Page 1

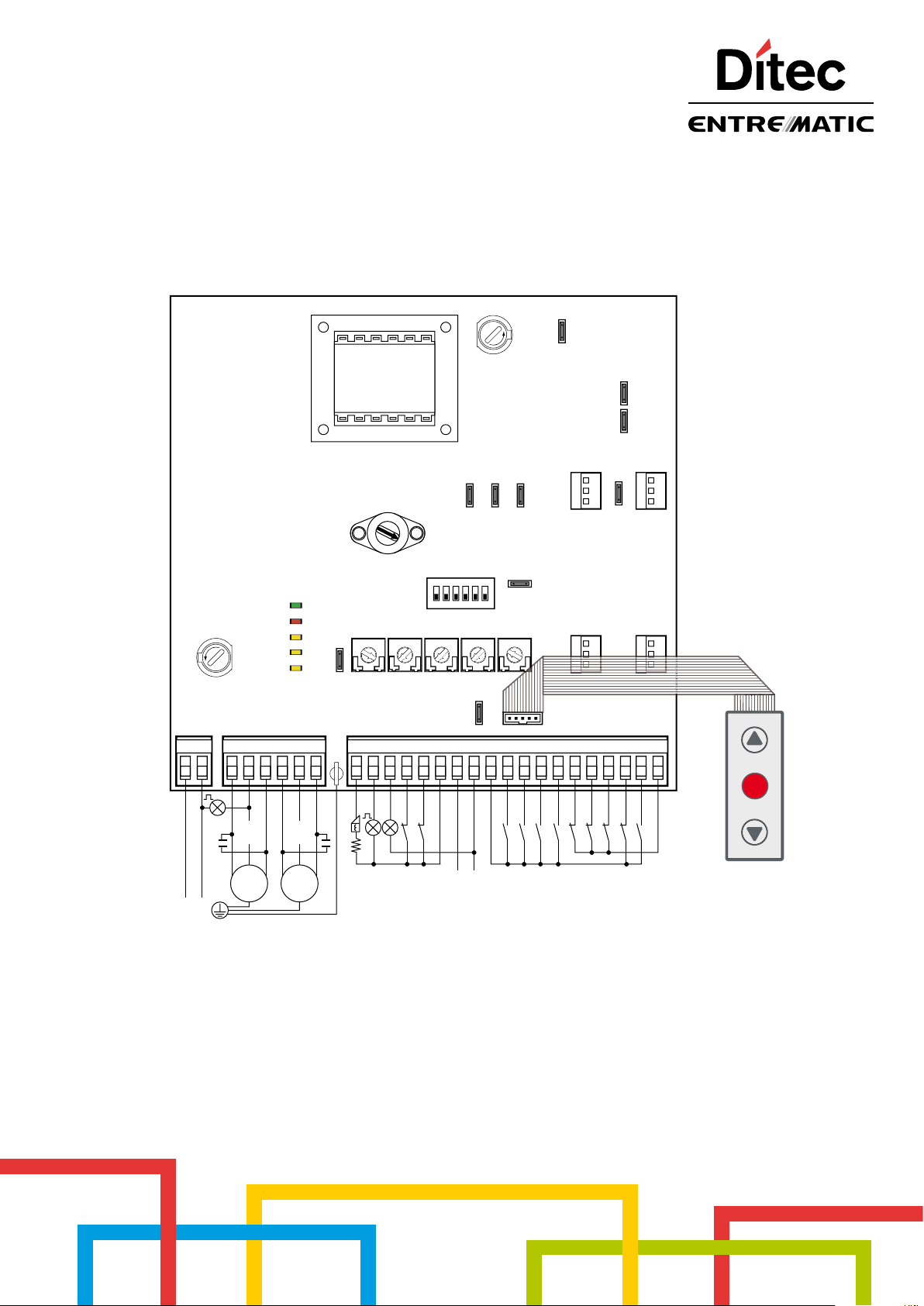

Ditec LOGICM

Control panel installation manual for 230 V~ automation with one or two motors.

IP1854EN

LOGICM

POWER

F

U

S

E

F1

SA

IN

11

12

JR6

4

2

1

RF

TM

TC RP TR R1

15 14 13 12 11 00112345678920 41UWVXZYLN

F2

E

S

U

F

D5 S5 JT

1ON23456

OM

EO

J7

JR4

NIO

AUX

JR10

SO

AUX

LN

Power suuply

M1

1~

com

M2

1~

com

Safety reopening

Closing safety device

Stop

Safety test

Partial opening

Lamp

Electric lock

Flashing light

Limit switch

Limit switch

Opening

Automatic closing

Accessories output

Closing

Step by step

Opening safety device

www.ditecentrematic.com

Page 2

2

IP1854EN - 2013-03-01

Page 3

Index

i

STOP

Subject Page

1. General safety precautions 4

2. EC declaration of conformity 4

3. Technical data 4

3.1 Applications

4. Commands 5

Self-controlled safety edge

4.1

5. Outputs and accessories 6

6. Adjustments 7

6.1 Tri mm er

6.2 Dip-switch

6.3 Jumper

6.4 Signals

7. Start-up 9

8. Troubleshooting 10

9. Example application for two-motors swing gates 11

10. Example application for one-motor swing gate 12

11. Example application for sliding gate 13

12. Example application for barrier 13

13. Example of parallel 14

4

5

7

7

8

8

Caption

This symbol indicates instructions or notes regarding safety issues which require particular attention.

