Direct Air PHRV, PHRVR96 Installation, Operation And Maintenance Manual

PHRV

Heat Recovery Ventilator

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

The Best

Limited Warranty

in the Business

• The heat recovery aluminum core has a

limited lifetime war

• The motors found in all Powrmatic HRV’s

require no lubrication, and are factory

balanced to prevent vibration and promote

ilent operation.

s

• The limited warranty covers normal use.

It does not apply to any defects,

malfunctions or failures as a result of

improper installation, abuse, mishandling,

misapplication, fortuitous occurrence or

any other circumstances outside

Powrmatic’s control.

• Inappropriate installation or

maintenance may result in the

cancellation of the war

• Any unauthorized work will result in

the cancellation of the warranty.

• Powrmatic is not responsible for any

incidental or consequential damages

incurred in the use of the ventilation

system.

• Powrmatic is not responsible for providing

an authorized service centre near the

purchaser or in the general area.

• Powrmatic reserves the right to supply

refurbished parts as replacements.

• Transportation, removal and installation

fees are the responsibility of the purchaser.

• The purchaser is responsible to adhering

to all codes in effect in his area.

• The warranty is limited to 5 years on

parts and 7 years on the motor from the

date of purchase, including parts replaced

during this time period. If there is no

proof of purchase available, the date

associated with the serial number will be

used for the beginning of the warranty

period.

* This war

ranty is the exclusive and only

warranty in effect relative to the ventilation

system and all other warranties either

essed or implied are invalid.

expr

***Illustrations &

images in this

manual may not be

exactly like unit

pur

illustrations &

images are for

examples only.***

ranty.

ranty.

chase, these

TABLE OF CONTENTS

TECHNICAL DATA

PHRVR96 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Mounting the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Location & Ducting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

xamples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

E

ir Flow Balancing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

A

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Modes Of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Optional Remote Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

ELECTRICAL CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .... 15

Sizing (Example) for maximum airflow normally required.

HRVs are typically sized to ventilate the whole house at a minimum of 0.35 air changes per

hour. To calculate, simply take the square footage of the house (including basement) and multiply by the height of the ceiling to get cubic volume. Then, divide by 60 and multiply by 0.35.

Example: SQFT of House 1100

Basement 1100

Total SQFT 2200

Height of ceiling x 8

Cubic volume 17600

/ 60

Maximum airflow required (CFM) 293

x 0.35

103

* Always consult your local code for sizing requirements in your area.

Alternate Method

Room classification Number of rooms CFM (L/s) CFM Required

Master bedroom x 20 cfm (10 l/s) =

Basement yes or no =

Bedrooms x 10 cfm (5 l/s) =

Living room x 10 cfm (5 l/s) =

Others x 10 cfm (5 l/s) =

Kitchen x 10 cfm (5 l/s) =

oom x 10 cfm (5 l/s) =

Bathr

if yes add 20 cfm / 10 l/s

if no = 0

1 cfm = 0.47189 l/s

Laundr

1 l/s = 3.6 m3/hr

2

Utility r

y r

oom

oom

entilation Requirements

otal V

T

x 10 cfm (5 l/s)

x 10 cfm (5 l/s) =

(add last column )

=

=

Compact top port design HRV with easy-mount wall bracket.

Brings a continuous supply of fresh air into a home while

exhausting an equal amount of contaminated air. HRVs use

what is called a “sensible” heat recovery core. This special

core transfers heat from the exhaust air stream to the

incoming air stream. Fresh incoming air is tempered by the

heat that is transferred from the outgoing air to save on

energy costs. The PHRV96 is equipped with automatic

defrost mechanisms so even if you live in the coldest climates you can use your HRV all year long.

FEATURES

• Super Compact Size

• Top Port Design Fits in Tight Spaces

• Includes Easy-Mount Wall Bracket

• Aluminum Heat Recovery Core

• 4” (100mm) Duct Connections

• No Balancing Required

• Easy Access Service Door

• 3’ (914mm) Plug-in Power Cor

Automatic Exhaust Defr

•

to Always Stay in Ventilation Mode

• Only 26 lbs (12 kg)

• Electr

• Easy Core Guide Channels For Removing Core

• Multiple Speed Operation

ostatic Filters (washable)

d

ost Allows Units

PHRV96

SPECIFICATIONS

CASE 24 gauge galvanized steel. Baked powder coated paint,

grey. Cabinet fully insulated with 1" (25 mm) aluminum foilface high density polystyrene foam to prevent condensation

and meet the requirements of the UL 94HF.

MOTORS Two (2) German-manufactured, factory-balanced

ebm™ motors with backward curved blades. Motors come

with permanently lubricated sealed ball bearings to

guarantee long life and maintenance-free operation. Seven

(7) year warranty. Steep fan curves requires no balancing of

airflows.

