Page 1

3” Chipper/Shredder

!

MODEL # 106817

Operation Manual

is safety alert symbol identies important safety messages in

this manual. Failure to follow this important safety information

may result in serious injury or death.

Part # 107162 Rev A

Page 2

For Service or Questions

Call 1-877-487-8275

720-287-5182

www.dirtyhandtools.com

Dirty Hand Tools® is a brand of

1100 W 120th Ave, Suite 600

Westminster, CO 80234 • 720-287-5182

Page 3

Table of Contents

Important Safety Information

Intended Use ..............................................................................4

Personal Protective Equipment ..................................................4

General Safety ............................................................................5

Safety Decals ..............................................................................6

Assembly Instructions

Attaching the Kick Stand ............................................................7

Attaching the Wheels..................................................................7

Attaching the Hopper Guard ......................................................7

Attaching the Handle ..................................................................8

Attaching the Debris Bag ............................................................8

Chipper/shredder Overview .........................................................9

Operating Precautions ................................................................10

Operation

Preparation ................................................................................11

Pre-start Inspection ...................................................................12

Startup .......................................................................................13

Shutting Down ..........................................................................13

Operation Recommendations ....................................................14

Maintenance

Maintenance Schedule ..............................................................15

Shredding Hammer Rotation and Replacement .......................18

Chipping Knives Sharpening and Replacement ........................19

Assembly and Parts Lists

Chipper/Shredder Assembly .....................................................20

Chipper/Shredder Assembly Parts List .....................................21

Engine and Housing Assembly .................................................22

Engine and Housing Assembly Parts list ..................................23

Chipper Rotor Assembly ...........................................................24

Chipper Rotor Assembly Parts List ..........................................25

Troubleshooting ..........................................................................26

Storage .........................................................................................27

Warranty & Specications ......................................... Back Cover

3

Page 4

Important Safety Information

!

WARNING

WARNING: Read and thoroughly understand all instructions

and safety information before assembling or operating this chipper/

shredder. Failure to do so may cause serious injury or death. Do not

allow anyone to operate this chipper/shredder who has not read

this manual. As with all power equipment, a chipper/shredder can

be dangerous if assembled or used improperly. Do not operate this

chipper/shredder if you have doubts or questions concerning safe

operation.

Call our customer service department at 720-287-5182,

1-877-487-8275, or visit www.dirtyhandtools.com if you have any

questions or concerns about the safe operation of this equipment.

!

Intended Use

Do Not Use the chipper/shredder for any purpose other than

chipping tree limbs and branches or shredding leaves and garden

debris for which it was designed. Any other use is unauthorized and

may result in serious injury or death.

Personal Protective Equipment

When operating this chipper/shredder it is essential that you wear

safety gear including goggles or safety glasses, steel toed shoes and

tight fitting gloves (no loose cuffs or draw strings). Always wear ear

plugs or sound deafening headphones to protect against hearing loss

when operating this chipper/shredder. Always wear sturdy footwear.

Never wear sandals, sneakers or open shoes, and never operate the

chipper/shredder with bare feet. Do not wear loose clothing that

might get caught in moving parts.

DANGER

!

CAUTION

Read the entire Operation Manual before using this equipment!

California Proposition 65 Warning

Engine exhaust, some of its constituents and certain product

components contain or emit chemicals known to the state of

California to cause cancer and birth defects or other reproductive

harm.

4

Page 5

Important Safety Information

General Safety

Failure to follow warnings, cautions, assembly and operation instructions

in the Operation Manual may result in serious injury or death.

!

DANGER

READ THE OPERATION MANUAL BEFORE USE

SINGLE PERSON OPERATION ONLY!

THIS UNIT MEETS OR EXCEEDS

ANSI B7162000 SAFETY STANDARDS

• Do not permit children to operate this equipment at any time. Do

not permit others that have not read and understood the complete

Operation Manual to operate this equipment.

• Keep all people and pets a minimum of 10 feet away from the work area

when operating this chipper/shredder.

• Do not operate the chipper/shredder when under the influence of

alcohol, drugs or medication.

• Do not allow a person who is tired or otherwise impaired or not

completely alert to operate the chipper/shredder.

!

DANGER

THE CHIPPER SHREDDER HAS SPINNING BLADES

THAT CAN AMPUTATE HANDS AND FEET.

DO NOT PLACE HANDS OR FEET IN THE HOPPER OR

CHIPPER INLET, OR DISCHARGE CHUTE.

is unit discharges debris at high speed. Always wear protective eyewear

when operating. Keep all bystanders away a safe distance.

• Always make sure the shredding chamber, shredder hopper, and

chipper inlet are empty before starting.

• Never attempt to clear clogs from the chipper inlet, shredder hopper

or discharge chute while the unit is running.

• Never use indoors or in a conned area. e engine emits carbon

monoxide which is an odorless and colorless poisonous gas.

• Handle fuel with care; it is highly flammable. Use an approved fuel

container. Never add fuel to a running engine or hot engine.

• Never ll fuel tank indoors. Fill outdoors with extreme care.

• Replace gas cap securely and cleanup spilled fuel before restarting.

• Never make any adjustments while the engine is running.

• Never allow material to build up around the engine.

• Never allow material to build up in the discharge area.

• Always stand to the side of the chipper cone when feeding tree limbs

and branches into the unit.

• Never operate the unit on a slope, or on a wet or slippery surface.

• Never leave the machine running unattended.