This symbol indicates informations which are useful for correct product function.

This symbol indicates instructions or notes intended for technical and expert personnel.

This symbol indicates operations not to be effected for not compromise the correct operation of the automation.

This symbol indicates options and parameters which are only available with the indicated item.

This symbol indicates options and parameters which are not available with the indicated item.

IP1854EN - 2013-03-01

3

Page 4

1. General safety precautions

i

This installation manual is intended for qualified personnel only.

Installation, electrical connections and adjustments must be performed in accordance with Good Working Methods and in

compliance with applicable regulations.

Before installing the product, carefully read the instructions. Bad installation could be hazardous.

The packaging materials (plastic, polystyrene, etc.) should not be discarded in the environment or left within reach of children,

as these are a potential source of hazard.

Before installing the product, make sure it is in perfect condition.

Do not install the product in an explosive environment and atmosphere: gas or inflammable fumes are a serious hazard risk.

Before installing the motors, make all structural changes relating to safety clearances and protection or segregation of all areas

where there is risk of being crushed, cut or dragged, and danger areas in general.

Make sure the existing structure is up to standard in terms of strength and stability. The motor manufacturer is not responsible

for failure to use Good Working Methods in building the frames to be motorized or for any deformation occurring during use.

The safety devices (photocells, safety edges, emergency stops, etc.) must be installed taking into account: applicable laws and

directives, Good Working Methods, installation premises, system operating logic and the forces developed by the motorized door.

The safety devices must protect any areas where the risk exists of being crushed, cut or gragged, or where there are any other

risks generated by the motorized door.

Apply hazard area notices required by applicable regulations.

Each installation must clearly show the identification details of the motorized door.

When necessary, connect the motorized door to a reliable earth system made in accordance with applicable safety regulations.

During installation, maintenance and repair, interrupt the power supply before opening the lid to access the electrical parts.

The protective casing of the automation must be removed by qualified personnel only.

To handle electronic parts, wear earthed antistatic conductive bracelets. The motor manufacturer declines all responsibility

in the event of component parts being fitted that are not compatible with the safe an correct operation.

For repairs or replacements of products only original spare parts must be used. The installer shall provide all information relating

to automatic, manual and emergency operation of the motorized door, and provide the user with operating instructions.

2. EC Declaration of conformity

The manufacturer Entrematic Group AB with headquarters in Lodjursgatan 10, SE-261 44 Landskrona, Sweden

declares that the control panel Ditec LOGICM is in conformity with the provisions of the following EC directives:

EMC Directive 2004/108/CE;

Low Voltage Directive 2006/95/CE.

Landskrona, 29-01-2013 Marco Pietro Zini

(President & CEO)

3. Technical data

LOGICM LOGICMJ

Power supply 230 V~ 50/60 Hz 120 V~ 60 Hz

F1 fuse F6,3A F6,3A

F2 fuse F3,15A F3,15A

One motor output 230 V~ 5A max 120 V~ 6,3A max

Two motor output

Accessories power supply 24 V

Temperature min -20 °C max +55 °C min -20 °C max +55 °C

Degree of protection IP55 IP55

Dimensions 187X2 61X105 187X2 61X105

230 V~

2x2,5A max

0,5 A 24 V 0,5 A

120 V~

2x3,15A max

NOTE: the given operating and performance features can only be guaranteed with the use of DITEC accessories and

safety devices.

