Page 1

DISPLAY Elektronik GmbH

LCD MODULE

DEM 20485 SBH-PW-N

Product Specification Version : 5.1.0

14/July/2008

Page 2

GENERAL SPECIFICATION

MODULE NO. :

DEM 20485 SBH-PW-N

CUSTOMER P/N

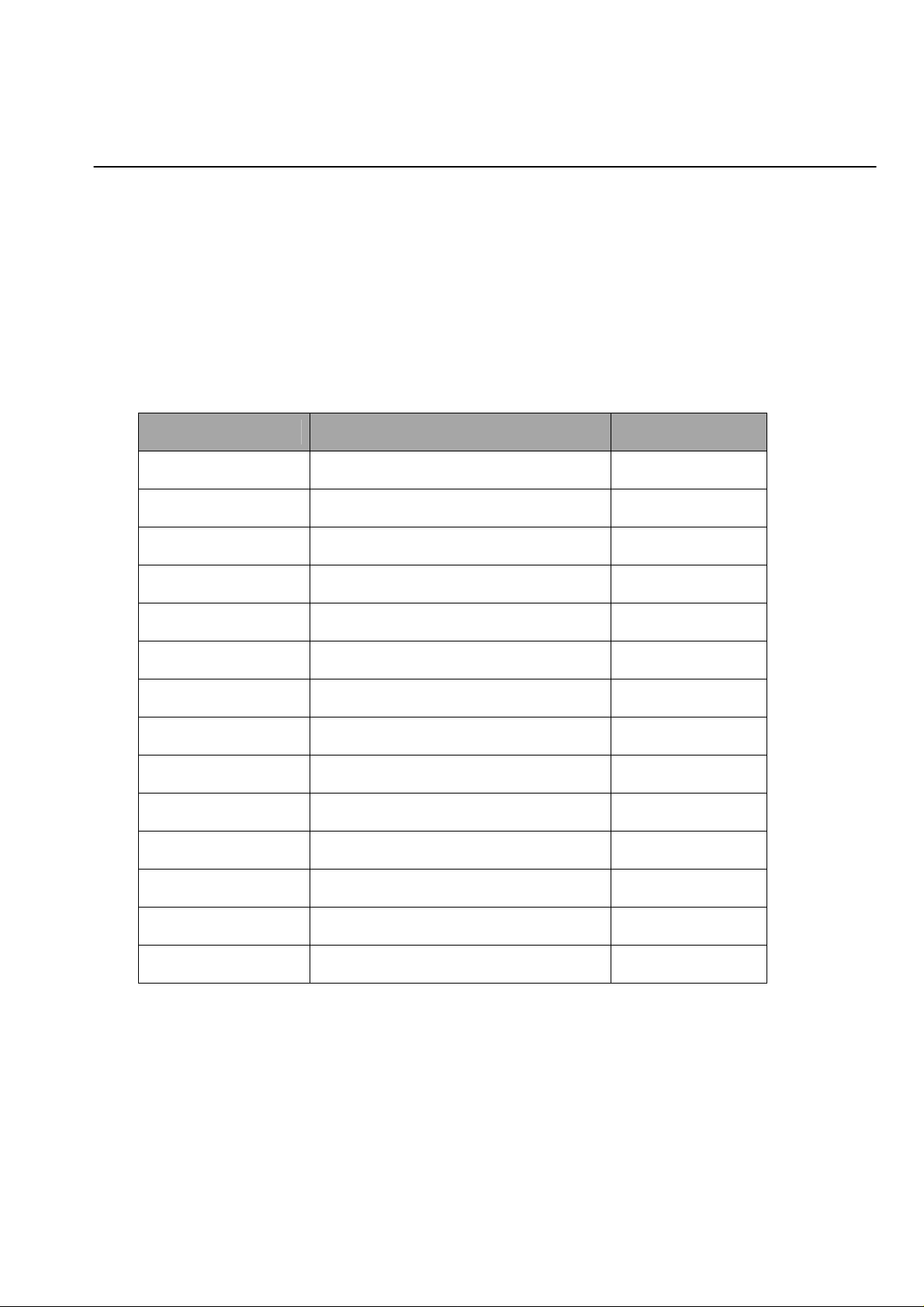

VERSION NO. CHANGE DESCRIPTION DATE

0 ORIGINAL VERSION 17.12.2002

1 ADDING VERSION 27.07.2003

2 ADDING VERSION 04.11.2003

3 ADDING VERSION 26.04.2005

4 MODIFY DESCIPTION 19.06.2006

5 MODIFY DESCRIPTION 11.04.2007

5.1.0 CHANGE IC 14.11.2007

PREPARED BY: LSY DATE: 14.11.2007

APPROVED BY: MH DATE: 14.07.2008

Page 3

DEM 20485 SBH-PW-N Product Specification

CONTENTS

1. FUNCTIONS & FEATURES .................................................................................................................2