5

Page 6

Important Safety Information

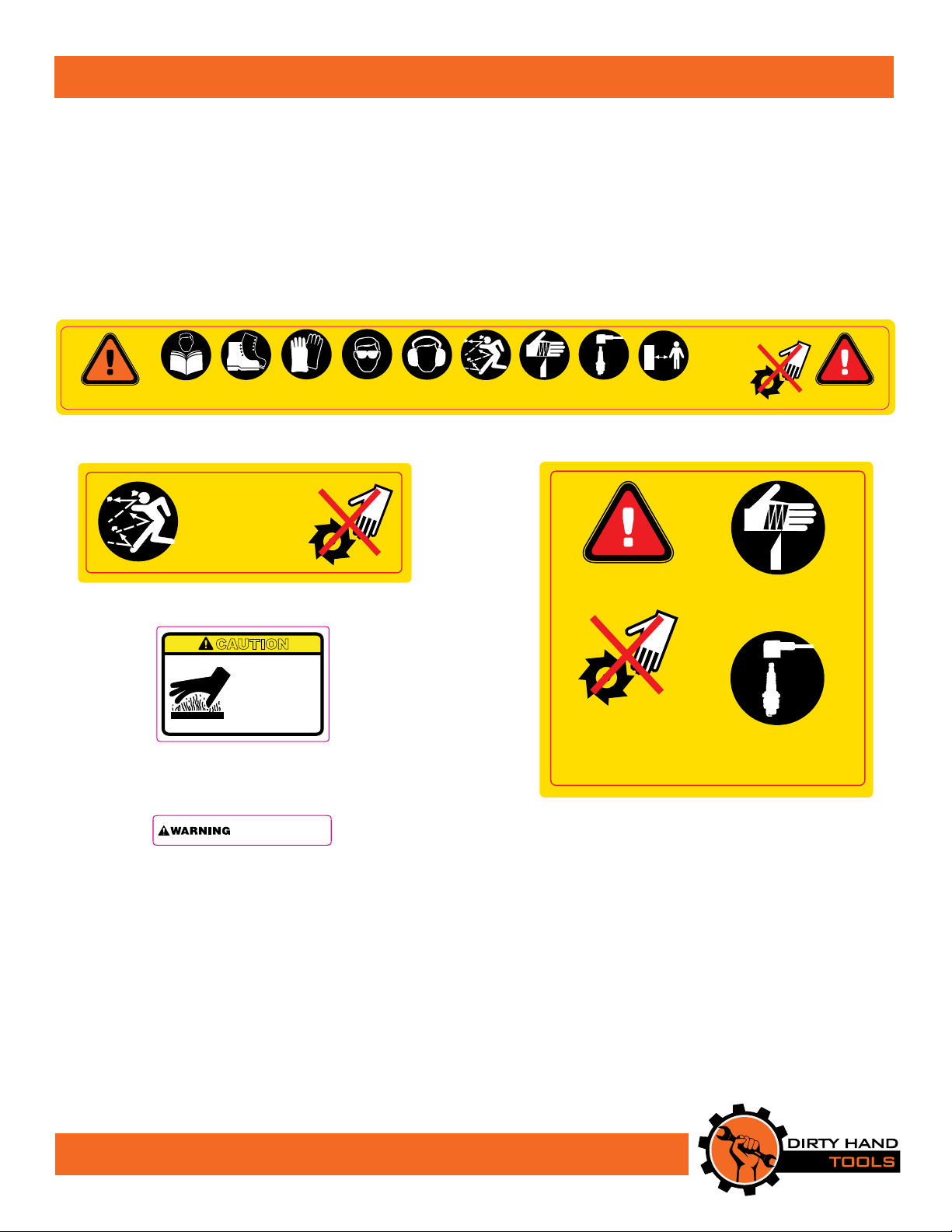

Safety Decals

Safety labels on the chipper/shredder are to remind you of

important information while you are operating the unit.

Make sure all safety warning decals are attached and in

readable condition. Replace missing or defaced decals. Contact

Dirty Hand Tools at 1-877-487-8275 for replacement decals.

