Direct Color Systems Directjet 1024UV, Directjet 1014UV Getting Started Manual

Go to table of contents

Getting

Started

Guide

DCS_Direct_Jet_1024UV_1014UV_Getting_Started_Guide_2.1.docx

Notices The information in this document is subject to change without notice.

NO WARRANTY OF ANY KIND IS MADE WITH REGARD TO THIS MATERIAL, INCLUDING,

BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE.

No liability is assumed for errors contained herein or for incidental damages in connection

with the furnishing, performance, or use of this material.

This document contains proprietary information which is protected by copyright. All rights

are reserved. No part of this document may be photocopied, reproduced, or translated into

another language without prior written consent.

Trademark IBM is a registered trademark of International Business Machines

Acknowledge- Corporation. Windows is a trademark of Microsoft Corporation. All other

ments product and company names mentioned herein are the trademarks of their respective

owners.

Technical If you require technical assistance, contact a technical representative at 860-829-1027

Support or email techsupport@directcolorsystems.com

Technical information and downloads are available on our FTP site:

ftp://ftp.directcolorsystems.com/.

The FTP site requires a Login and password.

You will be prompted to put in a user name and password. (If you are not prompted then

double click on a file)

Passwords are as follows and are case sensitive:

Login: dcs

Password: dcsftp

Corporate Direct Color System s®

99 Hammer Mill Rd

Rocky Hill, CT 06067

T: 860-829-2244

F: 860-829-2255

Email: info@directcolorsystems.com

Web Site: www.directcolorsystems.com

EAA Rua do Alto Das Torres, 942

4430-009 Vila Nova De Gaia, Portugal

Email: EAAinfo@directcolorsystems.com

DCS_Direct_Jet_1024UV_1014UV_Getting_Started_Guide_2.1.docx

Equipment

Certificate of

Compliance This Equipment has been t ested and found to be within complian ce with

CE Compliance:

• Directiv e 2006/95/E C

Printing Edition 2.1 – February 2013

History Driver installation instructions updated

Printed in the USA

© Copyright 2013, Direct Color, LLC. All rights reserved.

DCS_Direct_Jet_1024UV_1014UV_Getting_Started_Guide_2.1.docx

Table of Contents

SAFETY AND PRECAUTIONS……………………………………………….………………………………….…….…….…..…6

GETTING STARTED WITH THE HARDWARE…………………………………..……………….….….….……………7

Control Panel Button Descriptions………………………………………….…………………………..…..………..8

Choosing a Location……………………………………………………….………………………………...….…..…...9

Applying Power………………………………………………………………………………………….….….………...10

Turning the Printer On For the First Time…………………………………….…………….……...…………...10

Filling Ink Cartridges………………………………………………………………………………….………………….11

Resetting Cartridge Chips…………………………………………………….……………………….……………....13

Installing Cartridges……………………………………………………………………………………….…………....13

Checking Ink Levels…………………………………………………….……………………………………………....13

DRIVER INSTALLATION…………………………………………………………………………………………….……………..15

USING THE DIRECT JET PRINTER……………………………………………………………………………………….…….16

Connect the USB Cable and Verify Communication…………………………………………………………....16

Initial setup after install or moving the printer…………………………………………………………………..16

Preparing the Table………………………………………………………………………………………………………..16

Loading Substrates onto the Table…………………………………………………………………………………...17

Printing onto Reflective, Shiny and/or Mirrored Surfaces…………………………………………………....18

Nozzle Check………………………………………………………………………………………………………………....20

Cleaning the Print Head…………………………………………………………………………………………………..21

DCS_Direct_Jet_1024UV_1014UV_Getting_Started_Guide_2.1.docx 4 | Page

Direct Jet 1024UV/1014UV Getting Started Guide

Thank You...

…for choosing a Direct Color Systems

exceptional output quality on a variety of substrates. The Direct Jet's ability to print to many different

materials without the need for surface pre-coating or undercoating represents a sound investment in time

and productivity that will put you ahead of your competition.

