Page 1

DIRECTED ENERGY, INC.

PDG-2515/2520

Digital Delay and Pulse Generator

OPERATING MANUAL

www.directedenergy.com

THE PULSE OF THE FUTURE

Page 2

THE PULSE OF THE FUTURE

Page 3

PDG-2515/2520 Operating Manual

Table of Contents

Table of Contents...................................................................................................i

List of Figures ......................................................................................................iv

Safety Warning.....................................................................................................v

PDG-2515 Operating Manual ...............................................................................1

Quick Start Guide..................................................................................................1

What’s In The Box?...........................................................................................1

Unpacking......................................................................................................... 1

Setup.................................................................................................................1

Power Up ..........................................................................................................1

Front Panel Controls & Connections.................................................................1

Encoder .........................................................................................................1

Output Button.................................................................................................2

Menu Button ..................................................................................................2

Enter Button ...................................................................................................2

Up Arrow Button ............................................................................................2

Down Arrow Button........................................................................................2

X10 Button.....................................................................................................2

PW/PRF Button .............................................................................................3

Out 1 and Out 2.............................................................................................3

Sync Out........................................................................................................3

Trigger In .......................................................................................................3

Power LED.....................................................................................................3

Front Panel Controls & Connections.................................................................3

AC Power Entry Module ................................................................................3

Example Setup..................................................................................................4

Product Overview..................................................................................................5

Description ........................................................................................................5

Functions & Features........................................................................................5

Specifications....................................................................................................6

Applications.......................................................................................................7

Safety ...................................................................................................................7

Operating Safety Summary...............................................................................7

Power Source................................................................................................7

Grounding......................................................................................................7

Cover Removal..............................................................................................7

General Operating Precautions .....................................................................7

Servicing Safety Summary................................................................................8

PREPARATION FOR USE................................................................................8

General..........................................................................................................8

Initial Inspection.............................................................................................8

Electrical Installation......................................................................................8

Operation..............................................................................................................8

Page i

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 4

PDG-2515/2520 Operating Manual

Operating Tips...................................................................................................8

Power-Up Procedures.......................................................................................9

FRONT PANEL OPERATING INSTRUCTIONS ...............................................9

THE CHANNEL MENU..................................................................................9

THE OUTPUT MENU ....................................................................................9

THE LOGIC MENU......................................................................................10

THE CONFIGS MENU.................................................................................11

Operating Modes.............................................................................................11

Timing Diagram ...........................................................................................11

Pulse Generator Mode.................................................................................12

Pulse Count Mode.......................................................................................13

Divide By N Mode........................................................................................14

Burst Mode ..................................................................................................15

Single Shot Mode ........................................................................................16

Troubleshooting Guide........................................................................................17

PDG-2520 Operating Manual .............................................................................18

Quick Start Guide................................................................................................18

What’s In The Box?.........................................................................................18

Unpacking.......................................................................................................18

Setup...............................................................................................................18

Power Up ........................................................................................................18

Front Panel Controls & Connections...............................................................18

Encoder .......................................................................................................18

Output Button...............................................................................................19

Menu Button ................................................................................................19

Enter Button .................................................................................................19

Up Arrow Button ..........................................................................................19

Down Arrow Button......................................................................................19

X10 Button...................................................................................................19

PW/PRF Button ...........................................................................................20

Out 1, Out 2, Out 3, Out 4............................................................................20

Sync Out......................................................................................................20

Trigger In .....................................................................................................20

Power LED...................................................................................................20

Front Panel Controls & Connections...............................................................20

AC Power Entry Module ..............................................................................20

Example Setup................................................................................................21

Product Overview................................................................................................22

Description ......................................................................................................22

Functions & Features......................................................................................22

Specifications..................................................................................................23

Applications.....................................................................................................24

Safety .................................................................................................................24

Operating Safety Summary.............................................................................24

Power Source..............................................................................................24

Grounding....................................................................................................24

Page ii

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 5

PDG-2515/2520 Operating Manual

Cover Removal............................................................................................24

General Operating Precautions ...................................................................24

Servicing Safety Summary..............................................................................25

PREPARATION FOR USE..............................................................................25

General........................................................................................................25

Initial Inspection...........................................................................................25

Electrical Installation....................................................................................25

Operation............................................................................................................25

Operating Tips.................................................................................................25

Power-Up Procedures.....................................................................................26

FRONT PANEL OPERATING INSTRUCTIONS .............................................26

THE CHANNEL MENU................................................................................26

OUTPUT MENU1 ........................................................................................26

OUTPUT MENU2 ........................................................................................27

THE CONFIGS MENU.................................................................................28

Operating Modes.............................................................................................28

Timing Diagram ...........................................................................................28

Pulse Generator Mode.................................................................................29

Pulse Count Mode.......................................................................................30

Divide By N Mode........................................................................................31

Burst Mode ..................................................................................................33

Single Shot Mode ........................................................................................33

Troubleshooting Guide........................................................................................35

Communications and Remote Operation:...........................................................36

RS232 Operation:............................................................................................36

GPIB Operation:..............................................................................................36

Reply:..............................................................................................................37

The ASCII commands:....................................................................................37

The Command Set:.........................................................................................37

Error Set:.........................................................................................................39

Contact DEI ........................................................................................................40

Web.................................................................................................................40

Sales Customer Service & Support.................................................................40

Technical Customer Service & Support...........................................................40

Factory Service & Support..................................................................................41

Product Service...............................................................................................41

Technical Support ...........................................................................................41

Warranty.............................................................................................................42

Page iii

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 6

PDG-2515/2520 Operating Manual

List of Figures

Figure 1 Logic & Polarity Functional Diagram.....................................................11

Figure 2 Timing Diagram ....................................................................................12

Figure 3 Example 1: Pulse Generator Mode.......................................................13

Figure 4 Example 2: Pulse Generator Mode.......................................................13

Figure 5 Example: Pulse Count Mode ................................................................14

Figure 6 Example 1: Divide by N Mode...............................................................15

Figure 7 Example 2: Divide by N Mode...............................................................15

Figure 8 Example: Burst Mode ...........................................................................16

Figure 9 Logic & Polarity Functional Diagram.....................................................28

Figure 10 Timing Diagram ..................................................................................29

Figure 11 Example 1: Pulse Generator Mode.....................................................30

Figure 12 Example 2: Pulse Generator Mode with logic.....................................30

Figure 13 Example: Pulse Count Mode ..............................................................31

Figure 14 Example 1: Divide by N Mode.............................................................32

Figure 15 Example 2: Divide by N Mode.............................................................32

Figure 16 Example: Burst Mode..........................................................................33

Figure 17 Example: Single Shot Mode................................................................34

Page iv

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 7

PDG-2515/2520 Operating Manual

Safety Warning

SAFE OPERATING PROCEDURES AND PROPER USE OF THE EQUIPMENT

ARE THE RESPONSIBILITY OF THE USER OF THIS SYSTEM.

Directed Energy, Inc. (DEI) provides information on its products and associated

hazards, but it assumes no responsibility for the after sale operation and safety

practices.

Users are responsible for reading and understanding all safety precautions listed

in this manual prior to operation of the equipment. There are no user serviceable

parts in this product, please contact the factory for service information.

Page v

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 8

PDG-2515/2520 Operating Manual

PDG-2515 Operating Manual

Quick Start Guide

This quick-start guide provides a step-by-step guide to manually operating the

PDG-2515. Please refer to the appropriate sections of the manual for additional

instructions and guidelines. The SAFETY warnings in the manual must be read

and understood prior to operating the PDG-2515.

What’s In The Box?

1ea. PDG-2515 Digital Delay & Pulse Generator

1ea. Power Cord

2ea. 50 Ohm Coaxial Output Cable

1ea. Operating Manual

Unpacking

Carefully remove each component listed above. Your PDG-2515 and

accessories were inspected at the factory prior to shipment. Inspect the PDG2515, power cord and output cables for signs of shipping damage. If any damage

is noted contact the factory prior to operating the equipment.

