Page 1

Figure 1

Microphone Lift ML-2011

Installation Instructions

Structural attachment points will depend upon your specific installation. The

MicLift is designed to hang above the finished ceiling so your microphone is

slightly below the bottom of the finished ceiling. The actual mounting height will

vary depending upon your architectural situation. Structural channel and

threaded rods are common methods to install mounting points at the appropriate

height above the finished ceiling. The unit is shipped with a ¾” diameter conduit

that is 2” long reference to the right of figure 3.

tel: 303.412.0399 www.displaydevices.com

fax: 303.412.9346 tech@displaydevices.com

5880 Sheridan Blvd., Arvada, Colorado 80003

Page 2

NOTE

The lift is shipped fully assembled for installation into an unfinished ceiling application.

To install in a finished ceiling, you must disassemble the lower trim ring prior to

installation into the finished ceiling or ceiling tile.

The MicLift is designed to operate via our three-button remote or contact closures. See

the Control Interface section for control assignments.

The unit is designed to be mounted above the bottom of the finished ceiling.

Do’s and Don’ts

** Do not operate the lift up when the microphone cable is swinging – unit can jam.

** Do not replace or extend the factory-installed microphone cable.

** Do not operate the lift without the factory-installed weight (located at the end of the

cable) The weight is also the upper limit switch activation mechanism.

** When using directional microphones operate the lift 30 times to relax the cables

memory. The lift is cycled more that 30 times before shipping. The solenoid will get hot

if the unit is run continuously and could stop normal operation, so allow a couple

minutes between each cycle. Adjust the direction of the microphone after lengthy

operation.

MINIMUM WEIGHT CAPACITY: 2.5 OZ - MAXIMUM WEIGHT CAPACITY: 9 OZ

The weight that is provided with the lift is 2.5 ounces. Call tech support if your

microphone assembly is over 6.5oz.

TYPICAL INSTALLATION –

physical installation

1.)

Install the mounting plate above the bottom of the finished ceiling so the

ceiling bezel will be flush with the bottom surface. Use ½”

nuts/bolts/washers. Attach to structural channel or other solid mounting

surface. Be sure the plate is level: front-to-back and side-to-side.

