Page 1

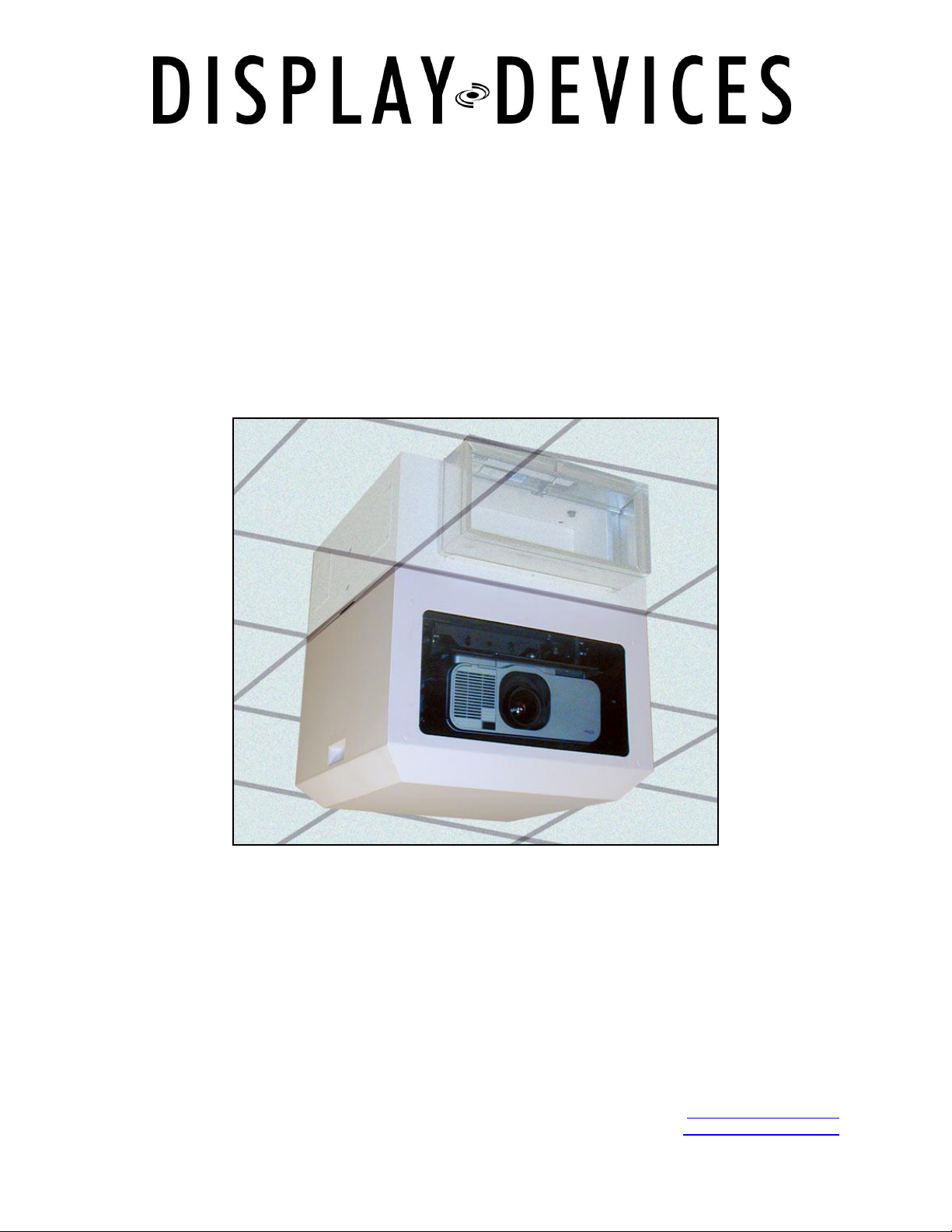

SE-B1

Sound Enclosure

Installation Manual

READ ALL INSTRUCTIONS BEFORE BEGINNING INSTALLATION

03/08 1

tel: 303.412.0399 www.displaydevices.com

fax: 303.412.9346 tech@displaydevices.com

5880 Sheridan Blvd., Arvada, Colorado 80003

Page 2

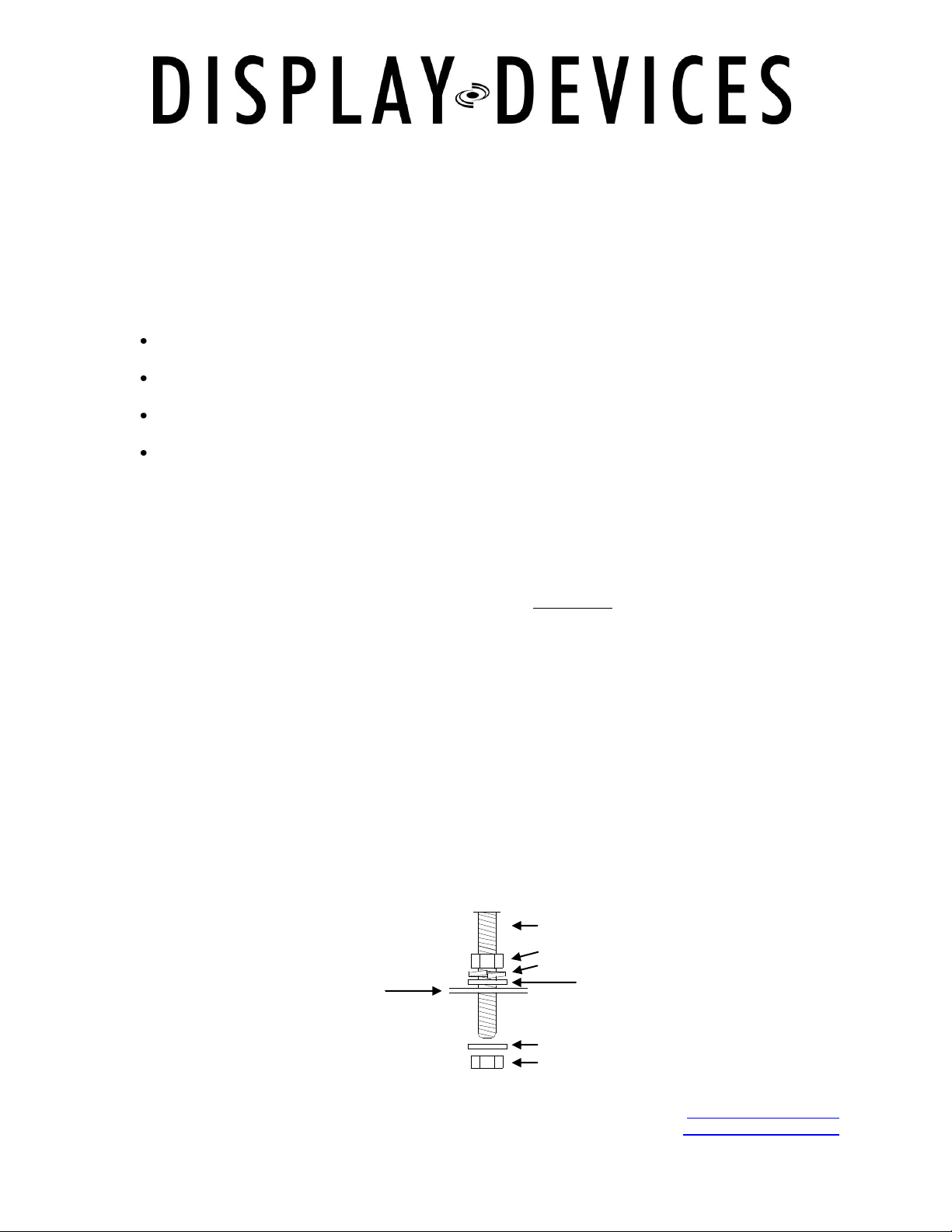

Threaded rod

Nut

Flat washer

Split lock washer

Flat washer

Nut

Sound Enclosure

SE Series Sound Enclosures

Thanks for purchasing a Display Devices product. We’re sure your customer will use this product for

years to come. Our products are designed to be maintenance-free saving you future service time. If you

experience any difficulties, please contact us at 303-412-0399. Thank you for your support.

