Direct Air PHRV 140, PHRV 150, PHRVR 155, PHRV 200, PHRVR 160 Installation, Operation And Maintenance Manual

...

PHRV(R) Series

Heat Recovery Ventilator

PHRV 140

PHRV 150

PHRV 200

PHRVR 155

PHRVR 160

PHRVR 205

PHRVR 210

PHRVR 305

IMPORTANT - PLEASE READ THIS MANUAL

BEFORE INSTALLING UNIT

CAUTION - Before installation, careful consideration must be given to how this system

will operate if connected to any other piece of mechanical equipment, i.e. a forced air furnace

or air handler, operating at a higher static. After installation, the compatibility of the two piec-

es of equipment must be confirmed by measuring the airflow’s of the Heat Recovery

Ventilators by using the balancing procedure found in this manual.

It is always important to assess how the operation of any HRV may interact with vented com-

bustion equipment (i.e. Gas Furnaces, Oil Furnaces, Wood Stoves, etc.).

NEVER - install a ventilator in a situation where its normal operation, lack of operation or par-

tial failure may result in the backdrafting or improper functioning of vented combustion equipment!!!

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

The Best

Limited Warranty

in the Business

• The heat recovery polypropylene core has

a limited lifetime warranty.

• The motors found in all Powrmatic HRV’s

require no lubrication, and are factory

balanced to prevent vibration and promote

silent operation.

• The limited warranty covers normal use.

It does not apply to any defects,

malfunctions or failures as a result of

improper installation, abuse, mishandling,

misapplication, fortuitous occurrence or

any other circumstances outside

Powrmatic’s control.

• Inappropriate installation or

maintenance may result in the

cancellation of the warranty.

TABLE OF CONTENTS

TECHNICAL DATA

PHRVR 160 & PHRVR 210................................................................................ .3

PHRV 150 & PHRV 200 .................................................................................... 5

PHRVR 305 .................................................................................................... 7

PHRV 140, PHRVR 155 & PHRVR 205............................................................... 9

OPERATION............................................................................................................11

Modes Of Operation ........................................................................................11

Optional Remote Controls ............................................................................... 12

Intellitek Multi-Function Controls EDF5 ...............................................................12

INSTALLATION........................................................................................................13

Mounting the Unit ......................................................................................... 13

Location & Ducting ......................................................................................... 14

Examples ....................................................................................................... 17

Air Flow Balancing ......................................................................................... 21

• Any unauthorized work will result in

the cancellation of the warranty.

• Powrmatic is not responsible for any

incidental or consequential damages

incurred in the use of the ventilation system.

• Powrmatic is not responsible for providing

an authorized service centre near the

purchaser or in the general area.

• Powrmatic reserves the right to supply

refurbished parts as replacements.

• Transportation, removal and installation

fees are the responsibility of the purchaser.

• The purchaser is responsible to adhering

to all codes in effect in his area.

• The warranty is limited to 5 years on

parts and 7 years on the motor from the

date of purchase, including parts replaced

during this time period. If there is no

proof of purchase available, the date

associated with the serial number will be

used for the beginning of the warranty

period.

* This warranty is the exclusive and only

warranty in effect relative to the ventilation

system and all other warranties either

expressed or implied are invalid.

***Illustrations &

images in this

manual may not be

exactly like unit

purchase, these

illustrations & imag-

es are for examples

only.***

MAINTENANCE ..................................................................................................... 23

TROUBLESHOOTING............................................................................................... 24

ELECTRICAL CONNECTIONS ............................................................................. ... 25

Sizing (Example) for maximum airflow normally required.

HRVs are typically sized to ventilate the whole house at a minimum of 0.35 air changes per

hour. To calculate, simply take the square footage of the house (including basement) and multiply by the height of the ceiling to get cubic volume. Then, divide by 60 and multiply by 0.35.

Example: SQFT of House 1100

Basement 1100

Total SQFT 2200

Height of ceiling x 8

Cubic volume 17600

/ 60

Maximum airflow required (CFM) 293

x 0.35

103

* Always consult your local code for sizing requirements in your area.

