Page 1

PROJECTOR LIFTS

LCD-100, DL3B, DL3W

Installation &

Owners Manual

Vox: (303) 412-0399 On the Web:

Fax: (303) 412-9346 www.displaydevices.com

5880 N. Sheridan Blvd. tech@displaydevices.com

Arvada, CO 80003

Page 2

Contents

Important Installation Notes 3

Lift Placement 4

Lift Preparation 5

Ceiling Finish Methods 6

Enclosure Housing/Lifts Installation 7

Enclosure Housing – Side Panel Removal 8

Lift Installation 9

Enclosure Housing – Side Panel Replacement 10

Connecting Power 11

Projector Mounting 13

Cabling the Lift 14

Ceiling Closure 16

Adjustments 19

Specifications 19

Lift Removal 20

Maintenance and Safety 20

Emergency Operation 21

Remote Control Operation and Programming 22

Lift Communications Codes 25

Programming Chart 29

Troubleshooting Chart 30

Digital 9-pin Interface Schematics 31

Warranty 32

Feedback Form 33

1/17/07

2

Page 3

Important Installation Notes

Before starting…

DO Read all instructions before installation.

DO Leave wood blocks in place to protect you and the lift from damage until fully and

securely mounted.

DO Ensure the electrical outlet is readily accessible and complies with the lift and

projector specifications for voltages and amperages. (Show diagrams of 110v and 220v

receptacles.)

DO Check above the ceiling for obstructions, i.e., water pipes, wires, cables, duct work,

extreme temperature variations, etc. before beginning installation.

DO Ensure the ceiling structure is capable of holding at least four times the combined

weight of the lift and projector. This is a minimum requirement. Follow any local or

state codes that apply to your specific area.

DO Plan out your mounting hardware and tool requirements before installation.

DO Attach the projector, ceiling closure system, or other items to the lift only when the

lift has been properly installed and tested.

CAUTION:

Anytime that you are installing or performing maintenance on the lift,

disconnect power at the receptacle or breaker/fuse panel, program the lift to

MANUAL MODE, or activate the NO MOVEMENT switch on the side of the

control box to prevent inadvertent movement of the lift.

1/17/07

3

Page 4

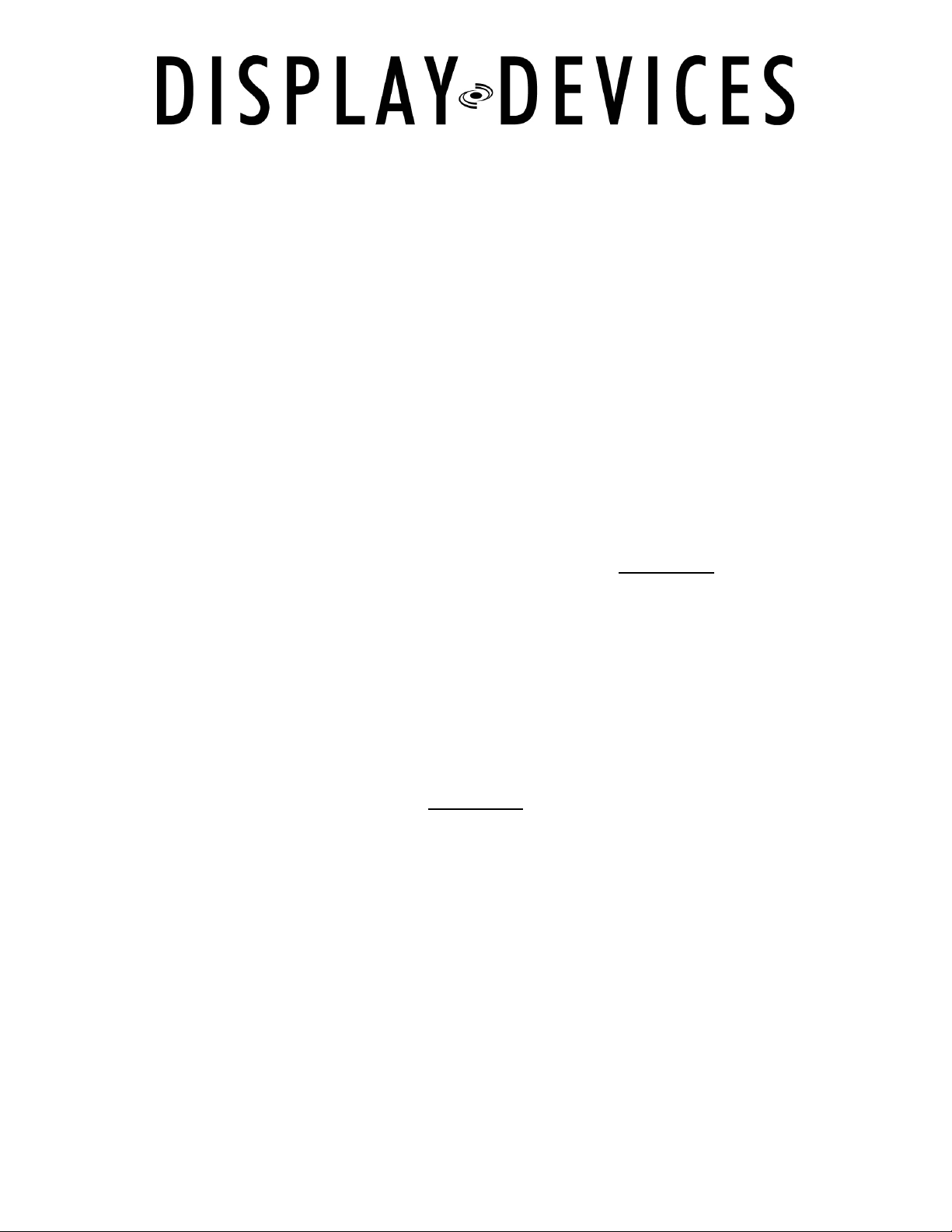

Lens Offset

Lift Placement and Location

Many projector lenses are not centered on the chassis of the projector. Ensure that the

centerline of the lens is aligned perpendicular to the center of the screen. Position the

lift offset the same distance as the offset of the projector lens. If your projector has

horizontal lens shift this is not as critical. We recommend offsetting the lift for optimum

projector alignment.

