Directed Electronics Viper 5904, Python 594, Clifford 590.4X, Viper 5204, Clifford 520.4X Installation Manual

...Page 1

Responder HD Models

Viper 5904

Clifford 590.4X

Python 594

Security and Remote Start

Installation Guide

This product is intended for installation by a professional

installer only! Attempts to install this product by a person other than a trained professional may result in severe

damage to a vehicle’s electrical system and components.

© 2011 Directed Electronics, Vista, CA

N5904 2011-09b

Page 2

Bitwriter®, Code Hopping™, Doubleguard®, ESP™, FailSafe®, Ghost Switch™, Learn Routine™, Nite-Lite®, Nuisance Prevention® Circuitry, Revenger®, Silent Mode™,

Soft Chirp®, Stinger®, Valet®, Vehicle Recovery System®,

VRS®, and Warn Away® are all Trademarks or Registered

Trademarks of Directed Electronics.

The Bitwriter® (p/n 998U)

requires chip version 2.7 or

newer to program this unit.

Bitwriters with a date code of 6a or older require an IC upgrade (p/n

998M). Some bitwriters with a date code of 6B do not require the IC

upgrade, refer to tech tip # 1112 for more information.

Page 3

Contents

Warning! safety first ........................................................................................................................ 4

Wiring Diagram ............................................................................................................................. 5

Wiring Connections ........................................................................................................................ 6

Main Harness (H1), 6-pin connector ........................................................................................... 6

H2 Harness, 24-pin connector ................................................................................................... 6

Remote Start, (H3) 10-pin connector ........................................................................................... 7

Door Lock, 3-pin connector ......................................................................................................... 7

Adjusting the Sensor ........................................................................................................................ 7

Initializing Virtual Tach (not needed w/hardwire tach inputs) ................................................................ 7

Learning the Tach (not needed with Virtual Tach) ................................................................................. 8

Neutral safety switch interface .......................................................................................................... 8

Testing the neutral safety switch ................................................................................................... 8

Remote Start Shutdown/Startup Diagnostics ....................................................................................... 9

Remote Pairing ............................................................................................................................. 10

Programming System Features ........................................................................................................ 11

Feature Menus .............................................................................................................................. 12

Menu 1 - Security .................................................................................................................... 12

Menu 2 - Convenience ............................................................................................................. 14

Menu 3 - Remote start .............................................................................................................. 16

Bitwriter - Only Options ................................................................................................................. 18

Basic Remote Functions .................................................................................................................. 20

Reset and Deletion ........................................................................................................................ 20

Long Term Event History ................................................................................................................. 20

Table of Zones .............................................................................................................................. 21

Troubleshooting: Alarm .................................................................................................................. 21

Troubleshooting: Remote Start ......................................................................................................... 22

Page 4

Warning! safety first

The following safety warnings must be observed at all times:

• Due to the complexity of this system, installation of this product must only be performed by an authorized

Directed Electronics dealer.

• When properly installed, this system can start the vehicle via a command signal from the remote control.

Therefore, never operate the system in an area that does not have adequate ventilation.

The following precautions are the sole responsibility of the user; however, authorized Directed Electronics

dealers should:

• Never use a test light or logic probe when installing this unit. Always use a multimeter.

• Never operate the system in an enclosed or partially enclosed area without ventilation (such as a ga-

rage).

• When parking in an enclosed or partially enclosed area or when having the vehicle serviced, the remote

start system must be disabled using the installed toggle switch. It is the user’s sole responsibility to prop-

erly handle and keep out of reach from children all remote controls to assure that the system does not

unintentionally remote start the vehicle.

• USER MUST INSTALL A CARBON MONOXIDE DETECTOR IN OR ABOUT THE LIVING AREA ADJACENT

TO THE VEHICLE. ALL DOORS LEADING FROM ADJACENT LIVING AREAS TO THE ENCLOSED OR PAR-

TIALLY ENCLOSED VEHICLE STORAGE AREA MUST REMAIN CLOSED AT ALL TIMES.

Use of this product in a manner contrary to its intended mode of operation may result in property damage,

personal injury, or death. Except when performing the Safety Check outlined in this installation guide, (1)

Never remotely start the vehicle with the vehicle in gear, and (2) Never remotely start the vehicle with the

keys in the ignition. The user is responsible for having the neutral safety feature of the vehicle periodically

checked, wherein the vehicle must not remotely start while the car is in gear. This testing should be performed

by an authorized Directed Electronics dealer in accordance with the Safety Check outlined in this product

installation guide. If the vehicle starts in gear, cease remote start operation immediately and consult with the

user to fix the problem immediately.

After the remote start module has been installed, test the remote start module in accordance with the Safety

Check outlined in this installation guide. If the vehicle starts when performing the Neutral Safety Shutdown

Circuit test, the remote start unit has not been properly installed. The remote start module must be removed

or properly reinstalled so that the vehicle does not start in gear. All installations must be performed by an

authorized Directed Electronics dealer.

OPERATION OF THE REMOTE START MODULE IF THE VEHICLE STARTS IN GEAR IS CONTRARY TO ITS INTENDED MODE OF OPERATION. OPERATING THE REMOTE START SYSTEM UNDER THESE CONDITIONS

MAY RESULT IN PROPERTY DAMAGE OR PERSONAL INJURY. IMMEDIATELY CEASE THE USE OF THE UNIT

AND REPAIR OR DISCONNECT THE INSTALLED REMOTE START MODULE. DIRECTED ELECTRONICS WILL

NOT BE HELD RESPONSIBLE OR PAY FOR INSTALLATION OR REINSTALLATION COSTS.

Remote starters for manual transmission pose significant risks if not properly installed and operated. When

testing to ensure the installation is working properly, only remote start the vehicle in neutral gear, on a flat

surface and with a functional, fully engaged parking brake. Do not allow anyone to stand in front of or behind

the vehicle.

This product should not be installed in any convertible vehicles, soft or hard top with a manual transmission.

Installation in such vehicles may pose certain risk.

4

© 2011 Directed Electronics. All rights reserved.

