

On MLS2 and MLS1 lights, 50-watt bulbs are standard; however, 35-watt bulbs

are recommended if users desire more “burn” time. MLS lights are also available

with H1- or MR11-style HID light heads, providing up to 180 minutes of rated

“burn” time.

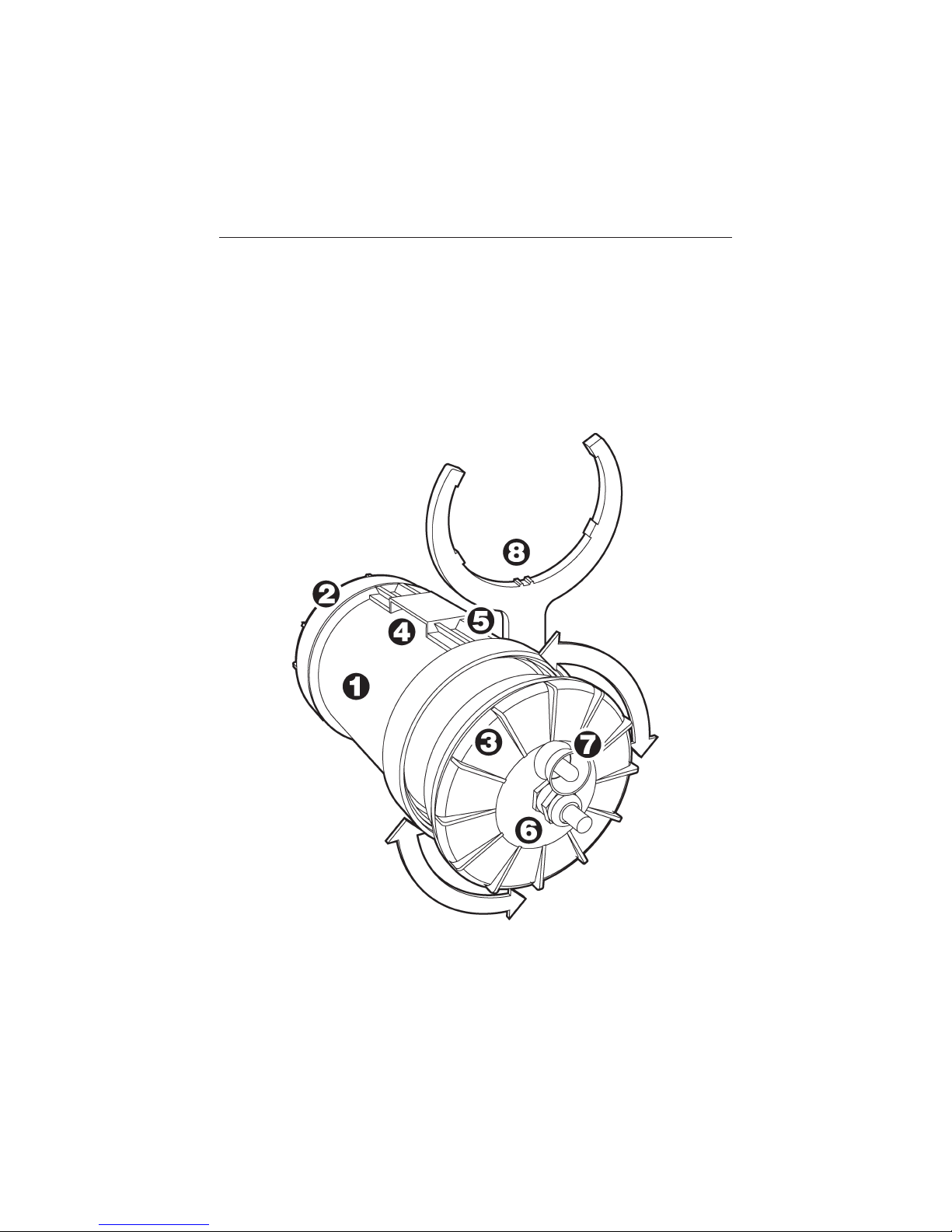

Here is a guide to the MLS canister features shown in the accompanying

illustration.

1. Canister Section MLS canisters are made from a high-strength, injection-molded,

synthetic material. It is extremely durable. Each MLS light is pressure tested at

the factory; canisters are depth rated to 500 feet/150 meters. As you have already

Page 11

Light System Owner’s Manual Page 11

seen, canister sections can be daisy-chained together, using the same O-ring seal

as is used by the lids (end caps). The design of the canister creates built-in air

spaces between the battery pack and housing. These air spaces displace water and

create lift to help offset the weight of the batteries. Without these air spaces,

the battery canisters would be up to 15.0 pounds/6.8 kg negative under water.

Because of the air spaces, the canisters are much closer to being neutrally buoy-

ant. For example, each MLS canister section, with its battery, is approximately

1.5 pounds/0.7 kg negative in fresh water — substantially less than the 8.0

pounds/3.6 kg it weighs out of water.

Figure 5 MLS canister features.

2. Canister Lid (Female) This lid (end cap) goes on the end of the canister opposite

the power cord. As with all canister sections and lids, it seals with a large Buna-N

Page 12

Light System Owner’s Manual Page 12

(Nitrile) O-ring. You make this seal simply by tightening the lid one quarter turn,

by hand or with the special MLS Canister Wrench described shortly.

3. Canister Lid (Male) This lid contains the sealing gland, power cord and, possibly,

the toggle switch (more on these items shortly).

4. Belt Slot The canister’s built-in belt slot accommodates standard 2.0-inch/50 mm

webbing. This allows the canister to be mounted, if desired, to weight belts,

harness waist straps, tank cam straps and similar items.

5. Dovetail Ridges The dovetail ridges on either side of the belt slot are where one

can mount the supplied attachment clamps, described below.

6. Sealing Gland and Power Cord This is what connects the battery canister to the

light head. The power cord is made from a special, heavy-duty material, designed

to stand up to the rigors of underwater use. Unlike conventional power cord

material, it is not hollow, making it diffi cult for any water that might enter a light

head or canister to travel through the power cord to other components. There

are sealing glands at both ends of the power cord. These glands help form a

watertight seal where the cord enters the canister and light head.

7. Toggle Switch The toggle switch option allows lights to be turned on and off at the

canister. You can read more about MLS switching options on page 17.

8. MLS Canister Wrench After just a few dives, divers will likely fi nd that you

can easily tighten or remove their MLS canister lids by hand. However, should

they need a little assistance removing a lid, the canister wrench (which comes

standard with every MLS1 and MLS2) provides the leverage needed to made

the job even easier.

9. Attachment Clamps A wide variety of hardware and methods are available to

attach MLS battery canisters to tanks, BCs, harnesses and other equipment. If

you are not using the built-in belt slot to attach your MLS canister to your other

equipment, you will most likely use a method that employs the MLS attachment

clamps that appear in the accompanying illustration. These clamps can be used

in conjunction with D-rings, quick links, snaps and a variety of other hardware.

They are a standard item on all MLS systems.

