Page 1

POWER POST DRIVER

O

I

!

MODELS # 103400 & 104369

Operation Manual

is safety alert symbol identies important safety messages in

this manual. Failure to follow this important safety information

may result in serious injury or death.

Part # 104615 Rev B

Page 2

For Service or Questions

Call 1-877-487-8275

720-287-5182

www.dirtyhandtools.com

Dirty Hand Tools® is a brand of

1100 W 120th Ave, Suite 600

Westminster, CO 80234 • 720-287-5182

Page 3

Table of Contents

Important Safety Information

Intended Use ..............................................................................4

Personal Protective Equipment ..................................................4

General Safety ............................................................................5

Safety Decals ..............................................................................6

Pre-Operation Check ...................................................................7

Power Post Driver Overview ........................................................8

Filling with Gasoline and Oil .....................................................10

Starting the Engine .....................................................................11

Operation ....................................................................................12

Maintenance

Maintenance Check List ...........................................................13

Checking/Changing Engine Oil ...............................................14

Replacing the Air Cleaner .........................................................15

Changing/Cleaning the Spark Plug ..........................................16

Spark Arrestor Cleaning/Replacement ......................................17

Crankshaft and Piston Lubrication ...........................................18

Troubleshooting ..........................................................................18

Parts List......................................................................................19

Warranty & Specications ......................................... Back Cover

3

Page 4

Important Safety Information

!

WARNING

WARNING: Read and thoroughly understand all instructions

and safety information before assembling or operating this Power

Post Driver. Failure to do so may cause serious injury or death.

Do not allow anyone to operate this equipment who has not read

this manual. As with all power equipment, a Power Post Driver

can be dangerous if assembled or used improperly. Do not operate

this equipment if you have doubts or questions concerning safe

operation.

Call our customer service department at 720-287-5182,

1-877-487-8275, or visit www.dirtyhandtools.com if you have any

questions or concerns about the safe operation of this equipment.

!

DANGER

Intended Use

Do Not Use the Power Post Driver for any purpose other than

for which it was designed. e Power Post Driver was designed to

drive fence posts, ground rods, form pins, and other similar items

into the ground. Any other use is unauthorized and may result in

serious injury or death.

Personal Protective Equipment

When operating this Power Post Driver it is essential that you wear

safety gear including goggles or safety glasses, adequate clothing

and tight fitting gloves. Always wear ear plugs or sound deafening

headphones to protect against hearing loss when operating this

Power Post Driver. Always wear sturdy footwear. Never wear

sandals, sneakers or open shoes, and never operate the Power Post

Driver with bare feet. Bystanders should wear safety glasses and

hearing protection while in the presence of this power tool during

operation.

!

CAUTION

Whenever you leave the operation position to raise or position a

fence post or make other adjustments always shut o the engine.

4

Page 5

Important Safety Information

General Safety

Failure to follow warnings, cautions, assembly and operation

instructions in the Operation Manual may result in serious injury

or death.

!

DANGER

READ THE OPERATION MANUAL BEFORE

OPERATION.

• Do not permit children to operate this equipment at any time.

Do not permit others that have not read and understood the

complete Operation Manual to operate this equipment.

• Keep all people and pets away from the work area when

operating the Power Post Driver.

• Do not operate the Power Post Driver when under the influence

of alcohol, drugs or medication.

• Do not allow a person who is tired or otherwise impaired or not

completely alert to operate the Power Post Driver.

!

DANGER

ALWAYS CHECK FOR THE PRESENCE OF

UNDERGROUND UTILITIES BEFORE USING

THE POWER POST DRIVER

• Always operate the Power Post Driver in the vertical position.

• Never use the Power Post Driver inside a contained area, exhaust

produced as Carbon Monoxide is a dangerous poison.

• Never, under any conditions, remove, bend, cut, fit, weld, or

otherwise alter standard parts on the Power Post Driver.

• Improper maintenance could lead to serious injury.