Setup

Connect OUT1 and/or OUT2 to an appropriate load using 50 Ohm coaxial cable

(included).

Plug the AC power cord into the rear power entry module of the PDG-2515, and

into an appropriate AC socket.

Power Up

Turn on the PDG-2515 by pressing the power button located above the power

entry module in the rear of the unit.

The front panel display will read initialize and display the software and hardware

versions internal to the unit on the front panel. After a few moments the unit will

finish initialization and the first screen/menu that will appear is the menu for

CHANNEL 1. Note: The buttons and encoder on the front panel will have no

effect as the unit comes up from initialization.

Front Panel Controls & Connections

Encoder

This is for varying the parameters such as Frequency, Pulse Width, Delay,

Trigger Source, etc.

Page 1

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 9

PDG-2515/2520 Operating Manual

Output Button

The output button enables/disables the pulse output.

Menu Button

This button is for navigating the PDG-2515 menus.

Enter Button

Used for variables that will be permanently stored in the unit or require

setup times internal to the PDG-2515. When a question mark appears

after the variable, the enter button will “confirm” or in some cases save

that particular setting.

Up Arrow Button

The UP ARROW button allows the user to go up in any particular menu to

change selections. If the user is at the top selection it will wrap back

around to the bottom selection.

Down Arrow Button

The DOWN ARROW button allows the user to go down in any particular

menu to change selections. If the user is at the bottom selection it will

wrap back around to the top selection.

X10 Button

The X10 button is used when varying parameters that have exponents

that can change by a power of 10. By pressing the X10 button the user

can increment the exponent within its acceptable range. This allows the

user to quickly set the parameters, without having to excessively scroll the

encoder wheel. The X10 button functions with the following commands:

Set Pulse Width 1 and 2

Set Delay 1 and 2

Set Frequency (*Note: if depressed while dialing in frequency it will

increase the frequency at a much higher rate)

Set Counters/Bursts/Packets

The X10 button is effectively a 10X multiplier. For example, when

setting frequency, the resolution of the encoder wheel is three digits

(i.e. 1.00Hz, 10.0Hz, 100Hz, 1.00KHz). Therefore without adjusting

the range, the encoder wheel must be turned many times to

increase the frequency from 1Hz to 100Hz. However if the

frequency is set to 1.00Hz, if the X10 button is pressed once, it

changes to 10.0Hz. If it is pressed twice, it changes to 100Hz.

Setting the delay and pulse width is similar to setting frequency. For

example, to set the delay to 300ns, set the delay to 25ns, press the

Page 2

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 10

PDG-2515/2520 Operating Manual

X10 button once to increment it to 250ns, then rotate the encoder

wheel to increase it to 300ns. At this point, pressing the X10 button

again would increase the delay to 3.00us, pressing it again

increments it to 30.0us, etc.

An additional function is that if it is held while changing ANY

frequency value, after multiplying the value by a factor of ten, if the

encoder is moved it will increase/decrease at a much faster rate.

This makes the switching frequency much quicker and easier.

PW/PRF Button

This is for varying the parameters Frequency and Pulse Width and

toggling between the two settings quickly. If you are in any menu that is

not a CHANNEL MENU, it will flip you immediately to the CHANNEL 1

menu and the FREQUENCY setting.

Out 1 and Out 2

These are the pulse output connectors. The outputs of the PDG-2515

should be connected to the inputs of the receiving instrument or system

using 50 Ohm coaxial cable. For optimal pulse fidelity, these outputs

should be terminated into 50 Ohms.

Sync Out

This is a 5V signal into 1 meg-Ohm or 2.5V signal into 50 Ohms that is

synchronous with the frequency generator trigger. This is designed to

assist the user in triggering when monitoring the output signals with an

oscilloscope, or for use in triggering an external instrument.

Trigger In

This is an input signal into 1KOhms used for external Pulse Repetition

Frequency (PRF) triggering. It is designed to allow the user to trigger

multiple PDG-2515 units from a single pulse generator. This allows the

user to create synchronous waveforms from multiple units.

Power LED

Indicates that the power switch on the rear of the unit is in the ‘on’ position

and that AC power is applied to the unit.

Front Panel Controls & Connections

AC Power Entry Module

The driver is grounded through the grounding conductor of the AC power

cord. To avoid electrical shock, plug the driver into a properly wired

receptacle before making connection to any input or output connectors.

Use only a power cord that is in good condition.

Page 3

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 11

PDG-2515/2520 Operating Manual

The PDG-2515 accepts input voltages of 90-264VAC, 47-63Hz.

Example Setup

The default setup is 1 kHz, with zero delay and 100 us pulse on both channels.

The pulse in not inverted and the pulse mode is in continuous pulse generation

mode which means that pulse count is not available. By pressing the OUTPUT

button on the front panel you will see these pulses on the respective outputs.

Turning the encoder with the pulses enabled and the unit will sweep the

frequency on the fly, hitting the X10 button will bring you to 10 times the

frequency. Pressing the down arrow twice will highlight the pulse width selection.

Turn the encoder and the width will sweep. Try this with the polarity setting; it will

change on the fly. Turn off the pulses.

Press MENU to continue to the settings for CHANNEL 2. Its default is the same

as CHANNEL 1.

Hitting MENU again will bring up the OUTPUT MENU. This menu allows the unit

to change pulse modes, disable and enable the outputs (depending on the pulse

mode), choose internal or external trigger (depending on the pulse mode) and

choose whether the sync is based off CHANNEL 1 or 2.

Hitting the arrow keys allows the user to decide which settings on the current

menu they would like to adjust. Press the up arrow once to scroll around to the

bottom of the menu or press the down arrow 5 times. The contrast setting will be

highlighted.

Turn the encoder to adjust the contrast. The contrast will adjust “on the fly” and a

question mark will appear at the end of the contrast. Hit ENTER and save the

contrast saving into the non-volatile memory of the unit, this setting will saved

into the unit and keep this in memory even after power-down.

Page 4

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 12

PDG-2515/2520 Operating Manual

Product Overview

Description

The PDG-2515 is a two channel digital delay/pulse generator. Each channel

offers independently adjustable delay and width, with 25 nanosecond resolution.

Up to five user configurations may be stored in internal non-volatile memory, and

recalled through the easy to understand front panel.

Functions & Features

Delay And Width and

Duty Cycle.

Frequency

Resolution

Trigger Sources

Pulse Generator

Mode

Pulse Count Mode

Divide By N Mode

Burst Mode

Each channel provides independently adjustable

delay and width, with 25ns resolution. The duty

cycle is limited based on the frequency. The duty

cycle is limited approximately by the equation:

MAX DC = 97-[(1E-5)*FREQ].

Pulse repetition frequency from single shot to

continuous pulses from 100 mHz to 3.0 MHz.

100mHZ to 1.0 MHz -> 3 digits

1.0 MHz + -> 2 digits

Internal, External, Single Shot.

Generates pulses at the rate set by the internal

frequency generator, or by an external trigger.

Outputs pulses at the rate set by the internal

frequency generator or external trigger and stops

after N pulses.

Channel 1 operates in continuous mode, channel 2

pulses every Nth pulse on channel 1.

Generates a burst of pulses, repeating at a

frequency.

Counted Burst Mode

Store And Recall

Generates a burst of pulses, and stops after N

bursts.

Stores up to 5 user configurations in non-volatile

memory.