Page 5

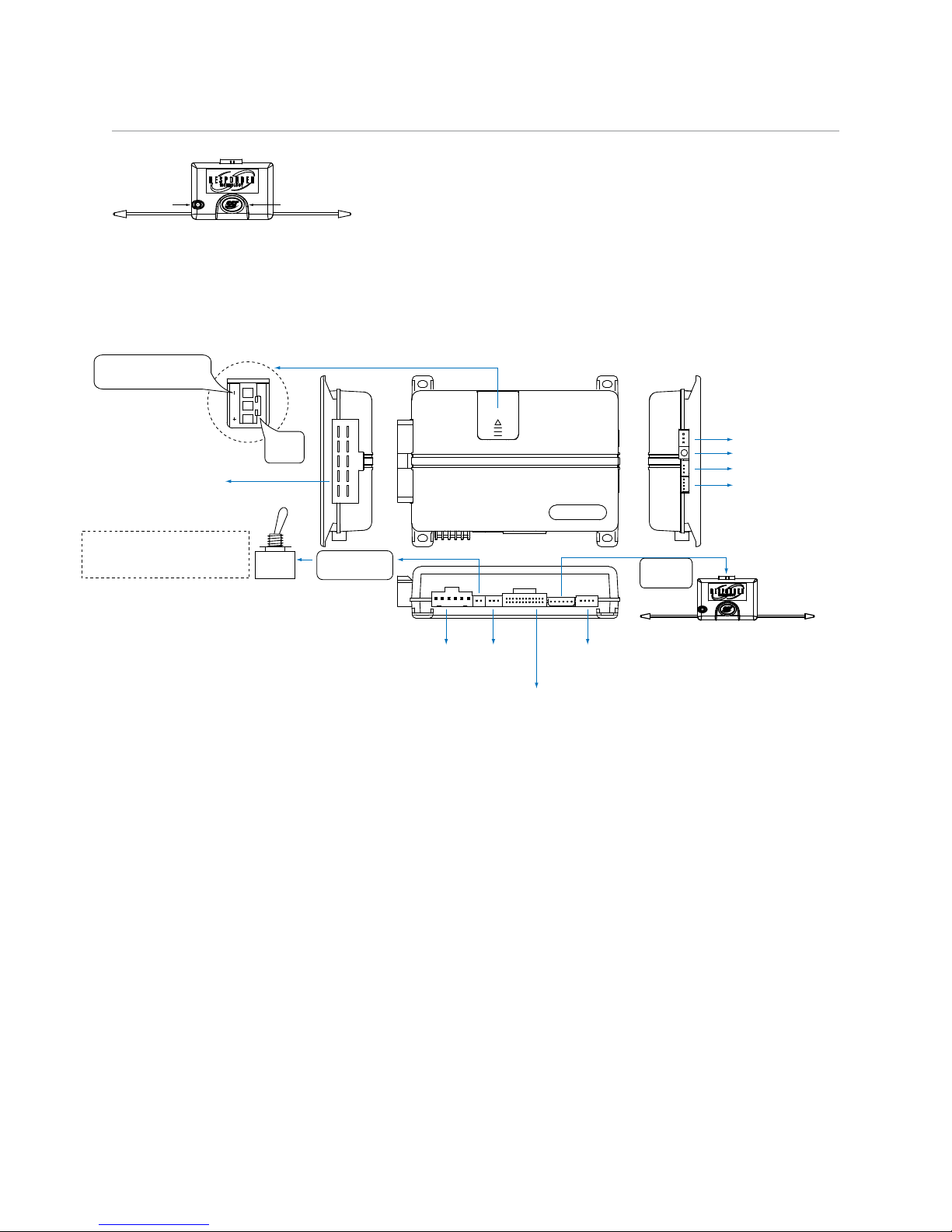

Wiring Diagram

Menu

Wheel

Menu

Wheel

Menu

Wheel

Status LED

Control Center 6711T

LIGHT FLASH POLARITY

(10A (MAXIMUM) FUSE JUMPER)

10A FUSE

MINI ATM

RPN: 8540

Remote Start

10-pin Harness

IMPORTANT! Neutral Safety

switch must be plugged in

and in the ON position

Control button

ON

Neutral Safety

Switch

Main 6-pin

Harness

Door Lock

Port

Bitwriter/SmartStart Port

Thermistor/Temp Sensor

Sensor 1

Sensor 2

5x04

RF Port

for IVU

Control Center

D2D Port (for external

Xpresskit interface module)

Aux/Shutdown/Trigger 24-pin Harness

Note:

Sensor ports 1 and 2 cannot support sensor 508D due to current limitations. These ports are also

constant power and ground connections.

© 2011 Directed Electronics. All rights reserved.

5

Page 6

Wiring Connections

Main Harness (H1), 6-pin connector

H1/1

H1/2 BLACK (-) CHASSIS GROUND

H1/3 BROWN (+) SIREN OUTPUT

H1/4 WHITE/BROWN PARKING LIGHT ISOLATION WIRE - PIN 87a of onboard relay

H1/5 WHITE PARKING LIGHT OUTPUT

H1/6 ORANGE (-) 500mA GROUND WHEN ARMED OUTPUT

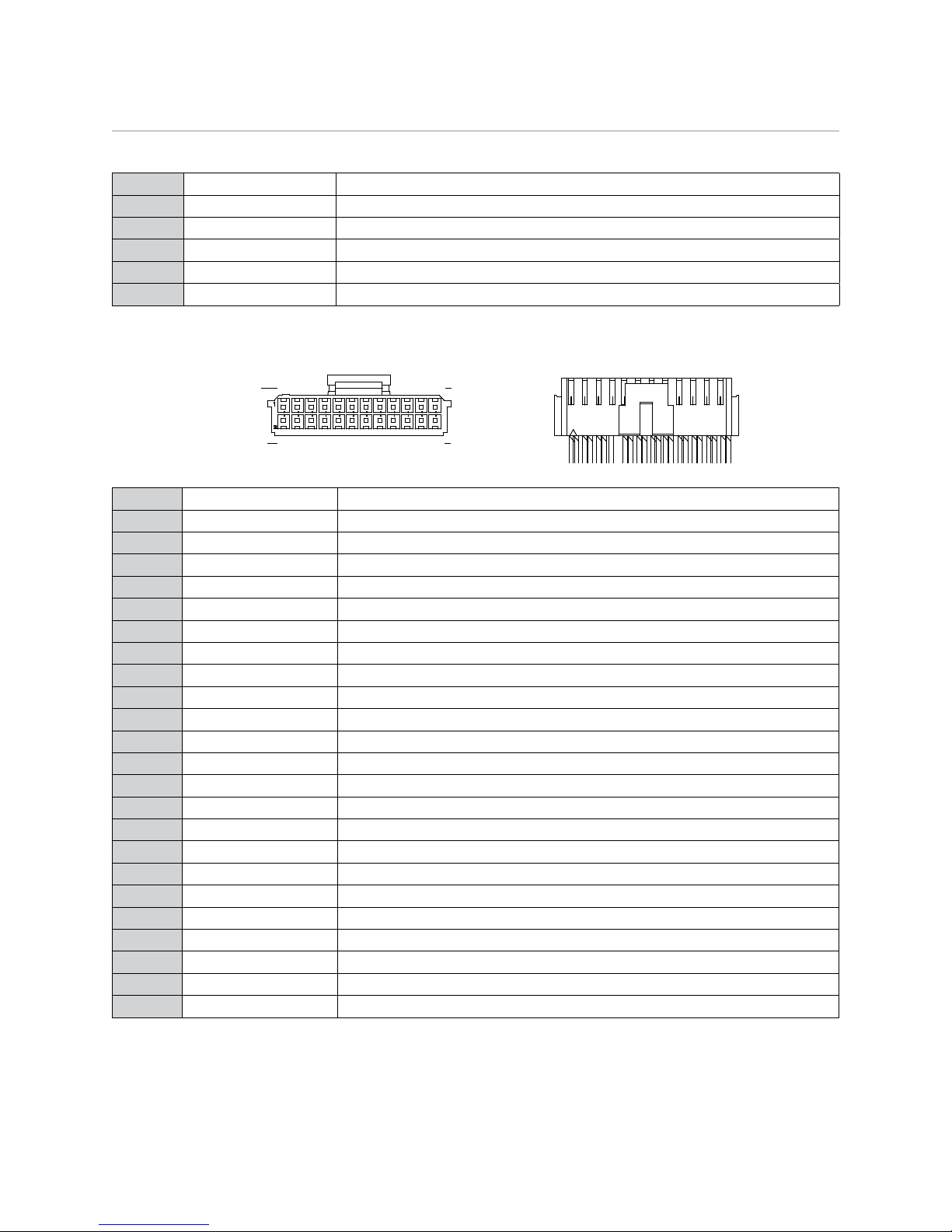

H2 Harness, 24-pin connector

RED (+)12VDC CONSTANT INPUT

1 3 5

2 4 6 24

INSERTION SIDE

H2/1

H2/2 BLACK/WHITE (-) NEUTRAL SAFETY INPUT

H2/3 BLUE/WHITE (-) 200mA 2ND STATUS /REAR DEFOGGER OUTPUT

H2/4 GREEN/BLACK (-) 200mA OEM ALARM DISARM OUTPUT

H2/5 RED/WHITE (-) 200mA TRUNK RELEASE OUTPUT

H2/6 GREEN (-) DOOR TRIGGER INPUT (N/C* OR N/O)

H2/7 BLACK/YELLOW (-) 200mA DOME LIGHT SUPERVISION OUTPUT

H2/8

H2/9 DARK BLUE (-) 200mA STATUS OUTPUT

H2/10 PINK (-) 200mA IGNITION 1 OUTPUT

H2/11 WHITE/BLACK (-) 200mA AUX 3 OUTPUT

H2/12 VIOLET (+) DOOR TRIGGER INPUT

H2/13 WHITE/VIOLET (-) 200mA AUX 1 OUTPUT

H2/14 VIOLET/BLACK (-) 200mA AUX 2 OUTPUT

H2/15 ORANGE/BLACK (-) 200mA AUX 4 OUTPUT

H2/16 BROWN (+) BRAKE SHUTDOWN INPUT

H2/17 GREY (-) HOOD PIN INPUT (N/C OR N/O)