Alternate Method

Room classification Number of rooms CFM (L/s) CFM Required

Master bedroom x 20 cfm (10 l/s) =

Basement yes or no =

Bedrooms x 10 cfm (5 l/s) =

Living room x 10 cfm (5 l/s) =

Others x 10 cfm (5 l/s) =

Kitchen x 10 cfm (5 l/s) =

Bathroom x 10 cfm (5 l/s) =

if yes add 20 cfm / 10 l/s

if no = 0

Laundry room x 10 cfm (5 l/s) =

1 cfm = 0.47189 l/s

2

1 l/s = 3.6 m3/hr

Utility room

x 10 cfm (5 l/s) =

Total Ventilation Requirements

(add last column )

=

PHRVR Series

PHRVR 160 & PHRVR 210

Introducing the NEW PHRVR series of Heat Recovery

Ventilators (HRV) by Powrmatic. Incoming fresh outdoor air

is filtered before it is heated by the stale outgoing air

through a polypropylene heat recovery core. The HRV then

distributes the preheated fresh filtered air throughout the

home by direct ductwork installed specifically for the HRV or

through the ductwork of a forced-air system.

SPECIFICATIONS

CASE 22 gauge galvanized steel on the PHRV 210 & 24

gauge galvanized steel on the PHRVR 160. Baked powder

coated paint, grey. Insulated with 1" (25 mm) high density

polystyrene foam to prevent condensation and meet the

requirements of the Underwriters Laboratories 94HB.

MOTORS Two (2) German-manufactured, factory-balanced

ebm™ motors with backward curved blades. Motors come

with permanently lubricated sealed bearings guarantee long

life and maintenance-free operation. Seven (7) year warranty.

CORE A polypropylene heat recovery core configured for an

efficient cross-flow ventilation. Core is 9" x 9" (229 x 229

mm) with a 15" (380 mm) depth {PHRVR 160} or 12" x 12"

(305 x 305 mm) with a 15" (380 mm) depth {PHRVR 210}.

Cores are manufactured to withstand extreme temperature

variations.

FILTERS Two (2) Washable Electrostatic Panel Type Air Filters,

PHRVR 160

(3mm),

0.125" (3mm).

is 8.5" (216mm) x 15" (380mm) x 0.125"

PHRVR 210

is 11.75" (298mm) x 15" (380mm) x

FEATURES:

• Compact Design

• Electrostatic Filters (washable)

• Airflow Balancing Using Powrmatic's Easy "TRUE" Motor

Adjustment

• External Screw Type Dry Contacts For Push Button

Timers (RTS 2), Dehumidistat 1, Dehumidistat 2

& 5MR Intellitek control.

• Easy Core Guide Channels For Removing Core

• Better Packaging For More Protection In Shipping

OPTIONAL CONTROLS

• 5MR – Digital Multi-Function Control

• DEH. 2 – Mechanical Low Voltage Dehumidistat with

On/Off Switch

• DEH. 1 – Mechanical Low Voltage Dehumidistat

• RTS 2 – 15 Minute Push Button Timer

• AQS 1 – Air Quality Sensor

External screw type dry contacts (provided)

CONTROLS External three (3) position (Low/Stand By/

Medium) rocker switch that will offer continuous ventilation.

Powr m a tic of f ers a variet y of e x t ernal c o n trols.

(see optional controls)

DEFROST A preset 5 minute defrost sequence is activated at

an outdoor air temperature of 23ÞF (-5ÞC) and lower.

During the defrost sequence, its mechanism uses a

motorized damper to temporarily block the incoming fresh

air stream allowing the warm air from the home to circulate

through the HRV. The exhaust blower shuts down & the

supply blower switches into high speed to maximize the

effectiveness of the defrost strategy.

The unit then returns to normal operation for 25 minutes,

and continues cycle.

SERVICEABILITY Core, filters, motors and drain pan can be

easily service d thr ough lat ched acc ess d oor. Core

conveniently slides out with ease on an improved railing

system. Electrical box, placed on the outside of the unit,

can also be easily accessed.

Powrmatic, reserves the right to modify, at any time and without notice, any or all of its products’ features, designs, components and specifications to maintain their technological leadership position.