2

Page 3

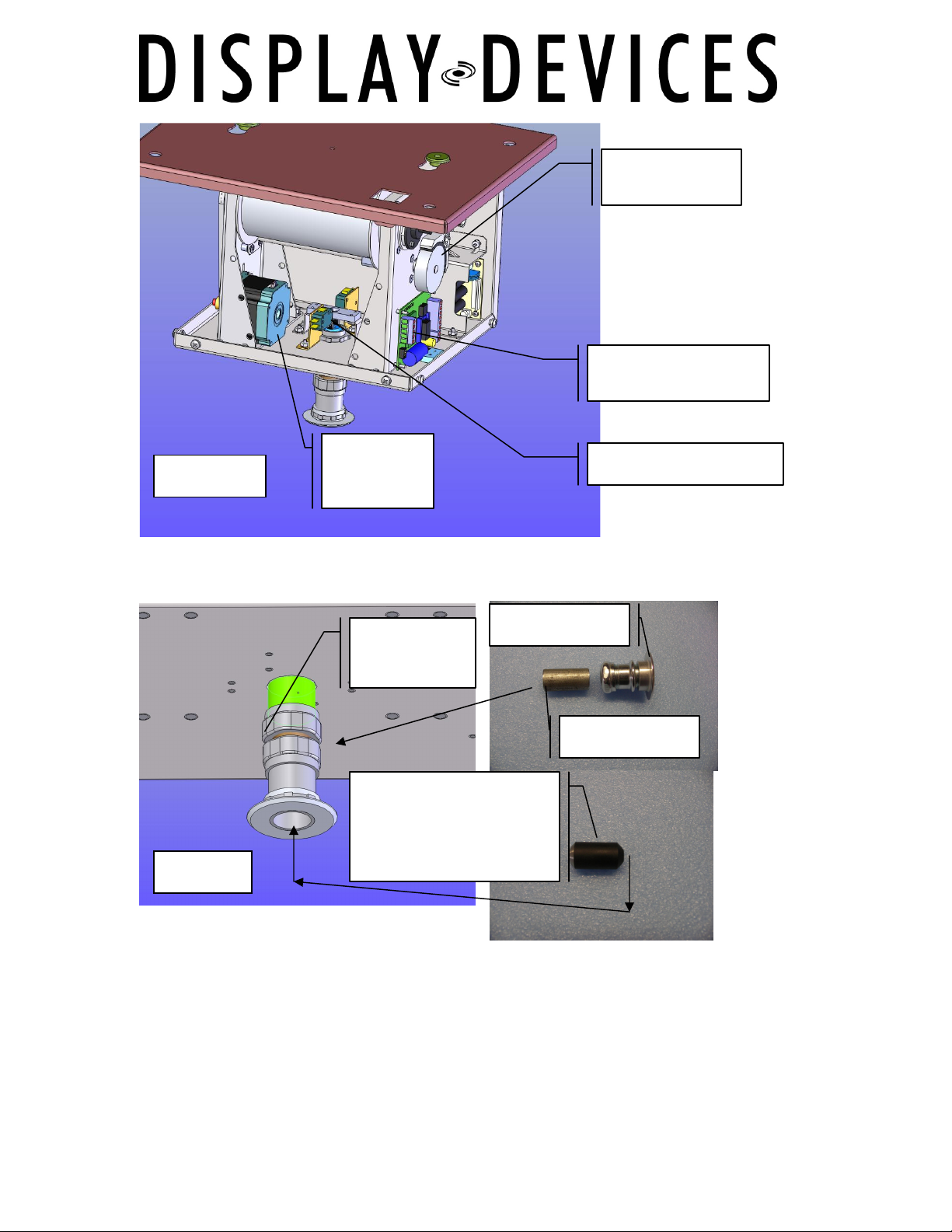

Brake

Mechanism

Microphone Lift

control board

Figure 2

Figure 3

Stepper

Motor

Upper piece

Fixed in lift

Limit switch activation

mechanism and

factory-installed

weight

Upper Limit switch

Ceiling Bezel

¾ “Conduit

2.)

3.)

4.)

Install the mounting plate using ½” hardware. Attach to structural channel

or a solid mounting surface. Be sure the plate is level front-to-back and

side-to-side.

Add a plumb bob to the mounting plate at the indicator hole and hang the

bob down to ceiling. This is the center point for the hole cutout location for

the microphone assembly.

Cut a 1.75” hole in the ceiling aligned with the plumb bob.

3

Page 4

5.)

6.)

7.)

8.)

9.)

Raise the lift to the mounting plate – insert the lugs into the key holes and

slide to narrow side of key hole slot.

Install the locking screw on the side of the unit.

There is a 2” long ¾ “ diameter conduit shipped with the unit, use a longer

piece if needed. Lower the microphone and weight down through the hole,

and thread through the conduit, conduit fitting, and ceiling bezel. Run this

assembly up through the hole and lock in place by tightening the upper nut

which if fixed to the bottom of the microphone lift.

Replace ceiling bezel.

If you’re installing this unit for purposes other than what the above

installation procedure describes, please call Display Devices Technical

Services at (303) 412-0399 for further assistance.

4

Page 5

Optional Speed Adjustment –

The MicLift’s lowering and raising speed can be changed from slow to fast.

The recommended speed is the factory default – slow.

Remove power to the unit.

Remove the side cover then remove the control board electronics cover. The jumper

is not connected and must be placed on both pins.