• Always use two hands and grip the Power Post Driver firmly

when operating.

5

Page 6

Important Safety Information

• Never run the engine in an enclosed area or without

proper ventilation as the exhaust from the engine

contains carbon monoxide, which is an odorless, tasteless,

and deadly poisonous gas.

• Fill the gasoline tank outdoors with the engine off and

allow the engine to cool completely.

• Do not operate the engine with the air cleaner or cover

over the carburetor air-intake removed, except for

adjustment. Removal of such parts could create a fire

hazard.

• e muer and engine become very hot with use and

can cause a severe burn; do not touch. Allow the engine

to cool before refueling, doing maintenance, or making

adjustments.

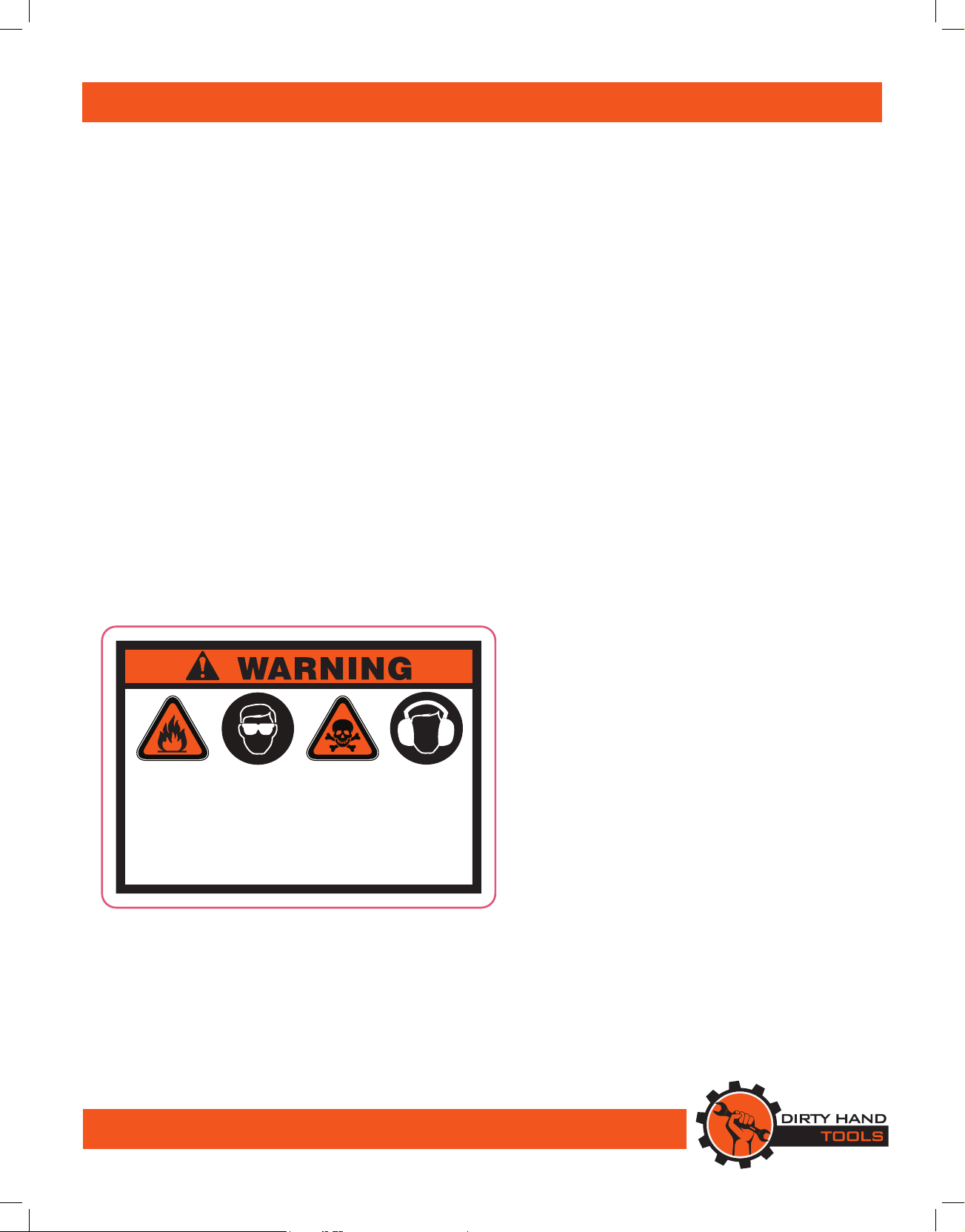

Safety Decals

Safety labels on the brush mower are to remind you

of important information while you are operating the

unit. Make sure all safety warning decals are attached

and in readable condition. Replace missing or defaced

decals. Contact Dirty Hand Tools at 1-877-487-8275 for

replacement decals.

READ OPERATOR’S MANUAL BEFORE USE

Allow engine to cool down before refueling

Gasoline is highly flammable, use caution

Do not operate indoors or enclosed areas

Exhaust contains Carbon Monoxide

Check for underground utilities before use

6

0 0 0 0 0 0

Page 7

Pre-Operation Check

1. Visually inspect your Power Post Driver before use. e interior

of the chuck tube should be checked for obstructions, damage

or wear to the chuck tube and anvil inside. e outer surfaces of

the driver should also be inspected for any defects.

2. Do not use the Power Post Driver if there is any damage or

wear until the damage or wear is corrected and repaired.

3. Check all fluid levels, i.e. engine oil and fuel and fill as needed

as per manufacturer’s specifications. Proper oil level is essential

to the proper operation of the Power Post Driver.

!

