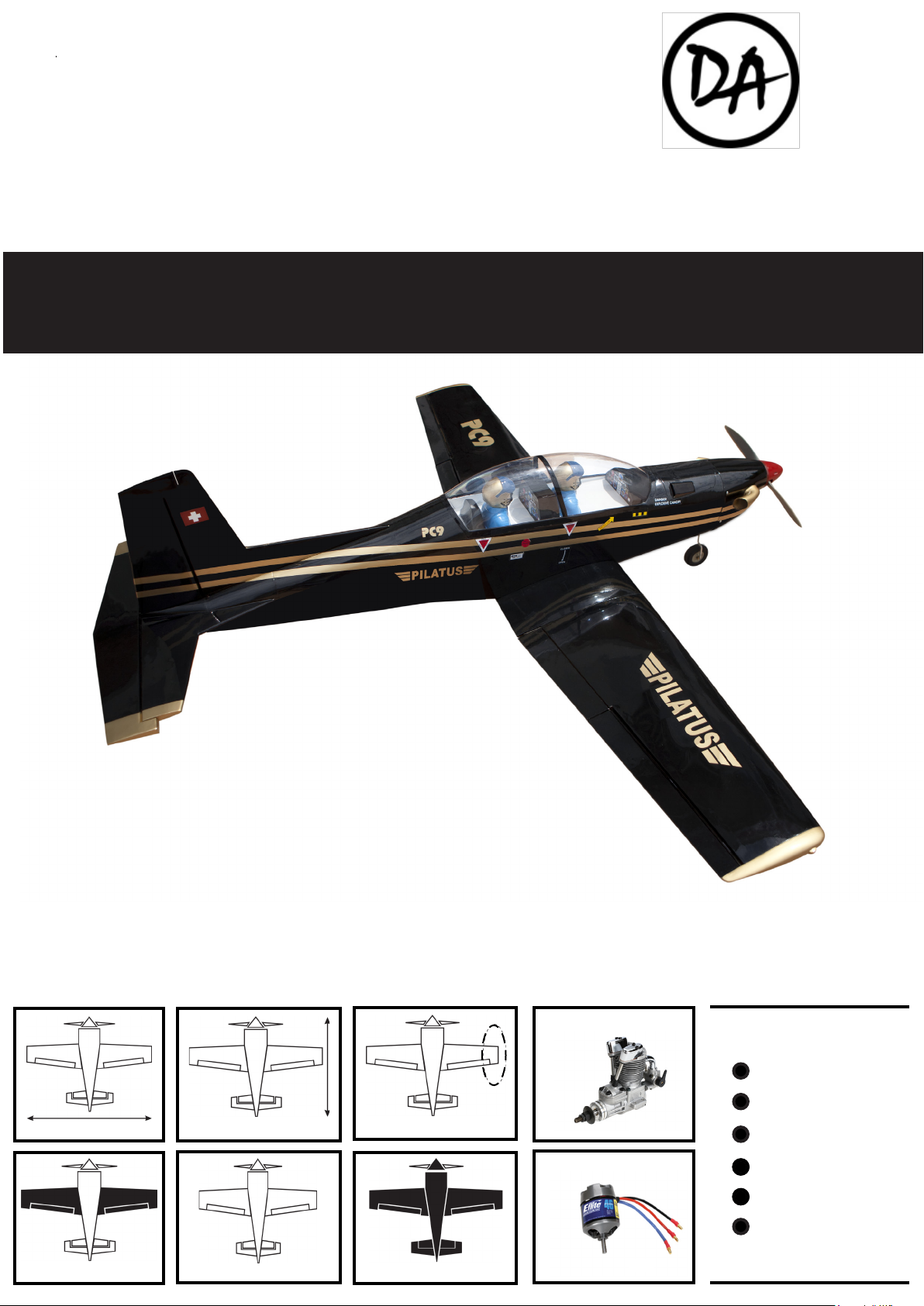

Direct Airscale PILATUS PC 9 Technical Instructions

Direct Airscale

scale model

Code : 3642

TECHNICAL INSTRUCTIONS

May change without notice

PILATUS PC 9

1.80m 1.68m

50dm

2

3.7kg

ASYMM

4.8kg

install Kit

YES

install Kit

YES

SERVOS

Ailerons

Rudder + wheel

Elevator

Flaps

Retract

Gas or bec

1

CONGRATULATIONS.

ank you for choosing a Direct Airscale model. If you have any problems do not hesitate to consult

our website. Especially the section CLUB DA (Direct Airscale club) for each plane where you will nd

information. You also can consult me directly by phone but try to be a maximum shorter . ank

you. You also can participate in the interaction you’ll nd at general chapter CLUB DA.