Projection Distance

If using a fixed focal length lens -- the screen-to-lens distance is critical. Offset the lift

position to compensate for the lens-to-lift difference. See your specific projector

manual for detail.

1/17/07

Fixed lens: measure distance lens-to-screen not

lift-to-screen

4

Page 5

1 2 3 4

Default setting

Lift Preparation

Unpack Lift – remove phillips head screws & lag screws securing frame & lift to the

pallet. (photo of LCD-100 with Option 4). The lift is shipped upside down. Leave the

wood blocks and plastic tie wraps in place.

Control Box

NOTE:

SET DIP SWITCHES before you install the lift. Be sure there is no power connected to

the lift. The control box is located inside the lift on the upper frame. Depending upon

your lift model the location and orientation of the control box varies.

Dip switches are located under the small access panel on the Control Box attached to

the lift frame. Use a 1/16” Hex driver to open.

ON OFF

SW1 Aux AC Trigger (see SW2 below) Aux AC Trigger is on all the time

SW2 Aux AC Trigger upon going down Aux AC Trigger at show position

SW3 12V out turns off upon going up 12V out turns off at top position

SW4 12V out turns on upon going down 12V out turns on at show position

Dip Switch SW1: configuration only works in automatic mode.

Set the 12 volt trigger and AC Trigger based on your system design.

The factory default setting will not change for most installations.

ON

OFF

1/17/07

5

Page 6

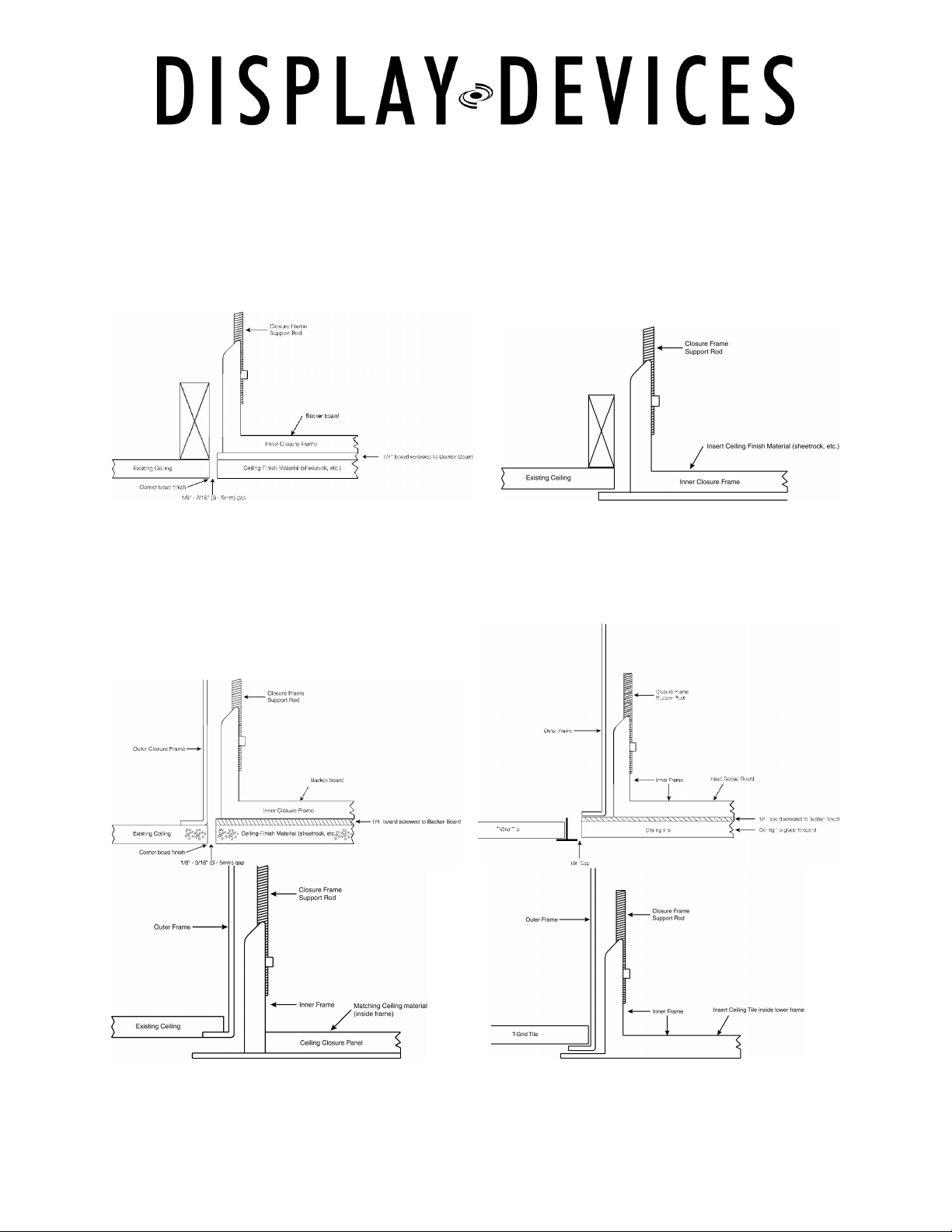

Typical Ceiling Finish Methods

Determine your ceiling closure system (OPT 1 – 4) and finish method as it can effect

the vertical placement of the lift.