WARNING

READ MANUAL

BEFORE

OPERATING

WEAR

PROTECTIVE

FOOTWARE

PROTECTIVE

OBJECTS MAY BE

THROWN

AMPUTATION

HAZARD

KEEP HANDS

A WAY

106731 - Amputation Hazard Decal

CAUTION

HOT

SURFACE

DO NOT TOUCH

106047 - Hot Surface Decal

WEAR

CLOTHING

106047

WEAR

GOGGLES OR

EYEWARE

WEAR NOISE

REDUCTION

HEADPHONES

CAUTION

OBJECTS

MAY BE THROWN

106730 - Warnings Decal

106731

SHARP BLADES

KEEP HANDS

& FEET AWAY

DETACH

SPARK PLUG

BEFORE SERVICING

106732

DANGER

AMPUTATION

HAZARD

KEEP HANDS

A WAY

KEEP

SAFE

DISTANCE

NO

HANDS

BELOW

THIS

LEVEL

DANGER

SHARP BLADES

KEEP HANDS

& FEET AWAY

DETACH

SPARK PLUG

BEFORE SERVICING

106730

CHECK OIL BEFORE

STARTING ENGINE

101053

106732 - Sharp Blades Decal

101053 - Check Oil Decal

6

Page 7

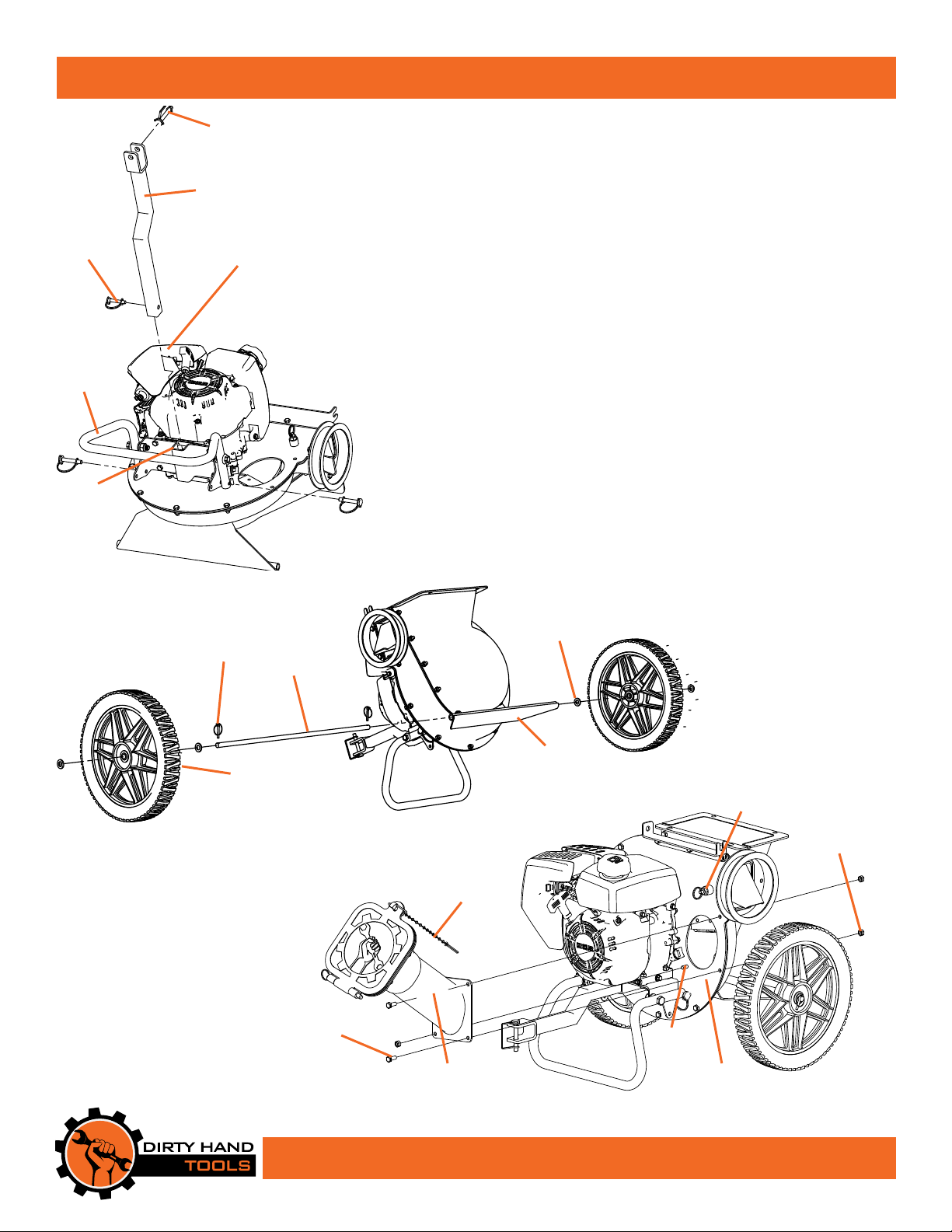

Assembly

LOCK

PIN

STAND

RECEIVER

HITCH

PIN

DRAWBAR

ENGINE

ASSEMBLY

Figure 1

1. Deploy Stand (see Figure 1).

1. Set engine assembly on at surface and swing the stand into position.

2. Insert the lock pins into the holes in the stand base to secure.

3. Fully insert the drawbar in the receiver and insert the lock pin.

4. Attach the hitch pin to the end of the drawbar.

Note: Drawbar installation is optional for towing behind vehicle.

e drawbar can install in two dierent positions depending upon the

hitch height of the tow vehicle.

2. Attach Wheels (see Figure 2).

1. Tilt the engine assembly forward until it rests on the drawbar.

2. Slide the axle through the wheel bracket.

3. Position wheels on the axle using washers on both sides.

4. Insert lynch pins to secure wheels to the axle.

3. Attach Inlet Tube (see Figure 3).

1. Align inlet tube with stud bolt on the closure plate and secure with

M8 nylock nut.

2. Fasten inlet tube to closure plate with M8 x 20 bolt and M8 nylock

nuts in 2 places.

3. Attach lynch pin chain to spring plunger.

LYNCH PIN

(2 Plcs)

WHEEL

(2 Plcs)

AXLE

M8 x 20

BOLT

(2 PLCS)

Figure 2

LYNCH PIN

CHAIN

INLET

TUBE

WASHER

(2 Plcs)

WHEEL

BRACKET

Figure 3

STUD

BOLT

SPRING

PLUNGER

CLOSURE

PLATE

M8

NYLOCK NUT

(3 PLCS)