Slow speed – no jumper connected

Fast speed – jumper connected

Physical Installation

5

Page 6

Electrical, Signal and Control Installation

AC POWER

Audio Signal Remote Control

AC POWER 3 Pin XLR

6

Page 7

Remote Control - Pin out

1 UP

2 DOWN

3 STOP

4 COMMON

5 12V trigger in

6 +5V out

1.) Remove the j-box cover plate and connect AC power leads with wire nuts:

ground = green, neutral = white, hot = black.

2.) Connect the hardwired hand-held remote control to the 5-pin Phoenix

connector in the center j-box.

3.) Connect audio signal to the 3-pin XLR-f.

Three-button control – Contact Closure

‘Up’ button to pin 1

‘Down’ button pin 2

‘Stop’ button to pin 3

Common for all buttons to pin 4

Pin 5 & 6 are not used

Programming Show Position

Programming can only be done with the three-button control. If other methods of

triggering the lift are normally used, first program the lift with the remote and then

configure the lift for the other trigger method.

1.

Send lift to top position (‘Up’ button).

2.

Press and hold ‘Stop’ button for ten seconds.

3.

Press the ‘Down’ button. Lift will travel down. Press ‘Stop’ at the proper

show position. THIS MUST BE DONE IN ONE MOTION, DO NOT PRESS UP,

DOWN, OR STOP FOR FINE-TUNING OF POSITION.

4.

At proper position, press and hold the ‘Stop’ button for 10 seconds.

5.

Lift is now set. If you start the procedure and wish to quit after step 2, you

must reset power to the lift before normal operation will resume.

7

Page 8

Programming Ramping Distance

You may determine the location where the lift slows its acceleration. Programming can

only be done with the three-button control. If other methods of triggering the lift are

normally used, first program the lift with the remote and then configure the lift for the

other trigger method.

1 Send lift to top position (‘Up’ button).

2 Press and hold ‘Stop’ button for 10 seconds.

3 Press the ‘Down’ button. Lift will travel down. Press ‘Stop’ at the position where

you would like the microphone to begin slowing down. We recommend no less

than six inches below the finished ceiling. THIS MUST BE DONE IN ONE

MOTION. DO NOT PRESS UP, DOWN, OR STOP FOR FINE TUNING OF

POSITION.

4 At proper position, press and hold the ‘Stop’ and ‘UP’ buttons for 10 seconds.

5 Lift is now set. Press ‘Up’ to send the lift to the home position. Press ‘Down’ to

lower the lift, and ‘Up’ to send it to home position and verify where the ramping

point is. If you start the procedure and wish to quit after step 2, you must reset

power to the lift before normal operation will resume.

Refer to figure 2. The microphone lift is held in place by a solenoid brake

mechanism, so when the lift is told to move the brake will pull back and the

stepper motor will run to the lift to the desired programmed location.

Microphone Cable

The balanced microphone cable is connected to the 3-pin XLR. The color code of the

cable is braided/ground – pin 1, Blue/Blue with white stripe – pin 2, White/white with

blue stripe – pin 3. It is very important that the weight is on the cable. If the weight is

removed and you operate the lift, YOU WILL DESTROY THE MICROPHONE AND

LIFT! Also, make sure any splice is below the weight near the microphone.

8

Page 9

Optional Control Support

The next two control methods involve adding jumper wires on the Phoenix connector in

the center j-box. They are presented here for information only; please contact DDI for

further directions.

Low-Voltage Control signal and Single-Latching Contact

It is required that the lift is installed and the show position has been set. After setting

show position, jumpers must be added to the connector as shown below.

Low voltage (5 vdc < V < 24 vdc) control signal:

Voltage

Ground

Jumper from N4 Pin 1 to Pin 4, and N4 Pin 2 to Pin 4.

Trigger Voltage to pin 5.

Trigger Voltage ground to N4, pin 4.

(applied voltage sends lift up, no voltage sends lift down)

Single latching contact:

Jumper from N4 Pin 1 to Pin 4, and N4 pin 2 to pin 4.

Contacts between N4 Pin 5 and Pin 6.

(contact closed sends lift up, contact open sends lift down)

•

•

9

Loading...

Loading...