Our PILATUS PC 9 is presented in a black and gold livery military parade, held by the Swiss

and Bulgarian armies among others. It is a light aircra that we have equipped a tricycle mechanical retracts. A kit for the installation of an electric motor is provided. It is naturally stable with wings in the format “hang” rectangular double dihedral tailplane and rejected very

rear of the fuselage. Proudly camped on its tricycle landing gear, it is pleasant to look at and fun

to drive. Quite presentable in meetings warbird or interclub. In all modesty is a must 1.80m that

will feel. To respect the genuine our model PC9 is equipped with aps that this type of wing allows to train the reactions induced by the output of the landing aps. e aps are slot eect which

enhances their sweetness and power liing. All characteristics that should take a lot of votes.

WARNING

If you are inexperienced with basic r/c ight we strongly recommended you contact the nearest

model aircra club. Experienced members will help you to install additional accessories to put your

aircra airworthy. e club will ensure your training and you will avoid ying illegally and destroy

your aircra from the rst ight.

ADDITIONAL ITEMS REQUIRED.

• Propulsion set depending your choice :

gas or electric.

• Radio set minimum 4 channels.

• 4 servos.

• Propeller.

• Electric lipo pack or Ni-Mh.

• Switch or Bec controller and fuse.

TOOLS AND SUPPLIES.

• ick cyanoacrylate glue.

• 30 minute epoxy.

• Electric drill.

• Assorted drill bits.

• Modelling knife.

• Straight ruler.

• Miscellaneous sandpaper.

• 90° builder’s triangle.

• Wire cutters.

• Tape & T-pin

• A set of small keys 6 section

• A set of screw drivers

KIT CONTENTS.

• Light and rigid balsa and plywood construction

• Fuselage and wings built and Oracover ® covered

• Decoration and lettering print on cover

• Painted clear canopy

• 2 Pilots included

• 2 dash boards

• Rigid wire landing gear

• Mechanical retracts included (3 wheels)

• Controlled front wheel

• Spinner

• Fiber cowl

• Methanol engine installation kit (tank, motor

mount, ...)

• Electric motor installation kit (part wooden

lipo kit ...)

• All mounting hardware , screws , ttings ,

linkages , ...

• English mounting instructions with photos

• Country translations send beside

2

TIPS FOR ASSEMBLY

To prevent damage to the coating cover

your workbench with a cloth or blanket.

Do not pull on the packaging you may be

too much pressure and break your plane.

Carefully unpack the wings and fuselage using scissors or a cra knife. Open aware of

hardware apart and sort all parts in order to

understand who goes where. Store in a series of independent small boxes. When you

work, do not let scews, miscellaneous hardware, accessories and tools below dierent

parts of your aircra. Check constantly. Before gluing carefully prepare all the parts,

try them and if needed dig slots a bit more.

Work slowly and read many time technical instructions to be sure to understand all

tricks.Repeat gestures before using glue. If

overows do not use acetone on coatings

and plastics. Oen simply wipe with a paper

towel.

Drill your 45° holes about 2mm before the

edge. Be careful not to cross! Cut hinges

taking into account the thickness of the

wing. Introduce all hinges. e hinges must

be pressed closer, gently so that the oset is

reasonable. To check the alignment of the 3

hinges use simply your eye. If you need to

reduce the oset just push a bit more. Flaps

are manipulated to test the exibility of operation. Monitoring the orientation of the

hinge pins to be perpendicular to the rotational movement.