WARNING

THE POWER POST DRIVER IS SHIPPED WITHOUT

FLUIDS. OIL MUST BE ADDED TO THE ENGINE

BEFORE STARTING.

Overfilling of the oil will result in loss of power and may cause

permanent damage to the engine.

!

WARNING

USE ALL RECOMMENDED SAFETY EQUIPMENT.

4. Secure the driver on a solid surface, i.e. tailgate, bench, or clear,

solid ground and position your body in a safe position. DO

NOT start the driver anywhere but an open, well-ventilated

area. It is recommended that the Power Post Driver only be

used outdoors and never inside an enclosed building.

7

Page 8

Power Post Driver Overview

Carrying

H andle

Crankcase

Cov er

T humb

O n/ O ff

S witch

EP DM

F oam Grip

O

I

I dle L ock

S witch

T hrottle

T rigger

I dle L ock

R elease

F uel F ill

Cap

F uel

T ank

H ammer

Cov er

8

Page 9

Air

Cleaner

Power Post Driver Overview

R ecoil

S tarter

P riming

B ulb

Choke

S witch

F uel F ill

Cap

F uel

T ank

Mufer

O il F ill/

Dipstick

EP DM

F oam Grip

9

Page 10

Filling with Gasoline and Oil

!

WARNING

ADD OIL BEFORE STARTING THE ENGINE

e Power Post Driver is shipped without uids installed.

Keep the caps on the fuel and oil fills until you are ready to pour

either gasoline or oil into the correct fill.

1. Place the machine on a level surface, add some SAE 10-30W

engine oil into the oil fill and wait one minute for the oil to

settle, then continue filling with oil.

2. Check the dipstick and continue adding oil a little at a time,

rechecking the dipstick until the oil reaches the fill mark. Be

careful not to overfill.

3. Fill the fuel tank with fresh, unleaded gas (min. 85 Octane),

to 1/4” from the top of the ll neck to allow for expansion. Be

careful not to overll and reinstall the cap before starting.

!

WARNING

ALWAYS FILL THE TANK WITH

ENGINE OFF AND COOL.

ALWAYS CHECK THE OIL LEVEL

BEFORE OPERATING.

Allow the engine to cool for at least two minutes before removing

the fuel cap.