2. MECHANICAL SPECIFICATIONS.....................................................................................................2

3. EXTERNAL DIMENSIONS...................................................................................................................3

4. BLOCK DIAGRAM................................................................................................................................3

5. PIN ASSIGNMENT.................................................................................................................................4

6. PCB DRAWING AND DESCRIPTION ................................................................................................4

7. BACKLIGHT VOLTAGE AND CURRENT ........................................................................................6

8. DISPLAY DATA RAM............................................................................................................................6

9. MAXIMUM ABSOLUTE LIMIT..........................................................................................................7

10. ELECTRICAL CHARACTERISTICS ...............................................................................................7

11. CONTROL AND DISPLAY COMMAND...........................................................................................9

12. STANDARD CHARACTER PATTERN (ST7066-0A) ....................................................................10

13. LCM INITIALIZING BY INSTRUCTION......................................................................................11

14. LCD MODULES HANDLING PRECAUTIONS.............................................................................13

15. OTHERS...............................................................................................................................................13

Version: 5.1.0 PAGE: 1

Page 4

DEM 20485 SBH-PW-N Product Specification

1. FUNCTIONS & FEATURES

MODULE NAME LCD TYPE Remark

DEM 20485 SBH-PW-N STN Blue Transmissive Negative Mode RoHS Conformed

z Viewing Direction : 6 o’clock

z Driving Scheme : 1/16 Duty Cycle, 1/5 Bias

z Power Supply Voltage : 5.0 Volt (typ.)

z Backlight Color : LED, White, Lightguide

z V

z Display contents : 20 x 4 Characters (5x8 dots, Format: 208 Kinds )

z Internal Memory : CGROM (10,080 bits )

: CGRAM (64 x 8 bits )

: DDRAM (80 x 8 bits for Digits)

z Interface : Easy Interface with a 4-bit or 8-bit MPU

z Operating Temperature : -20°C to +70°C

z Storage Temperature : -25°C to +75°C

Adjustable For Best Contrast : 4.5 Volt (typ., VDD-V5)

LCD

2. MECHANICAL SPECIFICATIONS

z Module Size : 98.00 x 60.00 x 14.10 mm

z Character Pitch : 3.55 x 5.35 mm

z Character Size : 2.95 x 4.75 mm

z Character Font : 5 x 8 dots

z Dot Size : 0.55 x 0.55 mm

z Dot Pitch : 0.60 x 0.60 mm

z Dot Gap : 0.05 mm

Version: 5.1.0 PAGE:

2

Page 5

DEM 20485 SBH-PW-N Product Specification

3. EXTERNAL DIMENSIONS

4. BLOCK DIAGRAM

DB0~DB7

E

R/W

RS

V0

VDD

VSS

LCD

Controller

LSI

ST7066U

COM1~COM16

SEG1~SEG40

Control signals

LCD PANEL

4 Line x 20 Characters

SEG41~SEG120

SEGMENT

DRIVER

ST7063

SEGMENT

DRIVER

ST7063

SEG121~SEG200

A

K

Version: 5.1.0 PAGE:

BACKLIGHT

3

Page 6

DEM 20485 SBH-PW-N Product Specification

5. PIN ASSIGNMENT

Pin No. Symbol

1 VSS

2 VDD

3 V0 Power Supply for LCD

4 RS

5 R/W

6 E Enable signal

7 DB0

8 DB1

9 DB2

10 DB3

11 DB4

12 DB5

13 DB6

14 DB7

15 LED-(K) Place also refer to 6.1 PCB Drawing and description

16 LED-(A) Place also refer to 6.1 PCB Drawing and description

Function

Ground terminal of module

Power supply of module +5V

Register Select

RS=0 (Instruction Register)

RS=1 (Data Register)

Read or Write

R/W=1 (Read)

R/W=0 (Write)

Bi-directional Data Bus, Data Transfer is performed

Once, thru DB0~DB7, in the case of interface data.