Direct Jet printers have many distinct advantages that will help you produce high quality graphics in record time.

• The Direct J et 1024UV accepts material up to 6" (152 mm) thick and the Direct Jet 1014UV model accepts

material up to 4" (102mm) thick.

• The Direct Jet 1024UV model accepts substrates up to 13" (330 mm) x 24" (610 mm) in size and has

a printable area of 10" (254mm) x 24" (610 mm). The Direct Jet 1014UV model accept s sub strates

up to 13" (33 0 mm) x 14" (356 mm) in size and has a printable area of 10" (254 mm) x 14" (356

mm).

• Innovative Multisolve™ UV-LED inks pri nt and bond to plastic, wood, stone, etc. Using our adhesion

promoter, the inks will bind to many difficult surfaces, such as glass or stainless steel.*

• Prints white ink.

• Prints clear ink.

• A print speed of 2.75 minutes to print an 8" x 10" image bi-directionally at 1440 x 720 dpi / High Speed.

• Exceptional print resolution of up to 5760 dpi.

• Direct Jet UV printers print from any IBM-PC

bit versions using Direct Color Systems' exclusive Color Byte RIP (Raster Image Processing) software.

* A

ll substrates should be tested for image receptivity, adhesion and durability with final acceptance and suitability

determined by the customer. Direct Color Systems® makes no warranty, expressed or implied.

®

Direct Jet UV printer. Your printer is designed to provide you with

®

or compatible computer running Windows

®

7 or 8, 32- and 64 -

DCS_Direct_Jet_1024UV_1014UV_Getting_Started_Guide_2.1.docx 5 | Page

Safety and Precautions

SAFETY AND PRECAUTIONS

• Please read thes e guidelines before operating your Direct Jet printer .

• Keep all inks, solvents and lubricants out of the reach of children.

• Use only approved cleaning agents and solvents and then only for the purposes specified in

this guide.

• Use only genuine Multisolve™ UV-LED inks.

• Keep inks in a cool, dark and dry location.

• Inks must be used in opaque cartridges only.

• This printer produces potentially harmful UV light. Protect eyes and skin from exposure.

• Avoid physical contact with the printer's table and print head while the printer is in

operation.

• Avoid dropping items or spilling liquids in or on the printer.

• Keep hair, jewelry or loose clothing away from the moving parts of the printer.

• Lifting this printer by hand requires a minimum of two people.

• Do not attempt to repair this machine without prior DCS authorization. Unless specified in

this guide, only qualified service personnel should attempt any disassembly, repair or access

to internal components. If you need to make mechanical adjustments, turn off your printer

and disconnect it from all power and data sources.

• Safety Glasses and gloves should be used whenever filling ink cartridges

or manually cleaning the print head. These symbols will be used

throughout this manual as a reminder to use safety glasses and gloves.

Wear protective gear whenever there is exposure to the inks, regardless

of whether a symbol is displayed.

For prolonged exposure, DCS recommends Butyl Black or Ethylene Vinyl

Alcohol Copolymer laminated gloves.

• The Adhesion Promoter should not be used in an enclosed area without adequate

ventilation. RESPIRATORY PROTECTION: If exposure can exceed the PEL/TLV,

use only NIOSH/MSHA approved air-purifying or supplied air respirator

operated in a positive pressure mode per the NIOSH/OSHA 1981 occupational

health guidelines for chemical hazards.

