Page 1

Model 2000

Installation Guide

© 2001 Directed Electronics, Inc. Vista, CA N122 3-01

Rev. B 1.0

®

Page 2

2 © 2001 Directed Electronics, Inc. Vista, CA

table of contents

Bitwriter™, Code Hopping™, DEI®, Doubleguard®, ESP™, FailSafe®, Ghost Switch™, Learn

Routine™, Nite-Lite®, Nuisance Prevention Circuitry®, NPC®, Revenger®, Silent Mode™, Soft Chirp®,

Stinger®, Valet®, Vehicle Recovery System®, VRS®, and Warn Away® are all Trademarks or Registered

Trademarks of Directed Electronics, Inc.

What Is Included . . . . . . . . . . . . . . . . . . . . . 3

Installation Points to Remember . . . . . . . . . . 4

Deciding on Component Locations . . . . . . . . . 5

Siren . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Control Module. . . . . . . . . . . . . . . . . . . . . 5

Valet/Program Switch . . . . . . . . . . . . . . . . 5

Status LED . . . . . . . . . . . . . . . . . . . . . . . 5

Finding the Wires You Need . . . . . . . . . . . . . . 6

Obtaining Constant 12V . . . . . . . . . . . . . . . 6

12V Switched Ignition Wire . . . . . . . . . . . . 6

Starter Wire. . . . . . . . . . . . . . . . . . . . . . . 7

(+) Parking Light Wire . . . . . . . . . . . . . . . . 7

Making Your Wiring Connections. . . . . . . . . . . 8

Primary Harness (H1), 14-Pin Connector . . . . . 9

Primary Harness Wire Connection Guide. . . . . 10

Making Siren Connections . . . . . . . . . . . . . . 14

Enabling the Back-Up Battery Siren . . . . . . 14

Plug-In LED and Valet/Program Switch. . . . . . 15

On-Board Doubleguard Shock Sensor . . . . . . . 15

Transmitter/Receiver Learn Routine. . . . . . . . 16

System Features Learn Routine. . . . . . . . . . . 17

Features Menu . . . . . . . . . . . . . . . . . . . . . . 18

Feature Descriptions . . . . . . . . . . . . . . . . . . 18

Multi-Level Security Arming . . . . . . . . . . . . . 19

Nuisance Prevention Circuitry. . . . . . . . . . . . 20

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 20

Arming Diagnostics . . . . . . . . . . . . . . . . . 20

Disarming Diagnostics . . . . . . . . . . . . . . . 20

Table of Zones . . . . . . . . . . . . . . . . . . . . . . 21

Troubleshooting . . . . . . . . . . . . . . . . . . . . . 21

Wiring Quick Reference Guide . . . . . . . . . . . 24

Page 3

© 2001 Directed Electronics, Inc. Vista, CA 3

what is included

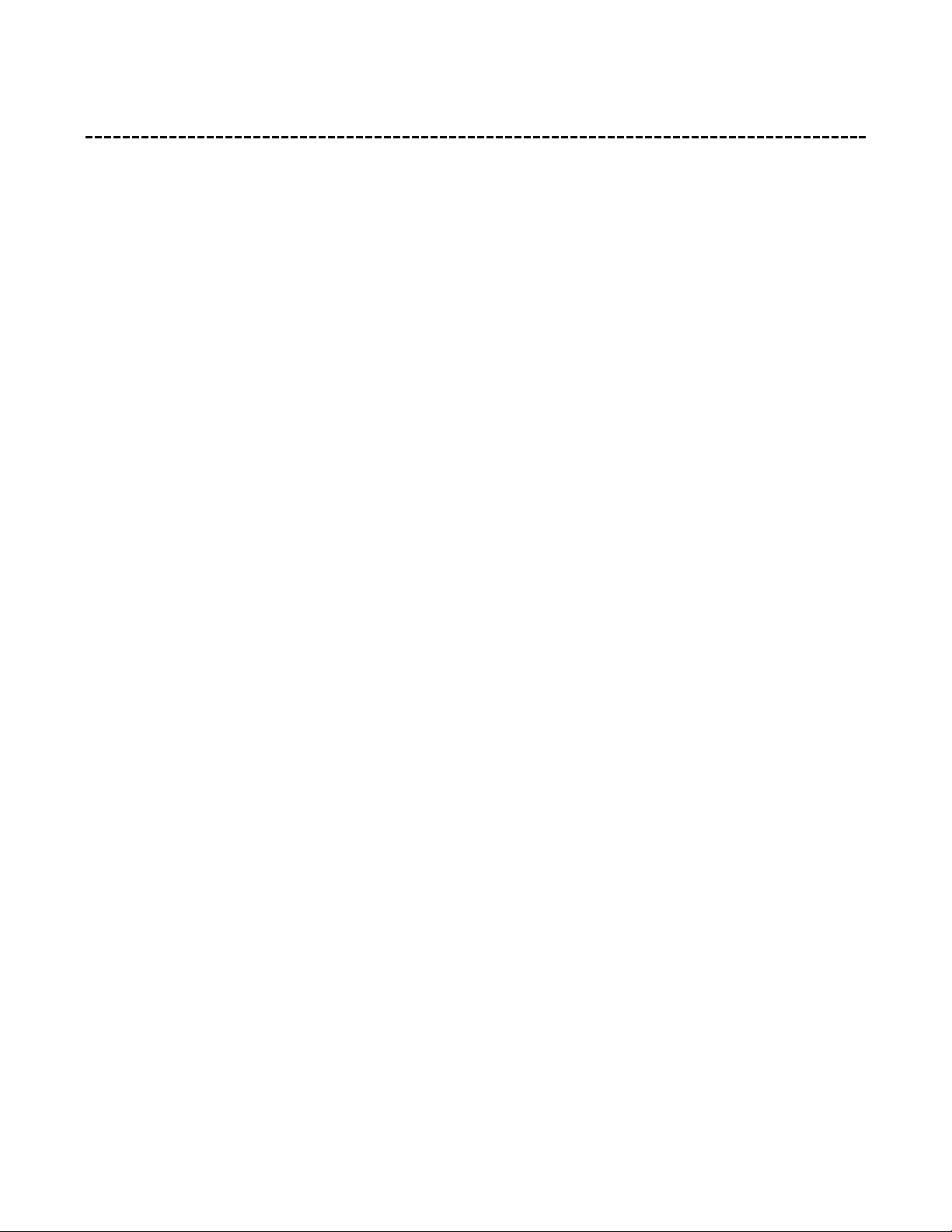

Shock Sensor

Sensitivity

Adjustment

H1 Primary

Harness Port

(14-Pin Connector)

White

LED Port

(2-Pin Connector)

Blue Valet

Switch Port

(2-Pin Connector)

■ The control module (see diagram)

■ Two 470T Series remote transmitters

■ Primary harness

■ A plug-in status LED

■ A plug-in Valet

®

switch

■ An on-board shock sensor

■ A back-up battery siren

■ Two back-up battery siren keys

■ A mercury tilt switch (for motorcycle installations)

Antenna

Page 4

4 © 2001 Directed Electronics, Inc. Vista, CA

installation points to remember

This system has many unique features, some of which require unique testing procedures! Carefully review both

this installation guide and the owner’s guide before beginning the installation or this system, particularly the

wiring diagrams.

■ The control module’s PC board is protected with a conformal coating which will combat condensation build-