Length is 8-bits; and twice, thru DB4~DB7 in the case

of interface data length is 4-bits.

Upper four bits first then lower four bits.

6. PCB DRAWING AND DESCRIPTION

DEM20485

R2

R3

R4

R

R

R1

J1

6

5

U1

U2

U3

J5

J4

J3

J2

K

A

R8

R7

J6

1

Version: 5.1.0 PAGE:

16

4

Page 7

DEM 20485 SBH-PW-N Product Specification

6.1 DESCRIPTION:

6-1-1.The polarity of the pin 15 and the pin 16

symbol

J2,J4 Each solder-bridge Each open Each closed Anode Cathode

J3,J5 Each solder-bridge Each closed Each open Cathode Anode

Note: In application module, J2=J4= open and J3=J5=0 Ohm

6-1-2. The metal-bezel is set be on ground when the J1=0 Ohm

Note: In application module, J1=0 Ohm

6-1-3. The LED resistor on board are used when J6 is open

Note: In application module, J6=open

6-1-4.The R7 and the R8 are the LED resistor.

Note: In application module, R7=12 Ohm, R8=open

6.2 Example application

6-2-1. The LED resistor should be bridged as following. Then customer needs to use internal resistors

J6

symbol

state

J3,J5 J2, J4

LED Polarity

15 Pin 16 Pin

R7

R8

6-2-2.The 15 pin is the cathode and the 16 pin is the anode as following

J4

J5 J2

0 Ohm resistor

0 Ohm resistor

6-2-3.The metal-bezel is on ground as following.

J1

J3

0 Ohm resistor

Version: 5.1.0 PAGE:

5

Page 8

DEM 20485 SBH-PW-N Product Specification

7. BACKLIGHT VOLTAGE AND CURRENT

Item Symbol MIN. TYP. MAX. Unit Conditions

Forward Voltage Vf 4.0 - V

Forward Current If 40 60 80 mA Vf=4.0V

Power Dissipation Pd 0.24 W Vf=4.0V

Reverse Voltage VR 4.0 V

Reverse Current IR - 0.40 mA

Luminous Intensity LV 300 450 600 cd/m

Luminous Uniformity 70 %

Chromaticity coordinate

Emission W avelength

λ p

X=0.27

Y=0.27

White nm

-

X=0.33

Y=0.33

2

=20mA, Ta=25°C

I

f

=4.0V

V

f

Each chip

8. DISPLAY DATA RAM (DDRAM)

DISPLAY POSITION

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

FIRST LINE 00 01 02 03 04 05 06 07 08 09 0A 0B 0C 0D 0E 0F 10 11 12 13

SECOND LINE 40 41 42 43 44 45 46 47 48 49 4A 4B 4C 4D 4E 4F 50 51 52 53

THIRD LINE 14 15 16 17 18 19 1A 1B 1C 1D 1E 1F 20 21 22 23 24 25 26 27

FOURTH LINE 54 55 56 57 58 59 5A 5B 5C 5D 5E 5F 60 61 62 63 64 65 66 67

DDRAM ADDRESS

Version: 5.1.0 PAGE:

6

Page 9

DEM 20485 SBH-PW-N Product Specification

7

9. MAXIMUM ABSOLUTE LIMIT (Ta=25°C)

Item Symbol Standard value Unit

Power supply voltage VDD -0.3 ~ +7.0 V

LCD Driver voltage V

V

LCD

-10.0 ~ VDD+0.3 V

DD

Input voltage VIN -0.3 ~ VDD+0.3 V

Operating temperature Topr -20 ~ +70 °C

Storage temperature Tstg -25 ~ +75 °C

10. ELECTRICAL CHARACTERISTICS

10-1 DC Characteristics(VDD=5.0V, Ta=-20~+70°C)

Item Symbol

Operating Voltage V

Supply Current I

LCD Driving Voltage

V

DD

DD

LCD

Standard Valu e

MIN TYP MAX

4.5 5 5.5 ------- V

---- 0.2 0.5

3.0 --- 10.0

10-2 AC Characteristics (VDD=5.0V, Ta=-20~+70°C)