Lift with Option 1 ceiling closure frame/panel

OPT1L

OPT1L 2X2

OPT3L or 4L

OPT3L or 4L 2X2

(Hard Ceiling)

OPT1

Option 3/4 Enclosure Frame

with Option 1 ceiling closure frame/panel

OPT3L or 4L

OPT3L or 4L 2X2

(T-grid Ceiling)

OPT3 or 4

OPT3 or 4 2X2

(Hard Ceiling)

OPT3 or 4

OPT3 or 4 2X2

(T-grid Ceiling)

1/17/07

6

Page 7

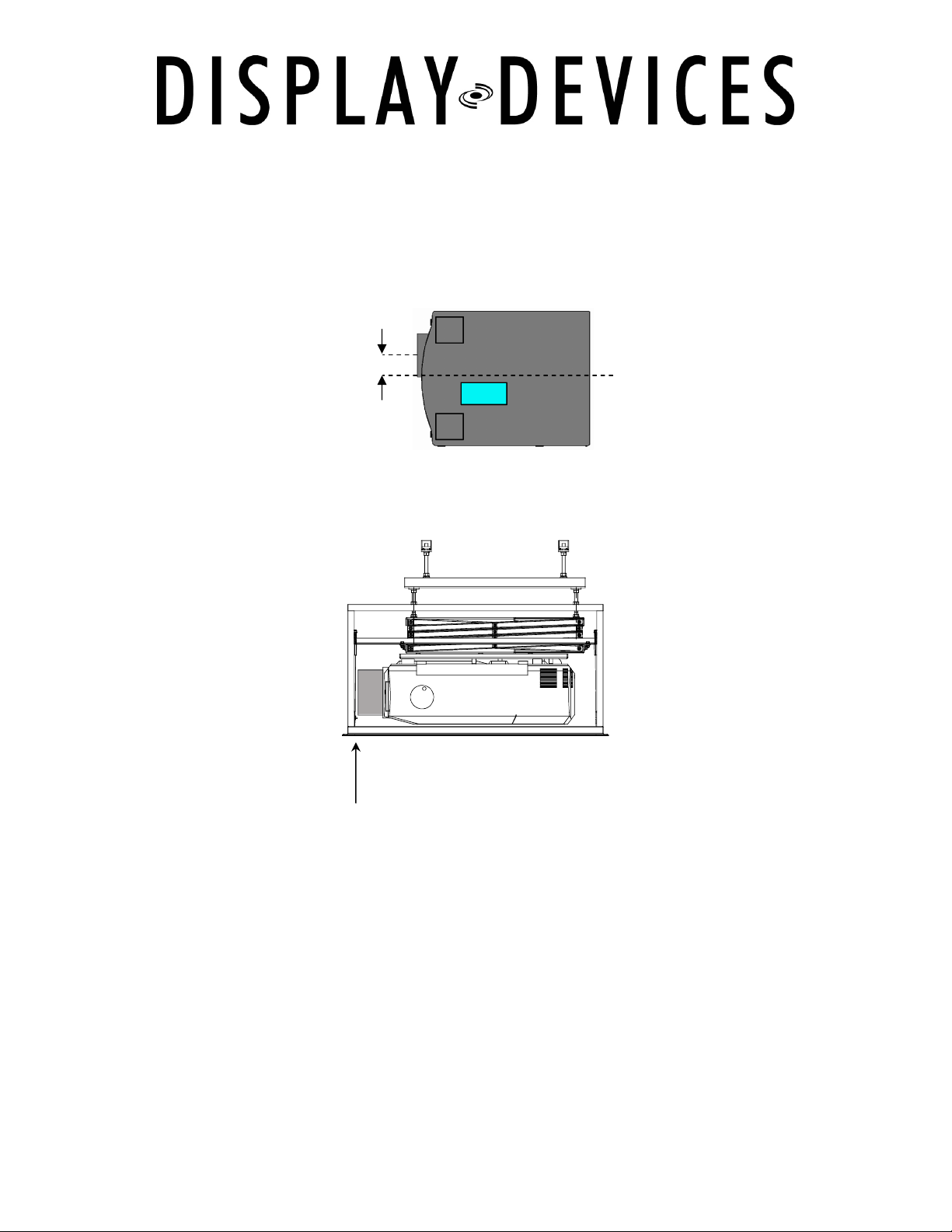

Attach to structural ceiling

Installation – Enclosure Housing and Lifts

Mounting hardware is not provided unless you ordered the option UMK (Universal

Mounting Kit). Be sure to have all your mounting hardware and tools readily accessible

before installation. Consult your local building codes for proper structural attachment.

Tools you will need:

Safety glasses, Socket set, Box wrenches, Adjustable wrench, Magnetic torpedo level

(two, if possible), Ladders or manlift, Genie Lift or heavy straps and pulleys (for DataLift

and DataLite Models), Knockout kit or Hole saw, ½” Drill and/or ½” Hammer drill.

If space permits: use

structural channel left-toright and front-to-back for

better positioning of the lift.

We recommend you install mounting hardware into a structural channel. All hardware

should be at least ½” (M12) in diameter for the DataLift (DL3B) and DataWide

(DL3W) series, or 3/8 ” (M10) for the DataLite (LCD100) series.

You should use angled stabilizers if threaded rods extend 2’ (60 cm) or more between

structural channel and the lift. You should also leave the threaded rods slightly loose to

ease in alignment and leveling after installing the lift. You need to make sure all

hardware is securely tightened at the end of your installation.

1/17/07

7

Page 8

Optional Enclosure Housing –Side Panel Removal

If you are not installing the OPT3 (Plenum Housing Enclosure) or OPT4 (Non-Plenum

Housing Enclosure) proceed to Part 4.

The OPT4 is the enclosure frame without side panels. You may skip the steps on the

OPT3 panels if you are installing the OPT4 only.

Use a Sharpie pen to mark the alignment of the side panels to the frame so you can

reinstall them from the side they were removed from. Take note the location of the

electrical outlet and the signal cables in relation to the lift location. Mark where you

want knock-outs for cable pass-through on the side panels -usually in the opposite

upper corners. (½” knockout for control/video cables & 1¼” knockout for AC power)

Keep these cables away from each other to avoid electromagnetic interference.

Remove the screws holding side panels from the frame, then lift out the plenum panels.

Be careful, the edges and corners are SHARP!

The lift is shipped upside-down with the specific projector’s mounting adapter bolted to

the bottom of the frame.

The outer frame will have a white sticker indicating the FRONT and TOP side of the

frame.

Note:

DataLite and DataLift models attach to the pre-installed bolts on the top of the

enclosure frame. DataWide models attach to pre-drilled horizontal holes on the front

and rear channels.

For DataLift (DL3B) and DataLite (LCD100) be sure the lift hanging hardware is installed

in the frame before mounting the enclosure to the structural ceiling.

Optional Enclosure – Mounting

Remove the mounting adapter from the bottom frame of the lift (7/16” socket/wrench).