The Sound Enclosure is designed to relocate projector noise to above a false ceiling. Sound Enclosures

work best when installed as part of a complete sound isolation system. For optimum sound isolation, we

recommend the following:

Add intake and exhaust ducts to the enclosures’ fire dampers – six feet or longer – this disperses

the sound away from the area it originates.

Insulate around the upper cavity on top of the ceiling tiles/media. Insulating this area increases

the barrier you create between the viewer and the noise source.

Plumb the unit to an external fresh air source, plumb the exhaust to another area away from the

viewing room.

Air intake is located on the projection port side.

Tools required

Phillips head screwdriver

Powered screwdriver with Phillips bit

¾”, 9/16” and 7/16” socket and open end wrenches

5” socket extension

Important:

DO Ensure the ceiling structure is capable of holding at least four times the combined weight of the

enclosure and projector. This is a minimum requirement. Follow any local or state codes that apply to

your specific area. We recommend two people and a material lift for this installation.

1.) Install structural support for sound enclosure unit – utilize 3/8” (M10) threaded rod and

2.) Remove access panel(s) to access mount holes (on the 2x2 configuration, one set of mount

3.) Raise the unit up on a material lift to the appropriate vertical height. The seam where the

: Material Lift

hardware to bolt the unit into place. We recommend using a structural channel above the

unit for lateral positioning of the box.

holes are accessible at the fan intake). You may also reach in through the projector port for

access.

upper and lower cavities are together in the closed position should be slightly above your

finished ceiling line. Be sure to have a sufficient amount of threaded rod to provide leveling

room. Add hardware as follows for leveling: above unit – nut/lock washer/flat washer;

underside of unit – washer and nut. Do not tighten yet.

03/08 2

tel: 303.412.0399 www.displaydevices.com

fax: 303.412.9346 tech@displaydevices.com

5880 Sheridan Blvd., Arvada, Colorado 80003

Page 3

4.) Use a bubble level to level the unit front-to-back and side-to-side. Tighten hardware.

5.) To attach the fire dampers to the intake and exhaust ports, use the enclosed Phillips-head

sheet metal screws.

6.) Add runs of ductwork on the intake and exhaust fire dampers. Addition of ducts disperses

the sound above the ceiling further away from the projector. Sound isolating ductwork is

recommended. If additional sound dampening is desired, we recommend an auto sound

insulation material.

7.) CAUTION: After the unit is hung in position, the lower portion of the enclosure will want to

lower due to gravity if not latched! Slide the lower portion of the unit down until it reaches

the stop point. Be sure to use pull evenly on the cavity handles. DO NOT TRY TO LOWER

OR OPEN ONLY USING ONE HANDLE.

8.) Verify the mount position front-to-back and side-to-side. Adjust the position of the mount if

required. Front-to-back: loosen the (4) 3/4” bolts on the “L” brackets in the side Unistrut

channels. Move the mount/cross rails to the appropriate position – tighten the hardware in

the side channels. (THESE ARE UNISTRUT NUTS AND WILL TURN/UNLOCK WHEN

LOOSENED – BE SURE THEY ROTATE WHEN TIGHTENED AND LOCK INTO CHANNEL). To

position the mount left to right inside the enclosure, loosen the (4) 7/16” bolts on the tilt axis.

With a long extension socket wrench, insert

9.) Loosen the (4) thumbscrews on the mount (only 2 if it is a small mount footprint). Slide the

mount back so the thumbscrews align with the large holes on the keyway slots. Remove the

mount interface plate.

10.) Align the mount interface plate to the projector and attach with the enclosed hardware.

11.) Install the projector with the attached interface plate. Raise thumbscrews up in the slots,

then slide the projector forward until it stops. Tighten the thumbscrews. Be sure to keep a

2” clearance from the projector’s exhaust fans to the wall of the unit.

12.) Plumb AC power to the power supply – remove a knock-out and secure with strain relief.

Power input is on the power supply with an IEC connector.

13.) Plug your projector into the switched power outlet inside on the power supply.

14.) Remove another knock-out to route your projector signal/control cables. Secure with strain

relief.

15.) Remove blue film from glass then position in projection port. Add top hold down strip and

(2) 14”-20 nuts. Tighten nuts until glass is snug between gaskets.