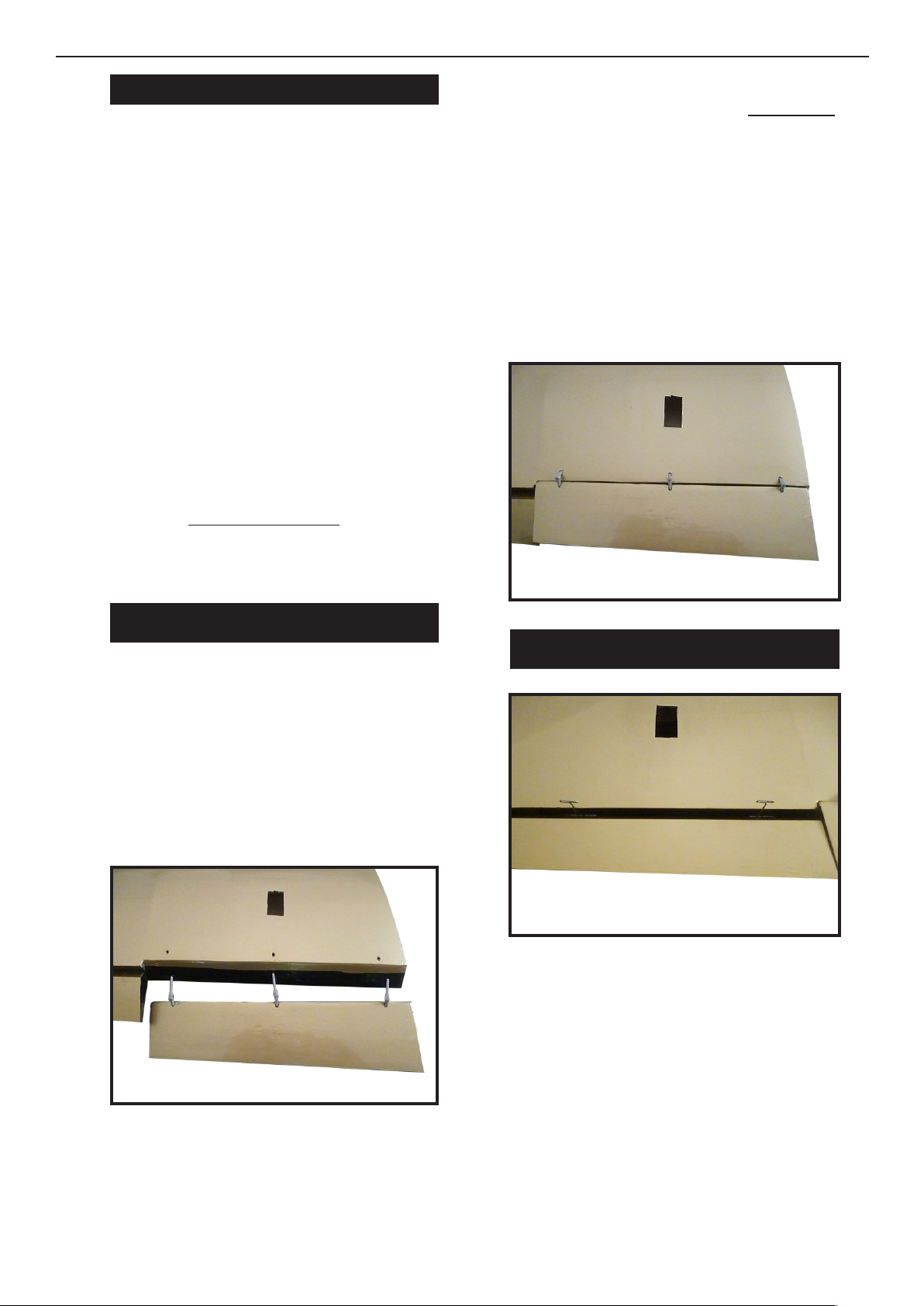

HINGING THE FLAPS.

To ensure the mobility of aps we planned

cylindrical hinges. e trick is that these

hinges are installed at 90°mean 45°on each

side. See photos. at way when you leave

the aps deport these hinges and shutters

create a slot eect that brings the li in addition to limiting the braking eect of turbulence aps and thus repel the stall speed.

INSTALLING HINGES GENERAL.

All hinges are pre-installed but not glued.

Before removal for sizing carefully locate all

positions with a ballpoint pen not to create a

gap for the collage.Note the middle hinge so

that the same amount is depressed in both

parties. Plant may also serves as a needle

stop which provides the necessary play and

exibility. If you use the cyano coat once all

the hinges with a veil of cyano.

