Page 1

11

© 2005 Directed Electronics, all rights reserved

N9405T 11-05

IInnttrroodduuccttiioonn

Congratulations on your purchase of the 9405T

back up sensor, designed to aid operation when

backing up your vehicle. Simple to operate and

use, the 9405T back up sensor notifies you with a

series of beeps, voice announcements, and incorporates an LED display to notify you when the

rear of your vehicle approaches an object or

obstruction.

Before using the 9405T back up sensor, be sure to

practice and test the product in order to familiarize yourself with the display, beep indicators, and

detection zones as they vary by vehicle.

WWaarrnniinngg::

Improper use of the back up

sensor could result in injury or death!

This back up sensor is strictly a drive

assist device. It is not a substitute of

driver's responsibilities when backing up

the vehicle. Please drive carefully and follow all local

and federal laws when backing up your vehicle.

Directed Electronics does not guarantee or assume any

liability for injuries or damage that occur while backing

your vehicle. This product should not be considered a

safety device for any purpose. Proper driving skills,

including slowing down, using your mirrors, and having

another person as a visual assist are all proper precautions to be taken in order to safely back your vehicle.

NNoottee::

Changes or modifications to this unit not

expressly approved by the party responsible for compliance will void the user's authority to operate the

equipment. Any change(s) to the equipment will void

FCC compliance.

NNoottee::

This equipment has been tested and found to

comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against

harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful

interference to radio communications. However, there

is no guarantee that interference will not occur in a par-

ticular installation. If this equipment does cause

harmful interference to radio or television reception,

which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

--Re-orient or relocate the receiving antenna.

--Increase the separation between the equipment and

the receiver.

--Connect the equipment into an outlet on a circuit

different from that to which the receiver is connected.

--Consult the dealer or an experienced radio/TV technician for help.

1. Detection distance: 1~ 8.4 feet

2. Wireless from ECU to Digital Matrix LED

Display

3. Self-test function activated by reverse gear

4. 3–Color matrix LED dashboard display shows

the object's location

5. Anti-false alert technology

6. All weather design (water resistant)

7. Volume switch (low/medium/high)

Operating Voltage: 9V to 16V

Display current required: less than 200mA

Buzzer: 70–90dB

Temperature: -40° to 176° F (-40° to +80° C)

■ ECU (Electronic Control Unit)