Before performing any adjustments to the Power Post Driver or

any maintenance, stop the engine, wait five minutes to allow parts

to cool.

10

Page 11

Choke

O pen

P osition

T hrottle

T rigger

P riming

B ulb

Figure 1

Engine O N /

O F F S witch

F uel R eturn

L ine

I dle L ock

S witch

Starting the Engine

Starting the Engine

1. To start a COLD engine, move the choke lever upwards to

the CLOSED position (see Figure 1). Lock the throttle by

depressing the trigger and while the trigger is depressed, push

in the button next to the thumb switch. Hold the button in and

release the trigger. e throttle is now in the high idle position

(see Figure 2).

2. To start a WARM engine, move the choke lever downwards to

the OPEN position and do not lock the throttle into the high

idle position.

3. Press the priming bulb repeatedly until fuel can be seen in the

clear-plastic fuel return tube (see Figure 1).

4. Slide the engine ON/OFF switch on throttle handle down or

into the ON position. Grasp the recoil starter handle and pull

lightly until you feel resistance, then pull quickly towards you

and return the recoil starter slowly. To prevent damage to the

starter, do not allow the recoil starter cord to snap back against

the engine.

5. If the choke lever was moved to the CLOSED position to

start the engine, gradually move it to the open position as the

engine warms up. As the engine warms up also release the high

idle lock slightly depressing the trigger and then immediately

releasing it. Use caution as to not engage the clutch.

!

WARNING

Figure 2

TO PREVENT PERSONAL INJURY OR DAMAGE TO

O

THE POST DRIVER TURN THE ENGINE TO THE OFF

POSITION BEFORE FOLLOWING THE

I

RESTARTING A HOT ENGINE PROCEDURE

Restarting a Hot Engine

If the engine is operated at high ambient temperature, then turned

off and allowed to sit for a short period, it may not restart on the

first pull of the recoil starter. Follow the following

1. Turn the engine switch to the OFF (see Figure 2).

2. Move the choke lever to the OPEN position (see Figure 1).

3. Hold the throttle trigger in the MAX speed position.

4. Pull the recoil starter handle 3 to 5 times.

5. Follow the Starting the Engine instructions above with the

choke lever in the OPEN position.

11

Page 12

Operation

Driving a T-Post

1. Have an assistant hold the t-post in the desired horizontal

position or manually drive the t-post into the ground a short

distance, so that it is free standing upright.

2. With the engine running, position the post driver over the top of

the t-post, gripping the handles firmly (see Figure 3).

3. e Power Post Driver should be positioned at the same angle as

the t-post that it will be driving (see Figure 4).

4. Apply steady downward pressure to the handles while depressing

the throttle trigger slightly to engage the clutch and hammer.

5. Once you are confident that the post is driving into the ground

straightly, depress the throttle trigger fully to operate at

maximum speed until the post is driven to the desired depth.

NOTE: Using a level will help ensure driving the post into the

ground at a perpendicular angle.

6. Release the throttle trigger dropping the engine RPM back to

idle before removing from the post.

7. When the engine has returned to idle, proceed to the next post

repeating the steps outlined above.

Figure 3

12

Figure 4

Page 13

Maintenance

!

WARNING

BEFORE PERFORMING ANY MAINTENANCE

PROCEDURE STOP THE ENGINE, WAIT FIVE 5

MINUTES TO ALLOW ALL PARTS TO COOL.

Regular maintenance is the way to ensure the best performance

and long life of your machine. Please refer to this manual and the

engine manufacturer’s owner’s manual for maintenance

procedures.