Raise the Option 3 or 4 housing to the mounting points – add washer and nuts, then

tighten. Make sure the threaded rod you are attaching to does not protrude further

than ¼” past the nut. If there is too much threaded rod in the housing, the lift may

not be high enough in the housing – then your closure panel may contact the projector

prior to closing fully. After you have the mounting structure and/or housing installed in

the ceiling, you are ready to raise the lift into position and mount it.

1/17/07

8

Page 9

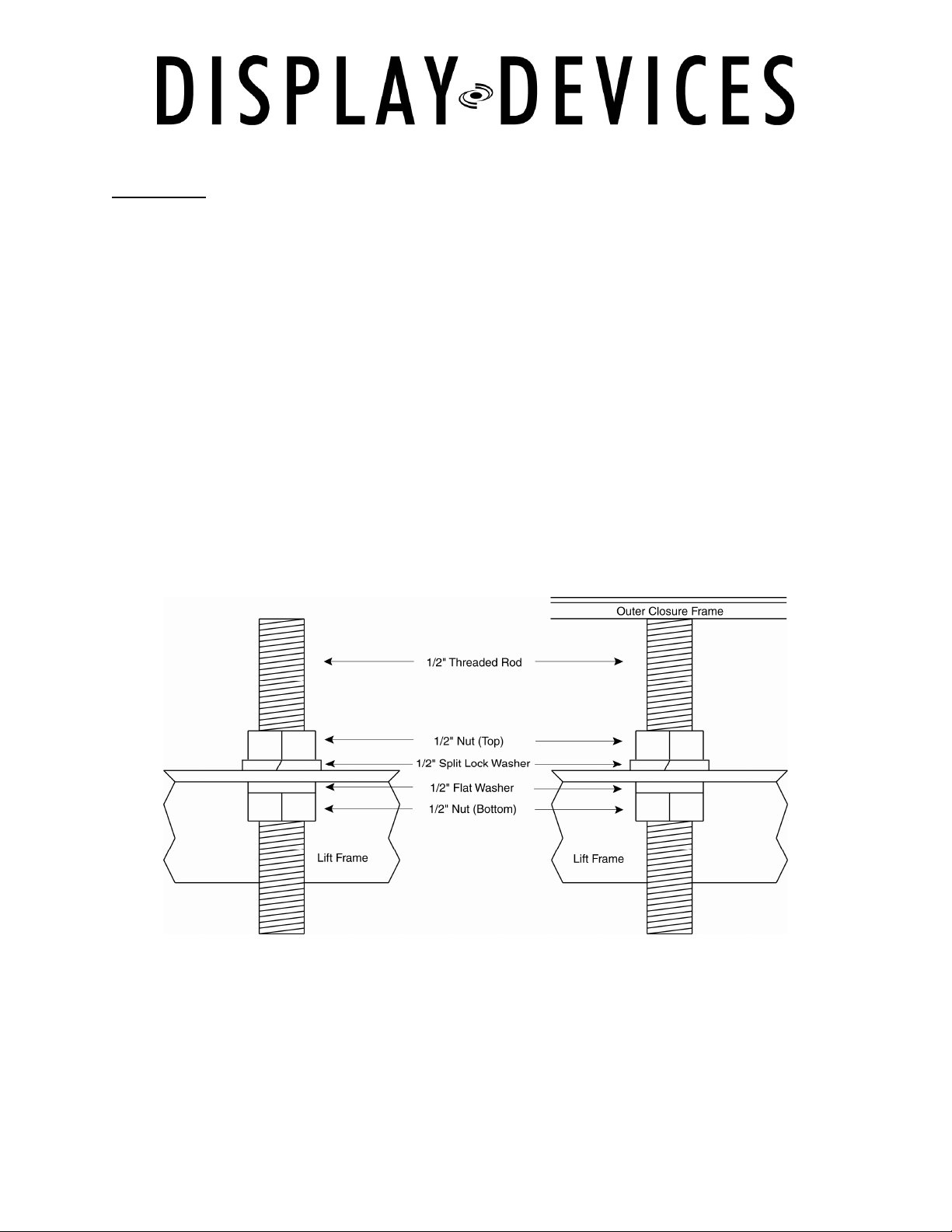

Hardware Order

Lift Installation

CAUTION!

The lift is heavy. Take proper safety precautions and get adequate help when

raising the lift. We recommend using a Genie™ or scissor-type lift when

installing the heavier DataLift and DataWide models. Add a safety line to the

lift to prevent it from falling to the floor in the event of an accident.

Remove the mounting adapter from the bottom frame of the lift (7/16” socket/wrench).

Before you begin, be sure the threaded rods have a nut and split washer above the lift

frame, and a flat washer and nut below the frame. These can be temporarily held in

place with tape, glue or gum.

Use 3/8” hardware for the DataLite models, and 1/2” hardware for the larger, heavier

DataLift and DataWide models.

Raise the lift into position and add hardware. Follow the hardware order to ensure

stability and accuracy when leveling the lift after you have successfully mounted it.

1/17/07

9

Page 10

Note:

The following are some of the most important steps in proper lift installation!

Use a torpedo or bubble level to level the top frame of the lift. You may want to use

more than one.

1. Level the lift from the right front to the left front.

2. Level the lift from left front to left rear.

3. Level the lift from right front to right rear.

4. Level the lift from right rear to left rear.

5. Recheck.

6. Recheck again.

7. To be absolutely positive, recheck again.

8. Tighten all hardware.

You may cut the tie wraps and remove the wood shipping blocks. Be sure to remove all

blocks and all tie wraps on both sides of the lift.

Optional Enclosure - Side Panel Replacement

If this is a plenum-rated housing, (OPT3), you can now replace the side panels that

are not knocked out. Be sure the correct panel goes on the correct side of the frame.

Next, install the strain relief/cable clamps in the panels that are knocked out, with the

screws on the inside, facing down.

It may be convenient to put the cables through at this time, depending upon the

ceiling’s finish and accessibility. If it is drop-tile ceiling, accessibility should not a

problem.

If the ceiling is a finished sheetrock or other solid material, you may need to feed the

cables through the connectors first, before you reinstall the panels.