up, however the system is NOT WATERPROOF. This system and all of its components MUST be installed in a

location where they cannot become wet or be submerged in water.

■ We recommend insulating all your soldered or crimped connections with heat shrink or electrical tape. We

also recommend spraying a silicone sealant on all your connections and plugs AFTER they are connected and

plugged in. Spraying beforehand prevents good electrical connections.

■ This unit is equipped with Nuisance Prevention Circuitry, which can bypass zones that are repeatedly trig-

gered, causing them to appear not to work. For a detailed description of this feature, refer to the Nuisance

Prevention Circuitry section of the Owner's Guide.

■ If possible, consult with the customer to determine the location of the Status LED.

■ Never mount components where they can be easily disconnected, or where they might interfere with normal

operation or obstruct service technicians.

After the installation is complete:

■ Before mounting the control module, in conditions where moisture or condensation may build up around the

control module's Molex plugs, we recommend applying white lithium grease or an electrical conductive-type

grease around the control module’s Molex plug contacts to prevent the terminals from oxidizing.

■ Make sure to test all functions. The “Using Your System” section of the owner’s guide is very helpful when

testing the system.

Page 5

© 2001 Directed Electronics, Inc. Vista, CA 5

deciding on component locations

Some things to remember when mounting the siren:

■ Mount the siren with screws, taking care that the screws do not come in contact with any wire harnesses or

fluid lines.

■ Keep it away from heat sources. Radiators, exhaust manifolds, turbochargers, and heat shields are all loca-

tions to avoid.

■ Mount it where a thief cannot easily disconnect it. Both the siren and its wires should be difficult to find.

This usually involves disguising the wire to look like a factory harness.

■ Point the siren down so water does not collect in it.

■ When installing this system in watercraft, the siren must be mounted in a compartment that does not take

in water.

Some things to remember when mounting the control module:

■ Mount the control module with the screws or with zip ties.

■ When locating the control module, keep it away from any heat sources or obvious leaks. Also keep the com-

ponents and harnesses as far from the exhaust system as possible.

■ The higher the control module is mounted, the better the transmitter range will be.

■ When installing this system in watercraft, the control module must be mounted in a compartment that does

not take in water.

The switch should be well hidden. It should be placed so passengers or stored items (such as near a luggage

carrier or saddlebags) cannot accidentally hit it. The switch fits in a

9

/32-inch hole.

IMPORTANT! When the vehicle is delivered, please show the user where the switch is located and

how to disarm the system with it.

Things to remember when positioning the Status LED:

■ It should be visible from both sides and the rear of the vehicle, if possible.

■ It needs at least

1

/

2-inch clearance to the rear.

