Displax SKINFIT User Manual

TECHNOLOGY FOR THE MULTITOUCH GENERATION

MKT.331.1 | DISPLAX SKIN FIT | DISPLAXTM MULTITOUCH TECHNOLOGIES 1

SKIN FIT

USER GUIDE

LARGE MULTITOUCH PROJECTED CAPACITIVE

TECHNOLOGY FOR THE MULTITOUCH GENERATION

MKT.331.1 | DISPLAX SKIN FIT | DISPLAXTM MULTITOUCH TECHNOLOGIES 2

DOCUMENT REVISION HISTORY AND APPROVAL

Release date

Code

Prepared by

Approved by

2017/12/12

MKT.331.1

António Rocha

Nuno Fernandes

Pedro Marques

Pedro Talaia

Tom Kermeen

CONTACT

Displax S.A.

Parque Industrial de Adaúfe

Rua Soldado Manuel Magalhães, 68

4710-167 Braga, Portugal

URL: http://displax.com/

Tel.: +351 253 265 506

e-mail: touch@displax.com

GPS: N 41° 36' 06'' (41.60167); W 08° 24' 38'' (8.41056)

PRODUCT COMPLIANCE

DISPLAX is a certified company under the ISO 9001

standard which establishes the requirements for a

quality management system, meaning that our

R&D, production, support, sales and marketing

processes are organized around quality

management practices to guarantee the

effectiveness of our work and the satisfaction of our

clients.

Our products are compliant with RoHS - Restriction of

Hazardous Substances, meaning that they do not

contain substances which might put at peril the

product users, they are also compliant with the

Electromagnetic Compatibility Directive 2014/30/EU,

meaning that they can be integrated with other

electronic components without provoking

interferences over the regular functionality of other

components or parts.

All our products have the CE certification mark, which

can be ascribed to our products since they are

compliant with RoHS and with the

Electromagnetic Compatibility Directive 2014/30/EU,

and they are developed, manufactured and

supported under a certified quality system.

TECHNOLOGY FOR THE MULTITOUCH GENERATION

MKT.331.1 | DISPLAX SKIN FIT | DISPLAXTM MULTITOUCH TECHNOLOGIES 3

FCC COMPLIANCE – WARNING

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference

that may cause undesired operation.

Changes or modifications not expressly approved by the party responsible

for compliance could void the user's authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by one or

more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that

to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

TECHNOLOGY FOR THE MULTITOUCH GENERATION

MKT.331.1 | DISPLAX SKIN FIT | DISPLAXTM MULTITOUCH TECHNOLOGIES 4

ABOUT SKIN FIT .......................................................................................... 6

PRE-INSTALLATION .......................................................................................... 6

SKIN FIT SPECIFICATIONS .......................................................................... 6

TOUCH SENSOR ......................................................................................... 8

TOUCH CONTROLLER ................................................................................. 9

FLEXIBLE FLAT CABLE (FFC) ..................................................................... 10

INTEGRATION BETWEEN THE TOUCH CONTROLLER AND THE FLEXIBLE

FLAT CABLE (FFC) .................................................................................... 10

UNPACK THE PRODUCT ........................................................................... 11

OVERVIEW ..................................................................................................... 11

RESOURCES NEEDED .................................................................................... 11

WORK PROCEDURE ...................................................................................... 11

LAMINATION ............................................................................................ 13

OVERVIEW ..................................................................................................... 13

PERMANENT VERSION .................................................................................. 13

OBJECTIVE ..................................................................................................... 13

PEOPLE REQUIRED ........................................................................................ 13

RESOURCES NEEDED .................................................................................... 13

INSTALLATION PROCEDURE ......................................................................... 14

LAMINATION QUALITY .................................................................................. 23

REMOVABLE VERSION .................................................................................. 24

PRODUCT SERIAL NUMBER ........................................................................... 26

INTEGRATION GUIDE ............................................................................... 27

MOUNTING THE GLASS WITH THE TOUCH SENSOR ON A DISPLAY .......... 27

INTEGRATING THE TOUCH CONTROLLER ................................................... 29

INTEGRATION EXEMPLIFICATION: ................................................................ 31

CONNECTING THE SKIN TOUCH CONTROLLER .......................................... 33

DISPLAX CONNECT ................................................................................. 34

OVERVIEW ..................................................................................................... 34

MINIMUM REQUIREMENTS ............................................................................ 34

DISPLAX CONNECT DOWNLOAD ............................................................... 34

HOW TO INSTALL: WINDOWS 7 OR HIGHER ............................................... 35

HOW TO UNINSTALL: WINDOWS 7 OR HIGHER .......................................... 38

HOW TO INSTALL: MAC OS X ....................................................................... 39

HOW TO UNINSTALL: MAC OS X ................................................................. 39

HOW TO INSTALL: UBUNTU ........................................................................... 40

HOW TO UNINSTALL: UBUNTU ...................................................................... 41

HOW TO USE ‘DISPLAX CONNECT’ ............................................................. 43

KEYBOARD SHORTCUTS ................................................................................ 49

MULTIPLE DEVICES ........................................................................................ 50

HOW TO CONFIGURE ................................................................................... 51

CONFIGURATION WIZARD ........................................................................... 51

MANUAL CONFIGURATION ......................................................................... 60

GEOMETRIC CALIBRATION .......................................................................... 63

ADVANCED GEOMETRIC CALIBRATION .................................................... 64

ADVANCED CALIBRATION – DRAG MODE ............................................... 66

TOUCH INJECTION STATUS ........................................................................... 69

SECURITY PIN ................................................................................................. 70

TOUCH TEST ................................................................................................... 71

TECHNOLOGY FOR THE MULTITOUCH GENERATION

MKT.331.1 | DISPLAX SKIN FIT | DISPLAXTM MULTITOUCH TECHNOLOGIES 5

NUMBER OF TOUCHES .................................................................................. 74

OPTIMIZATION ............................................................................................... 75

PALM AND ARM DETECTION ....................................................................... 76

SENSOR .......................................................................................................... 79

LOAD & SAVE TOUCH CONTROLLER SETTINGS ......................................... 86

TUIO ................................................................................................................ 87

OBJECT RECOGNITION ................................................................................ 88

TOUCH CONTROLLER FIRMWARE UPDATE ................................................. 92

LOAD TOUCH CONTROLLER FIRMWARE .................................................... 95

DISPLAX CONNECT UPDATE ........................................................................ 98

FACTORY RESET ........................................................................................... 101

PRESSURE DETECTION ................................................................................. 102

MULTI MONITOR CALIBRATION ................................................................. 103

HOW TO USE WITH OTHER OPERATING SYSTEMS ..................................... 105

WARRANTY ............................................................................................ 107

TECHNOLOGY FOR THE MULTITOUCH GENERATION

MKT.331.1 | DISPLAX SKIN FIT | DISPLAXTM MULTITOUCH TECHNOLOGIES 6

ABOUT SKIN FIT

PRE-INSTALLATION

Please check the packing list that was sent to you together with your Skin Fit

unit(s) and make sure that you received all the components, namely: Touch

Sensor; Touch Controller; Ground cable; USB cable and the Packing list.

Always be very careful when handling Skin Fit, as the Touch Sensor is fragile.

‘DISPLAX Connect’, the Control Panel where Skin Fit is configured, runs on

Windows (7 or higher versions), OS X (Yosemite and El Capitan) and Ubuntu

(14.04. LTS) and requires the graphic card to support Open GL 2 or higher.

After configuring Skin Fit, the settings are stored in the Touch Controller, so you

can switch to a PC with another Operating System. See the Spec File for the

list of supported OS.

If you are using a laptop, make sure to plug the power adapter. Running with

a laptop using only the battery has shown that it does not always provide

enough power to the USB port for Skin Fit to work properly.

Avoid using frontal USB ports on desktop PCs. Traditionally these ports do not

comply with USB standards and may not provide enough power for Skin Fit to

run properly.

SKIN FIT SPECIFICATIONS

Skin Fit outlook:

a) High speed

b) Versatile and adaptable product

c) Wide range of glass thickness

d) Features XTR-Shield™ Plus, the most advanced generation of

DISPLAX’s proprietary noise filtering technology

Benefits:

a) Superb touch experience

b) Wide variety of application and use

c) Versatility and ease of integration

d) Highly customizable

Key features:

a) Flexible projected capacitive sensor

b) 40 simultaneous touches

c) 5 milliseconds response time

d) Works up to 15 mm glass thickness

e) HID (Human Interface Device) – works with a wide range of Operating

Systems

f) XTR-Shield™ Plus – Most advanced noise filtering technology

TECHNOLOGY FOR THE MULTITOUCH GENERATION

MKT.331.1 | DISPLAX SKIN FIT | DISPLAXTM MULTITOUCH TECHNOLOGIES 7

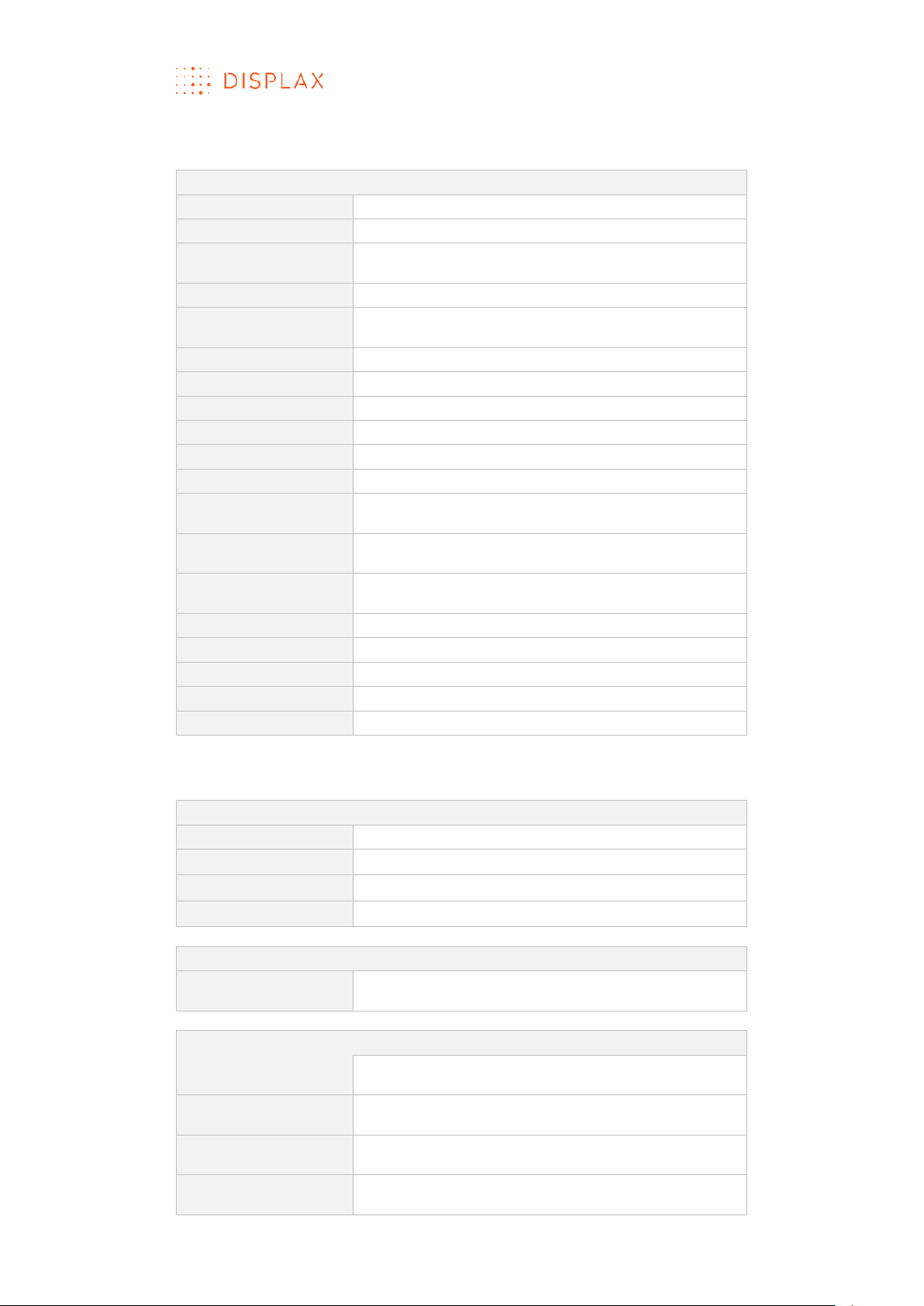

Specifications:

GENERAL

Detection method

Projected Capacitive Technology

Input method

Finger and gloved finger

Number of

simultaneous touches

40

Sensor thickness

100 micron transparent polymer

Noise Shielding

DISPLAX XTR-Shield™ Plus, a proprietary noise

filtering technology

Sizes

20’’ to 105’’

Aspect ratio

16:9, 4:3, custom formats

Controller

Printed circuit board with mini USB connector

Adhesive

Permanent, removable

Substrate

Float Glass, Gorilla Glass

Interface

HID

OS with multitouch

Windows 10, 8, 7*, Ubuntu 12.04, Linux**, Android**,

Chrome OS ***

OS with single touch

Mac OS X Yosemite (multitouch support through

TUIO bridge)

OS with mouse

emulation

Spinetix Media Player HMP 200, Samsung SSP D

Series

Data connectivity

USB 2.0

Touch accuracy

0,53% of sensor diagonal

Sensor weight

260 g

Controller weight

42 g

USB cable length

2 m

*Home Premium SP1; Professional SP1; Ultimate x64 SP1

** Depending on kernel and multitouch support.

*** 39.0.2171.85(64-bit)

PERFORMANCE

Substrate thickness

Up to 15 mm

Touch response

5 milliseconds

Finger separation

2,64% of sensor diagonal

Calibration

Available using control panel: no drift

POWER CONSUMPTION

Average power

consumption (P)

USB powered @ 5 V

Operation consumption: 250 mA

RELIABILITY

Operating

temperature range

-20 °C to 70 °C

Storage temperature

range

-40 °C to 135 °C

Operating humidity

range

0% to 96%

Storage humidity

range

0% to 100%, except controller

TECHNOLOGY FOR THE MULTITOUCH GENERATION

MKT.331.1 | DISPLAX SKIN FIT | DISPLAXTM MULTITOUCH TECHNOLOGIES 8

Touch Sensor life time

expectancy

Unlimited

Touch Controller life

time expectancy

1 million hours

Warranty

2 years

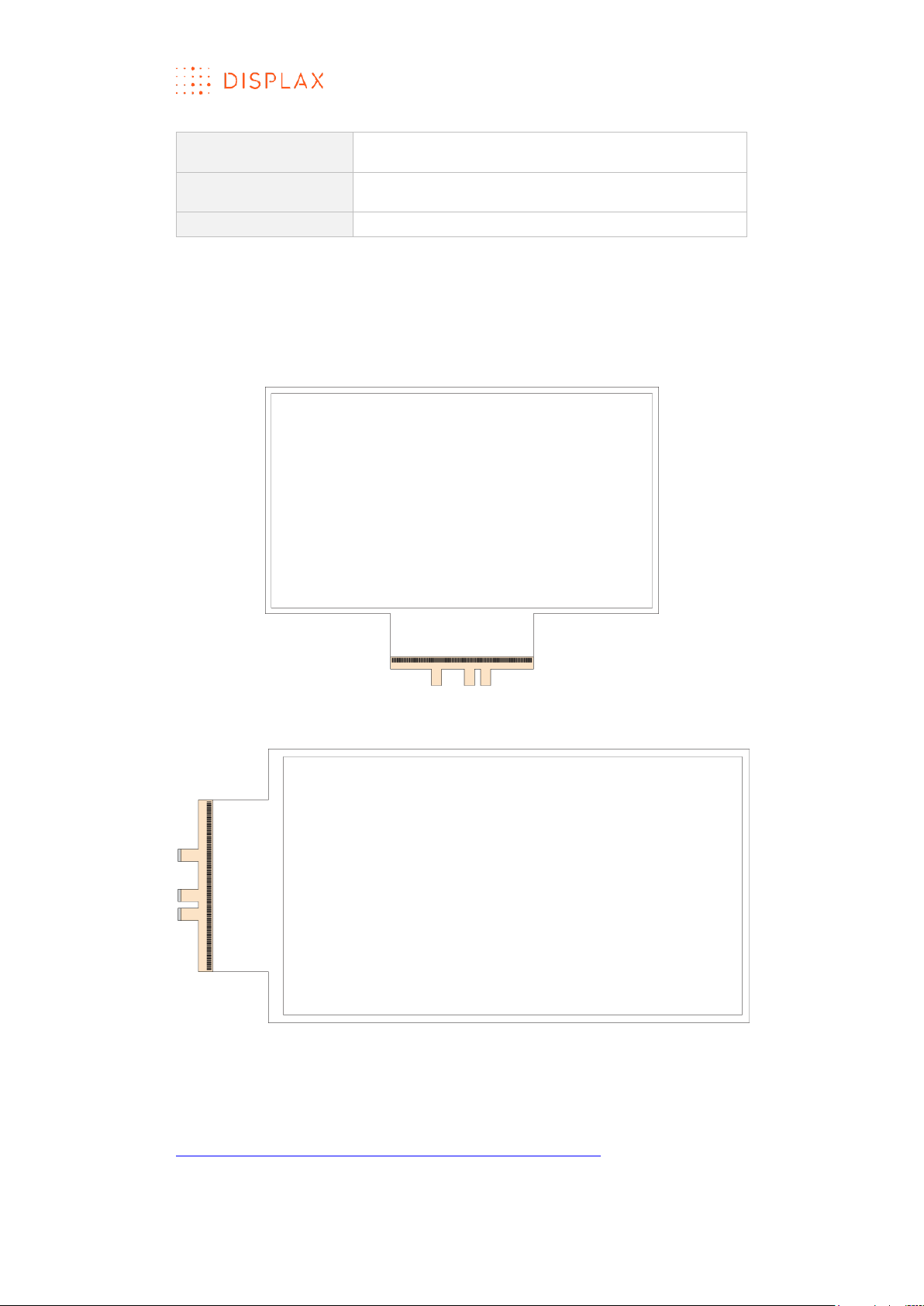

TOUCH SENSOR

The Touch Sensor is composed of a transparent polymer film with a

conductive grid and 1 polyester film Flexible Flat Cable.

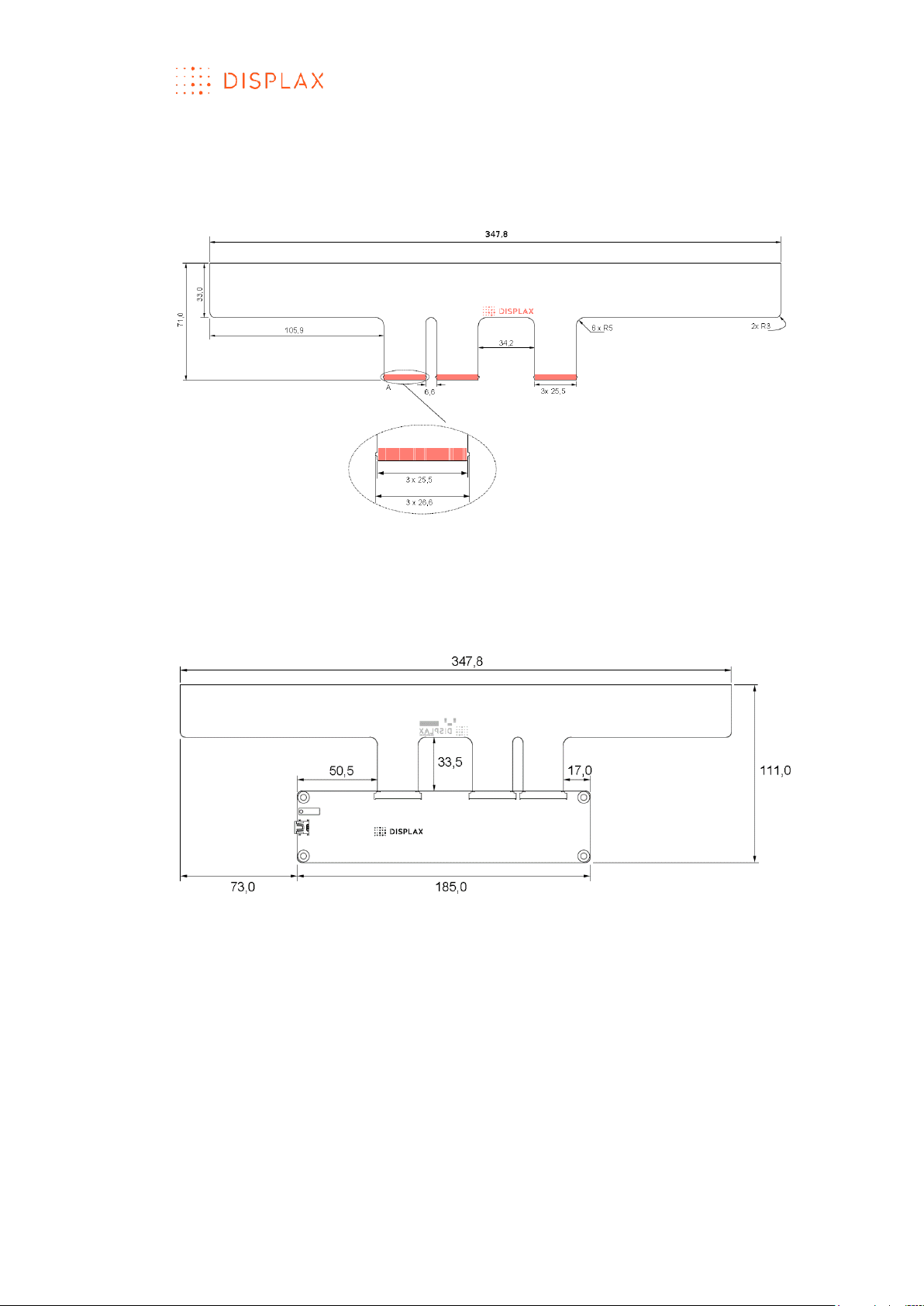

Skin Fit – Touch Sensor, bottom tail version

Skin Fit – Touch Sensor, side tail version

For more information, refer to DISPLAX Skin Fit Standard Drawings document,

available for download in the following link:

http://login.displax.com/?op=20&id_item=4906&id_file=0

TECHNOLOGY FOR THE MULTITOUCH GENERATION

MKT.331.1 | DISPLAX SKIN FIT | DISPLAXTM MULTITOUCH TECHNOLOGIES 9

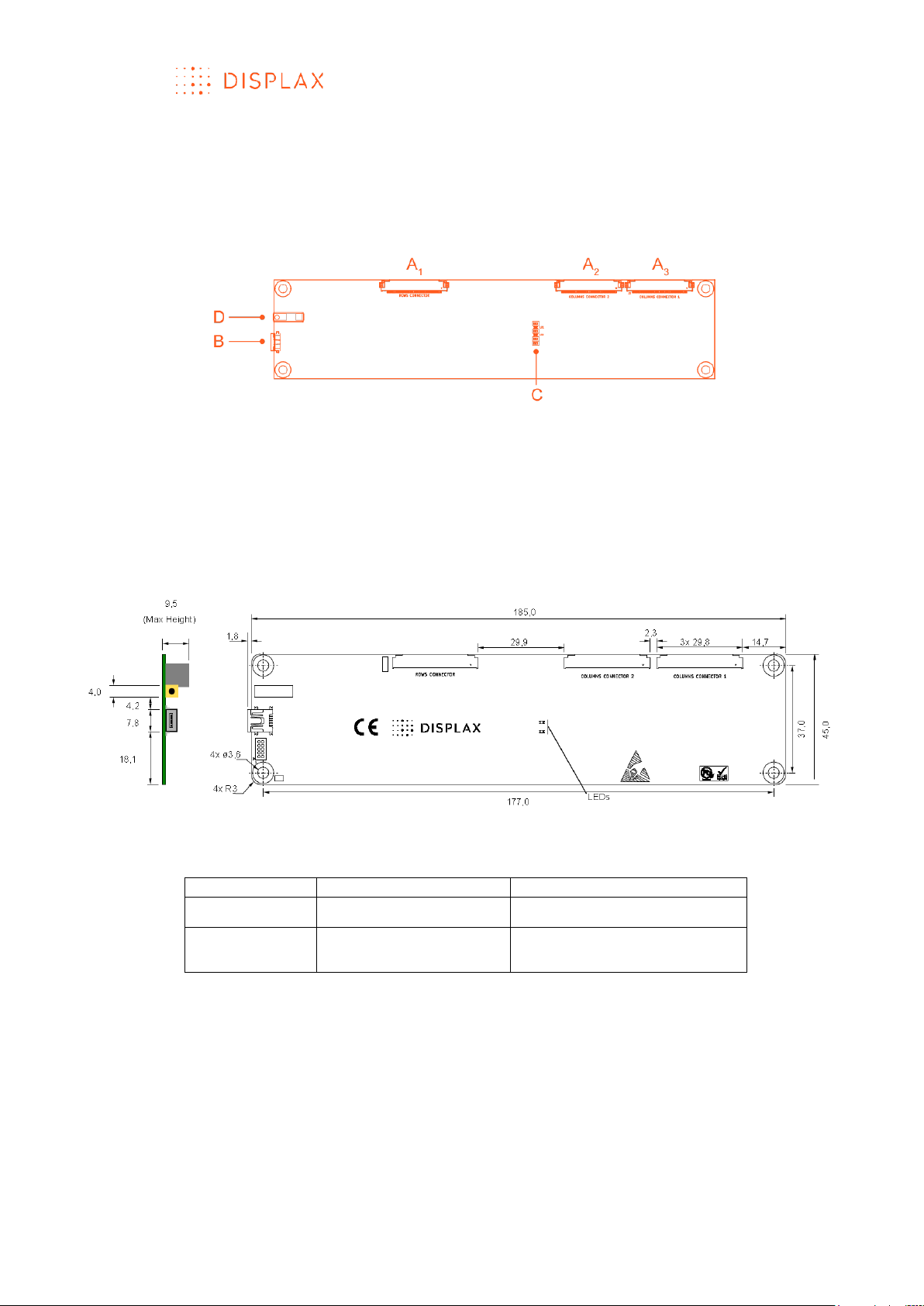

TOUCH CONTROLLER

The Touch Controller is a fiberglass board of 185 x 45 x 9,5mm.

The screw holes are M3 or M3.5.

A1 / A2 / A3– Flexible Flat Cable (FFC) Connector

B – Mini USB Port

C – LEDs

D – Ground cable port

Touch Controller dimensions:

Touch Controller led status

Led status

Normal Operation (HID)

Device Firmware Update

Red led

Fast blinking

On

Orange led

On with touch

Off without touch

Slow blinking

TECHNOLOGY FOR THE MULTITOUCH GENERATION

MKT.331.1 | DISPLAX SKIN FIT | DISPLAXTM MULTITOUCH TECHNOLOGIES 10

FLEXIBLE FLAT CABLE (FFC)

FFC dimensions:

INTEGRATION BETWEEN THE TOUCH CONTROLLER AND

THE FLEXIBLE FLAT CABLE (FFC)

TECHNOLOGY FOR THE MULTITOUCH GENERATION

MKT.331.1 | DISPLAX SKIN FIT | DISPLAXTM MULTITOUCH TECHNOLOGIES 11

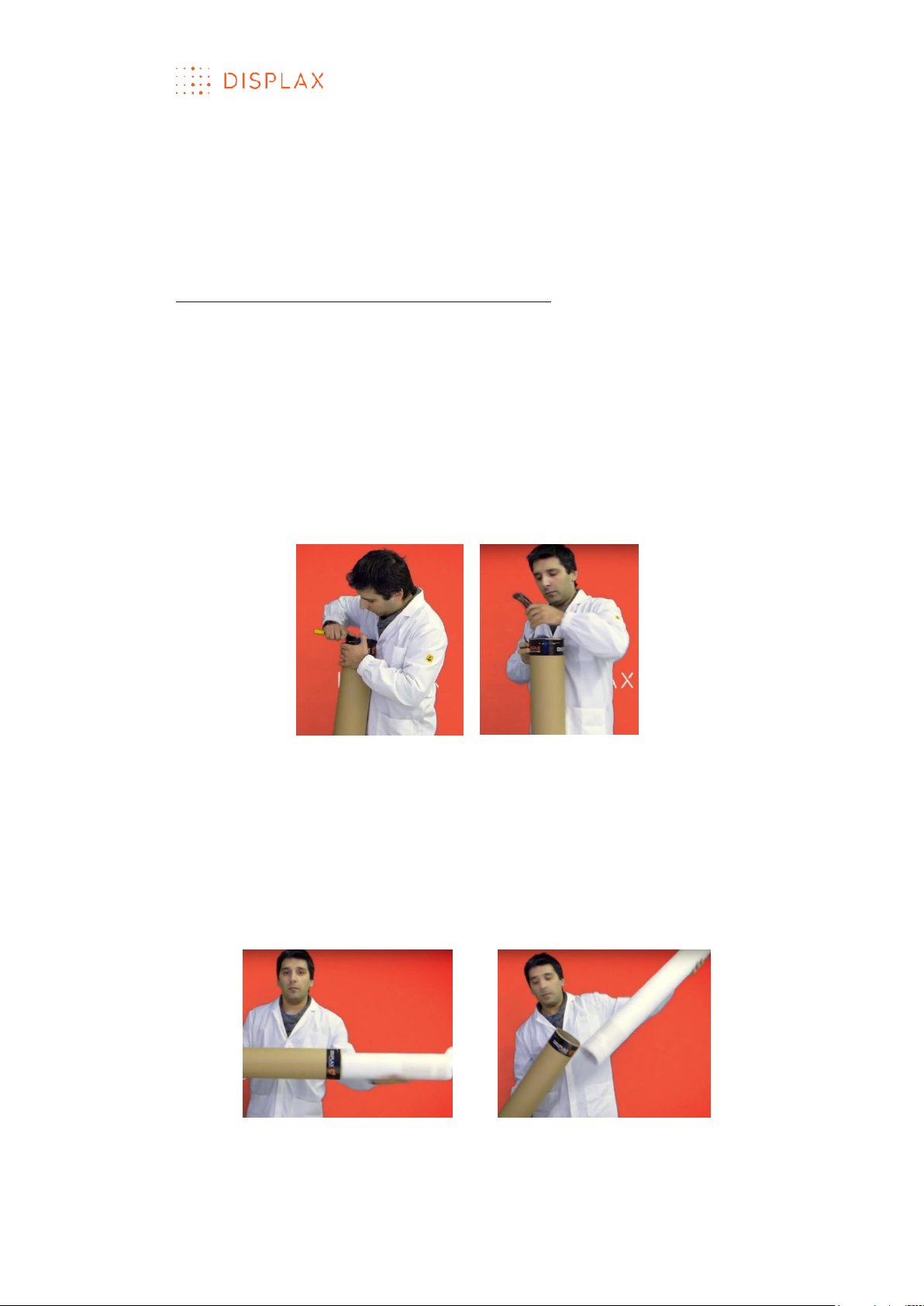

UNPACK THE PRODUCT

OVERVI EW

This section provides a step by step guide on how to unpack the Skin product,

before its lamination.

Watch the unpacking video:

https://www.youtube.com/watch?v=ePth5KP0L8k

Note: Your product may present a different design from the one presented

in this user guide and instruction video.

RESOURCES NEEDED

A cutter and a clean plain table.

WORK PROCEDURE

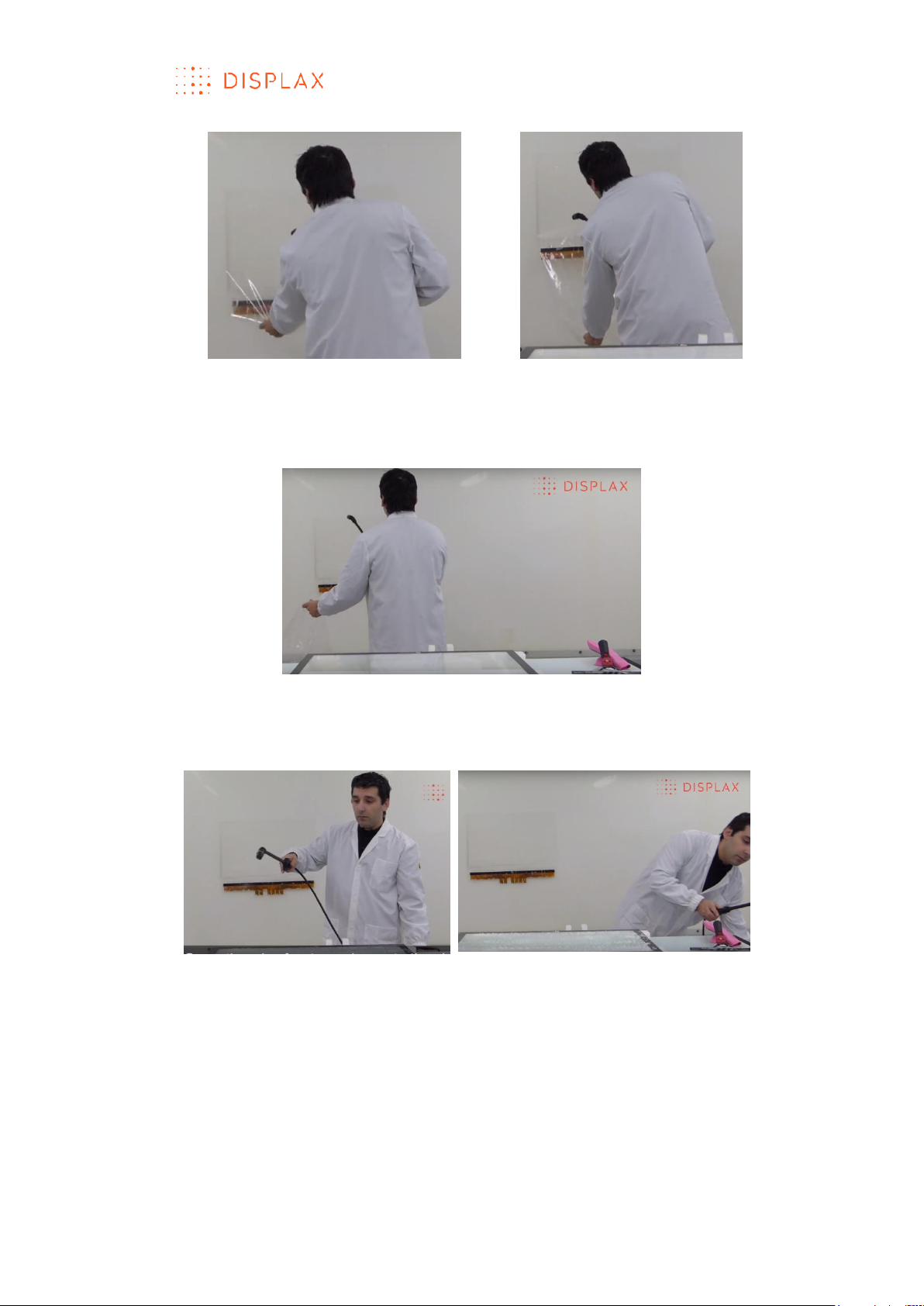

1. Open the tube from the top side with the help of a cutter (Fig.1).

Fig.1

2. The touch sensor is wrapped around an inner tube inside the main tube.

Remove all the items inside the inner tube:

1. Touch controller(s);

2. USB and Ground cables;

3. Packing list.

3. Remove the inner tube (Fig.2):

Fig.2

TECHNOLOGY FOR THE MULTITOUCH GENERATION

MKT.331.1 | DISPLAX SKIN FIT | DISPLAXTM MULTITOUCH TECHNOLOGIES 12

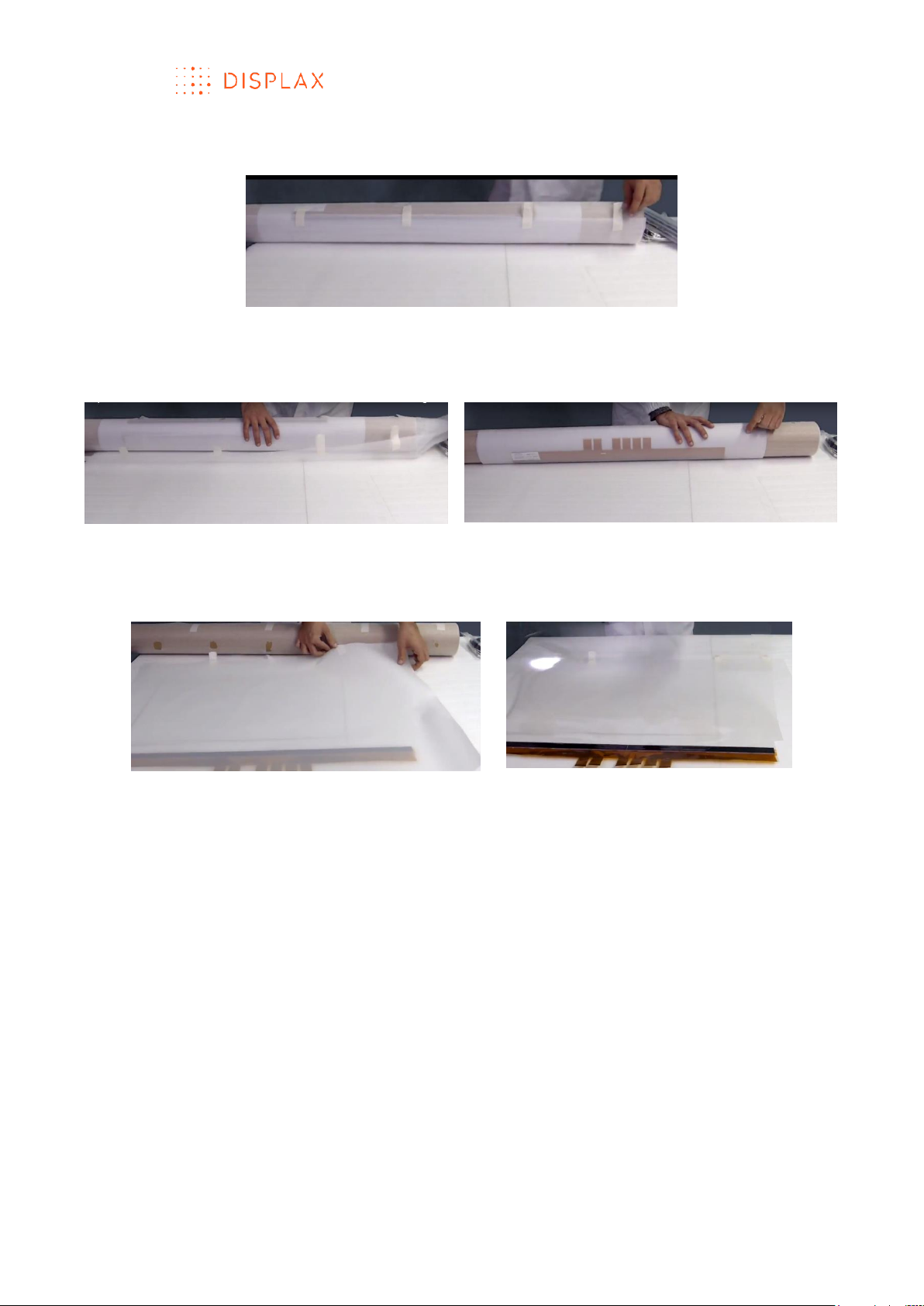

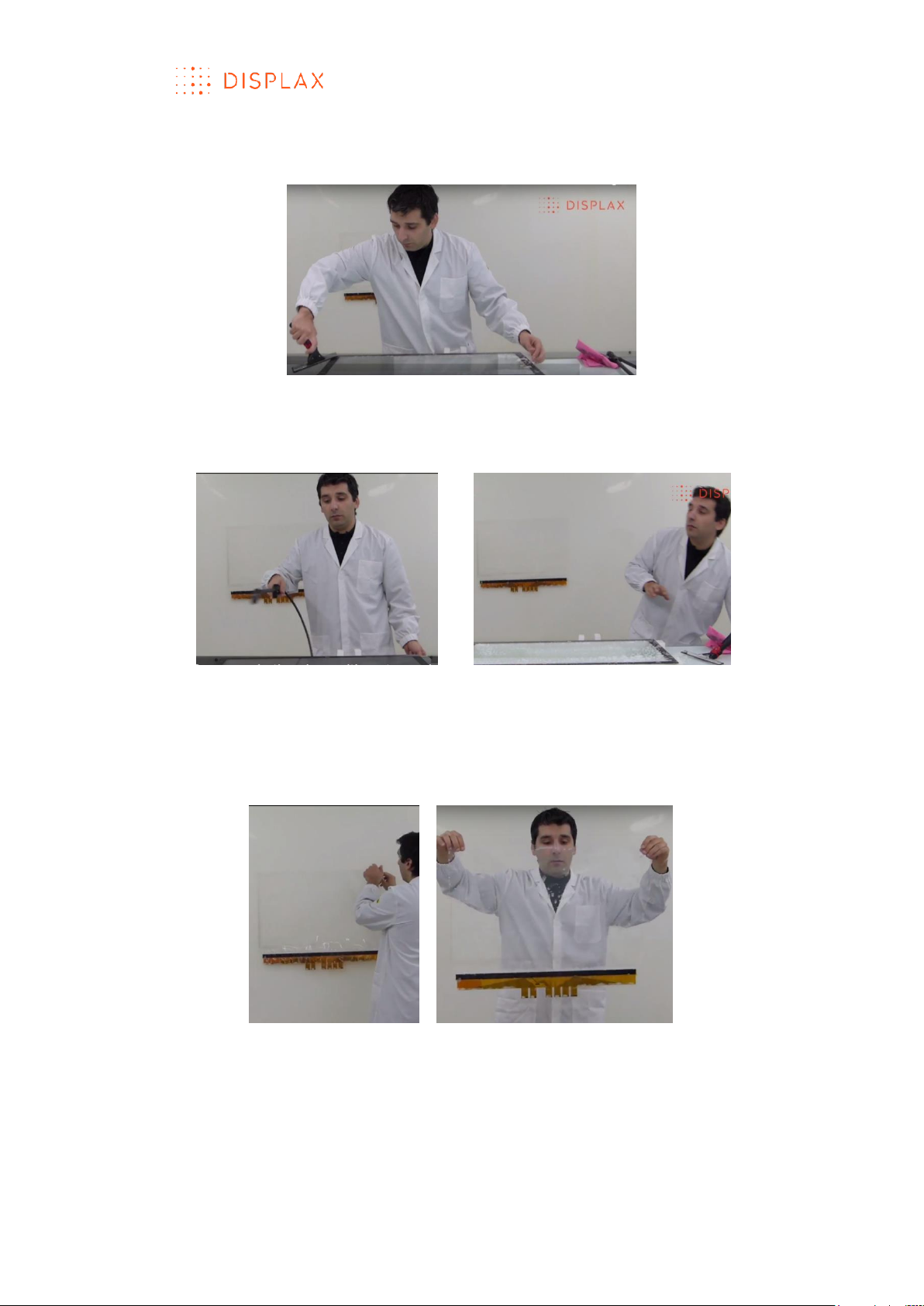

4. Unroll the Touch Sensor on top of a flat clean table (Fig. 3).

Fig. 3

a) Detach all the stickers to remove the foam layer (Fig.4);

b) Unroll the touch sensor over the table (Fig.5);

Fig.4

Fig.5

c) Detach the remaining stickers (Fig.6);

d) Free the unrolled touch sensor from the foam and other protection

layers (Fig.7).

Fig.6

Fig.7

TECHNOLOGY FOR THE MULTITOUCH GENERATION

MKT.331.1 | DISPLAX SKIN FIT | DISPLAXTM MULTITOUCH TECHNOLOGIES 13

LAMINATION

OVERVI EW

The Touch Sensor must be laminated on a non-conductive substrate, such as

glass, acrylic plate, corian, wood, mirror or other material, or surface where

we want to process multitouch recognition events.

The Touch Sensor of Skin Ultra has a permanent adhesive, which means that

after its lamination you cannot remove it and reuse it.

The Touch Sensor of Skin Fit and Skin Dualtouch is available in two versions:

permanent and removable.

The permanent version after lamination cannot be removed and reused.

The permanent version is the most common Touch Sensor version.

The removable version can be removed from the substrate where it has been

laminated and reapplied to a different substrate, as long as you remove it

gently and carefully to avoid damaging the Touch Sensor grid.

This section describes how to laminate the permanent and removable Touch

Sensor versions.

For the permanent version, a video has been created to enhance our

understanding of this procedure.

URL: https://www.youtube.com/watch?v=X4u-SKIjR9g

PERMANENT VERSION

OBJECTIVE

To laminate the Touch Sensor on a non-conductive substrate.

This description has been illustrated using ‘Glass’ but other non-conductive

substrates can be used.

PEOPLE REQUIRED

One person is required to perform the lamination on glass if the sensor has less

than 32 inches.

It is advisable involving a second person to support the lamination activities,

especially for Touch Sensors exceeding 32 inches. In this case, both persons

will pick up the Touch Sensor, one on each side, to avoid creasing and

tearing the sensor grid.

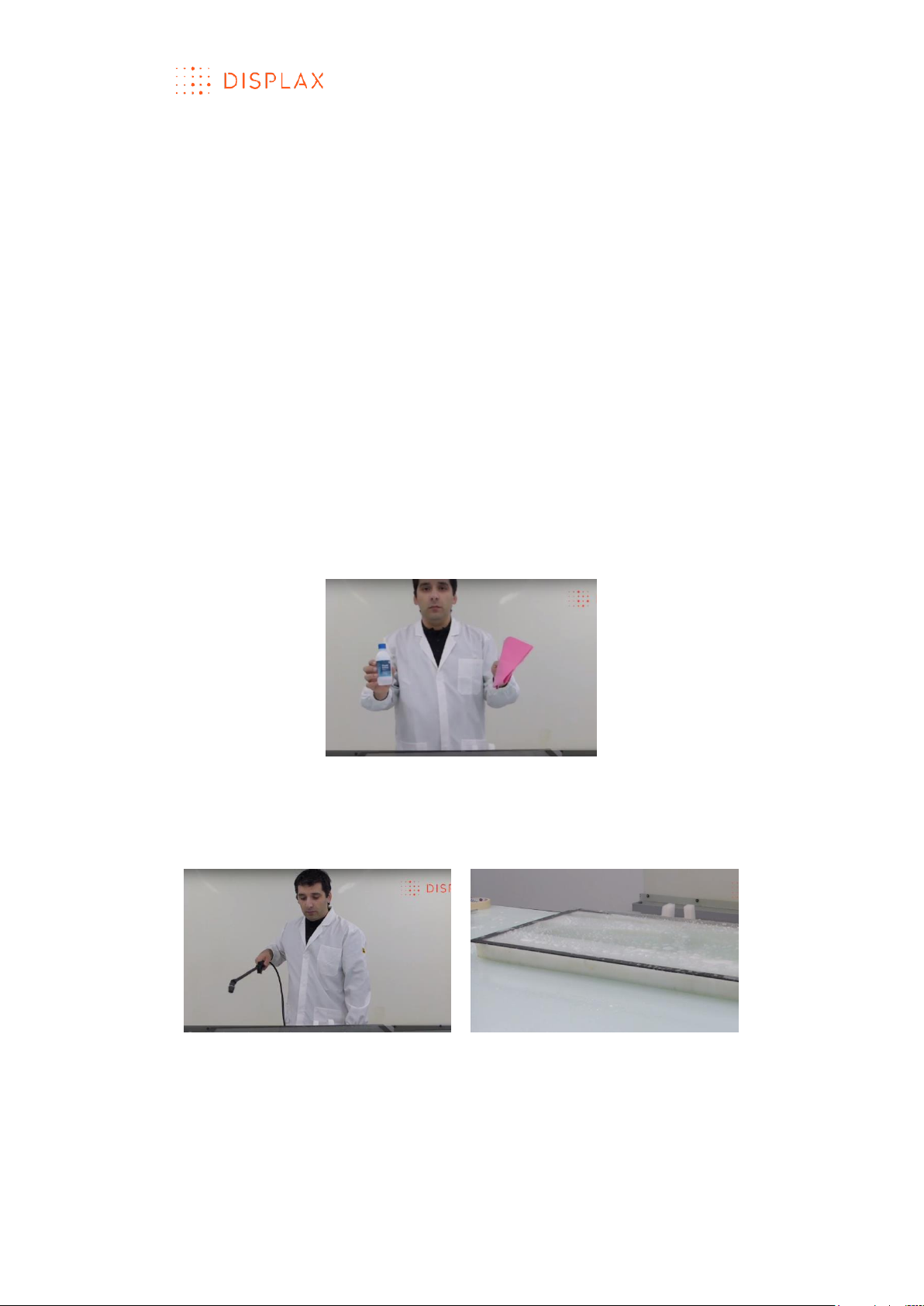

RESOURCES NEEDED

Before starting the Touch Sensor lamination, make sure you have the

following tools and equipment:

Soft cleaning lint free cloths;

Ethylic alcohol;

Dishwashing detergent with a neutral pH;

Distilled or bottled water;

Liquid sprayer, containing a solution with distilled or bottled water and

about 10% of the dishwashing detergent with a neutral pH, hereafter

referred as soapy water;

TECHNOLOGY FOR THE MULTITOUCH GENERATION

MKT.331.1 | DISPLAX SKIN FIT | DISPLAXTM MULTITOUCH TECHNOLOGIES 14

Squeegee;

X-acto or blade.

Scratch free surface to laminate the Touch Sensor on glass.

INSTALLATION PROCEDURE

The Touch Sensor must be handled carefully to avoid creasing or tearing.

Rippling may occur during delivery, but this will disappear during the

lamination process.

Always lay the Touch Sensor on a soft scratch free surface.

After unpacking the Touch Sensor, laminate it on a non-conductive substrate.

In here, the lamination process is illustrated using ‘Glass’.

To laminate the Touch Sensor, please refer to the following steps:

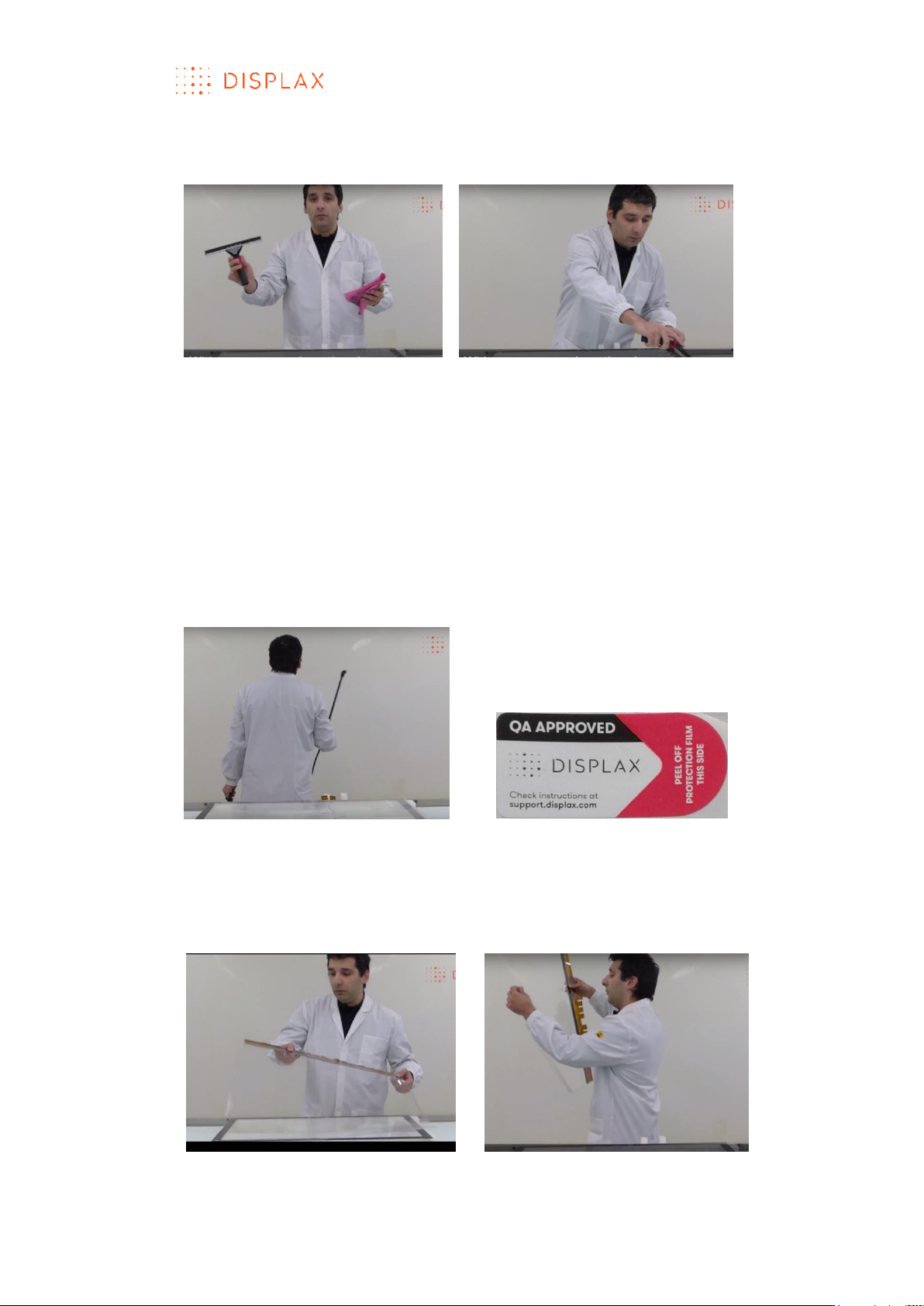

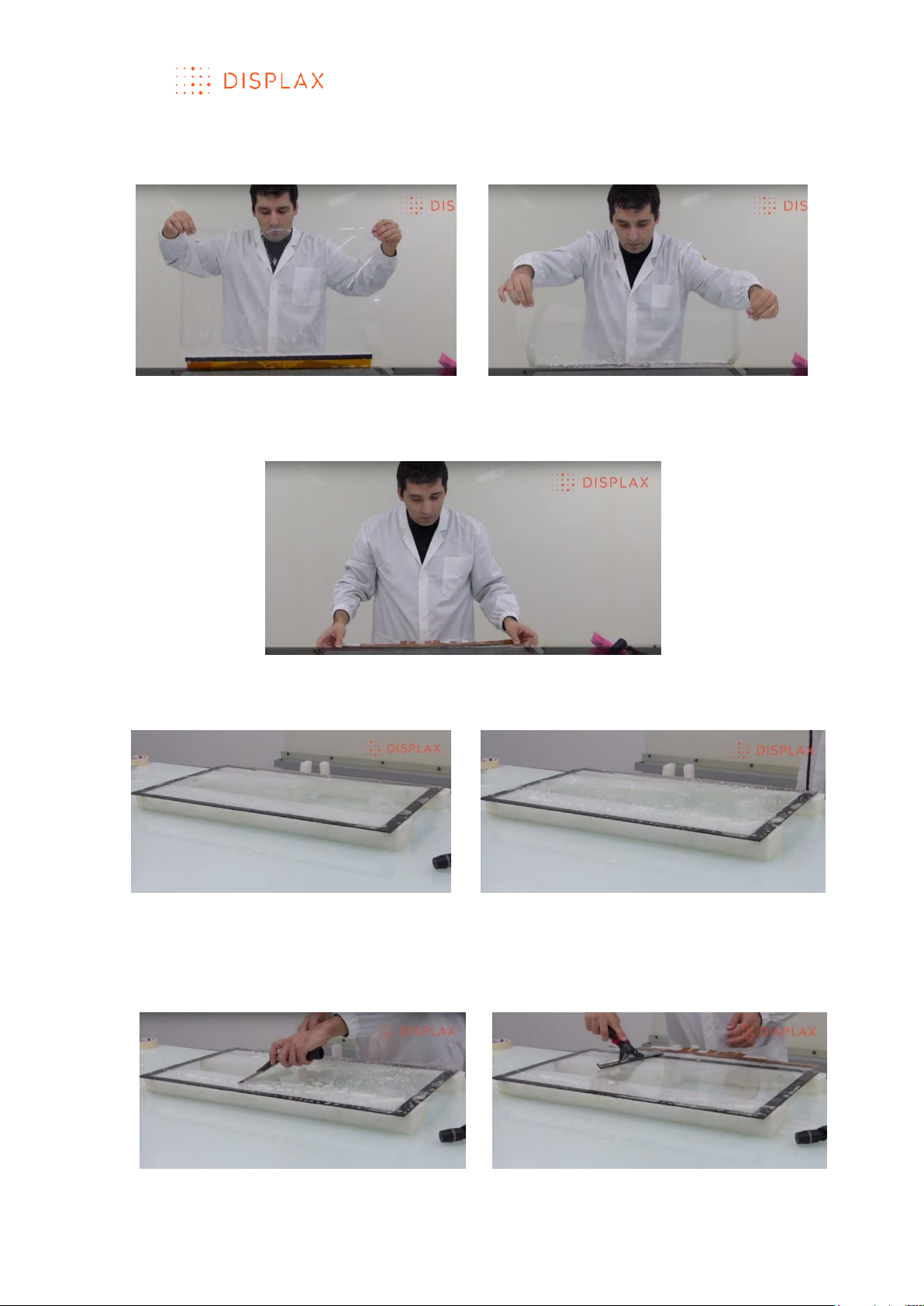

1. Clean the glass

Dirt and other contaminants allow pockets of air that undermine the

necessary seal for a good installation. Thoroughly clean the glass, with a lint

free cloth and ethylic alcohol, making sure it is free of dust, oils or grease

(Fig.1).

Fig.1

After cleaning the glass spray it with the mentioned solution containing

distilled or bottled water and about 10% of the dishwashing detergent with a

neutral pH (Fig.2).

Fig.2

TECHNOLOGY FOR THE MULTITOUCH GENERATION

MKT.331.1 | DISPLAX SKIN FIT | DISPLAXTM MULTITOUCH TECHNOLOGIES 15

Use a squeegee to remove the water (Fig.3),

Be sure that the glass is completely clean.

