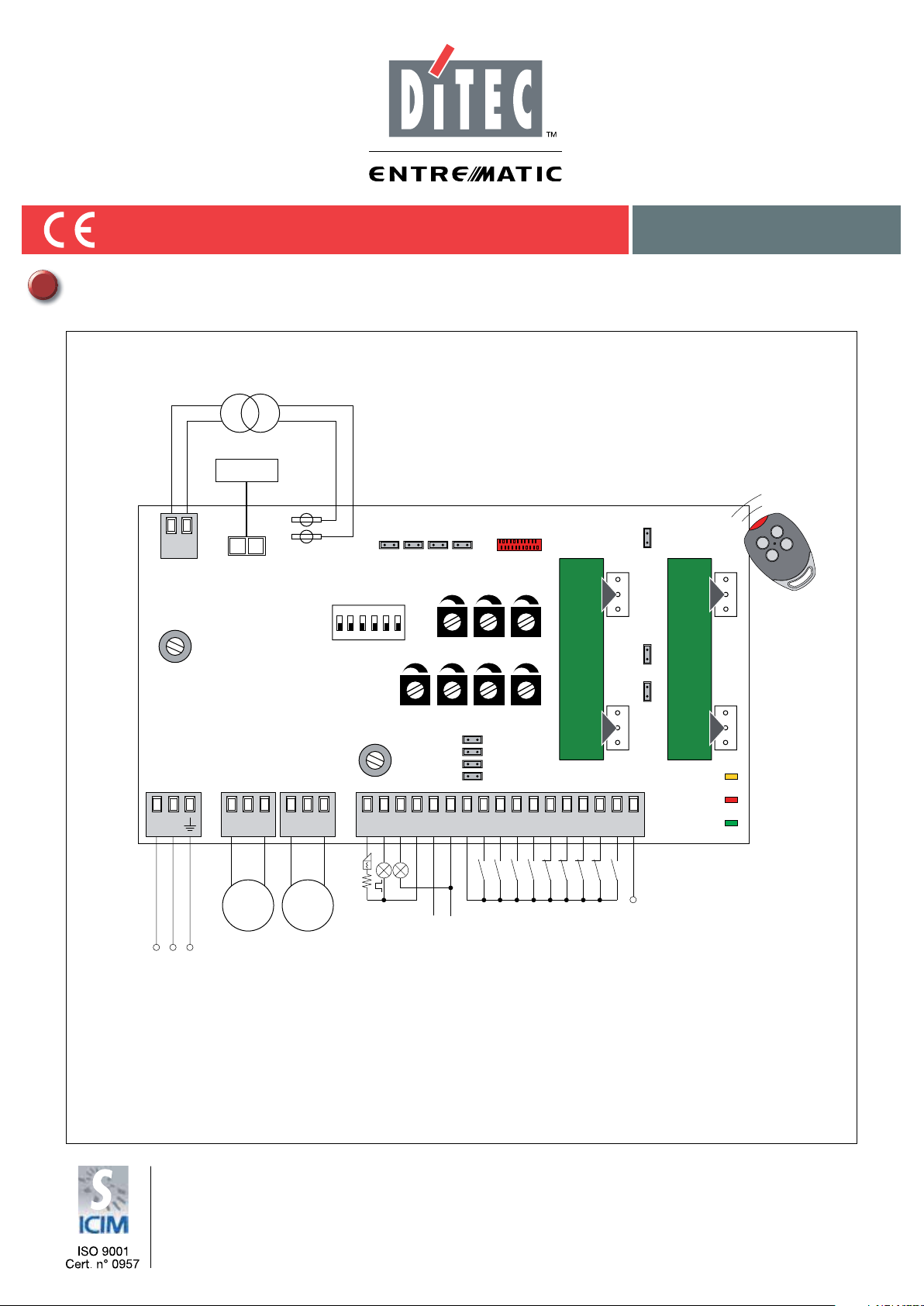

Page 1

VIVAH

EN

Installation manual for control panel for automations with one or two 24 V= motor.

Transformer

BATKH

IP1776EN

rev. 2012-02-20

TRF

F1

LN

Power supply

BAT

24 V~

ON

OFF

36 35 34 33 32 31

24V=

Motor 2

24V=

Motor 1

FC

123 4 5 6

SO EO OM

COM

TC TR RP

AUX1

VM M1 M2 R1

F2

S1

S2

S3

S4

1514130011234567892041

-

+

Closing

Electric lock

Flashing light

Opening

Automatic closing

Safety stop

Safety stop

Step-by-step

Safety re-opening

FS

NIO

JR14

Stop

Safety test

Partial opening

AUX2

IN

SA

POWER

ALARM

GOL4

Gate open indicator light

Output 24 V= / max 0.5 A

DITEC S.p.A.