Page 5

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 13

PDG-2515/2520 Operating Manual

A

A

A

A

A

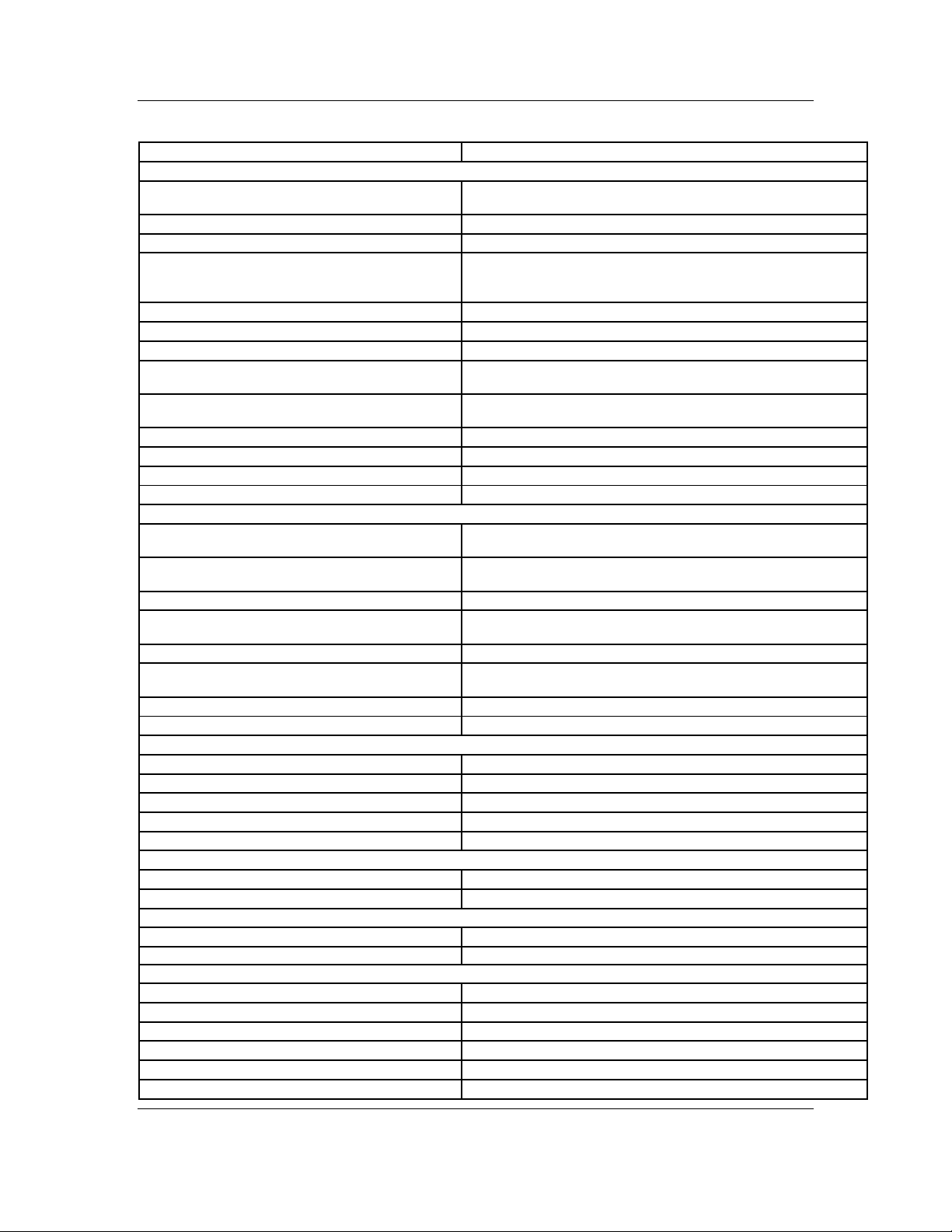

Specifications

PARAMETER Value

OUTPUTS

Output Channels Two (2) outputs, each with independent digitally controlled delay

and pulse width

Delay Range 0 to 99.9 Seconds

Pulse Width Range 25 Nanoseconds to 99.9 Seconds

Delay And Pulse Width Resolution 25 Nanoseconds below 1 Microsecond

50 Nanoseconds from 1 Microsecond to 10 Microseconds

3 Digits Above 10 Microseconds

ccuracy (Delay and Pulse Width) ±2%

Time Base 120MHz Frequency Synthesizer

Delay Jitter (1st Sigma) TBD

Trigger Delay (External Trigger to SYNC (T0)

Output

Internal Throughput Delay (SYNC (T0) To Output 1

Or Output 2 Rising Edge)

Output Rise & Fall Times (Into 50Ω)

Over/undershoot <5%

mplitude +4V into 50W

Output Connectors BNC, Front Panel

INTERNAL RATE GENERATOR

Modes Continuous, Single-Shot, Burst, External Trigger, Divide By N,

Rate Single-Shot or 100 millihertz to 3MHz (Internal)

Resolution 3 Digits (<1MHz), 2 Digits (>1MHz)

ccuracy (Continuous, Pulse Count, Output-2

Modes)

ccuracy (Burst Mode) ±2%

Rate Jitter (Continuous, Pulse Count, Output-2

Modes), 1

Rate Jitter (Burst Mode), 1st Sigma TBD

Burst and Pulse Count Mode 2 to 65,535 Pulses per Burst or Count

EXTERNAL TRIGGER INPUT

Type Positive Edge Trigger

Input Amplitude

Input Impedance

Minimum Trigger Pulse Width 25ns

Input Trigger Connector BNC, Front Panel

T0 (SYNC) OUTPUT

T0 (Sync) Output

Connector BNC, Front Panel

COMPUTER INTERFACE

Interface Type N/A

Interface Connector N/A

GENERAL

Internal Non-Volatile Storage 5 Configurations

Operating Temperature Range 0°C to +40°C

Cooling Requirements

Input AC Power 90-264VAC, 47-63Hz, 28W Maximum

Dimensions (H X W X D) 3 ½” H x 8” W x 6 1/4” D (8.9cm H x 20.3cm W x 15.9cm D)

Weight 2 lbs. (.9kg) Approximate

st

Sigma

75 Nanoseconds

<25 Nanoseconds

<5 Nanoseconds

Pulse Count

Single-Shot to 5MHz (External Trigger)

25 PPM

TBD

TTL into 1KΩ

1KΩ

TTL output into 1 MegΩ, 4.5V into 50Ω

ir cooled

Page 6

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 14

PDG-2515/2520 Operating Manual

Applications

The versatile functionality of the PDG-2515 makes it ideal for the needs of

numerous applications as a small bench top instrument. The delay resolution and

width resolution of each channel allow a unique ability to offset control signals,

coupled with ability to logically manipulate the outputs together to form gate

signals or specific waveforms make automation of testing and control an easier

process.

Safety

Normal use of test equipment exposes the user to a certain amount of danger

from electrical shock because testing may be performed with exposed voltages

present, dictating the use of caution when operating or servicing this equipment.

The following is a summary of general safety precautions that must be observed

during all phases of operation and repair of the PDG-2515.

Operating Safety Summary

The safety information contained in this summary is for both operating and

servicing personnel. Specific warnings may be found throughout this manual, but

may not appear in this summary.

Power Source

The PDG-2515 is designed to operate from a regulated power source. To

assure proper system operation the input voltage should not vary by more

than 10% from the recommended specification. The PDG-2515 accepts

input voltages from 90VAC to 264VAC at 47Hz to 63Hz.

A protective grounding connection by way of the grounding conductor in

the AC power cord is essential.

Grounding

The PDG-2515 is grounded through the grounding conductor of the AC

power cord. To avoid electrical shock, plug the PDG-2515 into a

properly wired receptacle before making connection to any input or

output connectors. Use only a power cord that is in good condition.

Cover Removal

To avoid personal injury, do not remove the covers. Do not operate the

PDG-2515 while the covers are removed. Operating the unit with the top

cover removed voids any and all warranties associated with the PDG-

2515.

General Operating Precautions

Do not open the unit while the system is in operation. Use caution when

handling or removing the output cables while the unit is operating. Turn off

Page 7

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 15

PDG-2515/2520 Operating Manual

equipment when making connections in high voltage or high current

circuits. Discharge high voltage capacitors after removing power.

Servicing Safety Summary

DEI strongly recommends that all repairs and adjustments be performed by

factory qualified personnel. DEI will not be responsible for personal injury or

damage to the pulse generator that occurs during repair by any party other than

the factory. Any repairs, adjustments or modifications made by anyone other than

authorized DEI personnel voids the factory warranty.