3

A

B C D

E

5TH port for recirculation defrost type models only

Fresh Air

From Outside

Stale Air

To Outside

Fresh Air

To Inside

Stale Air

From Inside

5

TH

port for recirculation defrost models

only can be ducted or left open

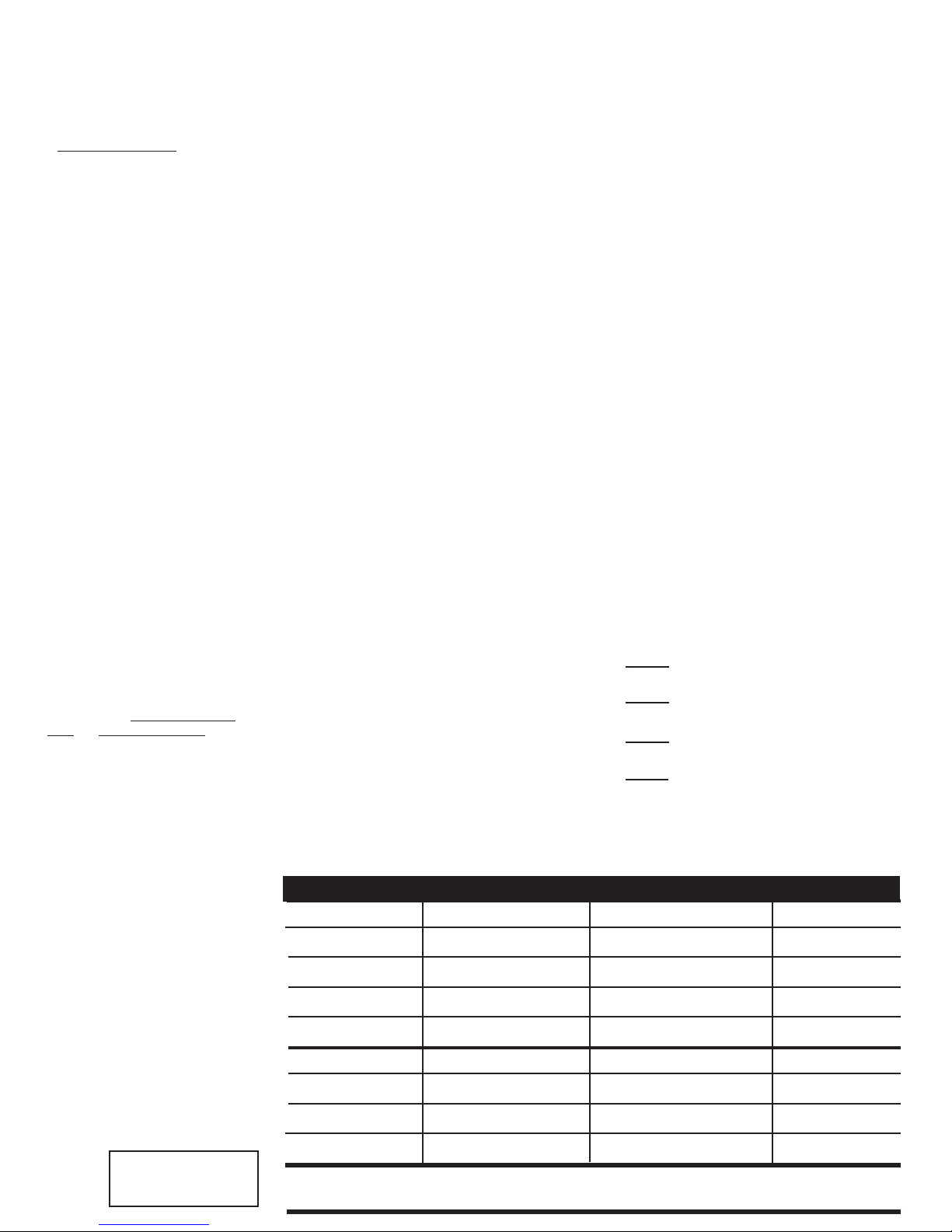

PHRVR 160 & PHRVR 210 Series HRV

Dimensions

6"

Model A B C D E

PHRVR 160 2

PHRVR 210 2 1/4" (56mm) 27 7/8" (707mm) 2 5/8" (67mm) 17 3/8" (441mm) 20 1/2" (520mm)

Fan Performance

1.2

1

0.8

0.6

0.4

Static Pressure (in WC)

0.2

0

190 38 57 76 94 114

400 80

Airflow

1

Airflow (L/s)

SHR(D) 2005R

SHR(D) 1505R

PHRVR 160

120 160

Airflow (cfm)

/4" (56mm) 23 1/2" (596mm) 2 5/8" (67mm) 17 3/8" (441mm) 17 3/8" (441mm)

Performance Data

300

250

PHRVR 210

200 240

200

150

100

50

0

Model

Apparent Sensible

Effectiveness at

32ºF (0ºC)

PHRVR 160 72 % 69 %

PHRVR 210 71 % 76 %

AIRFLOW CAP. cfm (L/s) @ 0.4 on High Speed

Static Pressure (Pa)

Power

• Volts 120 VAC

• Amperage

PHRVR 160 1.5 Amps Total

PHRVR 210 1.9 Amps Total

• Phase Single Phase

Apparent Sensible

Effectiveness at

-13ºF (-25ºC)

4

PHRV Series

PHRV 150 & PHRV 200

Introducing the NEW PHRV series of Heat Recovery

Ventilators (HRV) by Powrmatic. Incoming fresh outdoor air

is filtered before it is heated by the stale outgoing air

through a polypropylene heat recovery core. The HRV then

distributes the preheated fresh filtered air throughout the

home by direct ductwork installed specifically for the HRV or

through the ductwork of a forced-air system.