Via Mons. Banfi, 3 - 21042 Caronno Pertusella (VA) - ITALY

Tel. +39 02 963911 - Fax +39 02 9650314

www.ditec.it - ditec@ditecva.com

Page 2

INDEX

Subject Page

1. General safety precautions 3

2. EC declaration of conformity 4

3. Technical data 4

3.1 Applications

4. Connection of power supply 4

5. Commands 5

5.1 SOFA1-SOFA2 self-controlled safety edge

6. Outputs and accessories 7

7. Adjustments 8

7.1 Selection of automation type

8. Connection of motors 11

9. Start-up 12

10. Troubleshooting 13

11. Example application for one-motor automations 14

12. Example application for two-motors swing gates 15

13. Example application for up-and-over doors with in-parallel motors 16

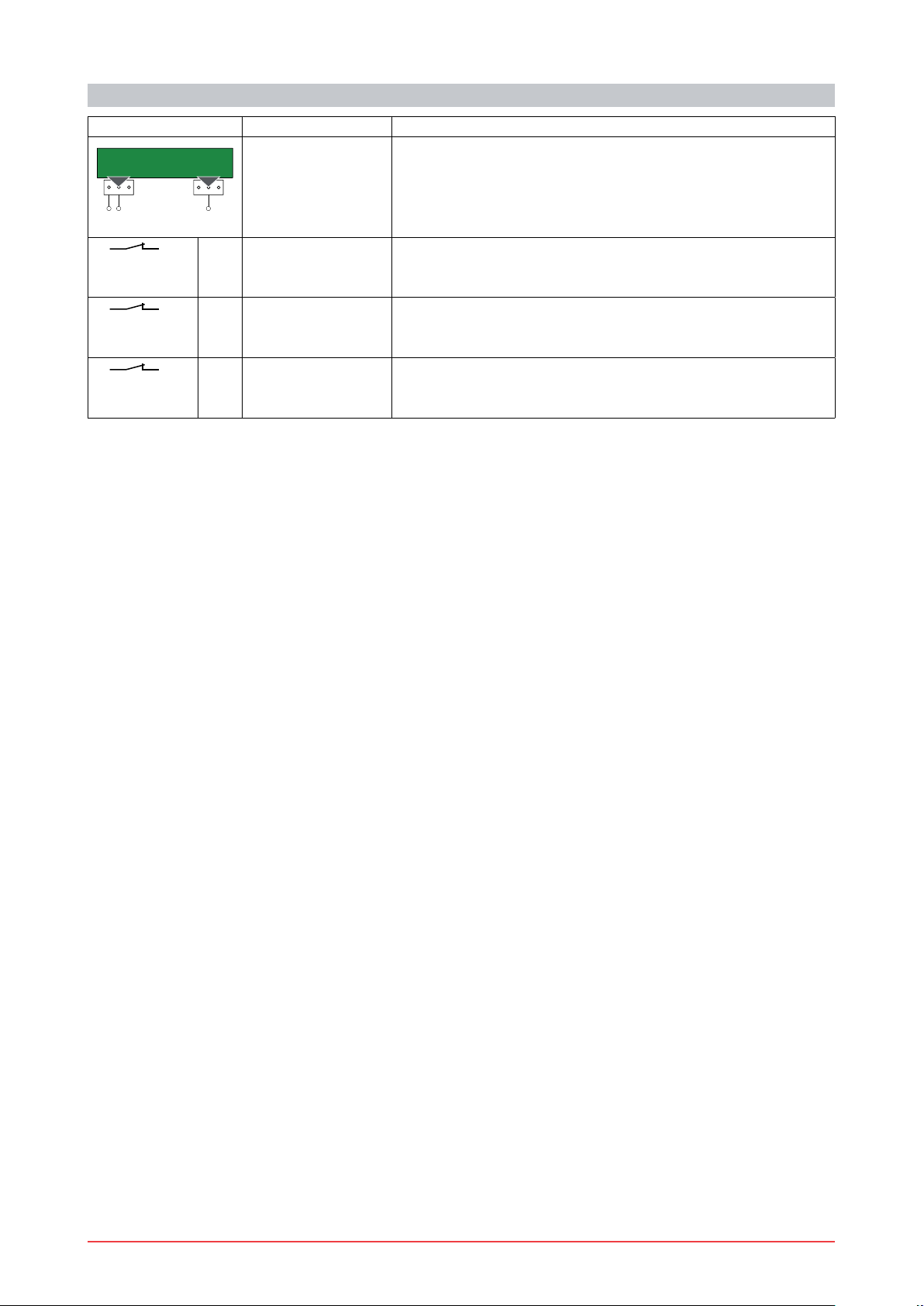

CAPTION

4

6

10

This symbol indicates instructions or notes regarding safety issues which require particular attention.

This symbol indicates informations which are useful for correct product function.

i

This symbol indicates instructions or notes intended for technical and expert personnel.

This symbol indicates operations not to be effected for not compromise the correct operation of the

STOP

automation.

This symbol indicates options and parameters which are only available with the indicated item.

This symbol indicates options and parameters which are not available with the indicated item.

All right reserved

All data and speci¿cations have been drawn up and checNed with the greatest care. The manufacturer cannot

however taNe any responsibility for eventual errors, ommisions or incomplete data due to technical or illustrative

purposes.

IP1776EN 2012-02-20

2

Page 3

1. GENERAL SAFETY PRECAUTIONS

This installation manual is intended for professionally competent personnel only.

The installation, the power connections and the settings must be completed in conformity with Good

:orNing Methods and with the regulations in force.

Before installing the product, carefully read the instructions. Bad installation could be ha]ardous. The pacNaging

materials (plastic, polystyrene, etc.) should not be discarded in the environment or left within reach of children,

as these are a potential source of hazard.

Before beginning the installation checN that the product is in perfect condition.

'o not install the product in explosive areas and atmospheres the presence of Àammable gas or fumes represents a serious threat to safety.

The safety devices (photocells, sensitive edges, emergency stop, etc.) must be installed taNing into account

the provisions and the directives in force, Good :orNing Methods, the installation area, the functional logic of

the system and the forces developed by the automation.

Before maNing power connections, checN that the rating corresponds to that of the mains supply. A mul-

tipolar disconnection switch with a contact opening gap of at least 3 mm must be included in the mains

supply. ChecN that upstream of the electrical installation an adequate residual current circuit breaNer and an

overcurrent cut out are ¿tted.

When requested, connect the automation to an effective earthing system carried out as indicated by current

safety regulations.