■ The LED fits in a

9

/

32-inch hole.

locations for the status LED

locations for the valet/program switch

locations for the control module

locations for the siren

Page 6

6 © 2001 Directed Electronics, Inc. Vista, CA

finding the wires you need

Now that you have decided where each component will be located, you’re going to find the wires in the vehicle

that the security system will be connected to.

IMPORTANT! Do not use a 12V test light to find these wires! Use a digital multimeter for all testing.

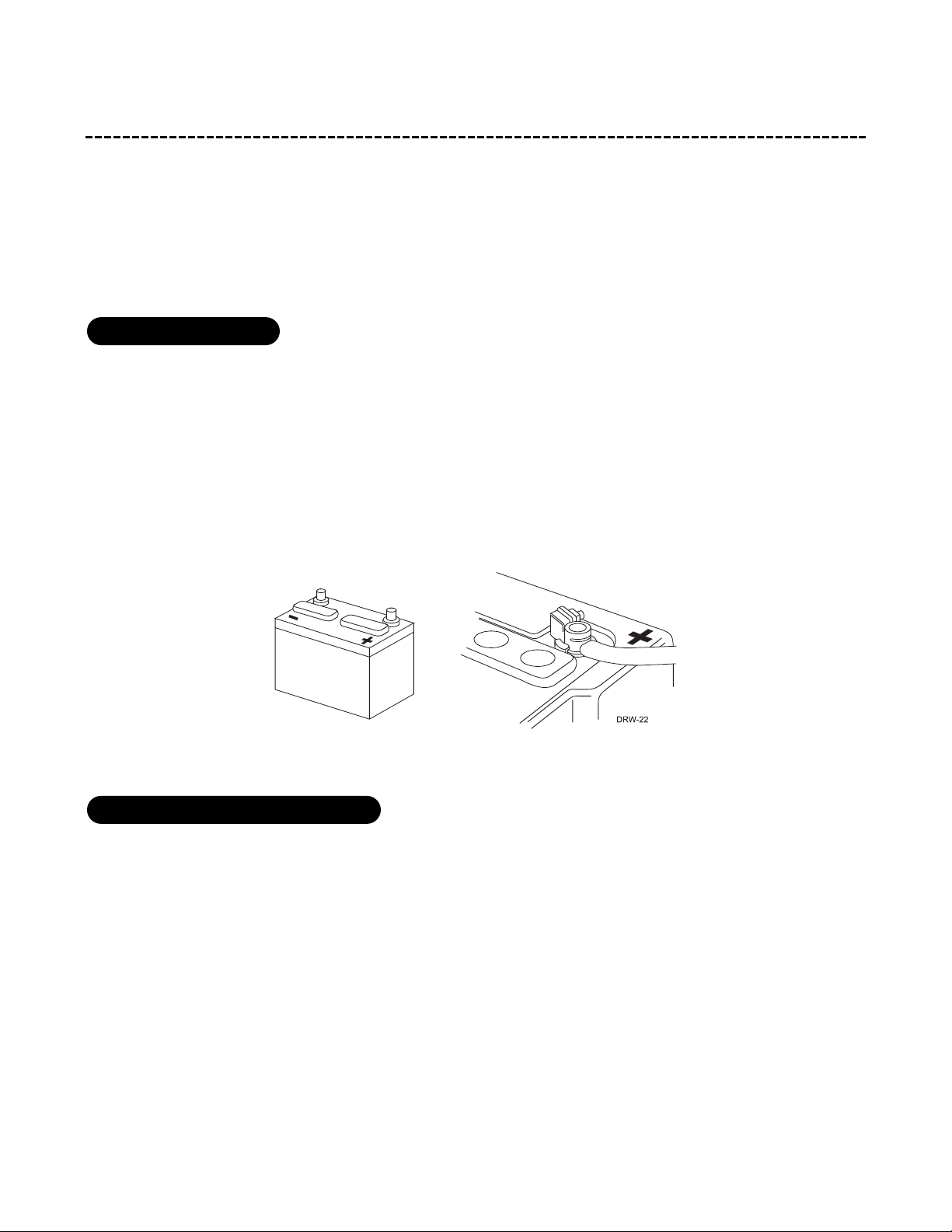

We recommend two possible sources for 12V constant: the (+) terminal of the battery, or the constant supply to

the ignition switch. Always install a fuse within 12 inches of this connection. If the fuse also will be powering

other circuits, fuse accordingly.

IMPORTANT! Do not remove the fuse holder on the red wire. It ensures that the control module has

its own fuse, of the proper value, regardless of how many accessories are added to the main power

feed.

The ignition wire is powered when the key is in the run and start positions. This is because the ignition wire

powers the ignition system (spark plugs, coil) as well as the fuel delivery system (fuel pump, fuel injection com-

puter). Accessory wires lose power when the key is in the start position to make more current available to the starter

motor.