H2/18 VIOLET/YELLOW (-) 200mA STARTER OUTPUT

H2/19

H2/20 GREY/BLACK (-) DIESEL WAIT TO START INPUT

H2/21 WHITE/BLUE (-) REMOTE START/ TURBO TIMER ACTIVATION INPUT

H2/22 ORANGE (-) 200mA ACCESSORY OUTPUT

H2/23 VIOLET/WHITE TACHOMETER INPUT

H2/24 GREEN/WHITE (-) 200mA OEM ALARM ARM OUTPUT

PINK/WHITE (-) 200mA IGNITION/FLEX RELAY CONTROL OUTPUT

BROWN/BLACK (-) 200mA HORN HONK OUTPUT

BLUE (-) TRUNK PIN/ INSTANT TRIGGER INPUT (N/C OR N/O)

23PINK/WHITE VIOLET/WHITE

GREEN/WHITEBLACK/WHITE

*The Normally Closed setting will only work if one of the vehicle's doors is connected. If more than one door

is to be monitored, then it is recommended to use the Xpresskit DTIMAZDA or tech tip # 1921 on www.directechs.com to interface with these types of vehicles.

6

© 2011 Directed Electronics. All rights reserved.

Page 7

Remote Start, (H3) 10-pin connector

H3/1 PINK (+) IGNITION 1 INPUT/OUTPUT

H3/2

H3/3 ORANGE (+) ACCESSORY OUTPUT

H3/4 VIOLET (+) STARTER OUTPUT (CAR SIDE OF THE STARTER KILL)

H3/5 GREEN (+) STARTER INPUT (KEY SIDE OF THE STARTER KILL)

H3/6

H3/7

H3/8

H3/9

H3/10 NC No Connection

RED/WHITE (87) FLEX RELAY +12V INPUT (30A FUSED)

RED IGNITION 1 +12V INPUT (30A FUSED)

PINK/WHITE (30) FLEX RELAY OUTPUT (car side of ign, acc or starter wire)

PINK/BLACK (87a) FLEX RELAY INPUT (key side of ign, acc or starter wire if needed)

RED/BLACK ACCESSORY/STARTER RELAY +12V INPUT (30A FUSED)

Door Lock, 3-pin connector

1 BLUE (-) 500mA UNLOCK OUTPUT

2 EMPTY NOT USED

3 GREEN (-) 500mA LOCK OUTPUT

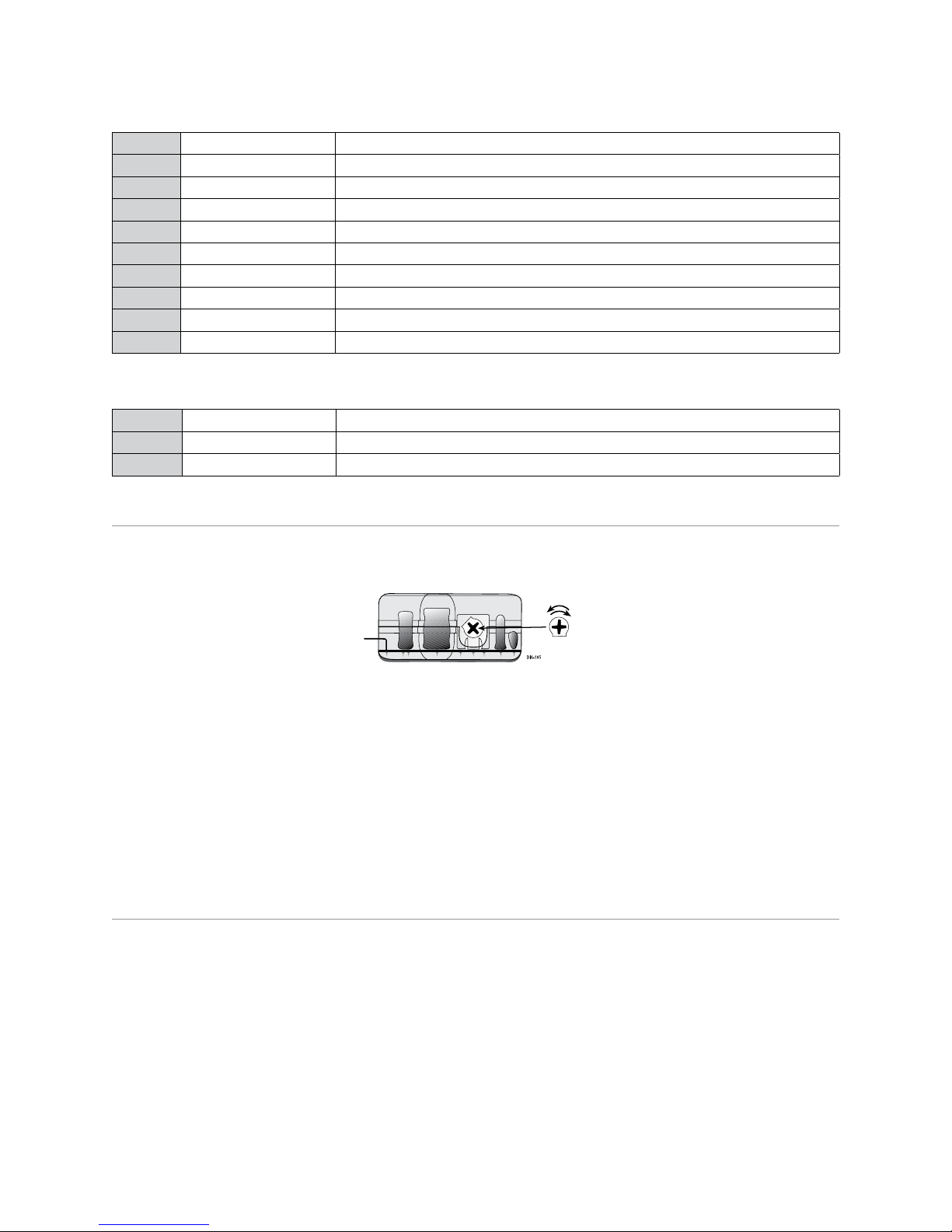

Adjusting the Sensor

Important! Make sure the vehicle is disarmed. The shock sensor sensitivity can be adjusted by using a trimmer

tool to turn the potentiometer.

Adjusting the sensor:

1. Disarm the system, turn the ignition Off.

2. With the sensor mounted in its permanent location, locate the trim pot on the shock sensor module and

using a trimmer tool:

• Turn the potentiometer clockwise for increased sensitivity or

• Turn it counterclockwise for decreased sensitivity

Note: You can test the new setting by cautiously impacting the vehicle with increasing intensity while not-

ing the LED status on the shock sensor. The LED turns on for a short duration for small impacts before turn-

ing off (indicating a warn-away trigger). The impact level required to fully trigger the alarm is indicated

when the LED remains on for a longer duration before turning off.

Note: This adjustment cannot be performed using the remote control.

Initializing Virtual Tach (not needed w/hardwire tach inputs)

To program Virtual Tach:

1. After the install is complete, remote start the engine. The programming operation may require 3 cranks of

the starter before the engine starts and runs. Do not turn off the remote start if this happens, it is a normal

programming operation.

2. Once the engine begins running, let it run for at least 30 seconds.

3. Using the Remote, send the Remote start command to turn remote start off. Virtual Tach is programmed.

To reset Virtual Tach, go into the Reset and Deletion section of this guide. Virtual Tach cannot be reset with

the Bitwriter.

Note: Virtual Tach cannot be used in MTS Manual Transmission Mode. It is also not recommended for diesel

trucks.

© 2011 Directed Electronics. All rights reserved.

7

Page 8

Virtual Tach handles disengaging the starter motor during remote starting – it does not address over-rev. If the

customer wants to have the over-rev protection capability, the tach wire must be connected.