Page 13

Light System Owner’s Manual Page 13

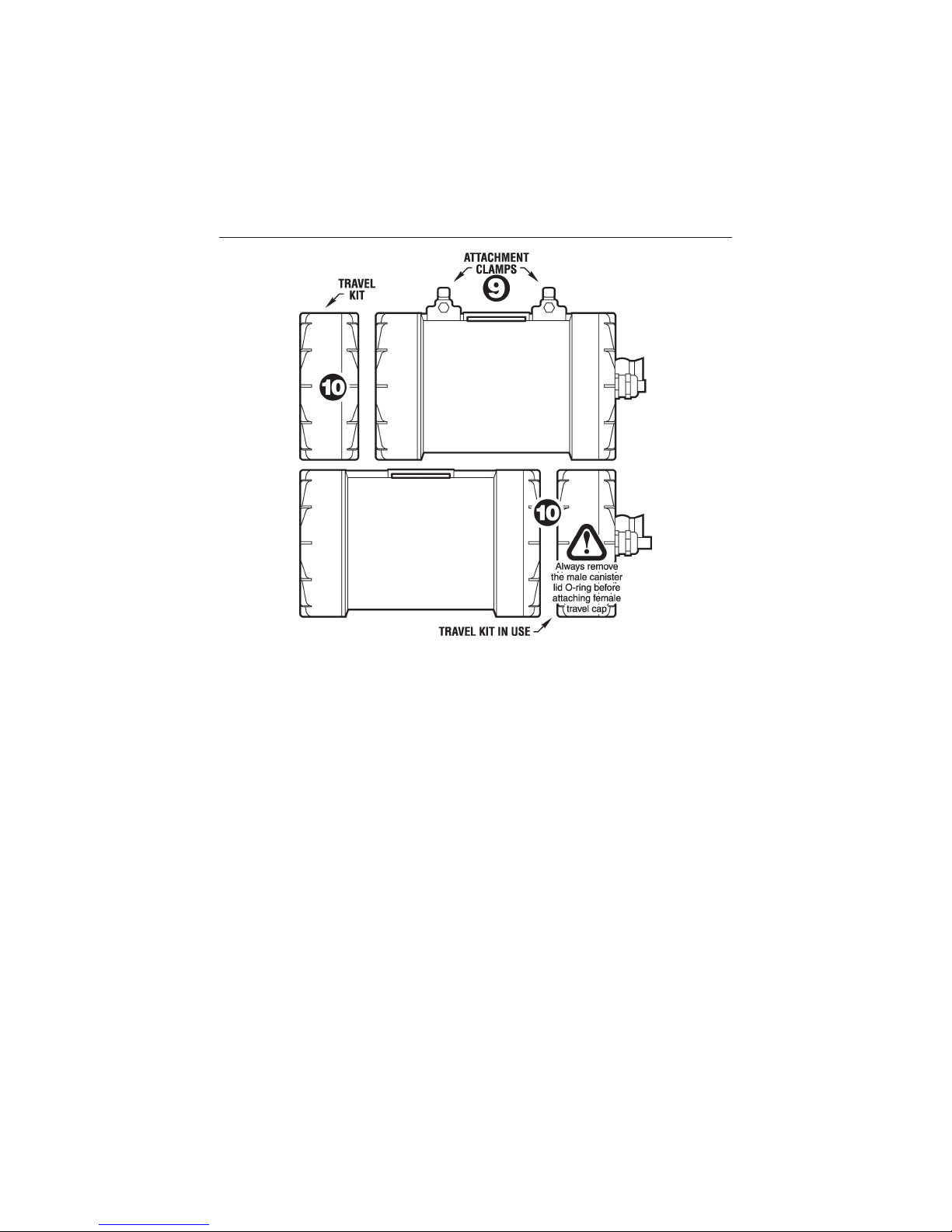

Figure 6 Additional MLS battery canister features

10. Tr av el Cap As discussed later in this manual, it is important you do not transport

your MLS1 or MLS2 with the battery connected. Doing so can result in

accidental activation of the light, which in turn can cause fi re or damage to

expensive equipment, due to the high temperatures at which the light’s quartz

halogen bulbs burn.

Additionally, you should not transport an MLS canister with the battery

inside and both canister lid O-rings in place. Doing so could allow a potentially

dangerous build-up of hydrogen gas over time.

It might seem you could avoid these problems simply by transporting MLS

batteries separate from their canisters. Unfortunately, doing so would leave a

battery pack’s connector strips exposed, and subject them to accidental shorting.

The better way to avoid these problems is to use the MLS Travel caps, shown

in the accompanying illustration. These are included with each MLS1 or MLS2.

The MLS Travel Caps consist of plain, gray male and female MLS canister lids.

(These are designed solely for surface use and cannot be taken under water.)

During transit, use the plain male lid (minus O-ring) to keep the battery pack

safely inside the canister body. At the same time, mate the plain female lid

to the male lid with the light cord, thus better protecting its contact points.

Page 14

Light System Owner’s Manual Page 14

Additionally, divers can use the small container created by joining a male and

female canister lid to store O-rings, silicone lubricant, bulbs and other spare

parts.

PVC Canisters The three available PVC canister models (Wreck, Wreck2 and

Classic) are formed from a single piece of extruded poly-vinyl chloride pipe. This

is the same material used to construct custom-made diver propulsion vehicles for

deep exploration dives. It makes an excellent pressure vessel — one that does not fl ex

at depth (and thus require battery pack bulkheads to keep the mounting hardware

from coming loose). PVC canisters are rated for depths of up to 400 feet/120 meters.

Among PVC canister features:

➤ PVC canister lights share many features in common with the MLS1 and MLS2

canisters. These features include: the use of special, solid-core power cords; and,

the use of special non-corroding sealing glands designed specifi cally for underwater

use.

Figure 7 Wreck, Wreck2 and Classic lights.

➤ PVC canisters seal using conventional quick-release latches (no special tools

required) and thick, highly-compressible O-rings. These make especially easy to

achieve an effective, water-tight seal.

Page 15

Light System Owner’s Manual Page 15

Here is additional information on each of the three PVC canister models:

➤ Wreck Light The Dive Rite Wreck Light is designed to provide a cost-effective

alternative to bulky, hand-held rechargeable lights. It gives divers the power of a

belt-, harness- or tank-mounted battery canister, combined with the freedom of a

light head that, while ultra-compact in size, provides illumination that equals or

exceeds that of nearly all top-of-the-line hand-held dive lights. Wreck lights come

with an mounting loop for 2.0-inch/50mm webbing.

Equipped with a 10-watt Compact HID light head, the Wreck Light canister

can provide up to a maximum of two hours of “burn” time. The standard quartzhalogen light head for this canister contains a 20-watt MR-11 bulb, providing up to

60 minutes of rated “burn” time from the light’s 12-volt/2.9-amp battery pack (this

is the maximum recommended wattage for this light). Sixty minutes of “burn” time

is also available when using the H1-style or MR11-style HID heads.

➤ Wreck2 Light This two-battery version of the Wreck Light is ideally suited for divers

for whom canister length is not as much of a concern as overall canister bulk

(diameter). A special mounting strap facilitates waist, tank or harness mounting.

The Wreck2 Light is available with H1, MR11 or MR16 quartz-halogen light

heads, of with H1- or MR11-style HID light heads. The standard 35-watt quartz-

halogen bulb provides up to 90 minutes of rated “burn” time from the 12-volt/5.8-

amp battery pack; 120 minutes of “burn” time is available with the HID light

heads.