PREPARATION FOR USE

General

After unpacking, initial inspection and electrical installation procedures

should be performed to assure that the unit is in good working order. If it is

determined that the unit is damaged, the carrier should be notified

immediately. Repair problems should be directed to the service

department,

Directed Energy, Inc. (DEI),

Fort Collins, Colorado.

Telephone: (970) 493-1901

FAX: (970) 493-1903

EMAIL: deiinfo@directedenergy.com

Initial Inspection

• Inspect unit for exterior mechanical damage.

• Inspect power input cord and input power module for obvious signs of

damage.

Electrical Installation

Standard units are shipped ready for use with a nominal 90 - 264 VAC input.

Operation

This section provides basic operating instructions for the PDG-2515 hardware.

Operating Tips

1. The two output channels have synchronized frequencies. Pulse width and

pulse delay settings of one channel are dependent on the frequency of the

other channel. When changing frequency be aware that both pulse width

and delay are within range on both channels.

2. When using the 10X button to increase the rate at which the frequency

changes, when it is first depressed the value will change by 10X, further

Page 8

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 16

PDG-2515/2520 Operating Manual

change is accomplished by using the encoder while holding the 10X

button down.

Power-Up Procedures

The unit should be powered up using the following procedures:

Connect OUT 1 and/or OUT 2 to an appropriate load using 50 Ohm coaxial cable

(See Section 6.0).

Plug the AC power cord into the PDG-2515, and into an appropriate AC socket.

Turn on the PDG-2515 by pressing the power button on the rear of the unit

located above the power entry .

Configure the unit from the front panel. See the quick-start guide in Section 1.0 of

this manual for specific operating instructions, and Sections 8 and 9 for detailed

operation instructions.

FRONT PANEL OPERATING INSTRUCTIONS

THE CHANNEL MENU

The CHANNEL MENU will display which channel menu the unit is in on

the top of the display. Changing the settings is done by simply rotating the

encoder or pressing the X10 button. When the setting has reached it’s

maximum value on the encoder it will stop increasing the value as the

encoder turns. The X10 button on the other hand will set the value to the

nearest minimum exponent value when the maximum value has been

reached (example: 500 kHz will go to 500 mHz). This maximum value is

set by the internal limitations of the unit and also the pulse settings (ie:

pulse delay and duty cycle). In order the change which setting to adjust

the up and down arrows will highlight the current setting. In the CHANNEL

MENU all settings can be done while the unit is enabled, all settings can

“sweep”. Changing the pulse width and delay settings while enabled will

not effect the pulse, the change will take place on the next available clock

cycle internally. The frequency needs to be stopped and adjusted and

then turned back on internally. This means that there could be some delay

while sweeping frequency before the next frequency takes hold, this is

more noticeable as the frequency is near to slower limits while the unit

syncs up again to the internal oscillator. The polarity sweep will take hold

immediately, as will the disable and enable functions. The polarity function

will flip the polarity of the output. Pulse count will only be available in pulse

count and burst modes.

THE OUTPUT MENU

The OUTPUT MENU is where the unit can change its mode, disable a

channel, change the trigger, change the base of the sync, and also adjust

Page 9

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 17

PDG-2515/2520 Operating Manual

the contrast settings of the unit. The operating modes will be discussed in

more detail in section 9.0. Enabling and disabling a channel can also

happen on the fly in pulse generation and Divide By N modes. In pulse

count mode this needs to be set before hand so the unit does not sit in an

unknown state if it has not finished it’s count set, therefore, the unit will not

allow it to be changed while pulsing. In Burst mode, disabling the channel

is not available and both are enabled. When the mode is switched from

Burst mode, the enable/disable settings will return to where they were

previous to Burst mode. The trigger can be set to internal or external in

pulse generation and pulse count modes. Note that the unit will “lock up”

until it has finished it’s pulse count in external mode so the external

triggering device must give it AT LEAST as many pulses as is entered. If

this does not occur, the device can be “released” by switching modes. The

sync can also be run off channel 1 or channel 2. This is especially useful

in Divide By N mode and pulse count mode. Not that in Burst mode, the

sync is a packet period limited by at most 95% duty cycle regardless of

this setting.

The contrast setting can also be changed in this menu. If the contrast is

adjusted by using the encoder knob or using the x10 button, a ‘?’ will

appear at the end of the setting. This means that while the unit is powered

this is the setting that the unit will retain but when powered down and

powered up again the unit will revert to the last saved contrast. By

depressing the ENTER button the contrast will be saved in non-volatile

memory and the unit will come up under this contrast setting. The contrast

is has numerous settings, and a coarse and a fine adjust. The letter is a

course adjustment and the number is the fine adjust. The course adjust is

manipulated with the x10 button and the fine adjust is set by the encoder

knob.

THE LOGIC MENU

The LOGIC MENU allows the user to logically AND or OR outputs OUT1

and OUT2. LOGIC1 will output on the OUT1 channel (note: the invert

function will invert the channel AFTER the logic has been applied – this is

shown in the LOGIC AND POLARITY FUNCTIONAL DIAGRAM below).

LOGIC2 will output on the OUT2 channel.

Page 10

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 18

PDG-2515/2520 Operating Manual

Figure 1 Logic & Polarity Functional Diagram

THE CONFIGS MENU

The CONFIGS MENU allows the user to save or load up to 5 different

configurations. After selecting the appropriate configuration to either load

or save (1 through 5) hit the ENTER button and the configuration of the

unit will be saved. If the user tries to load a configuration that has not been

saved yet, the unit will send an error message of “Not Valid Config” and

nothing will be loaded. If the load or save is successful the active

configuration (ACTIVE CON: X) will reflect this with the correct setting.

*Note: if any values are changed, the active configuration will no longer be

valid and will reflect either -- or a ‘0’.

Operating Modes

Timing Diagram

The timing diagram below defines the frequency, delay and width

variables, and their temporal relationship to the T0 frequency generator

signal.

Page 11

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 19

PDG-2515/2520 Operating Manual

Figure 2 Timing Diagram

Please note that in external trigger mode, all outputs are delayed from the

leading edge of the external trigger signal.

Pulse Generator Mode

In Pulse Generator Mode, the PDG-2515 generates pulses at the

specified frequency denoted in the CHANNEL MENU (changing the

frequency on either channel will change the frequency on both channels

simultaneously – the frequencies are not independent in this mode). If

externally triggered, the rate is set by the external trigger (i.e. one pulse is

output each time a rising edge occurs on the TRIGGER input.

The delay of each of the outputs is relative to the leading edge of the

SYNC output in internal frequency generator and single shot modes. In

external trigger mode, the delay is relative to the leading edge of the

external trigger input.

The pulse width and delay for each channel are independently variable.

Page 12

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 20

PDG-2515/2520 Operating Manual

Figure 3 Example 1: Pulse Generator Mode

Figure 4 Example 2: Pulse Generator Mode

Pulse Count Mode

In Pulse Count Mode, the PDG-2515 generates a series of pulses, the

number of which is set by the PULSE CT variables on the respective

channel menu. When the number of pulses output on an output channel

equals the number set, the output of that channel is automatically disabled

and the output LED will reflect this

Page 13

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 21

PDG-2515/2520 Operating Manual

The PULSE CT variable for each channel can be set to any value between

1 and 65,535. In setting the PULSE CT, the x10 button will increase this

number by a factor of ten and the encoder wheel will increase/decrease

the number of pulses incrementally by one. For example, to set the count

to 1,500, first set the count to 15 using the encoder wheel, then press the

X10 button two times. The first press will increment the count to 150, and

the second to 1,500.

Pressing the OUTPUT button enables the output pulse series. The Pulse

On LED will illuminate until the pulse series is completed, at which time

the LED will extinguish. Each time the PULSE ON button is pressed, the

output pulse series will be generated.

In Internal PRF mode, the frequency (repetition rate) of the pulses are

determined by the internal frequency generator. If externally triggered, the

frequency of the pulses is determined by the frequency of the input trigger.