Maintenance Checklist

Maintenance Before After Every Every Every

Procedure Each Use 10 Hours 25 Hours

50 Hours 250 Hours

Check Engine Fuel Level X X X X

Check and Tighten all Fasteners X

Check Air Cleaner X

Clean/Replace Air Cleaner* X

Change Engine Oil** X X

Check Crankshaft & Piston lubrication X

Remove/Service Hammer and Anvil X

* Clean/change air filter more frequently if in dusty environment

** After the first 10 hours of operation change the engine oil, thereafter every 25 hours of operation

13

Page 14

Maintenance

Checking the Engine Oil

Check the engine oil level before each use, or every 10 hours

if operated continuously. Check the engine oil level with the

engine stopped and in a level position.

1. Remove the oil fill cap/dipstick and wipe it clean with a

paper towel (see Figure 5).

2. Insert and remove the oil filler cap/dipstick without screwing

it into the oil filler neck, then remove it to check the oil level

shown on the dipstick.

3. If the oil level is near or below the lower limit mark on

the dipstick, fill to the bottom edge of the oil fill hole with

SAE 10-30W engine oil. See the SAE Viscosity Chart for

other oil weights and temperatures (see Figure 6). To avoid

overfilling or underfilling, be sure the engine is in a level

position while adding oil.

4. Reinstall the oil filler cap/dipstick and tighten securely.

L ower

L imit

O il F ill

Cap

O il F ill

H ole

Changing the Engine Oil

1. Allow the engine to cool slightly. e engine oil will flow

more quickly when still warm. Be careful of draining hot oil.

2. Remove the oil fill cap, invert the power driver and carefully

drain the engine oil into an approved container for disposal.

3. Return the power driver to its upright position on a level

surface.

4. Some oil will remain in the engine after draining. When

refilling with fresh oil, start with about 2 ounces. Slowly add

SAE 10-30W engine oil into the oil fill and wait one minute

for the oil to settle, then continue filling with oil. Slowly add

enough oil to fill to the bottom edge of the oil fill hole (see

Figure 5).

5. Replace the dipstick. Be careful not to overfill.

Maximum

Oil Level

Minimum

Oil Level

Figure 5

SAE VISCOSITY GRADES

30W

10W - 30W

5W - 30W

- 2 0 0 2 0 4 0 6 0 8 0 1 0 0 ° F

AVERAGE OUTSIDE TEMPERATURE

14

Figure 6

Page 15

Maintenance

Replacing the Air Cleaner (Model 104369 - Honda Engine)

1. Press the latch tab on the top of the air cleaner cover and

remove the cover (see Figure 7).

2. Inspect the air cleaner filter. Clean or replace dirty air filter.

Always replace damaged air filter. Reinstall the air filter and

air cleaner cover.

Air

F ilter

Air F ilter

Cov er

Air F ilter

U pper

L atch T ab

U pper

L atch T ab

Air

Cleaner

Cov er

L ower

L atch T abs

Figure 7

Replacing the Air Cleaner (Model 103400 - DHT Engine)

1. Loosen the air filter cover latch (see Figure 8).

2. Set the air filter cover aside.

3. Remove the air filter.

4. Carefully clean the air filter with hot water and a mild detergent,

squeeze the water out and allow to dry. Soak the filter in fresh

oil, squeeze the excess oil out and replace in the filter housing.

5. Re-install the air filter cover.

Cov er

L atch

!

WARNING

To avoid personal injury or damage to the engine

do not run the engine without an air lter.

Figure 8

15

Page 16

Maintenance

Changing/Cleaning the Spark Plug

e recommended spark plug is the correct heat range for

normal engine operating temperatures. An incorrect spark plug

can cause engine damage.

H ex

B olt

Recommended Spark Plug: CM5H (NGK), CMR5H (NGK)

1. Remove the hex bolt on top of the engine cover (remove

two hex bolts on the top of the cover on the DHT engine

model) and slide the cover off (see Figure 9). Disconnect the

spark plug cap, and remove any dirt from around the spark

plug area. Remove the spark plug with a 5/8-inch spark plug

wrench (see Figure 10).