Fig.3

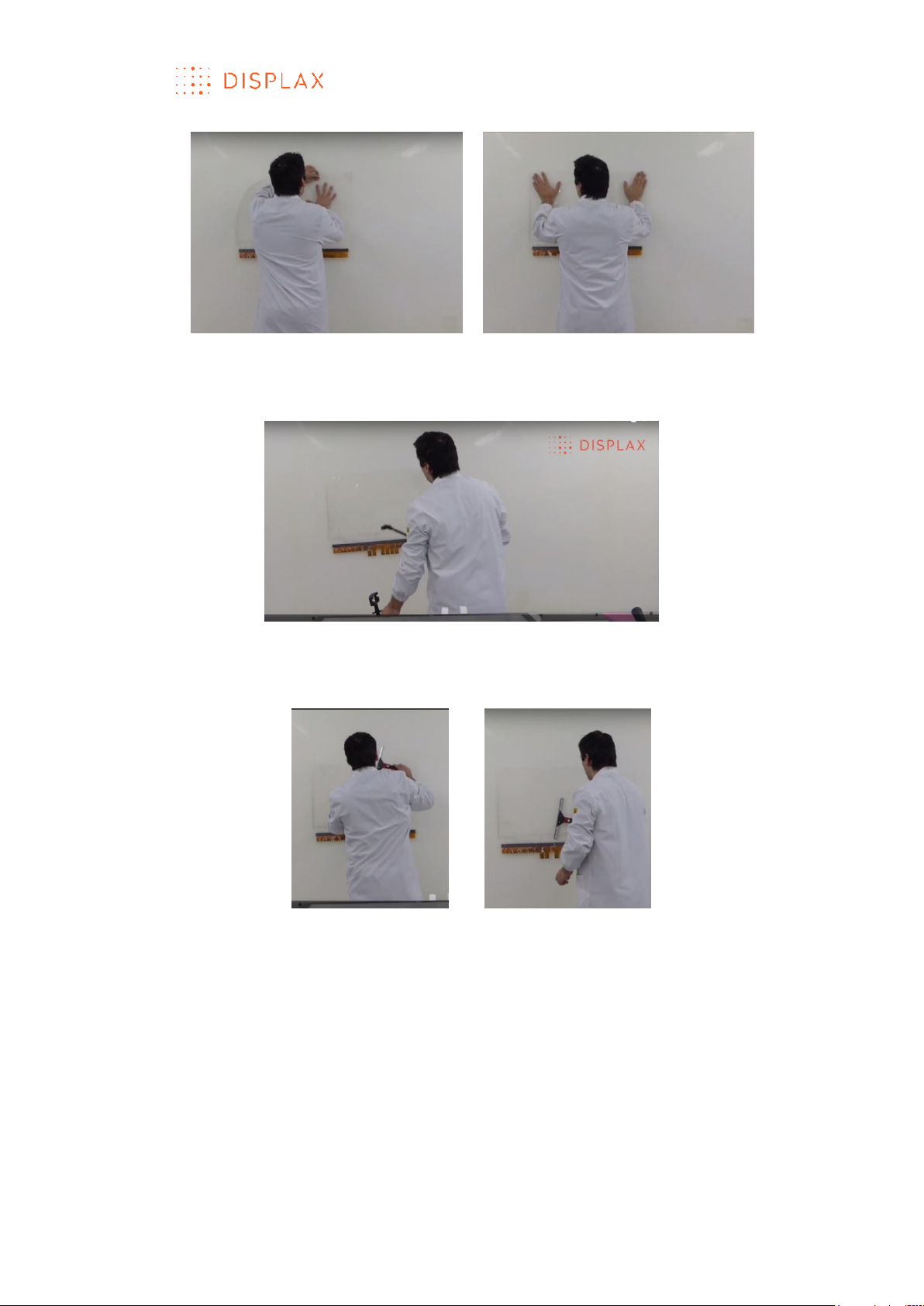

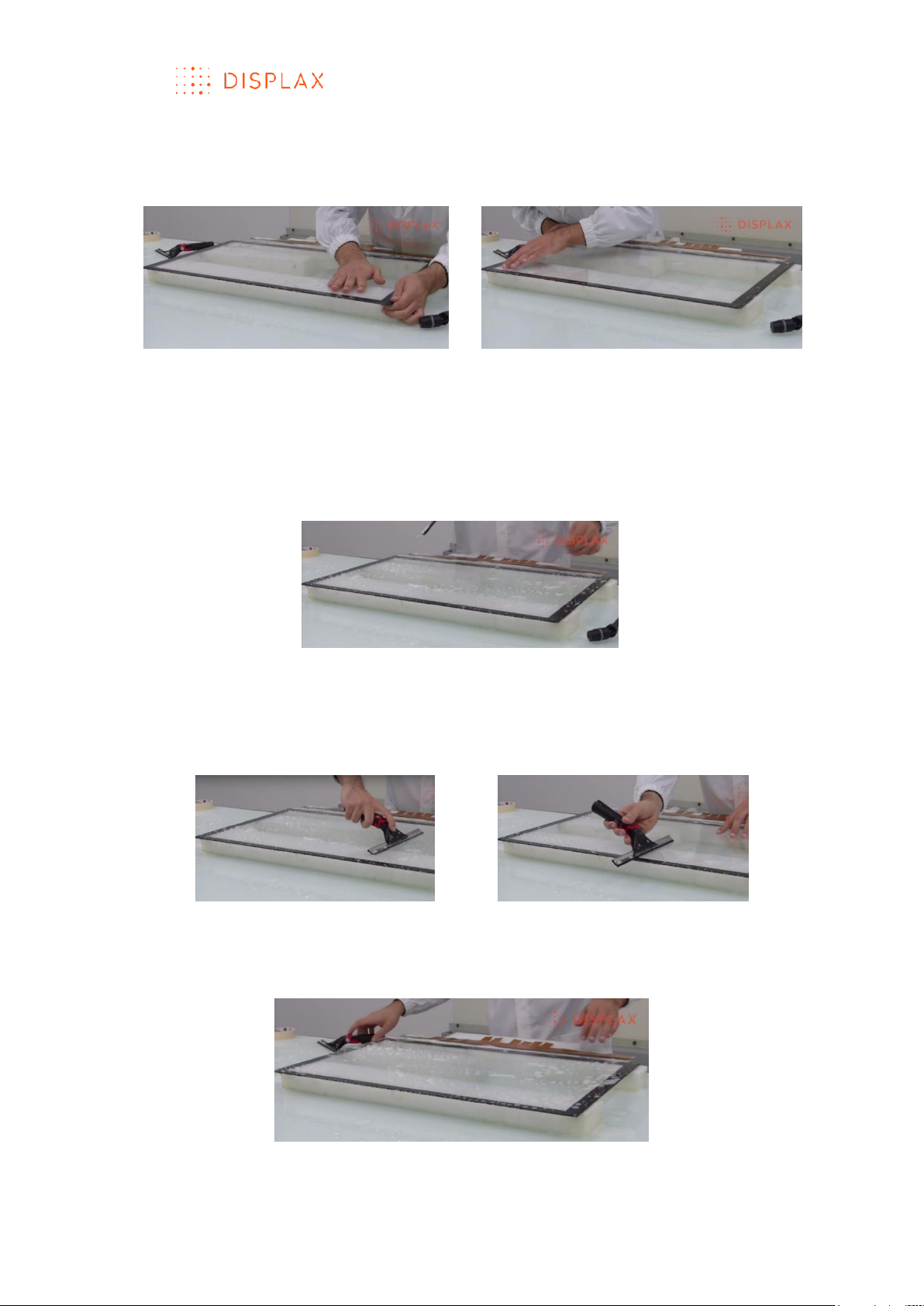

2. Peel off the Touch Sensor protection layer.

To peel off the Touch Sensor protection layer, you can either use:

a) a lamination wall, or

b) a clean and scratches free table.

In this work instruction a lamination wall has been used (Fig.4).

When using a table, the process is exactly the same but the operations are

executed in the horizontal position.

3. Wet the lamination wall with soapy water in order to adhere the Touch

Sensor to the wall (Fig.4)

Fig.4

Fig.5

4. Pick the Touch Sensor and stick it to the lamination wall with the protection

layer facing the user view (Fig.6 and 7). This layer is the one which has a sticker

“QA APPROVED” (Fig.5), signaling the layer to be removed;

Fig.6

TECHNOLOGY FOR THE MULTITOUCH GENERATION

MKT.331.1 | DISPLAX SKIN FIT | DISPLAXTM MULTITOUCH TECHNOLOGIES 16

Fig.7

5. Apply soapy water to the Touch Sensor to ensure its adherence to the

lamination wall (Fig.8).

Fig.8

6. With a squeegee, remove some of the soapy water, to secure the sensor

on the lamination wall (Fig.9).

Fig.9

TECHNOLOGY FOR THE MULTITOUCH GENERATION

MKT.331.1 | DISPLAX SKIN FIT | DISPLAXTM MULTITOUCH TECHNOLOGIES 17

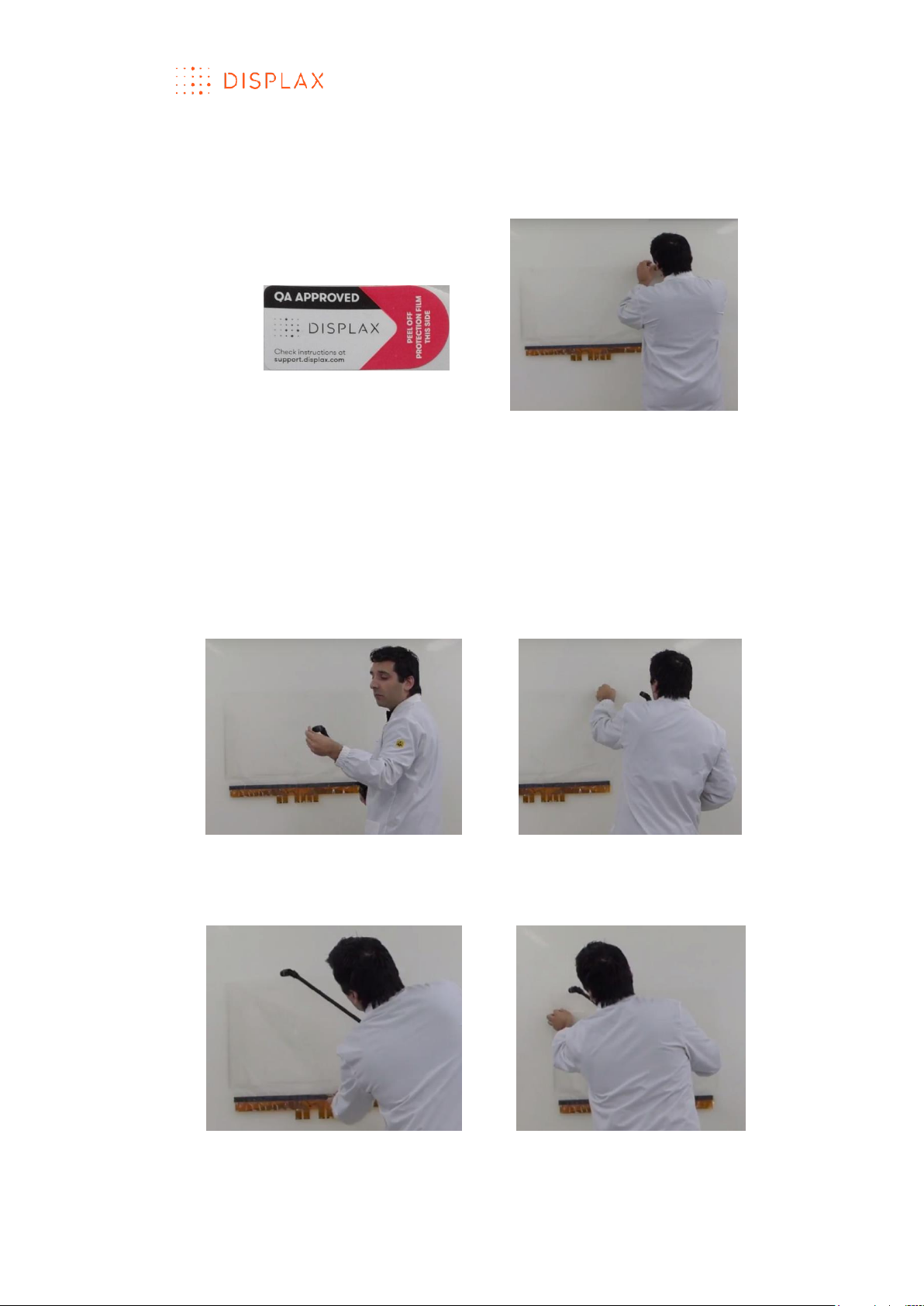

7. With the help of the “Quality approved” sticker remove the Touch Sensor

protection layer (Fig.10).

The “Quality approved” sticker is placed over one edge of the protection

layer and will help us lift and pell-off this protection cover.

Fig.10 With the help of the “Quality approved” sticker peel the Touch Sensor

protection layer

8. Pell-off the Touch Sensor protection layer while continuously spraying soapy

water and pulling-off the protection layer.