■ Digital Matrix LED Display

■ 4–ultrasonic sensors

■ 4–ultrasonic sensor connecting cables

■ 3–sheet metal screws

■ 18.5mm hole saw

WWhhaatt iiss IInncclluuddeedd

SSppeecciiffiiccaattiioonnss

FFeeaattuurreess

9405T Back Up

Sensor

Page 2

22

© 2005 Directed Electronics, all rights reserved

N9405T 11-05

TToooollss RReeqquuiirreedd

■ Tape measure

■ Electric Drill

■ Digital Multi-Meter

■ Wire stripper

■ Electrical tape

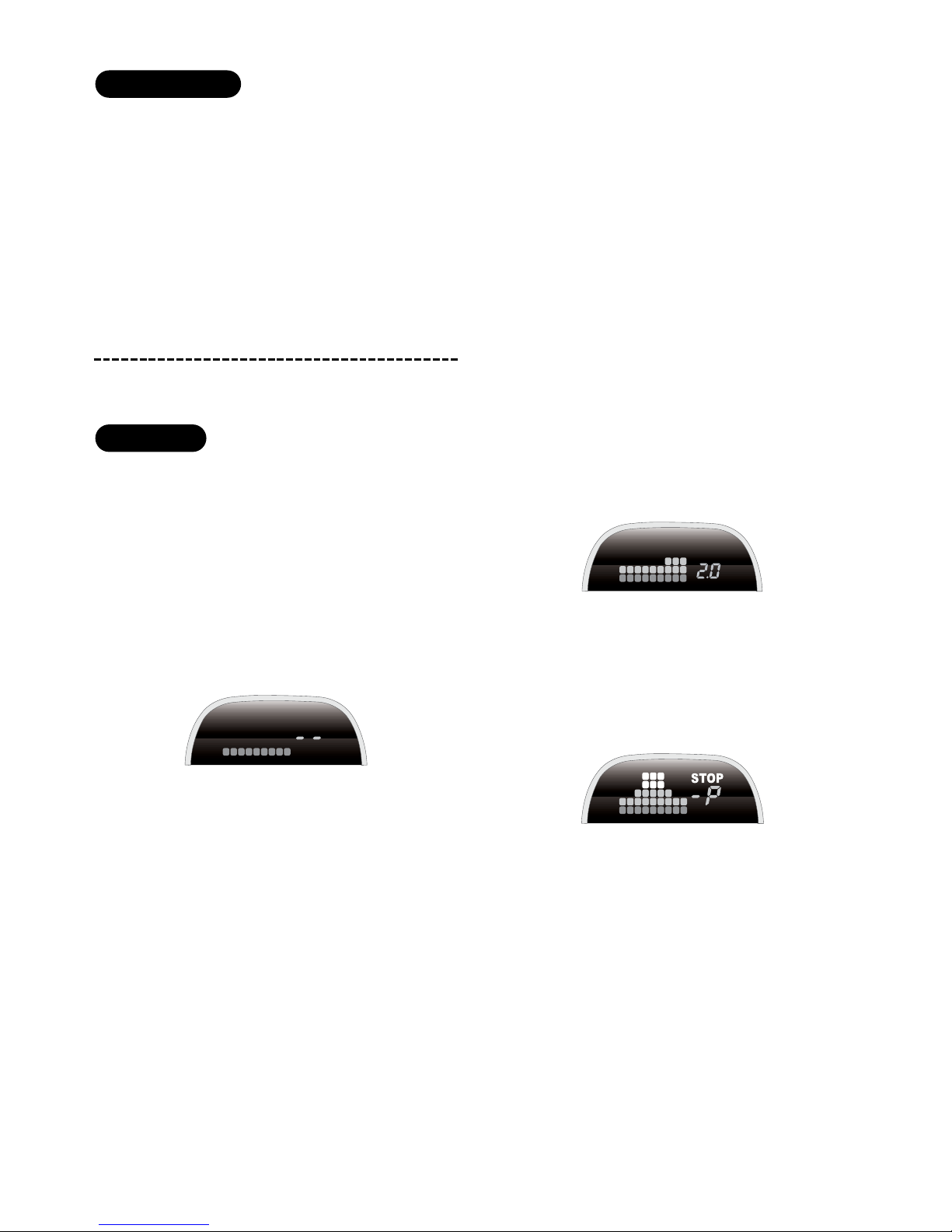

OOppeerraattiioonn

The following illustrations show the general reac-

tion of the backup system sensing and display

The system will first test all the sensors when the

reversing gear is engaged (see

Self-Test

Function

), and then the system starts sensing

objects to the rear of your vehicle.

a. The object distance is—greater than 8.5Ft:

Zone 1 Green LED of display will flash.

b. The object distance is—8.4–1Ft:

The display will show the distance by the

digital number displayed and show the

object's location in the Matrix LED Display.

c When the object distance is—less than 1Ft:

"-P" will be displayed and "Stop" will flash.