During installation, maintenance and repair operations, cut off the power supply before opening the cover to

access the electrical parts.

To handle electronic parts, wear earthed antistatic conductive bracelets. The manufacturer of the moto-

risation declines all responsibility in the event of components which are not compatible with the safe and

correct operation of the product.

For repairs or replacements of products only original spare parts must be used.

3

IP1776EN 2012-02-20

Page 4

2. EC DECLARATION OF CONFORMITY

An

ga

a

an

aging

g

reror

Manufacturer: DITEC S.p.A.

Address: via Mons. Ban¿, 3 21042 Caronno P.lla (VA) - ITALY

declares that the control panel VIVAH is in conformity with the provisions of the following EC directives:

EMC Directive 2004/108/EC;

Low Voltage Directive 2006/95/EC.

Caronno Pertusella, 13-12-2010 Silvano Angaroni

(Managing Director)

Siano

3. TECHNICAL DATA

VIVAH

Power supply 230 V~ / 50-60 Hz

F1 fuse F2A

F2 fuse F2.5A

Motor output 24 V= / 2 x 12 A max

Accessories power supply 24 V= / 0.5 A

Temperature -20 °C / +55 °C

Degree of protection IP55

Box dimensions 238x357x120

NOTE: the given operating and performance features can only be guaranteed with the use of DITEC

i

accessories and safety devices.

3.1 Applications

4. CONNECTION OF POWER SUPPLY

Fix the control panel permanently. Pass the cables along from the lower side of the container.

Before connecting the power supply, maNe sure the plate data correspond to that of the mains power supply.

An omnipolar disconnection switch with minimum contact gaps of 3 mm must be included in the mains supply.

ChecN that upstream of the electrical installation there is an adequate residual current circuit breaNer and a

suitable overcurrent cutout.

Use a 3x1.5 mm FROR 450/750V type electric cable and connect to the terminals L (brown), N (blue),

(yellow/green) in the automation.

Secure the cable using a special cable clamp.

MaNe sure there are no sharp edges that may damage the power supply cable.

Connection to the mains power supply, in the section outside the automation, is made with independent channels

and separated from the connections to the control and safety devices.

IP1776EN 2012-02-20

4

Page 5

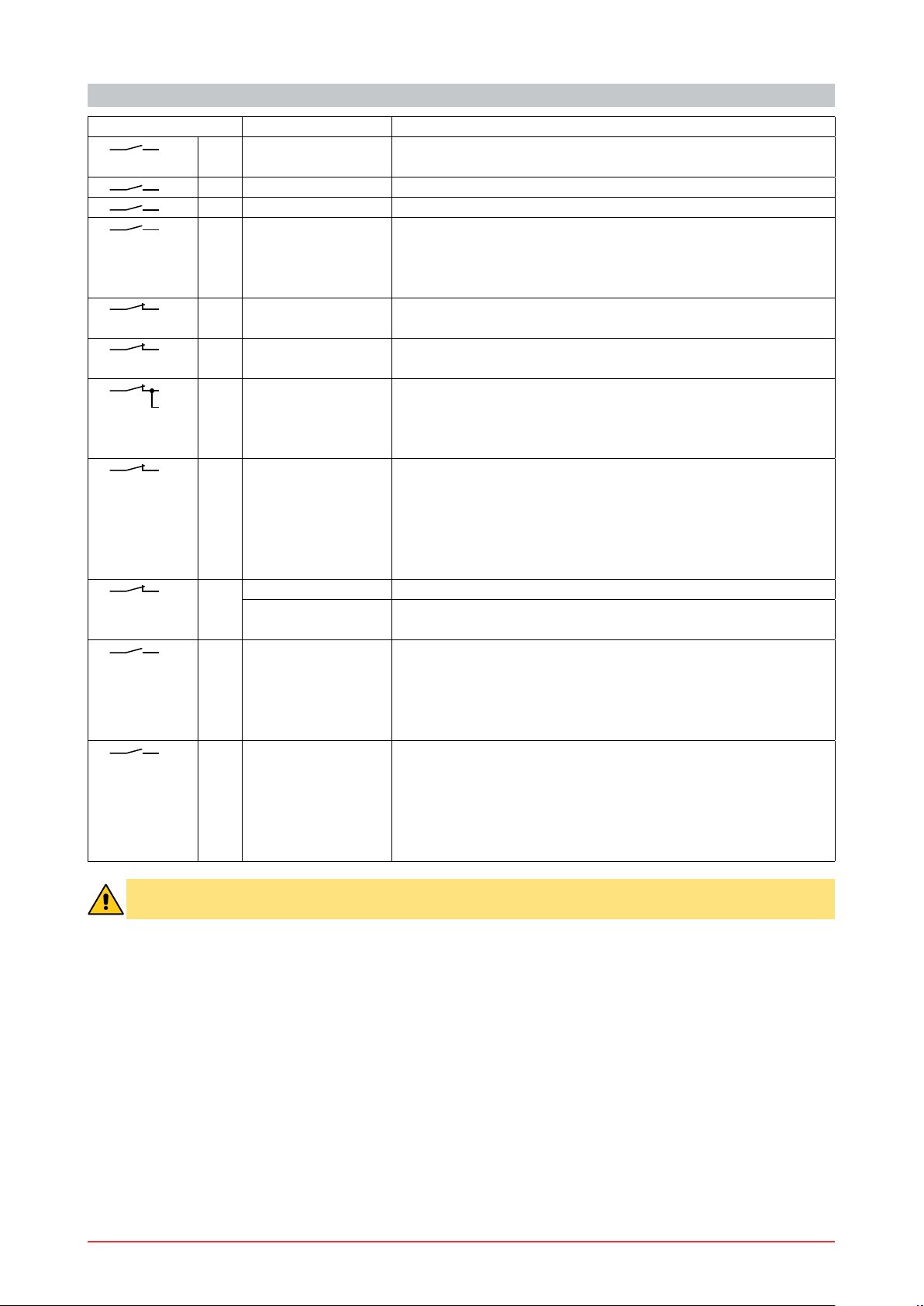

5. COMMANDS

Command Function Description

1

1

1

1 5 N.O. STEP-BY-STEP The closing of the contact activates opening or closing operations