To perform this task, wet your fingers (Fig.11) and carefully release the

protection layer from the user side.

While you remove the protection layer, spray the adhesive surface with the

soapy water solution (Fig. 12, 13 and 14). It is important to pull back the liner

close to the Touch Sensor.

Fig.11 Be sure that your fingers are wet

Fig.12 Start peeling off the protection

layer by pulling the sticky tape

together with the protection layer

Fig.13 Gently pull the sensor protection layer while applying soapy water to the Touch

Sensor glue side

TECHNOLOGY FOR THE MULTITOUCH GENERATION

MKT.331.1 | DISPLAX SKIN FIT | DISPLAXTM MULTITOUCH TECHNOLOGIES 18

Fig.14 Pull the protection layer and apply soapy water until removing it completely.

9. Spray soapy water over the Touch Sensor glue area after removing its

protection (Fig.15)

Fig.15

10. Spray soapy water over the glass where the Touch Sensor lamination will

be performed (Fig.16)

Fig.16

TECHNOLOGY FOR THE MULTITOUCH GENERATION

MKT.331.1 | DISPLAX SKIN FIT | DISPLAXTM MULTITOUCH TECHNOLOGIES 19

11. Clean the glass using a squeegee

Be sure that the glass is completely clean (Fig.17)

Fig.17

12. Before starting the Touch Sensor lamination spray the glass with soapy

water (Fig.18)

Fig.18

13. Carefully and gently detach the Touch Sensor from the lamination wall

(Fig.19)

If the Touch sensor has more than 32’’ two people may be required to avoid

creasing and tearing the sensor grid.

Fig.19

TECHNOLOGY FOR THE MULTITOUCH GENERATION

MKT.331.1 | DISPLAX SKIN FIT | DISPLAXTM MULTITOUCH TECHNOLOGIES 20

14. Position the Touch Sensor and apply its glue side on top of the wet glass

(Fig.20)

Fig.20

15. Gently and carefully align the Touch Sensor to the glass surface (Fig.21)

Fig.21

16. Spray the touch sensor on glass with soapy water (Fig.22)

Fig.22

17. Use the squeegee to laminate the Touch Sensor to the glass by lightly and

gently removing the soapy water, ensuring the Touch Sensor is correctly

positioned and without any dirt or particles (Fig.23)

Fig.23

TECHNOLOGY FOR THE MULTITOUCH GENERATION

MKT.331.1 | DISPLAX SKIN FIT | DISPLAXTM MULTITOUCH TECHNOLOGIES 21

19. Verify and gently adjust the margins of the Touch Sensor to the Glass

active area (Fig.24). The active area is the one in which we want to process

touch signals.

Fig.24

20. Again, for a 2nd time, spray the Touch Sensor on glass with soapy water

(Fig.25)

We should repeat the lamination process by applying once again soapy

water to the Touch Sensor on glass, but now we can apply more pressure to

the squeegee to remove the water and to ensure a more permanent

lamination.

Fig.25

21. Gently but with more pressure remove the soapy water with the

squeegee, to ensure a more consistent adhesion between the Touch Sensor

and the glass (Fig.26)

Fig.26

22. Again, for a 3rd time, spray the Touch Sensor on glass with soapy water

(Fig.27)

Fig.27

TECHNOLOGY FOR THE MULTITOUCH GENERATION

MKT.331.1 | DISPLAX SKIN FIT | DISPLAXTM MULTITOUCH TECHNOLOGIES 22

23. With a little more pressure remove the soapy water with the squeegee to

ensure a permanent adhesion between the glass and the Touch Sensor

(Fig.28)

Fig.28

24. If needed, repeat the process one last time: apply the soapy water and

remove it with the squeegee (Fig.29)

Fig.29

25. After the lamination process you can gently pass a clean lint free cloth all

over the laminated product to remove remaining water (Fig.30)

Fig.30

26. Leave the Touch Sensor laminated on glass drying for 24 hours (Fig.31)

If water bubbles remain between the Touch Sensor and the glass, do not be

tempted to force them out. These bubbles should evaporate during the 24

hours drying period.

If feasible the drying area should have air conditioning to control and monitor

the air heat and humidification levels:

a) The temperature of the air should be between 20 and 25 ºC;

b) The humidity level should be between 30% and 45%;

c) The drying time should be of 24 hours.

TECHNOLOGY FOR THE MULTITOUCH GENERATION

MKT.331.1 | DISPLAX SKIN FIT | DISPLAXTM MULTITOUCH TECHNOLOGIES 23

The drying area should have a structure to place the Touch Sensor on glass.

This structure, should have a foam covering or coating the areas where the

glass will be in contact with the support structure parts. Fig.31 depicts this

condition, we can see a foam covering the areas in contact with the glass

and/or Touch Sensor.

Fig.31

Once the Touch Sensor is dry you can connect it to the Touch Controller.

LAMI NATION QUALITY

BEFORE DRYING

1. Misalignment between the glass and the laminated Touch Sensor

Edge and squareness misalignment between the glass and the Touch Sensor

are permissible but we recommend that they do not exceed a tolerance

interval between 1 and 2 mm for Touch Sensors between 20 and 50 inches

and between 1 and 4 mm for Touch Sensors between 51and 105 inches. A

posteriori, this misalignment can be compensated by running the Touch

Controller software on which we can define the Active Touch Sensor area to

perform the Touch Sensor geometrical calibration.

2. Overall lamination quality

Bubbles are permissible as long as they are deemed to disappear per

evaporation after the drying period.

Bubbles, coiled hair and lint, blemishes, contaminations and scratches are

not permissible.

Scratches on the Touch Sensor active area (which will be visible to the user)

may be permissible if they are very thin, no more than 5 millimetres long and

with a thickness of about 15 microns, unless the client defines other quality

requirements.

AFTER DRYING

Bubbles, coiled hair and lint, blemishes, contaminations and scratches are

permissible if they will be covered by the LCD or other display borders.

Scratches on the Touch Sensor visible area may be permissible if they are very

thin, making them imperceptible among the Touch Sensor grid, and they do

not exceed three occurrences, unless the client defines other quality

requirements.

TECHNOLOGY FOR THE MULTITOUCH GENERATION

MKT.331.1 | DISPLAX SKIN FIT | DISPLAXTM MULTITOUCH TECHNOLOGIES 24

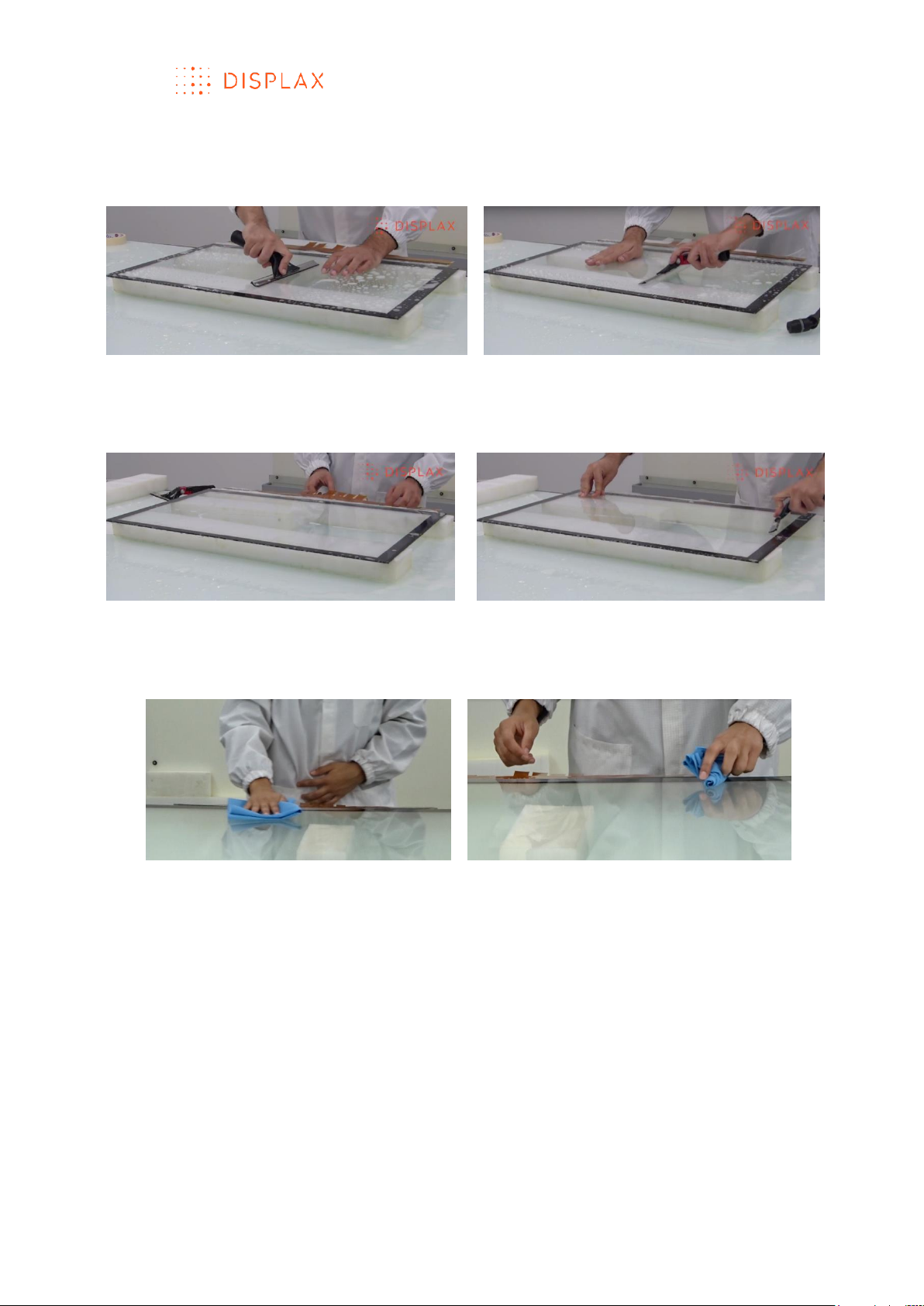

CLEANING THE LAMINATED TOUCH SENSOR BEFORE

INTEGRATION

Clean the laminated product comprising the Glass and the Touch Sensor

before its integration on a LCD or other Display.

Carefully clean the glass, and gently clean the Touch Sensor making sure no

finger print, dirt or other contaminant are left.

Use a soft cleaning lint free cloth previously wet with soapy water, and clean

both sides.

Proceed with a visual inspection to ensure that no finger print, dirt or other

contaminant is left.

The glass with the Touch Sensor shall be inspected and verified on both sides

at a close distance of about one foot with good quality ambient light.

REMOVABLE VERSION

The removable version does not have a protective layer to be removed

exposing the glue like on the permanent version.

In the removable version, the Touch Sensor must be laminated over a

backing adhesive provided with the Skin Fit or Skin Dualtouch product.

This backing adhesive, named “cling”, is a transparent polymer, which must

be applied over a determined substrate, like glass. In this description, we refer

to ‘glass’, but other non-conductive substrates can also be used.

Clean the glass, proceeding in the same way as described in step 1of the

permanent version, to ensure the glass is duly clean without any dirt, lint,

finger-tip or other contaminant, then you should decide on the correct

position to place the “Cling” over the glass.

To ensure the “Cling” adhesion to the glass spray soapy water all over the

glass where you want to laminate the “Cling”.