FEATURES:

• Compact Design

• Electrostatic Filters (washable)

• Balancing Dampers Included In Installation Kit

(not factory installed)

• External Screw Type Dry Contacts For Push Button

Timers (RTS 2), Dehumidistats 1, Dehumidistat 2

& 5MR Intellitek control.

• Easy Core Guide Channels For Removing Core

• Better Packaging For More Protection In Shipping

OPTIONAL CONTROLS

• 5MR – Digital Multi-Function Control

• DEH. 2 – Mechanical Low Voltage Dehumidistat with

On/Off Switch

• DEH. 1 – Mechanical Low Voltage Dehumidistat

• RTS 2 – 15 Minute Push Button Timer

• AQS 1 – Air Quality Sensor

SPECIFICATIONS

CASE 22 gauge galvanized steel on the PHRV 200 & 24

gauge galvanized steel on the PHRV 150. Baked powder

coated paint, grey. Insulated with 1" (25 mm) high density

polystyrene foam to prevent condensation and meet the

requirements of the Underwriters Laboratories 94HB.

MOTORS Two (2) German-manufactured, factory-balanced

ebm™ motors with backward curved blades. Motors come

with permanently lubricated sealed bearings guarantee long

life and maintenance-free operation. Seven (7) year warranty.

CORE A polypropylene heat recovery core configured for an

efficient cross-flow ventilation. Core is 9" x 9" (229 x 229 mm)

with a 15" (380 mm) depth (PHRV 150) or 12" x 12" (305 x

305 mm) with a 15" (380 mm) depth (PHRV 200). Cores are

manufactured to withstand extreme temperature variations.

FILTERS Two (2) Washable Electrostatic Panel Type Air Filters,

PHRV 150 is 8.5" (216mm) x 15" (380mm) x 0.125"

(3mm), PHRV 200 is 11.75" (298mm) x 15" (380mm) x

0.125" (3mm).

CONTROLS External three (3) position (Low/Stand By/

Medium) rocker switch that will offer continuous ventilation.

Powrmatic offers a variety of external controls. (see optional

controls)

DEFROST A preset 5 minute defrost sequence is activated at

an outdoor air temperature of 23ÞF (-5ÞC) and lower.

During the defrost sequence, the supply blower shuts down

& the exhaust blower switches into high speed to maximize

the effectiveness of the defrost strategy.

The unit then returns to normal operation for 25 minutes,

and continues cycle.

SERVICEABILITY Core, filters, motors and drain pan can be

easily service d thr ough lat ched acc ess d oor. Core

conveniently slides out with ease on an improved railing

system. Electrical box, placed on the outside of the unit, can

also be easily accessed.

External screw type dry contacts (provided)

Powrmatic, reserves the right to modify, at any time and without notice, any or all of its products’ features, designs, components and specifications to maintain their technological leadership position.