How to find (+)12V ignition with your multimeter:

1. Set to DCV or DC voltage (12V or 20V is fine).

2. Attach the (-) probe of the meter to battery ground.

3. Probe the wire you suspect of being the ignition wire. The ignition switch harness is an excellent place to

find this wire.

finding the 12V switched ignition wire

obtaining constant 12V

Page 7

© 2001 Directed Electronics, Inc. Vista, CA 7

4. Turn the ignition key switch to the run position. If your meter reads (+)12V, go to the next step. If it doesn’t,

probe another wire.

5. Now turn the key to the start position. The meter display should stay steady, not dropping by more than a

few tenths of a volt. If it drops close to or all the way to zero, go back to Step 3. If it stays steady at (+)12V,

you have located an ignition wire.

The starter wire provides 12V directly to the starter motor or to a relay controlling the starter motor.

How to find the starter wire with your multimeter:

1. Set to DCV or DC voltage (12V or 20V is fine).

2. Attach the (-) probe of the meter to battery ground.

3. Probe the wire you suspect of being the starter wire. The starter relay/starter wire is an excellent place to

find this wire. Remember you do not need to interrupt the starter at the same point you test it. Hiding your

starter kill relay and connections is always recommended.

4. Turn the ignition key switch to the start position. Make sure the vehicle is not in gear! If your meter reads

(+)12V, go to the next step. If it doesn’t, probe another wire.

5. Cut the wire you suspect of being the starter wire.

6. Attempt to start the vehicle. If the starter engages, reconnect it and go back to Step 3. If the starter does

not turn over, you have the right wire.

The (+) parking light wire is often found near the parking light switch or side marker light.

NOTE: Many motorcycles and recreational vehicles do not have front running lights. On this type of

vehicle, you may want to use the separate left and right turn signal circuits for light flash purposes.

How to find a (+) parking light flash wire with your multimeter:

1. Set to DCV or DC voltage (12V or 20V is fine).

2. Attach the (-) probe of the meter to battery ground.

3. Probe the wire you suspect of being the parking light wire.

4. Turn on the parking lights. If your meter shows (+)12V, turn off the parking lights and make sure it goes back

to zero.

5. If it does return to zero, turn the parking lights back on and, using the dash light dimmer control, turn the

brightness of the gauge lights up and down. If the meter changes more than a volt when using the dimmer,

look for another wire. If it stays relatively close to (+)12V, you have found your parking light wire.

finding a (+) parking light wire

finding the starter wire

Page 8

8 © 2001 Directed Electronics, Inc. Vista, CA

making your wiring connections

Before making your connections, plan how your wires will be routed. For instance, the red 12V constant input

and the orange ground-when-armed output (for the starter kill relay) will often be routed together to the igni-

tion switch harness. In order to keep the wiring neat and make it harder for a thief to find, you may wish to

wrap these wires together in electrical tape or conceal them in tubing similar to what the manufacturer used.

Wire ties can be used to keep your harnesses neat and out of the way of any moving parts.

There are two acceptable ways of making a wire connection - solder connections and crimp connectors. When

properly performed, either type of connection is reliable and trouble-free. Regardless of whether you solder your

connections or you use mechanical-type crimp-on connections, ensure that all connections are mechanically

sound and that they are insulated.

Cheap electrical tape, especially when poorly applied, is not a reliable insulator. It often falls off in hot weather.

Use good-quality electrical tape or heat shrink.

■ Never twist-and-tape the wires together without soldering.

■ Never use “fuse taps”, as they can damage fuse box terminals.

■ For watercraft, we recommend using solder connections and insulating them with heat shrink to avoid corrosion.

If you use tapping connectors such as 3M T-Taps (not to be confused with Scotch-Locks), avoid using them in

higher-current applications (constant 12V, ground, etc.). Some tapping connectors are inferior in quality and

should be avoided.

Page 9

© 2001 Directed Electronics, Inc. Vista, CA 9

primary harness (H1), 14-pin connector

______

______

______

______

______

______

______

______

______

______

______

______

______

______

*NOTE: These wires are interchangeable.

WHITE (+) LIGHT FLASH OUTPUT #2

BLACK/WHITE* STARTER KILL OUTPUT

RED/WHITE (-) CHANNEL 2 OUTPUT

WHITE/BLUE (-) CHANNEL 3 OUTPUT

BLACK/WHITE* STARTER KILL INPUT

BROWN (-) SIREN OUTPUT

YELLOW (+) IGNITION INPUT

RED (+) 12V CONSTANT POWER

WHITE (+) LIGHT FLASH OUTPUT #1

BLUE (-) INSTANT TRIGGER/MERCURY TILT SWITCH INPUT

ORANGE (-) GROUND-WHEN-ARMED 500 mA OUTPUT

LIGHT GREEN/BLACK (-) OPTIONAL MULTIPLEXED SENSOR INPUT

BLACK (-) BATTERY GROUND

GREEN (-) CLOSED LOOP

H1/1

H1/2

H1/3

H1/4

H1/5

H1/6

H1/7

H1/8

H1/9

H1/10

H1/11

H1/12

H1/13

H1/14

Page 10

10 © 2001 Directed Electronics, Inc. Vista, CA

primary harness wire connection guide

This wire can be used to protect a part of the vehicle where a trigger is desired when the wires of the connec-

tion are not in contact, rather than in contact. This closed loop connection is useful for protecting things such

as saddlebags, luggage carriers, etc. that could be easily removed from a motorcycle or other recreational vehicle.

