Dionex UltiMate FLM-3100, UltiMate FLM-3300, UltiMate FLM-3200, UltiMate FLM-3100B, UltiMate FLM-3300B Operating Instructions Manual

...Page 1

UltiMate 3000 Series

Flow Managers and

Thermostatted Column Compartments

Operating Instructions

Revision: 1.1

Date: September 2007

© 2007 Dionex

Page 2

UltiMate 3000 Series: Flow Managers and Column Thermostats

Operating Instructions

Page 3

Declaration of Conformity

Product: Flow Manager and Column Compartment

Types: FLM-3100, FLM-3200, FLM-3300

FLM-3100B, FLM-3200B, FLM-3300B

Dionex Softron GmbH herewith declares conformity of the above products

with the respective requirements of the following regulations:

• Low-Voltage Equipment Directive 73/23/EEC

changed by 93/68/EEC

• EMC Directive 2004/108/EG

The electrical safety of the products was evaluated based on the following

standard:

• EN 61010-1: 2002

Safety requirements for electrical equipment for measurement, control

and laboratory use

Part 1: General Requirements

The Electromagnetic Compatibility (EMC) of the products was evaluated

based on the following standard:

• DIN EN 61326: 2004

Electrical equipment for measurement, control and laboratory use

EMC Requirements

This declaration is issued for the manufacturer

Dionex Softron GmbH

Dornierstrasse 4

D-82110 Germering

by the President, Dr. Peter Jochum.

August 1, 2007 _________________________

Dr. Peter Jochum

Operating Instructions Page I

Page 4

UltiMate 3000 Series: Flow Managers and Column Thermostats

Page II Operating Instructions

Page 5

UltiMate 3000 Series: Flow Managers and Column Thermostats

Table of Contents

1 Introduction................................................................................................................... 1

1.1 How to Use This Manual.......................................................................................1

1.2 Safety Information .................................................................................................1

1.2.1 Symbols on the Instrument and in the Manual .................................................. 2

1.2.2 General Safety Precautions................................................................................ 3

1.2.3 Consignes Générales de Sécurité....................................................................... 5

1.3 Intended Use .......................................................................................................... 8

1.4 Federal Communications Commission (FCC) Note.............................................. 8

2 Overview ........................................................................................................................9

2.1 Product Overview .................................................................................................. 9

2.2 Theory of Operation (UltiFlow) ..........................................................................11

2.3 Supported Configurations.................................................................................... 12

2.3.1 General............................................................................................................. 12

2.3.2 Biocompatible Flow Managers........................................................................ 13

2.4 General Flow Manager Design............................................................................ 17

2.5 Column Switching Valve..................................................................................... 18

2.6 Flow Splitter ........................................................................................................ 19

2.7 Front Panel Display and Controls........................................................................ 20

2.8 Rear Panel Connectors......................................................................................... 21

2.9 Leak Sensors........................................................................................................22

2.10 System Wellness..................................................................................................23

3 Installation................................................................................................................... 25

3.1 Facility Requirements.......................................................................................... 25

3.2 Unpacking............................................................................................................ 25

3.3 Positioning the Flow Manager in the UltiMate 3000 System.............................. 26

3.4 Connecting the Flow Manager............................................................................. 27

3.4.1 USB.................................................................................................................. 27

3.4.2 Power Connection............................................................................................ 27

3.4.3 Digital I/O........................................................................................................ 28

3.5 Opening the Front Panel Door............................................................................. 28

3.6 Preparing the Flow Manager ............................................................................... 29

3.6.1 Installing a Separation Column .......................................................................31

3.6.2 Connecting the Capillaries to the Column Switching Valve...........................35

3.6.3 Installing a Trap Column.................................................................................36

3.6.4 Connecting the Flow Splitter...........................................................................37

3.7 Manual Injection Port .......................................................................................... 39

Operating Instructions Page i

Page 6

UltiMate 3000 Series: Flow Managers and Column Thermostats

4 User Interface ..............................................................................................................41

4.1 Power-Up.............................................................................................................41

4.2 Status Screen........................................................................................................ 41

4.3 Soft Key Menus ................................................................................................... 42

4.4 Menu Structure and Layout ................................................................................. 43

4.4.1 Main Menu....................................................................................................... 45

4.4.2 Control Menu................................................................................................... 46

4.4.3 Information Menu............................................................................................ 47

4.4.4 Configuration Menu......................................................................................... 48

5 Software Control by Chromeleon ............................................................................. 49

5.1 General................................................................................................................. 49

5.2 Installing the Flow Manager in Chromeleon.......................................................49

5.3 Assigning the Flow Splitter ................................................................................. 56

5.4 Operating the Flow Manager with Chromeleon .................................................. 57

5.5 Column Identification System (Column ID) .......................................................58

5.6 Splitter Identification System (Splitter ID).......................................................... 59

5.7 Diagnostics........................................................................................................... 60

6 Troubleshooting ..........................................................................................................61

6.1 Overview.............................................................................................................. 61

6.2 Error Messages .................................................................................................... 62

6.3 Chromeleon Diagnostics Messages ..................................................................... 66

7 Routine Maintenance.................................................................................................. 69

7.1 General Notes ...................................................................................................... 69

7.2 Maintenance Intervals.......................................................................................... 71

7.3 Flow Control Valve .............................................................................................72

7.4 Replacing the Fuses ............................................................................................. 73

7.5 Drying the Fluid Leak Sensor.............................................................................. 74

7.6 Exchanging the Splitter Cartridge) ...................................................................... 76

7.7 Column Switching Valve..................................................................................... 79

7.8 Shutting Down the Flow Manager....................................................................... 81

8 Technical Information................................................................................................ 83

9 Accessories, Consumables and Spare Parts ............................................................. 85

9.1 Standard Accessories (included in the shipment)................................................ 85

9.2 Consumables, Spare Parts, and Optional Accessories......................................... 86

10 Technical Appendix - Pin Assignment...................................................................... 91

11 Index............................................................................................................................. 93

Page ii Operating Instructions

Page 7

UltiMate 3000 Series: Flow Managers and Column Thermostats

1 Introduction

1.1 How to Use This Manual

The layout of this manual is designed to provide quick reference to the sections of interest

to the user. However, in order to obtain a full understanding the flow manager and

thermostatted column compartment, Dionex recommends that you review the manual

thoroughly before beginning operation of the module.

Almost all descriptions in the manual apply to all flow managers of the UltiMate 3000 system

and cover both the standard (stainless steel) and biocompatible models. Therefore, the terms

"the flow manager" and/or "the FLM" are used throughout the manual. If some detail applies

to only one model or version, the model (or version) is identified by name.

Note: The device configuration may vary (e.g., one or two column switching valves);

therefore, not all descriptions necessarily apply to your particular instrument.

The descriptions in this manual refer to firmware version 2.30 and Chromeleon

version 6.80 Service Pack 2.

The information contained in this manual is subject to change without notice and should

not be construed as a commitment by Dionex. Dionex assumes no responsibility for any

errors that may appear in this document. This document is believed to be complete and

accurate at the time of publication. In no event shall Dionex be liable for incidental or

consequential damages in connection with or arising from the use of this document.

CHROMELEON® is a registered trademark of Dionex. UltiMate™ is a trademark of Dionex.

All other trade or company names mentioned are subject to the copyright and the property and

trademark rights of the respective companies.

All rights reserved, including those for photomechanical reproduction and storage on

electronic media. No part of this publication may be copied or distributed, transmitted,

transcribed, stored in a retrieval system, or transmitted into any human or computer language,

in any form or by any means, electronic, mechanical, magnetic, manual, or otherwise, or

disclosed to third parties without the express written permission of Dionex.

1.2 Safety Information

The CE Mark label and cTUVus Mark safety label on the instrument indicate that the

instrument is in compliance with the related standards (→ pages I and II).

Operating Instructions Page 1

Page 8

UltiMate 3000 Series: Flow Managers and Column Thermostats

1.2.1 Symbols on the Instrument and in the Manual

The table below shows the symbols used on the instrument:

Symbol Description

Alternating current—Courant alternatif

˜

Power supply is on (−) — L'instrument est mis sous tension (−) and

Power supply is off (O)— L'instrument est mis hors tension (O)

Surface becomes hot during operation—La surface devient chaude lors du

fonctionnement.

Refer to the operating instructions to prevent risk of harm to the operator and to

protect the instrument against damage.

Référez-vous au ce manuel pour éviter un risque de blessure à l'opérateur et/ou de

protéger l'instrument contre des dommages.

Label according to the "Measures for Administration of the Pollution Control of

Electronic Information Products" (China RoHS) guideline

Étiquette "Measures for Administration of the Pollution Control of Electronic

Information Products" (China RoHS)

WEEE (Waste Electrical and Electronic Equipment) label—For more information,

refer to the WEEE Information section in the manual binder.

Étiquette de WEEE (Waste Electrical and Electronic Equipment) —Pour plus

d'information, référez-vous à la section WEEE Information dans ce fichier.

At various points throughout the manual, messages of particular importance are indicated by

certain symbols:

Tip: Indicates general information, as well as information intended to

optimize the performance of the instrument.

Important: Indicates that failure to take note of the accompanying information

could cause wrong results or may result in damage to the instrument.

Important: Indique que ne pas tenir compte de l'information jointe peut conduire

à de faux résultat ou endommager l'instrument.

Warning: Indicates that failure to take note of the accompanying information

may result in personal injury.

Avertissement: Indique que ne pas tenir compte de l'information jointe peut

entraîner des blessures corporelles.

Page 2 Operating Instructions

Page 9

UltiMate 3000 Series: Flow Managers and Column Thermostats

1.2.2 General Safety Precautions

When working with analytical instrumentation, you should know the potential hazards of

using chemical solvents.

Tips: Before initial operation of the flow manager, make sure that you are familiar

with the contents of this manual.

Observe any warning labels on the device and refer to the related sections in

these operating instructions.

For the general safety precautions in French, refer to Consignes Générales

de Sécurité (→ page 5).

Please observe the following general safety precautions when operating the instrument or

carrying out any maintenance work:

• Install the HPLC system in a well-ventilated laboratory. If the mobile phase includes

volatile or flammable solvents, do not allow them to enter the workspace.