1

1

1

7

1

1

1 9 N.O. HOLD-TO-RUN

1

2 N.O. AUTOMATIC

CLOSING

3 N.O. OPENING The closing of the contact activates the opening operation.

4 N.O. CLOSING The closing of the contact activates the closing operation.

6 N.C. OPENING

SAFETY

7 N.C. CLOSING

SAFETY

6

N.C. SAFETY STOP All operations are stopped and/or blocNed when the safety con-

8 N.C. REVERSE

SAFETY CONTACT

9 N.C. STOP The opening of the safety contact stops the current operation.

EMERGENCY

STOP

FUNCTION

20 N.O. PARTIAL OPENING The closing of the contact activates a partial opening operation

The permanent closing of the contact enables automatic closing.

in the following sequence: open-stop-close-open.

NOTE: if automatic closing is enabled, the stop is not permanent

but lasts for a duration set by TC.

The opening of the safety contact stops the opening operation in

progress and prevents future opening operations.

The opening of the safety contact stops the closing operation in

progress and prevents future closing operations.

tact is opened.

NOTE: it does not carry out the disengagement operation.

WARNING: use with photocells only.

The opening of the safety contact triggers a reversal of motion

(re-opening) during closing.

With SO=ON with the automation stopped, the opening of the

contact prevents any operation.

With SO=OFF with the automation stopped, the opening of the

contact only prevents the closing operation.

Connect the opening and closing commands to terminal 9 instead

of terminal 1 (9-3, 9-4, 9-20).

The opening of the 1-9 contact enables the hold-to-run function:

- hold-to-run opening 1-3;

- hold-to-run closing 1-4.

NOTE: any safety device, automatic closing and plug-in card

inserted in AUX1 or AUX2 is disabled.

of motor 1 (M1) of the duration set with the RP trimmer.

Once the automation stops, the partial opening control performs the opposite operation to the one performed before stop.

NOTE: if automatic closing is enabled, the stop is not permanent

but lasts for a duration set by TC.

WARNING: make a jumper for all the N.C. contacts if not in use. The terminals with the same number

are equal.

5

IP1776EN 2012-02-20

Page 6

5.1 SOFA1-SOFA2 self-controlled safety edge

Command Function Description

SOFA1-SOFA2

0411

1

6 N.C. OPENING

1 7 N.C. CLOSING

1

8 N.C. REVERSE

SAFETY TEST Place the SOFA1-SOFA2 device into its housing for plug-in cards

AUX1 or AUX2.

With JR14=OFF, connecting terminal 41 enables a safety edge

test cycle before every operation. If the test fails the SA led Àashes

and the test is repeated.

Connect the output contact of device to terminals 1-6 on the con-

SAFETY

trol panel (in series with the photocell output contact, if installed).

ATTENTION: make a jumper among 41-6 contacts if not used.

Connect the output contact of device to terminals 1-7 on the con-

SAFETY

trol panel (in series with the photocell output contact, if installed).

ATTENTION: make a jumper among 41-7 contacts if not used.

Connect the output contact of device to terminals 1-8 on the con-

SAFETY CONTACT

trol panel (in series with the photocell output contact, if installed).

ATTENTION: make a jumper among 41-8 contacts if not used.

IP1776EN 2012-02-20

6

Page 7

6. OUTPUTS AND ACCESSORIES

Output Value - Accessories Description

Accessories power supply. Power supply output for external ac-

01

-

+

1 13

0

0

0

0

AUX1

AUX2

14

14

15 24 V= / 300 mA

15 12 V~ / 15 W

COM

24 V= / 0.5 A

24 V= / 3 W

LAMPH

24 V= / 25 W

24 V= / 25 W

cessories, including automation status lamp.

Electronically protected output.

Automation status lamp (proportional).

The light switches off when the automation is closed; the light

switches on when the automation is open; the light Àashes with a

variable frequency while the automation is operating.

Flashing light. With DIP6=OFF activated during opening and closing

operations.

Output protected by F2 fuse.

Courtesy light. With DIP6=ON an external courtesy light that turns

on for 180 s with every opening (total or partial), step-by-step and

closing command can be connected.

Output protected by F2 fuse.

Electric block. It is activated when the automation is closed.

Output protected by F2 fuse.

Electric lock. Connect the supplied 8.2 ȍ / 5W resistance in series.

Output protected by F2 fuse.

The control panel has two housings for plug-in cards such as a radio receiver type, magnetic loops, etc.

Plug-in card operating is selected using DIP1.

WARNING: the plug-in cards must be inserted and removed with

the power supply disconnected.

DO NOT USE

BAT

BATKH

2 x 12 V / 2 Ah

Battery operating. The batteries are Nept charged when the power

supply is on. If the power supply is off, the control panel is powered

by the batteries until power is re-established or until the battery

voltage drops below the safety threshold. If this occurs, the control

panel turns off.

WARNING: the batteries must always be connected to the control

panel for charging. 3eriodically check the ef¿ciency of the batteries.