Important: After successfully learning Virtual Tach, a small minority of vehicle starters

may over crank or under crank during remote start. The Bitwriter can be used fine tune

the starter output time in 50mS increments to compensate for such an occurrence.

Learning the Tach (not needed with Virtual Tach)

To learn the tach signal:

1. Start the vehicle with the key. Within 5 seconds, press and hold the Control button.

2. After 3 seconds the status LED on your Control Center lights constant when the tach signal is learned.

3. Release the Control button.

Note: When the tachometer is programmed, the main unit automatically enters the Tachometer engine

checking mode.

Since this unit has the capability to learn the tachometer with the analog input or through D2D from an

interface module, the unit gives confirmation as to which source the unit has learned from. After learning the

tach and releasing the Control button, the system:

Flashes the parking lights once if programmed using the analog tach wire.

Flashes the parking lights twice if programmed using the interface module through D2D.

.

Neutral safety switch interface

Some vehicles do not have an electrical neutral safety switch. Instead, the vehicle has a mechanical neutral

safety switch that physically interrupts the starter wire and is used when the vehicle is in any drive gear. If the

remote start is interfaced before this switch, it will provide protection from starting in gear. However, some

vehicles combine the column shift mechanism and the mechanical neutral safety switch into one mechanical

part.

Important: You must complete the remote start system installation before doing the following test. Ensure that the remote start system is functioning normally. This includes connecting to the brake as a shut-down.

Testing the neutral safety switch

1. Make sure there is adequate clearance to the front and rear of the vehicle because it may move slightly.

2. Make sure the hood is closed and there are no remote start shut-downs active.

3. Set the emergency brake.

4. Turn the key to the “run” position, this releases the shifter.

5. Place the car in drive (D).

6. Place your foot directly over the brake pedal, but do not depress it. Be ready to step on the brake if the

starter engages.

7. Activate the remote start system.

8. If the starter engages, immediately depress the brake to shut the remote start system down. If the

starter does not engage, no additional safety

system is required.

If the starter engages and the vehicle is a General Motors product or Dodge Dakota pickup, refer to

www.

directechs.com

which prevents the starter from engaging. If the vehicle is not a General Motors product or a Dodge

Dakota pickup, please call Directed Electronics Technical Support for an alternative shut-down method.

Do not return the vehicle to the customer until this feature is properly installed!

for Document 1008 under the Resource tab. For an alternative shut-down method

8

© 2011 Directed Electronics. All rights reserved.

Page 9

Remote Start Shutdown/Startup Diagnostics

Shutdown diagnostics: If the remote start activates but fails to stay running, the remote start module has the

ability to inform you of what may have caused the remote start failure. Before performing shutdown diagnostics it is important that you let the remote start shut off on its own i.e. let it attempt to start 3 times then shut

down, if this is not done the unit will report the shutdown you used to shut off the remote start.

Note: Shutdown diagnostics does not report if the vehicles factory immobilizer is causing the problem.

To perform shutdown diagnostics:

1. With the ignition Off, press and hold the Control button (on Control Center).

2. Tu rn the ignition On and then back Off while holding the Control button.

3. Release the Control button.

4. Press and release the Control button. The status LED flashes to report the last shutdown for one minute or

until the ignition is turned on, as shown in the following table:

Status LED Flashes Shutdown Mode

1 flash Runtime expired

2 flashes Over-rev shutdown

3 flashes Low or no RPM

4 flashes Transmitter shutdown (or optional push button)

5 flashes (+) Brake shutdown

6 flashes (-) Hood shutdown

7 flashes Timer mode/Turbo mode/Manual mode error *

8 flashes Neutral safety shutdown

9 flashes Low battery (voltage mode)

10 flashes Alarm triggered **

11 flashes Wait-to-start input timed out

* Timer mode error: Ignition is on or shutdown input is active when activating timer mode.

Turbo mode error: Turbo mode is programmed off, engine is not on or shutdown input is active.

Manual mode error: MTS mode not enabled.

** Alarm was triggered during remote start sequence.

Startup Diagnostics: If the vehicle fails to activate the remote start, the remote start module will notify you via

your Responder HD 2-way remote control and will flash the parking lights on the vehicle to notify you of what

caused the no-start situation.

Parking Light Flashes

5 flashes Brake wire is active

6 flashes Hood pin wire is active

7 flashes Manual transmission mode is enabled and not initialized.

8 flashes Neutral safety wire has no ground or the neutral safety switch is Off.

© 2011 Directed Electronics. All rights reserved.

9

Page 10

Remote Pairing

AUX

AUX

AUX

AUX

Prepare the vehicle system to be Paired with a new remote

1. Open a door.

2. Tu rn the key to the ON position.

3. Within 5 seconds press and release the Control button on the Control Center one time.

4. Within 5 seconds, press and hold the Control button on the Control Center. The status LED will flash one

time and the siren then chirps to confirm the vehicle is ready for remote pairing.

5. Release the Control button and proceed below.

Note: If no remote pairing results, the system will exit after 60 seconds.

Prepare the Responder HD 2-way remote control to be Paired with the system:

Remote Pair matches your HD remote to the system. Make sure the HD remote is set for the desired Car 1

(Default) or Car 2 operation for the system it will be paired with.

1. With the HD remote control display blank, press in and hold the menu wheel for 3 seconds until

screen appears.

2. Toggle the menu wheel until

Adjustments

screen appears

3. Press in on the menu wheel to enter.

4. In the

Adjustments

menu highlight

Remote Pair

and press in the Menu Wheel to go to the Remote Pair

screen. Follow the on screen instructions:

I. Press and hold the

button until tones are played.

II. The system chirps the siren to indicate it has learned the HD remote ID and is sending its ID to the

remote.

III. Release

button.

5. Successful or Failed Pair: The HD remote control indicates a successful or failed pairing on the display.

After a successful pairing, it then returns to the

Remote Pair

screen, press the

button to attempt another pairing.

Adjustments

menu. If pairing fails, it returns to the

Settings

Prepare the vehicle system to be Paired with the companion or a new 1-way remote as described above.

Note: If no remote pairing results, the system will exit after 60 seconds.

Prepare the companion 1-way remote control to be Paired with the system:

Make sure the remote is set for the desired Car 1 (Default) or Car 2 operation for the system it will be paired

with.

1. Press and hold the

button for 8 seconds.

Note: If Car 2 mode is on, ignore the Car Select beep after 3 seconds.

2. Wait for the Transmit LED to light solid and the remote to beep. Release the

3. Press the

4. Within 5 seconds, press the

button for 1 second. The transmit LED will blink 3 times and beep 3 times.

button.

button.

5. The vehicle siren will chirp. You have now successfully learned the remote to the vehicle remote start and

security system.

6. Press the

button two times to exit learn routine on the remote. The transmit LED will turn off and exit

tone will sound.

10

© 2011 Directed Electronics. All rights reserved.

Page 11

Programming System Features

AUX

The System Features Learn Routine dictates how the unit operates. It is possible to access and change most of

the feature settings using the Control button.

1. Open a door.

2. Tu rn the ignition on, then off.

3. Select a Menu. Press and hold the Control button. The number of siren chirps indicates the menu num-

ber. 1 chirp indicates menu 1, 2 chirps - menu 2 and 3 chirps for menu 3.

4. When the desired menu chirps are heard, release the Control button.

5. Select a Feature. Press and release the Control button the number of times corresponding to the feature

you wish to change. Then press and hold one more time to select the features.

6. Program the Feature. While holding the Control button, you can program the feature using the remote

control.

For features with only two options;

For features with more than two options;

= option 1 while

= option 2.

selects the options in ascending order, while

selects them in

descending order.

Note: Pressing

button resets the feature to the factory default.

Once a feature is programmed:

• Other features can be programmed within the same menu

• Another menu can be selected

• The learn routine can be exited if programming is complete

To access another feature in the same menu:

1. Press and release the Control button the number of times necessary to advance from the feature you just

programmed to the next one you want to program.

2. Then press the Control button once more and hold it.

To select another menu:

1. Press and hold the Control button.

2. After 3 seconds, the unit advances to the next menu and the siren chirps, indicating which menu has been

accessed.