3.1 Applications

4

IP1854EN - 2013-03-01

Page 5

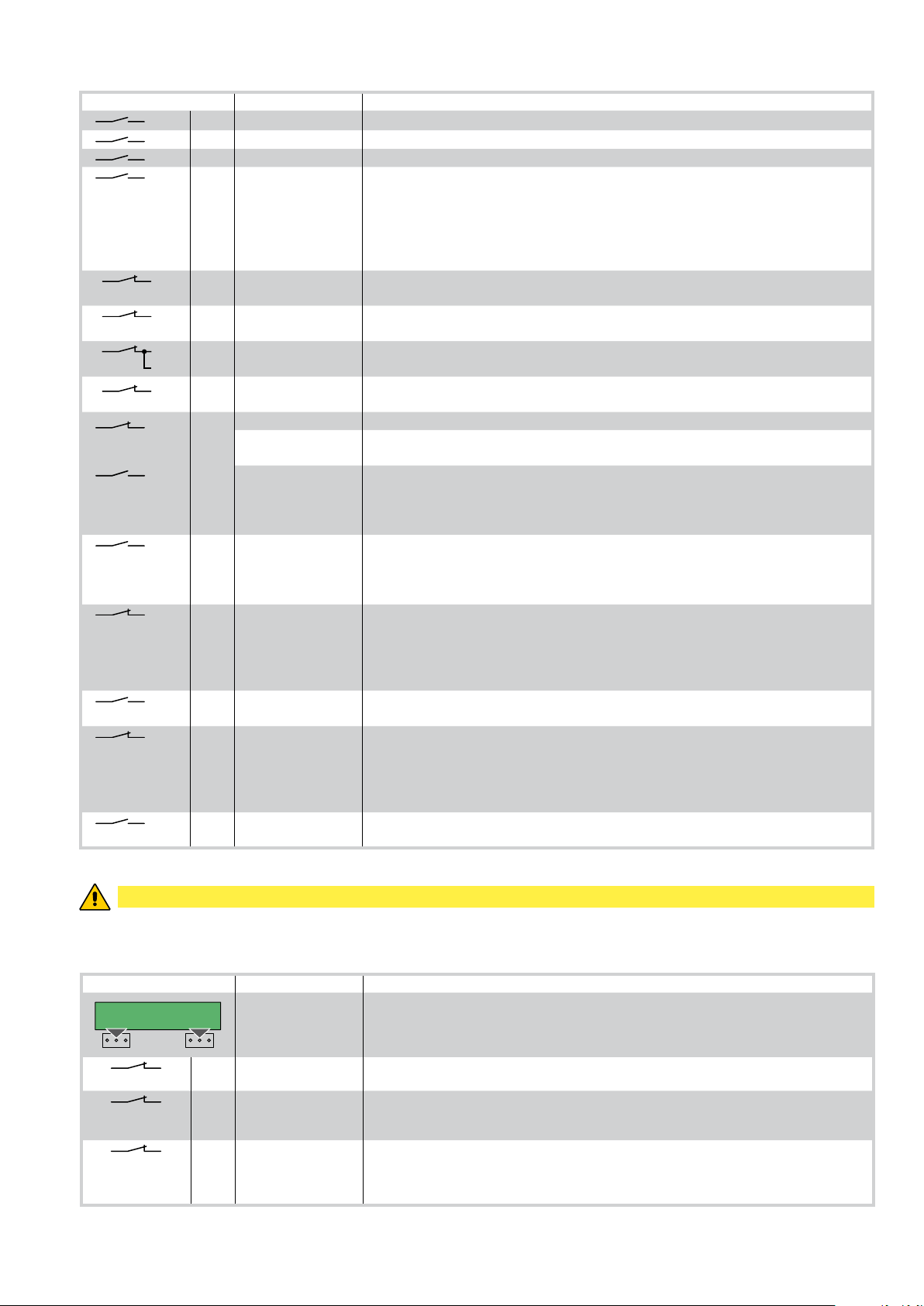

4. Commands

Command Function Description

1

1

1

1

41

41

41

7

41

1

1

1

0

0

0

0

2 N.O. AUTOMATIC CLOSING Permanently closing the contact enables automatic closing.

3 N.O. OPENING The opening operation starts when the contact is closed.

4 N.O. CLOSING The closing operation starts when the contact is closed.

5 N.O. STEP-BY-STEP With D5=ON closing the contact starts a sequential opening or closing operation: open-stop-

close-open.

With D5=OFF closing the contact starts a sequential opening or closing operation: open-stopclose-stop-open.

Note: if automatic closing is enabled, with S5=ON the stop is not permanent but at a time that

is set by the TC, with S5=OFF the stop is permanent.

N.C. OPENING SAFETY

6

DEVICE

N.C. CLOSING SAFETY

7

DEVICE

6

N.C. SAFETY STOP Opening the safety contact stops and prevents any movement.

8 N.C. REVERSAL SAFETY

DEVICE

9 N.C. STOP Opening the safety contact stops the current operation.

EMERGENCY STOP To enable the emergency stop function (e.g. with a specific red button), connect the opening

9 N.O. HOLD-TO-RUN

FUNCTION

20 PARTIAL OPENING Closing the contact activates a partial opening operation of the door wing powered by motor 1,

11

11 N.O. M2 PROXIMITY

12 N.C. M1 LIMIT SWITCH With TC=MAX, the limit switch contact opening stops closing movement of motor 1 (M1).

12 N.O. M1 PROXIMITY

N.C. M2 LIMIT SWITCH With TC=MAX, the limit switch contact opening stops closing movement of motor 2 (M2).

LIMIT SWITCH

LIMIT SWITCH

Opening the safety contact stops the current opening operation in progress and impedes any

future opening operations.

Opening the safety contact stops the current closing operation in progress and impedes any

future closing operations.