• For minimum interference effects, all components of the analytical system should be

connected to the same mains output (same phase).

• The flow manager is primed with a mixture of isopropanol and water (20:80). During

initial operation of the flow manager, make sure that the used solvents used are miscible.

Otherwise, follow the appropriate intermediate steps.

• To prevent damage to the flow manager when lifting or moving, always lift the unit by the

bottom sides or sides. Lifting the flow manager by the bottom front or by the front panel

door may damage the door.

• The front panel tilts downward. Do not place any heavy objects on the open front panel

door. This may damage the door.

• Do not touch any metal parts inside the column chamber while the temperature set point is

> 50 °C (122 °F). Wait for the chamber to cool down, for example, before changing a

column or before performing any maintenance procedures.

• When operating the HPLC system, always set a lower pressure limit for the system pump.

This prevents damage resulting from leakage or from running the pump dry.

• When connecting the capillaries, make sure that the connectors are free from

contaminants. Even minute particles may cause damage to the flow splitter, flow control

valve, and column.

Operating Instructions Page 3

Page 10

UltiMate 3000 Series: Flow Managers and Column Thermostats

• Use only standard HPLC solvents (HPLC-grade: 0.2 µm filtered) and buffers that are

compatible with components in the flow path of the flow manager. Note the special

properties of the solvents such as viscosity, boiling point, UV absorption (UV/VIS

detector), and refractive index (refractive index detector).

Buffer concentration: typically up to 1 mol/L (0.1 mol/L if chloride ions are present).

• After operation, rinse out buffers and solutions that form peroxides from your HPLC

system.

• Before switching from buffer to organic solution, rinse the analytical system thoroughly

with deionized or HPLG-grade water.

• When switching to another solvent, ensure that the new solvent is miscible with the one

contained in the pump. Otherwise, the analytical system can be damaged; for example, by

flocculation.

• Avoid open flames and sparks, in particular if the mobile phase includes volatile or

flammable solvents.

• If a leak occurs, turn off the flow manager immediately, stop the pump flow, and remedy

the situation.

• When the front, side or rear panels are removed, dangerous electrical connections will be

exposed. Disconnect the flow manager from all power sources before removing the panels.

Remove panels only when instructed to do so in these instructions.

• Always replace blown fuses with the original spare fuses from Dionex (→ Replacing the

Fuses, page 73).

• Replace faulty power cords and communication cables.

• Many organic solvents and buffers are toxic. Know the toxicological properties of all

mobile phases that you are using.

• If the toxicological properties of a sample are unknown to you, treat it as if it contains a

potentially harmful substance.

• Wear goggles when handling mobile phases or operating the instrument. An eye wash

facility and a sink should be close to the unit. If any mobile phase splashes on the eyes or

skin, wash the affected areas with sufficient water and seek medical attention.

• Dispose of all waste mobile phase in an environmentally safe manner that is consistent

with all local regulations. Do not allow flammable and/or toxic solvents to accumulate.

Follow a regulated, approved waste disposal program. Never dispose of flammable and/or

toxic solvents through the municipal sewage system

Page 4 Operating Instructions

Page 11

UltiMate 3000 Series: Flow Managers and Column Thermostats

• In an UltiMate 3000 system, some tubing is made of PEEK. While this polymer has

superb chemical resistance to most organic solvents, it tends to swell when it is in contact

with trichlormethane (CHCl3), dimethyl sulfoxide (DMSO), or tetrahydrofuran (THF). In

addition, it is attacked by concentrated acids such as sulfuric acid and nitric acid (swelling

or attack by acid is not a problem with brief flushing procedures).

• Do not use PEEK tubing that is stressed, bent, or kinked.

• Wear goggles when handling fused silica tubing (e.g., during, installation and cutting).

• Before interrupting operation for several days or more, observe the precautions in Shutting

Down the Flow Manager (→ page 81).

• Use original Dionex spare parts only. Substituting non-Dionex parts or using non-Dionex

accessories may impair the performance of the instrument.

• Do not use the module in ways other than those described in this manual.

1.2.3 Consignes Générales de Sécurité

Veuillez noter: Avant de commencer à utiliser l'instrument, assurez-vous que vous

vous êtes familiarisés avec le contenu de ce manuel.

Observez les étiquettes d'avertissement sur l'appareil et référez-vous

aux sections correspondantes dans ce mode d'emploi.

Veuillez observer les consignes générales de sécurité suivantes lorsque vous utilisez

l'instrument ou que vous procédez à des opérations de maintenance:

• Installez le système HPLC dans un laboratoire bien ventilé. Si la phase mobile contient des

solvants volatils ou inflammables, empêchez qu'ils ne pénètrent dans l'espace de travail.

• Afin d'éviter au maximum les interférences, tous les éléments du système analytique

doivent être raccordés à la même ligne secteur (même phase).

• L'instrument est stocké sous isopropanol et eau. Au cours démarrage de l'instrument,

assurez-vous que les solvants utilisés soient miscibles. Sinon, suivez les étapes

intermédiaires appropriées.

• Lorsque vous soulevez ou l’instrument, tenez-le toujours par le dessous ou par les côtés de

l'unité. Soulever l’instrument par la partie avant inférieure ou par le panneau avant peut

endommager la porte.

• Ne placez aucun objet lourd sur la porte ouverte du panneau avant. Ceci pourrait

endommager la porte.

Operating Instructions Page 5

Page 12

UltiMate 3000 Series: Flow Managers and Column Thermostats

• Ne touchez à aucune partie en métal à l'intérieur du compartiment de colonne tant que le

point de réglage de température est > 50 °C (122 °F). Attendez que le four refroidisse, par

exemple, avant de changer une colonne ou avant de procéder à tous travaux de

maintenance.

• Réglez toujours une limite de pression minimum pour le système HPLC. Ceci prévient les

dommages résultant de fuites ou du fonctionnement à sec de la pompe.

• Lorsque vous connectez les capillaires, assurez-vous que les raccords sont exempts de tout

contaminant. Même d'infimes particules peuvent causer des dommages au système (ex.

diviseur de débit, vanne de régulation de débit et colonne).

• Utilisez uniquement des solvants HPLC (qualité HPLC : filtrés à 0.2 µm) et des sels

compatibles avec les composants des circuits hydrauliques de l’instrument. Vérifiez les

propriétés spécifiques des solvants telles que la viscosité, le point d'ébullition, l'absorption

UV (détecteur UV/VIS) et l’indice de réfraction (réfractomètre).

Concentration en sels: généralement inférieure à 1 mol/L (0.1 mol/L si présence d’ions

chlorure).

• Après utilisation, purgez le système des tampons et des susceptibles de former des

peroxydes.

• Lorsque vous passez d’une solution saline à un solvant organique, effectuez un rinçage

intermédiaire du système HPLC à l'eau dé-ionisée ou qualité HPLC.

• Lorsque vous passez à un autre solvant, assurez-vous que le nouveau solvant soit miscible

avec celui qui se trouve dans le système HPLC. Dans le cas contraire, le système HPLC

peut être endommagé; par exemple, par des floculations!

• Evitez les flammes nues et les sources d’étincelles à proximité, en particulier si la phase

mobile contient des solvants volatils ou inflammables.

• Si une fuite se produit, arrêtez immédiatement l’instrument, stoppez le débit de la pompe

et remédiez au problème.

• Quand les capots de protection de l’appareil sont démontés, vous êtes exposés à des

connexions électriques sous haute tension. Débranchez l'instrument de toute source

d'alimentation électrique avant de retirer les capots. Ne démontez les capots de protection

que si cela est explicitement demandé au cours de ces instructions.

• Remplacez toujours les fusibles grillés par des fusibles de rechange d'origine Dionex

(→ Replacing the Fuses, page 73).

• Remplacez les cordons d'alimentation électrique et les câbles de communication

défectueux.

• De nombreux solvants organiques et solutions salines sont toxiques. Informez-vous des

propriétés toxicologiques de toutes les phases mobiles que vous utilisez.

• Les propriétés toxicologiques de nombreux échantillons peuvent être mal connues. Au

moindre doute concernant un échantillon, traitez-le comme s'il contenait une substance

potentiellement dangereuse.

Page 6 Operating Instructions

Page 13

UltiMate 3000 Series: Flow Managers and Column Thermostats

• Portez des lunettes de protection lorsque vous manipulez des phases mobiles ou que vous

utilisez l'instrument. Une installation permettant de se laver les yeux ainsi qu'un lavabo

doivent se trouver à proximité du système. Si une phase mobile, quelle qu'elle soit, entre

en contact avec vos yeux ou votre peau, rincez abondamment la zone affectée à l’eau, puis

consultez un médecin.

• Débarrassez-vous de tous les déchets de phase mobile de manière écologique,

conformément à la règlementation en vigueur au niveau local. Empêchez impérativement

l'accumulation de solvants inflammables et/ou toxiques. Suivez un programme

d'élimination des déchets règlementé et approuvé. Ne jetez jamais de solvants

inflammables et/ou toxiques dans le système municipal d'évacuation des eaux usées.

• Dans un système UltiMate 3000, certains tubes sont en PEEK. Bien que ce polymère

présente une excellente résistance chimique à la plupart des solvants organiques, il a

tendance à gonfler lorsqu'il est en contact prolongé avec du chloroforme (CHCl3), du

diméthyle sulfoxyde (DMSO) ou du tétrahydrofurane (THF). De plus, il est attaqué par

des acides concentrés tels que l'acide sulfurique et l'acide nitrique (ces acides peuvent

cependant être utilisés dans le cadre de procédures de nettoyage, à condition que

l’exposition soit brève).

• N'utilisez pas de tubes PEEK écrasés, pliés ou abîmés.

• Portez des lunettes de protection lorsque vous manipulez des capillaires en silice fondue

(par example pendant l'installation ou découper).

• Avant d'interrompre le fonctionnement pendant plusieurs jours ou plus, observez les

précautions figurant en Shutting Down the Flow Manager (→ page 81).

• Utilisez des pièces de rechange d'origine Dionex. Effectuer des remplacements par des

pièces ne provenant pas de Dionex ou utiliser des accessoires ne provenant pas de Dionex

peut affecter les performances de l'instrument.

• N'utilisez pas l'instrument de manière autre que celles décrites dans ce manuel.