5

A

B C D

E

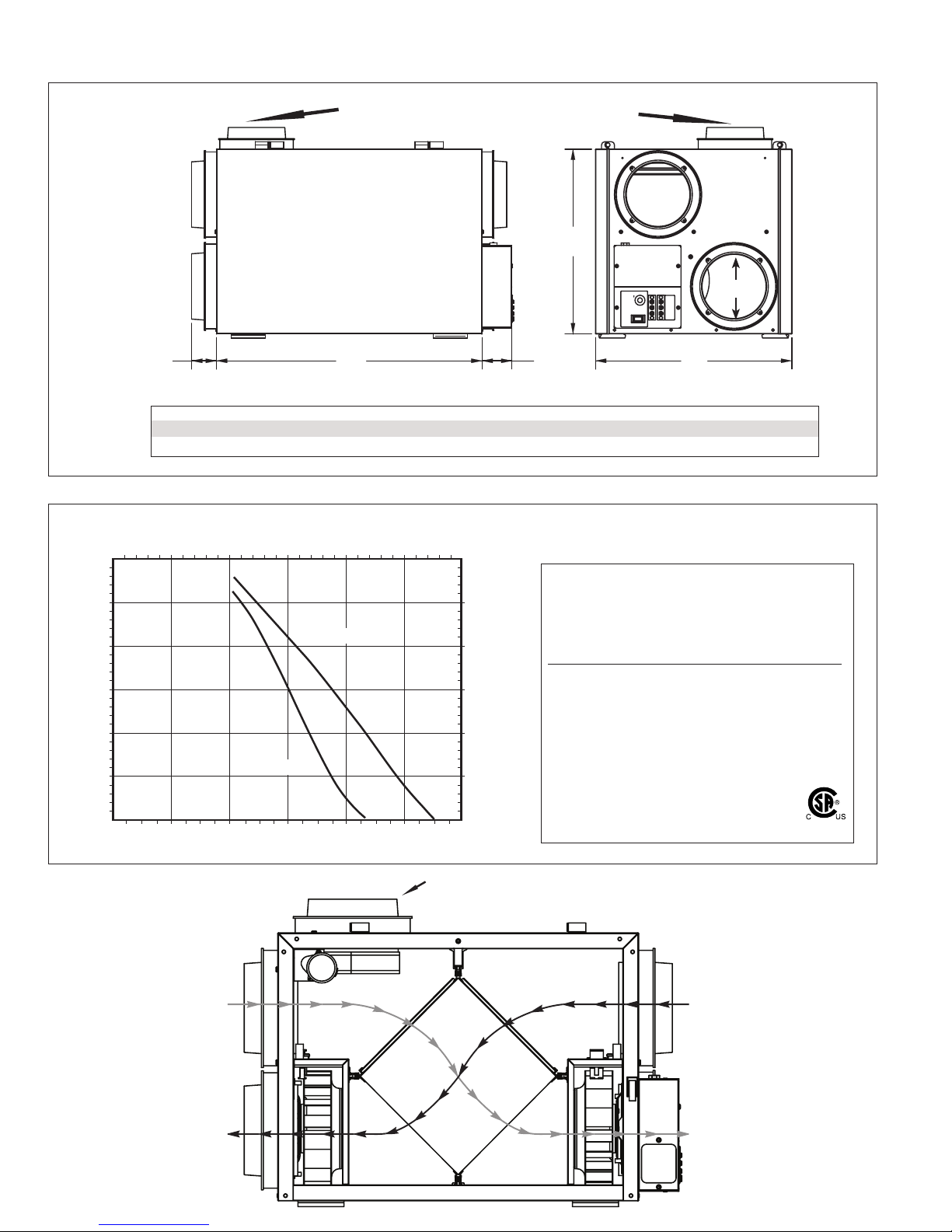

PHRV 150 & PHRV 200 Series HRV

Dimensions

Model A B C D E

PHRV 150 2 1/4" (56mm) 23 1/2" (596mm) 2 5/8" (67mm) 17 3/8" (441mm) 16 1/8" (413mm)

PHRV 200 2 1/4" (56mm) 27 7/8" (707mm) 2 5/8" (67mm) 17 3/8" (441mm) 20 1/2" (520mm)

6"

Fan Performance

1.2

1

0.8

0.6

0.4

Static Pressure (in WC)

0.2

0

190 38 57 76 94 114

400 80

Airflow

Airflow (L/s)

PHRV 200

SHR 2004

SHR 1504

PHRV 150

120 160

Airflow (cfm)

200 240

300

250

200

150

100

Static Pressure (Pa)

50

0

Performance Data

Model

PHRV 150 72 % 69 %

PHRV 200 71 % 76%

AIRFLOW CAP. cfm (L/s) @ 0.4 on High Speed

Power

• Volts 120 VAC

• Amperage

PHRV 150 1.5 Amps Total

PHRV 200 1.9 Amps Total

• Phase Single Phase

Apparent Sensible

Effectiveness at

32ºF (0ºC)

Apparent Sensible

Effectiveness at

-13ºF (-25ºC)

Fresh Air

From Outside

Stale Air

To Outside

6

Stale Air

From Inside

Fresh Air

To Inside

PHRVR 305

SPECIFICATIONS

CASE 22 gauge galvanized steel. Baked powder coated paint,

grey. Insulated with 1" (25 mm) high density polystyrene

foam to prevent condensation and meet the requirements of

the Underwriters Laboratories 94HB.

MOTORS Two (2) German-manufactured, factory-balanced

ebm™ motors with backward curved blades. Motors come

with permanently lubricated sealed bearings guarantee long

life and maintenance-free operation. Seven (7) year warranty.

CORES Two (2) polypropylene heat recovery cores configured

for an efficient cross-flow ventilation. Core is 12" x 12" (305

x 305 mm) with a 15" (380 mm) depth. Cores are

manufactured to withstand extreme temperature variations.

Introducing the PHRVR 305 series of Heat Recovery

Ventilators (HRV) by Powrmatic. As with previous designs,

incoming fresh outdoor air is filtered before it is heated by

the stale outgoing air. The HRV then distributes the

preheated fresh filtered air throughout the home by direct

ductwork installed specifically for the HRV or through the

ductwork of a forced-air system.