The learn routine exits if any of the following occurs:

• The open door is closed

• The ignition is turned On

• There is no activity for 30 seconds

• The Control button is pressed too many times

© 2011 Directed Electronics. All rights reserved.

11

Page 12

Feature Menus

Default settings are Opt. 1 (in bolder type). New features are bold with grey background.

Menu 1 - Security

Menu

Item

Feature Opt. 1 Opt. 2 Opt. 3 Opt.4 Opt. 5+

1

System Arming Mode

2

Panic Mode

Confirmation Chirps

3

Siren Duration

4

Ign-controlled Locks

5

Door Lock Pulses

6

7

Door Lock Output Duration

Ignition Controlled 2nd Unlock

8

Comfort Closure

9

10 Horn Function

11 Hood Switch type

12 Sensor Full trigger

13 Door Switch Type

14 Trunk Switch Type

15 Remote Button unlock (Ign off)

Active

On

On w/Warn

chirps On

30 sec.

No Ign- locking

Single

0.8 sec.

2nd unlock on

Ign-control after

first unlock

No Comfort

Closure

Full Alarm Only

Normally Open

Single

Normally open

Normally open

On

Passive Arm

w/o lock

Ign Off only Off

On w/Warn

chirps Off

60 sec.

Lock & Unlock Lock Only Unlock Only

Double Unlock

Only

3.5 sec. 0.4 sec.

2nd unlock on

Ign-control with

first unlock

Comfort Closure 1

Siren Function

20 ms

Normally

closed

Double

Normally

closed

Normally

closed

Off

Passive Arm

w/lock

Off w/ Warn

chirps On

Double Lock

Only

Comfort Closure 2

Siren Function

30 ms

Auto re-arm

w/o lock

Off w/ warn

chirps Off

Double Lock &

Unlock

Siren Function

40 ms

Auto re-arm w/

lock

Siren Function

50 ms

1. System Arming mode

1. Active: the transmitter must be used to arm the system

2. Passive Arm w/o lock: after exiting the vehicle the system will automatically arm. The doors will not

lock

3. Passive Arm w/lock: after exiting the vehicle the system will automatically arm and lock the doors

4. Auto re-arm w/o lock: if the vehicle is not entered after receiving a disarm command, the system will

automatically re-arm. The doors will not lock

5. Auto re-arm w/lock: if the vehicle is not entered after receiving a disarm command, the system will

automatically re-arm and lock the doors

2. Panic Mode

1. On: the Panic output can be activated at any time

2. Ign Off Only : the Panic output can be activated only when the ignition is off

3. Off: the Panic output is defeated

3. Confirmation Chirps

1. On w/Warn Chirps On: arm, disarm, and sensor warn-away chirps are active

2. On w/Warn Chirps Off: arm and disarm chirps are active, warn-away chirps are defeated

3. Off w/Warn Chirps On: arm and disarm chirps are defeated, warn-away chirps are active

4. Off w/Warn Chirps Off: arm, disarm, and sensor warn-away chirps are defeated

12

© 2011 Directed Electronics. All rights reserved.

Page 13

4. Siren Duration

1. 30sec: the siren output for full trigger activations and Panic mode is 30 seconds

2. 60sec: the siren output for full trigger activations and Panic mode is 60 seconds

5. Ign-controlled Locks

1. No Ign-locking: the door lock/unlock outputs will not activate when ignition is turned on/off

2. Lock & Unlock: the door lock & unlock output will activate when ignition is turned on & off

3. Lock Only: the door lock output will activate when ignition is turned on

4. Unlock Only: the door unlock output will activate when ignition is turned off

6. Door Lock Pulses

1. Single: the door lock & unlock outputs will pulse once

2. Double Unlock only: the unlock output only will pulse twice

3. Double Lock Only: the lock output only will pulse twice

4. Double Lock & Unlock: the lock & unlock outputs will pulse twice

7. Door Lock Output Duration

1. 0.8 sec.: the door lock output pulses will be 800 ms in duration

2. 3.5 sec.: the door lock pulses will be 3.5 seconds in duration

3. 0.4 sec.: the door lock pulses will be 400 ms in duration

8. Ignition Controlled 2nd Unlock

1. After first unlock: for Ign-controlled unlocking, the 2nd unlock will activate 800 ms after the first (driver

door) unlock

2. With first unlock: for Ign-controlled unlocking, the 2nd unlock will activate at the same time as the first

(driver door) unlock

9. Comfort Closure

1. No comfort Closure: Comfort Closure is defeated when arming

2. Comfort Closure 1: the door lock pulse (or 2nd pulse for double pulses) will remain on for 20 seconds.

3. Comfort Closure 2: 800mS following the end of the door lock pulse (or 2nd pulse for double pulses);

the door lock output will turn on again for 20 seconds.

10. Horn Function

1. Full Alarm Only: the horn output will pulse only during full trigger events.

2. Siren Function 20/30/40/50ms: The horn output will emulate the siren output with selectable output

timing to compensate for OEM horn inefficiency.

11. Hood Switch Type

1. Normally Open: for vehicles with a hood switch that rests at ground when the hood is OPEN

2. Normally Closed: for vehicles with a hood switch that rests at ground when the hood is CLOSED

12. Sensor Full Trigger

1. Single: full trigger activation of only one sensor is required to fully trigger the alarm

2. Double: full trigger activation of two sensors within a ten second period is required to fully trigger

the alarm.

13. Door Switch Type

1. Normally Open: for vehicles with door switches that rest at ground when the door is OPEN

2. Normally Closed: for vehicles with door switches that rest at ground when the door is CLOSED

14. Trunk Switch Type

1. Normally Open: for vehicles with a trunk switch that rests at ground when the trunk is OPEN

2. Normally Closed: for vehicles with a trunk switch that rests at ground when the trunk is CLOSED

15. Remote Button Unlock (Ign off)

1. On: a message telling the 2-way remote control to unlock the keypad is sent each time the vehicle

ignition is turned off

2. Off: no message is sent

© 2011 Directed Electronics. All rights reserved.

13

Page 14

Menu 2 - Convenience

Menu

Feature Opt. 1 Opt. 2 Opt. 3 Opt.4 Opt. 5+

Item

1 One-time Bypass

2 Nuisance Prevention

3 Override Pulse count

4 Door Trigger Error Chirp

5 Ign-controlled Dome light

6 OEM Alarm Disarm w/Aux-

Trunk

7 OEM Alarm Disarm Output

8 OEM Alarm Disarm Pulses

9 Aux 1 Output type

10 Aux 1 Linking

11 Aux 2 Output Type

12 Aux 2 Linking

13 Aux 3 Output Type

14 Aux 3 Linking

15 Aux 4 Output Type

16 Aux 4 Linking

17 Aux/Trunk Output type

One time

bypass Off

On

1

On

On

On

With Unlock

1

Validity

No Linking

Validity

No Linking

Validity

No Linking

Validity

No linking

Validity

One time

bypass On

Off

2 3 4 5

Off

Off

Off

Before Unlock Remote Start

2

Latch Latch/reset/ign 30 sec. Timed Off (5)/2nd

Link to Arm Link to Disarm Link to Arm/

Latch Latch reset/ign 30 sec. Timed Off (5)/2nd

Link to Arm Link to Disarm Link to Arm/

Latch Latch reset/ign 30 sec. Timed Off (5)/2nd

Link to Arm Link to Disarm Link to Arm/

Latch Latch reset/ign 30 sec. Timed Off (5)/2nd

Link to Arm Link to Disarm Link to Arm/

Off 2nd unlock

Only

disarm

Disarm

Disarm

Disarm

unlock (6)

Link to Remote

Start only

unlock (6)

Link to Remote

Start only

unlock (6)

Smart Key

Control (Link to

Remote Start

Off)

Unlock (6)

Link to Remote

Start Only

1. One-time Bypass

1. Off: One-Time Bypass is not available

2. On: the One-Time Bypass feature will defeat Passive Arming once and, if Armed by remote control,

will defeat Comfort Closure and Aux outputs linked to Arming

2. Nuisance Prevention

1. On: sensors that trigger excessively will be defeated until they have been stable for more than one

hour

2. Off: sensors will not be defeated if triggered excessively

3. Override Pulse Count

• 1-5: sets the number of presses (1-5) on the Control Button required to override the alarm system

4. Door Trigger error Chirp

1. On: if the door trigger is active when arming, the siren will emit a chirp and a message will be sent

to the 2way remote control as an alert

2. Off: an active door trigger when arming will not create an alert output

5. Ign-controlled Dome light

1. On: the dome light output will activate when the ignition is turned off

2. Off: the dome light output will not activate when the ignition is turned off

14

© 2011 Directed Electronics. All rights reserved.