1/17/07

10

Page 11

Connecting Power

Verify voltage at the outlet/power source for the projector/lift. You can now connect the

lift’s power cord to a properly rated electrical circuit in the ceiling near the lift.

Next, plug the remote control unit cable into either of the two 9-pin control remote

ports on the side of the control box.

Tighten the cable clamps / strain relief connectors as required.

If using the 12V trigger and/or AC Trigger, plug 1/8” mono mini plug on the sides of the

control box at this time. Be sure the cable won’t interfere with the lift mechanics.

Do not use a stereo mini connector.

(Tip / Ring / Sleeve)

Use the provided 1/8” mono mini connector.

(Tip / Sleeve)

Be sure the cables do not sag into the lift mechanism during its operation.

Remove the tie wraps and remove the wood shipping blocks. Be sure to remove all

blocks and all tie wraps on both sides of the lift.

Caution!

If you do not remove the wood blocks, and attempt to lower the lift, they will

fall out when the unit is lowered. If you forget to remove the tie wraps from

the wood blocks and scissor mechanisms, lift damage will occur.

After following these precautions, you are now ready to turn on the power switch on

the lift control box.

On the side of the control box, you will find the small black switch labeled NO

MOVEMENT. The lift is shipped from the factory with the NO MOVEMENT switch in the

ON position.

Flip the NO MOVEMENT switch to the OFF position. The LED will then blink twice. If the

NO MOVEMENT switch is on, the STATUS LED on the control box and the remote

control will be on solid -non blinking.

1/17/07

11

Page 12

12VDC Out

No Movement Switch

12VDC In

Main Power Switch

AC Input

AC Trigger

Caution!

Make sure all tools, cables and body parts are clear of the lift before pushing

the UP button.

With the hand-held remote control, press the UP button to send the lift to the home

position. Refer to the separate manual for the remote control (enclosed) for details on

operation of the remote and program the lift’s functions.

For this installation, here is a guide to the LEDs on the control box and the remote, and

what the blinking means:

If the LED… It means… Fix it by…

Is Continuously Blinking The NO MOVEMENT switch on

the side of the control box is

activated. This disables all

movement of the lift.

Blinks twice (after unit is

powered up, LED then stops

blinking

Blinks three times Dual motor current problems* Call DDI technical support

Blinks four times Motor is not moving Check the power to the motor

Blinks five times ** Low AC line voltage Check circuit voltage

Blinks six times Cables off the drum Re-cable the drum(s)

Blinks seven times Lower limit safety switch

*

2004 or earlier – non-volatile memory corrupted

**

stops automatically after voltage is restored to proper level

The lift is operational

activated

Moving the switch to the OFF

position

or for a mechanical

obstruction on the lift

Follow steps on page 7 of the

remote instructions

Circuit

Breaker

Remote

Control

Input Ports

1/17/07

AC Configuration

DIP Switches

Refer to the Remote Control Operators Manual for clarification as needed.

12

Page 13

Front

Back

UP

DOWN

STOP

OVERRID

E

Projector Mounting

Most lifts are shipped with the projector mounting adapter attached. Remove it from

the lower frame of the lift, if you have not already done so.

Find the projector’s center of gravity using a dowel, pipe or broom handle.

Invert your projector and attach the mounting adapter to the bottom of the projector

with the enclosed hardware.

Use the Remote Control to lower the lift to a good working height – see the Remote

Control Operation section for further information.

Place the lift in manual mode - use a small point (straightened paperclip) press and hold

the OVERRIDE button then press the UP button. Release UP then release

OVERRIDE.

Test the unit by pressing the DOWN button. It should move only when the button is

depressed. The lift will stop when the button is released.

Attach the adapter to the lift with the projector’s center of gravity under the wire rope

and eye bolts of the lift. If you ordered OPT11- Pre-wire package proceed to Part 7.

SET

These two bottoms are accessed with a small point

1/17/07

13

Page 14

Cabling the Lift

Caution:

Using large-diameter RGB and other signal and/or control cable is not

recommended on Display Devices’ lifts.

This type of cable has too large of a bend radius to allow it to fit in the cable

management clips mounted on the outside of the scissor assembly.

If your system uses large cables, keep them coiled neatly to the top of the lift, and

provide an interconnected miniature RGB cable to make the run down through the cable

management clips to the projector.

Attaching the Cables

Using the hand-held remote, bring the lift down to the MAINTENANCE position. See the

separate Remote Manual to learn how to program this position. The signal, power and

control cables can now be routed into the cable management clips on sides of the

scissor assembly.

When routing the cables always start at the fixed end of the scissor on the bottom

frame. Your cable routing will end at the fixed end of the scissor on the top frame.

1/17/07

14

Page 15

The lift is shipped with a sample cable in the clips – after reviewing the sample cable remove. Attach your cables in a likewise manner. Small cable tie wraps are supplied for

securing the cables into the clips.

Use both of the small holes when attaching the cables to the clips. Leave a loop at the

end of each scissor.

Carefully route the projector cables starting at the bottom scissor towards the front of

the lift and work towards the top front of the lift. Be careful you do not allow the

cables to twist.

NOTE:

It is common practice to keep the signal cables (audio, video, RGB) separate from the

projector power and control cables to prevent signal interference. Utilize the clips on

both sides of the lift for isolation.

Raise the lift to its home position with the UP button (in MANUAL mode) slowly,

carefully, and intermittently. Observe carefully the cables rigged to the sides of the lift

and watch for any problems.

Bring the lift down with the DOWN button. Again, watch for any problems and ensure

proper overall operation. Do this several times.

If you did not set the 12-volt trigger and AC configuration, revisit Part 1 and set the Dip

Switches for your system design.

You are now ready to attach the ceiling panel closure system.

1/17/07

15

Page 16

Slider (X2)

Slider (X2)

CTB Mount (X2)

CTB Mount (X2)

Assembly (X4)

Assembly (X4)

Ceiling Closure System – CTB Mounts & Sliders

Threaded Rod

Option 1 Lipless

Ceiling Closure Frame

Threaded Rod

Option 1 Lipped

Ceiling Closure Frame

NOTE: If you are not installing an OPT1 Ceiling Closure Frame, proceed to Part 8.