The delay of each of the outputs is relative to the leading edge of the T0

SYNC output.

Figure 5 Example: Pulse Count Mode

Divide By N Mode

In Divide by N Mode, OUT1 generates continuous output pulses (as in

Pulse Generator Mode), and OUT2 generates an output pulse every “Nth”

Output 1 pulse. The divisor is set through the Div Out1 By variable in the

FREQ DIV in the CHANNEL2 menu. The X10 button will multiply this

number by a factor of 10.

Page 14

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 22

PDG-2515/2520 Operating Manual

Be aware that coming out of this mode, if any variables are out of range by

going into a mode that conflicts with these settings, the channel/channels

will be set back to the default values.

Figure 6 Example 1: Divide by N Mode

Figure 7 Example 2: Divide by N Mode

Burst Mode

In Burst Mode, a set number of pulses (the burst packet) are output from

OUT1. Each burst packet is sent at the packet frequency. The burst

packet will start ONE period of the burst packet frequency after the rising

edge of the packet frequency (OUT 2 will ALWAYS output the packet

Page 15

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 23

PDG-2515/2520 Operating Manual

frequency at a limited duty cycle and cutoff any length of burst after that

length of time). The software will not check to check timing constraints in

this mode, meaning that if the timing if violated, the output may be

erroneous and not predictable (only while the constraints are violated – for

example if the number of bursts exceeds the time period of the packet

frequency this would violate the hardware of the unit). Violating the timing

can be a number of things such as a burst frequency larger than the

packet frequency, more pulses/delays than allowed in a single packet so

that timing overlaps, etc. The timing constraints are left up to the user’s

configurations so that the unit may be used to it’s full potential, however

the user may want to output a signal that does not violate any timing

constraints to receive a correct burst and frequency.

Figure 8 Example: Burst Mode

Single Shot Mode

In this mode, the pulse widths and the pulse delays can be set to their

maximum values without any timing constraints. After the OUTPUT button

is depressed, OUT1 and OUT2 will generate a single pulse according to

the individual channel settings.

Page 16

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 24

Troubleshooting Guide

PDG-2515/2520 Operating Manual

No power LED or screen

does not come up.

Pulse exhibits excessive

ringing.

Frequency limits. Check duty cycle of EACH channel, both channels

Pulse Width limits. Check the frequency and duty cycle. Note that duty

Pulse Delay limits. Check the frequency and duty cycle. Note that duty

In external trigger pulse is

not stable or consistent

with settings.

In Burst Mode pulse is

not stable or consistent

with settings.

Configuration will not

load.

Sync output not a square

wave or has excessive

ringing.

Check power source, power switch (located on rear

of unit).

Check load impedance.

must be within the specifications of the unit to

increase the frequency. Note that duty cycle of a

channel is the addition of the pulse width and the

delay.

cycle of a channel is the addition of the pulse width

and the delay settings.

cycle of a channel is the addition of the pulse width

and the delay settings.

Check duty cycle of input trigger signal, check that

the signal frequency and trigger signal duty cycle are

within specification.

Check to make sure timing constraints are not

exceeded; duty cycle of frequency is not exceeded

with the addition of extra pulses.

Make sure a valid configuration had been previously

saved in configuration slot.

Check sync lines termination; note that sync does

not have same impedance as output lines.

Page 17

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 25

PDG-2515/2520 Operating Manual

PDG-2520 Operating Manual

Quick Start Guide

This quick-start guide provides a step-by-step guide to manually operating the

PDG-2520. Please refer to the appropriate sections of the manual for additional

instructions and guidelines. The SAFETY warnings in the manual must be read

and understood prior to operating the PDG-2520.

What’s In The Box?

1ea. PDG-2520 Digital Delay & Pulse Generator

1ea. Power Cord

2ea. 50 Ohm Coaxial Output Cable

1ea. Operating Manual

Unpacking

Carefully remove each component listed above. Your PDG-2520 and

accessories were inspected at the factory prior to shipment. Inspect the PDG2520, power cord and output cables for signs of shipping damage. If any damage

is noted contact the factory prior to operating the equipment.

Setup

Connect OUTputs to an appropriate load using 50 Ohm coaxial cable (included).

Plug the AC power cord into the rear power entry module of the PDG-2520, and

into an appropriate AC socket.

Power Up

Turn on the PDG-2520 by pressing the power button located above the power

entry module in the rear of the unit.

The front panel display will read initialize and display the software and hardware

versions internal to the unit on the front panel. After a few moments the unit will

finish initialization and the first screen/menu that will appear is the menu for

CHANNEL 1. Note: The buttons and encoder on the front panel will have no

effect as the unit comes up from initialization.

Front Panel Controls & Connections

Encoder

This is for varying the parameters such as Frequency, Pulse Width, Delay,

Trigger Source, etc.

Page 18

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 26

PDG-2515/2520 Operating Manual

Output Button

The output button enables/disables the pulse output.

Menu Button

This button is for navigating the PDG-2520 menus.

Enter Button

Used for variables that will be permanently stored in the unit or require

setup times internal to the PDG-2520. When a question mark appears

after the variable, the enter button will “confirm” or in some cases save

that particular setting.

Up Arrow Button

The UP ARROW button allows the user to go up in any particular menu to

change selections. If the user is at the top selection it will wrap back

around to the bottom selection.

Down Arrow Button

The DOWN ARROW button allows the user to go down in any particular

menu to change selections. If the user is at the bottom selection it will

wrap back around to the top selection.

X10 Button

The X10 button is used when varying parameters that have exponents

that can change by a power of 10. By pressing the X10 button the user

can increment the exponent within its acceptable range. This allows the

user to quickly set the parameters, without having to excessively scroll the

encoder wheel. The X10 button functions with the following commands:

Set Pulse Width 1, 2, 3, and 4

Set Delay 1, 2, 3, and 4

Set Frequency (*Note: if depressed while dialing in frequency it will

increase the frequency at a much higher rate)

Set Counters/Bursts/Packets

The X10 button is effectively a 10X multiplier. For example, when

setting frequency, the resolution of the encoder wheel is three digits

(i.e. 1.00Hz, 10.0Hz, 100Hz, 1.00KHz). Therefore without adjusting

the range, the encoder wheel must be turned many times to

increase the frequency from 1Hz to 100Hz. However if the

frequency is set to 1.00Hz, if the X10 button is pressed once, it

changes to 10.0Hz. If it is pressed twice, it changes to 100Hz.

Setting the delay and pulse width is similar to setting frequency. For

example, to set the delay to 300ns, set the delay to 25ns, press the

Page 19

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 27

PDG-2515/2520 Operating Manual

X10 button once to increment it to 250ns, then rotate the encoder

wheel to increase it to 300ns. At this point, pressing the X10 button

again would increase the delay to 3.00us, pressing it again

increments it to 30.0us, etc.

An additional function is that if it is held while changing ANY

frequency value, after multiplying the value by a factor of ten, if the

encoder is moved it will increase/decrease at a much faster rate.

This makes the switching frequency much quicker and easier.

PW/PRF Button

This is for varying the parameters Frequency and Pulse Width and

toggling between the two settings quickly. If you are in any menu that is

not a CHANNEL MENU, it will flip you immediately to the CHANNEL 1

menu and the FREQUENCY setting.

Out 1, Out 2, Out 3, Out 4

These are the pulse output connectors. The outputs of the PDG-2520

should be connected to the inputs of the receiving instrument or system

using 50 Ohm coaxial cable. For optimal pulse fidelity, these outputs

should be terminated into 50 Ohms.

Sync Out

This is a 5V signal into 1 meg-Ohm or 2.5V signal into 50 Ohms that is

synchronous with the frequency generator trigger. This is designed to

assist the user in triggering when monitoring the output signals with an

oscilloscope, or for use in triggering an external instrument.

Trigger In

This is an input signal into 1KOhms used for external Pulse Repetition

Frequency (PRF) triggering. It is designed to allow the user to trigger

multiple PDG-2520 units from a single pulse generator. This allows the

user to create synchronous waveforms from multiple units.