Page 15

6. OEM Alarm Disarm w/Aux/Trunk (H2/4 wire)

1. On: the OEM Alarm Disarm wire will pulse as programmed when the Aux/Trunk output is activated

2. Off: the OEM Alarm Disarm wire will not pulse when the Aux/Trunk output is activated

7. OEM Alarm Disarm Output (H2/4 wire)

1. With Unlock: the OEM Alarm Disarm wire will pulse as programmed at the same time as the unlock

(Blue) wire

2. Before Unlock: the OEM Alarm Disarm wire will pulse as programmed before the unlock wire

3. Remote start only: the OEM Alarm Disarm wire will pulse as programmed during remote start only

8. OEM Alarm Disarm Pulses (H2/4 wire)

1. 1: the OEM Alarm Disarm wire will pulse once per operation

2. 2: the OEM Alarm Disarm wire will pulse twice per operation

9. Aux 1 Output Type (H2/13 wire)

1. Validity: when the Aux command is received the wire will turn on and remain on until the command

ceases

2. Latch: when the Aux command is received the wire will turn on and remain on until the command is

received again

3. Latch/reset/Ignition: when the Aux command is received the wire will turn on and remain on until the

command is received again or the ignition is turned on/off

4. Timed: when the Aux command is received the wire will turn on for the programmed time duration

(default 30sec)

5. Off: the output will not activate for a remote control command, use this option when the Aux command controls an external device such as a garage door module

6. 2nd unlock: the wire will operate as 2nd unlock and will not activate for remote control commands

10. Aux 1 Linking

1. No Linking: the Aux output will not activate for a remote control command

2. Link to Arm: the Aux output will activate for the Arm command

3. Link to Disarm: the Aux output will activate for the Disarm command

4. Link to Arm/Disarm: the Aux output will activate for the Arm & Disarm commands

5. Link to Remote Start: the Aux output will activate for any Remote Start activation

11. Aux 2 Output Type

• Refer to Aux 1 Output Type descriptions

12. Aux 2 Linking

• Refer to Aux 1 Linking descriptions

13. Aux 3 Output Type

• Refer to Aux 1 Output Type descriptions

14. Aux 3 Linking

• Options 1-4: Refer to Aux 1 Linking descriptions

• Option 5: SmartKey Control (Link to Remote Start Off): The Aux output will pulse once following

Remote Start shut down for vehicles with push button engine stop operations. During runtime, if any

door is opened remote start will shut down immediately and pulse the output.

15. Aux 4 Output Type

• Refer to Aux 1 Output Type descriptions

16. Aux 4 Linking

• Refer to Aux 1 Linking descriptions

17. Aux/Trunk Output Type

• Refer to Aux 1 Output Type descriptions

© 2011 Directed Electronics. All rights reserved.

15

Page 16

Menu 3 - Remote start

Menu

Feature Opt. 1 Opt. 2 Opt. 3 Opt.4 Opt. 5+

Item

1 Transmission Mode

2 Engine Checking Mode

3 Cranking Time

4 Remote Start Runtime

5 Activation Pulse Count

6 Turbo Mode

7 Timer Mode Runtime

8 Flex Relay Function

9 Diesel Start Delay

10 Accessory during Diesel Start

Delay

11 Status 2 Output

12 Parking Light Output

13 Anti-grind Output

14 Tach Mode Starter Release

15 Vehicle Temp

Auto Report

16 Remote Start Safelock

Manual

Virtual Tach

0.6 sec.

12 min.

1

No Turbo Mode

12 min.

Ignition 2

Wait-to Start

input

On

Status

Constant

On

Normal

Off

Off

Automatic

Voltage Off Tachometer

0.8 sec. 1.0 sec. 1.2 sec. 1.4 (5)/ 1.6

24 min. 60 min.

2

On-1 min. On-3 min. On-5 min.

3 min. 6 min. 9 min.

Accessory 2 Starter 2

Timed 15 sec. Timed 30 sec. Timed 45 sec.

Off

Latch Rear

Defogger

Pulsed Off

Off

Increase Decrease

On

On

Pulse Rear

Defogger

(6)/ 1.8 (7)

2.0 (8)/ 4.0

(9)

On- 10 min.

1. Transmission Mode

1. Manual: requires ‘Tachometer’ for the Engine Checking Mode, and requires the user to successfully

perform a procedure when parking the vehicle before remote starter will engage

2. Automatic: uses any of the Engine Checking Modes and does not require any special procedures

when parking

2. Engine Checking Mode

1. VirtualTach: battery voltage drop/rise during cranking determines when the starter output is released.

During runtime, constant voltage level is monitored to determine if the engine is running

2. Voltage: starter output during cranking is a programmed duration (Set in Cranking Time). During

runtime, constant voltage level is monitored to determine if the engine is running

3. Off: starter output during cranking is a programmed duration (Set in Cranking Time). The remote start

will keep the ignition/accessories active for the programmed runtime whether the engine is running

or not

4. Tachometer: tachometer input signal during cranking and runtime to determine when the starter output is released and if the engine is running.

3. Cranking Time

• 0.6/0.8/1.0/1.2/1.4/1.6/1.8/2.0/4.0 seconds: determines the starter output duration during

cranking for the ‘Voltage’ and the ‘Off’ Engine Checking Mode options

4. Remote Start Runtime

• 12/24/60 minutes: sets engine runtime during normal remote start operations

5. Activation Pulse Count

• 1/ 2 pulses: sets the number of remote control commands received or Activation Input required to

activate and de-activate remote start

Page 17

6. Turbo Mode

1. No turbo Mode: Turbo mode is not available

2. On – 1/3/5/10 minutes: Turbo Mode is available and, when activated, the engine will run for the

duration set per the selected option

7. Timer Mode Runtime

• 12/3/6/9 minutes: sets the runtime when the engine is started by the Timer Mode and SmartStart

features

8. Flex Relay Function

1. Ignition 2: the relay will emulate the Ignition 1 output during remote start

2. Accessory 2: the relay will emulate the Accessory 1 output during remote start

3. Starter 2: the relay will emulate the Starter output during remote start

9. Diesel Start Delay

1. Wait-to-start input: (-) input on the Grey/black (H2/20) WTS wire will delay the starter output until

the ground ceases.

2. Timed 15/30/45 seconds: delays the starter output per the selected option, the WTS wire does not

function.

10. Accessory during Diesel Start Delay

1. On: the Accessory outputs (H3/3 high current and H2/22 low current) will be ON during diesel

start delay

2. Off: the Accessory outputs (H3/3 high current and H2/22 low current) will be OFF during diesel

start delay

11. Status 2 Output (Blue/White H2/3 wire)

1. Status: the output will activate before the ignition outputs turn on, and de-activate after they turn off

during remote start

2. Latch rear defogger: the output activates 10 seconds after start if the interior temperature is below

55˚F. It turns off after 10 minutes or upon remote start off

3. Pulse rear defogger: the output activates (for 800 ms) 10 seconds after start if the interior temperature

is below 55˚F.

12. Parking Light Output

1. Constant: the lights will turn on solid during remote start

2. Pulsed: the lights will pulse on/off during remote start

3. Off: the lights will be off during remote start

13. Anti-grind Output

1. On: the high current starter relay will be activated during remote start as anti-grind protection.

2. Off: the high current starter relay will not be activated during remote start, no anti-grind protection

is available.