IInnttrroodduuccttiioonn

TToooollss RReeqquuiirreedd

Page 3

33

© 2005 Directed Electronics, all rights reserved

N9405T 11-05

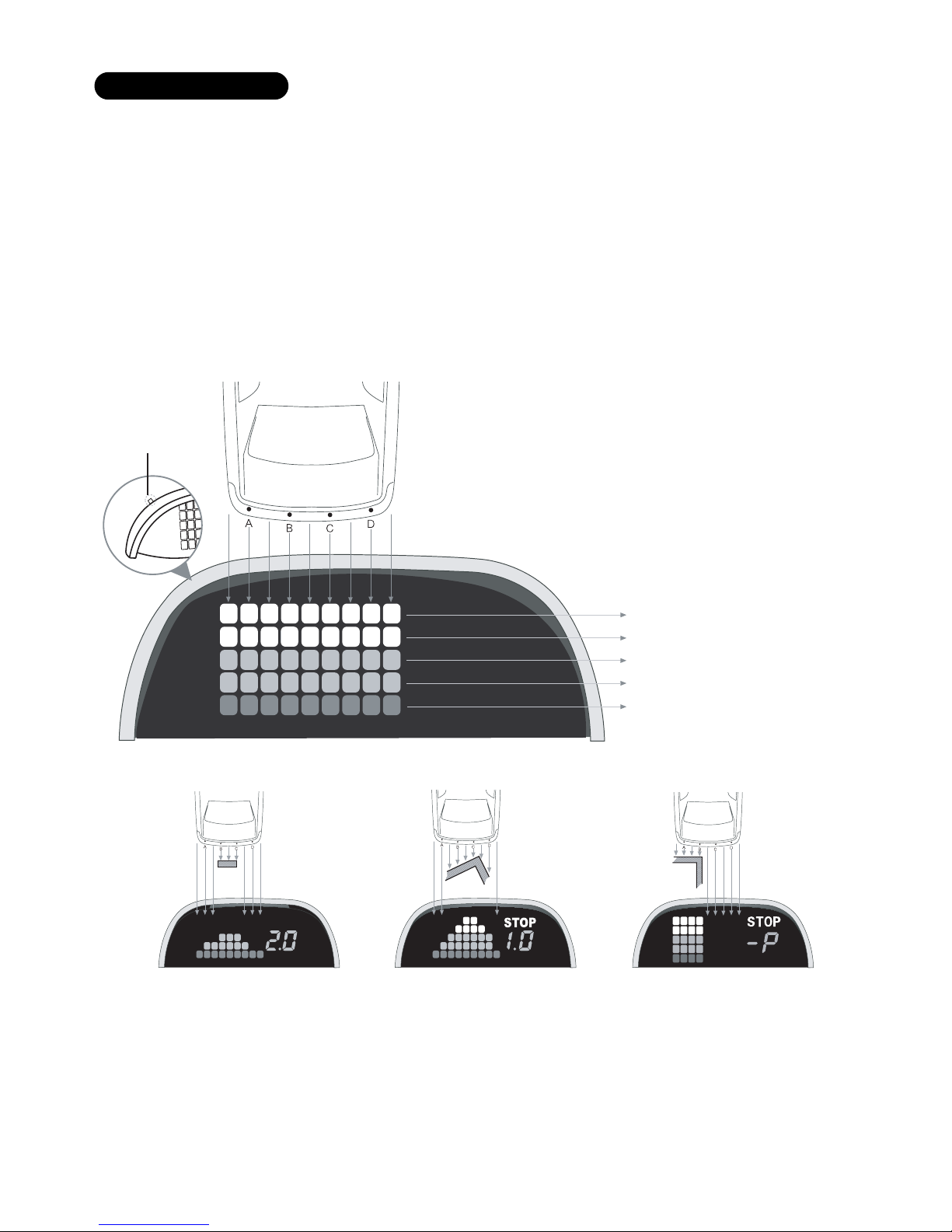

The illustrations below show the LED display

when detecting different shaped objects.

The volume switch located at the top left of the

display has three settings. This switch has the

following options.

z Beeps only, low volume

zz Beeps with voice, low volume

zzz Beeps with voice, high volume

DDiiggiittaall MMaattrriixx LLEEDD DDiissppllaayy

Volume switch

1Ft, Zone 5 (Red LED)

1.0–1.9Ft, Zone 4 (Red LED)

2.0–2.8Ft, Zone 3 (Orange LED)

2.9–4.8Ft, Zone 2 (Orange LED)

4.9–8.4Ft, Zone 1 (Green LED)

Page 4

44

© 2005 Directed Electronics, all rights reserved

N9405T 11-05

As your vehicle backs up towards an object, the

beep warning will first be none when the object

is beyond 8.4 feet away. Then, it will start

beeping at short intervals. As you get closer to

the object the beeps will lengthen until it

becomes a constant tone. Stop the vehicle, you

are now at less than 1 foot from the object. If the

volume switch is on a voice support position, the

distance and stop command will also be

announced as you back up.