Power LED

Indicates that the power switch on the rear of the unit is in the ‘on’ position

and that AC power is applied to the unit.

Front Panel Controls & Connections

AC Power Entry Module

The driver is grounded through the grounding conductor of the AC power

cord. To avoid electrical shock, plug the driver into a properly wired

receptacle before making connection to any input or output connectors.

Use only a power cord that is in good condition.

Page 20

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 28

PDG-2515/2520 Operating Manual

The PDG-2520 accepts input voltages of 90-264VAC, 47-63Hz.

Example Setup

The default setup is 1 kHz, with zero delay and 100 us pulse on both channels.

The pulse in not inverted and the pulse mode is in continuous pulse generation

mode which means that pulse count is not available. By pressing the OUTPUT

button on the front panel you will see these pulses on the respective outputs.

Turning the encoder with the pulses enabled and the unit will sweep the

frequency on the fly, hitting the X10 button will bring you to 10 times the

frequency. Pressing the down arrow twice will highlight the pulse width selection.

Turn the encoder and the width will sweep. Try this with the polarity setting; it will

change on the fly. Turn off the pulses.

Press MENU to continue to the settings for CHANNEL 2. Its default is the same

as CHANNEL 1. Pressing the MENU button twice more will bring the user

through to the last channel menu.

Hitting MENU again will bring up the first output menu, OUTPUT MENU1. This

menu allows the unit to change pulse modes, disable and enable the outputs

(depending on the pulse mode), and choose whether the sync is based off

CHANNEL 1, 2, 3, or 4.

Hitting MENU again will bring up the second output menu, OUTPUT MENU2.

This menu allows the unit to select the trigger, adjust the contrast, and select the

logic applied to the output of CHANNEL 1, 2, 3, and 4.

Hitting the arrow keys allows the user to decide which settings on the current

menu they would like to adjust. Press the up arrow once to scroll around to the

bottom of the menu or press the down arrow 5 times. The contrast setting will be

highlighted.

Turn the encoder to adjust the contrast. The contrast will adjust “on the fly” and a

question mark will appear at the end of the contrast. Hit ENTER and save the

contrast saving into the non-volatile memory of the unit, this setting will saved

into the unit and keep this in memory even after power-down.

Page 21

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 29

PDG-2515/2520 Operating Manual

Product Overview

Description

The PDG-2520 is a four channel digital delay/pulse generator. Each channel

offers independently adjustable delay and width, with 25 nanosecond resolution.

Up to five user configurations may be stored in internal non-volatile memory, and

recalled through the easy to understand front panel.

Functions & Features

Delay And Width and

Duty Cycle.

Frequency

Resolution

Trigger Sources

Pulse Generator

Mode

Pulse Count Mode

Divide By N Mode

Each channel provides independently adjustable

delay and width, with 25ns resolution. The duty

cycle is limited based on the frequency. The duty

cycle is limited approximately by the equation:

MAX DC = 97-[(1E-5)*FREQ].

Pulse repetition frequency from single shot to

continuous pulses from 100 mHz to 3.0 MHz.

100mHZ to 1.0 MHz -> 3 digits

1.0 MHz + -> 2 digits

Internal, External, Single Shot.

Generates pulses at the rate set by the internal

frequency generator, or by an external trigger.

Outputs pulses at the rate set by the internal

frequency generator or external trigger and stops

after N pulses.

Channel 1 and Channel 3 operates in continuous

mode. Channel 2 and Channel 4 pulses every Nth

pulse.

Burst Mode

Counted Burst Mode

Store And Recall

Generates a burst of pulses, repeating at a

frequency on Channel 1.

Generates a burst of pulses, and stops after N

bursts.

Stores up to 5 user configurations in non-volatile

memory.

Page 22

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 30

PDG-2515/2520 Operating Manual

A

A

A

A

A

Specifications

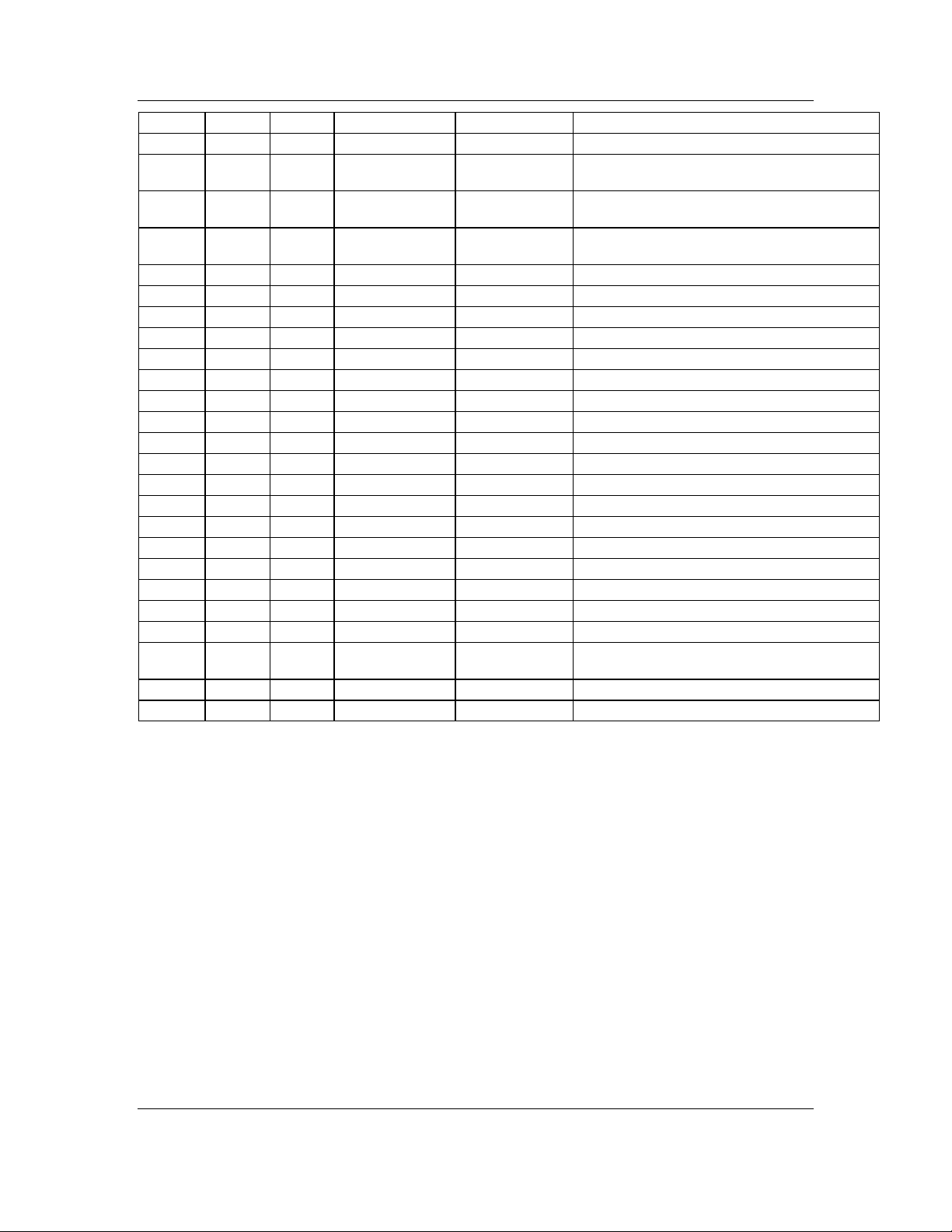

PARAMETER Value

OUTPUTS

Output Channels Four (4) outputs, each with independent digitally controlled delay

and pulse width

Delay Range 0 to 99.9 Seconds

Pulse Width Range 25 Nanoseconds to 99.9 Seconds

Delay And Pulse Width Resolution 25 Nanoseconds below 1 Microsecond

50 Nanoseconds from 1 Microsecond to 10 Microseconds

3 Digits Above 10 Microseconds

ccuracy (Delay and Pulse Width) ±2%

Time Base 120MHz Frequency Synthesizer

Delay Jitter (1st Sigma) TBD

Trigger Delay (External Trigger to SYNC (T0)