3

Hinge.

Paste all hinges on the xed parts (wings,

tail).

Aer a reasonable period of time depending on the glue used permanently installed

mobile appendages ensuring that there is a

slight clearance for free movement of friction . During drying maneuver the pieces

to make sure everything runs smoothly. If

epoxy clean the excess glue with paper. Do

not use acetone.

HINGING THE ELEVATORS.

Proceed as described at general, then check

the edge ns are aligned and move free.

See below pictures.

HINGING THE RUDDER.

Proceed as described at general, then check

the edge ns are aligned and move free.

See below pictures.

HINGING THE AILERONS.

Proceed as described at general, then check

the ns are aligned wingtip and move free.

See below pictures.

4

AILERONS CONTROL HORN.

Aileron control horn : See below pictures.

2 sets.

M3x40mm

CONTROL HORN

M3 SCREW.

Ep oxy.

Aluminum washer.

ELEVATOR CONTROL HORN.

Install the elevator control horn using the

same method as same as the aileron control

horns.

2 sets.

M3 Lock nut.

18mm

Wing bottom.

Aluminum washer.

Ep oxy.

Control horn M3

Aluminum washer.

Horizontal

Stabilizer.

Aluminum washer.

Horizontal

Stabilizer.

M3x45mm

Ep oxy.

Elevator.

M3 Lock nut.

Ep oxy.

Aileron control horn.

Aileron

FLAP CONTROL HORN.

Repeat the process for the ap control horn.

Flap control horn.

18mm.

Elevator control horn.

5

RUDDER CONTROL HORN.

ENGINE MOUNT INSTALLATION.

Using the same techniques used aileron

control horn. See picture below.

2 sets.

M3x45mm

Control horn M3

Aluminum washer.

Ep oxy.

See below pictures. Make yourself the template of your engine on paper.

.

M4x30mm

Mark and drill 4 holes for engine mount.

Insert 4 blind nuts to rewall.

read locker glue.

Fuselage

Aluminum washer.

Fuselage

18mm

Rudder

M3 Lock nut.

Ep oxy.

Rudder.