Note: it does not carry out the disengagement operation. Use with photocells installed only.

Opening the safety contact triggers a reversal of motion (re-opening) during a closing operation.

and closing controls to terminal 9 instead of 1 (9-3, 9-4, 9-20).

Permanently opening the safety contact enables the operator presence dependent function.

In this state, the opening (1-3, 1-20) and closing (1-4) controls function only if held in the pressed position and the automation stops when the controls are released.

All safety switches, the step-by-step control and the automatic closing function are disabled.

of the duration set with the RP trimmer.

Once the automation stops, the partial opening control performs the opposite operation to the

one performed before stoppage.

With OM=OFF (1 motor mode) and DIP2=OFF, the limit switch stops closing movement of motor

1 (M1).

With OM=OFF (1 motor mode) and DIP2=ON, the limit switch stops opening movement of motor

1 (M1).

See Chapters 9-10, example 4.

With OM=OFF (1 motor mode) and DIP2=OFF, the limit switch stops opening movement of

motor 1 (M1).

With OM=OFF (1 motor mode) and DIP2=ON, the limit switch stops closing movement of motor

1 (M1).

See Chapters 9-10, example 4.

WARNING: Make a jumper on all N.C. contacts if not in use. The terminals with the same number are equal.

4.1 Self-controlled safety edge SOFA1-SOFA2 or GOPAVRS

Command Function Description

SOFA1-SOFA2

GOPAV

1

1

1

6 N.C. OPENING SAFETY

7 N.C. CLOSING SAFETY

8 N.C. REVERSAL SAFETY

IP1854EN - 2013-03-01

SAFETY TEST Place the SOFA1-SOFA2 or GOPAVRS device into its housing for plug-in cards AUX.

Connecting terminal 41 enables a safety edge test cycle before every operation.

If the test fails the SA led flashes and the test is repeated.

Connect the output contact of device SOFA1-SOFA2 to terminals 1-6 on the control panel (in

DEVICE

DEVICE

DEVICE

series with the photocell output contact, if installed).

Connect the output contact of device SOFA1-SOFA2 to terminals 1-7 on the control panel (in

series with the photocell output contact, if installed).

Connect the output contact of device SOFA1-SOFA2 to terminals 1-8 on the control panel (in

series with the photocell output contact, if installed).

ATTENTION: for quick operation on the safety edge, connect it to contact 1-6 or to contact 1-7.

5

Page 6

5. Output and accessories

4901 23

UVW

XYZ

Output Value - Accessories Description

Accessories power supply.

24 V 0,5 A

Power supply output for external accessories, including automation status lamp.

NOTE: the maximum absorption of 0.5 A corresponds to the sum of all terminals 1.

AUX

11 ...

12 ...

13 ...

14 ...

15 ...

15 ...

SOFA1-SOFA2

GOPAV

1

1

1

0

0

0

24 V 3 W

24 V 3 W

24 V 3 W

LAMPH

24 V 50 W

24 V 1,2 A

12 V~ 15 W

The control panel has two spaces for coupling board, type radio receivers, magnetic loops etc.

The coupling board working mode is selected by DIP1.

WARNING: the plug-in cards must be inserted and removed with the power supply disconnected.

Automation open lamp.

Only with limit switch 0-11 (NC) connected and in one motor mode (jumper OM=OFF) will the lamp

extinguish when automation is closed.

Automation closed lamp.

Only with limit switch 0-12 (NC) connected and in one motor mode (jumper OM=OFF) will the lamp

extinguish when automation is open.

Automation open lamp.

A lamp lights up that extinguishes only when automation is closed.

Flashing light.

Activated during opening and closing operations.

24 V electric block.

Activated upon every opening command.

24 V electric motor brake.

With JR6=OFF, OM=OFF and DIP5=ON, the output is active for the entire duration of the opening

or closing motion.

24 V electric lock. With EO=OFF the output is on and the automation is closed.

12 V electric lock.

Connect the supplied 8.2 Ω / 5 W resistance in series. Activated upon every opening command

Motor 1 (M1).

230 V~ 2,5 A

M1

M2

NL

NL

W... ...

X... ...

120 V (LOGICMJ)

230 V~ 2,5 A

120 V (LOGICMJ)

LAMP

230 V~ 100 W

120 V~ (LOGICMJ)

230 V~ 100 W

120 V~ (LOGICMJ)

Terminal W must be connected to the common motor phase connection. The condenser must be

connected between the U and V phases.

Note: if the direction of rotation of the motor is incorrect for the desired direction of movement,

swap the U and V phases.

Motor 2 (M2).

Terminal Z must be connected to the common motor phase connection. The condenser must be

connected between the X and Y phases.

Note: if the direction of rotation of the motor is incorrect for the desired direction of movement,

swap the X and Y phases.

Flashing light.

Activated during opening and closing operations.

Courtesy light.