➤ Classic Light The Classic Light is designed to meet the needs of divers seeking a

more traditional exploration light. It is available with H1, MR11 or MR16 quartz-

halogen light heads. The Classic Light’s standard 50-watt bulb will provide up

to 150-180 minutes of rated “burn” time from the light’s 12-volt/14-amp battery

pack. The standard mounting loop facilitate attachment to waist straps or other

2.0-inch/50mm webbing.

Batteries

Battery Type All Dive Rite light systems use sealed, lead-acid batteries (also known

as gel cells). In comparison to NiCad batteries, sealed lead-acid batteries are largely

maintenance free. After each dive, you simply connect them to their charger, plug the

charger into a wall socket, and allow them to fully recharge. It does not matter how

much or how little you used a lead-acid battery during a dive. It will not develop a

memory of a particular dive time. In fact, the only way you can seriously harm a gel

cell battery is to do the very thing you must do to maintain a NiCad battery; that is,

fully or nearly fully discharge it (a condition known as deep discharge). If you ever see

your bulb take on a yellowish appearance, turn it off immediately. Failure to do so can

severely damage the battery and charger, and substantially shorten their life.

Page 16

Light System Owner’s Manual Page 16

Better yet, consult the “burn time” chart appearing on page 45, and keep light

usage well within the times shown for the battery and bulb you are using. Doing so

will greatly extend battery life.

In summary, lead-acid batteries—while slightly heavier than their NiCad

counterparts—are considerably less of a headache to live with. They enable you to

spend your time between dives relaxing, rather than staying up late to do battery

maintenance.

Battery Packs Depending on the unit chosen, a canister will contain one or two

12-volt batteries, assembled into a single battery pack. All Dive Rite battery packs

have user-replaceable fuses so that, in the event of an accidental short or reversal in

polarity, the fuse will blow before battery damage takes place.

Figure 8 MLS1 and MLS2 battery packs.

➤ MLS1 and MLS2 battery packs reside in special MLS battery carriers. These

carriers have contact strips along the top, so that simply by sealing them inside

their respective canisters, the batteries are automatically connected and ready to

be switched on.

Page 17

Light System Owner’s Manual Page 17

Figure 9 Wreck, Wreck2 and Classic Light battery packs.

➤ PVC light system battery packs (Wreck Light, Wreck2 and Classic Light) are self-

contained and utilize a standard, two-pole “trailer plug” connection. These are

more resistant to saltwater corrosion than “banana” plugs and, unlike banana plugs,

are readily available from auto-parts and electronics stores, even in remote areas.

Switch Mechanisms

Dive Rite light systems incorporate one of two different switch mechanisms. They

are:

➤ A toggle switch…

➤ …and an actuator head.

Toggle Switch A toggle switch is a simple on/off switch mounted on the male

battery canister lid. It is ideally suited for on-camera video lights and light heads

that are normally kept in a helmet mount. In these instances, it is generally easier to

activate a toggle switch than it is to remove the light head from its holder to turn it

on. The battery canister and toggle switch, however, must be within easy reach of the

diver for this system to be effective.

Dive Rite uses special, environmentally sealed toggle switches in its lights.

This way, if any hydrogen gas escapes from the battery, the toggle switch will

minimize ignition potential. Outside the canister, a switch guard helps protect

against accidental activation.

Actuator Head To activate a light system with an actuator, you simply twist the light

head clockwise while holding on to its base. This is particularly benefi cial when the

battery canister is mounted next to or below a diver’s tank(s)—in which case getting

to a canister-mounted toggle switch would be diffi cult. An added benefi t of actuator

heads is that they enable divers to quickly switch from one type of light head to

another—in the fi eld—without special tools. Many users own two or more actuators,

so that they always have the one best suited to their next dive. Actuator mechanisms

are available on MLS quartz-halogen H1 and MR16 light heads only.

Page 18

Light System Owner’s Manual Page 18

Figure 10 To ggle and actuator switch light heads.

Light System Packages

Dive Rite light system components are available in convenient packages that include:

➤ Battery canister.

➤ Light head.

➤ Choice of switching mechanism (when available).

➤ A 115 or 230-volt AC battery charger.

Item numbers for these packages are as follows:

Wreck Wreck2 Classic

MLS1 MLS2 Light Light Light

Compact HID (Toggle) MLS1/Compact HID WRECK1/Compact HID

H1 HID (Toggle) MLS1/HID-18 WRECK2/HID

MR11 HID (Toggle) MLS1/HID-MR11 WRECK1/HID-MR11 WRECK2/HID-MR11

H1 Quar tz Halogen (Actuator) MLS1/H1.A MLS2/H1.A

H1 Quartz Halogen (Toggle, Short) MLS1/H1.TS MLS2/H1.TS WRECK-H1 Classic-H1

MR11 Quar tz Halogen (Toggle) MLS1/MR11.T MLS2/MR11.T WRECK1 WRECK2-MR11 Classic-MR11

MR16 Quartz Halogen (Actuator) MLS1/MR16.A MLS2/MR16.A

MR16 Quar tz Halogen (Toggle) MLS1/MR16.T MLS2/MR16.T WRECK2-MR16 Classic-MR16

Page 19

Light System Owner’s Manual Page 19

Light System Accessories

A wide variety of accessories are available for the Dive Rite light systems. They

include:

➤ Spare batteries and chargers.

➤ Helmets and helmet light holders.

➤ Hand mounts.

Additionally, Dive Rite makes a number of accessories that adapt light components

for underwater video applications, such as wide-angle Lumidyne refl ectors for H1

light heads, high-color temperature MR16 bulbs, wet-pluggable power cords, and

more.

Spare Batteries and Chargers Dive Rite lighting systems come standard with a

battery pack and 12-volt charger. Many light system users purchase a second battery

pack and charger. This way, they always have a second battery ready to for the next

dive. Item numbers for these components are:

Item Number Description

6119 MLS Battery Pack, MLS1

6118 MLS Battery Pack, MLS2

6309 Battery Pack, Wreck Light

6314 Battery Pack, Wreck2

6317 Battery Pack, Classic

6024 MLS Charger, for MLS

6024 Charger, for Wreck2, Classic

6310 Charger, Wreck Light

Helmets and Helmet Light Holders Dive Rite helmets (item number 2031) are

designed to help protect wearers from head impact when riding diver propulsion

vehicles (DPVs or “scooters”) and diving in overhead environments with minimal

clearance. They are also valuable in situations in which divers need both hands free,

such as when in low visibility or artifact hunting. Quick-release helmet light holders

(item number 6125) enable users to mount light heads and back-up lights of similar

diameter to these helmets.

Page 20

Light System Owner’s Manual Page 20

Figure 11 Helmet and Helmet Light Holder

The light holder allows divers to snap these light heads and back-up lights in and

out with ease. Light holders come in very handy when scootering, surveying, lobster

hunting or in any other situation that requires hands-free lighting control.

Figure 12 Hand mounts.

Hand Mounts These enable divers to attach a light head to the back of either hand,

without interfering with that hand’s ability to perform other functions.