Lower the lift to a workable height. Install the CTB mounts to the corresponding holes

in the front and rear on the lower frame of the lift. (If your system includes the EMRCM

Rotating Option, attach the CTB to the EMRCM lower frame). See the supplemental

EMRCM/LIFT Interface directions.

Use ¼-20 x 1” bolts, ¼” split lock washers, and ¼” flat washers to attach the CTB

mounts to the lower lift frame.

Place the sliders on top of the CTB mount tabs that extend out from the right and left

sides. Add hardware but do not tighten the sliders to the tabs completely as they will

need to be adjusted for alignment.

1/17/07

16

Page 17

CTB Mount (X2)

NOTE:

If you have the 2X2 configuration, you will not use the sliders (front-to-back bars).

Option 1 2X2 Lipless

Ceiling Closure Frame

For a Lipless Closure System (OPT1L, OPT3L) cut a plywood backer board and ceiling

media (drywall, ceiling tile) 3/8” smaller than the hole cut out in the ceiling.

Glue or screw the ceiling media to the backer board. Add two 1” x 4” wood supports

across the width of the closure frame. Screw through the wood supports into the

plywood backer board.

NOTE:

Leave enough play in the screws to slide the ceiling closure for precise alignment of the

panel. Prep the ceiling closure panel by painting it to match the existing ceiling.

If you have a Lipped Closure System (OPT1, OPT3), fit your ceiling tile or other ceiling

media within the closure frame.

1/17/07

17

Page 18

Ceiling Closure System – Threaded Rod Attachment

Thread the (4) ¼-20 rods into the ceiling closure frame, stopping about 1½” from the

bottom.

Lift the closure panel and insert the rods into the slider.

Add the nylon shoulder bushing, spring, ¼” flat washer, and ¼-20 lock washer on the

top end of the rod.

Carefully raise the lift using the remote control.

Be sure the inner closure frame is centered inside the OPT3 or OPT4 outer frame. After

the closure panel is centered, tighten the bolts that attach the sliders to the CTB

mounts.

Finally, adjust the rods so that the ceiling closure panel fits flush with the ceiling.

When adjusting the Lipped Closure System (OPT1, OPT3), the springs should compress

about 1/8” to 1/4”.

1/17/07

18

Page 19

Final Adjustments

Operate the lift up and down several times to verify all adjustments and ensure proper

overall operation.

Place the lift in Manual Mode – press and hold Override, press and release UP, relase

Override. Raise the lift to its home position with the UP button slowly, carefully, and

intermittently. Observe carefully the cables rigged to the sides of the lift to watch for

any problems.

Bring the lift down with the DOWN button. Again, watch for any problem and ensure

proper overall operation. Adjust the closure system as needed.

Operate the lift up and down several times.

Place the lift in automatic mode. (press and hold OVERRIDE, press and release STOP.

If you did not set the 12-volt trigger and AC configuration, revisit Part 1 and set the Dip

Switches for your system design.

The lift is now installed and ready for operation.

Specifications

DataLite LCD-100 DataLift DL3B DataWide DL3W

Operating

Temperature Range

Horsepower 1/12 – 110V or 220V 1/12 – 110V or 220V 1/12 x 2 – 110V or 220V

Current Draw .6A @ 110V

32° – 104°F

0° – 40°C

.3A @ 220V

32° – 104°F

0° – 40°C

1.2A @ 110V

.6A @ 220V

32° – 104°F

0° – 40°C

2.4A @ 110V

1.2A @ 220V

1/17/07

19

Page 20

Lift Removal

Disconnect all cables from the projector. It may be necessary to remove all cabling from

the cable management clips on the side of the lift if disconnects were not installed.

Remove the Ceiling Closure Panel.

Remove the projector from the lift.

Place wood blocks between the upper and lower frame of the lift, and secure them with

tie wraps. The wood should be ½” to 1” longer than the fully-retracted lift height to

prevent the limit switches from being crushed. Close the lift up until contact is made

with the blocks.

Disconnect the AC power and remote control cables.

Support the lift with an appropriate support system (Genie Lift, winch, rope / pulley).

After the lift is secured, remove the mounting hardware. Caution: mounting hardware

may fall when removed.

Lower the lift from the ceiling, and crate for transport.

Maintenance & Safety

All Display Devices lifts are virtually maintenance-free.

Annual safety checks are suggested to insure continued reliability and safe operation.

Inspect lifting cables for wear.

Inspect drive belt/chain for any wear.

If equipped with safety strap(s), verify that they are drawing smoothly in and out of the

clutch area, and that there is no sign of wear and tear. Also check them for proper

locking operation with a quick tug on the strap(s).

Check motor and bearings for any leakage.

Verify limit switch operation.

1/17/07

20

Page 21

Emergency Operation

If your lift has traveled below the service position, and activated the lower limit safety

switch, you will need to refer to the Remote Manual, and/or follow the steps below.

1) Open the back cover of the handheld remote control case, or remove the switch

plate from the wall box.

(More detailed information is in the Remote Control Manual page 26.)

2) Press and hold the STOP button for 15 seconds to clear the error. Press the

EMERGENCY button in the circuit board, press the UP button and release, then

release the EMERGENCY button. The Lift should travel upward.

3) Verify operation and reprogram positions if necessary. See the Remote Control

Manual enclosed as a supplement.

If the above steps do not resolve the problem, call Technical Support at 303.412.0399

during normal business hours, or E-mail Display Devices, Inc. at

tech@displaydevices.com.

1/17/07

21

Page 22

Front

Back

UP

DOWN

STOP

OVERRIDE

Remote Control Unit

The Display Devices hand-held Remote Control Unit is a versatile, multi-functional

programmable unit for lift operation.

The UP button moves the lift to the home position in AUTOMATIC mode, and raises the

unit intermittently on command (in MANUAL mode).

The DOWN button lowers the lift to its SHOW position in AUTOMATIC mode, and

lowers the unit intermittently on command in MANUAL mode.

The STOP button stops the lift’s motion while in AUTOMATIC mode.

The OVERRIDE held down then followed by the DOWN button will lower the lift to

service position while in Automatic Mode.

The SET and OVERRIDE buttons on the back of the unit are used in combination with

the three command buttons on the front to program lift functions.