Operating Instructions Page 7

Page 14

UltiMate 3000 Series: Flow Managers and Column Thermostats

1.3 Intended Use

The flow manager is designed to perform equally well as a dependable system for routine

analyses or as a sophisticated research instrument for use in nano, capillary, and micro

HPLC (high performance liquid chromatography) applications, especially as part of the

UltiMate 3000 system. However, it can also be used with other HPLC systems if adequate

control inputs and outputs are available. A PC with USB port is required.

The flow manager is controlled by the Chromeleon Chromatography Management System.

Being part of the UltiMate 3000 system, the detector can also be operated with other data

systems, such as Analyst® (Applied Biosystems/MDS Sciex), Compass™/ HyStar™ (Bruker

Daltonics), or Xcalibur™ (Thermo Scientific). To do so, installation of the DCMS

Chromatography Mass Spectrometry Link) software is required in addition to the installion of

the data system.

Please note that the flow manager may only be operated with the accessories originally

supplied with the instrument (→ page 85) and within its technical specifications (→ page 83).

Link

(Dionex

Use only standard solvents and water of at least HPLC grade (0.2 µm filtered), or better LCMS grade and buffers that are compatible with components in the flow path of the flow

manager. If water from water purification systems that are not properly maintained is used,

polymeric contamination may seriously damage the column and may rapidly block solvent

filters. Note the special properties of the solvents such as viscosity, boiling point, UV

absorption (UV/VIS detector), and refractive index (refractive index detector).

Buffer concentration: typically up to 1 mol/L (0.1 mol/L if chloride ions are present).

If there is a question regarding appropriate usage, contact Dionex before proceeding.

Dionex is not liable for any damage, material or otherwise, resulting from inappropriate or

improper use of the instrument.

1.4 Federal Communications Commission (FCC) Note

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the U.S. FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference, in which case the user will be required to

correct the interference at his expense.

Page 8 Operating Instructions

Page 15

UltiMate 3000 Series: Flow Managers and Column Thermostats

2 Overview

2.1 Product Overview

The flow manager is a reliable module of the UltiMate 3000 system and performs equally

well as a dependable system for routine analyses or as a sophisticated research instrument

for nano, capillary, and micro HPLC applications. The design has been optimized for

minimum dead volume and maximum efficiency.

• The flow splitter (→ Fig. 1, page 11) delivers the low flow rates required for nano,

capillary, and micro HPLC applications. The flow manager is fitted with a flow splitter

identification system that allows you to store splitter-specific information on a chip card

and read it out whenever you want.

• An electronic splitter identification module (→ Splitter Identification System (Splitter ID),

page 59) automatically adapts the system settings to the used splitter cartridge. The

module also allows you to store splitter-specific information (split ratio, flow control

settings) on a chip card and read it out whenever you want. In addition, the parameters

required for flow splitting are set automatically.

• UltiFlow™ technology with active control of the splitter flow keeps the set flow rates

constant, independent of outside influences. Thus, the flow rate is not influenced by the

solvent composition, solvent gradients, different viscosities, or analyses at different

temperatures. In the same way, effects from column ageing and partial clogging will be

compensated.

• Thermoelectric elements heat or actively cool the column chamber and all internal

components to the desired temperature. Heat exchangers allow fast temperature changes

and ensure independence from the ambient temperature, even if the temperature set point

is below the ambient temperature.

• The flow manager allows compartment cooling by max. 15K from the ambient

temperature. The lower temperature limit is +5 °C (+41 °F).

• The columns can be warmed up to max. +85 °C (+185 °F). An increase in temperature

from 20 °C to 50 °C (68 °F to 122 °F) is realized in less than 25 minutes. This corresponds

to an average performance of 2-4 K per minute.

• Temperature control allows keeping the column temperature constant. If the ambient

temperature changes during the analysis, the increased heating or cooling ensures that the

column temperature remains constant. The maximum deviation is ± 0.1 °C.

• Several columns of different length (maximum length: 30 cm) can be installed in the

column chamber. An electronic column identification module allows GLP-compliant

documentation of the column type and all important column parameters (→ Column

Identification System (Column ID), page 58).

Operating Instructions Page 9

Page 16

UltiMate 3000 Series: Flow Managers and Column Thermostats

• Depending on the configuration, the flow manager is equipped with one or two column

switching valves (→ Supported Configurations, page 12), e.g., for applications that require

different columns at frequent intervals at similar temperatures.

• The flow manager is fully controlled by the Chromeleon Chromatography Management

System, providing a high degree of system integration.

• All surfaces in the column chamber are made of materials that provide maximum

resistance to the most commonly used HPLC solvents.

• The flow managers of the UltiMate 3000 system are available as biocompatible versions,

also. For information about the characteristics of the biocompatible devices, refer to

section 2.3.2 (→ page 13).

Page 10 Operating Instructions

Page 17

UltiMate 3000 Series: Flow Managers and Column Thermostats

r

Valve

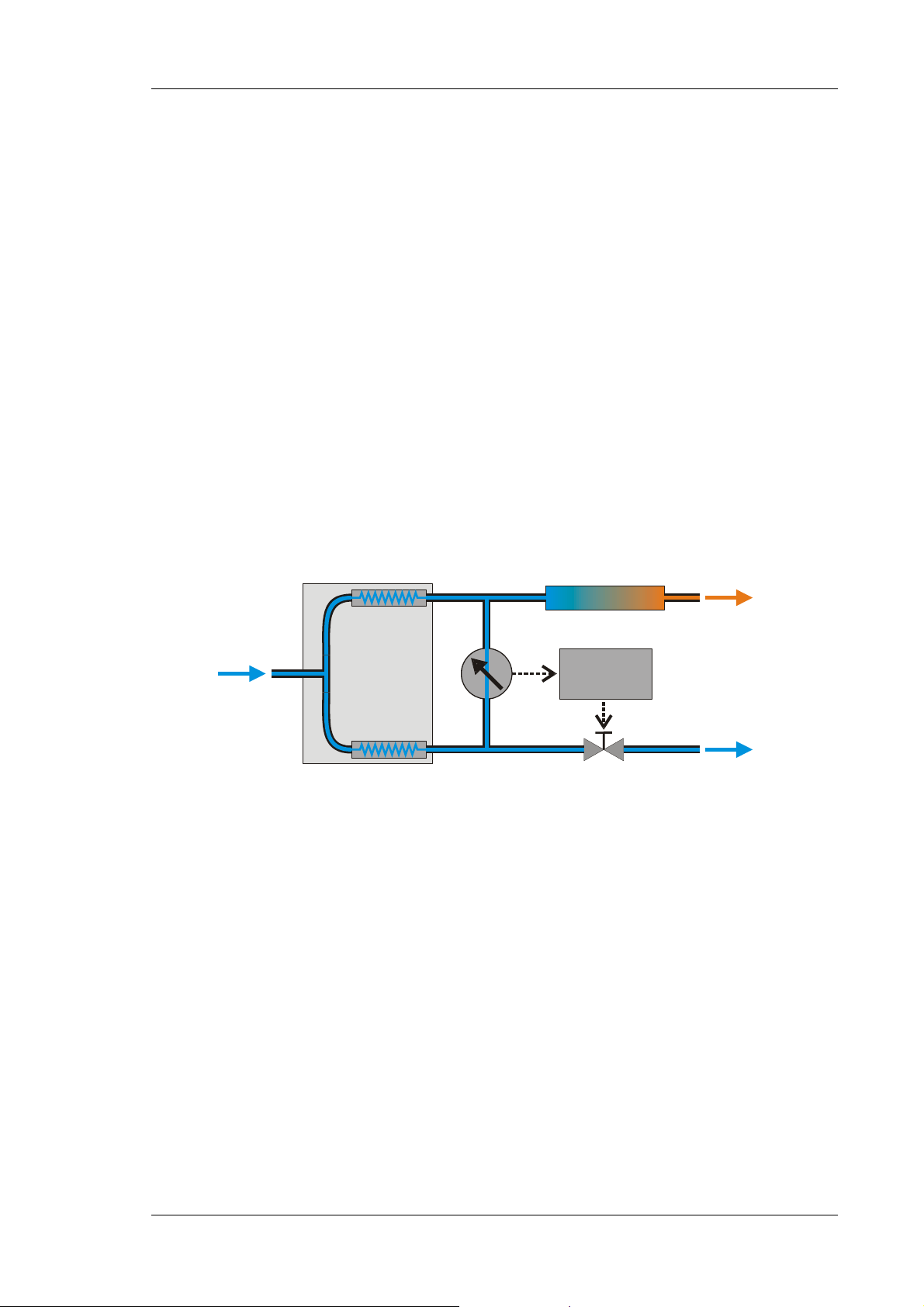

2.2 Theory of Operation (UltiFlow)

The fundamental requirement on a flow manager for liquid chromatography is the ability

to create constant low flow rates for nano, capillary, and micro HPLC applications, as well

as to equalize the temperature. The flow managers of the UltiMate 3000 system are fitted

with a flow splitter with integrated flow control that ensures constant flow rates, ranging

from micro liter to nano liter flows. The flow rate is influenced neither by varying column

backpressures nor by the temperature or solvent viscosity.

The flow splitter is equipped with two fluidic resistors that split the flow from the pump in

the reciprocal ratio of the resistance. To ensure identical pressure drop at both resistors, the

outputs of the flow splitter are connected via a cross arm with integrated flow meter. A

controller adjusts the unbalance flow to a very low offset value near zero to flush the cross

arm with fresh solvent permanently. To ensure this, the waste path includes an adjustable

valve that adjusts in dependence of the column pressure (→ Fig. 1).

This innovative method creates constant low flow rates based on the split ratio and the pump

flow. Different lowest flow rates are created by different pump flow rates, but they are always

split according to the split ratio. This is independent of the solvent composition and the

column pressure.

Column

Control

Detecto

Waste

Pump

Flow splitter

Flow meter

1:100

Fig. 1: Operation principle of flow splitting with control

For temperature equalization, temperature stability is more important than the absolute

precision of the setting. The flow manager contains advanced electronic circuits that can

maintain the selected temperature with a precision of ±0.1 °C.

