12-1044

FVM100 Hand-held Probe

User Guide

Foreword

Thank you for purchasing our products. Before assembly and use,

make certain that all of the parts you have ordered are present. Check

the packaging carefully as some parts are small and can be overlooked.

Also, locate any additional parts and accessories you may have

purchased.

Safety Conventions

You should understand the following conventions before using the

product described in this manual.

CAUTION

Refers to a potential product hazard, it requires a procedure which, if

not correctly followed, may result in component damage. Do not

proceed unless you understand and meet the required conditions.

- 1 -

Introduction

rtable,

video microscope used to inspect fiber optic

ly, it is used to

reach connectors that are

installed on the “backside” of patch panels

or inside hardware devices. It eliminates the

or disassemble hardware devices prior to

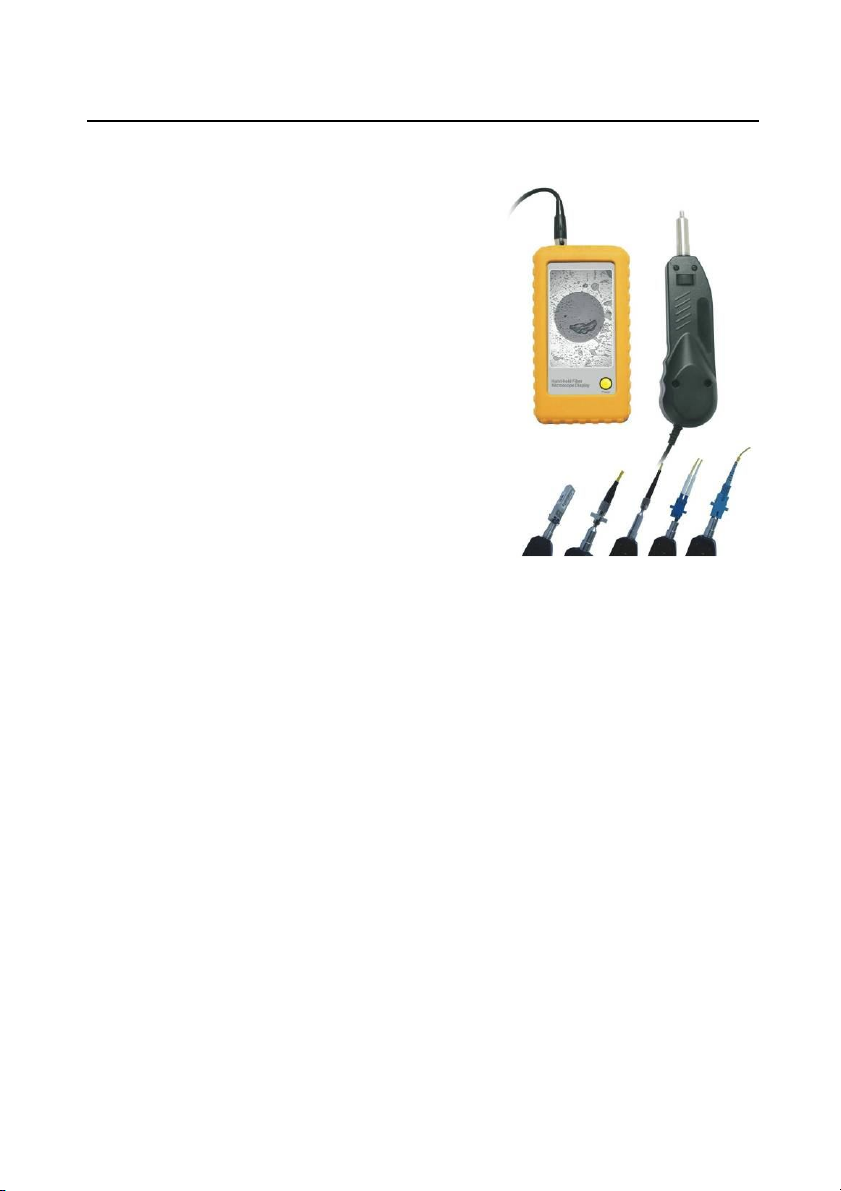

FVM100 Hand-held Probe Introduction

The FVM100 Hand-held Probe is a po

terminations. More specifical

inspect hard-to-

need to access the backside of patch panels

inspection.