2. Inspect the spark plug. Replace it if damaged or badly

fouled, if the sealing washer is in poor condition, or if the

electrode is worn. Measure the spark plug electrode gap with

a wire-type gauge. For good performance, the spark plug

must be properly gapped and free of deposits. Correct the

gap, if necessary, by carefully bending the side electrode. Gap

should be: 0.60 0.70 mm (0.024 0.028 in)

3. Install the spark plug carefully, by hand, to avoid crossthreading. After the spark plug is seated, tighten with a

5/8-inch spark plug wrench to compress the sealing washer.

When installing a new spark plug, tighten 1/2 turn after the

spark plug seats to compress the washer.

4. When reinstalling the original spark plug, tighten 1/8 1/4 turn after the spark plug seats to compress the washer.

A loose spark plug can overheat and damage the engine.

Overtightening the spark plug can damage the threads in

the cylinder head.

5. Attach the spark plug cap to the spark plug. Reconnect the

spark plug cap.

6. Install the top cover, and tighten the 5mm hex bolt securely.

Engine

Cov er

S park

P lug Cap

Figure 9

S park

P lug

16

Figure 10

Page 17

Maintenance

Spark Arrestor Cleaning/Replacement

1. Remove the 5mm hex bolt on top of the engine cover and slide

the cover off (see Figure 9).

2. Remove the three 4mm x 6mm self-tapping screws from the

spark arrester and remove the spark arrester and the exhaust filter

from the muffler (see Figure 11).

3. Pinch the exhaust filter, strike lightly with a finger, and remove

carbon deposits. Be careful not to strike strongly. e exhaust

filter must be free of breaks and holes. If it is damaged or fouled

excessively, replace with a new exhaust filter.

4. Use a brush to remove carbon deposits from the spark arrester

screen. Be careful to avoid damaging the screen. e spark

arrester must be free of breaks and holes. Replace the spark

arrester if it is damaged.

5. Install the exhaust lter and spark arrester in the reverse order

of disassembly. When you install the spark arrester, the spark

arrester’s outlet must point to the side opposite the spark plug.

6. Replace the engine cover, reinstall the hex bolt and tighten

secu re ly.

S park

Arrester

O utlet

S elf- T apping

S crews

Mufer

Exhaust

F ilter

S park

Arrester

Figure 11

17

Page 18

Maintenance

O

I

Crankshaft and Piston Lubrication

1. Remove four hex bolts and crankshaft cover (see Figure 12).

2. Inspect the color and amount of grease inside the crankcase.

ere should be a ring of grease collected to the wall inside

the crankcase. Should the depth of the ring from the wall

inward measure 1/4” or less this indicates the grease is low.

3. If the amount of grease is low, add a small amount. e

maximum level should not be more than 1/2”.

NOTE: Overfilling with grease can damage the power driver.

4. If the grease is discolored, clean out old grease and add new

grease level with the bottom edge of the crank pin head.

5. Inspect the o-ring seal and replace it on the crankcase cover.

6. Replace the crankcase cover and tighten the hex bolts.

H ex B olts

4 P laces

Crankshaft

Cov er

Figure 12

Crankshaft grease

should be between

1 / 4 ” to 1 / 2 ” thick

on inside walls and

be clear, if dark or

discolored it should

be replaced.

Troubleshooting

PROBLEM SOLUTION

Engine will not start • Add gas to gas tank

• Connect spark plug wire to spark plug

• Move choke upwards to CLOSED position

Engine runs rough, oods during operation • Clean or replace air cleaner

Engine is hard to start • Drain old fuel and replace with fresh

• Make sure spark plug cap is securely attached to plug

Engine misses or lacks power • Clean or replace air cleaner

• Replace spark plug and adjust gap

• Drain, clean and rell gas tank

Engine stops suddenly • Low quality or deteriorated gasoline, drain and replace

• Spark plug cap is damaged or loose

• Move choke downwards to OPEN position after start

Power Post Driver runs slowly • Engine oil too full, check dipstick and remove some oil

Recoil is dicult to pull • Remove the spark plug and pull the recoil starter cord

several times until it pulls freely. Replace spark plug.