7

Page 8

Assembly

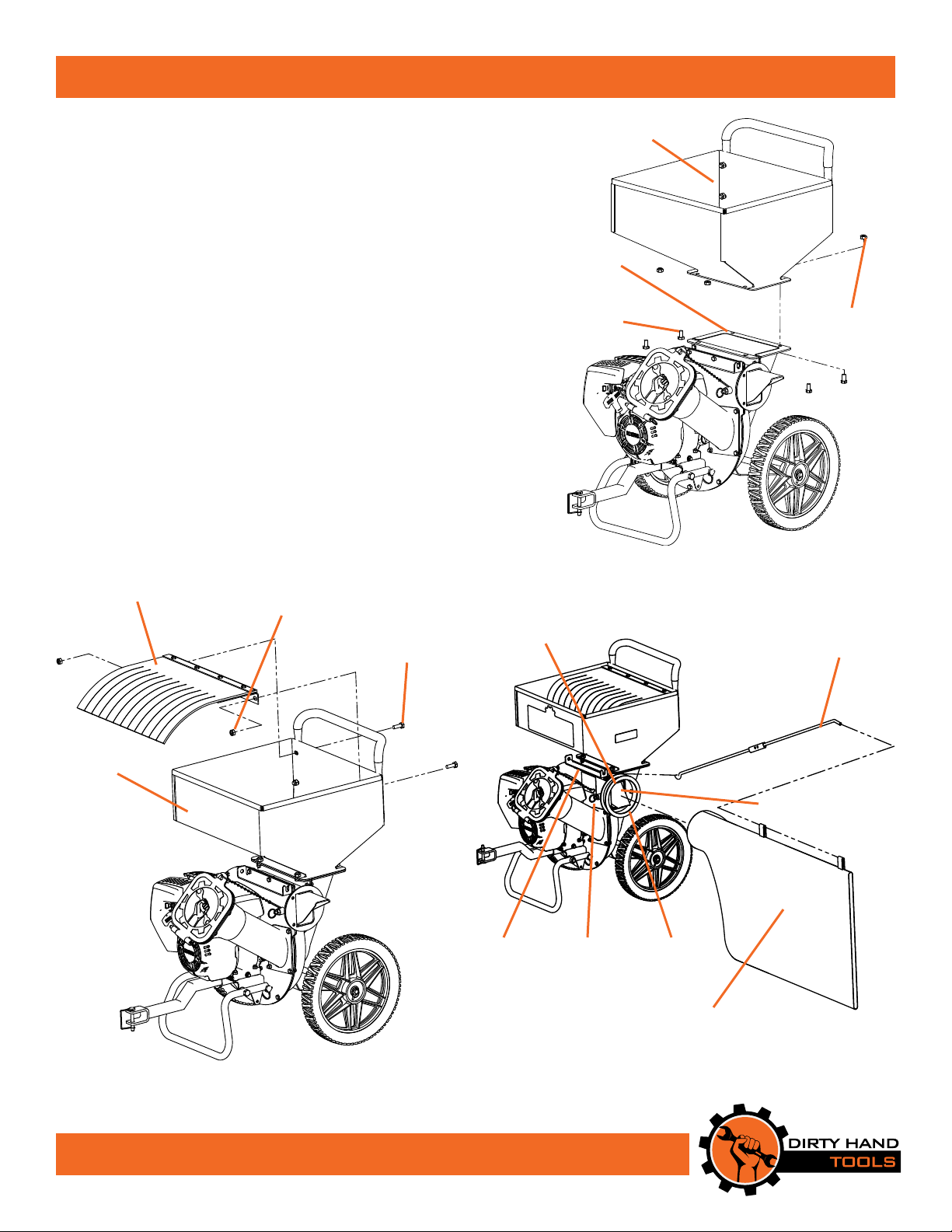

4. Attach Hopper.

1. Position hopper on shredder inlet ange (see Figure 4).

2. Attach with four M10 x 20 Bolts and M10 Nylock nuts.

5. Install Shredder Safety Guard

1. Position the shredder guard inside the hopper (see

Figure 5).

2. Attach using two M10 x 30 Bolts and M10 Nylock

nuts.

6. Install Debris Collection Bag

1. Unfold bag support arm and lock into straight position

as shown (see Figure 6).

2. Feed end of bag support arm into hole of the bag arm

bracket and rest in u-shaped slot.

3. Slide bag onto support arm, drawing the bag inlet over

the discharge ange and tighten the draw string.

SHREDDER

SAFETY

GUARD

M10 NYLOCK

NUT, 2 Plcs

M10 X 30

BOLT, 2 Plcs

SHREDDER

INLET FLANGE

M10 X 20 BOLT,

4 Plcs

U-SHAPED

SLOT

HOPPER

M10 NYLOCK

NUT, 4 Plcs

Figure 4

BAG SUPPORT

ARM

HOPPER

8

Figure 5

BAG ARM

BRACKET

SPRING

PLUNGER

DEFLECTOR

DISCHARGE

FLANGE

DEBRIS COLLECTION

BAG

Figure 6

Page 9

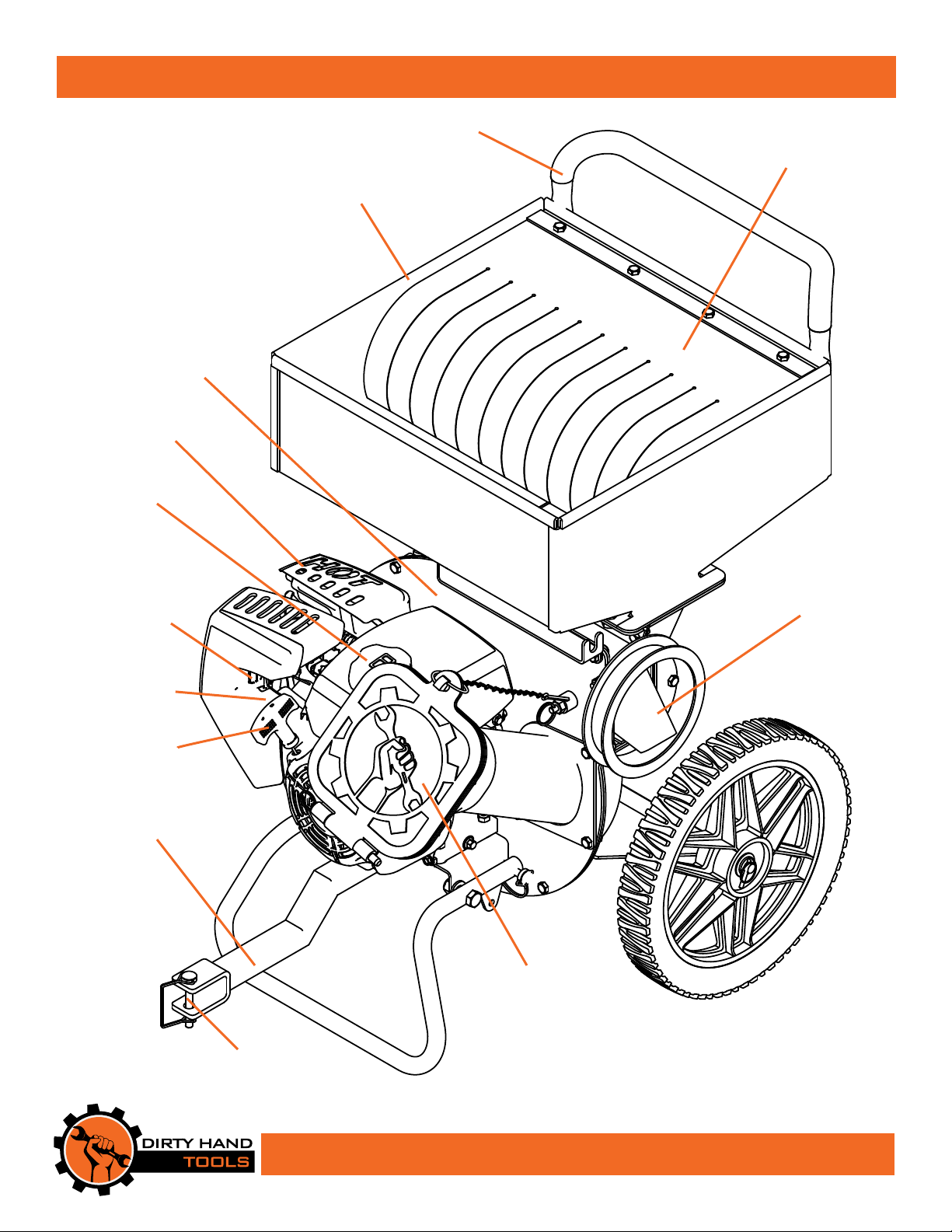

Chipper/Shredder Overview

DEBRIS

BRACKET

MUFFLER

FUEL

FILL

HANDLE

SHREDDER

GUARD

HOPPER

BAG

ENGINE

CONTROL

LEVER

GAS LINE

SHUT OFF

RECOIL

HANDLE

TOW BAR

(REVERSIBLE)

DEFLECTOR

CHIPPER

INLET

COVER

HITCH

PIN

9

Page 10

Operating Precautions

!