➤ Standard Hand Mount (item number 6126) This is a rectangular handle with a

helmet light holder attached to its top. The hand mount is popular among cave

and wreck explorers.

➤ “ Ergo” Hand Mount (item number 6126E) This is a variation on the standard hand

mount that enables users to change the angle of the hand mount, relative to that

of the light holder. Many divers feel this better conforms to the natural shape

of the hand.

The H1 “Short” head comes with an “Ergo” hand mount permanently attached to

the refl ector body. This refl ector/hand mount combination (item number 6253E) is

available separately and will work with other H1 light heads as well.

Video Bulbs and Refl ectors Video lighting options for Dive Rite light systems include

special bulbs for quartz-halogen MR16 light heads, and a special video refl ector for

H1-style quart-halogen and HID light heads.

Page 21

Light System Owner’s Manual Page 21

➤ MR16 “High Color Temperature” Bulbs The 50-watt MR16 video bulb (part

number 6266WHC) outputs light with a color temperature of approximately

4,800 degrees Kelvin—much closer to that of the sun than is typical of most

quartz-halogen bulbs. It also provide a broader beam than standard MR16 bulbs

(be aware, however, there is still something of a “hot” spot in the center). Still,

due to its inherent ruggedness, the MR16 head is a good choice if a video light

is subject to potential abuse.

Figure 13 Lumedyne Refl ector

➤ Lumedyne Refl ector for H1 MLS and HID Light Heads This special 4

3

⁄4-inch

parabolic refl ector provides a soft, even diffused light, and can also be used to

provide on- or off-camera video lighting. While the parabolic refl ector provides

a substantially broader, more even beam than MR16 video bulbs, it requires a

little extra care to avoid damage. Item number are 6270 for the MLS version, and

6270HID for the HID version.

Using Your Light System

Now that you know a little about your light system, let’s get into some of the

step-by-step procedures for using it. In this section, we will cover:

➤ Tr ansporting your light system.

➤ Charging your light system.

➤ Assembling your light system.

➤ Mounting your light system.

Ironically, the one thing we won’t spend too much time discussing is how to use

your light system under water. Presumably, you’ve taken advanced, specialty or video

courses that taught you the basics of using dive lights. If you’ve not had such training,

by all means, obtain it. Other than that, the only real instructions for using your

light system under water are:

Page 22

Light System Owner’s Manual Page 22

➤ Tu rn the light on.

➤ Point it at what you want to see (or illuminate).

➤ Tr y not to shine it in your own eyes—or anyone else’s.

That last point is the one we must take somewhat seriously. Your light system may

well be several times more powerful than any dive light you’ve used prior to this. It

can blind or impair the vision of you and others for up to several minutes. This

is certainly not safe.

You should also give thought to the impact high-intensity lighting can have

on aquatic life. If you shine your light system directly in the eyes of fi sh and other

animals, you can blind them for up to several minutes. During this time, they may

severely injure themselves by bumping into coral and rocks. They will also be a the

mercy of predators, and without much of their natural defenses.

Give careful thought to the safety and comfort of other divers, marine animals

and yourself. “Watch where you point that thing—okay?”

Transporting Your Light System

If you are like most folks, you probably did not take delivery of your light system

at the dive site, just prior to going under. You most likely picked it up at your local

Dive Rite dealer, and are now (we hope!) reading this manual before going on your

next dive trip. Thus, an immediate concern is what is the safest and best way to

transport your light system to and from dive sites and home?

The Most Important Step in Transporting (and Storing) Your Light System

This single most important step in transporting your light system is this:

Do not transport your light system with the light head and

battery connected. Doing so may substantially increase the

risk of fi re or explosion, which in turn can lead to damage to

equipment, serious personal injury or death.

Why is this important? When not immersed in water, light system bulbs get hot. Very

hot. Hot enough to start fi res, melt through plastic crates and burn holes through

expensive BCs and dive suits. Trust us, we’ve seen these things happen.

The only way to prevent them from happening is to make certain your light

can not turn on accidentally while being transported to and from dive sites and

home. To do that, you need to:

➤ In the case of an MLS canister light, disconnect the battery by removing the male

canister lid and replacing it with the male Travel Kit lid.

Page 23

Light System Owner’s Manual Page 23

➤ In the case of a PVC canister light, transport the battery inside the canister, but

leave it unplugged.

Other Pearls of Transportation and Storage Wisdom This is pretty much

common sense. Don’t pack your light system so that it can fall or be damaged by

other equipment. The H1 refl ector, in particular, likes to assume unusual shapes if

you put heavy objects on top of it. Unfortunately, none of these shapes will enhance

its performance.

Even though your light system uses sealed batteries, these batteries will still

off-gas minute quantities of hydrogen gas. Larger battery packs, in particular, will

off-gas more hydrogen than their smaller counterparts. Therefore, you should never

transport or store your light system with the battery pack sealed inside the canister in

such a manner that this gas cannot escape.

Build-up of hydrogen gas inside your light system canister

over prolonged periods increases the risk of fi re or explosion,

which can in turn result in equipment damage, serious personal

injury or death. To help prevent accidental shorting of battery

contacts when transporting or storing your light system, keep

the battery pack inside its canister, but do not seal this lid

in place with an O-ring, as doing so may prevent dangerous

hydrogen gas from venting.

Charging Your Light System

By now we assume that you’ve gotten home with your light system, but it will still

be a few days (or hours) before you have the opportunity to take it diving. Before

you take your light in the water, it is important you make sure the battery is fully

charged.

Connecting the Battery and Charger Here are the steps you want to follow next:

➤ If you have not already done so, either open your light system’s canister, so that

you have access to the battery, or remove the battery pack completely from the

canister.

➤ If yours is an MLS battery, plug the connector that comes from the charger into

the block at the top of the battery, as shown on the next page.

➤ If yours is an PVC light, mate the two “trailer plug” connectors, also shown on

the next page.

Page 24

Light System Owner’s Manual Page 24

➤ After the battery and charger are connected to one another (and only then), plug

the charger and any other necessary adapters into the wall socket

Figure 14 MLS charger set up.

Figure 15 PVC charger set up.

Page 25

Light System Owner’s Manual Page 25

There are two reasons why you should connect the battery and charger before

plugging the unit into the wall.

➤ Doing so will minimize the possibility that the connectors will short out when

the wrong connector prongs accidentally touch one another with current fl owing.

(This could damage the charger’s electronic circuitry.)

➤ You also minimize the possibility that the connectors will spark when they come

into contact with one another.

How Long to Charge How long your battery will need to fully charge will depend

on a variety of factors, including the type of charger supplied with your light. Your

charger may have instructions appearing on it that tell you to charge for a specifi c

length of time. If so, follow the instructions to the letter.

In lieu of specifi c charging instructions, your chargers may have an indicator

light. If so, leave the battery and charger plugged in until the indicator light begins

to fl icker or disappears, or changes from red to green. How long will this take? If the

battery has been used, and a more signifi cant level of discharge has taken place, it

will take longer for the battery to fully charge. Charging time for a fully discharged

battery may range from four to twelve hours or more. Also, the older your battery

becomes, the longer it may take recharge after comparable periods of use.