The EMERGENCY OVERRIDE button should only be accessed in case the lower limit

switch is activated. This will be discussed later.

* It is recommended to keep the handheld 9-pin remote attached to the control box in

addition to any control system (Crestron/AMX/etc.) for easy maintenance override or

control system failure.

EMERGENCY – accessible only

with back cover removed

SET

These two bottoms are accessed with a small point

1/17/07

22

Page 23

Front

Back

UP

DOWN

STOP

OVERRIDE

Front

Back

UP

DOWN

STOP

OVERRIDE

Program the lift to MANUAL MODE –

To set Show and Service positions the lift must be in Manual Mode.

1. Use a small point (straightened paperclip) press and hold the OVERRIDE button

then press the UP button. Release UP then release OVERRIDE.

2. Test the unit by pressing the DOWN button. It should move only when the button

is depressed. The lift will stop when the button is released.

SET

These two bottoms are accessed with a small point

Set the SHOW position

This is the intermediate level for “on screen” projection. Be sure to start this procedure

from the HOME position.

1. Program the remote to MANUAL MODE (OVERRIDE + UP). Press and hold the

OVERRIDE button, then press the UP button. Release UP, then release

OVERRIDE.

2. Lower the lift with the DOWN button to its desired projection position.

3. To program the remote to the SHOW position, press and hold the SET button then

press the UP button. Release UP, then release SET.

4. To return the remote to the AUTOMATIC MODE, press and hold the OVERRIDE

button, followed by the STOP button. Release STOP, then OVERRIDE.

5. Return the lift to the HOME position by pressing the UP button once.

6. Test the operation of the lift to verify it has accepted your program.

7. Press the DOWN button once. The lift will travel to its programmed position. If the

lift does not travel to the position just programmed, repeat this process.

* Remember, the remote must be in AUTOMATIC MODE for the commands to operate

correctly.

SET

These two bottoms are accessed with a small point

1/17/07

23

Page 24

Front

Back

UP

DOWN

STOP

OVERRIDE

Set the SERVICE / MAINTENANCE position

This is lower than the SHOW setting, bringing the lift to a level making maintenance,

service, lamp and filter changes, and projector adjustments easier. Be sure to start this

procedure from the HOME position.

1. Program the remote to MANUAL MODE – (OVERRIDE + UP). Press and hold

the OVERRIDE button, then press the UP button. Release UP, and then

release OVERRIDE.

2. Lower the lift with the DOWN button to its desired position for the easiest

access for maintenance and repair.

3. To program the remote to the SERVICE/MAINTENANCE position, press and hold

the SET button, followed by the STOP button. Release the STOP, and then

SET buttons.

4. To return the remote to the AUTOMATIC MODE, press and hold the OVERRIDE

button, followed by the STOP button. Release the STOP, and then OVERRIDE

buttons.

5. Return the lift to the HOME position by pressing the UP button once.

6. Test the operation of the lift to verify it has accepted your program. Press and

hold the OVERRIDE button, followed by the DOWN button. The lift will travel

to its programmed position.

Remember, the remote must be in AUTOMATIC MODE for the programmed positions

operate correctly.

SET

These two bottoms are accessed with a small point

Return to AUTOMATIC MODE

1. Press and hold the OVERRIDE button, followed by the STOP button. Release the

STOP then OVERRIDE buttons.

In the AUTOMATIC MODE, the lift will automatically descend to the proper show level,

rise to the HOME position, and descend to its lower limit service and maintenance.

1/17/07

24

Page 25

Access Service/Maintenance Position

Press and hold OVERRIDE then press DOWN – release. The lift will lower to service

position while in Automatic Mode.

LED Communications Codes

BLINKING LEDs ON THE REMOTE OR CONTROL BOX

If the LED is… It means… Fix it by…

Continuously Blinking The NO MOVEMENT switch

on the side of the control

box is activated. This

disables all movement of

the lift.

Blinks twice (after unit is

powered up, LED then

stops blinking

Blinks three times Dual-motor current problem Call DDI Tech Service.

Blinks four times Motor is not moving Check the power to the

Blinks five times Low AC line voltage Check circuit voltage

Blinks six times Cables off the drum Re-cable the drum(s)

Blinks seven times Lower limit safety switch

The lift is operational

activated

Clearing Errors: Press and hold the STOP button for 15 seconds and release. If the

same error occurs, call Display Devices technical support.

Moving the switch to the

OFF position.

motor or for a mechanical

obstruction on the lift

First cycle the power off

then on and take note of

what the LED does upon

power up. Follow steps on

the next page.

1/17/07

25

Page 26

Lower limit switch

Recover Lift from LOWER LIMIT SWITCH ACTIVATION and EMERGENCY

OVERRIDE

When the Lift is lowered beyond its lower limit or Service/Maintenance position, a small

wheel bearing activates a safety shut-off on the lower limit switch. It is located on the

channel near the wheel bearing on the scissors. If the lift will not respond to any

command buttons and the LED on the remote and Control box blinks seven times,

proceed with the following.

The procedure is also required

if a new control box is installed.

1. Remove the back cover of the remote control with a small Phillips-head

screwdriver. Now you have access to the EMERGENCY OVERRIDE button on

the circuit board.

2. If the LED is blinking you must clear the error. Press and hold the STOP button

for 15 seconds then release.

3. Hold in the EMERGENCY OVERRIDE button, followed by the UP button. The

lift will return to its HOME position in the ceiling, allowing the lift to reset its

memory.

4. Put the cover back on the remote.

5. Put the lift into MANUAL MODE (OVERRIDE + UP).

6. Press the OVERRIDE and SET buttons at the same time. This allows you to set

a new Electronic Lower Limit position for the lift.

7. Press and hold the DOWN button until the small wheel bearing on the upper

frame is ½ inch from tripping the lower safety switch (release button before

wheel bearing touches switch) or reaches the desired SERVICE/MAINTENANCE

position (but not so low as to activate the safety switch again!)

8. Press both the OVERRIDE and SET buttons at the same time. This will reset

the electronic lower limit switch.