DDiiggiittaall MMaattrriixx NNuummeerriicc DDiissppllaayy

NNOOTTEE::

Initially the system will beep when the vehicle is

put into reverse.

Audio warning Distance on display LED matrix display

1.0 ft

1.0~2.8 ft

-P

Zone 5

Zone 4Zone 5

Zone 2Zone 3

2.9~4.8 ft

4.9~8.4 ft

8.4ft~1.0 ft

The digital number

on display will show

every 0.1M change

of distance

Zone 1

Page 5

55

© 2005 Directed Electronics, all rights reserved

N9405T 11-05

Detection errors may occur due to the following

cases:

Smooth sloping surface

Smooth round object

Items absorbing sound, e.g. cotton

1. Heavy rain or snow, a contaminated or

damaged sensor(s) could result in detection

errors.

2. Check to ensure the system is in order before

use.

3. Clean sensors of any mud or debris.

Immediately replace any damaged sensor

when detected by the system.

4. Do not paint over the sensors as this will

affect the systems performance and accuracy.

5. Heavy smoke or vapor from exhaust, due to a

cold start or a poorly running engine can also

result is a false reading.

The back-up system only activates when the

vehicle is placed in reverse gear. When placed in

reverse gear the system first does a diagnostic

check to ensure the system is fully functional and

reports any sensor malfunctions within the back-

up system.

If all the sensors are normal, the system will beep

once and the LED display will flash once.

If there is any malfunction with the sensors, the

system will beep 3-times to indicate that one or

more sensors have problems. The flashing red

LED(s) will indicate which sensor(s) is malfunc-

tioning.

SSeellff--TTeesstt FFuunnccttiioonnFFaallssee RReeaaddiinnggss

The flashing LED indicates the problem sensor

The total number of the problem sensors

Sensor A has problem (E1: 1 problem sensor)

Sensor A,D have problem (E2: 2 problem sensors)

Page 6

1. Verify that the size of the supplied hole saw

is compatible to the diameter of the sensor

before drilling your bumper. Use a scrap piece

of wood for this test.

NNoottee::

Before drilling any holes in the vehicle ensure

that the the area behind is clear of any electrical,

hydraulic, or support members, etc.

2. Install the sensor vertically, the "up" arrow

must be pointing up.

3. Each sensor is numbered, ensure that they are

installed as shown on the illustration.0

SSeennssoorr IInnssttaallllaattiioonn

66

© 2005 Directed Electronics, all rights reserved

N9405T 11-05

IInnssttaallllaattiioonn

NNoottee::

Before installing system let the

components of the exhaust system cool

down. This will make the installation safer

and preclude heat damage to the back up

sensor wiring or components.

The following illustration shows the general loca-

tion of the components of the back up system.

IInnssttaallllaattiioonn DDiiaaggrraamm

Display

Sensors

ECM

Connect to

reversing light(+)

Connect to

ignition wire (+)

1 foot 8 inches

~2 feet 3

inches

0.3L 0.4L 0.3L

5~8 inches 5~8 inches

Page 7

77

© 2005 Directed Electronics, all rights reserved

N9405T 11-05

EExxaammppllee SSeennssoorr PPllaacceemmeenntt CCaallccuullaattiioonn::

1. Measure the mounting distance between the

proposed locations for sensor A and sensor D.

For this example (not to be used for your

vehicle) let’s say that measures 48”.

2. Then 0.3L is 0.3 X 48” = 14.4”

and 0.4L is 0.4 X 48” = 19.2”

3. Hence, the distance that sensor B is from

sensor A is 14.4 inches, and the distance that

sendor C is from sensor D is 14.4 inches. The

distance between sensor B and C will be

19.2”.

NNOOTTEE::

These distances are approximate as mounting

locations have to be selected based on clearance behind

the bumper and any obstructions or bumper curvatures

on the surface of the bumper.

4. Drill the holes in the bumper as indicated in

the diagrams above and install the sensors.

Sensors A and D should

NNOOTT

be mounted on

the curve of the bumper.