If you will not be using your light system for some time, you should disconnect

the battery and charger before leaving them unattended. During this time, some

slight discharge will occur. For this reason, you should reconnect the charger and

bring the battery pack back up to it full voltage every 30 days, and again just before

you take you light system on a dive.

Failure to disconnect your battery and charger before leaving

them unattended for extended periods may cause damage to

these items and increase the risk of fi re or explosion.

Assembling Your Light System

You will remember that, at the beginning of this manual, we encouraged you to not

wait until you are on the verge of diving to practice assembling and disassembling

your light system. You will discover that, with just a little bit of practice, this becomes

a simple, streamlined procedure.

Disconnecting From the Charger Obviously, you can’t take the battery with you

if it is still connected to a wall socket. To safely disconnect the battery from its

charger:

Page 26

Light System Owner’s Manual Page 26

➤ Begin by unplugging the charger from the wall socket.

➤ Then disconnect the battery from the charger.

Install the battery pack inside the battery canister body, if it is not already there.

Remember, it is important you not connect the battery to the light head until you

arrive on site and are getting ready to dive.

Figure 16 Use this procedure if you need to separate two-section canisters.

MLS Canister Assembly Once on site, your next step will be to remove, clean,

inspect and, if necessary, lubricate the O-ring found on the male battery canister lid.

This is something you should do every time you assemble the canister.

To remove the O-ring, place your thumbs on the side of the O-ring, approximately 2 inches/50mm apart. Now push your thumbs together gently. Doing so

should form a bulge. You can now grasp this bulge and use it to gently roll the

O-ring out of its groove and off the lid.

After removing the O-ring, you should clean any dirt or sediment from it by

rinsing it in a stream of hot, fresh water from your faucet. Allow the hot water to

run for several minutes. The heat of the water will help cause the silicone to liquefy,

making it easier for the water to rinse off dirt, sand and salt.

After rinsing, wipe off excess water with a lint-free cloth or allow the O-ring to

air dry. Now inspect the O-ring for cuts, nicks and any other unusual signs of wear.

Replace the O-ring, if necessary.

Lubricating the canister lid O-ring is the most important step you can take in

keeping your battery canister from fl ooding. The O-ring should be evenly lubricated

Page 27

Light System Owner’s Manual Page 27

with silicone grease until it is slightly tacky. Next, put a very thin coat of silicone

on the inside lip of the canister, where the O-ring will make contact (this will help

keep the O-ring from binding as the lid screws down. By checking your O-ring

before each use, you will help avoid a build-up of grease that could attract dirt or

other contaminants.

Once you have removed, cleaned, inspected and, lubricated the O-ring, put it

gently back in its groove on the battery canister lid, as shown below.

Figure 17 Proper canister lid O-ring position.

To close the battery canister, begin by orienting the battery contacts on the male

lid to those on the battery pack, as shown below. Do not worry about getting these

contacts backwards; the lid will only close if the contacts are oriented correctly.

Figure 18 Orienting battery contacts prior to closing the lid.

Page 28

Light System Owner’s Manual Page 28

Next, position the canister lid so that its threads make contact with those of the

canister body. Turn the lid back and forth until you fi nd the point at which the

threads allow you to push the lid as far as possible into the canister, without actually

screwing it in place.

Figure 19 To seat the lid, prior to turning it, push down evenly on both sides with

your thumb.

To make sure that the lid will screw in smoothly, push down with both thumbs,

as shown above. If the lid is properly seated, you will have approximately the same

amount of gap between the lid and the canister body as shown on the next page.

Now tighten the lid by turning it one-quarter turn clockwise. When your light

is new, you may need to use the canister wrench the fi rst few times you tighten the

lid (this all but guarantees you will also need the wrench to remove the lid). After this,

you should only need to hand tighten the lid to make a good seal; using the MLS

canister wrench unnecessarily will only make the canister harder to open. If you have

diffi culty tightening the lid, try re-seating it as shown in Figure 19. It may also help

to apply a light coating of silicone grease to the canister lid threads.

If you have installed the lid correctly, you will know it; it will simply “feel”

right. If it does not feel entirely right, try repeating the steps outlined here. With

practice, you will discover that installing the canister lid quickly becomes a simple

and fairly straightforward procedure.

Page 29

Light System Owner’s Manual Page 29

Figure 20 The correct amount of gap between the lid and canister body, both just before

(left) and after (right) tightening.

PVC Light Assembly This is a fairly straightforward operation (see illustration, next

page). The steps are:

➤ Remove and inspect the canister lid O-ring. Remove any dirt or grease by rinsing

the O-ring in warm, soapy water, then drying with a lint-free wipe. Make certain

the seating surfaces on the canister and lid are equally clean.

➤ If the O-ring appears abnormally dry, apply a very light coating of silicone grease.

Use only enough grease so that the O-ring has a dull sheen. Excess grease will

only serve to attract dirt.

➤ Replace the O-ring on the canister lid.

➤ Plug the connector coming from the canister lid into its counterpart on the battery

wiring harness.

➤ Tu ck the connectors and wiring harness inside the canister, along with the foam

spacer that keeps the battery from moving around, if one was provided with your

light.

➤ Use the latches to close and seal the lid. As you do, be sure to push down on both

latches simultaneously, to help ensure you put pressure on the O-ring evenly.

Page 30

Light System Owner’s Manual Page 30

Figure 21 PVC light assembly.

H1 Lens Inspection Dive lights equipped with HI heads (both quartz-halogen and

HID models) require a further step. Prior to taking these lights under water, remove

the refl ector and make certain the base of the lens (test tube) is resting tightly against

its contact point on the metal light head body. If you detect any sort of a gap here,

push in on the top of the lens to move it back into place.

Failure to ensure that H1 lenses are in their proper position,

prior to taking a light under water, can result in serious equip-

ment damage that is not covered under warranty.

Page 31

Light System Owner’s Manual Page 31

Testing Light Operation

After closing the battery canister, you will want to check to make certain that the

light is operating properly. If your canister is fi tted with a toggle switch mechanism,

this is fairly easy. Simply move the toggle switch into the “on” position for one or two

seconds—just long enough to make sure the light is functioning correctly.

Do not attempt to test HID light operation out of the water.

When not immersed in water, HID bulbs output signifi cant UV

radiation, and can cause serious eye damage.

Additionally, once activated, HID bulbs must burn for at least four minutes, to allow

the bulb to come up to full operating temperature. If you turn an HID bulb on,

then turn it immediately off again, as you would with a quartz-halogen bulb, you

risk severely damaging the bulb.

If you own an HID light, you must accept the fact you can only test its

operation as you enter the water, or immediately prior to descending. Once your

HID light is turned on, leave it on until the end of the dive.

Even with quartz-halogen lights, you should not let your light system burn

out of water, except for brief intervals to check light function. Extended out-of-water

burn time can damage the light.

Figure 22 Actuator head orientation.

Page 32

Light System Owner’s Manual Page 32

Actuator Head Testing/Operation If your light system is equipped with an actuator

head, you will want to familiarize yourself with its on/off positioning before entering

the water. The illustration on the previous page shows which way to rotate the

actuator to turn the light on and off. If you look straight down at the tip of the

actuator, clockwise is “on;” counter-clockwise is “off.”

Rotate the actuator until the light comes on. Now back off one-quarter turn.

