DITTEL P6001FD User Manual

P6001FD

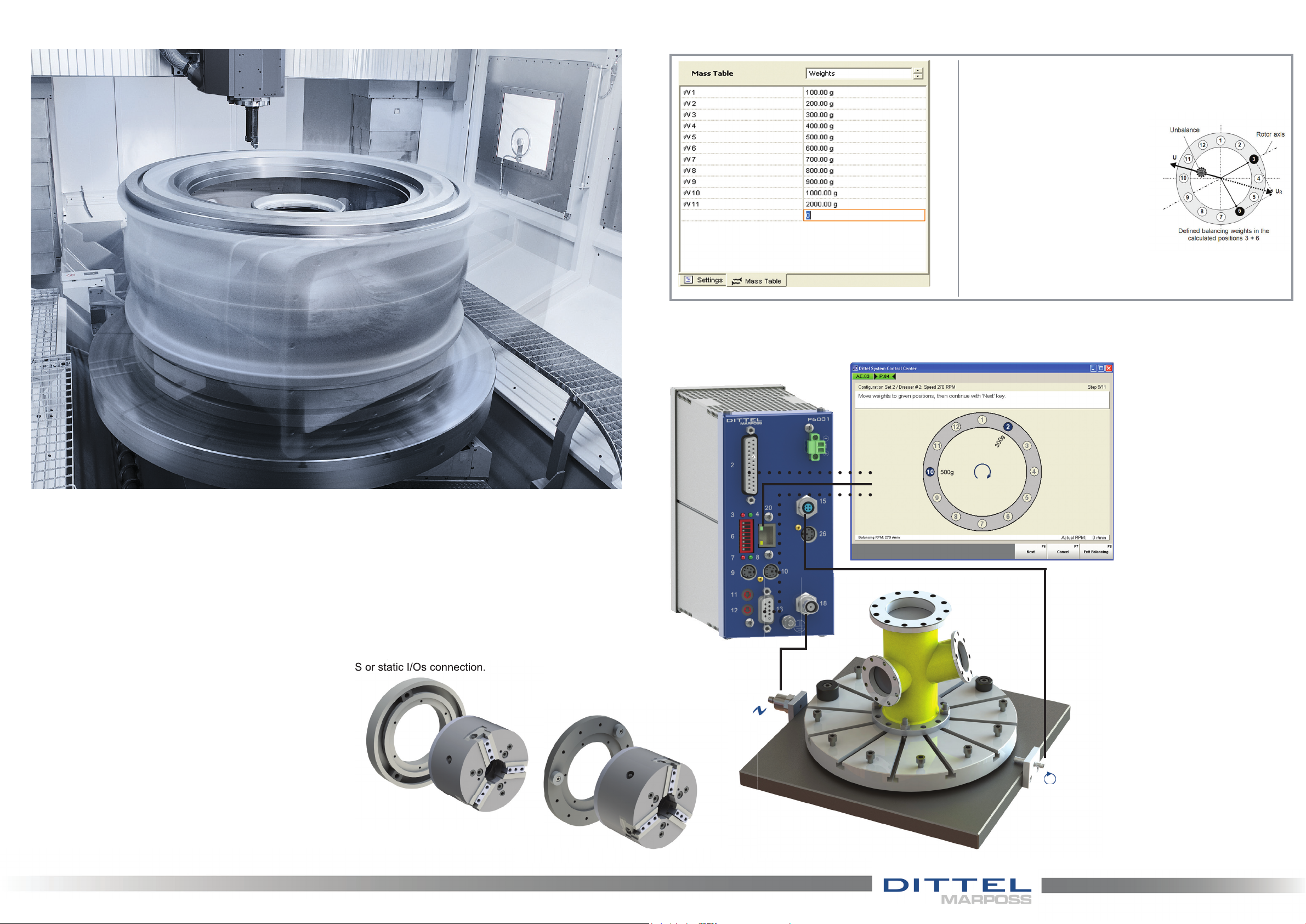

Manually

Single-Plane Balancing

Product overview

Manually

Single-Plane Balancing

• rotating workpieces´ tables with low RPM range

• asymmetrical workpieces

• milling - and (vertical) turning machines

picture: Gildemeister

Pre-Balancing with the fi xed

position method:

Compensation of balancing

by adding defi ned weights

(e.g. screws, measure weights)

at specifi c positions.

Maximally 24 defi ned places

with 2-3 balancing weights.

Special features

Filtered-RPM-Unbalance

monitoring for RPM

range 80-6000 1/min

Unbalance is on machine tools the most common

source of vibrations. Balancing of the tool holder

and the spindle can be of great help.

What has become a standard over the last decades on grinding machines, has gained interest

also both on combined (milling and turning) and on

vertical turning machines especially when asymmetrical workpieces have to be handled. Keeping

the vibration as low as possible increases the working life of the bearings as well as of the tools and

results in a better workpiece’s surface quality.

The P6001FD module is the last addition to the

Dittel pre-balancing P6000 family and is purposely designed for the use on machine tools rotating

at low RPM.

The workpiece table’s unbalance on a pre-defi ned

plane is detected during a pre-balancing cycle

and subsequently compensated fi xing known ba-

lancing weights on calculated position on the rotating table.

The P6001FD suggests the best balancing weight

to be used out of a freely programmable weights’

table. A fi xed positions algorithm is used to determine the best positions out of a maximum of 24 in

which to fi x two or three weights. The electronics

offers also a continuous monitoring function of the

vibration level of the rotating table.

The P6001FD can be programmed, used and its

functions visualized through the machine control

unit or any Windows based PC. The signals can

be exchanged to and from the machine via a Profi BUS or static I/Os connection.

angular method

Continuous unbalance

monitoring

Intelligent and

customizable graphical

user interface

Profi BUS and static I/Os

communication channels

Visualitazion through

Ethernet connection

Simple software integration

Simple factory reset

function in case of servicing

(series setup)

Individual adjustable

user levels

fi xed position

method

M7002/MA7002

Loading...

Loading...