CORE Aluminum heat recovery core configured for efficient

cross-flow ventilation. Core is 8.5˝ x 8.5˝ (216 x 216 mm)

with a 8˝ (205 mm) depth. Cores are manufactured by

Fantech to withstand extreme temperature variations.

FILTERS Two (2) Washable Electrostatic Panel Type Air Filters,

8.5˝ (216mm) x 8˝ (203mm) x 0.125˝ (3mm).

CONTROLS Unit is designed to accommodate the whole

series of Fantech HRV controls.

DEFROST

an outdoor air temperature of 23°F (-5°C) and lower. During

the defrost sequence, the supply blower shuts down & the

exhaust blower switches into high speed to maximize the

effectiveness of the defrost strategy. The unit then returns

to normal operation for 25 minutes, and continues cycle.

SERVICEABILITY Core, filters, motors and drain pan can be

easily accessed through latched door. Core conveniently

slides out on our new easy glide core guides. 10˝ (250mm)

of clearance is recommended for removal of core.

DUCT

rubber gasket for easy sealing.

DRAIN 1/2˝ (13mm) OD (outside diameter) drain spout

pr

W

motors, and 5 year on parts.

A preset 5 minute defrost sequence is activated at

CONNECTION

ovided, entir

ARRANTY

4˝ (100mm) steel duct connections with

e bottom of unit cover

Limited lifetime on aluminum cor

ed by pan.

e, 7 year on

ACCESSORIES

• EDF1 – Multi-function control

• RTS3 – 20/40/60 minute over-ride

15 minute over-ride

TS2

• R

• COM 4P – 4˝ Weather Hoods

• FEL 4 – 4˝ 90˚ Elbow

• CG 4

Distributed by:

Fantech, reserves the right to modify, at any time and without notice, any or all of its products’ features,

designs, components and specifications to maintain their technological leadership position.

–

4˝ Adjustable Grille

–

(1 supply & 1 exhaust)