9. Return the remote to AUTOMATIC MODE (OVERRIDE + STOP).

10. Press the UP button, and allow the lift to travel up to its home position.

11. Operate the lift to verify the Show and Maintenance positions are programmed.

1/17/07

26

Page 27

1/17/07

27

Page 28

Summary of the Remote Control Functions

The OVERRIDE and SET buttons are hidden on the back of the remote control. The

lower button is OVERRIDE and the top button is SET. A straightened paper clip or

similar device will be needed to activate them.

When using the OVERRIDE and SET buttons, these buttons must be pressed first and

released last in the sequence.

To set the show position, press and hold SET, press UP, release UP, and then release

SET.

Automatic Mode:

UP moves lift to the top position, DOWN moves lift to show position, and STOP stops

the motion of the lift.

UP, DOWN, and STOP are functional while the lift is moving.

Manual Mode:

UP and DOWN buttons move the lift only while the buttons are depressed. Unit will stop

at the top limit switch.

STOP stops the motion of the lift at the current position.

OVERRIDE & DOWN from the show position moves the lift to the maintenance position.

OVERRIDE & UP from any position will place the lift into manual mode.

OVERRIDE & STOP terminates the manual mode and returns the lift to automatic mode.

SET & UP sets show position and only works in manual mode.

SET & STOP set the maintenance position and only works in manual mode.

When in the automatic mode, press and hold OVERRIDE, then press STOP & UP

together to place the unit into test mode. This will continually cycle the lift between

home and show positions, pausing at each position. To terminate, press stop.

The NO MOVEMENT switch is located on the control box mounted to the lift frame and

disables all movement of the unit. Remote control buttons become inactive.

EMERGENCY OVERRIDE & UP raises the lift only after the lower safety switch has been

triggered.

Holding the STOP button for 10 seconds will clear the last Communication Code

(blinking LED).

1/17/07

28

Page 29

Programming Maintenance and Show Positions

Put the lift into MANUAL

MODE – Press

OVERRIDE & UP

Press DOWN to lower

lift to desired

Maintenance position

(lift will stop when button

is released)

Set Maintenance

Position

Press SET & UP

Return to AUTO mode

Press OVERRIDE &

STOP. Press UP

button, lift should travel

to home position

To test:

Press OVERRIDE &

DOWN buttons, lift

should travel to position

just set and then stop

Press DOWN to lower

lift to desired Show

position (lift will stop

when button is released)

Set Show Position

Press SET & UP

Return to AUTO mode

Press OVERRIDE &

STOP. Press UP

button, lift should travel

to home position

To test:

Press DOWN button, lift

should travel to position

just set and then stop

If yes, press UP

and lift is ready for

operation

1/17/07

If No, press UP

and start again

If No, press UP

and start again

If yes, press UP

and lift is ready for

operation

29

Page 30

10 second delay

to beginning

beginning

beginning

beginnin

g

beginning

box

sound

problems?

Call DDI

travel upward?

YES: Does the lift

proceed to beginning

release adjustments –

NO: Call DDI for brake

proceed to

control box –

NO: Plug motor into

YES: Is the motor

unit is ready to use

2 BLINKS: Normal –

connector plugged

Indicated by click

YES: Is the brake

releasing properly?

into control box?

have any

mechanical

NO: Does the lift

frame engaged?

NO: Are the safety

switches on the top

control box

replacement

NO: Call DDI for

call DDI

mechanical problems,

YES: If the lift has any

proceed to

jumper past the

YES: Release or

switch, rest power,

box

YES: Plug in the

slot. Call DDI for

replacement parts

NO: Call DDI for

replacement control

box

NO: Call DDI for

replacement control

then call DDI for

YES: Verify wiring

replacement control

beginning

– proceed to

YES: Reset breakers

YES:

Are the circuit

breakers tripped?

NO: Correct wiring

to match schematic

NO: Is the remote

control connected?

NO:

proceed to

Hook up power –

Troubleshooting Chart

1/17/07

– proceed

SOLID LED: no

blinks – Turn No

Movement Switch off

parts

for replacement

motor failure. Call

3 BLINKS: ** dual

YES:

Blinks?

Number of LED

** 2004 or earlier is non-

volatile memory corrupted

sound?

NO: Does the lift

make a click of hum

4 BLINKS:

Does the lift move?

YES:

unplugged?

Is the slot sensor

wheel damaged or

IS THE LED

ACTIVE UPONM

POWER UP? after

YES: Turn lift off,

restore power, turn

lift of and proceed to

line voltage

voltage. Verify low

5 BLINKS: Low AC

call DDI for

6 BLINKS: Safety

switch triggered –

see manual for

override process

7 BLINKS: Safety

switch is triggered –

instructions

NO: Is the unit

receiving power?

Verify w/ voltmeter

30

Page 31

1/17/07

31

Page 32

Warranty

This product is warranted against defects in material and labor for 12 months from the date of shipment

from Display Devices, Inc. Unit must not exhibit previous alterations or repairs except those performed

by an authorized Display Devices dealer, distributor or factory service center.

Exclusions:

Lack of routine maintenance, normal wear and tear, misuse, improper operation or installation, neglect,

abuse or acts of nature.

Fax or mail to:

Display Devices, Inc.

5880 N. Sheridan Blvd.

Arvada, CO 80003

(v) 303-412-0399

(f) 303-412-9346

Company Information:

Name:

Address:

City/State/Zip:

Phone:

Fax:

Dealer purchased through:

Date purchased:

Model #:

Serial #:

Comments:

1/17/07

32

Page 33

Help us help you!

We value your feedback about our products. Any input you can provide will help us

design and build better products for you. Please take a few minutes to answer the

following questions. Use a 1 to 10 scale with 1 being poor to 10 being excellent.

When complete, fax it back to us at 303-412-9346. Thanks for your support!

Product Quality

Appearance of finish

Packaging

Dimensionally correct

Mounting Bracket alignment (if applicable)

Installation

Ease of installation

Understandability of Manual

Customer Service

How was your purchasing experience?

Was the product shipped on time?

Was your order shipped complete?

Product Improvement

Are there any features or options you would like to have available?

If we designed and built a new product for you, what would it be?

What can we do better for you next time?

Order Number

Name Company

Phone Fax

E-mail

1/17/07

33

Loading...

Loading...