The thermo-optimized design reduces the time required to equilibrate the temperature between

the column and the solvent. The Peltier elements of the flow manager heat up and cool down

the columns. The heat exchanger inside the column chamber also helps to bring the air and all

components in the chamber to the desired temperature, including the flow splitter and column

switching valve(s).

Operating Instructions Page 11

Page 18

UltiMate 3000 Series: Flow Managers and Column Thermostats

These procedures ensure that

• The temperature of the stationary phase remains constant over the total column length.

• The column and the solvent have the same temperature during the analysis.

In this way, analytical separation is performed at the nominal temperature, thus, minimizing

fronting and tailing as well as retention time variations.

2.3 Supported Configurations

2.3.1 General

For an overview of the currently available models, refer to the list below. If you have any

questions, do not hesitate to contact your Dionex sales representative or distributor.

Application Description Part No.

FLM-3100 with two 10-port micro switching valves 5720.0010

Nano HPLC

Capillary

and/or

Monolithic

HPLC

Micro HPLC

FLM-3100B, same as FLM-3100, but biocompatible version 5721.0010

FLM-3200 with 10-port micro and 6-port nano switching valves (1 each) 5720.0020

FLM-3200B, same as FLM-3200, but biocompatible version 5721.0020

FLM-3300 with one 10-port micro switching valve 5720.0030

FLM-3300B, same as FLM-3300, but biocompatible version 5721.0030

Tip: These flow managers are fitted with a splitter cartridge

for a split ratio of 1:1000.

FLM-3100 with two 10-port micro switching valves 5720.0015

FLM-3100B, same as FLM-3100, but biocompatible version 5721.0015

FLM-3200 with 10-port micro and 6-port nano switching valves (1 each) 5720.0025

FLM-3200B, same as FLM-3200, but biocompatible version 5721.0025

FLM-3300 with one 10-port micro switching valve 5720.0035

FLM-3300B, same as FLM-3300, but biocompatible version 5721.0035

Tip: These flow managers are fitted with a splitter cartridge

for a split ratio of 1:100.

FLM-3100 with two 10-port micro switching valves 5720.0018

FLM-3100B, same as FLM-3100, but biocompatible version 5721.0018

FLM-3200 with 10-port micro and 6-port nano switching valves (1 each) 5720.0028

FLM-3200B, same as FLM-3200, but biocompatible version 5721.0028

FLM-3300 with one 10-port micro switching valve 5720.0038

FLM-3300B, same as FLM-3300, but biocompatible version 5721.0038

Tip: These flow managers are fitted with a splitter cartridge

for a split ratio of 1:6.

Page 12 Operating Instructions

Page 19

UltiMate 3000 Series: Flow Managers and Column Thermostats

Tip: All flow managers are equipped with a flow splitter. When the flow

manager is operated with Chromeleon, systems for column and/or splitter

identification are supported (→ sections 5.5, page 58 and 5.6, page 59).

For information about how to replace a cartridge, refer to section 7.6 (→ page 76).

For information about the switching valve, refer to section 2.5 (→ page 18).

If you have any questions, do not hesitate to contact your Dionex sales representative or

distributor.

2.3.2 Biocompatible Flow Managers

The FLM-3100B, FLM-3200B, and FLM-3300B flow managers extend UltiMate 3000

flow manager series by biocompatible device versions. Except for the flow splitter parts

that are exposed to solvent and the switching valve(s) with the connected components, the

biocompatible flow managers are identical to the standard devices (stainless steel).

Therefore, almost all descriptions of the standard devices apply to the biocompatible

versions, also. If some detail applies to only one version, the version will be identified. The

differences are as follows:

Switching valve

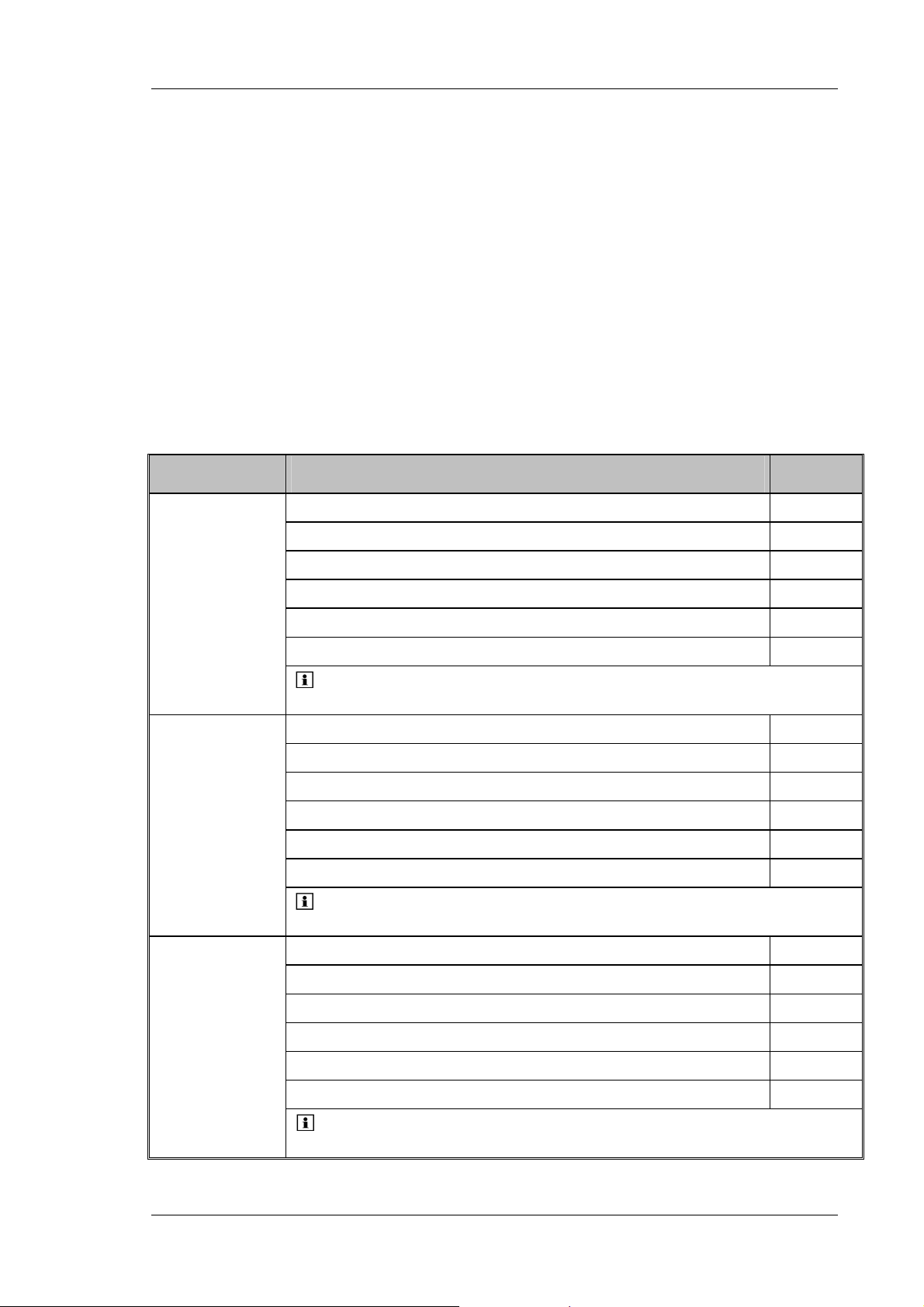

The biocompatible flow managers are fitted with PAEK switching valves. As PAEK valves

have deeper connection ports (→ Fig. 2), preassembled fitting connections (see below) must

be used. This is essential for a zero dead volume connection.

Fitting not

preassembled correctly

Switching valve

Fitting

preassembled correctly

Fig. 2: Capillary connection on the switching valve

Important: Do not use a stainless steel nut and/or ferrule to connect the

components to the PAEK valve. To avoid damage to the valve, use only

the supplied capillaries and fittings, as well as original Dionex spare

parts.

Important: N’utilisez jamais de vis et/ou ferrules métalliques pour les connexions

sur une vanne biocompatible en PAEK. Afin d’éviter tout dommage à

la vanne, utilisez seulement les capillaires et raccords fournis, ainsi que

des pièces d’origine Dionex.

Operating Instructions Page 13

Page 20

UltiMate 3000 Series: Flow Managers and Column Thermostats

Follow the steps below to connect the components to the biocompatible switching valve.

The description refers to the connection of a nano column, but applies to the other

components, as well.