Available Applications

Patch Panel Inspection

Many patch panels are designed to allow the front connector to be easily

inspected, but the back one is often difficult to access. Inspecting the

connector on the front side of the panel can usually be performed with a

simple fiber inspection microscope. However, the back connectors are not

as easily inspected with traditional microscopes, thus requiring

time-consuming troubleshooting. The FVM100 offers a fast and effective

means of installing, troubleshooting or maintaining fiber optic patch

panels.

Inspection of Cable Assemblies

When Video Inspection Probe is equipped with proper Adapter Tip, you can

also inspect patch cords, pigtails, and cable assemblies.

- 2 -

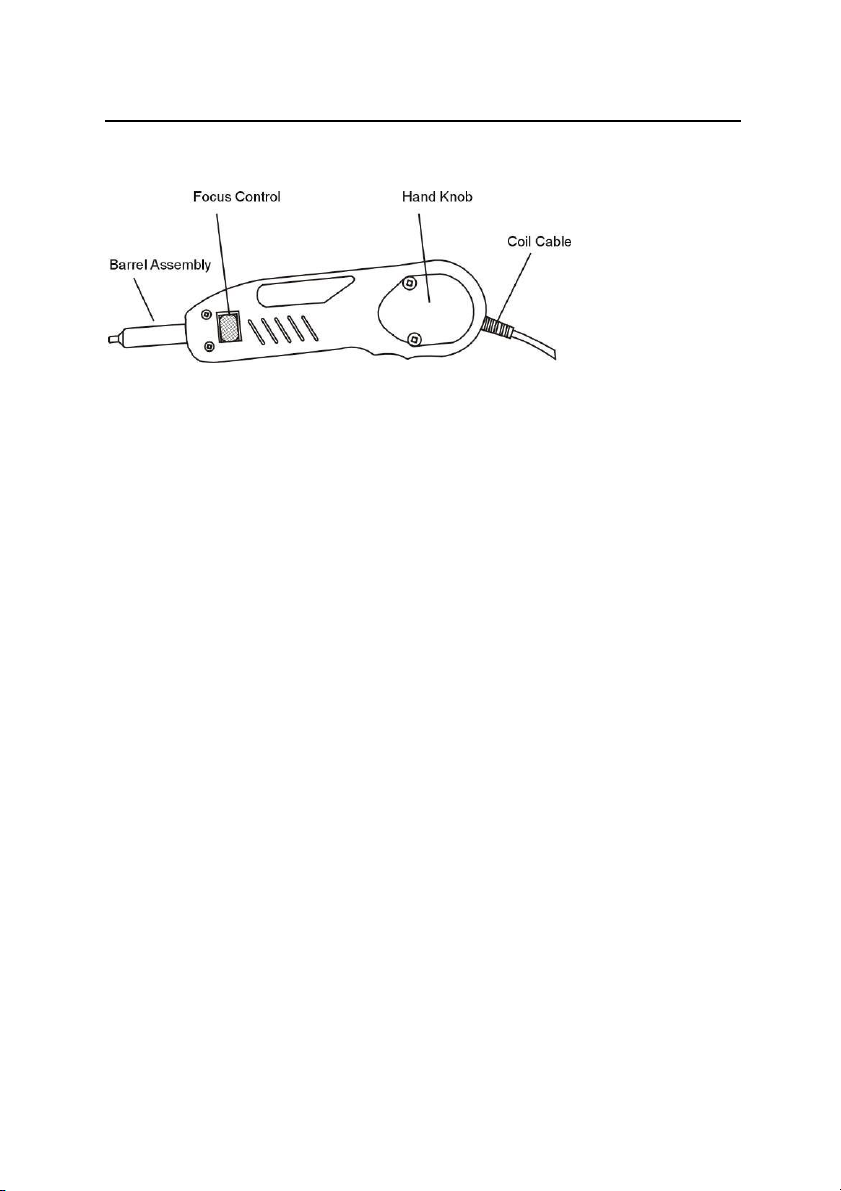

Structure/Parts

A. Analog Probe

This probe utilizes an analog CCD, which outputs an NTSC or a PAL

signal. The signal is routed through a 4-pin connector that routes

power into the probe, and the video signal out of the probe. This unit is

suitable for use with our hand held LCD display.

a 1. Barrel Assembly

The barrel assembly houses the optics which accommodates different

adapters, such as FC, SC, ST, LC, E2000, MTRJ and other customized PC

or APC adapters.

a 2. Focus Control

The default setting of magnification is 250x. When the figure shows on

monitor, screw the focus control to make it clearest.