Connect this wire through the object being protected and then to the battery ground loop. Then, if the contact

is broken on this wire when the alarm system is armed, the alarm will sound.

NOTE: When armed, the system checks to ensure that ground is present on this wire. If ground is

not present on this wire, the system will ignore the zone (see Table of Zones section of this guide)

and will not respond to the zone again until the system has been disarmed and rearmed.

Connect this wire to the vehicle’s negative battery terminal using a ring connector. We recommend grounding all

your components to the same point.

Inputs shorter than 0.8 seconds will trigger the Warn Away response, while inputs longer than 0.8 seconds will

trigger the full alarm sequence and report Zone 4. If installing an optional DEI

®

dual stage sensor, connect both

the blue and the green wires of the optional sensor to this input.

This wire supplies (-) ground as long as the system is armed. This output ceases as soon as the system is dis-

armed. This wire can be used to turn on an optional sensor or to ready an optional accessory, such as a pager

module.

H1/4 ORANGE (-) ground-when-armed 500 mA output

H1/3 LIGHT GREEN/BLACK (-) optional multiplexed sensor input

H1/2 BLACK (-) battery ground

H1/1 GREEN (-) closed loop

Page 11

© 2001 Directed Electronics, Inc. Vista, CA 11

Connect this wire to one of the mercury tilt switches’ wires. Connect the other tilt switch wire to battery ground.

(These wires are interchangeable.) The mercury should only bridge the contacts if the motorcycle is tilted off its

stand. A negative (-) input to this wire will cause an instant trigger, which will report on Zone 1.

Only one of these wires will need to be used (they are interchangeable) if the motorcycle (or recreational vehicle)

has a front running light. The wire should be connected to the (+) parking light wire, as described in the Finding

the Wires You Need section of this manual. These outputs are protected with 7.5 amp fuses. Never increase the

value of the light flash fuse. If more current is required, use an external relay.

NOTE: Many motorcycles and recreational vehicles do not have front running lights. If the vehicle

does not have a front running light, you may want to use the separate left and right turn signal

circuits for flash purposes. Note that the on-board light flash relay has two isolated outputs (H1/6

WHITE and H1/14 WHITE) which are provided for this reason. (See the following diagram.)

IMPORTANT! This should be the LAST connection of your installation.

We recommend connecting this wire to the positive (+) battery terminal for power, as described in the Finding

the Wires You Need section of this manual. This is a vital connection for the system, so it must be solid and well

insulated. The harness must be unplugged from the control module. Use the supplied fuseholder, and don't forget

to put the 15A fuse in after everything else is connected! Before connecting this wire, remove the supplied fuse.

H1/7 RED (+) 12V constant power

H1/6 and H1/14 WHITE (+) light flash outputs

H1/5 BLUE (-) instant trigger/mercury tilt switch input (for motorcycle installations)

Page 12

12 © 2001 Directed Electronics, Inc. Vista, CA

Connect this wire to an ignition wire as described in the Finding the Wires You Need section of this manual. This

wire must show (+)12V with the key in the run position and during cranking. Make sure that this wire cannot be

shorted to the chassis at any point.

The siren should be mounted away from excessive heat sources, such as the exhaust manifold. Connect the H1/9

wire to the brown wire of the siren. For the remaining siren connections, refer to the Making Siren Connections

section of this guide.

Use one of these wires as a starter kill input and the other as a starter kill output (these wires are interchangeable).

This wire provides a (-) 200 mA output whenever the transmitter button(s) controlling Channel 3 is pressed. This

output can be programmed to provide the following types of outputs (see System Features Learn Routine section

of this guide):

■ An instant validity output will send a signal immediately when the buttons controlling Channel 3 are

pressed. The signal will last as long as the transmission is received.

■ A latched output will send a signal continuously when the Channel 3 transmitter button(s) is pressed and

will continue until the button(s) is pressed again.

■ A latched/reset with ignition output works similar to the latched output, but will also reset (output will

stop) when the ignition is turned on then off.

■ A 30-, 60- or 90-second timed output will send a signal for 30, 60, or 90 seconds, respectively, when the

Channel 3 transmitter button(s) is pressed.

IMPORTANT! Never use this wire to drive anything except a relay or a low-current input! This

transistorized output can only supply (-)200 mA, and connecting directly to a solenoid, motor, or

other high-current device will cause the module to fail.

H1/11 WHITE/BLUE (-) channel 3 output

H1/10 and H1/13 BLACK/WHITE starter kill wires

H1/9 BROWN (-) siren output

H1/8 YELLOW (+) ignition input

Page 13

© 2001 Directed Electronics, Inc. Vista, CA 13

When the system receives the code controlling Channel 2 for longer than 1.5 seconds, the red/white wire will

supply an output as long as the transmission continues. This can be used to operate an optional relay-driven

function.