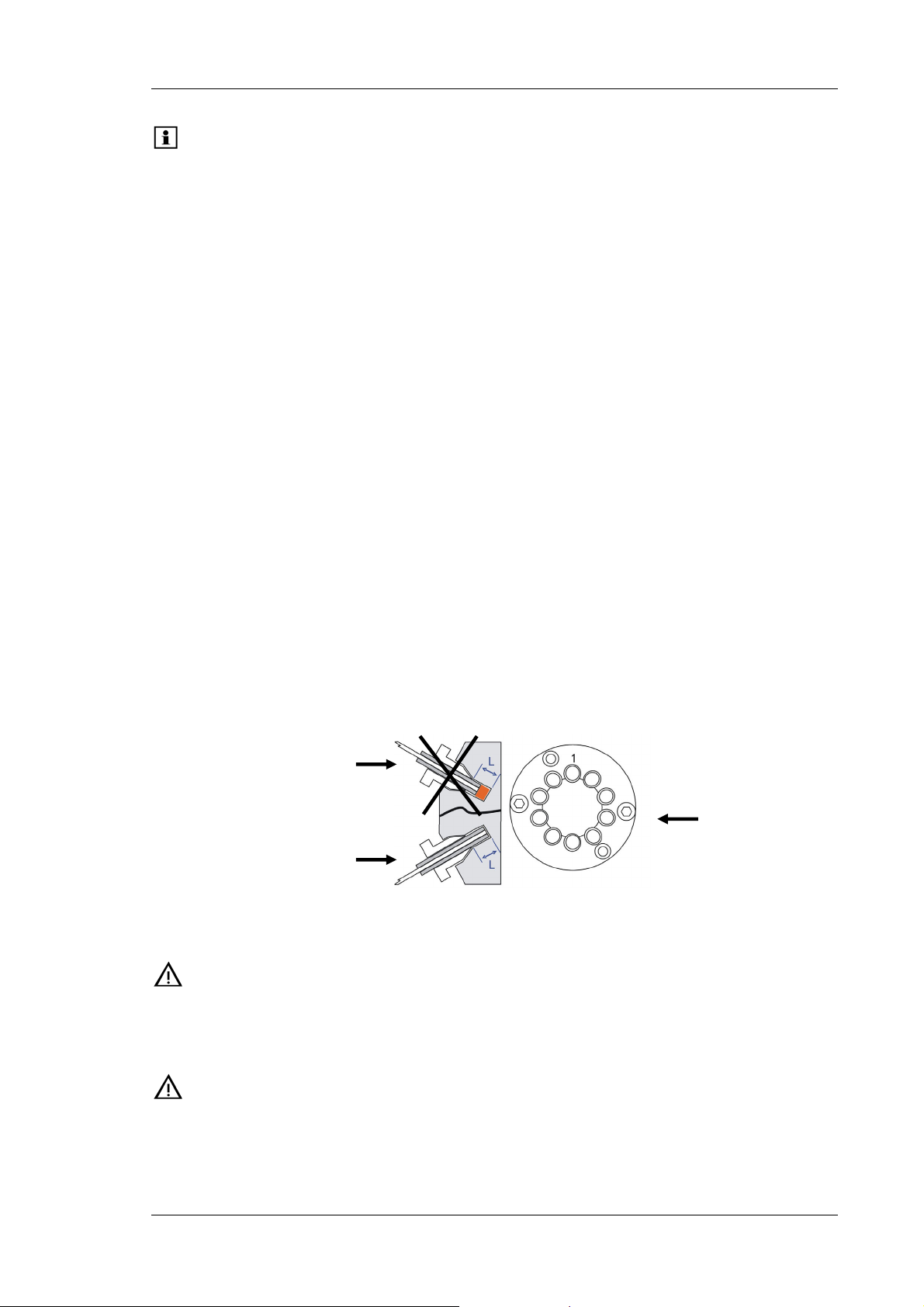

1. To establish a zero dead volume fitting connection between the column and the

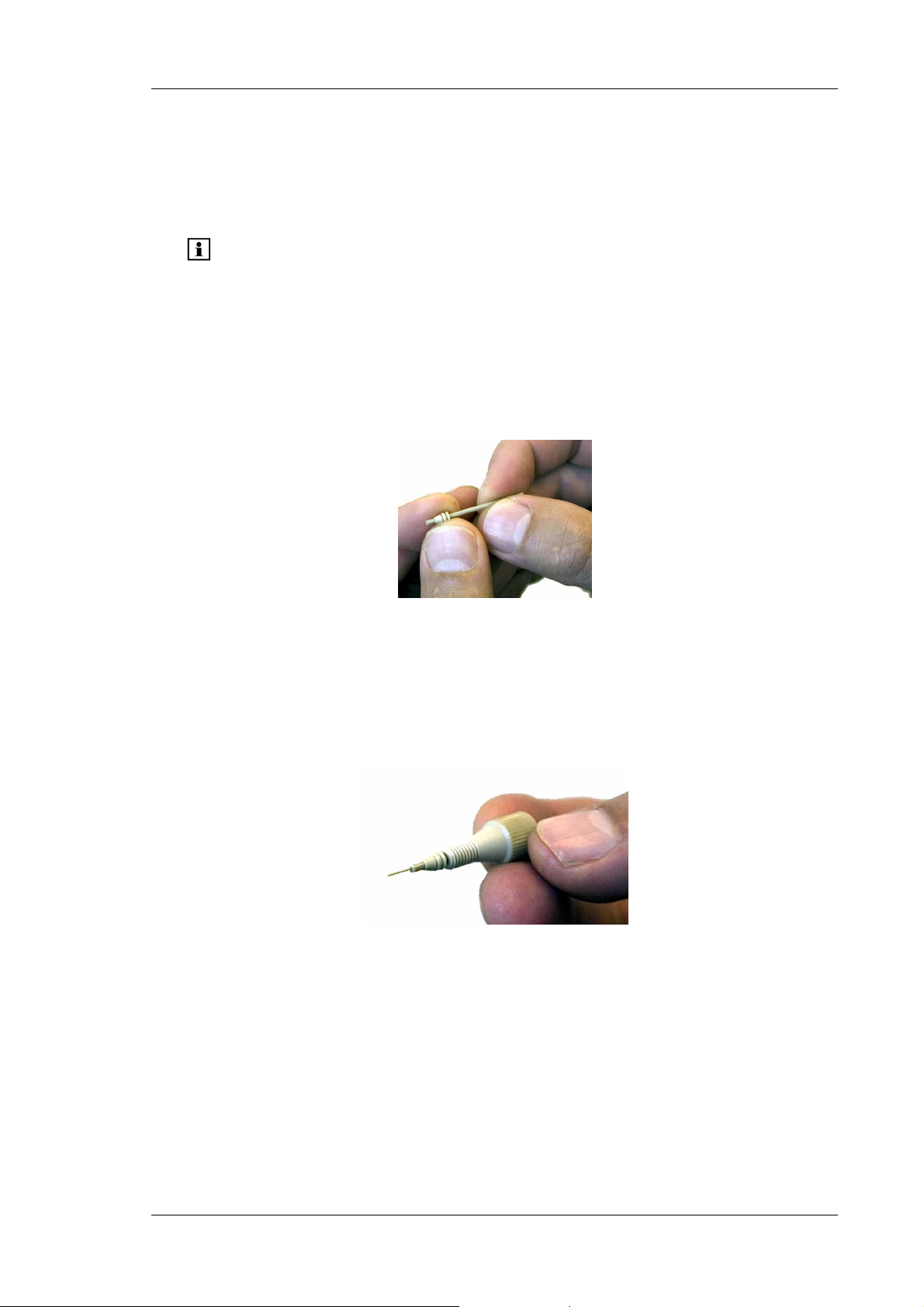

switching valve, a finger-tight nut, ferrule, and sleeve are required. Slide the fingertight nut and the ferrule onto the sleeve as shown in Fig. 3.

Column

Sleeve Finger-tight nut Ferrule

Fig. 3: Fitting connection

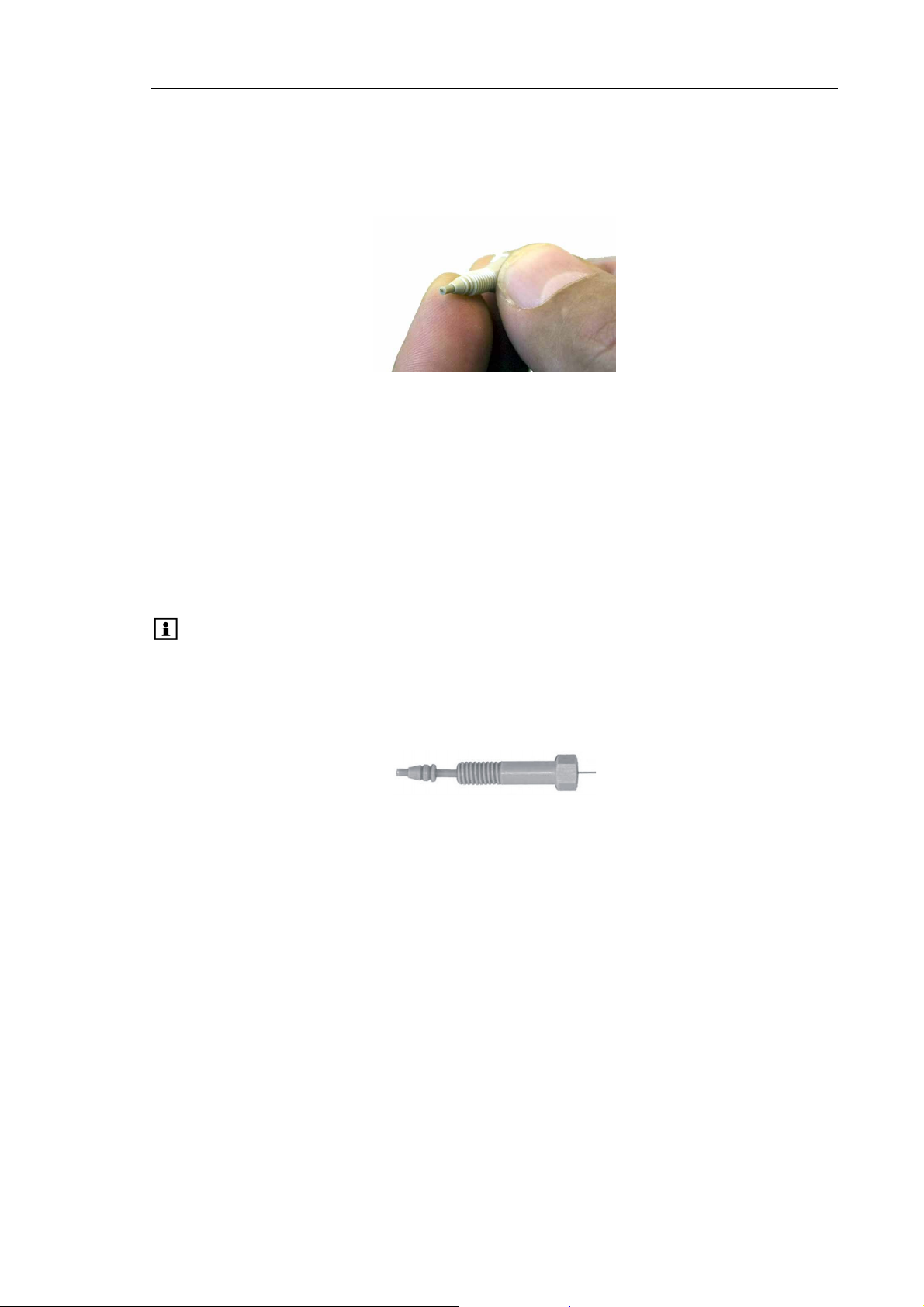

2. Insert the sleeve with the nut and the finger-tight nut in a port on the preassembly tool

(part no. 6000.0065) and tighten the nut by two or three manual turns. (The

preassembly tool is included in the application kits for the biocompatible UltiMate

3000 system.)