3

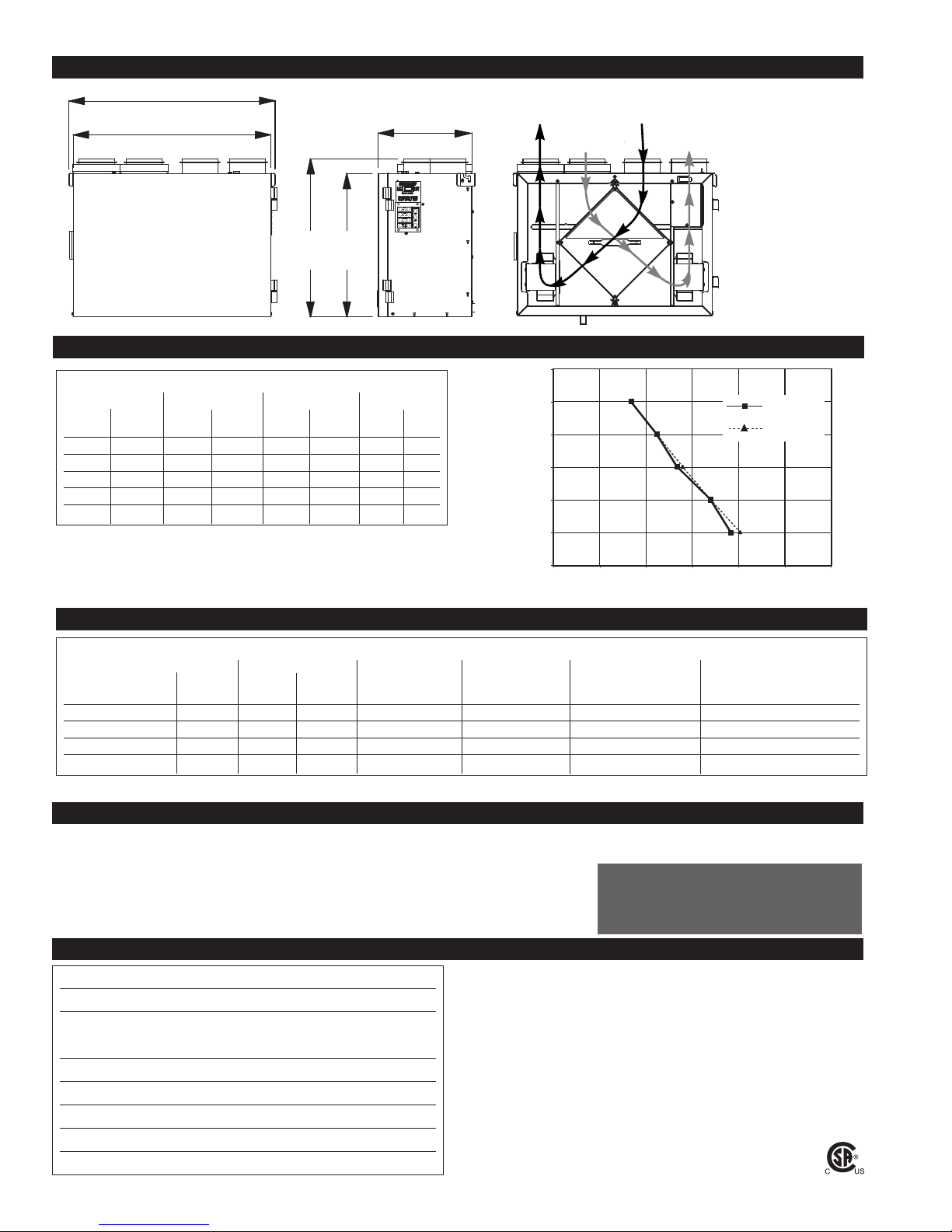

Dimensions & Airflow

0

0.1

0.2

0.3

0.4

0.5

0.6

0 25 50 75 100125 150

cfm (l/s = n x 0.47)

in w.g. (Pa = n x 248)

N

et Supply

Net Exhaust

22.50"

(572mm)

21.50"

(546mm)

-

Ventilation Performance

All units feature three foot plug-in power cord with 3-prong plug.

17.20"

(436mm)

15.60"

(396mm)

10.20"

(259mm)

Stale Air

To Outside

From Outside

From Inside

Fresh Air

Stale Air

Fresh Air

To Outside

• Continuous ventilation

mode of supply and

exhaust airstreams

10˝ (254mm) of clear-

•

ance is recommended

for removal of core

EXT. STATIC

PRESSURE

NET SUPPLY

AIR FLOW

GROSS AIR FLOW

SUPPLY EXHAUST

Pa in wg L/s cfm L/s cfm L/s cfm

25 0.1 45 96 47 99 49 104

50 0.2 40 85 41 88 41 88

75 0.3 32 67 33 69 34 72

100 0.4 26 56 27 58 28 58

125 0.5 20 42 20 43 20 43

Energy Performance

SUPPLY

TEMPERATURE

NET

AIRFLOW

˚C ˚F L/s cfm

POWER

CONSUMED

WATTS

Heating 0 32 26 55 36 57 67 –

0 32 32 68 40 55 63 –

0 32 39 83 40 54 60 –

-25 -13 34 72 35 53 66 –

SENSIBLE

RECOVERY

EFFICIENCY

APPARENT

SENSIBLE EFFEC-

TIVENESS

RECOVERY/MOISTURE

TRANSFER

Specifications and Ratings

• Model: PHRV96

• Total assembled weight: 26 lbs (12kg)

• Cabinet: 24 ga. steel w/powder coat finish

• Motors: ebm motors w/backward curved blades

• Filters: 2 washable electrostatic filters

8.5" (216mm) x 8" (205mm) x 0.125" (3mm)

• Insulated with 1" (25 mm) aluminum foil-face

high density polystyrene foam to prevent

condensation and meet the requirements of

the UL 94HF.

• Core: Aluminum

8.5˝ (216mm) x 8.5˝ (216mm) x 8˝ (205mm)

• Supply & exhaust ducts: 4˝ (100mm)

• Mounting: Wall bracket included

• Electrical requirements:

Volts Frequency Amps Watts

115V

60Hz

3' plug-in power cor

0.36A 40W

d w/ 3-prong plug

LATENT

Contacts

Submitted by: Date:

Qty: Model #:

Comments:

Project #:

Location:

Architect:

Engineer:

Contractor:

4

INSTALLATION

PRACTICAL TIPS

• Install the unit close to the outside

wall on which the supply and

exhaust hoods will be mounted.

• Have a nearby power supply 120

Volts, 60Hz. (power cord is 3

feet long)

• Mount the unit as level as

possible in order to allow proper

condensate drainage.

LOCATION

The HRV must be located in a heated space where it will be possible to conveniently service the unit. Typically the HRV

ould be located in the mechanical room or an area close to the outside wall where the weatherhoods will be mounted.

w

If a basement area is not convenient or does not exist, a utility room or laundry or closet may be used.

Attic installations are not normally recommended due to:

Connecting the following appliances to the HRV

These appliance may cause lint, dust or grease to collect in the HRV , damaging the unit.

NOTE: Connecting any of these type of appliances to the HRV will invalidate your warranty

- the complexity of work to install

- freezing conditions in the attic

- difficulty of access for service and cleaning

clothes dryer

-

- range top

- stovetop fan

- central vacuum system

is not recommended,

including:

• Have access to a water drain for

the condensate of the unit during

defrost.

• Have a certain amount of heat

around the unit (attic installation

is not recommended).