10-2-1 Write mode

Characteristic Symbol Min Type Max Unit Test PIN

Enable Cycle Time t

Enable Pulse Time T

Enable Rise/Fall Time

T

R

Address Set-up Time T

Address Hold Time T

Data Set-up Time T

Data Hold Time T

C

PW

T

,

AS

AH

DSW

H

F

1200 --- --- ns E

460 --- --- ns E

--- --- 25 ns E

0 --- --- ns R/W,RS,E

10 --- --- ns R/W,RS,E

80 --- --- ns DB0~DB7

10 --- --- ns DB0~DB7

Condition

V

=5V,fosc=270kHz

DD

Test

VDD-V5

Unit

mA

V

Version: 5.1.0 PAGE:

Page 10

DEM 20485 SBH-PW-N Product Specification

10-2-2 Read mode

Characteristic Symbol Min Type Max Unit Test PIN

Enable Cycle Time t

Enable Pulse Time T

Enable Rise/Fall Time

Address Set-up Time T

Address Hold Time T

Data Set-up Time T

Data Hold Time T

T

R

C

PW

T

,

AS

AH

DDR

H

1200 --- --- ns E

480 --- --- ns E

F

--- --- 25 ns E

0 --- --- ns R/W,RS,E

10 --- --- ns R/W,RS,E

--- --- 320 ns DB0~DB7

10 --- --- ns DB0~DB7

Version: 5.1.0 PAGE:

8

Page 11

DEM 20485 SBH-PW-N Product Specification

11. CONTROL AND DISPLAY COMMAND

Command RS R/W DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

clear

Display

Return home L L L L L L L L H --- 1.52ms

Entry mode

Set

Display

on/off

control

Cursor

or

Display Shift

L L L L L L L L L H 1.52ms

L L L L L L L H I/D SH 37us

L L L L L L H D C B 37us

L L L L L H S/C R/L --- --- 37us

Execution time

(fosc=270KHz)

Remark

Write “20H” to DDRAM and set

DDRAM address to “00H” from AC

Set DDRAM address to

"00H"from AC and return

cursor to its original position

if shifted.The contents of

DDRAM are not changed.

Sets cursor move direction

and specifies display shift.

These operations are

performed during data write

and read.

D=1:entire display on

C=1:cursor on

B=1:cursor position on

Set cursor moving and

display shift control bit,and

the direction,without

changing DDRAM data.

DL:interface data is 8/4 bits

function

Set

Set CGRAM

address

Set DDRAM

address

Read busy

flag&

address

Write data

to RAM

Read data

from RAM

L L L L H DL N F --- --- 37us

L L L H AC5 AC4 AC3 AC2 AC1 AC0 37us

L L H AC6 AC5 AC4 AC3 AC2 AC1 AC0 37us

L H BF AC6 AC5 AC4 AC3 AC2 AC1 AC0 0us

H L D7 D6 D5 D4 D3 D2 D1 D0 37us

H H D7 D6 D5 D4 D3 D2 D1 D0 37us

N:number of line is 2/1

F:font size is 5x11/5x8

37 us

Set CGRAM address in

address counter

Set DDRAM address in

address counter

Whether during internal

operation or not can be

known by reading BF.The

contents of address counter

can also be read.

Write data into internal

RAM

(DDRAM/CGRAM)

37 us

Read data from internal

RAM

(DDRAM/CGRAM)

37 us

Note:

Be sure the ST7066U is not in the busy state(BF=0)before sending an instruction from the MPU to the

ST7066U.If an instruction is sent without checking the busy flag,the time between the first instruction and next

instruction will take much longer than the instruction time itself.Refer to Instruction Table for the list of each

instruction execution time.

Version: 5.1.0 PAGE:

9

Page 12

DEM 20485 SBH-PW-N Product Specification

12. STANDARD CHARACTER PATTERN (ST7066-0A)

Lowerr(4bit)

LLLL

LLLH

LLHL

LLHH

LHLL

LHLH

LHHL

Upper(4bit)

LLLL

CG RAM

(1)

(2)

(3)

(4)

(5)

(6)

(7)

LLLH LLHL LLHH LHLL LHLH LHHL LHHH HLLL HLLH HLHL HLHH HHLL HHLH HHHL HHHH

LHHH

HLLL

HLLH

HLHL

HLHH

HHLL

HHLH

HHHL

(8)

(1)

(2)

(3)

(4)

(5)

(6)

(7)

HHHH

Version: 5.1.0 PAGE:

(8)

10

Page 13

DEM 20485 SBH-PW-N Product Specification

13. LCM INITIALIZING BY INSTRUCTION

13-1 8-bit interface mode

Power on

Wait time > 40ms Condition : fosc=270khz

After VDD> 4.5v

0 1-line mode

Function set

RS RW DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

0 0 0 0 1 1 N F X X 0 5 x 8 dots

Wait for more than 37us

0 display off

Display on/off control

RS RW DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

0 0 0 0 0 0 1 D C B 0 cursor off

Wait for more than 37us 0 blink off

Display clear

RS RW DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

0 0 0 0 0 0 0 0 0 1

Wait for more than 1.52ms

Entry mode set

RS RW DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

0 0 0 0 0 0 0 1 I/D SH

0 entire shift off

Initialization end

0 decrement mode

N

F

D

1 2-line mode

1 5 x 11 dots

1 display on

C

1 cursor on

B

I/D

SH

1 blink on

1 increment mode

1 entire shift on

Version: 0 PAGE:

11

Page 14

DEM 20485 SBH-PW-N Product Specification

13-2 4-bit interface mode

RS RW DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0 0 1-line mode

0 0 0 0 1 0 X X X X

0 0 0 0 1 0 X X X X 0 5 x 8 dots

0 0 N F X X X X X X

Wait for more than 37us

RS RW DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

0 0 0 0 0 0 X X X X 0 cursor off

0 0 1 D C B X X X X

Wait for more than 37us

RS RW DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

0 0 0 0 0 0 X X X X

0 0 0 0 0 1 X X X X

Wait for more than 1.52ms

Entry mode set 0 decrement mode

RS RW DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

0 0 0 0 0 0 X X X X 0 entire shift off

0 0 0 1 I/D SH X X X X

Initialization end

Power on

Wait time > 40ms

After VDD> 4.5v

Function set

Display on/off control 0 display off

0 blink off

Display clear

Condition : fosc=270khz

N

F

D

1 2-line mode

1 5 x 11 dots

1 Display on

C

B

I/D

SH

1 cursor on

1 blink on

1 increment mode

1 entire shift on

Version: 5.1.0 PAGE:

12

Page 15

DEM 20485 SBH-PW-N Product Specification

14. LCD MODULES HANDLING PRECAUTIONS

Please remove the protection foil of polarizer before using.

The display panel is made of glass. Do not subject it to a mechanical shock by dropping it from a high place, etc.

If the display panel is damaged and the liquid crystal substance inside it leaks out, do not get any in your mouth. If

the substance come into contact with your skin or clothes promptly wash it off using soap and water.

Do not apply excessive force to the display surface or the adjoining areas since this may cause the color tone to

vary.

The polarizer covering the display surface of the LCD module is soft and easily scratched. Handle this polarize

carefully.

To prevent destruction of the elements by static electricity, be careful to maintain an optimum work environment.

-Be sure to ground the body when handling the LCD module.

-Tools required for assembly, such as soldering irons, must be properly grounded.

-To reduce the amount of static electricity generated, do not conduct assembly and other work under dry conditions.

-The LCD module is coated with a film to protect the display surface. Exercise care when peeling off this protective

film since static electricity may be generated.

Storage precautions

When storing the LCD modules, avoid exposure to direct sunlight or to the light of fluorescent lamps. Keep the

modules in bags designed to prevent static electricity charging under low temperature / normal humidity conditions

(avoid high temperature / high humidity and low temperatures below 0°C). Whenever possible, the LCD modules

should be stored in the same conditions in which they were shipped from our company.

15. OTHERS

Liquid crystals solidify at low temperature (below the storage temperature range) leading to defective orientation of

liquid crystal or the generation of air bubbles (black or white). Air bubbles may also be generated if the module is

subjected to a strong shock at a low temperature.

If the LCD modules have been operating for a long time showing the same display patterns may remain on the

screen as ghost images and a slight contrast irregularity may also appear. Abnormal operating status can be resumed

to be normal condition by suspending use for some time. It should be noted that this phenomena does not adversely

affect performance reliability.

To minimize the performance degradation of the LCD modules resulting from caused by static electricity, etc.

exercise care to avoid holding the following sections when handling the modules:

- Exposed area of the printed circuit board

- Terminal electrode sections

Version: 5.1.0 PAGE:

13

Loading...

Loading...