Fig. 4: Preassembly tool

Important: To avoid damage to the biocompatible switching valve, neither

preassemble the fitting connection on the switching valve nor use

any tool to tighten the finger-tight nut.

Important: Afin d’éviter tout dommage à la vanne d’injection biocompatible,

ne l’utilisez jamais pour le pré-sertissage des raccords, et n’utilisez

aucun outil pour visser les raccords à serrage manuel.

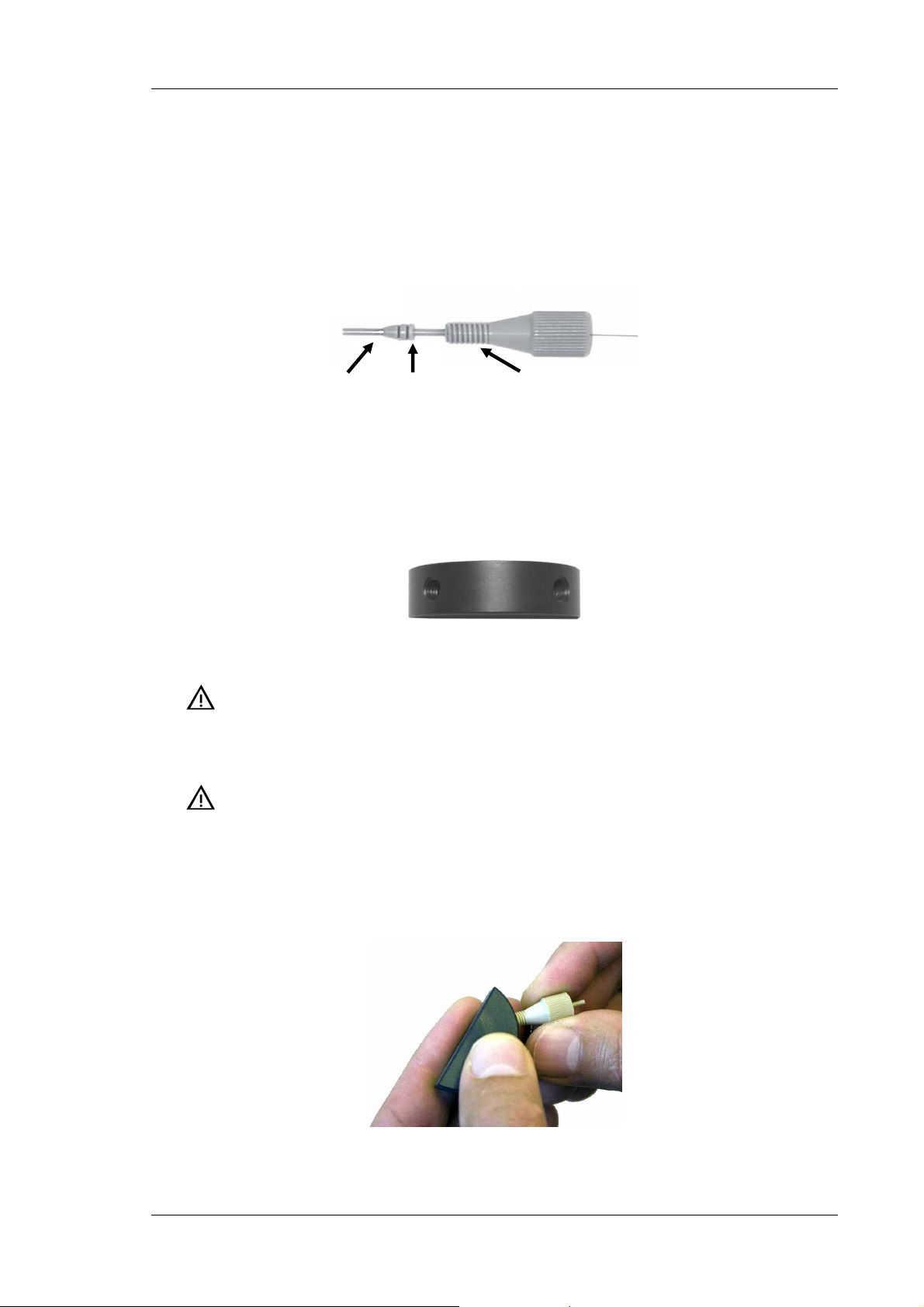

3. Push the sleeve all the way into the port. It is essential for a zero dead volume

connection that the assembly seats firmly.

Fig. 5: Preassembling the fitting connection

Page 14 Operating Instructions

Page 21

UltiMate 3000 Series: Flow Managers and Column Thermostats

4. Tighten the nut in the port until it is finger tight.

5. Carefully turn the nut an additional 1/4 turn (90°) past the point at which the ferrule

starts to grab the sleeve.

Tip: Dionex cannot provide a torque specification because the force

required to tighten the nut can vary due to the friction between nut

and the thread, as well as the composition and wall thickness of the

component to be connected.

6. Remove the preassembled fitting from the tool and inspect the fitting. When you

gently pull the ferrule, you should not be able to move the ferrule on the sleeve. If the

ferrule sleeve moves laterally (→ Fig. 6), re-insert the fitting all the way into the

preassembly tool and tighten it an additional 1/8 turn past finger-tight.

Fig. 6: Inspecting the fitting

7. Remove and re-inspect the fitting. Repeat the previous step if necessary.

8. Insert the column (or the fused silica capillary) all the way through the sleeve until it

extends the sleeve (→ Fig. 7).

Fig. 7: Inserting the column

Operating Instructions Page 15

Page 22

UltiMate 3000 Series: Flow Managers and Column Thermostats

9. Pull the column back (→ Fig. 8) and install the preassembled fitting with the column

to the appropriate port on the switching valve. Make certain that the column does not

extend the sleeve when installing it into the port

Fig. 8: Pulling the column back

10. Tighten the nut finger-tight. To avoid the formation of dead volumes, make certain

that the column inlet enters all the way to the bottom of the valve port (e.g. push the

column into the valve).

11. Tighten the nut additional 1/4 turn past finger-tight.

12. Start flow delivery and check for leakage. In case of any leakage, stop flow delivery

and remove the fitting. Repeat steps 8 till 11.

Tip: If you cannot use finger-tight fittings due to limited space, you may use the

long hex style nuts, instead (→ Fig. 9; part no. 6721.0017; the nuts are

included in the application kits for the biocompatible UltiMate 3000 system,

also). Follow the above steps and then connect the hex nut to the

appropriate port on the switching valve. Tighten the nut with a ¼" wrench.

Fig. 9: Long hex style nut

Page 16 Operating Instructions

Page 23

UltiMate 3000 Series: Flow Managers and Column Thermostats

2.4 General Flow Manager Design

7

7

5 5 6

5 5 6

1 2 3 4

1 2 3 4

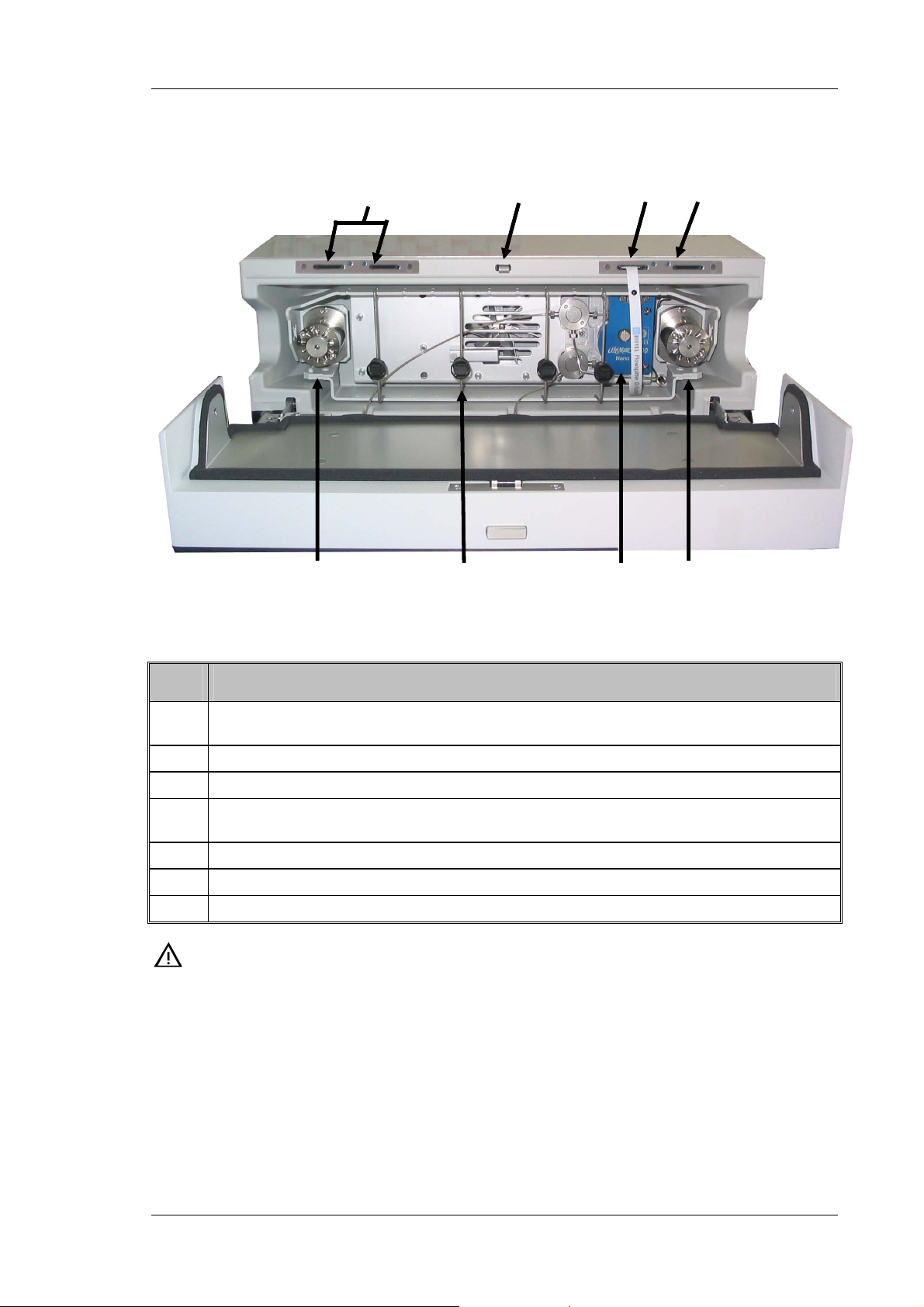

Fig. 10: Open FLM-3100 (here: with two 2-position/10-port switching valves)

No. Description

1 Switching valve (2-position/10-port micro switching valve)

(in Chromeleon: ValveLeft or MsvPosition, depending on the device type)

2

Column bracket with column clip (→ section 3.6.1, page 31)

3

Flow splitter (→ section 7.6, page 76)

4 Switching valve (if installed: 2-position/10-port micro valve or 2-position/6-port nano valve)

(in Chromeleon: ValveRight)

5

Slots for the column ID chip cards (→ section 5.5, page 58)

6

Slot for the flow splitter chip card (→ section 5.6, page 59)

7

Locking mechanism for the front panel door (→ section 3.5, page 28)

Important: Use only the capillaries shipped with the flow manager and original

spare capillaries from Dionex. Install the capillaries and fittings only at

the positions for which they are intended.