In one motor mode only (jumper OM=OFF and no motor connected to terminals X-Z-Y), a courtesy

light may be connected, which activates for 180 s each time a total or partial opening command

or closing command is received.

6

IP1854EN - 2013-03-01

Page 7

Output Value - Accessories Description

J7

60 s

10 s

MIN=0 s MAX=120 s

1

0 s

30 s

Membrane push-button panel (PT3).

Starts the opening operation.

Note: to activate the closing operation, connect the connector of the push-button panel to J7

(rotated by 180°).

Membrane push-button panel (PT3).

Causes the blocking of the movement.

Membrane push-button panel (PT3).

Starts the closing operation.

Note: to activate the opening operation, connect the connector of the push-button panel to J7

(rotated by 180°).

6. Adjustments

6.1 Trimmer

Trimmer Description

TM

MIN=10 s MAX=120 s

TR

3 s

MIN=0 s

20 s

30 s

TC

RF

4

3

5

2

Setting the operating time. From 10 to 120 s.

NOTE: with NC limit switch, set TM=MAX.

Setting motor 1 (M1) closing delay time.

When closing, motor 1 (M1) starts after a delay set with TR from 0 to 30 s relative to M2. When opening, motor 2

(M2) starts after a delay of 3 s relative to M1.

If TR=MIN, the door wings start simultaneously.

NOTE: we recommend setting TR=MIN with non-overlapping door wings, and setting TR>3 s with overlapping door

wings.

Setting automatic closing time. From 0 to 120 s.

With DIP3=OFF, once a safety switch has been activated, the counter starts as soon as the safety switch is released

(for example, after passing through the photocells), and lasts for a period of time set with TC (50%).

With DIP3=ON, the counter starts when automation is opened and lasts for the entire duration set with TC (100%).

NOTE: after the activation of the stop command, once contact 1-9 has closed again, automatic closing is only enabled after a total, partial or step-by-step opening command.

Power setting.

Sets voltage supplied to motor (1=MIN / 5=MAX).

R1

Setting obstacle thrust.

The control panel is equipped with a safety system that stops motion if an obstacle is encountered during an opening

operation and either stops or reverses motion during a closing operation.

MIN

MAX=disabled

R1=MIN gives maximum obstacle sensitivity (minimum thrust).

R1=MAX disables detection (maximum thrust).

RP

Setting motor 1 (M1) partial aperture.

From 0 to 30 s.

6.2 Dip-switch

DIP Description OFF

DIP1 Radio mode. Step-by-Step. Opening.

DIP2 Direction selection with OM=OFF (one mo-

Opens towards right. Opens towards left.

tor mode).

DIP3 Restore automatic closing time. 50% 100%

DIP4 Automation status at power on.

Indicates how the control panel considers

automation when powered up.

Open.

NOTE: with a limit switch installed, preferably set DIP4=OFF.

DIP5 Electric lock release. Disabled. Enabled.

DIP6 Preflashing set at 3 s. Disabled during opening.

Enabled only with automatic closing and

with TC setting greater than 3 s.

ON

Closed.

NOTE: if the automatic closing function is

not used, preferably set DIP4=ON.

Enabled for both opening and closing.

IP1854EN - 2013-03-01

7

Page 8

6.3 Jumper

Jumper Description OFF ON

JR4 Overtravel reduction.

Reduces the overtravel distance for the

door wing.

JR6 Application type. Sliding gate. Other applications.

NIO Electronic antifreeze system. Maintains

motor function even at low ambient temperatures.

NOTE: for correct operation, the control

panel must be exposed to the same ambient temperature as the motors.

JR10 Maximum power at start. Disabled.

OM Automation type. One motor automation (M1 only). Automation with two independent motors.

D5 Step-by-step sequence. Open-stop-close-stop-open. Open-stop-close-open.

S5 Step-by-step sequence stop duration. Permanent.

JT Closing operation time. Set with TM+4 s.

EO Electric lock function. Powered with automation closed. Powered for 1 s at the beginning of the

SO Reversal safety switch func-tion. With automation stopped and contact 41-8

Disabled.

NOTE: set JR4=OFF is the motor is equipped with an electric brake.

Enabled.

ATTENTION: do not use with LOGICMJ.

The motor starts with the voltage set with RF.

(Automatic closing disabled).

NOTE: set JT=OFF with hydraulic or friction

gearmotor.

open, opening operations are permitted.

Enabled.

NOTE: preferably set JR4=ON if the door

wing performs an excessive overtravel.

Disabled.

Enabled.

The motor starts at maximum power for 1 s.

Temporary.

(Automatic closing enabled).

Automatic.

opening operation.

With automation stopped and 41-8 open, all

operations are disabled.

6.4 Signals

LED On Flashing

POWER

SA

IN

11

12

24 V power supply /

Indicates that at least one of the safety contacts is open. Safety test failure (terminal 41).

Operations count performed (only when control panel is switched

on):

= 1000 operations

Activated at every command and adjustment to the dip-switch

and jumper.