IMPORTANT! Never use this wire to drive anything but a relay or a low-current input! The transistorized output can only supply 200 mA of current. Connecting directly to a solenoid, motor, or other

high-current device will cause it to fail.

This output can be programmed to provide the following types of outputs (see System Features Learn Routine

section of this guide):

■ When the transmitter button(s) controlling Channel 2 is pressed for longer that 1.5 seconds, a delayed valid-

ity output will send a signal as long as the transmission is received.

■ A latched output will send a signal continuously when the Channel 2 transmitter button(s) is pressed and

will continue until the button(s) is pressed again.

■ A latched/reset with ignition output works similar to the latched output, but will also reset (output will

stop) when the ignition is turned on then off.

■ A 30-, 60- or 90-second timed output will send a signal for 30, 60, or 90 seconds, respectively, when the

Channel 2 transmitter button(s) is pressed.

Refer to H1/10 BLACK/WHITE starter kill wire description.

Refer to H1/6 WHITE (+) light flash output wire description.

H1/14 WHITE (+) light flash output

H1/13 BLACK/WHITE starter kill wire

H1/12 RED/WHITE channel 2, 200mA (-) output

Page 14

14 © 2001 Directed Electronics, Inc. Vista, CA

making siren connections

Instructions for connecting the siren wires are described below.

Connect this wire to a fused source of constant 12V. Be sure to connect this wire to a source capable of

handling the required current draw, such as the vehicle battery.

Connect this wire to the (-) ground terminal of the vehicle battery.

Connect this wire to the (-) brown siren output of the security system.

This input is required for recharging the back-up battery siren. Connect this wire to the ignition wire of the

vehicle. This wire must show (+)12V with the key in the run position and during cranking. Make sure that this

wire cannot be shorted to the chassis at any point.

Before enabling the back-up battery siren, make sure that all siren connections have been made and power is

being supplied to the siren.

WARNING! If the siren lock switch is turned to the enable position without power being connected,

the back-up battery siren will sound.

To enable the siren:

1. Remove the water protective cap on the back of

the siren to expose the siren lock switch.

2. Insert the siren key into the siren lock switch

and turn the key to the RIGHT to enable the

back-up battery siren.

3. Remove the siren key and replace the water

protective cap on the back of the siren.

enabling the siren

YELLOW (+) ignition input

BROWN (-) siren input

BLACK (-) chassis ground

RED (+)12V constant

Page 15

© 2001 Directed Electronics, Inc. Vista, CA 15

plug-in LED and valet/program switch

These plug into the module. The Status LED plugs into the white two-pin socket, while the Valet®/Program switch

should be plugged into the blue two-pin socket. The Status LED and the Valet/Program switch each fit into a

9

/32

-inch hole.

Status LED Valet®/Program Switch

on-board doubleguard shock sensor

There is a Doubleguard®shock sensor inside the control unit. Adjustments are made via the rotary control as indi-

cated above. Since the shock sensor does not work well when mounted firmly to metal, we recommend against

screwing down the control module. The full trigger of the on-board shock sensor reports zone 2. (See Table of

Zones section of this guide.)

NOTE: When adjusting the sensor, it must be in the same mounting location that it will be after

the installation is completed. Adjusting the sensor and then relocating the module requires readjustment.

NOTE: For watercraft, we recommend turning off the shock sensor whenever the craft is in the water

to avoid false triggers. For instructions on how to bypass the shock sensor, refer the Multi-Level

Security Arming section of this guide.

Page 16

16 © 2001 Directed Electronics, Inc. Vista, CA

transmitter/receiver learn routine

The system comes with two transmitters that must be “taught” to the receiver. Use the following learn routine

to program the transmitters, add transmitters to the system or to change button assignments if desired.

IMPORTANT! All remotes that will be used with the system must be programmed at the same time.

Each time the learn routine is accessed and a remote is successfully learned by the system, any

other remotes that had previously been programmed will be erased.

1. Make sure that the system is disarmed.

2. Turn the ignition ON-OFF-ON-OFF-ON. The siren will chirp to indicate that the transmitter is ready to be pro-

grammed.

3. Press the transmitter button(s) that corresponds to one of the Auto-Learn Configurations (1, 2 or 3) in the

table below. Auto-Learn Configuration 1 (separate arm and disarm buttons) is the default setting that the

transmitters come programmed with from the factory.

4. The siren will chirp to confirm that the desired Auto-Learn Configuration has been programmed.

5. Repeat Steps 1-4 until all transmitters have have been taught to the receiver.

The learn routine will be exited when the ignition is turned off or if 10 seconds elapse between programming

steps. The siren will emit a short chirp and then a long chirp to indicate that the learn routine has been exited.

FOR PRESS

AUTO-LEARN TRANSMITTER BUTTON I BUTTON II BUTTONS I AND II

CONFIGURATION BUTTON(S) FUNCTION FUNCTION FUNCTION

1 I and II Arm only, Panic Disarm, Channel 2 Channel 3

2 I Arm, Disarm, Panic Channel 2 Channel 3

3 II Channel 2 Arm, Disarm, Panic Channel 3

Page 17

© 2001 Directed Electronics, Inc. Vista, CA 17

system features learn routine

The System Features Learn Routine™dictates how the unit operates. It is possible to access and change any of

the feature settings using the Valet

®

/Program switch.