If you forget which way is “on,” under water, rotate the actuator no more than a

half-turn in either direction. If the light fails to come on, rotate it no more than a full

turn in the opposite direction to see if it illuminates.

Under no circumstances rotate the actuator more than one full

turn under water, without being absolutely certain you know

which direction is on and off. If you continue to rotate the

actuator in the wrong direction, you will eventually remove

it and water will fl ood the sensitive connection points inside.

This can seriously damage the light.

Conversely, you should never tighten the actuator until

it can no longer turn. Doing so may jam the two actuator

components together so hard they cannot be unlocked. It is only

necessary to turn the actuator one-quarter turn past the point

at which the bulb comes on.

Also, on the H1 head, do not use the refl ector adjustment screw as leverage to turn

the actuator on and off. Doing so may cause the adjustment screw mounting to

break. If the actuator does not turn easily, the O-rings or threads probably need

lubrication. See page 38 for more information on actuator O-ring lubrication.

Mounting Your Light System

Before taking your light system under water, you will have to determine the best

way to mount the battery canister to the rest of your equipment. There are a nearly

infi nite number of ways to do this. This section will cover some of the most common

mounting techniques, including:

➤ Waist and tank mounting.

➤ Tr anspac mounting.

Dive Rite sells a wide variety of snaps, clips, D-rings and other mounting hardware

to facilitate the process.

Waist Mounting All Dive Rite light system canisters are equipped with a loop or

slot for waist mounting. If your tank harness utilizes an exposed, 2.0-inch/50 mm

Page 33

Light System Owner’s Manual Page 33

waist strap—or you have suffi cient room on your waist for an additional 2.0-inch/50

mm waist strap—you can simply slide this strap through this loop or slot. (A special

adapter, part number 6299, is available for waist mounting MLS2 canisters; this

adapter places a waist-band slot at the mid point between the two canister sections.)

Figure 23 Wa ist mounting MLS canisters.

As shown in the accompanying illustrations, to keep the light system from sliding

back and forth on this strap, you can use an additional two-inch quick-release buckle

to lock the canister in place.

Page 34

Light System Owner’s Manual Page 34

Figure 24 Wa ist mounting PVC light canisters.

Tank Mounting Yo ur light system waist mounting loop/slot can also be used to

attach it to 2.0-inch/50 mm tank cam straps. This method is well suited to divers

using single cylinders.

When tank mounting a light system canister, try to keep the battery pack as

close to the body as possible, so as not to throw off your center of gravity. Some

BC tank bands are not well suited for tank mounting light system canisters. If yours

is among these BCs, you may be able to solve the problem by using a separate

2.0-inch/50 mm tank strap (part number 2032), just to hold the light to the tank.

Transpac Mounting If you own a Dive Rite Transpac, you can also use two of the

six, 1.0-inch/25 mm D-rings on the back side of the BC to attach your light to, as

shown in the accompanying illustrations.

Page 35

Light System Owner’s Manual Page 35

Figure 25 One method of attaching MLS canisters to Dive Rite Transpac harnesses/

Some of the hardware you use to accomplish this may include carabiners, doubleended sliding-bolt snaps and surgical tubing. Due to the wide variation in human

sizes and shapes, you will likely need to experiment to fi nd the ideal combination of

mounting hardware. When you get it right, however, the canister will seem to fl oat in

the “valley” between your Transpac air cell and the side of your body.

Figure 26 Attaching PVC light canisters to Dive Rite Transpac harnesses.

Page 36

Light System Owner’s Manual Page 36

Figure 27 Wreck2 lights have special attachment strap which can be used for waist, tank

or Transpac mounting.

Attaching Clips to Light Heads In addition to mounting their battery canister to

waist straps, BCs or tanks, most light system users attach a small snap to the light

head, so that they can clip the head to a D-ring on their BC or tank harness when

it is not in their hand.

Maintaining Your

Light System

Having invested in your light system, you undoubtedly want it to last. This section

covers how to care for your light system so that it gives you years of relatively

trouble-free service. In this section, we will discuss:

➤ Post-diving maintenance and care.

➤ Changing actuators.

➤ Changing or replacing bulbs.

➤ Making batteries last.

➤ Dealing with fl ooding or other damage.

As we mentioned earlier, if you have questions whose answers you cannot fi nd in this

manual, contact your local authorized Dive Rite dealer, or contact Dive Rite directly,

using the information appearing on the front cover.

Page 37

Light System Owner’s Manual Page 37

Post Dive Maintenance and Care

Immediately upon surfacing from every dive, perform the following steps:

➤ Inspect your light system for signs of leakage or other damage. (Your light system

may have continued to function normally, even though water was inside.)

➤ Rinse the unit thoroughly in fresh water and allow it to dry.

➤ Open the canister lid. After doing so, remove the O-ring and store it separately

(this will allow hydrogen gas to escape during transit). One convenient place to

store MLS canister O-rings is to wrap the O-ring twice around the batter contact

posts inside the lid). Removing canister lid O-rings further helps prolong its life.

Doing so also helps ensure that MLS O-rings are not in place when you attach the

female travel cap to the canister lid. Were you to attach the female travel cap with

the O-ring in place, removing it later could be diffi cult.

As you can see, these steps are pretty much common sense.

Changing Actuators

Changing actuators is a very simple and straightforward procedure. The most important step is to remember to do it above water! (Okay, we’re kidding—for the most

part. Nevertheless, there are people out there who have tried to change fi lm in their

Nikonos under water, so you never know…) Here are the steps to follow:

➤ Make certain that the light head has been thoroughly rinsed and dried following

the previous dive.

➤ If you have not already done so, disconnect the battery by removing the canister lid

and putting the female travel cap in place.

➤ Unscrew the actuator head you wish replace by turning it counter-clockwise until

it comes free from its base.

➤ Carefully lift the actuator head off its base.

Once the actuator is off the base, you will notice the grounding spring wrapped

around the threads on the base.

Ta ke care not to lose this spring, or to contaminate it with

dirt or grease.

➤ Inspect the two O-rings at the base of the actuator for a build up of dirt or

sediment. If necessary, wipe this area clean with a lint-free cloth, then remove and

re-lube the O-rings.

Page 38

Light System Owner’s Manual Page 38

➤ Screw the new actuator back in place, by turning it clockwise.

➤ Re-connect the battery and test the light to make certain it turns on and off.

O-ring Lubrication Whether installing a new actuator, or simply turning your light

system on and off, the light head should turn easily. If it does not, the O-rings at the

base of the actuator most likely need lubrication. Here are the steps to follow:

➤ Remove the actuator head, following the steps outlined previously.

➤ Remove the grounding spring and put it in a safe place, taking care not to get

grease or dirt on it.

➤ Remove the two O-rings from their grooves by fi rst pinching them so a small bulge

appears, and them rolling them off the end of the actuator.

➤ Clean any dirt or grease from the O-ring grooves with a cotton swab.

➤ Wipe any excess grease or dirt from the O-rings using a lint-free cloth, then inspect

the O-rings carefully for nicks, cracks or deformities. (Replace any O-rings that

show signs of damage.)