Indicates that the 0-11 limit switch contact is open.

Indicates that the 0-12 limit switch contact is open.

= 10000 operations

/

/

/

8

IP1854EN - 2013-03-01

Page 9

7. Starting

i

• Bridge the NC safety contacts with a jumper.

• Before starting up, check the application type selected. In the case of single door wing automation, set OM=OFF. For sliding

gate automation, set JR6=OFF.

• Any limit switches installed must be adjusted so that they are triggered near the mechanical opening and closing end stops.

Set TM=MAX.

NOTE: limit switches must be kept pressed until the operation has been completed.

• If no limit switches are installed, bridge terminals 0-11 and 0-12 with jumpers and set TM to half.

• Set RF=3 and R1 to half.

• Set TR>3 s in the case of automation with two overlapping door wings.

• Switch on power.

ATTENTION: The following operations are performed with no safety devices

• Swap the motor polarity if the direction of motion of the door wings is incorrect.

NOTE: the first closing operation requested after a power outage is performed, if TR>MIN, with one door wing at a time (first the

door wing powered by motor M2, then the door wing powered by motor M1), whereas if TR=MIN, the door wings start simultaneously.

• Perform opening and closing commands and check that the automation functions correctly and that the limit switches (if

installed) are correctly set.

• Connect the safety devices (removing the relative jumpers) and check that they function correctly.

• If required, activate automatic closing and adjust with the TC trimmer.

• Set RF to a position that allows the automation to function correctly while ensuring the safety of the user in the event of col-

lision.

• Set obstacle thrust with R1.

NOTE: if the door wing closing second encounters an obstacle, both door wings are reopened. The subsequent closing operation

is performed one door wing at a time.

• Ensure that the forces exerted by the door wings are compliant with EN12453-EN12445 regulations.

• If required, set the partial aperture of motor 1 with RP.

• If required, connect the radio receiver to the relative AUX connector, programme the transmitters as described in the relative

manual and check that all elements function correctly.

WARNING: the plug-in cards must be inserted and removed with the power supply disconnected.

• Connect any other accessories and check operation.

• Once the start up and check procedures are completed, close the container.

NOTE: in the event of servicing or if the control panel is to be replaced, repeat the start-up procedure.

IP1854EN - 2013-03-01

9

Page 10

8. Troubleshooting

Problem Possible causes Remedy

Automation does not open or close. No power.

(POWER led off).

Short circuited accessories.

(POWER led off).

Blown line fuse.

(POWER led off).

Safety contacts are open.

(SA led on).

Safety contacts not correctly connected or

self-controlled safety edge SOFA1-SOFA2 not

functioning correctly.

(SA led flashing).

Release microswitch open (if installed). Check that the hatch is closed correctly and the

The motor thermal overload switch is open. Check for continuity between the phases of the

Automation opens but does not close. Safety contacts are open.

(SA led on).

Safety contacts not correctly connected or

self-controlled safety edge SOFA1-SOFA2 not

functioning correctly.

(SA led flashing).

Photocells activated.

(SA led on).

The automatic closing does not work. Check that contact 1-2 is closed.

External safety devices not activating. Incorrect connections between the photocells

and the control panel.

Check that the control panel is powered correctly.

Disconnect all accessories from terminals 0-1

(voltage must be 24 V=) and reconnect one at

a time.

Replace fuse.

Check that the safety contacts are closed correctly (N.C.).

Check connections to terminals 6-7-8 on control

panel and connections to the self-controlled

safety edge SOFA1-SOFA2.

microswitch makes contact.

motors disconnected from the control panel.

Check that the safety contacts are closed correctly (N.C.).

Check connections to terminals 6-7-8 on control

panel and connections to the self-controlled

safety edge SOFA1-SOFA2.

Check that the photocells are clean and operating correctly.

Connect NC safety devices together in series

and remove any bridges on the control panel

terminal board.

10

IP1854EN - 2013-03-01

Page 11

9. Example application for two-motors swing gates

<MAX <MAX

<MAX <MAX

<MAX <MAX

<MAX <MAX

=MAX <MAX

When the LOGICM control panel is used in automation applications with two swinging door wings, one of the

following operating modes may be selected.

Example 1 - Door wings stop against mechanical end stops and in

the event of obstacle detection.

Set an operating time of 2-3 s longer than the effective time taken by

the door wing (TM<MAX) and bridge terminals 0-11-12 with jumpers.

In this configuration, each door wing will come to a stop against mechanical opening and closing end stops and in the event of obstacle

detection.

Example 2 - Door wings stop against limit switches and in the event

of obstacle detection.

The NC contacts of the opening and closing limit switches are connected in series with the motor phases.

Set an operating time TM<MAX and bridge terminals 0-11-12 with

jumpers.