CAUTION

READ, UNDERSTAND AND FOLLOW ALL OF THE

PRECAUTIONS BELOW.

Always perform the pre-start checklist before starting the engine.

• Never operate the chipper/shredder without safety guards and covers

in place.

• Keep hands, feet, and clothing away from rotating parts. Keep

clear of chipper/shredder tines at all times.

• Use extreme caution when operating on or crossing gravel drives,

walks, or roads. Stay alert for hidden hazards or trac.

• If a limb or branch becomes stuck in the chipper inlet or debris

becomes clogged in the shredder hopper, stop the engine, remove

the wire from the spark plug, manually remove the obstacle before

restarting the engine.

• Engine muer will be hot from operation. Do not touch it with

bare skin or a severe burn may result.

• Do not run the engine indoors; exhaust fumes are deadly.

• Do not overload the chipper/shredder by trying to process too much

debris at one time or force a limb in the chipper inlet that is a greater

diameter than the machine’s capacity.

• Never operate the chipper/shredder on slippery surfaces.

• Use only attachments and accessories approved by the manufacturer.

• Never operate the chipper/shredder without good visibility or

adequate light.

• Take precautions when leaving the machine unattended. Stop the

engine, wait for all moving parts to stop, and make certain guards and

shields are in place.

• Shut o the engine when leaving the operating position for any

reason. Wait for all moving parts to stop before attempting to dislodge

debris, or limbs.

• e chipper/shredder blades are extremely sharp. Avoid contact with

bare hands at all times.

10

Page 11

Operation

!

CAUTION

DO NOT ATTEMPT TO START ENGINE

BEFORE ADDING OIL TO ENGINE

e engine is shipped from the factory without oil.

Use only the recommended weight of oil for a 4-cycle engine (See

Engine Operation Manual).

OIL

YOU MUST ADD ENGINE

OIL BEFORE STARTING

THE ENGINE.

NOTE: Upon start-up and shut-down, you may hear the metal-tometal sound of the triangular hammers and J-hammers positioning

themselves on the rotor. is is normal.

Chipper Operation

e chipper is designed to handle tree limbs and branches up

to 3”. e chipping knives also permit the processing of coarse

organic matter like corn stalks. Tree branches must be inserted largeend first into the chipper inlet. Since occasional kick-backs may

occur, always stand off to the side of the unit. Allow the self-feeding

action of the unit to draw the sticks in.

NOTE: CHALK THE WHEELS BEFORE OPERATION!

Shredder Operation

e shredder is designed to shred light brush, leaves, and

other soft but bulky organic waste. As material, no larger than

1/2 inch in diameter, is loaded into the shredder hopper it is pulled

into the path of the triangular and J-hammers by air flow.

Operating Location

Select an area with firm, level ground, covered by dirt or grass.

Do not operate on wet or slick surfaces, or near bystanders.

Locate and organize the materials to be processed so that you

don’t have to walk in front of the inlet or discharge openings,

and so you have adequate room to work safely.

!

CAUTION

DO NOT ALLOW DEBRIS TO COLLECT

ON THE ENGINE.

A DANGER OF FIRE OR DAMAGE

TO THE ENGINE MAY RESULT.

11

Page 12

Operation

Preparation for Operation

Fill Engine Crankcase with Oil

1. Add oil according to engine manual. Do not overll. Use

a clean, high quality detergent oil. Use no special additives

with recommended oils. Do not mix oil with gasoline.

Oil level must be full. Check the oil level by removing oil

ll plug. Oil level should be up to the bottom of the ll

plug opening (see Figure 7).

2. Always check oil level before starting engine. Refer to

engine manual for capacity and type of oil to use.

Pre-Start Inspection

1. Make sure safety shields are in place and nuts & bolts are

secure.

2. Check oil level in engine crankcase. See your engine

manual for procedure and specications.

3. Inspect air cleaner for cleanliness.

4. Check the fuel supply. Fill the fuel tank no closer than 1

inch from top of tank to provide space for expansion. See

your engine manual for fuel recommendations.

5. Be sure spark plug wire is attached and spark plug is

tightened securely.

6. Examine underneath and around engine for oil or fuel

leaks.

7. Inspect fuel hoses for tightness and to ensure there is no

fuel seepage.

8. Look for signs of engine damage.

9. Remove excessive debris from muer area and air inlets

near the recoil starter.

OIL FILL

PLUG

Figure 7

OIL DRAIN

PLUG

12

Page 13

CHOKE

RUN

ENGINE

CONTROL

LEVER

OFF

STOP

Operation

Starting the Engine

Turn fuel shut-off valve to ON position.

Cold Starts

1. Move the engine control lever to the left (choke) position (see

Figure 8).

2. Pull recoil handle out slowly one time and allow to return

normally.

3. Pull recoil handle out slowly but with force, and allow rope to

return normally.

Note: You must overcome the inertia of the ywheel.

4. When engine starts, gradually move the engine control lever to the

right (fast) wide open position to increase engine speed.

Restarting A Warm Engine

Restarting an engine that is already warm from previous running does

not normally require use of the choke.

1. Move the engine control lever to “Run” position.

2. Pull the recoil handle out slowly but with force until engine starts.

Allow rope to return normally. Repeat until engine starts.

3. Adjust the engine control lever speed to “fast” (wide open position)

for best chipper/shredder operation.

Figure 8

Idle Speed

Use the “slow” position on the engine control lever to reduce stress

on the engine when chipping or shredding is not being performed.

Lowering the engine speed to “idle” will help extend the life of the

engine, as well as conserve fuel and reduce the noise level of the

equipment.

Operating Speed

For normal shredding and chipping, set the throttle lever to “fast”.

Shutting Down

1. To stop the engine at any time, move the engine control lever to

the STOP position.