Reuse used fittings and ferrules only for the same capillary connection.

This is to avoid increased dead volume.

To connect the capillaries to the switching valve, install only the

ferrules and fitting screws provided in the accessories kit.

Operating Instructions Page 17

Page 24

UltiMate 3000 Series: Flow Managers and Column Thermostats

Important: Utilisez uniquement les capillaires fournis avec l'instrument et les

capillaires de rechange d'origine Dionex. Installez les capillaires et les

raccords uniquement dans les positions pour lesquelles ils sont prévus.

La réutilisation des raccords et ferrules n’est possible que pour la

connexion capillaire d’origine, afin d’éviter l’apparition de volumes

morts.

Pour brancher les capillaires à une vanne d'injection, installez

uniquement les ferrules et les raccords livrés avec la vanne et respectez

les instructions d'installation du fabricant.

2.5 Column Switching Valve

Depending on the instrument configuration, the flow manager is equipped with one or two

switching valves (2-position/10-port micro and/or 2-position/6-port nano valves), e.g., for

applications that require different columns at frequent intervals at similar temperatures.

The switching valve automatically selects the column to be used. The valve is installed in the

column chamber and is brought to the temperature equilibrium as well. The valve positions are

programmed and controlled in Chromeleon. (For details, refer to the Chromeleon online

Help.)

For information about how to connect the capillaries to the valve, refer to Connecting the

Capillaries to the Column Switching Valve (→ page 35).

For more information about the valve, refer to the technical appendix (→ page 91).

Page 18 Operating Instructions

Page 25

UltiMate 3000 Series: Flow Managers and Column Thermostats

2.6 Flow Splitter

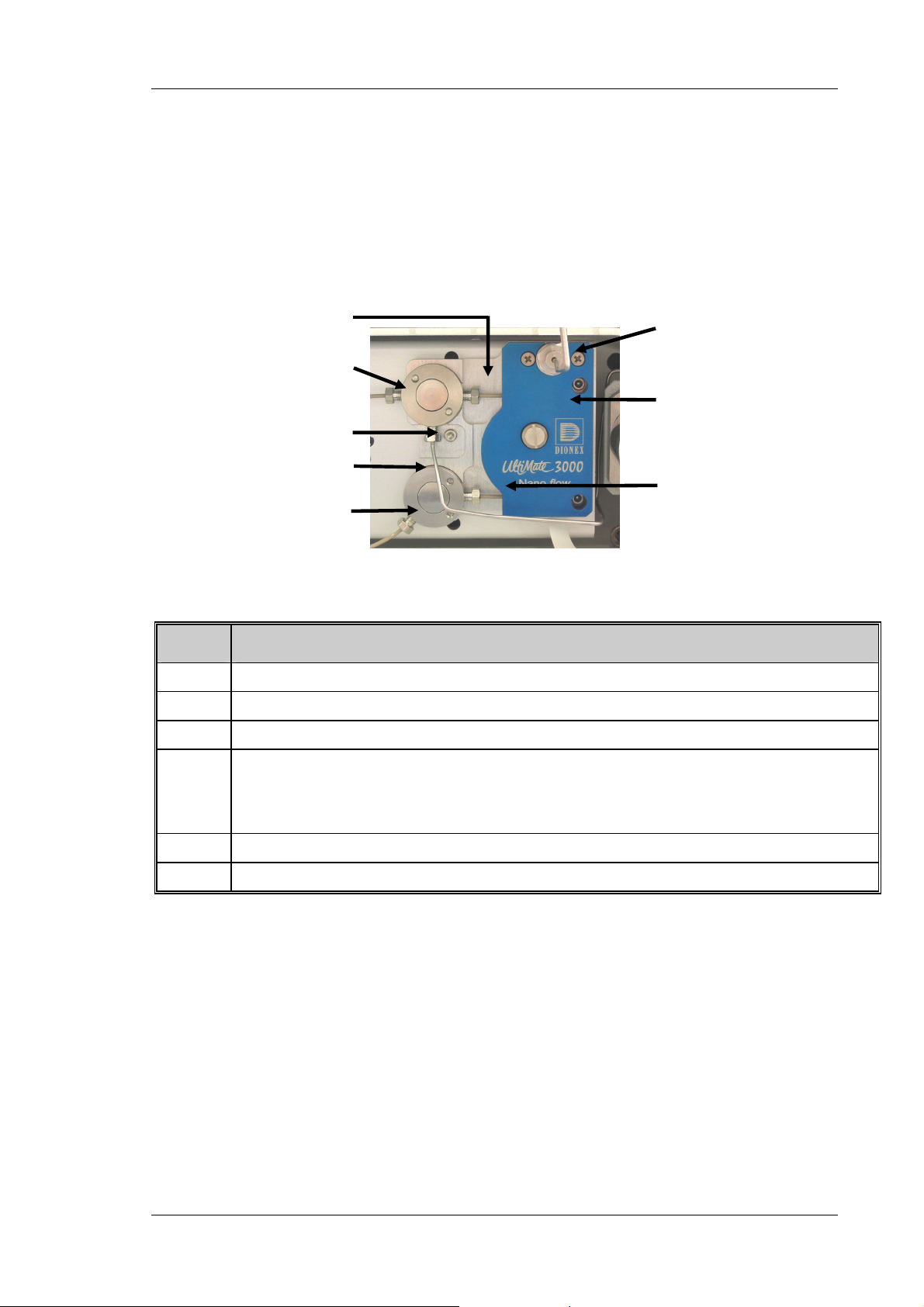

The flow manager is equipped with a flow splitter (→ Fig. 11) that delivers the low flow

rates required for nano, capillary, and micro HPLC applications. Splitter cartridges with

different split ratios are available for the different applications.

For information about the cartridge types and installation details, refer to section 7.6

(→ page 76).

1

2

3

4

2

6

5

1

Fig. 11: Flow Splitter

No. Description

1 Splitter cartridge outlets

2 Flow sensor connectors

3 Flow control valve connector

4 Capillary connector, depending on your application. (The nano (capillary or micro) flow set in

Chromeleon is output here.)

For the application shown in Fig. 24 (→ page 35), connect the capillary to the flow manager's

right switching valve (port 4).

5 Splitter cartridge

6 Pump connector

Operating Instructions Page 19

Page 26

UltiMate 3000 Series: Flow Managers and Column Thermostats

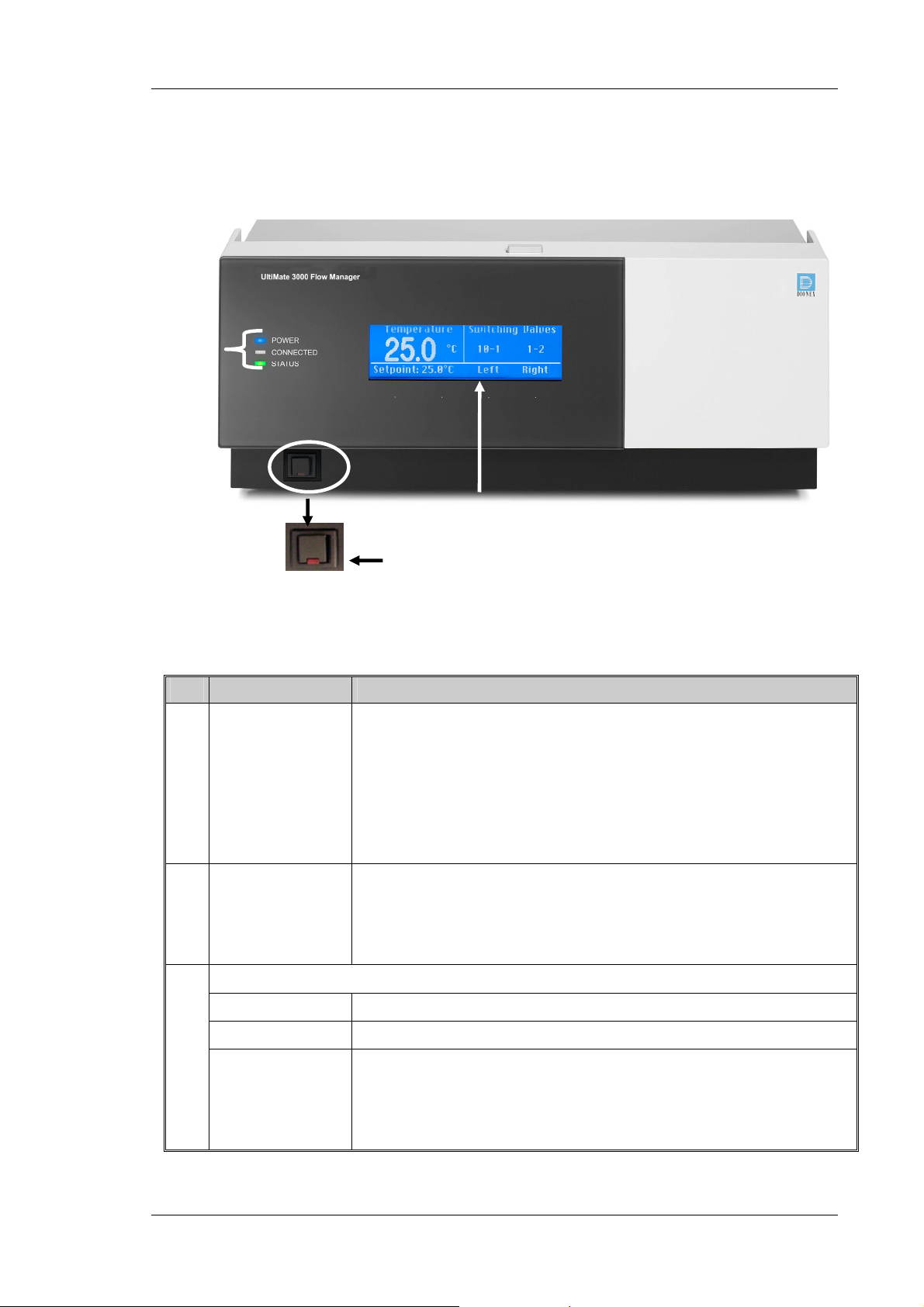

2.7 Front Panel Display and Controls

3

1

2

Fig. 12: Front panel

No. Front Panel Element Description

1 Display Shows information about the flow manager, e.g.:

- General information upon power-up (→ section 4.1, page 41)