NOTE: the operating temperature of the rechargeable batteries is

approximately +5°C/+40°C.

7

IP1776EN 2012-02-20

Page 8

7. ADJUSTMENTS

Description OFF ON

DIP1 Plug-in cards operation.

NOTE: it sets the operating mode of the

plug-in cards connected on AUX1 and

AUX2.

DIP2 Restore automatic closing time. 50% 100%

DIP3 Automation status at power on.

Indicates how the control panel considers

automation when powered up.

DIP4 Electric lock release. Disabled. Enabled.

Electric block operation.

NOTE: only with EO=OFF.

DOKE

DIP5 3 seconds preÀashing. Disabled during opening.

DIP6 Output 0-14 operation. Flashing light. Courtesy light.

Description OFF ON

FC Limit switch mode selection. Stop limit switch. Slow down limit switch.

SO Reversal safety switch function. With the automation blocNed,

EO Electric lock operation. Powered for 2.5 s at the

OM Automation type. Automation with 1 motor or

Step-by-step. Opening.

Open. Closed.

NOTE: if the automatic closing function is not used,

preferably set DIP3=ON.

NOTE: when the electric lock

is installed, set DIP4=ON.

Powered for the entire

opening and closing opera-

Powered only with the automation closed.

tion.

Enabled for both opening

Enabled only with automatic

and closing.

closing with TC>3 s.

With the automation blocNed,

if the contact 1-8 is open, it

is possible to activate the

if the contact 1-8 is open,

any operation is impossible.

opening operation.

Powered for 1.2 s at the

beginning of the opening

operation.

beginning of the opening

operation.

Automation with 2 indepenwith 2 motors in parallel.

dent motors.

FS FUTURE USE //

NIO Electronic antifreeze system.

Enabled. Disabled.

Maintains motor function even at low ambient temperatures.

JR14 Safety test terminal 41. Enabled. Disabled.

IP1776EN 2012-02-20

8

Page 9

Trimmer Description

TC

120 s

0 s Disabled

Setting automatic closing time. From 0 to 120 s.

With DIP2=OFF, once a safety switch has been activated, the counter starts as soon

as the safety switch is released (for example after passing through the photocells),

and lasts for a period of time set with trimmer TC (50%).

With DIP2=ON, the counter starts when automation is opened and lasts for the entire

duration set with trimmer TC (100%).

NOTE: after the activation of the stop command, once contact 1-9 has closed again,

automatic closing is only enabled after a total, partial or step-by-step opening command.

TR

0 s

10 s

3 s

20 s

30 s

Setting motor 1 (M1) closing delay time. From 0 to 30 s.

When closing, motor 1 (M1) arrives after a delay set with trimmer TR relative to motor

2 (M2).

When opening, motor 2 (M2) starts after a delay of 3 s relative to motor 1 (M1).

With TR=MIN the door wings start simultaneously.

NOTE: setting TR=MIN with non-overlapping door wings and setting TR>3 s with

overlapping door wings is recommended.

RP

Motor 1 (M1) partial opening adjustment.

Adjust the percentage of partial opening of motor 1 (M1) from 10% to 100% of the total

10% 100%

VM

operation.

Operation speed adjustment.

Adjusts the automation operation speed.

min max

M1-M2

The closing speed is the same as the opening speed.

Motor 1 (M1) operating time adjustment. From 5 s to 30 s.

Motor 2 (M2) operating time adjustment. From 5 s to 30 s.

5 s 30 s

(or from 5 s to 45 s depending on the settings in paragraph 6.4).

The opening/closing operation is shown in chapters 11, 12 and 13: the operation consists of a part with the speed set with trimmer VM, the duration set with trimmer M1/

M2 and deceleration to a ¿xed speed when both opening and closing.

When opening, this deceleration lasts a maximum of 10 s and when closing, it lasts

until the mechanical stop or a stop limit switch is reached (with FC=OFF).

R1

Force adjustment.

The control panel is ¿tted with a safety device which, when it detects an obstacle:

min max

- during opening, stops movement with a disengagement operation;

- during closing, before deceleration, inverts movement;

- during closing, during deceleration with FC=ON stops movement and with FC=OFF

inverts movement.

9

IP1776EN 2012-02-20

Page 10

LED On Flashing

IN

SA

POWER ALARM

Receipt of command or change in status of

a dip-switch.

At least one of the safety contacts is open. Safety test failure (terminal 41).

Operations count performed (only when control panel is switched on):

= 1000 operations

= 10000 operations

Power supply on. Incorrect selection of type of auto-

mation (jumper S1, S2, S3, S4).

NOTE: the signal lasts 10 s after which the

control panel is automatically reset.

Absence of motor or

incorrect selection of jumper OM.

NOTE: the signal lasts 10 s after which the

control panel is automatically reset.

/

7.1 Selection of automation type

Automation type S1 S2 S3 S4

Factory settings

OBBI3BH, ARCBH N.O. N.C. N.C. N.C.

CUBIC30H, CUBIC6H N.C. N.O. N.C. N.C.

CUBIC30H+CUBIC30LI,

CUBIC6H+CUBIC6TC

CUBIC6H+CUBIC6TIG

BOX3SH N.C. N.C. N.C. N.O.

ARC1BH, DOR1BH (recommended dimensions) N.C. N.O. N.C. N.O.

ARC1BH (limit dimensions) N.O. N.O. N.O. N.C.

DOR1BH (limit dimensions) N.O. N.C. N.C. N.O.

FACIL3H N.C. N.C. N.O. N.O.

DOKE N.O. N.O. N.C. N.C.

LUXO3BH, LUXO4BH N.O. N.O. N.C. N.O.