Note: Due to the inertia of the ywheel, extra time is required for the

engine to fully stop.

2. Close fuel shut-o valve.

13

Page 14

Operation

Chipping Recommendations

• Prune branches down close to the main branch to make feeding them into the

chipper inlet easier.

• Large, hard, dried tree branches that resist chipping can be processed by

rotating them as you alternately insert and retract them.

• Material conditions vary, sometimes exceeding the capacity of the equipment.

If the material to be chipped is extremely hard, kicks back forcefully when

being fed into the chipper inlet, or cannot be easily controlled, remove

the material immediately and set it aside. Do not attempt to process these

materials.

• If additional force is required to insert materials into the chipper, the blades

probably need to be sharpened. Consult the Troubleshooting and Repair

section of this manual, or see your authorized dealer.

• Maintain control of the materials you are feeding to prevent them from

whipping around.

• Do not insert short pieces of material into the chipper inlet by hand. Use a

larger piece of material to push them into the chipper inlet.

Shredding Recommendations

• Don’t overload the shredder by dumping large volumes of material into the

hopper opening.

• Alternate loads of wet and dry material to prevent the discharge from

becoming plugged.

• Never use any object to force material into the shredding chamber. It could

get caught in the shredding hammers, kick back, whip around, or cause injury

to the operator.

OPERATION TYPE OF MATERIAL SIZE METHOD

Shredding Dry or moist organic material Branches and twigs up to 1/2” Alternately chip or shred

including leaves, plants, flowers, diameter and 18” long. moist green waste with dry

fruits, or vegetables. waste to avoid plugging of

the discharge chute.

Process at a feeding rate that

allows the engine to maintain a

high rate of speed.

Chipping Long, thicker tree limbs or Tree limbs and branches, Bulky tree limbs should be

small bunches of smaller or bundles of small sticks pruned close to the main

sticks grouped together for grouped for easier handling. stem. Always use a shorter

ease of handling. Maximum diameter of approx. piece of wood to push end

3” (7.5 cm) pieces into the chipper inlet

Never place hands inside the

chipper inlet. Never chip

very hard or used dimensional

lumber (2x4’s etc.) or other

building materials. Never use

the chipper to process pressure treated wood products.

14

Page 15

Maintenance

!

WARNING

BEFORE PERFORMING ANY MAINTENANCE

PROCEDURE STOP THE ENGINE, WAIT FIVE 5

MINUTES TO ALLOW ALL PARTS TO COOL.

Disconnect the spark plug wire,

keeping it away from the spark plug.

Regular maintenance is the way to ensure the best performance

and long life of your machine. Please refer to this manual and the

engine manufacturer’s owner’s manual for maintenance procedures.

Maintenance Checklist

Maintenance Before Every Every

Procedure Each Use 25 Hours of Use 100 Hours

of Use

Check engine oil level.

Fill to correct level if necessary. X

Clean debris from engine exterior and X

the air cleaner. Cleaning the engine air

inlets near the recoil starter is critical

for proper air ow.

Check general equipment condition X

including guards, nuts, bolts, welds, etc.

Check chipper inlet and shredder hopper.

ese must be absolutely tight. X

Inspect chipping knives and rotate X

shredding hammers.

Check safety labels. X

Change the engine oil X

Clean/replace the air cleaner filter(s). X

Replace spark plug X

15

Page 16

Maintenance

!

WARNING

BEFORE PERFORMING ANY MAINTENANCE STOP

THE ENGINE & ALLOW ALL PARTS TO COOL.

Disconnect the spark plug wire,

keeping it away from the spark plug.

Engine Maintenance

Refer to the engine manual included with your equipment for

information on engine maintenance.

1. Always check oil level before starting engine. Fill to correct level

if necessary.

2. Change oil after first 5-8 hours of operation. Change oil while

engine is warm. Refill with new oil of recommended grade.

3. Check spark plug yearly or every 50 hours of operation.

4. Clean/replace air cleaner filter(s).

5. Keep engine and parts clean.

6. Check engine and equipment often for loose nuts and bolts, keep

these items tightened.

7. Check that the safety labels are in place and undamaged.

8. Check that the chipper inlet, shredder hopper, and discharge

guards are in place, undamaged and secure.

Changing the Oil

Change oil while engine is warm.

1. Clean area around oil fill cap/dipstick and drain plug.

2. Remove drain plug and oil fill cap/dipstick. Drain oil completely.

3. Reinstall drain plug.

4. Fill crankcase with new oil, up to point indicated on fill cap/

dipstick.

5. Reinstall oil fill cap/dipstick and tighten securely.

6. Dispose of used oil in accordance with local ordinances.

16

Page 17

Maintenance

Clean Debris from Engine & Chipper

Check for dirt and debris before each use and every 100 hours.

e engine requires air flow to cool itself and for combustion.

Before each use, clean any debris from the unit especially from

around the air shroud intake, air filter, and muffler. Every 100

hours, remove the engine air shroud and clean out any debris

from the engine cooling fins. We recommend having this service

performed by an authorized dealer.

Cleaning/Replacing the Air Filter(s)

NOTE: Operating engine with loose or damaged air cleaner

components could cause premature wear and failure. Replace all

bent or damaged components.

1. Unhook cover latch and remove air cleaner cover.

2. Remove and replace paper element.

3. Remove foam element; replace or wash in warm water with

detergent. Rinse and allow to air dry, then replace.

4. Reinstall air cleaner cover and secure cover latch.

Spark Plug Gap

0.03 in.

(0.76 mm)

NOTE: Paper element cannot be blown out with compressed air.

Breather Tube

Ensure both ends of breather tube are properly connected.

Servicing the Spark Plug

Clean out spark plug recess. Remove plug and examine for damage,

cracks or discoloration. Clean dirty spark plug, reset the gap and

replace in plug recess. Broken, cracked or chipped spark plugs

should be replaced.

1. Check gap using wire feeler gauge. Adjust gap to 0.03”

(0.76mm).

2. Install plug into cylinder head.

3. Torque plug to 20 ft. lb.

17

Page 18

Maintenance

Shredding Hammer Rotation and Replacement

e cutting edges of the shredding hammers may eventually

wear out requiring rotation of the hammer or replacement if

all cutting edges have been dulled. Triangular hammers can be

rotated twice after the first edge dulls, then flipped over once and

rotated again for a total of 6 edges. J-hammers can be flipped over

once for a total of two cutting edges.