NEW FEATURES:

• Balancing Dampers Included In Installation Kit

(not factory installed

• Electrostatic Filters (washable)

• External Screw Type Dry Contacts For Push Button

Timers (RTS 2), Dehumidistats 1, Dehumidistat 2

& 5MR Intellitek control

)

OPTIONAL CONTROLS

• 5MR – Digital Multi-Function Control

• DEH. 2 – Mechanical Low Voltage Dehumidistat with

On/Off Switch

• DEH. 1 – Mechanical Low Voltage Dehumidistat

• RTS 2 – 15 Minute Push Button Timer

• AQS 1 – Air Quality Sensor

FILTERS Two (2) synthetic high quality filters for better indoor

air quality and clean air.

CONTROLS External three (3) position (Low/Stand By/

Medium) rocker switch that will offer continuous ventilation.

Powr m a tic of f ers a variet y of e x t ernal c o n trols.

(see optional controls)

DEFROST A preset 5 minute defrost sequence is activated at

an outdoor air temperature of 23ÞF (-5ÞC) and lower.

During the PHRVR 305 defrost sequence, its mechanism

uses a motorized damper to temporarily block the incoming

fresh air stream allowing the warm air from the home to

circulate through the HRV. The exhaust blower shuts down &

the supply blower switches into high speed to maximize the

effectiveness of the defrost strategy.

The unit then returns to normal operation for 25 minutes,

and continues cycle.

SERVICEABILITY Core, filters, motors and drain pan can be

easily serviced through latched access door.

External screw type dry contacts (provided)

Powrmatic, reserves the right to modify, at any time and without notice, any or all of its products’ features, designs, components and specifications to maintain their technological leadership position.