LUXO5BH (recommended dimensions) N.C. N.C. N.O. N.C.

LUXO5BH (limit dimensions) N.O. N.C. N.O. N.C.

N.C. N.C. N.C. N.C.

N.C. N.O. N.O. N.C.

IP1776EN 2012-02-20

10

Page 11

8. CONNECTION OF MOTORS

Control panel

Motor 2

OBBI3BH BlacN Blue

ARCBH

ARC1BH

CUBIC30H BlacN Blue

CUBIC6H

CUBIC6HV

LUXO3BH

LUXO4BH

LUXO5BH

FACIL3H Blue BlacN

Motor 1

OBBI3BH BlacN Blue

ARCBH

ARC1BH

CUBIC30H BlacN Blue

CUBIC6H

CUBIC6HV

LUXO3BH

LUXO4BH

LUXO5BH

FACIL3H Blue BlacN

terminal

board

34 36

BlacN Blue

BlacN Blue

31/34 33/36

Control panel

terminal

board

31 33

BlacN Blue

BlacN Blue

31/34 33/36

2 1

1 2

Control panel

Motor 1

OBBI3BH Blue BlacN

ARCBH

ARC1BH

CUBIC30H Blue BlacN

CUBIC6H

CUBIC6HV

LUXO3BH

LUXO4BH

LUXO5BH

FACIL3H BlacN Blue

Motor 2

OBBI3BH Blue BlacN

ARCBH

ARC1BH

CUBIC30H Blue BlacN

CUBIC6H

CUBIC6HV

LUXO3BH

LUXO4BH

LUXO5BH

FACIL3H BlacN Blue

terminal

board

31 33

Blue BlacN

Blue BlacN

31/34 33/36

Control panel

terminal

board

34 36

Blue BlacN

Blue BlacN

31/34 33/36

11

IP1776EN 2012-02-20

Page 12

9. START-UP

WARNING The operations in point 4 are performed without safety devices.

The trimmer can only be adjusted with the automation idle.

At every start-up the control panel receives a RE6ET and the ¿rst operation is performed

at reduced speed (automation position acquisition)

and then motor M1).

1- MaNe a jumper for the N.C. safety contacts.

2- ChecN the application type selected. Select the type of automation with jumpers S1, S2, S3 and S4 as

described on page 10.

3- If installed, adjust the opening and closing stop limit switches.

NOTE: limit switches must be kept pressed until the operation has been completed.

4- Set TC=MAX and R1=MAX.

Set TR=MIN or TR>3 s in case of automation with two overlapping door wings.

5- Switch on and checN that the automation is operating correctly with subsequent opening and closing

commands.

If installed, checN that the limit switches are activated.

NOTE: if the direction of rotation of the motor is incorrect for the desired direction of the automation, swap

the power supply polarity 31-33 or 34-36.

6- If used, adjust the deceleration limit switches during opening and closing and set M1=MAX and M2=MAX.

Adjust trimmer VM and checN the opening speed and closing speed.

NOTE: if the wings reach the mechanical stops too quickly, advance limit switch intervention.

7- If the limit switches are not used:

set M1=50%, M2=50% and VM=50%;

checN that the automation is operating correctly with subsequent opening and closing commands;

WARNING: wait for the operation to complete before giving the next command.

adjust the operation time using trimmers M1 and M2 so that the wings approach the mechanical stops

slowly. We recommend setting a deceleration time that guarantees completion of the operation even in

the presence of friction or other adverse environmental factors (wind, ice, etc.).

8- Connect the safety devices (removing the relative jumpers) and checN they worN correctly.

9- If required, adjust the delay time during closing of motor 1 (M1) with trimmer TR.

10- If required, adjust the automatic closing time with the TC trimmer.

WARNING: the automatic closing time after a safety device has triggered depends on the DIP2 setting.

11- Set the obstacle thrust with the R1 trimmer.

NOTE: if the door wing closing second encounters an obstacle, both door wings are reopen and the

subsequent closing operation is performed one door wing at a time.

WARNING: check that the working forces exerted by the door wings are compliant with EN12453-EN12445

regulations.

12- If required, adjust the partial opening of motor 1 (M1) with trimmer RP.

13- If required, connect the radio receiver by placing it in the housing for plug-in cards AUX1 or AUX2 and

program the remote controls as indicated in the installation manual.

14- Connect any other accessories and checN they operate correctly.

15- Once the start-up and checN procedures are completed, close the container.

one wing at a time (¿rst motor M2

NOTE: in the event of servicing or if the control panel is to be replaced, repeat the start-up procedure.

i

IP1776EN 2012-02-20

12

Page 13

10. TROUBLESHOOTING

Problem Possible causes Remedy

The automation does not

open or close.

External safety devices not

activating.

The automation reopens by

itself, from the closing stop.

The Àashing light is not worNing.

The electric loc

Ning.

The remote control has limited range and does not

worN with the automation

moving.

N is not wor-

No power.

(POWER ALARM led off).

Short circuited accessories.

(POWER ALARM led off).

Blown line fuse.

(POWER ALARM led off).

Safety contacts are open.

(SA led on).

Motor(s) not connected.

(POWER ALARM led Àashing).

Wrong selection of automation type.

(POWER ALARM led Àashing).

Safety contacts not correctly connected

or self-controlled safety edge not

functioning correctly.

(SA led Àashing).

The opening and closing commands do

not worN.

Incorrect setting of jumper JR14. ChecN the connections of the safeties

Photocells are activated.

(SA led on).

The automatic closing does not worN. ChecN that the TC trimmer is not set at

Incorrect connections between the

photocells and the control panel.