16.) Finish ceiling tile tightly up to sides of upper box. Use insulating materials above ceiling tile to

isolate sound.

17.) Turn on the power supply, then turn on the projector and adjust your projected image to the

screen.

03/08 3

tel: 303.412.0399 www.displaydevices.com

fax: 303.412.9346 tech@displaydevices.com

5880 Sheridan Blvd., Arvada, Colorado 80003

Page 4

Fire Dampers

Finished

Ceiling Level

½” Mounting holes

Cable Knock-outs

Access Panels

18.) Slide the lower portion of the unit up until it latches.

19.) See the temperature controller section below to set fan temperature settings.

03/08 4

tel: 303.412.0399 www.displaydevices.com

fax: 303.412.9346 tech@displaydevices.com

2x2 Sound Enclosure shown

5880 Sheridan Blvd., Arvada, Colorado 80003

Page 5

Switched AC

Unswitched AC

AC input - On/Off Switch

RS232 Optional

Control Panel

Power Supply

Temperature Controller

Operation

The Programmable Cooling System provides two levels of fan control, an audible alarm, switched AC

power-down, and displays the current temperature of the enclosure.

Factory presets: Fan set 1: 70°

Fan set 2: 74°

Alarm: 100°

Power off: 104°

To start operation, turn on the AC switch on the power supply. The controller may sound an alarm, and

the fans will turn on for 10 to 20 seconds. The system will then reset to a start state.

03/08 5

tel: 303.412.0399 www.displaydevices.com

fax: 303.412.9346 tech@displaydevices.com

5880 Sheridan Blvd., Arvada, Colorado 80003

Page 6

Programming: There are four parameters to program. Each is programmed in the same

sequence. The control panel has four pushbuttons labeled SELECT MENU, Cursor UP,

Cursor DOWN and SAVE. The associated Power Supply is provided with an IEC AC power

cord and On / Off switch.

LED Display: The LED display provides two rows of text. When the system is powered

up, the LED display will read “Display Devices” and “Current Temp (number).” The twodigit number indicates the current temperature. Pressing the SELECT MENU button will

provide access to different programmable functions. If buttons are not pressed, the

display will automatically reset to “Current Temp” display after approximately 30 seconds.

Programming Temperature Control Level One: Press the SELECT MENU button once

and the display will read “Set Fan Lev1 (number)”. This number indicates the

temperature at which the Control One fans will begin operation. The second row of text

will change between “Current Temp” and current system status. If current temp is higher

than the programmed point for level 1 fans, the display will indicate “Fans On Level 1.”

Press the UP or DOWN button to select desired temperature for Control One fans. Press

SAVE.

Programming Temperature Control Level Two: Press the SELECT MENU button to

display “Set Fan Lev2 (number)”. This number indicates the temperature at which the

Control Two fans will begin operation. Press the UP or DOWN button to select desired

temperature for Control Two fans. Press SAVE.

Programming Alarm Level: Press the SELECT MENU button to display “Set Alarm Lev.

(number).” This number indicates the temperature at which the audible alarm will sound.

Press the UP or DOWN button to select desired temperature for Audible Alarm. Press

SAVE.

Programming Power Off: Pressing the SELECT MENU button again will show “Set

Power Lv”. This will provide removal of power from the switched AC outlet. Press the UP

or DOWN button to select desired temperature for removal of power at switched AC.

Press SAVE.

Selecting Temp. Standard: Pressing the SELECT MENU button again will show either

Fahrenheit or Celsius. Pressing the Up or Down buttons will change the temperature

format. Press SAVE.

03/08 6

tel: 303.412.0399 www.displaydevices.com

fax: 303.412.9346 tech@displaydevices.com

5880 Sheridan Blvd., Arvada, Colorado 80003

Page 7

03/08 7

tel: 303.412.0399 www.displaydevices.com

fax: 303.412.9346 tech@displaydevices.com

5880 Sheridan Blvd., Arvada, Colorado 80003

Page 8

03/08 8

tel: 303.412.0399 www.displaydevices.com

fax: 303.412.9346 tech@displaydevices.com

5880 Sheridan Blvd., Arvada, Colorado 80003

Loading...

Loading...