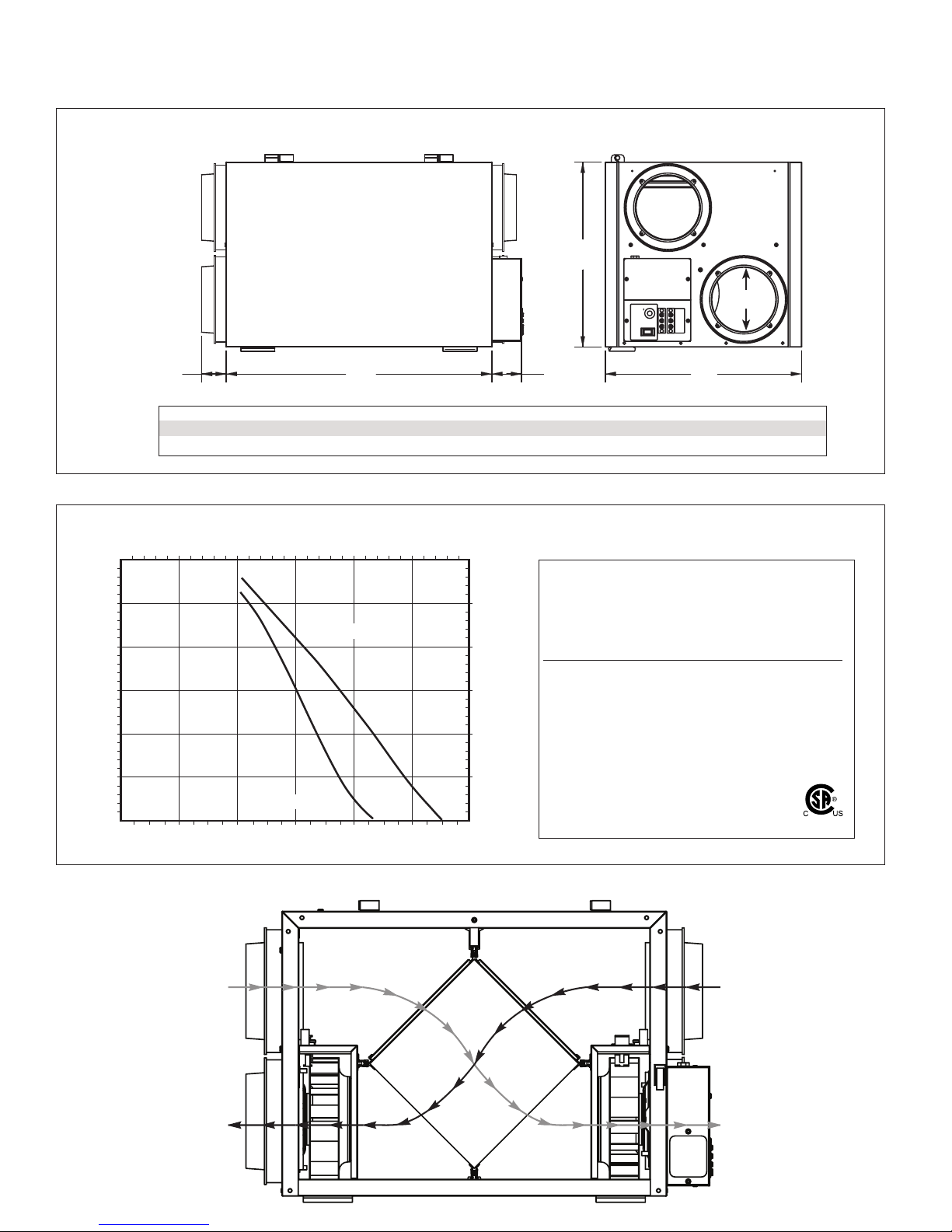

7

22.20"

564mm

17.36"

441mm

2.20"

56mm

2.20"

56mm

50.87"

1292mm

5TH port for recirculation defrost

type models only

5TH port for recirculation defrost models

only, can be ducted or left open

PHRVR 305 Series HRV

Dimensions

6"

Fan Performance

1.2

0.8

0.6

0.4

Static Pressure (in WC)

0.2

19.000.00 38.00 57.00 76.00 94.00 114.00 123.00 142.00 162.00

1

0

40.000.00 80.00

Airflow

120.00 160.00

Airflow (L/s)

PHRVR 305

SHR3005R

200.00 240.00 280.00 320.00 360.00

Airflow (cfm)

300.00

250.00

200.00

150.00

100.00

50.00

0.00

Performance Data

Model

PHRVR 305 92 % 91 %

AIRFLOW CAP. cfm (L/s) @ 0.4 on High Speed

Static Pressure (Pa)

Power

• Volts 120 VAC

• Amperage 2.7 Amps Total

• Phase Single Phase

Apparent Sensible

Effectiveness at

32ºF (0ºC)

Apparent Sensible

Effectiveness at

-13ºF (-25ºC)