• Installations close to the living

space, such as closets, should be

design and to minimize noise or

vibration transfers.

• Have access for future

maintenance. (10” is

recommended for removal of core)

ELECTRICAL

3 prong plug-in power card.

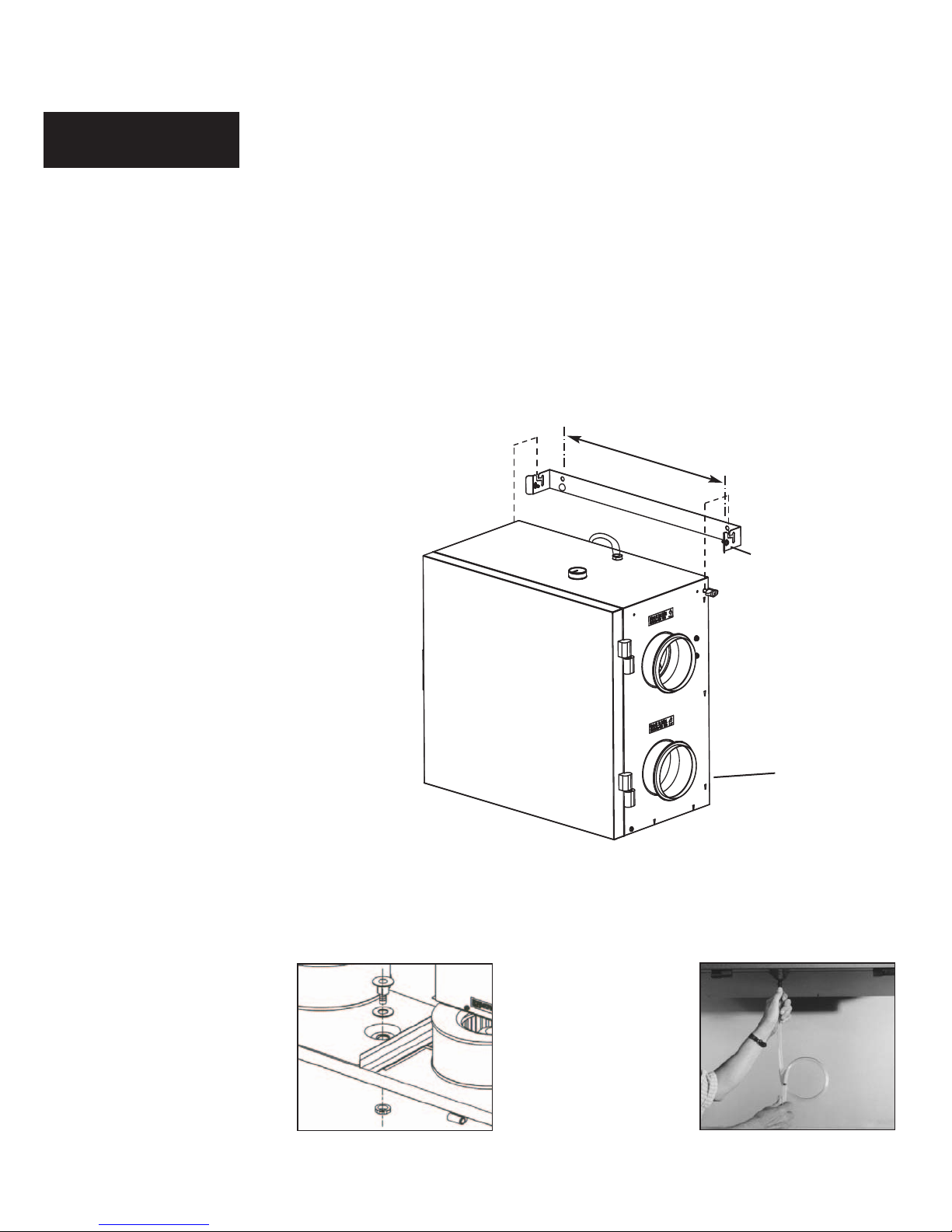

MOUNTING - EASY WALL MOUNT

Attach bracket to wall, lift unit

(26 lbs (12 kg) PHR

nuts into slots on bracket, tighten

ews to secure unit to bracket.

scr

Insert the safety screws & place

wall bumpers to level off the unit.

V96) & slide

16”

(406mm)

Safety screws (included)

Place bumpers on back

of unit (included)

INSTALLING DRAIN LINE - Drainline not included in kit

Through normal operation and during its defrost mode, the HRV may produce some condensation. This water should

flow into a nearby drain, or be taken away by a condensate pump. The HRV and all condensate lines must be installed in

a space where the temperature is maintained above the freezing point. A “P” trap should be made in the drain line. This

will prevent odors from being drawn back up into the unit.

1 Install the drain nipple.

2 Install the drain hose,

making a “P” trap

5

Loading...

Loading...