To rotate the shredding hammers:

1. Turn the engine off and wait for all moving parts to stop.

2. Disconnect the spark plug wire.

3. Remove (4) M10 Bolts that attach Hopper Assy. Li Hopper

Assembly from Chipper/Shredder and set aside (see Figure 11).

4. Tilt Chipper/Shredder forward and rest on drawbar.

5. Remove (11) M8 Nylock Nuts that attach Shredder Housing to

Chipper Shredder. Remove Wheel/Bracket Assembly, Shredder

Housing and Shredder Interface Plate (see Figure 9).

6. Rotate Flywheel to align Blade Attachment Bolts with access

holes. Remove (2) M8 Bolts, Flat Washers and Split Lock

Washers for each of the Chipper Blades. Reach thru the Chipper

Feed Tube to remove the Chipper Blade.

7. Note the assembly sequence of the hardware used to secure the

hammers. Using a 17mm wrench or socket remove the hex head

bolts and related hardware (see Figure 10).

8. Inspect the hammers, spacers, and hardware. If the spacer shows

signs of wear, replace it. Inspect and flip, or replace the hammers.

9. Reassemble the hammers, spacers, washers, and cap screws.

Torque the hex head bolts to 30-35 ft. lbs. e J-hammers may

be used facing in or out.

8. Repeat for all the hammers.

18

Figure 9

HEX HEAD

BOLT

TRIANGULAR

HAMMER

WASHER

J-HAMMER

Figure 10

LONG

SPACER

SHORT

SPACER

Page 19

Maintenance

Chipping Knives Sharpening and Replacement

e chipping knives should be sharpened or replaced when

tree limbs require extra force to feed into the chipper inlet.

e chipping knives may be sharpened at a 35 degree angle

until the distance between the edge of the blade bevel and

the mounting hole is less than 1/16” (1.6mm), see Figure 10.

Removing/Replacing Chipper Blades

1. Turn engine off and wait for all parts to stop.

2. Disconnect spark plug wire (not shown).

3. Remove (4) M10 Bolts that attach Hopper Assembly. Li

Hopper Assembly from Chipper/Shredder and set aside

(see Figure 11).

4. Tilt Chipper/Shredder forward and rest on drawbar.

5. Remove (11) M8 Nylock Nuts that attach Shredder

Housing to Chipper Shredder. Remove Wheel/Bracket

Assembly Shredder Housing and Shredder Interface Plate.

6. Rotate Flywheel to align Blade Attachment Bolts with

access holes. Remove (2) M8 Bolts, Flat Washers and

Split Lock Washers for each of the Chipper Blades. Reach

through the Chipper Inlet Tube to remove the Chipper

Blade. (See gure 12). Alternatively, the tube may be

removed for easier access.

7. Reassemble in reverse order. Tighten M8 hardware to 25

N-m (18 -lb) and M10 hardware to 50 N-m (36 -lb).

HOPPER

ASSEMBLY

1/16”

Min.

Order replacement blade Part # 106844

SHREDDER

HOUSING

CHIPPER KNIFE CUTTING EDGE

TOP VIEW

Figure 11

from Dirty Hand Tools.

WHEEL

BRACKET

ASSEMBLY

SIDE VIEW

35°

M8 NYLOCK

NUTS

11 Plcs

CHIPPER

BLADE

ACCESS

HOLES

SOCKET HEAD

CAP SCREW

LOCK

WASHER

SHREDDER

INTERFACE

PLATE

Figure 12

19

Page 20

Chipper/Shredder Assembly

17

4

10

18

14

16

13

12

15

19

25

31

30

23

6

20

32

33

34

29

26

28

27

8

9

7

20

11

23

3

2

21 22

24

5

1

Page 21

Chipper/Shredder Assembly Parts List

Item # Part # Description Qty.

1 101094 Trimmer Wheel Assembly 2

2 106558 Drawbar 1

3 106535 Axle Rod 1

4 102342 Lynch Pin, 3/16” x 1” 2

5 100181 Flat Washer, M12 4

6 100068 Hex Nut, Nylock, M10 x 1.5 4

7 102973 Hex Bolt, M10 x 1.5 x 20mm 4

8 106593 Bag Support Assembly 1

9 106761 Fabric Debris Collection Bag 1

10 102476 Lock Pin, Round, 5/16” x 1-3/8” 1

11 102485 Lock Pin, Square, 3/8” x 2-1/4” 1

12 106543 Feed Tube Check, Rubber 1

13 106546 Feed Tube Hinge Bezel 1

14 100130 Flat washer, M8 8

15 106903 Simple Feed Tube, 3.5” x 4” 1

16 100128 Hex Nut, Nylock, M8 x 1.25 8

17 106547 Feed Cover 1

18 102333 Detent Pin, 3/8” x 4” 1

19 102349 Lynch Pin, w/Chain, 7/16” x 1-1/2” 1

20 106839 Shredder deflector 1

21 106555 Foot Tube 1

22 106391 Hex Bolt, M12-1.75 x 40mm 2

23 100069 Hex Nut, Nylock, M12 x 1.75 6

24 102483 Lock Pin, Round, 3/8” x 1-3/4” 2

25 106552 Hopper 1

26 106553 Handle Bar 1

27 100165 Hex Bolt, M10-1.5 x 30mm 4

28 106861 Hopper Check Mount 1

29 106863 Hopper Check Support 1

30 106862 Hopper Check, Rubber 1

31 106864 Hopper Check retention 1

32 103901 Hex Bolt, M8 x 1.25 x 25mm 4

33 100128 Hex Nut, Nylock, M8 x 1.25 4

34 107221 Bag Flange 1

21

Page 22

Engine and Housing Assembly

17

19

21

11

13

3

10

16

1

9

2

15

22

12

18

4

20

22

5

7

14

6

8

Page 23

Engine and Housing Assembly Parts List

Item # Part # Description Qty.