1. Ignition: Turn the ignition on, then back off. (The H1/9 YELLOW wire must be connected.)

2. Select a feature: Press and release the Valet

®

/Program button the number of times corre-

sponding to the feature you wish to change. For example, to access the third feature, press

and release the Valet/Program button three times. Then press the button once more and

HOLD it. The siren will chirp the number of times corresponding to the feature you have

accessed.

3. Program the feature: While holding the Valet

®

/Program button, you can toggle between

the feature settings using the remote transmitter. If using a transmitter that has been pro-

grammed with either Autolearn Configuration 1 or 2, pressing will select the one-chirp

(default setting) and pressing will select the two-chirp setting. If using a transmitter

that has been programmed with Autolearn Configuration 3, these buttons have opposite

functions, so that pressing will select the one-chirp (default setting) and pressing

will select the two-chirp setting.

NOTE: Features 5, 6 and 7 each have multiple settings. Pressing will toggle through all

the possible settings.

4. Release the Valet

®

/Program button.

Once a feature is programmed:

■ Other features can be programmed.

■ The learn routine can be exited if programming is complete.

To access another feature:

1. After programming a feature (Step 3 above), press and release the Valet

®

/Program switch the number of times

necessary to advance from the feature you just programmed to the next one you want to program.

2. Then press the Valet®/Program switch once more and hold it.

Example: In Step 3 above, if you just programmed the third feature in the menu and you would like to program

the seventh feature in the menu, you would press and release the Valet®/Program switch four times and then

press it once more and hold it. The siren would chirp seven times to confirm access to the seventh feature.

Page 18

18 © 2001 Directed Electronics, Inc. Vista, CA

To exit the System Features Learn Routine, do one of the following:

■ Turn the ignition on.

■ No activity for longer than 15 seconds.

■ Press the Valet/Program switch too many times.

features menu

feature descriptions

1 ACTIVE/PASSIVE ARMING: When active arming is selected, the system will only arm when the transmitter is

used. When set to passive arming, the system will arm automatically 30 seconds after the ignition is turned off.

At 30 seconds, the siren will chirp to indicate that the system is armed.

2 CHIRPS ON/OFF: This feature controls the chirps that confirm the arming and disarming of the system.

3 SIREN DURATION 30/60 SECONDS: It is possible to program the unit to sound for 30 or 60 seconds during

the triggered sequence.

4 SIREN OUTPUT: The system can be programmed to output pulses instead of a continuous output when trig-

gered.

5 CHANNEL 2 DELAYED/LATCHED/LATCHED RESET WITH IGNITION/30-SECOND TIMED/60-SECOND TIMED/90-

SECOND TIMED: Channel 2 can be programmed for these output configurations. The unit is set to the default

delayed output. To change the configuration, use to toggle to the different settings.

FEATURE ONE-CHIRP TWO-CHIRP

NUMBER FEATURE SETTING (DEFAULT) SETTING

1 Arming Active Passive

2 Chirps On Off

3 Siren Duration 30 seconds 60 seconds

4 Siren Output Constant Pulsed

5 Channel 2 Delayed Latched/latched, reset with ignition/30/60/90

6 Channel 3 Instant Latched/latched, reset with ignition/30/60/90

7 Disarm Pulse Count 1 2/3/4/5

Page 19

© 2001 Directed Electronics, Inc. Vista, CA 19

6 CHANNEL 3 INSTANT/LATCHED/LATCHED RESET WITH IGNITION/30-SECOND TIMED/60-SECOND TIMED/90-

SECOND TIMED: Channel 3 can be programmed for these output configurations. The unit is set to the default

instant output. To change the configuration, use to toggle to the different settings.

7 DISARM PULSE COUNT 1 to 5 PULSES: This feature allows you to program the number of pulses used to man-

ually disarm the system using the Valet button. The factory default setting is one pulse. The unit can be set for

2 to 5 pulses using the two-chirp setting to select the pulse count.

multi-level security arming

Multi-Level Security Arming is a feature that allows you to select which of the system's inputs or sensors will be

active and which will be bypassed at the time that the system is armed. (See Table of Zones section in this guide.)

This feature is available only when using a remote that has been programmed with separate arm and disarm

buttons. Pressing the arm button again within five seconds of arming the system will activate the Multi-Level

Security Arming feature. Each time the arm button is pressed again, a different security level is selected. The

different security levels can be selected as follows:

■ Pressing one time: The siren chirps once. The system is armed.

■ Pressing a second time within five seconds: The siren chirps twice followed by a long chirp. Zone Two

is now bypassed.

■ Pressing a third time within five seconds: The siren chirps three times followed by a long chirp. Zone

Four is now bypassed.

■ Pressing a fourth time within five seconds: The siren chirps four times followed by a long chirp. Zones

Two and Four are now bypassed.