8

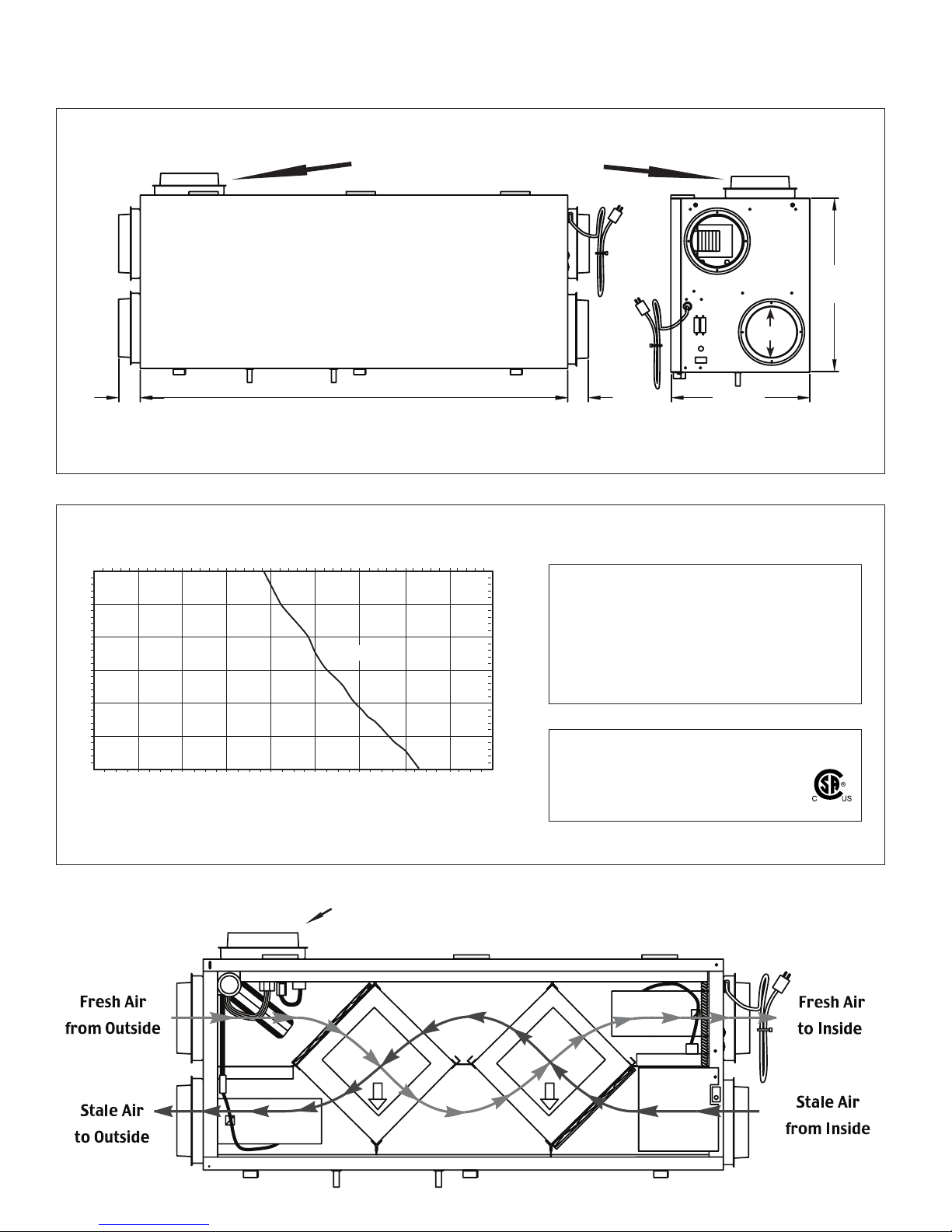

PHRV(R) Series

PHRV 140, PHRVR 155 & PHRVR 205

Introducing the PHRV(R) series of Heat Recovery Ventilators

(HRV) by Powrmatic. Incoming fresh outdoor air is filtered

before it is heated by the stale outgoing air through a

polypropylene heat recovery core. The HRV then distributes

the preheated fresh filtered air throughout the home by

direct ductwork installed specifically for the HRV or through

the ductwork of a forced-air system.

FEATURES:

• Compact Design

• Airflow Balancing Using Fantech's Easy "TRUE" Motor

Adjustment for models PHRVR 155 & PHRVR 205

• Electrostatic Filters (washable)

• Balancing Dampers Included In Installation Kit

(not factory installed)

• External Screw Type Dry Contacts For Push Button

Timers (RTS 2), Dehumidistats 1, Dehumidistat 2

& 5MR Intellitek control.

OPTIONAL CONTROLS

• 5MR – Digital Multi-Function Control

• DEH. 2 – Mechanical Low Voltage Dehumidistat with

On/Off Switch

• DEH. 1 – Mechanical Low Voltage Dehumidistat

• RTS 2 – 15 Minute Push Button Timer

• AQS 1 – Air Quality Sensor

External screw type dry contacts (provided)

SPECIFICATIONS

CASE 22 gauge galvanized steel. Baked powder coated paint,

grey. Insulated with 1" (25 mm) high density polystyrene

foam to prevent condensation and meet the requirements of

the Underwriters Laboratories 94HB.

MOTORS Two (2) German-manufactured, factory-balanced

ebm™ motors with backward curved blades. Motors come

with permanently lubricated sealed bearings guarantee long

life and maintenance-free operation. Seven (7) year warranty.

CORE A polypropylene heat recovery core configured for an

efficient cross-flow ventilation. Core is 9" x 9" (229 x 229

mm) with a 15" (380 mm) depth (PHRV 140 & PHRVR

155) or 12" x 12" (305 x 305 mm) with a 15" (380 mm)

depth (PHRVR 205). Cores are manufactured to withstand

extreme temperature variations.

FILTERS Two (2) Washable Electrostatic Panel Type Air Filters,

PHRV 140 & PHRVR 155 is 8.5" (216mm) x 15" (380mm) x

0.125" (3mm), PHRVR 205 is 11.75" (298mm) x 15"

(380mm) x 0.125" (3mm).

CONTROLS External three (3) position (Low/Stand By/

Medium) rocker switch that will offer continuous ventilation.

Powrmatic offers a var iety of exte rnal con tro ls to

compliment its units and allows you to appreciate its

functions to the fullest. (see optional controls)

DEFROST A preset 5 minute defrost sequence is activated at

an outdoor air temperature of 23ÞF (-5ÞC) and lower.

During the PHRV 140 defrost sequence, the supply blower

shuts down & the exhaust blower switches into high speed

to maximize the effectiveness of the defrost strategy.

During the PHRVR Series (PHRVR 155 & PHRVR 205)

defrost sequence, its mechanism uses a motorized damper

to temporarily block the incoming fresh air stream allowing

the warm air from the home to circulate through the HRV.

The exhaust blower shuts down & the supply blower

switches into high speed to maximize the effectiveness of

the defrost strategy.

The unit then returns to normal operation for 25 minutes,

and continues cycle.

SERVICEABILITY Core, filters, motors and drain pan can be

easily serviced through latched access door.

Powrmatic, reserves the right to modify, at any time and without notice, any or all of its products’ features, designs, components and specifications to maintain their technological leadership position.

9

Loading...

Loading...