Go to table of cont ents

DCS_Direct_Jet_1024UV_1014UV_Getting_Started_Guide_2.1.docx 6 | Page

Getting Sta rted w ith th e Har dware

Go to table of cont ents

GETTING STARTED WITH THE HARDWARE

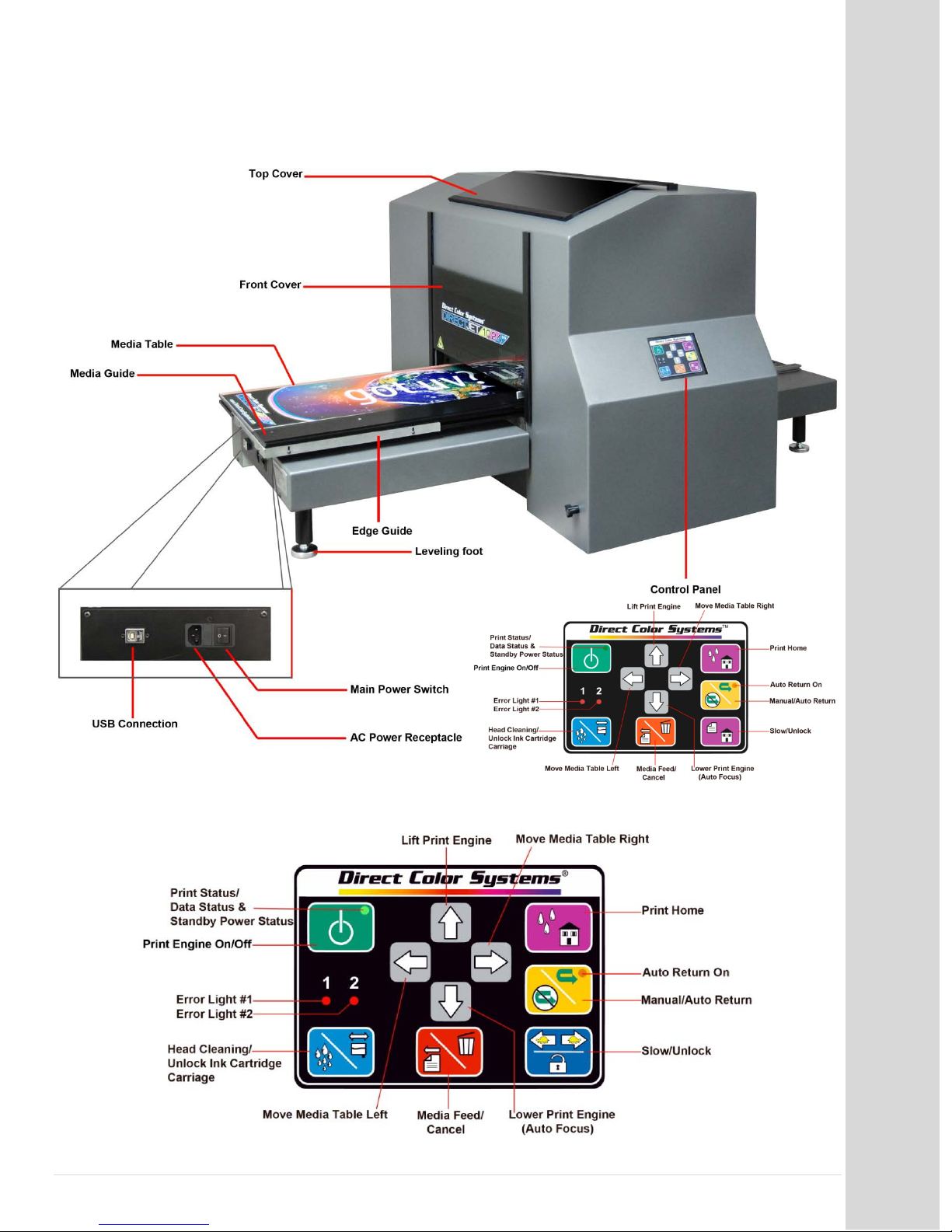

Below you will find diagrams of th e printer and it s parts. Be sure to familiarize yo urself with all

the individual parts and descriptio ns of printer as th ey will be ref erred to later in this guide.

Control Panel for Direct Jet with Optional Direct Drive

DCS_Direct_Jet_1024UV_1014UV_Getting_Started_Guide_2.1.docx 7 | Page

Loading...

Loading...