■ Pressing a fifth time within five seconds: The siren chirps five times followed by a long chirp. All input

zones, except the ignition, are now bypassed.

NOTE: For watercraft, we recommend turning off the shock sensor (Zone Two) whenever the craft

is in the water to avoid false triggers.

NOTE: Multi-Level Security Arming only applies to a single arming cycle. Once the system is disarmed and then re-armed, all the zones will be active again.

Page 20

20 © 2001 Directed Electronics, Inc. Vista, CA

nuisance prevention circuitry

Nuisance Prevention®Circuitry (NPC®) is designed to prevent repeating triggers, such as those from an

out-of-adjustment sensor or temporary environmental conditions. If NPC detects the same zone triggering three

times, and these three triggers are within an hour of each other, that zone will be bypassed for sixty minutes.

Remember this when testing: NPC's memory is reset with ignition, not by arming and disarming!

diagnostics

The system constantly monitors all of its inputs, or zones. When you arm the system, the siren will inform you

by chirping the siren and flashing the status LED in patterns, if any there are any status irregularities. When you

disarm the system, the siren will also indicate with extra chirps if the vehicle has been tampered with while you

were away.

If the siren chirps once when the system is initially armed and then chirps again a few seconds later, this indi-

cates that the system sensed an input that normally would have triggered it. This is called Bypass Notification.

The system will also ignore, or bypass, that zone until the trigger stops.

If four chirps are heard when disarming (Tamper Alert), the system was triggered in your absence. If five chirps

are heard, a zone was triggered so many times that Nuisance Prevention Circuitry has bypassed that zone. In

either case, the status LED will indicate which zone was triggered (see the Table of Zones section of this guide).

The system retains this information in its memory, and chirps four times each time the system is disarmed, until

the next time the ignition is turned on.

disarming diagnostics

arming diagnostics

Page 21

© 2001 Directed Electronics, Inc. Vista, CA 21

table of zones

When using the Diagnostic functions, use the Table of Zones to see which input has triggered the system. The

status LED will. It is also helpful in deciding which input to use when connecting optional sensors and switches.

troubleshooting

The system does not respond to transmitters:

■ Check the power and ground wires for voltage.

■ Are all of the system's transmitters programmed?

■ Check to see if the ignition wire is properly connected.

When the system arms I hear a second chirp:

■ Check all sensors, including the shock sensor, the tilt sensor, and the open loop trigger. If a sensor is trig-

gering when you arm your alarm, you will hear a second chirp, which indicates Bypass Notification. (Refer

to the Diagnostics section of the owner's guide.)

When the system is triggered, the siren pulses instead of sounding constantly:

■ The system's optional programming allows you to select for the siren to either pulse or sound constantly when

triggered. (Refer to the Features Menu section of this guide.)

The siren does not generate any sound:

■ Check to make sure that good connections have been made on all the siren wires.

■ Make sure that the back-up battery siren has been enabled. (See Making Siren Connections section of this

guide.)

ZONE NO. TRIGGER TYPE INPUT DESCRIPTION

1 Instant BLUE H1/5 mercury tilt switch input

2 On-Board Shock Sensor Heavy impact detected by the on-board shock sensor

3 Instant GREEN H1/1 closed loop

4 Multiplexed Input LIGHT GREEN/BLACK H1/3 optional sensor input

5 Instant YELLOW H1/8 ignition input

NOTE: The Warn Away response does not report on the LED.

Page 22

22 © 2001 Directed Electronics, Inc. Vista, CA

The siren sounds weak or garbled:

■ Check all the grounding points, including the siren ground and alarm ground.

■ Check the alarm for 12V output on the H1/9 BROWN wire.

■ For all motorcycle and recreational vehicle installations, a direct battery ground is recommended.

The starter kill does not work:

■ Does the H1/8 YELLOW wire test 12 volts during the crank or start cycle? If not, you may not have the true

ignition wire.

■ Is the correct starter wire being interrupted?

A sensor is not working:

■ NPC

®

may have been activated and the sensor may be bypassed. Insert the key and turn on the ignition to

reset the alarm.

■ Is the sensor initiating a trigger? Use a digital multimeter to determine whether or not the sensor is working.

■ Is the LED lit solid? The system may be in Valet Mode. (Refer to the Valet Mode section of the owner's guide.)

You cannot enter the programming mode with the Valet switch:

■ Is the Valet switch in the correct port? (Refer to the Plug-In LED and Valet/Program Switch section of this guide.)

■ Does the Valet switch have continuity when pressed?

■ Does the alarm test 12 volts upon ignition?

The lights do not flash:

■ Check the fuses on the H1/6 and H1/14 WHITE wires. Also check for 12-volt output on the H1/6 and H1/14

WHITE wires.

■ Make sure that the system is connected to a parking light lead, rather than an illumination lead.

Page 23

© 2001 Directed Electronics, Inc. Vista, CA 23

notes

Page 24

24 © 2001 Directed Electronics, Inc. Vista, CA

Loading...

Loading...