Limit switch not worNing.

(SA and IN leds Àashing).

Blown F2 fuse. Replace F2 fuse.

The radio transmission is impeded by

metal structures and reinforced concrete walls.

ChecN that the control panel is powered correctly.

Disconnect all accessories from terminals 0-1 (voltage must be 24 V=) and

reconnect one at a time.

Replace F1 fuse.

ChecN that the safety contacts are closed correctly (N.C.).

ChecN correct connection of motor(s).

ChecN the setting of jumper OM.

ChecN the correct selection of jumpers

S1, S2, S3 and S4.

ChecN connections to terminals 6-7-8

on control panel and connections to the

self-controlled safety edge.

ChecN that IN led comes on with each

opening and closing command.

as described on page 5-6.

ChecN that the photocells are clean

and operating correctly.

the maximum.

ChecN that contact 1-2 is closed.

Connect N.C. safety devices together in

series and remove any bridges on the

control panel terminal board.

ChecN the correct worNing of the limit

switches.

Install the antenna outside.

Substitute the transmitter batteries.

13

IP1776EN 2012-02-20

Page 14

11. EXAMPLE APPLICATION FOR ONE-MOTOR AUTOMATIONS

When the control panel is used in applications for automations with one swinging door wing, for up-andover doors or for sliding doors, these connections can

be made:

(Fig. 11.1) Use without limit switches.

Set OM=OFF.

Connect the motor as shown in the ¿gure.

NOTE: during the opening operation, the polarities

are those indicated in the ¿gure.

Set VM to the desired speed.

Set M1 so as to obtain slow down of the door wing

before the mechanical stop.

With the above connections the wing stops on the

opening and closing mechanical stop.

When the time set with M1 runs out:

on opening operation the slow down time is a

maximum of 10 s;

on closing operation the wing slows down until it

reaches the mechanical stop.

(Fig. 11.2) Use with slow down limit switches.

Set OM=OFF.

Connect the motor and slow down limit switches as

shown in the ¿gure:

>A@ opening slow down limit switch;

>C@ closing slow down limit switch.

Set VM to the desired speed.

Set M1=MAX.

With the above connections the wing stops on the

opening and closing mechanical stop.

After the slow down limit switch has been triggered

on opening operation and on closing operation the

maximum slow down time is 10 s.

(Fig. 11.3) Use with stop limit switch.

Set OM=OFF and FC=OFF.

Connect the motor and stop limit switches as shown

in the ¿gure:

>A@ opening stop limit switch;

>C@ closing stop limit switch.

NOTE: a single limit switch can also be installed.

Set M1<MAX.

Set VM to the desired speed.

Set M1 so as to obtain slow down of the door wing

before the limit switch is triggered.

With the above connections, the wing stops when

the limit switch operates.

When the time set with M1 runs out:

on opening operation the slow down time is a

maximum of 10 s;

on closing operation the wing slows down until it

reaches the stop limit switch.

-

+

-

+

36 35 34 33 32 31

24V=

Motor 1

max 10 s

M1

(VM)

1

OPENING CLOSING

-

+

-

+

36 35 34 33 32 31

A

VM

24V=

Motor 1

max 10 s

A

C

1

OPENING CLOSING

-

+

-

+

36 35 34 33 32 31

M1

(VM)

A

max 10 s

C

24V=

Motor 1

A

1

OPENING CLOSING

M1

OM

M1

OM

C

max 10 s

M1

FC

OM

C

M1<MAX

OM=OFF

M1

(VM)

M1=MAX

OM=OFF

VM

M1<MAX

FC=OFF

OM=OFF

M1

(VM)

1

Fig. 11.1

1N4007

1

Fig. 11.2

1N4007

1

Fig. 11.3

IP1776EN 2012-02-20

14

Page 15

12. EXAMPLE APPLICATION FOR TWO-MOTORS SWING GATES

When the control panel is used in applications for automations with two swinging door wings, these connections can be made:

(Fig. 12.1) Use without limit switches.

Connect the motors as shown in the ¿gure.

NOTE: during the opening operation, the polarities

are those indicated in the ¿gure.

Set VM to the desired speed.

Set M1 and M2 so as to obtain slow down of the

door wing before the mechanical stops.

With the above connections each wing stops on the

opening and closing mechanical stop.

When the time set with M1 runs out:

on opening operation the slow down time is a

maximum of 10 s;

on closing the wings slow down until they reach

the mechanical stop.

(Fig. 12.2) Use with slow down limit switches.

Connect the motors and slow down limit switches

as shown in the ¿gure:

>A@ opening slow down limit switch;

>C@ closing slow down limit switch.

Set M1=MAX and M2=MAX.

Set VM to the desired speed.

With the above connections each wing stops on the

opening and closing mechanical stop.

After the slow down limit switch has been triggered

on opening operation and on closing operation the

maximum slow down time is 10 s.

(Fig. 12.3) Use with stop limit switch.

Set FC=OFF.

Connect the motors and stop limit switches as shown

in the ¿gure:

>A@ opening stop limit switch;

>C@ closing stop limit switch.

NOTE: a single limit switch can also be installed for

each motor.

Set M1<MAX and M2<MAX.

Set VM to the desired speed.

Set M1 and M2 so as to obtain slow down of the

door wing before the limit switch is triggered.

With the above connections, each wing stops when

the limit switches operate.

When the time set with M1-M2 runs out:

on opening operation the slow down time is a

maximum of 10 s;

on closing operation the wings slow down until they

reach the stop limit switch.