In this configuration, each door wing will come to a stop against the

opening and closing limit switches and in the event of obstacle detection.

com

M11~M2

15 14 13 12 11 00112345678920 41

15 14 13 12 11 00112345678920 41UWVXZY

com

1~

Limit switch (230 V 5A)

TM

TM

TC RP TR R1

TC RP TR R1

Example 3 - Door wings stop against limit switches and reverse

motion in the event of obstacle detection.

Set an operating time TM=MAX and connect the closing limit

switch NC contacts to terminals 0-11-12 and the opening limit

switch NC contacts in series with the open phase of each motor.

With this configuration, each of the door wings stops when the limit

switches are activated.

In the event of obstacle detection while opening, only the door wing

that detects the obstacle stops, performing a disengagement operation, whereas during a closing operation, both door wings reopen.

Example 4 - Door wings stop against mechanical end stops and reverse motion in the event of obstacle detection.

Set an operating time 2-3 s greater than the effective time taken

by the door wing (TM<MAX) and connect the closing proximity limit

switch NO contacts to terminals 0-11-12, positioning the switches

2-3 s ahead of the mechanical end stop. In this configuration, each

door wings stops against its respective mechanical closing and opening end stop. In the event of obstacle detection while opening, only

the door wing that detects the obstacle stops, performing a disengagement operation. In the event of obstacle detection during closing

and before the activation of the proximity limit switch, the door wings

reopen; after the activation of the proximity limit switch, the door

wings stop against the obstacle.

Example 5 - The door wings stop against the limit switches when

opening and against the mechanical end stops when closing, and

reverse motion when an obstacle is detected.

Set an operating time 2-3 s greater than the effective time taken

by the door wing (TM<MAX) and connect the closing proximity limit

switches to terminals 0-11-12, positioning the switches 2-3 s ahead

of the mechanical end stop. Connect the opening NC limit switches

in series to the open phase of each motor. In this configuration, the

door wing stops against the mechanical end stop when closing, and

when the relative limit switch is activated when opening. When an

obstacle is detected during opening, the door wing stops, performing

a disengagement operation. In the event of obstacle detection during

closing and before the activation of the proximity limit switch, the

door wings reopen; after the activation of the proximity limit switch,

the door wings stop against the obstacle.

15 14 13 12 11 0 0112345678920 41UW VXZY

Opening limit switch (230 V 5A)

com

com

M11~M2

1~

15 14 13 12 11 0011234567892041

15 14 13 12 11 00112345678920 41UWVXZY

com

com

Opening limit switch (230 V~ 5A)

M11~M2

1~

TM TC RP TR R1

Closing

limit switch

TM TC RP TR R1

Closing

proximity switch

TM TC RP TR R1

Closing

proximity switch

IP1854EN - 2013-03-01

11

Page 12

10. Example application for one-motor swing gate

<MAX <MAX

<MAX <MAX

=MAX <MAX

<MAX <MAX

<MAX <MAX

When the LOGICM control panel is used in automation applications with one swinging door wing, one of the

following operating modes may be selected.

Example 1 - Door wing stops against mechanical end stops and in

the event of obstacle detection.

Set an operating time of 2-3 s longer than the effective time taken by

the door wing (TM<MAX) and bridge terminals 0-11-12 with jumpers.

In this configuration, the door wing will come to a stop against mechanical opening and closing end stops and in the event of obstacle

detection.

Example 2 - Door wing stops against limit switches and in the event

of obstacle detection.

The NC contacts of the opening and closing limit switches are connected in series with the motor phases.

Set an operation time TM<MAX and bridge terminals 0-11-12 with

jumpers.

In this configuration, the door wing stops against the opening and

closing limit switches and in the event of obstacle detection.

Example 3 - Door wing stops against limit switches and reverses

motion in the event of obstacle detection.

Set an operating time TM=MAX and connect the opening and closing

limit switch NC contacts to terminals 0-11-12.

In this configuration, the door wing stops when the limit switches

are activated.

In the event of obstacle detection while opening, the door wing stops,

performing a disengagement operation, whereas during a closing

operation, the door wing reopens.

M1

com

1~

15 14 13 12 11 00112345678920 41

15 14 13 12 11 00112345678920 41UWVXZY

Limit switch (230 V 5A)

15 14 13 12 11 00112345678920 41

TM TC RP TR R1

TM TC RP TR R1

TM TC RP TR R1

OM=OFF

OM=OFF

OM=OFF

Example 4 - Door wing stops against mechanical end stops and reverses motion in the event of obstacle detection.

Set an operating time of 2-3 s longer than the effective time taken by

the door wing (TM<MAX) and position the proximity limit switches 2-3

s ahead of the mechanical end stop.

In this configuration, the door wing stops against its respective mechanical closing and opening end stop.

In the event of obstacle detection before the activation of the proximity limit switch while opening, the door wing stops, performing a disengagement operation; after the proximity limit switch is activated,

the door wing stops against the obstacle.