• Check oil dipstick and remove some oil if necessary.

18

Page 19

Parts List

Item # Part Name Part Qty

4 5 4 4

3 8

1

2

3

4

1 Hex Bolts, M8x15 2

2 Top Handle Bolts, M8x20 4

3 Upper Handle 1

4 Fixed Plate 1

5 Handle Cup 2

6 Hex Bolts, M5x15 4

3 7

3 5

4 3

4 0

4 6

3 5

3 9

5

7 Crankcase Cover 1

8 O-Ring Seal 75x1.8 1

1 1

1 0

78

6

9 Crank Pin 1

10 Crankshaft 1

11 Hex Bolts, M6x25 6

12 Post Driver Body 1

13 Cylinder 1

14 Bush Bearing 2

9

15 Connecting Rod 1

16 12 Retainer 1

4 1

4 2

3 8

4 7

3 6

3 7

1 2

1 3

17 Wrist Pin 12x32 1

18 Piston 1

19 O-Ring Seal 37.5x3.5 3

20 Hammer 1

1 4

21 Anvil O-Ring Retainer 1

22 O-Ring Seal 40x5.3 2

1 5

1 7

3 4

3 3

3 2

2 3

2 2

2 4

2 5

1 6

1 8

1 9

2 0

2 1

2 6

2 7

2 8

2 9

23 Big Retainer 1

24 Anvil O-Ring Cup 1

25 Anvil 1

26 O-Ring Seal 45x3.5 1

27 O-Ring Seal 56x1.8 1

28 Chuck Tube 1

29 Lower Driver Body 1

30 Hex Bolts, M8x60 6

31 Handle Anti-Vibration Spring 4

32 Handle Tube 1

33 Switch 1

34 Handle Tube 2

35 Bearing, 6004-2RS 2

36 Bearing, 6000-2RS 1

37 42 Retainer 2

38 20 Retainer 2

39 Key, 4x4X12 1

40 Gear 1

3 1

3 0

41 Bearing, 6201-2RS 1

42 Hex Bolts, M6x30 4

43 Clutch Housing 1

44 Clutch Drum 1

45 Cover 1

46 Pin 2

47 Gasket 1

19

Page 20

Warranty & Specications

IMPORTANT NOTICE

We, the manufacturer, reserve the right to change the product and/

or specifications in this manual without notification. e manual is for

information usage only and the pictures and drawings depicted herein are

for reference only.

Warranty Repair and Service

Do not return this product to the store for warranty issues or repair. Call

our customer service department at 720-287-5182, 1-877-487-8275, or

visit www.dirtyhandtools.com for the location of the nearest service center.

Record the information below for future reference.

Model No.

Serial No.

Date of Purchase

Place of Purchase

Specications

SKU/Part No. 103400 104369

Description Power Post Driver Power Post Driver

Engine 31cc DHT Engine* 35cc Honda Engine*

EPA Approved EPA Approved

Engine Type 4-stroke, single cylinder 4-stroke, single cylinder

Engine Fuel Capacity 20.29 fluid ounces (600mL) 21.76 fluid ounces (643mL)

Engine Oil Capacity** 2.37 fluid ounces (70mL) 3.4 fluid ounces (100mL)

Dimensions 23”L x 13”W x 14” D 23”L x 13”W x 14” D

Weight 34 Lbs. (Shipping Weight 45 Lbs.) 34 Lbs. (Shipping Weight 45 Lbs.)

Warranty 2 Year / 2 Year Limited Warranty 2 Year / 2 Year Limited Warranty

*As rated by engine manufacturer

** Not included, shipped without engine oil

Dirty Hand Tools® is a brand of

1100 W 120th Ave., Suite 600

Westminster, CO 80234 • 720-287-5182

For Service or Questions

Call 1-877-487-8275

720-287-5182

www.dirtyhandtools.com

Loading...

Loading...