-

+

-

+

36 35 34 33 32 31

-

24V=

Motor 1

M1

(VM)

+

max

10 s

max

10 s

24V=

Motor 2

M2

(VM)

OPENING

+

36 35 34 33 32 31

VM

OPENING

-

A C

24V=

Motor 1

max

10 s

VM

+

A C

24V=

Motor 2

max

10 s

A A

+

36 35 34 33 32 31

M2

OPENING

A C

24V=

Motor 1

max

10 s

M1

(VM)

A C

24V=

Motor 2

max

A A

10 s

(VM)

-

-

12

12

12

M1 M2

M2

(VM)

M1 M2

VM

M1 M2

FC

M2

(VM)

M1<MAX

M2<MAX

CLOSING

M1=MAX

M2=MAX

1N4007

C C

max

10 s

CLOSING

M1<MAX

M2<MAX

FC=OFF

1N4007

C C

CLOSING

M1

(VM)

Fig. 12.1

VM

Fig. 12.2

M1

(VM)

Fig. 12.3

12

12

12

15

IP1776EN 2012-02-20

Page 16

13. EXAMPLE APPLICATION FOR UP-AND-OVER DOORS WITH IN-PARALLEL

MOTORS

When the control panel is used in applications for automations with up-and-over doors with two parallel

motors, these connections can be made:

(Fig. 13.1) Use without limit switches.

Set OM=OFF.

Connect the motors as shown in the ¿gure.

NOTE: during the opening operation, the polarities

are those indicated in the ¿gure.

Set VM to the desired speed.

Set M1 so as to obtain slow down of the door wing

before the mechanical stop.

With the above connections the wing stops on the

opening and closing mechanical stop.

When the time set with M1 runs out:

on opening operation the slow down time is a

maximum of 10 s;

on closing operation the wing slows down until it

reaches the mechanical stop.

(Fig. 13.2) Use with slow down limit switches.

Set OM=OFF.

Connect the motors and slow down limit switches

as shown in the ¿gure:

>A@ opening slow down limit switch;

>C@ closing slow down limit switch.

Set M1=MAX. Set VM to the desired speed.

With the above connections the wing stops on the

opening and closing mechanical stop.

After the slow down limit switch has been triggered

on opening operation and on closing operation the

maximum slow down time is 10 s.

(Fig. 13.3) Use with stop limit switch.

Set OM=OFF and FC=OFF.

Connect the motors and stop limit switches as

shown in the ¿gure:

>A@ opening stop limit switch;

>C@ closing stop limit switch.

NOTE: a single limit switch can also be installed.

Set M1<MAX. Set VM to the desired speed.

Set M1 so as to obtain slow down of the door wing

before the limit switch is triggered.

With the above connections, the wing stops when

the limit switch operates.

When the time set with M1 runs out:

on opening operation the slow down time is a

maximum of 10 s;

on closing operation the wing slows down until it

reaches the stop limit switch.

-

+

-

+

36 35 34 33 32 31

24V=

Motor 1

max 10 s

M1

(VM)

OPENING CLOSING

-

+

+

24V=

Motor 2

-

36 35 34 33 32 31

A

24V=

Motor 2

OPENING CLOSING

-

+

24V=

Motor 1

max 10 s

+

VM

-

C

S1

S2

S3

S4

A

36 35 34 33 32 31

A

24V=

Motor 2

OPENING CLOSING

24V=

Motor 1

(VM)

M1

C

S1

S2

S3

S4

max

A

10 s

M1

OM

M1

FC

OM

S1

S2

S3

S4

M1

OM

M1=MAX

OM=OFF

S1=ON

S2=ON

S3=ON

S4=OFF

M1<MAX

FC=OFF

OM=OFF

S1=ON

S2=ON

S3=ON

S4=OFF

C

M1<MAX

OM=OFF

S1=ON

S2=ON

S3=ON

S4=OFF

VM

max

C

10 s

M1

(VM)

M1

(VM)

Fig. 13.1

1N4007

Fig. 13.2

1N4007

Fig. 13.3

IP1776EN 2012-02-20

16

Page 17

17

IP1776EN 2012-02-20

Page 18

TM

DITEC S.p.A. Via Mons. Ban¿, 3 21042 Caronno P.lla (VA) Italy Tel. +39 02 963911 Fax +39 02 9650314

www.ditec.it ditec@ditecva.com

DITEC BELGIUM LOKEREN Tel. +32 9 3560051 Fax +32 9 3560052 www.ditecbelgium.be DITEC DEUTSCHLAND OBERURSEL

Tel. +49 6171 914150 Fax +49 6171 9141555 www.ditec-germany.de DITEC ESPAÑA ARENYS DE MAR Tel. +34 937958399

Fax +34 937959026 www.ditecespana.com DITEC FRANCE MASSY Tel. +33 1 64532860 Fax +33 1 64532861 www.ditecfrance.com

DITEC GOLD PORTA ERMESINDE-PORTUGAL Tel. +351 22 9773520 Fax +351 22 9773528/38 www.goldporta.com DITEC SWITZERLAND

BALERNA Tel. +41 848 558855 Fax +41 91 6466127 www.ditecswiss.ch DITEC ENTREMATIC NORDIC LANDSKRONA-SWEDEN

Tel. +46 418 514 50 Fax +46 418 511 63 www.ditecentrematicnordic.com DITEC TURCHIA ISTANBUL Tel. +90 21 28757850

Fax +90 21 28757798 www.ditec.com.tr DITEC AMERICA ORLANDO-FLORIDA-USA Tel. +1 407 8880699 Fax +1 407 8882237

www.ditecamerica.com DITEC CHINA SHANGHAI Tel. +86 21 62363861/2 Fax +86 21 62363863 www.ditec.cn

Loading...

Loading...