➤ Lubricate the O-rings by placing a small dab of silicone grease (part number 2052)

on your fi nger tips and working this into the O-rings. Remember, you only want

to have enough lubricant on the O-rings so that they present a uniform, shiny

appearance. Wipe any excess grease from the O-rings with a lint-free cloth.

➤ Replace the O-rings into their grooves, taking care not to damage them.

➤ Lubricate the actuator base threads with a small dab of silicone lubricant. You

should lubricate these threads on a regular basis; however, do not wipe off the

electrically conductive, anti-seize lubricant that we install on the threads at the

factory. This should remain in place for the life of the light; apply silicone lubricant

on top of it.

➤ Put the grounding spring back in place, taking care not to contaminate it with

dirt or grease.

➤ Reinstall the actuator head by screwing it on clockwise.

The actuator should now turn easily.

Changing or Replacing Bulbs

The ability to easily change or replace bulbs is among the keys to the light system’s

versatility. In the case of quartz-halogen lights, you can switch to lower-wattage bulbs

to extend burn time, or to higher-wattage bulbs to increase light output. You can also

easily replace bulbs that no longer function due to normal wear or impact damage.

Page 39

Light System Owner’s Manual Page 39

Only quartz-halogen bulbs and 10- watt Compact HID bulbs

are user-replaceable. Both 17- and 18-watt HID lights must be

returned to Dive Rite for bulb replacement.

H1 Bulbs Here are the steps to follow to change H1 bulbs:

➤ Make certain that the light head has been thoroughly rinsed and dried following

the previous dive.

➤ If you have not already done so, disconnect the battery by removing the canister lid

and putting the female travel cap in place.

➤ Remove the refl ector from the actuator by turning the locking screw counter-

clockwise until the refl ector slides off easily.

➤ Now, fi rmly pull the glass lens (test tube) off the end of the actuator. Do not twist

the lens during this process as it may tear one or both of the O-rings. If a tear does

occur, immediately replace the O-ring. (A tear may cause the light to leak.)

➤ The bulb will now be exposed. Hold the socket fi rmly with one hand and pull

the bulb out with the other. If you plan to re-use the bulb you are removing, take

care not to get fi ngerprints on it. (Fingerprint grease will cause bulbs to burn out

prematurely.) Grasp the bulb with a lint-free cloth, if need be, to prevent this from

happening. If you do get grease on a bulb, you can clean it off with alcohol.

Figure 28 Changing H1 bulbs.

➤ Examine the bulb contacts for signs of corrosion or any other indicators that water

may have gotten into the light head.

You are now ready to install the replacement bulb. Remember to inspect the replace-

ment carefully to ensure it is the correct voltage and wattage.

➤ Remove the replacement bulb from its package. Hold the bulb with a tissue or with

the wrapper, to avoid getting fi ngerprint grease on it.

➤ Next, fi rmly push the new bulb into the socket. Be careful to not put too much

side pressure on the bulb. This excessive pressure may cause the base of the bulb

to crack.

Page 40

Light System Owner’s Manual Page 40

At this point, you are probably thinking about lubricating the

lens O-rings. Don’ t do it. The heat of the bulb is suffi cient

to evaporate the lubricant, creating so much gas pressure that

the lens pops off under water. The O-rings should be clean and

shiny—but free of any lubricant.

➤ Now clean the inside of the lens, if required, to remove any dirt or grease. Examine

the lens for chips or cracks. If any problems exist, replace the lens because, if you

don’t, the waterproof seal may fail.

➤ Now, push the lens back into its correct position on the light head. To check if

the lens is in the correct position, look to make sure that the bottom of the lens

rests against the O-ring at the base of the light head, and that the lens O-rings

are fl at against the inside of the lens (they should form a solid black line all the

way around).

➤ Next, replace the refl ector by sliding it down onto the actuator body and tighten

the lock down screw in the guide slot.

➤ Finally, reconnect the battery to the wiring harness.

Test the light to make sure it comes on. If the light does not come on, check the fuse

you’ll fi nd on the battery pack wiring harness.

Do not bypass the fuse, as doing so may cause severe battery damage. (The fuses

help protect batteries from faulty chargers.) You will fi nd fuse fi ttings located on each

battery pack wiring harness. They take standard 15-amp automotive fuses.

Changing MR16 Bulbs (Old Style) Changing bulbs on older-style MR16 light

heads (those made prior to Fall, 1998) is a little different than changing H1 bulbs.

Here are the steps to follow:

➤ Make certain that the light head has been thoroughly rinsed and dried following

the previous dive.

➤ If you have not already done so, disconnect the battery by removing the canister lid

and putting the female travel cap in place.

➤ Remove the lens from the light head by fi rst unfastening the four screws that

hold it in place. To do so, you will need a 7⁄64-inch Allen wrench (closest metric

equivalent is 3 mm). Set the screws aside, taking care not to lose any of them.

➤ Remove and inspect the O-ring that surrounds the bulb. If it is damaged, obtain a

replacement. Otherwise, set it aside for re-installation later.

Page 41

Light System Owner’s Manual Page 41

➤ The bulb will now be exposed. Pull it out a few inches from the light head, as

shown below.

Figure 29 Changing MR16 bulbs.

➤ Hold the socket fi rmly with one hand and pull the bulb out with the other (the

bulb and refl ector are one piece). If you plan to re-use the bulb you are removing,

take care not to get fi ngerprints on it. (Fingerprint grease will cause bulbs to burn

out prematurely.) Grasp the bulb with a lint-free cloth, if need be, to prevent this

from happening.

➤ Examine the bulb contacts for signs of corrosion or any other indicators that water

may have gotten into the light head.

You are now ready to install the replacement bulb. Remember to inspect the replace-

ment carefully to ensure it is the correct voltage and wattage.

➤ Remove the replacement bulb from its box. Hold the bulb with a tissue or with the

wrapper, to avoid getting fi ngerprint grease on it.

➤ Next, fi rmly push the new bulb into the socket. When doing so, rest the edge of

the socket against the side of the light head, as shown in Figure 21. Be careful

to not put too much side pressure on the bulb. This excessive pressure may cause

the base of the bulb to crack.

➤ Push the bulb back into its recessed opening. A twisting motion will help keep

the wires from interfering.

➤ Clean and lubricate the lens O-ring and put it back in place. Take care not to get

grease on the bulb or refl ector.

➤ Now clean the inside of the lens, if required, to remove any dirt or grease. Examine

the lens for chips or cracks. If any problems exist, replace the lens because, if you

don’t, the waterproof seal may fail.

➤ Re-install the lens, using the four screws you previously set aside. Lubricate the

screws with silicone grease or “anti-seize.” Then tighten the screws by hand, as far

Page 42

Light System Owner’s Manual Page 42

as they will go. Next, use your

7

⁄64-inch/3 mm Allen wrench to tighten them a few

turns at a time. Use a rotation pattern, much as you would when putting a wheel

on a car. Make sure the screws are tightened evenly all around

➤ Finally, reconnect the battery to the wiring harness.

Test the light to make sure it comes on. If the light does not come on, check the fuse

inside the battery canister. If the fuse is blown, replace it. Do not bypass the fuse, as

doing so may cause severe battery damage.