14. Tach Mode Starter Release

1. Normal: the starter output will release normally during cranking (50% of the learned tachometer

value)

2. Increase: the starter output will release later during cranking (at 35% of the learned tachometer

value)

3. Decrease: the starter output will release sooner during cranking (at 35% of the learned tachometer

value)

15. Vehicle Temp Auto Report

1. Off: the report during remote start is defeated

2. On: the report is sent every 2 minutes during remote start if the temperature has changed (+/-) 1

degree since the last report

16. Remote start Safelock

1. Off: the Door lock and Factory Alarm Re-arm outputs will maintain the current status (locked/un-

© 2011 Directed Electronics. All rights reserved.

17

Page 18

locked) during remote start and after shut down

2. On: the Door lock and Factory Alarm Re-arm outputs will arm/lock the vehicle during remote start

and after shutdown

Bitwriter - Only Options

If programming with the Bitwriter®, the learn routine can be locked or unlocked. If the learn routine

has previously been locked, it must be unlocked with Bitwriter® - this cannot be done manually with

the Control button.

The Bitwriter® gives you access to a wider range of system options. These features and the adjustments

that may be programmed are described in the table below.

Menu

Feature Default Opt. 2 Opt. 3 Opt.4 Opt. 5+

Item

1 Zone 4 Sensor Type

2 Siren Duration

3 Aux/Trunk Icon Type

4 Aux 1 Timed Output

5 Aux 1 Icon Type

6 Aux 2 Timed Output

7 Aux 2 Icon Type

8 Aux 3 Timed Output

9 Aux 3 Icon Type

10 Aux 4 Timed Output

11 Diesel Start Delay Timer

12 Timer Mode Runtime

13 Timer Mode Starts

14 Timer mode intervals

Smart start low temp

15

Smart start high temp

16

Smart start low battery (volts) 10.5V Options: OFF, 9V to 12.5V in 0.5V increments

17

18 Sensor 1 Level

19

Starter Release Fine Tune

Feature Programming

20

Transmitter Programming

21

Remote Start Runtime

22

Virtual Tach Fine tune

23

None

30 sec.

Trunk

30 sec.

Pulsed

30 sec.

Pulsed

30 sec.

Pulsed

30 sec.

15 sec.

12 min.

6 starts

3 hr.

0° (F)

100° (F)

7

6

(normal)

Unlocked

Unlocked

12 min.

Not Initialized

Shock/Omni Field Distur-

bance

Options: 1 to 180 sec.

Window Sunroof Audio Lights/Left dr/Right dr/

Options: 1 to 90 sec.

Trunk Window Sunroof Audio/Lights/Left dr/

Options: 1 to 90 sec.

Trunk Window Sunroof Audio/Lights/Left dr/

Options: 1 to 90 sec.

Trunk Window Sunroof Audio/Lights/Left dr/

Options: 1 to 90 sec.

Options: 1 to 90 sec.

Options: 1 to 16 min.

Options: 1/2/3/4 to 24 (Starts) in increments of 2

Options: 1/2/3/4 to 24 in 2 hour increments

Options: OFF, -20° to 70° in 10° increments

Options: OFF, 40° to 130° in 10° increments

Options: 0 to 15 in increments of 1

Options: 0 to 20 in increments of 1

Locked

Locked

Options: 1 to 60 min.

Options: Not initialized, 0 to 1000 in 50 millisecond increments

Tilt Sensor Glass Break (5)/Ultra-

sonic (6)

Rear Hatch

Right dr/Rear Hatch/

Timed/Latched

Right dr/Rear Hatch/

Timed/Latched

Right dr/Rear Hatch/

Timed/Latched

18

© 2011 Directed Electronics. All rights reserved.

Page 19

1. Zone 4 Sensor Type: sets the Zone 4 (Sensor 2) name to be displayed in the Text Field for Warn-away

and Full Trigger activations

2. Siren Duration: sets the Full Trigger output duration in 1 second intervals up to 180 seconds.

3. Aux/Trunk Icon Type: sets the Accessory animation to be displayed on the screen when the Aux/Trunk

output is activated/de-activated

4. Aux 1 Timed Output: sets the output duration in 1 second intervals up to 90 seconds for Aux 1

5. Aux 1 Icon Type: sets the Accessory animation to be displayed on the screen when the Aux 1 output is

activated/de-activated

6. Aux 2 Timed Output: sets the Aux 2 “Timed” output in 1 second intervals up to 90 seconds

7. Aux 2 Icon Type: sets the Accessory animation to be displayed on the screen when the Aux 2 output is

activated/de-activated

8. Aux 3 Timed Output: sets the Aux 3 “Timed” output in 1 second intervals up to 90 seconds

9. Aux 3 Icon Type: sets the Accessory animation to be displayed on the screen when the Aux 3 output is

activated/de-activated

10. Aux 4 Timed Output: sets the Aux 4 “Timed” output in 1 second intervals up to 90 seconds

11. Diesel Start Delay Timer: sets the delay before engine crank in 1 second intervals up to 90 seconds for

diesel engine vehicles

12. Timer Mode Runtime: sets the duration of runtime when the engine is started by the Timer Mode and Smart

Start features

13. Timer mode Starts: sets the number of times the engine will be started by the Timer Mode and Smart Start

features

14. Timer mode Intervals: sets the number of hours between engine starts by the Timer Mode and Smart Start

features

15. Smart Start Low Temperature: sets the low temperature threshold required for Smart Start to start the

engine

16. Smart Start High Temperature: sets the high temperature threshold required for Smart Start to start the

engine

17. Smart Start Low battery (Volts): sets the low battery level threshold required for Smart Start to start the

engine

18. Sensor 1 level: directly sets the sensor level of the on-board shock sensor

19. Starter Release Fine Tune: adds or subtracts crank time in Tachometer mode in order to overcome engine

types that short crank or over-crank on the first start attempt

20. Feature Programming: locks and unlocks the user’s ability to enter the feature menus and manually

change the main unit programming using the Control Center

21. Transmitter Programming: locks and unlocks the user’s ability to enter the HHU/Reset menu and manually

change any functions using the Control Center

22. Remote Start Runtime: sets the duration of runtime when the engine is started by remote command

23. VirtualTach Fine tune: adds or subtracts crank time in VirtualTach mode in order to overcome engine types

that short crank or over-crank on the first start attempt

© 2011 Directed Electronics. All rights reserved.

19

Page 20

Basic Remote Functions

See Owner’s guide for functionality details on both the HD and 1-way companion remote control.

Reset and Deletion

If a feature/virtual tach needs to be reset or the remote controls need to be deleted, use the following procedure.

1. Open a door. (The green wire, H2/6, or the violet, H2/12 must be connected.)

2. Turn the ignition to the ON position (The heavy gauge pink wire must be connected).

3. Within 10 seconds, press and release the Control button: 2 times if you want to delete remotes, 3 times

to reset features or 4 times to reset virtual tach. These features are described next.

Delete remotes: This feature erases all remotes from the memory of the security system. This is useful

in cases when a customer’s remote is lost or stolen.

Note: This does not reset the programmed features of the security system or reset the Virtual Tach

setting.

Reset Features: This resets features all of the security system to the factory default settings.

Note: This feature does not delete the remotes from the security system or reset the Virtual Tach setting

Virtual Tach Reset: Deletes all previously learned values for Virtual Tach, and on the next remote start

sequence the unit begins virtual tach initialization.

Note: The “Zap” feature on the Bitwriter does not reset the Virtual tach setting.

4. Once you have selected the function step, press the Control button once more and hold it. The LED flashes

and the siren chirps to confirm the selected functional step. Do not release the Control button

5. While holding the control button, press the

the feature has been successfully reset.

Once the feature is reset, the Control button can be released.

button on the remote control. The unit chirps to confirm that

Long Term Event History

The system stores the last two full triggers in memory. These are not erasable. Each time the unit sees a full trigger, the older of the two triggers in memory is replaced by the new trigger. To access long term event history:

1. With the ignition Off, press and hold the Control button (on Control Center).

2. Tu rn the ignition On.

3. Release the Control button.

4. Within 5 seconds, press and release the Control button. The status LED flashes in groups indicating the last

two zones that triggered the unit for 1 minute or until the ignition is turned off. Refer to table of zones.