- 3 -

Structure/Parts

B. Hand-Held LCD Display

Standard: 3.5 inch Common Monitor

- 4 -

Structure/Parts

Optional: 3.5 inch Monitor-MEM

- 5 -

Structure/Parts

Monitor-MEM Function

1. Photo Snapping

When the ‘Power Switch’ is turned on, pressing ‘Camera’ would help

you take a photo for the inspection.

2. Data outputting

If you need to check the data saved in the SD card, you can either

connect the monitor via USB wire to your computer or take the SD

card out of the SD slot and read it with the card reader we offered.

These monitors can be powered by an output 110-240V DC/AC or a

rechargeable Li-ion battery equipped inside. Video input is dedicated

to PAL/NTSC formatted probe. All of the display’s controls are built into

the handle for easy access.

- 6 -

Structure/Parts

C. Standard Tips

- 7 -

Installation

Tip Assembly

Installing Tips on Probe

Assembly & Tip Installed Standard

Step 1

Locate tip you want to install and look at the threaded end. This

screw acts as a “key” and is already mounded with the Key Channel.

DO NOT try to screw the Key Channel off from the threaded Key,

which might destroy the whole probe.

Step 2

Slightly screw the Key that you need onto the Key Channel.

- 8 -

Installation

LCD Monitor Assembly & Controls

Using the LCD Display with the Probe

Connect the Probe to the Display

Step 1

Connect the cable from the probe to the monitor using the 4-pin

connector on the bottom of the monitor.

Step 2

Connect the AC power adapter/charger if necessary.

On/Off Control

(Toggle switch) Press upward to turn the unit on, press downward to

shut the unit off.

AC Power

Using the DC/AC power adapter has the following advantages:

Use external power (DC/AC power adapter/charger) to power the LCD

directly from a DC/AC power source, or charge the battery pack. Both

can be accomplished simultaneously.

- 9 -

General Information

Technical Specifications

Video Inspection Probe

Magnification 400x (9’’ Monitor) 250x (3.5’’ Monitor)

Resolution Ratio 0.5 um

Display 3.5’’ TFT-LCD, 960x240 pixels

Video Output NTSC / PAL

Weight/Dimensions 0.18 kg / 18 x 4 x 3.5 cm

Wire Length 1.2 M

Application

Adapter Type Description

25-U-M

(2.5mm UPC Male)

125-U-M

(1.25mm UPC Male)

25-A-M

(2.5mm APC Male)

125-A-M

(1.25mm APC Male)

25-U-F

(2.5mm UPC) Female)

LC-U-F

(LC UPC Female)

FC/SC/ST/E2000 patch cord UPC termination

LC/MU patch cord UPC termination

FC/SC/ST/E2000 patch cord APC termination

LC/MU patch cord APC termination

FC/SC/ST/E2000 UPC bulkhead

LC UPC bulkhead

- 10 -

General Information

SC-A-F

(SC APC Female)

FC-A-F

(FC APC Female)

LC-A-F

(LC APC Female)

Other Adapters can be offered on request.

Other Parts

Power Supply 12.6V rechargeable Li Battery

SC APC bulkhead

FC APC bulkhead

LC APC bulkhead

Monitor

Work/Storage Temp.

0.30 kg / 14.5 x 7.5 x 4 cm

0.40 kg / 17 x 10 x 4.5 cm

-20℃~+50℃ / -30℃~+60℃

Accessories

Type Function Description

Standard Accessories

Inspection Probe x1

3.5’’ monitor x1

Standard Accessories

25-U-M x1 ; 125-U-M x1

25-U-F x1 ; LC-U-F x1

Recharger ; Manual ; Carrying bag ; Li Battery

Optional Accessories

25-A-M ; 125-A-M ; SC-A-F ; FC-A-F ; LC-A-F

AV-USB 2.0 Converter

- 11 -

General Information

Warranty

We warrant this equipment against defects in material and

workmanship for a period of one year from the date of original

shipment. We also warrant that this equipment will meet applicable

specifications under normal use. During the warranty period, we will,

at our sole discretion, repair or replace for any defective product free

of charge should the equipment need to be repaired.

IMPORTANT

The warranty will become null and void if

• the equipment has been tampered with, repaired, or worked

upon by unauthorized individuals.

• the warranty label has been removed.

• product enclosure screws, other than those specified in this

manual, have been removed.

• the product enclosure has been opened, other than as explained

in this manual.

• the equipment serial number has been altered, erased, or

removed.

• the equipment has been misused, neglected, or damaged by

accident.

- 12 -

Loading...

Loading...