Changing MR11 Bulbs (Old Style) The procedure for changing bulbs in older-

style MR11 light heads is largely the same as previously outlined for changing MR16

bulbs. The key difference is that, where older-style MR16 lenses are held in place by

four screws, older-style MR11 lenses come off simply by unscrewing their retaining

rings like the lid of a jar.

Be aware that, where older-style MR16 lenses are siliconed to their retaining

rings, older-style MR11 lenses are not. There is also a gasket between older-style

MR11 lenses and their retaining rings that does not exist on older-style MR16

heads. When removing these items, take care not to drop or lose them. Lubricate the

retaining ring threads with silicone grease when reinstalling it.

Changing Compact HID/MR11/MR16 Bulbs (New Style) In Fall, 1998, Dive Rite

introduced a new style of MR11 and MR16 light head. Although identical to their

predecessors in term purpose and function, these new heads employ a noticeably

different method of changing bulbs.

Figure 30 Cross section of new-style MR11 and MR16 light heads.

As the accompanying illustration shows, there is an O-ring on each side of the lens.

The inner O-ring forms a water-tight seal; the outer O-ring locks the lens in place.

Page 43

Light System Owner’s Manual Page 43

Figure 31 Removing new-style MR11/MR16 lens.

To change bulbs on either of these new-style light heads, you begin by removing the

lens. To do so, pry the outer O-ring from its groove, as shown in Figure 23. Although

this particular O-ring is not responsible for making a water-tight seal, take care to

avoid cutting or nicking it.

Once this O-ring is removed, the lens should drop right out. At this point, you

can change the MR11 or MR16 bulb as outlined earlier.

The socket for the 10-watt Compact HID bulb will not move

around inside the light head; pull the bulb straight and push

it’s replacement straight in. Use caution when doing so; HID

bulbs are very expensive and not covered under warranty.

Before replacing the lens, inspect the sealing O-ring. If there is any build-up of sand,

salt or sediment, or if it lacks the slightly shiny appearance of a properly-lubricated

O-ring, remove the sealing O-ring from its groove. Clean the groove thoroughly with

a cotton swab. Wash the O-ring in soap and water, dry it with a clean cloth and apply

a light coating of silicone grease. Now place the O-ring back in its groove.

After putting the lens back in place, re-insert the locking O-ring in its groove.

The fi rst time you do, you may need to take a while to master the knack of working

the locking O-ring in place. At fi rst, there will likely be a distinct bulge, such as

appears in Figure 31. After you mash this bulge down, two smaller ones will tend to

appear in its place. Keep pushing down on these bulges until they all disappear. With

a little practice, it will become easy.

Page 44

Light System Owner’s Manual Page 44

Making Batteries Last

Dive light batteries will not last forever. Nevertheless, with conscientious care, they

can power dive lights for dozens of dives before needing replacement. If you use

Dive Rite light systems, it is important you understand the steps you must take to

prolong battery life. If you sell Dive Rite lights, it is important you help educate your

customers about these important steps. Just how long a dive light battery will last

depends on a variety of factors, including:

➤ Has the Battery Been Completely Discharged? Doing so will utterly destroy a gel-cell

battery, such as those used in Dive Rite lights — even if the battery is brand

new. These batteries are not NiCads; they will not develop a “memory” if not

completely discharged. Completely discharging a battery will only serve to destroy

its usefulness and void warranty coverage.

➤ Has the Battery Been Drained Below 10.5 Volts? This is the point at which a quartz-

halogen bulb’s output turns noticeably yellow. Continuing to use a dive light

beyond this point will seriously damage the battery and is nearly as bad a thing to

do as completely draining the battery. As soon as a diver sees his or her dive light’s

bulb go yellow, he or she must turn it off immediately to prevent further damage.

Better yet, divers should keep light use well within the expected “burn” time, to

prevent such an occurrence. (More on this shortly.)

➤ Has the Battery Been Properly Charged? A battery must be fully recharged immedi-

ately after use, then at least once every 30 days and again prior to use.

➤ How Old is the Battery? Battery life will diminish over time, regardless of whether

the battery is used. A three-year-old battery with 30 dives on it will most likely not

provide the burn time that a six-month-old battery with the same number of dives

will — even if properly maintained.

➤ Has the Light Been Properly Assembled? Flooding can result in all sorts of dive light

damage — including damage to batteries. All Dive Rite light systems are pressure

tested at the factory prior to delivery. When light systems are returned to Dive

Rite for warranty service, the fi rst thing we do is assemble the light precisely as

outlined in the owner’s manual, including proper lubrication and installation of

O-rings. We then pressure test the light, just as we did when new. If the light

passes this second pressure test, we have to assume that any reported fl ooding must

have resulted from failure to properly assemble the light as outlined in the owner’s

manual — in which case no warranty coverage is provided.

Page 45

Light System Owner’s Manual Page 45

Among the greatest factors affecting battery life is how far you keep actual battery use

within the battery’s expected burn time. If divers consistently use their batteries for

close to 100 percent of the expected burn time, battery life will be relatively short.

Color Wreck Light Wreck2 MLS1 MLS2/Classic

Temperature Average Expected Expected Expected Expected

Part in Degrees Bulb Life Burn Time Burn Time Burn Time Burn Time

Number Wattage Kelvin in Hours in Minutes in Minutes in Minutes in Minutes

HID Bulbs

Compact) 10 6000 1100 120 300

6315 (MR11) 17 6500 1100 60 120 180 360

6302 (H1) 18 6500 1100 60 120 180 360

MR16 Bulbs

6106 20 2950 3500 60 110 210 420

6128 35 2950 3500 90 120 240

6107 50 2950 3500 50 60 150

6107HC 50 4800 3500 50 60 150

6266 501 4800 3500 50 60 150

6266WHC 502 4800 3500 50 60 150

6108 75 2950 3500 45 100

6135 1003 3350 50 35 60

MR11 Bulbs

6226 20 2950 2000 60 110 210 420

6225 35 2950 2000 90 120 240

H1 Bulbs

6293 20 2850 2000 60 110 210 420

6283 35 2900 2000 90 120 240

6132 50 3300 50 50 75 180

6133 100 3300 50 35 60

1. Special high-color-temperature bulb (10° spot); works only with newer-style heads

2. Special high-color-temperature bulb (wide-angle); works only with newer-style heads

3. Special wide-angle video bulb

Page 46

Light System Owner’s Manual Page 46

On the other hand, if users keep actual battery use well within expected burn times,

battery life can be dozens upon dozens of dives — potentially exceeding 100 or

more dives. The table on the preceding page will help you determine the expected

burn time of a dive light when new. The times listed represent average maximum

expected burn times for new batteries in good condition. You should bear in mind,

however:

➤ We base the information appearing here on data supplied by the batteries’ manufac-

turer, and upon our own tests of how long it takes a properly charged battery,

under load, to reach an output of 10.5 volts. Battery manufacturers, however, may

change product specifi cations at any time, without warning. As a consequence the

information appearing here may not be true in the future.

➤ Batteries are not manufactured to the same tolerances as machined parts. New

batteries can easily provide more or less potential burn time than appears here.

(Which is one more reason to keep actual use well within rated burn times.)➤

Potential burn time will diminish over the life of the battery. You should not

assume that a battery which has been used several times, or which is more than

a few months old, will have the same potential burn time as a battery that is