Note: The Warn Away triggers are not stored to memory and is not reported.

20

© 2011 Directed Electronics. All rights reserved.

Page 21

Table of Zones

A zone is represented by the number of status LED flashes used by the system to identify a particular type of input.

Zone Description Input Description

1 Trunk Pin H2/19 Blue wire

2 Instant trigger: a heavier impact

detected by the onboard shock sensor

3 Door switch trigger H2/6 Green or H2/12 Violet wire

4 Instant trigger: For optional sensors Optional MUX port

5 Ignition trigger H3/1 Pink wire

6 Hood Pin H2/17 Grey wire

Shock sensor.

Troubleshooting: Alarm

Shock sensor doesn’t trigger the alarm:

1. Was the onboard shock sensor adjusted before the brain was mounted? If so re-adjust the sensor.

2. Has the onboard shock sensor been turned off? The sensor has the ability to be turned off when

adjusting.

3. Has the NPC® system been triggered? If so, you hear 5 chirps when disarming. To check this, turn the

ignition key on and off to clear the NPC® memory, and then retest the shock sensor. For a detailed

description of NPC®, see Nuisance Prevention Circuitry section of the owners guide.

Door input does not immediately trigger full alarm. Instead, chirps are heard for the first 3 seconds:

• That’s how the progressive two-stage door input works! This is a feature of this system even if the door

is instantly closed again, the progression from chirps to constant siren continues.

Closing the door triggers the system, but opening the door does not:

• Have you correctly identified the type of door switch system? This happens often when the wrong

door input has been used.

System does not passively arm until it is remotely armed and then disarmed:

1. Is passive arming programmed ON?

2. Are the door inputs connected? Is the H2/19 blue wire connected to the door trigger wire in the

vehicle? Either the H2/6 green or the H2/12 violet should be used instead.

Door input does not respond with the progressive trigger, but with immediate full alarm:

• Does the Status LED indicate that the trigger was caused by the shock sensor? (See Table of Zones sec-

tion of this guide.) The shock sensor, if set to extreme sensitivity, may be detecting the door unlatching

before the door switch sends its signal. Reducing the sensitivity can solve this problem.

Door locks operate backwards.

• This unit has easily-reversed lock/unlock outputs. Recheck wire connections to see if you have re-

versed these.

© 2011 Directed Electronics. All rights reserved.

21

Page 22

Troubleshooting: Remote Start

The remote start will not activate the remote start

1. Check remote startup diagnostics.

2. Is the neutral safety switch plugged in and turned on?

3. If the vehicle has an automatic transmission, make sure the remote start is programmed for Automatic

Transmission mode.

4. Is the remote programmed to the system?

5. Can the remote start be activated manually by applying a ground pulse to the H2/21 White/Blue

wire?

6. Check the harnesses and their connections. Make sure that the harnesses are completely plugged into

the remote start module. Make sure there are good connections to the vehicle wiring.

7. Check voltage and fuses on the main harness and on the heavy gauge remote start harness.

The remote start will activate, but the starter never engages.

1. Check for voltage on the purple starter wire two seconds after the remote start becomes active. If

there is voltage present, skip to Step 8. If there is not voltage present, advance to Step 2.

2. Check the 30A fuses.

3. If the gray/black wait-to-start wire is detecting ground upon activation, the starter will not crank.

4. Is the tach wire connected? If so disconnect it and remote start the vehicle to see if the purple wire

sends out voltage. If you get voltage you will need to go to an alternate tach source, the tach wire

you are currently on has a voltage spike upon ignition power up which can cause the remote start to

not send out the crank voltage.

5. Is the vehicle a Chrysler or GM with a multiplexed starter wire? The vehicle will not crank if the resis-

tance is incorrect on the multiplexed accessory/starter wire.

6. Is the vehicle a GM? If so the Brown 2nd accessory needs to be powered up on some of the vehicles

for the vehicle to crank.

7. If this is a manual transmission vehicle, the clutch will need to be bypassed (see tech tip # 10000 at

www.directechs.com)

8. Make sure the purple starter wire is connected on the starter side of the optional starter kill/anti-grind

relay.

9. Does the vehicle have an immobilizer? Some immobilizer systems will not allow the vehicle to crank

if active.

10. Check connections. The heavy gauge remote start input wires on the heavy gauge 10-pin connector

should have a solid connection. “T-taps” or “scotch locks” are not recommended.

The vehicle starts, but immediately dies.

1. Does the vehicle have an immobilizer? The vehicle’s immobilizer can cut the fuel and/or spark during

unauthorized starting attempts.

2. Is the remote start programmed for virtual tach or voltage sense? If so, the crank time may not be set

high enough. Voltage sense will not work on some vehicles.

3. Is the remote start in tach mode? If so has the tach been programmed to the system?

4. Check diagnostics. Sometimes a shutdown will become active during cranking or just after crank-

ing.

The vehicle starts, but the starter keeps running.

1. Is the system programmed for engine checking off or virtual tach or voltage sense? When pro-

grammed for either of these features, the engine cranks for the pre programmed crank time regardless of how long it takes for the vehicle to actually start. Adjust to a lower cranking time.

2. Was the Tach Learn successful? The LED must light solid and bright to indicate a successful learn.

3. Make sure that there is a tach signal at the purple/white tach input wire of the remote start. If there

is not a tach signal, recheck the connection to the vehicle’s tach wire and make sure the wire is not

broken or shorted to ground leading to the remote start.

4. Is an ignition or accessory output wire connected to the starter wire of the vehicle? Verify the color

of the starter wire in the vehicle and confirm that an ignition or an accessory output is not connected

to that wire.

22

© 2011 Directed Electronics. All rights reserved.

Page 23

The vehicle starts, but will only run for 10 seconds

1. Is the remote start programmed for voltage sense? If this does not work, a tach wire should be

used.

2. Check shutdown diagnostics.

The climate control system does not work while the unit is operating the vehicle.

1. Either the wrong accessory wire is being energized or more than one igni tion or accessory wire must

be energized in order to operate the climate control system.

2. If the vehicle has an electronic climate control system some will reset when the key is turned off and

then back on, unfortunately this is a function of the vehicle and cannot be bypassed.

MTS - Manual Transmission Start diagnostics

When enabling MTS, if you get a failure notification from the remote or the vehicle fails to remain started

check for following:

• Tachometer not connected or programmed.

• E-brake not connected to the remote start unit. The black/white H2/2 neutral safety wire must have

a ground when the parking brake is set.

• Foot must be off the brake when activating the MTS mode on the remote.

• Is the door open when enabling the MTS mode? If so this would cause the unit to enter Pit Stop Mode

and the remote start will continue to run when arming/locking the system.

• Is the door input connected? The system needs to see a door open then close after initiating the re-

mote start.

• Does the vehicle have a delayed dome light? If you are connected to the dome light wire and the

dome light is staying on after arming/locking the system, the system can exit the MTS mode.

• Make sure the neutral safety switch is plugged in and turned on.

MTS mode exiting diagnostics:

If the remote start has entered the MTS mode but exits the mode after the system is armed/locked. Check

these for possible causes.

• The vehicle door has been opened or the security system has been triggered in your absence.

• Does the vehicle have a delayed dome light circuit or does the dome light come on when the ignition

is shut off? If so you may need to go to the independent door inputs of the vehicle.

• If you are connected to the dome light wire in the vehicle and cannot connect the system to the

individual door inputs of the vehicle due to it having normally closed door inputs, you can use the

Xpresskit DTIMAZDA module or Tech Tip # 1921 at www.directechs.com to interface with these

types of circuits.

• The E-brake wire connected to the neutral safety input of the system loses ground when ignition

is turned off or after a certain amount of time, with these vehicles unfortunately there is no workaround.

• The E-brake wire connected to the neutral safety input of the system has a poor ground. Clean the

contacts on the switch or replace the switch.

© 2011 Directed Electronics. All rights reserved.

23

Loading...

Loading...