1 107140 Engine Kohler, RH265, 1” Shaft 1

2 106559 Engine Spacer 1

3 106906 Feed Tube Closure 1

4 106571 Flywheel Assembly 1

5 106518 Chipper Housing 1

6 106515 Shredder Interface 1

7 106514 Shredder Housing 1

8 106533 Axle Bracket 1

9 106556 Drawbar Bracket 1

10 106530 Bag Arm Bracket 1

11 106829 Spring Plunger Assembly 1

12 106598 Deflector 1

13 100059 Hex Nut, Nylock, M8 x 1.25 1

14 100128 Hex Nut, Nylock, M8 x 1.25 27

15 106808 Hex Bolt, M8 x 1.25X35mm 4

16 100125 Hex Bolt, M8 x 1.25X20mm 13

17 100021 Hex Head Bolt, 3/8-24 x 2” 1

18 100125 Hex Bolt, M8 x 1.25 x 20mm 5

19 106842 Flywheel Spacer 1

20 100611 Lock Washer, 3/8 1

21 100127 Lock Washer, M8 4

22 107173 Washer, Nylon, 9 ID x 27.5 OD 1

23

Page 24

Chipper Rotor Assembly

6

4

3

9

1

11

2

7

5

10

8

24

Page 25

Chipper Rotor Assembly Parts List

Item # Part # Description Qty.

1 106566 Flywheel 1

2 106844 3.5” Chipper Blade 2

3 106570 Flail Spacer 4

4 106572 Flail Bushing 4

5 106569 J-Flail 2

6 106568 Trident Flail 2

7 100089 Lock Washer, M10 4

8 100127 Lock Washer, M8 4

9 100130 Flat Washer, M8 4

10 104986 Hex Bolt, M8 x 1.25 x 16mm 4

11 104365 Hex Bolt, M10 x 1.5 x 50mm 4

25

Page 26

Troubleshooting

PROBLEM SOLUTION

Engine will not start • Add gas to gas tank.

• Connect spark plug wire to spark plug

• Engine control lever must be at choke for a cold start

Engine runs rough, oods during operation • Clean or replace air cleaner

• Move choke to RUN position

Engine is hard to start • Drain old fuel and replace with fresh. Use gas

stabilizer at end of season

• Make sure spark plug wire is securely attached to

spark plug

Engine misses or lacks power • Remove and clean fuel tank

• Clean or replace air cleaner

• Improper carburetor adjustment, take to authorized

engine service center

• Replace spark plug and adjust gap

• Drain and rell gas tank and carburetor

Engine exhaust is black. • Dirty air lter. Replace or clean air lter(s).

• Choke closed. Open choke.

Engine runs but no material is discharged. • Discharge chute clogged. Stop engine and clear

obstruction and debris.

• Engine not running at full speed. Move the Engine

control lever to the fast position.

Excessive branch vibration when chipping materials. • Chipper knives dull. Sharpen or replace knives.

• Tree limbs are extremely hard or dried out. Material is

not suitable for chipping.

Unusual noise or vibration • Rotor overloaded with material. Allow unit to clear

when chipping materials. before adding more material to the hopper.

• Hammers are broken, bent, or loose. Tighten or

replace hammers as necessary.

• Hammers frozen in place. Check for obstructions.

Alternate damp and dry materials to avoid clogging.

26

Page 27

Storage

!

WARNING

DO NOT STORE CHIPPER/SHREDDER IN

UNVENTILATED AREA

where fuel fumes may reach ame, sparks, pilot lights

or other ignition source.

Drain fuel outdoors away from any ignition sources.

Use only approved fuel containers.

Prepare for Storage

Follow the steps below to prepare your chipper/shredder for

storage. Read your engine manual for detailed instructions on

preparing the engine for storage.

1. Protect wheels and axles from rust: Remove lock pin and slide

wheel off hub. Coat the axles lightly with axle grease. Slide wheel

back on hub and insert lock pin.

2. Drain fuel system completely following engine manufacturer’s

instructions or add fuel stabilizer to prevent fuel from gumming

up during extended storage period.

3. While engine is still warm, drain the oil from the engine. Refill

with fresh oil of the recommended grade.

4. Clean external surfaces, engine and cooling fan.

5. Remove spark plug, pour one ounce of SAE 30 oil into spark

plug hole.

6. Plug hole and pull starter cord slowly to distribute oil evenly in

cylinder head area.

7. Reinstall spark plug. If there is any possibility of unauthorized

use or tampering, remove the spark plug and store it in a safe

place before storing the chipper/shredder unit.

Transporting

Always use the hopper handle and built-in wheels to move the

chipper shredder. Never lift the unit using the fuel tank for support.

If the unit must be lifted, always use at least two people, and always

grip the unit securely using the foot stand and hopper handle.

27

Page 28

Warranty & Specications

IMPORTANT NOTICE

We, the manufacturer, reserve the right to change the product and/

or specifications in this manual without notification. e manual is for

information usage only and the pictures and drawings depicted herein are

for reference only.

Warranty Repair and Service

Do not return this product to the store for warranty issues or repair. Call

our customer service department at 720-287-5182, 1-877-487-8275, or

visit www.dirtyhandtools.com for the location of the nearest service center.

Record the information below for future reference.

Model No.

Serial No.

Date of Purchase

Place of Purchase

Specications

SKU/Part No. 106817

Description 3” Chipper/Shredder

Engine Kohler RH265, 6.5 HP, 196cc*

Starting System Manual, Recoil

Chipping Capacity 3” Diameter

Shredding Capacity 1/2”

Hopper Size 20” x 19” x 7”

Wheel Size 14” Diameter x 2” width

Debris Collection 3 Bushel Capacity, Detachable Bag

Debris Bag Size 42”L x 24”H (1064x600mm)

Discharge Chute Adjustable, 4 Positions

Frame 10 Gauge Steel

Dimensions 34”L x 24” W x 39.5” H (864x610x1080mm)

Shipping Weight 220 Lbs. (99.8kg)

Warranty 2 Year / 2 Year Limited Warranty

*As rated by engine manufacturer

Dirty Hand Tools® is a brand of

1100 W 120th Ave., Suite 600

Westminster, CO 80234 • 720-287-5182

For Service or Questions

Call 1-877-487-8275

720-287-5182

www.dirtyhandtools.com

Loading...

Loading...