INSTALLING THE STOPPER

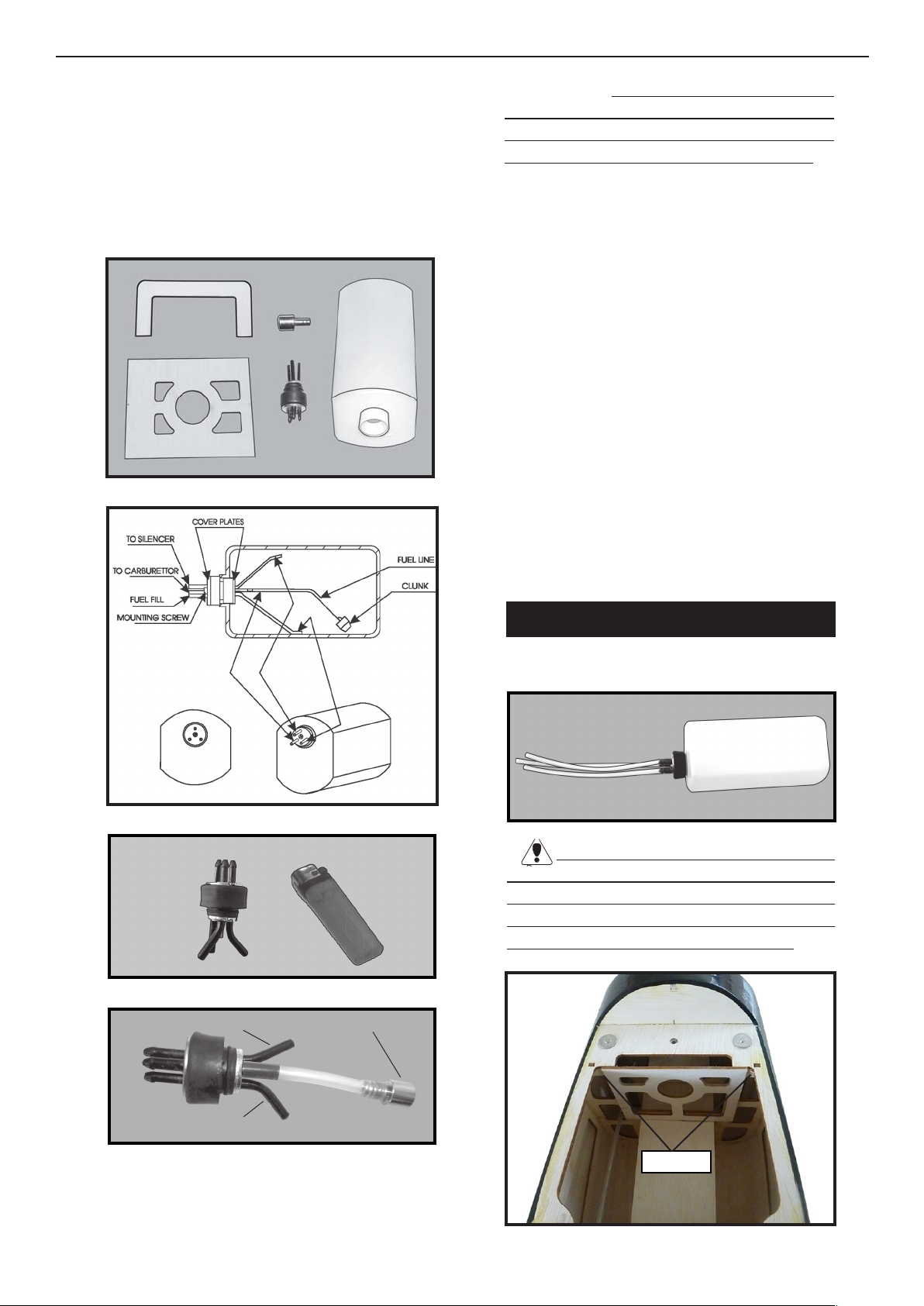

ASSEMBLY.

Rudder control horn.

1) Using a modeling knife, carefully cut

o the rear portion of one of the 3 nylon

tubes leaving 1/2” protruding from the

rear of the stopper. is will be the fuel

pick up tube.

6

2) Using a modeling knife, cut one length

of silicon fuel line. Connect one end of

the line to the weighted fuel pick up and

the other end to the nylon pick up tube.

Important: When the stopper assembly is

installed in the tank, the top of the vent tube

should rest just below the top surface of the

tank. It should not toch the top of the tank.

3) Carefully bend the second nylon tube up

at a 45º angle. is tube is the vent tube.

4) Test t the stopper assembly into the tank.

It may be necessary to remove some of the

ashing around the tank opening using a

modeling knife. If ashing is present, make

sure none falls into the tank.

5) With the stopper assembly in place, the

weighted pick-up should rest away from the

rear of the tank and move freely inside the

tank. e top of the vent tube should rest just

below the top of the tank. It should not touch

the top of the tank.

6) When satised with the alignment of the

stopper assembly tighten the 3 x 20mm machine screw until the rubber stopper expands

and seals the tank opening. Do not overtighten the assembly as this could cause the

tank to split.

FUEL TANK INSTALLATION.

Vent tube.

Fuel pick up

tube.

Glow Engine.

You should mark which tube is the vent

and which is the fuel pickup when you attach

fuel tubing to the tubes in the stopper. Once

the tank is installed inside the fuselage, it may

be dicult to determine which is which.

Fuel fill tube.

Carefully use a lighter or heat gun to permenently set the angle of the vent tube.

C/A glue.

7

Fuel tank.

C/A glue.