Output

Internal Throughput Delay (SYNC (T0) To Output 1

Or Output 2 Rising Edge)

Output Rise & Fall Times (Into 50Ω)

Over/undershoot <5%

mplitude +4V into 50W

Output Connectors BNC, Front Panel

INTERNAL RATE GENERATOR

Modes Continuous, Single-Shot, Burst, External Trigger, Divide By N,

Rate Single-Shot or 100 millihertz to 3MHz (Internal)

Resolution 3 Digits (<1MHz), 2 Digits (>1MHz)

ccuracy (Continuous, Pulse Count, Output-2

Modes)

ccuracy (Burst Mode) ±2%

Rate Jitter (Continuous, Pulse Count, Output-2

Modes), 1

Rate Jitter (Burst Mode), 1st Sigma TBD

Burst and Pulse Count Mode 1 to 65,535 Pulses per Burst or Count

EXTERNAL TRIGGER INPUT

Type Positive Edge Trigger

Input Amplitude

Input Impedance

Minimum Trigger Pulse Width 25ns

Input Trigger Connector BNC, Front Panel

T0 (SYNC) OUTPUT

T0 (Sync) Output

Connector BNC, Front Panel

COMPUTER INTERFACE

Interface Type RS232 or GPIB

Interface Connector DB9 or GPIB connector

GENERAL

Internal Non-Volatile Storage 5 Configurations

Operating Temperature Range 0°C to +40°C

Cooling Requirements

Input AC Power 90-264VAC, 47-63Hz, 28W Maximum

Dimensions (H X W X D) 3 ½” H x 8” W x 6 1/4” D (8.9cm H x 20.3cm W x 15.9cm D)

Weight 2 lbs. (.9kg) Approximate

st

Sigma

TBD

<25 Nanoseconds

<5 Nanoseconds

Pulse Count

Single-Shot to 5MHz (External Trigger)

25 PPM

TBD

TTL into 1KΩ

1KΩ

TTL output into 1 MegΩ, 4.5V into 50Ω

ir cooled

Page 23

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 31

PDG-2515/2520 Operating Manual

Applications

The versatile functionality of the PDG-2520 makes it ideal for the needs of

numerous applications as a small bench top instrument. The delay resolution and

width resolution of each channel allow a unique ability to offset control signals,

coupled with ability to logically manipulate the outputs together to form gate

signals or specific waveforms make automation of testing and control an easier

process.

Safety

Normal use of test equipment exposes the user to a certain amount of danger

from electrical shock because testing may be performed with exposed voltages

present, dictating the use of caution when operating or servicing this equipment.

The following is a summary of general safety precautions that must be observed

during all phases of operation and repair of the PDG-2520.

Operating Safety Summary

The safety information contained in this summary is for both operating and

servicing personnel. Specific warnings may be found throughout this manual, but

may not appear in this summary.

Power Source

The PDG-2520 is designed to operate from a regulated power source. To

assure proper system operation the input voltage should not vary by more

than 10% from the recommended specification. The PDG-2520 accepts

input voltages from 90VAC to 264VAC at 47Hz to 63Hz.

A protective grounding connection by way of the grounding conductor in

the AC power cord is essential.

Grounding

The PDG-2520 is grounded through the grounding conductor of the AC

power cord. To avoid electrical shock, plug the PDG-2520 into a

properly wired receptacle before making connection to any input or

output connectors. Use only a power cord that is in good condition.

Cover Removal

To avoid personal injury, do not remove the covers. Do not operate the

PDG-2520 while the covers are removed. Operating the unit with the top

cover removed voids any and all warranties associated with the PDG-

2520.

General Operating Precautions

Do not open the unit while the system is in operation. Use caution when

handling or removing the output cables while the unit is operating. Turn off

Page 24

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 32

PDG-2515/2520 Operating Manual

equipment when making connections in high voltage or high current

circuits. Discharge high voltage capacitors after removing power.

Servicing Safety Summary

DEI strongly recommends that all repairs and adjustments be performed by

factory qualified personnel. DEI will not be responsible for personal injury or

damage to the pulse generator that occurs during repair by any party other than

the factory. Any repairs, adjustments or modifications made by anyone other than

authorized DEI personnel voids the factory warranty.

PREPARATION FOR USE

General

After unpacking, initial inspection and electrical installation procedures

should be performed to assure that the unit is in good working order. If it is

determined that the unit is damaged, the carrier should be notified

immediately. Repair problems should be directed to the service

department,

Directed Energy, Inc. (DEI),

Fort Collins, Colorado.

Telephone: (970) 493-1901

FAX: (970) 493-1903

EMAIL: deiinfo@directedenergy.com

Initial Inspection

• Inspect unit for exterior mechanical damage.

• Inspect power input cord and input power module for obvious signs of

damage.

Electrical Installation

Standard units are shipped ready for use with a nominal 90 - 264 VAC input.

Operation

This section provides basic operating instructions for the PDG-2520 hardware.

Operating Tips

1. The four output channels have synchronized frequencies. Pulse width and

pulse delay settings of one channel are dependent on the frequency of the

other channels. When changing frequency be aware that both pulse width

and delay are within range on both channels.

2. When using the 10X button to increase the rate at which the frequency

changes, when it is first depressed the value will change by 10X, further

Page 25

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 33

PDG-2515/2520 Operating Manual

change is accomplished by using the encoder while holding the 10X

button down.

Power-Up Procedures

The unit should be powered up using the following procedures:

Connect OUTPUTs to an appropriate load using 50 Ohm coaxial cable (See

Section 6.0).

Plug the AC power cord into the PDG-2520, and into an appropriate AC socket.

Turn on the PDG-2520 by pressing the power button on the rear of the unit

located above the power entry .

Configure the unit from the front panel. See the quick-start guide in Section 1.0 of

this manual for specific operating instructions, and Sections 8 and 9 for detailed

operation instructions.

FRONT PANEL OPERATING INSTRUCTIONS

THE CHANNEL MENU

The CHANNEL MENU will display which channel menu the unit is in on

the top of the display. Changing the settings is done by simply rotating the

encoder or pressing the X10 button. When the setting has reached it’s

maximum value on the encoder it will stop increasing the value as the

encoder turns. The X10 button on the other hand will set the value to the

nearest minimum exponent value when the maximum value has been

reached (example: 500 kHz will go to 500 mHz). This maximum value is

set by the internal limitations of the unit and also the pulse settings (ie:

pulse delay and duty cycle). In order the change which setting to adjust

the up and down arrows will highlight the current setting. In the CHANNEL

MENU all settings can be done while the unit is enabled, all settings can

“sweep”. Changing the pulse width and delay settings while enabled will

not effect the pulse, the change will take place on the next available clock

cycle internally. The frequency needs to be stopped and adjusted and

then turned back on internally. This means that there could be some delay

while sweeping frequency before the next frequency takes hold, this is

more noticeable as the frequency is near to slower limits while the unit

syncs up again to the internal oscillator. The polarity sweep will take hold

immediately, as will the disable and enable functions. The polarity function

will flip the polarity of the output. Pulse count will only be available in pulse

count and burst modes.

OUTPUT MENU1

OUTPUT MENU1 is the menu where the unit can change its mode,

disable/enable a channel, and change the base of the sync. The operating

Page 26

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 34

PDG-2515/2520 Operating Manual

modes will be discussed in more detail in section 9.0. Enabling and

disabling a channel can also happen on the fly in all modes except Burst

Mode. In Burst mode, enabling/disabling the channels is not available and

Channel 1 and 2 are enabled, Channel 3 and 4 are disabled automatically.

When the mode is switched from Burst mode, the enable/disable settings

will return to where they were previous to Burst mode. The trigger can be

set to internal or external in pulse generation and pulse count modes.