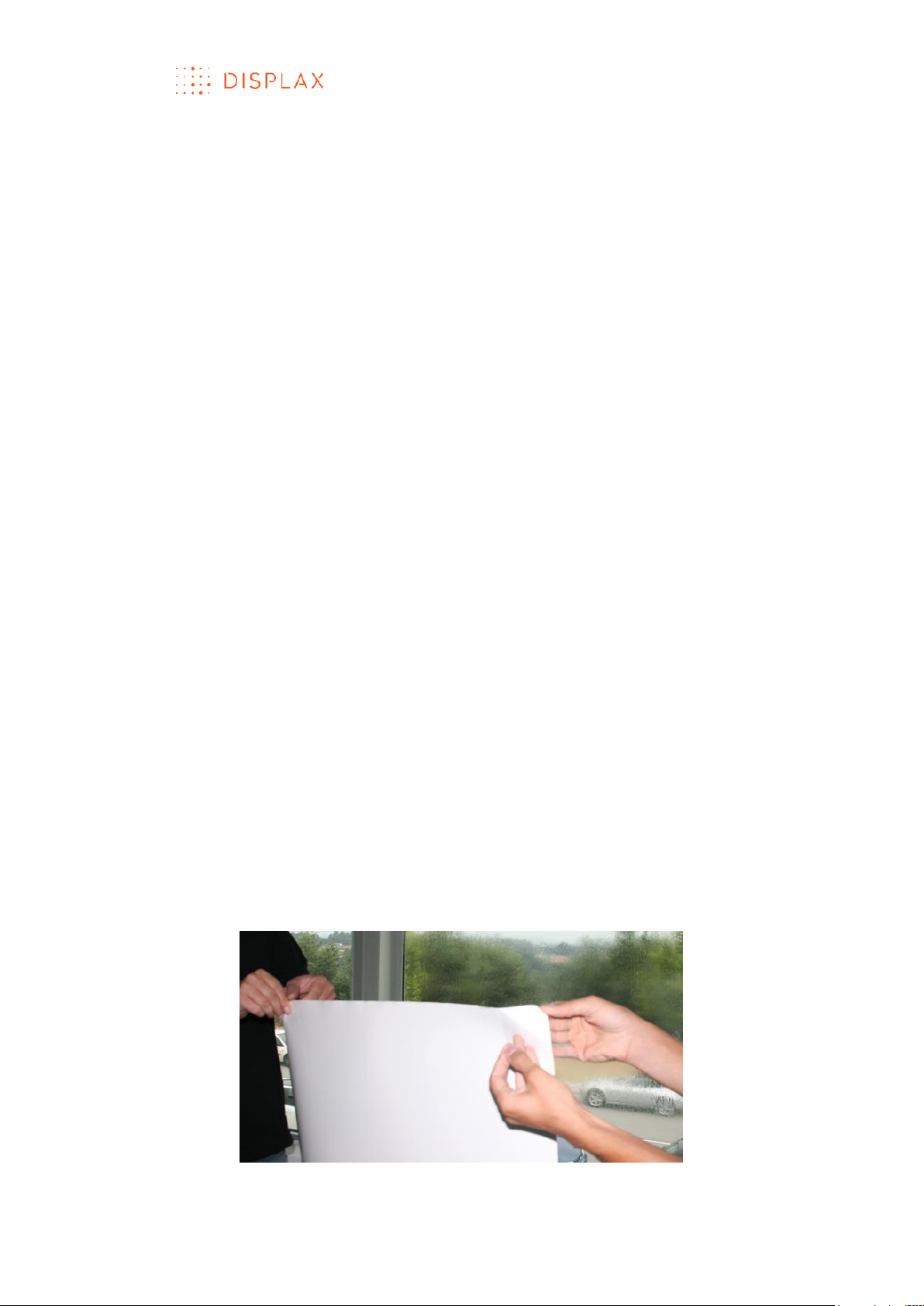

The “cling” is provided with a white protective substrate, which must be

removed (Fig.1). The exposed area must be placed facing the glass,

previously wet with soapy water, where we want to laminate the Touch

Sensor (Fig.2).

Fig.1 Carefully remove the white protection

TECHNOLOGY FOR THE MULTITOUCH GENERATION

MKT.331.1 | DISPLAX SKIN FIT | DISPLAXTM MULTITOUCH TECHNOLOGIES 25

Fig.2 Place the “Cling” against the glass, previously wet with soapy water, where

we want to laminate the Touch Sensor

Having the “Cling” over the glass, apply soapy water all over the “Cling” and

use a squeegee to clean and to laminate the “Cling” onto the glass, repeat

this process of applying soapy water and removing it with the squeegee for

another two times, making more pressure at each time to ensure the

adhesion of the “Cling” onto the glass. (Fig.3).

Fig.3 Apply soapy-water over the “Cling” to clean it and also to ensure its

adherence to the glass

The “Cling” by now should be laminated and free of any particles, finger-tips,

lint or other contaminant, and should be without any crease or bubble.

Having the “Cling” laminated onto the glass, we can now laminate the Touch

Sensor onto the “Cling”.

Carefully and gently clean the Touch Sensor using a soft cleaning lint free

cloth previously wet with soapy water, then proceed with a visual inspection

to ensure that no finger print, dirt or other contaminant is present.

To laminate the Touch Sensor over the “Cling” the steps are similar to the ones

described in the permanent version (see steps 15 to 26 of the permanent

lamination), those steps consist on:

1. Applying soapy water over the “Cling” on glass;

2. Positioning and placing the Touch Sensor over the “Cling” on glass;

TECHNOLOGY FOR THE MULTITOUCH GENERATION

MKT.331.1 | DISPLAX SKIN FIT | DISPLAXTM MULTITOUCH TECHNOLOGIES 26

3. Aligning the Touch Sensor active area with the area of the “Cling” on

glass;

4. Applying soapy water over the Touch Sensor;

5. Removing the soapy water with a squeegee to ensure the progressive

adhesion between the Touch Sensor and the “Cling” on glass;

6. Repeating for another two times the previous step, of applying soapy

water and removing it with the squeegee, but when doing it for a second

and third time more pressure should be applied at each term, to ensure

the Touch Sensor adhesion onto the “Cling” laminated on glass;

7. Carefully drying the laminated Touch Sensor surface and the area around

it;

8. Letting the laminated product to dry for a 24-hour period.

Once the Touch Sensor is dry you can connect it to the Touch Controller.

The same lamination quality parameters are applied to the permanent and

to the removable versions, see the above sections “Lamination quality” and

“Cleaning the laminated Touch Sensor before its integration on an LCD”.

To reuse the “Cling” and the “Touch Sensor” in another surface, they both

must be removed and handled gently and carefully.

Start by removing the Touch Sensor by lifting its edges and progressively lifting

the whole Touch Sensor.

After removing the Touch Sensor, remove the “Cling” from the glass by lifting

its edges and progressively detaching it from the glass.

Both the “Touch Sensor” and the “Cling” after its removal must be handled

carefully and gently to be reused in another substrate. We recommend

placing each component, the “Cling” and the “Touch Sensor” on individual

vegetable paper covered with foam.

To reuse the product components, please refer to the above described

procedure, but this time you will not have to remove the “Cling” white

protection substrate since it has already been removed in the first

application.

We do not recommend removing the cling more than two times, although a

third time might be possible depending on different handling, substrates, and

operational and environmental conditions. If the cling gets damaged, you

should replace the cling for a new one.

PRODUCT SERI AL NUMBER

The Touch Sensor serial number is placed on the left side of the FFCs.

The Touch Controller serial number is placed on its back.

The product package also has the same serial number.

TECHNOLOGY FOR THE MULTITOUCH GENERATION

MKT.331.1 | DISPLAX SKIN FIT | DISPLAXTM MULTITOUCH TECHNOLOGIES 27

INTEGRATION GUIDE

A video has been created to support the integration process:

URL: https://academy.displax.com/knowledgebase/integration/

Your product may present a different design from the one presented in this

user guide and instruction video.

Note:

This guide assumes you already have the Touch Sensor laminated on glass.

For more information on how to laminate, please refer to the lamination

guide.

MOUNTI NG THE GL ASS WITH THE TOUCH SENSOR ON A DISPLAY

Clean the LCD and the glass on which the Touch Sensor has been laminated.

Use a soft wet lint free cloth with dishwasher detergent to clean the glass. The

same solution can be used to clean the Touch Sensor, which should be

cleaned with care to avoid damaging the sensor electrodes, the flat flexible

cable and its solder joints.

To mount the glass with the Touch Sensor on the LCD apply foam gasket or a

double sided bonding tape (Fig.2) around the perimeter of the LCD to ensure

an air gap between the LCD and the Touch Sensor. An air gap is advisable

to reduce electromagnetic interferences from the LCD panel. The air gap

may vary between 1 to 10 mm, a bigger air gap makes the Touch Sensor less

sensitive to electromagnetic interferences. We recommend using an air gap

of at least 2 mm.

The foam gasket or double sided bounding tape should be non-sulphurous

and must maintain its adhesion properties at any temperature that the LCD

may be experiencing in normal use.

Fig.1

Having applied the foam gasket, place the laminated Touch Sensor over the

LCD panel with the Touch Sensor facing the LCD (Fig.2 and 3).

TECHNOLOGY FOR THE MULTITOUCH GENERATION

MKT.331.1 | DISPLAX SKIN FIT | DISPLAXTM MULTITOUCH TECHNOLOGIES 28

Fig.2

Fig.3

When positioning the laminated Touch Sensor over the LCD, carefully align

the active area of the LCD with the active area of the Touch Sensor

laminated on glass, also take into consideration the position of the flexible

cables to ensure the best alignment for mounting the PCB controller on the

back of the LCD.

Likewise, take into account that the backlight of the LCD is usually the noisiest

part. Traditionally, this component is placed in one of the sides of the display.

If your Touch Sensor is a side tail version, the sensor side where the PCB

Controller attaches should be on the same side of the LCD backlight since

the signal is stronger here, thus minimizing the impact of the noise from the

backlight. Contact your LCD manufacturer for more information regarding

the backlight location.

TECHNOLOGY FOR THE MULTITOUCH GENERATION

MKT.331.1 | DISPLAX SKIN FIT | DISPLAXTM MULTITOUCH TECHNOLOGIES 29

INTEGR ATING THE TO UCH CONTROLLER

To open the Touch Controller protection air bag, pierce the bag, using a

blade to release its air to make it easier to remove it in safety (Fig.4 and 5).

Fig.4

Fig.5

Define the position to secure the Touch Controller to the LCD (Fig.6).

Fig.6

When defining the Touch Controller position:

a) Make sure the flexible cable reaches comfortably the Touch Controller

(PCB);

b) Make sure there is a good access to the USB cable in that location;

c) Identify a grounding option for the Touch Controller;

d) Avoid, when possible, placing the Touch Controller near the LCD power

source.

Touch Controller integration - attach the Touch Controller to the back of the

LCD:

a) The Touch Controller cannot be directly placed on metal;

b) Use foam gasket or a double sided bonding tape to attach the Touch

Controller to the back of the LCD (Fig.7). The gasket must maintain its

adhesion properties at any temperature that the LCD may be

experiencing in normal use.

Fig.7

c) Make sure to have a minimum distance of 3 mm from the Touch

Controller to the LCD, to ensure that the electromagnetic noise from the

LCD doesn’t affect it. This distance can be created either by placing a

gasket under the Touch Controller, as previously described, or by using

TECHNOLOGY FOR THE MULTITOUCH GENERATION

MKT.331.1 | DISPLAX SKIN FIT | DISPLAXTM MULTITOUCH TECHNOLOGIES 30

metal standoffs connected to the LCD chassis above which the Touch

Controller can be placed and attached using screws threaded into the

metal standoffs. This procedure grounds the Touch Controller.

d) Ground the Touch Controller, either by using screws threaded into the

LCD metal chassis or by using the low impedance grounding cable

supplied with the Skin product which must be connected to the Touch

Controller socket (Fig.8 and 9) and to a metal part of the LCD chassis

(Fig.10). To connect the ground cable to the Touch Controller insert its

ending tip into the socket, and make sure it does stay securely fixed. Later

if you want to remove the ground cable from its socket use a tip of a pen

or a paper clip to unlock the ground cable connector (Fig.8 and 9).

Fig.8

Fig.9

Fig.10

e) In some applications the LCD may only have a plastic casing and

grounding to the LCD chassis is not an option. Other times the LCD

electricity plug doesn’t ground. In these cases, use the power socket to

ground the Touch Controller. Make sure there is a good access to the

ground cable (Fig.11 and 12).

Fig.11

Fig.12

Loading...

Loading...