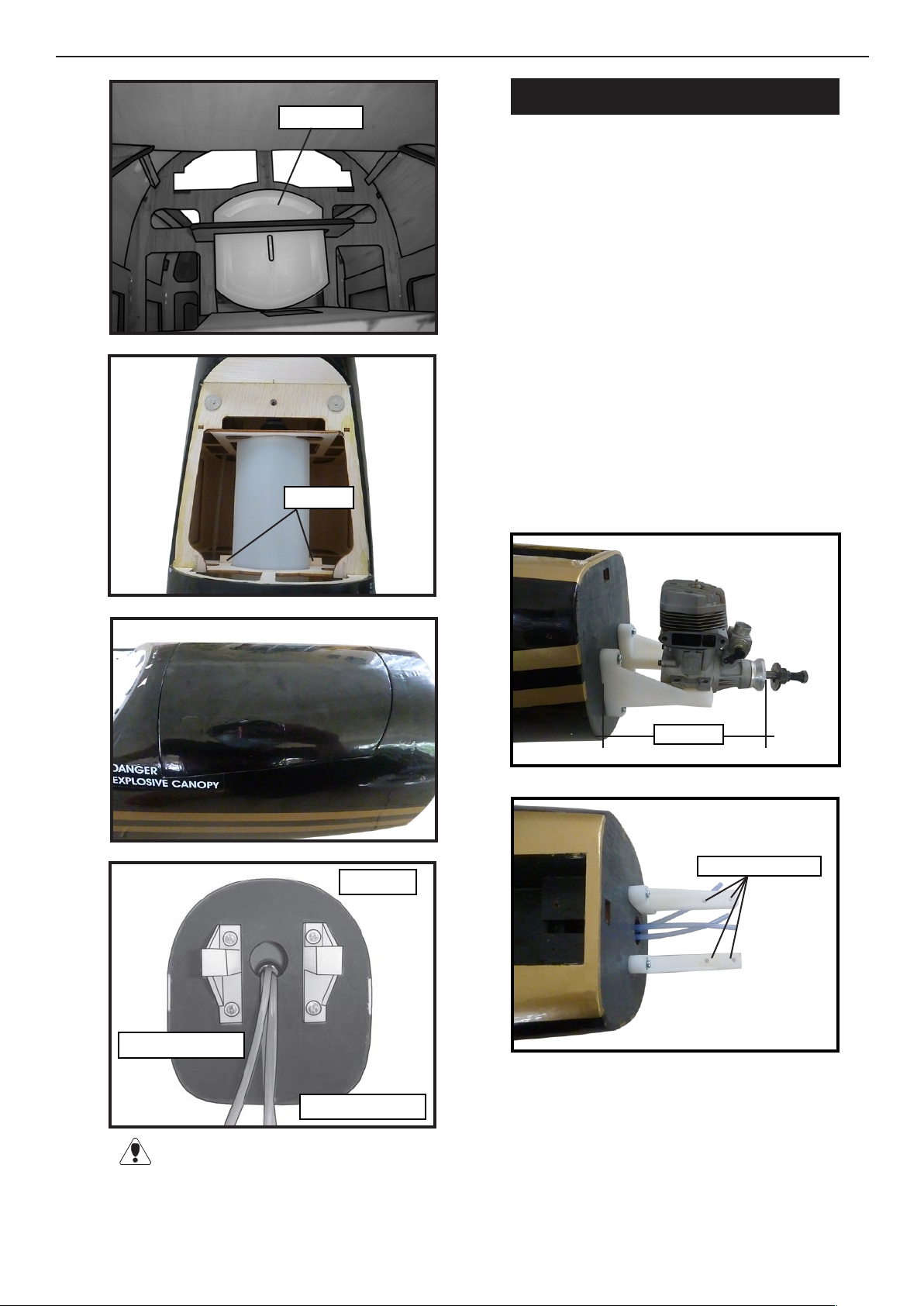

MOUNTING THE ENGINE.

1) Install the pushrod housing through the

predrilled hole in the rewall and into the

servo compartment. e pushrod housing

should protrude 1/4” out past the front of the

rewall. Make a Z-Bend 1/4” from one end

of the plain wire pushrod.

2) Place your engine onto the engine mount.

Adjust the engine is centered of the adges of

the engine case.

3) When you are satised with the alignment,

mark the location of the engine mounting.

4) Remove the engine. Using an drill bit,

drill the mounting holes through the engine

mount at the four location marked.

Vent tube.

Fuel pick up tube.

Fuel ll tube.

Blow through one of the lines to ensure

the fuel lines have not become kinked inside

the fuel tank compartment. Air should ow

through easily.

150mm

4.2mm diameter.

5) Bolt the engine to the engine mount using

the four machine screws. Double check that

all the screws are tight before proceeding.

6) Attach the Z-Bend in the pushrod wire to

the throttle arm on the carburetor.

8

Loading...

Loading...