In the event of obstacle detection during closing and before the activation of the proximity limit switch, the door wing reopens; after the

proximity limit switch is activated, the door wing stops against the

obstacle.

Example 5 - The door wing stops against the limit switch when opening and against the mechanical end stop when closing, and reverses motion in the event of obstacle detection.

Set an operating time of 2-3 s longer than the effective time taken

by the door wing (TM<MAX), position the proximity limit switches 2-3

s ahead of the mechanical end stop and connect the opening limit

switch NC in series to the opening phase of the motor.

In this configuration, the door wing stops against the mechanical

end stop when closing, and when the relative limit switch is activated when opening. When an obstacle is detected during opening,

the door wing stops, performing a disengagement operation. In the

event of obstacle detection during closing and before the activation of

the proximity limit switch, the door wing reopens; after the proximity

limit switch is activated, the door wing stops against the obstacle.

12

com

M1

1~

Opening limit switch (230 V 5A)

Closing limit switch

Opening limit switch

TM TC RP TR R1

15 14 13 12 11 0011234567892041

Closing proximity switch

Opening proximity switch

TM TC RP TR R1

15 14 13 12 11 00112345678920 41UWVXZY

Closing

proximity switch

OM=OFF

OM=OFF

IP1854EN - 2013-03-01

Page 13

11. Example application for sliding gate

When using the LOGICM control panel for sliding automation applications:

- set OM=OFF

- set JR6=OFF

- set TM=MAX

Connect the opening and closing limit switch NC contacts to terminals

0-11-12.

With this configuration, the door wing stops when the limit switches

are activated.

In the event of obstacle detection while opening, the door wing stops,

performing a disengagement operation, whereas during a closing

operation, the door wing reopens.

Select the correct opening direction with DIP2.

• In the event of automation with right-side opening seen from the

automation side (DIP2=OFF), connect the opening limit switch to

terminals 0-12 and closing limit switch to terminals 0-11.

• In the event of automation with left-side opening seen from the

automation side (DIP2=ON), connect the opening limit switch to

terminals 0-11 and the closing limit switch to terminals 0-12.

12. Example application for barriers

DIP2=OFF

DIP2=ON

1ON23456

=MAX <MAX

JR6=OFF

TM TC RP TR R1

15 14 13 12 11 00112345678920 41

Limit switch

Limit switch

OM=OFF

1ON23456

1ON23456

When using the LOGICM control panel for barrier applications:

- set OM=OFF

- set RF=5 (MAX)

- set TM=MAX

Select the correct opening direction with DIP2.

• In the event of automation with right-side opening seen from the

automation side (DIP2=OFF), connect the opening limit switch to

terminals 0-12 and closing limit switch to terminals 0-11.

• In the event of automation with left-side opening seen from the

automation side (DIP2=ON), connect the opening limit switch to

terminals 0-11 and the closing limit switch to terminals 0-12.

DIP2=OFF

DIP2=ON

4

3

5

2

1

1ON23456

=MAX <MAX

TM TC RP TR R1

15 14 13 12 11 00112345678920 41

Limit switch

Limit switch

OM=OFF

1ON23456

1ON23456

IP1854EN - 2013-03-01

13

Page 14

13. Example of automation in parallel

i

A B

The two automations [A] and [B] can be operated in parallel by making the connections indicated in the figure.

Commands 1-3 and the remote controls (with DIP1=ON) are equivalent to a total opening command.

Automatic closing is obtained by adjusting the TC trimmer not at the maximum and in the same position on both control panels.

N.B.: the opening and closing movements are not synchronised, including reopening after activation of the photocells.

WARNING: in the absence of safety edge SOFA1-SOFA2, connect commands 1-8 to the SWT card.

Commands 41-6 and 41-7 can only be connected on the respective control panel.

BIXLR22

SWT

LOGICM

0

JR1 JR2

6841

A

OUT2

0

6

8

6841

SWT

6

8

OM=OFF

OM=OFF

TM TC RP TR R1

ON

1

23456

23456

1

ON

Stop

Closing

TM TC RP TR R1

JR6=OFF

15 14 13 12 11 0011234567892041

Opening

Partial opening

Safety while opening

JR6=OFF

15141312110011234567892041

LOGICM B

14

IP1854EN - 2013-03-01

Page 15

All rights related to this material are the exclusive property of Entrematic Group AB.

Although the contents of this publication have been compiled with the greatest possible care, Entrematic Group AB cannot accept liability for any damage that might

arise from errors or omissions in this publication.

We reserve the right to make modifications without prior notice.

No part of this publication may be copied, scanned, adapted or modified without prior permission in writing from Entrematic Group AB.

IP1854EN - 2013-03-01

15

Page 16

IP1854EN - 2013-03-01

Entrematic Italy S.p.A.

Via Mons. Ban, 3 • 21042 Caronno P.lla (VA) Italy

Tel. +39 02 963911 Fax +39 02 9650314

www.ditecentrematic.com

Loading...

Loading...