Note that the unit will “lock up” until it has finished it’s pulse count in

external mode so the external triggering device must give it AT LEAST as

many pulses as is entered. If this does not occur, the device can be

“released” by switching modes. The sync can also be run off any channel

except under Burst Mode. This is especially useful in Divide By N mode

and pulse count mode. Not that in Burst mode, the sync is a packet period

limited by at most 95% duty cycle regardless of this setting.

OUTPUT MENU2

OUTPUT MENU2 is where the unit can change the trigger, adjust the

contrast settings of the unit, and set the logic applied to the output of all

Channels. The operating modes will be discussed in more detail in section

9.0. The trigger can be set to internal or external in pulse generation and

pulse count modes. Note that the unit will “lock up” until it has finished it’s

pulse count in external mode so the external triggering device must give it

AT LEAST as many pulses as is entered. If this does not occur, the device

can be “released” by switching modes. The sync can also be run off any

channel when the unit is not in Burst mode (Note that in Burst mode, the

sync is a packet period limited by at most 95% duty cycle regardless of

this setting and outputs on Channel2 as well as the SYNC output.

The contrast setting can also be changed in this menu. If the contrast is

adjusted by using the encoder knob or using the x10 button, a ‘?’ will

appear at the end of the setting. This means that while the unit is powered

this is the setting that the unit will retain but when powered down and

powered up again the unit will revert to the last saved contrast. By

depressing the ENTER button the contrast will be saved in non-volatile

memory and the unit will come up under this contrast setting. The contrast

is has numerous settings, and a coarse and a fine adjust. The letter is a

course adjustment and the number is the fine adjust. The course adjust is

manipulated with the x10 button and the fine adjust is set by the encoder

knob. Logic allows the user to logically AND or OR outputs OUT1 and

OUT2 with each other and OUT3 and OUT4 with each other. LOGIC1 will

output on the OUT1 channel (note: the invert function will invert the

channel AFTER the logic has been applied – this is shown in the LOGIC

AND POLARITY FUNCTIONAL DIAGRAM below). LOGIC2 will output on

the OUT2 channel, LOGIC3 will output on the OUT3 channel, and

LOGIC4 will output on the OUT4 channel.

Page 27

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 35

PDG-2515/2520 Operating Manual

Figure 9 Logic & Polarity Functional Diagram

THE CONFIGS MENU

The CONFIGS MENU allows the user to save or load up to 5 different

configurations. After selecting the appropriate configuration to either load

or save (1 through 5) hit the ENTER button and the configuration of the

unit will be saved. If the user tries to load a configuration that has not been

saved yet, the unit will send an error message of “Not Valid Config” and

nothing will be loaded. If the load or save is successful the active

configuration (ACTIVE CON: X) will reflect this with the correct setting.

*Note: if any values are changed, the active configuration will no longer be

valid and will reflect either -- or a ‘0’.

Operating Modes

Timing Diagram

The timing diagram below defines the frequency, delay and width

variables, and their temporal relationship to the T0 frequency generator

signal.

Page 28

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 36

PDG-2515/2520 Operating Manual

Figure 10 Timing Diagram

Please note that in external trigger mode, all outputs are delayed from the

leading edge of the external trigger signal.

Pulse Generator Mode

In Pulse Generator Mode, the PDG-2520 generates pulses at the

specified frequency denoted in the CHANNEL MENU (changing the

frequency on either channel will change the frequency on both channels

simultaneously – the frequencies are not independent in this mode). If

externally triggered, the rate is set by the external trigger (i.e. one pulse is

output each time a rising edge occurs on the TRIGGER input.

The delay of each of the outputs is relative to the leading edge of the

SYNC output in internal frequency generator and single shot modes. In

external trigger mode, the delay is relative to the leading edge of the

external trigger input.

The pulse width and delay for each channel are independently variable.

Page 29

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 37

PDG-2515/2520 Operating Manual

Figure 11 Example 1: Pulse Generator Mode

Figure 12 Example 2: Pulse Generator Mode with logic

Pulse Count Mode

In Pulse Count Mode, the PDG-2520 generates a series of pulses, the

number of which is set by the PULSE CT variables on the respective

channel menu. When the number of pulses output on an output channel

equals the number set, the output of that channel is automatically disabled

and the output LED will reflect this

Page 30

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 38

PDG-2515/2520 Operating Manual

The PULSE CT variable for each channel can be set to any value between

1 and 65,535. In setting the PULSE CT, the x10 button will increase this

number by a factor of ten and the encoder wheel will increase/decrease

the number of pulses incrementally by one. For example, to set the count

to 1,500, first set the count to 15 using the encoder wheel, then press the

X10 button two times. The first press will increment the count to 150, and

the second to 1,500.

Pressing the OUTPUT button enables the output pulse series. The Pulse

On LED will illuminate until the pulse series is completed, at which time

the LED will extinguish. Each time the PULSE ON button is pressed, the

output pulse series will be generated.

In Internal PRF mode, the frequency (repetition rate) of the pulses are

determined by the internal frequency generator. If externally triggered, the

frequency of the pulses is determined by the frequency of the input trigger.

The delay of each of the outputs is relative to the leading edge of the T0

SYNC output.

Figure 13 Example: Pulse Count Mode

Divide By N Mode

In Divide by N Mode, OUT1 and OUT3 generates continuous output

pulses (as in Pulse Generator Mode), and OUT2 and OUT4 generates an

output pulse every “Nth” Output pulse. The divisor is set through the Div

Out1 By variable in the FREQ DIV in the CHANNEL2 menu. The X10

button will multiply this number by a factor of 10.

Page 31

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 39

PDG-2515/2520 Operating Manual

Be aware that coming out of this mode, if any variables are out of range by

going into a mode that conflicts with these settings, the channel/channels

will be set back to the default values. Also be aware that channels 1 and

3 stay synchronized and channels 2 and 4 must have the same value for

N. The delays and pulse widths on these channels are all independent.

Figure 14 Example 1: Divide by N Mode

Figure 15 Example 2: Divide by N Mode

Page 32

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 40

PDG-2515/2520 Operating Manual

Burst Mode

In Burst Mode, a set number of pulses (the burst packet) are output from

OUT1. Each burst packet is sent at the packet frequency. The burst

packet will start ONE period of the burst packet frequency after the rising

edge of the packet frequency (OUT 2 will ALWAYS output the packet

frequency at a limited duty cycle and cutoff any length of burst after that

length of time). The software will not check to check timing constraints in

this mode, meaning that if the timing if violated, the output may be

erroneous and not predictable (only while the constraints are violated – for

example if the number of bursts exceeds the time period of the packet

frequency this would violate the hardware of the unit). Violating the timing

can be a number of things such as a burst frequency larger than the

packet frequency, more pulses/delays than allowed in a single packet so

that timing overlaps, etc. The timing constraints are left up to the user’s

configurations so that the unit may be used to it’s full potential, however

the user may want to output a signal that does not violate any timing

constraints to receive a correct burst and frequency. OUT 3 and OUT 4

are not available in this mode, they will stay at DC levels.

Figure 16 Example: Burst Mode

Single Shot Mode

In this mode, the pulse widths and the pulse delays can be set to their

maximum values without any timing constraints. After the OUTPUT button

is depressed, the OUTputs will generate a single pulse according to the

individual channel settings.

Page 33

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 41

PDG-2515/2520 Operating Manual

Figure 17 Example: Single Shot Mode

Page 34

MNPDG2515-2520R0.doc

© 2004 Directed Energy, Inc.

Page 42

Troubleshooting Guide

PDG-2515/2520 Operating Manual

No power LED or screen

does not come up.

Pulse exhibits excessive

ringing.

Frequency limits. Check duty cycle of EACH channel, both channels

Pulse Width limits. Check the frequency and duty cycle. Note that duty

Pulse Delay limits. Check the frequency and duty cycle. Note that duty

In external trigger pulse is

not stable or consistent

with settings.

In Burst Mode pulse is