NNoottee::

Before drilling any holes ensure the the area

behind is clear of any electrical, hydraulic, or support

members, etc.

NNoottee::

Wiring is shown and described is for a positive

reverse indicator system.

The ECU is water resistant, however, it is recom-

mended that the module be mounted in the trunk

compartment or for a truck in as much of a pro-

tected area as possible.

1. Use the 3-sheet metal screws to mount the

module.

2. Connect the white wire to reversing light(+)

EECCUU IInnssttaallllaattiioonn

1. Verify that the size of the

supplied hole saw (18.5mm)

is compatible to the diameter

of the sensor by first drilling

a test hole in a scrap piece of

wood.

sensor A

sensor B

sensor C

sensor D

ECU

white

black

GND

Mount ECU in trunk

or

for a truck in as much

of a protected

area as possible

reversing lingt(+)

UP

UP

2. Install the sensor vertically,

the "up" sign must be on

upside.

Connect the white wire

to reversing light(+)

Page 8

1. Each of the four sensor interconnecting

cables are numbered to match with the

number on the sensor cable.

2. To ensure a water resistant connection at the

sensors, the connectors should be seated so

that the O-ring on the connector is snug

against the collar of the jack before tighten-

ing the connector.

3. Run the sensor interconnecting cables up into

the trunk (or to the location of the ECU for a

truck) and connect to the ECU module. Ensure

that you connect the correct numbered sensor

lead to match the connector jack on the ECU

module (see illustration).

4. Connect the White wire to the reverse indica-

tor wire (refer to previous illustration).

5. Connect the Black wire to the vehicle’s

chassis (refer to previous illustration).

NNoottee::

Discuss with the vehicle owner the placement of

the display.

1. Connect the White wire to the (+) ignition

wire.

2. Connect the Black wire to the vehicle’s

chassis.

3. Clean the area of the dashboard where the

display is going to be mounted.

4. Remove the 3M sticker off the bottom of the

display.

5. Mount the display on the dashboard by firmly

pressing down on the display.

Use the following illustration to test and verify

the operation of the backup system.

WWaarrnniinngg::

Do not stand behind a moving

vehicle death or injury could occur. Prior

to testing, set the parking brake On,

ignition key On (not start), step foot on

brake and shift the vehicle into reverse.

AAfftteerr IInnssttaallllaattiioonn TTeesstt

DDiiggiittaall MMaattrriixx LLEEDD DDiissppllaayy

SSeennssoorr ttoo EECCUU ccaabblliinngg

88

© 2005 Directed Electronics, all rights reserved

N9405T 11-05

Black

White

Ground

Ignition

Input (+)

Page 9

99

© 2005 Directed Electronics, all rights reserved

N9405T 11-05

Ensure that the engine is not running while proceeding

with the following tests.

Test the system operation with a piece of wood

(8 inches wide x 3 feet, 3 inches high) after the

installation. Start with the wood more than 8.4

feet away from the vehicle. Then move the wood

closer to the vehicle and ensure that both the

audible, LED, and distance indicators display cor-

rectly.

No beep at power up or no LEDs flashing

1. Is power wire connected to ECU correctly?

2. Verify (+)12V at ECU when vehicle is in

reverse.

3. Verify the ground connection

4. Have you connected to the correct reversing

indicator wire?

5. Do you have a minimum of (+)12V and ground

at the display?

False warning tone or false LED flashing

1. Is the sensor mounted too low or pointing to

the ground?

Sensors do not detect any objects

1. Is the vehicle’s exhaust smoking? Correct or

allow it to clear before proceeding with

testing.

2. Are sensors properly plugged into the correct

sockets?

If the problem persists, please follow these steps:

1. For consumers: Contact your dealer

2. For Installer or dealer:

a. Replace the ECU and re-check the system.

b. Test the sensors with a known operative

ECU and retest using the flat wooden

board.

c. Plug the known operative sensors into the

ECU and re-check.

d. Contact Directed tech support.

TTrroouubblleesshhoooottiinngg

8.4Ft

Loading...

Loading...