- Status screen (→ section 4.2, page 41)

- Various functions and menus that can be accessed via soft keys

(→ section 4.3, page 42)

- Error messages (→ section 6, page 61)

2 Standby button Switches the flow manager to Standby mode (the LED is lighted).

To cancel Standby mode and resume operation, press the Standby button

again (the LED is not lighted).

Note: To allow the flow manager to change the mode, press the Standby

button for at least 1 second.

3

LEDs

Power The LED is blue when the flow manager is on.

Connected The LED is green when the flow manager is controlled by Chromeleon.

Status The LED is green when the flow manager has reached the target temperature

and no error has been detected.

The LED is orange when the flow manager has not yet reached the target

temperature or when the door is open.

The LED is red when an error has been detected, e.g., a leak.

Page 20 Operating Instructions

Page 27

UltiMate 3000 Series: Flow Managers and Column Thermostats

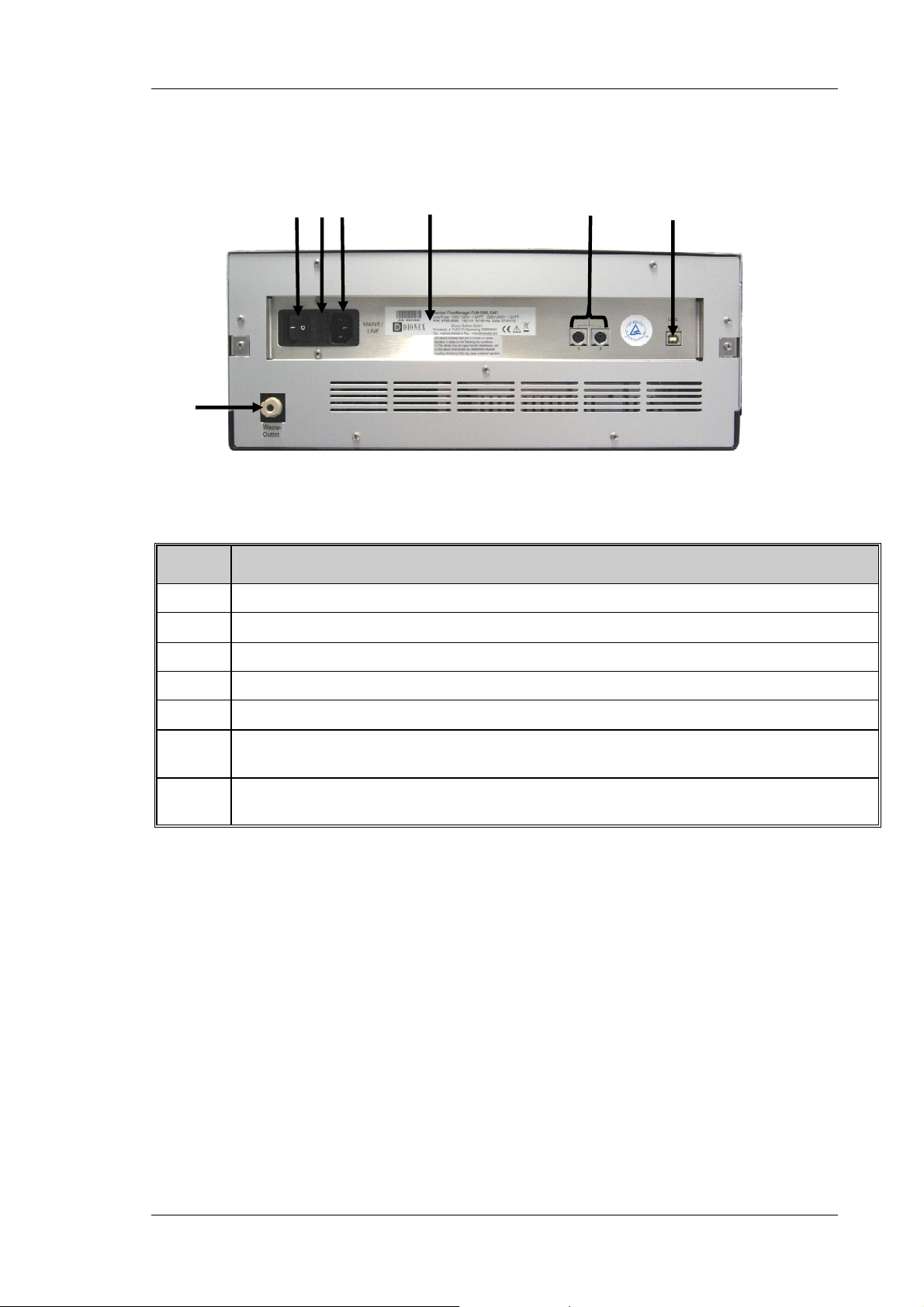

2.8 Rear Panel Connectors

1

3

2

4

7

Fig. 13: Rear panel connectors

No. Description

1 Power switch

2

Fuse holder (→ section 7.3, page 72)

6 5

3 Main power receptacle

4 Type label

5

6 USB (Universal Serial Bus Interface) port for connection to the server PC

7 Waste port for directing any liquid from the waste path of the flow splitter to an appropriate waste

Digital I/O for communication with external devices (→ section 3.4.3, page 28)

(→ section 3.4.1, page 27)

container, page 30)

Operating Instructions Page 21

Page 28

UltiMate 3000 Series: Flow Managers and Column Thermostats

2.9 Leak Sensors

The flow manager contains two leak sensors to detect any humidity or gases that may

accumulate in the column chamber. When a certain humidity or gas concentration is

reached in the chamber (while the door is closed), the corresponding sensor is activated.

Eliminate the cause for the leakage, wearing the appropriate protective clothing, and

ventilate the inside before closing the door.

In addition, the flow manager contains a fluid leak sensor to detect liquid leaks from the flow

control valve in the enclosure. The fluid leak sensor is installed in the rear of the enclosure (in

a tray on the right). When liquid is detected in tray, e.g., due to clogging of the waste outlet

(→ Fig. 18, page 30), the sensor is activated. Eliminate the cause for the leakage and dry the

sensor as described in section 7.5 (→ page 74).

On the Control > Leak control display menu (→ page 46), set the sensitivity for the sensors

and determine whether an acoustic beep shall alert you in case of an alarm. (You can open the

Leak control display menu also via the Leak soft key (→ page 42).)

If one of the sensors detects a leak, the Status LED on the instrument's front panel is red and

the related error message appears on the front panel display.

Tips: The Status LED remains red as long as the sensor is exposed to humidity,

gas, or moisture. The Clear soft key on the navigation bar (→ page 45)

allows you to remove the error message from the front panel display.

If a beep alerts you, you can turn off the beep for the current alarm from the

Control > Leak control display menu by setting All leak alarms to silent. If

the humidity or gas sensor was activated, you can turn off the alarm also by

opening the front panel door. Beeping stops in any case when the cause for the

leakage has been eliminated. A new beep sounds when one of the sensors is

activated again.

If the flow manager is operated by Chromeleon, you can also determine the

leak sensor mode in Chromeleon. If a sensor is activated, the related error

message appears on the front panel display and the error is logged in the

Chromeleon audit trail.

Inspect the flow manager for leaks every day. Tighten or replace leaking

capillary connections if necessary.

Page 22 Operating Instructions

Page 29

UltiMate 3000 Series: Flow Managers and Column Thermostats

2.10 System Wellness

The flow manager supports several system wellness and reliability features that can help

you detect small problems before they turn into big ones:

• Leak detector (→ page 21)

• Door status monitoring

• Column ID features for a GLP-compliant documentation of the column status

(→ Column Identification System (Column ID), page 58)

• Flow splitter ID for the documentation of the splitter type and characteristics

(→ Splitter Identification System (Splitter ID), page 59)

Tip: If the flow manager is operated by Chromeleon, the system wellness features

are also available in Chromeleon (→ Diagnostics, page 60).

If an error is found, the Status LED on the front panel is red and an error message appears

on the front panel display (→ Troubleshooting, page 61). If the flow manager is operated

by Chromeleon, the error is also logged in the Chromeleon Audit Trail.

Operating Instructions Page 23

Page 30

UltiMate 3000 Series: Flow Managers and Column Thermostats

Page 24 Operating Instructions

Page 31

UltiMate 3000 Series: Flow Managers and Column Thermostats

3 Installation

3.1 Facility Requirements

• Make sure that the installation site meets the power and environmental specifications

listed in the Technical Information section (→ page 83).

• Install the instrument in the laboratory on a stable surface that is free of vibrations.

• Make sure that the surface is resistant to solvents.

• Avoid locations with extreme changes in temperature (such as direct sunlight or drafts)

and high humidity.

• Allow sufficient clearance behind and to the sides of the flow manager for power

connections and ventilation. Do not place any objects between the flow manager and the

device located under the it in the system stack.

3.2 Unpacking

All electrical and mechanical components of the flow manager are carefully tested before

the instrument is shipped from the factory. After unpacking, please inspect the module for

any signs of mechanical damage that may have occurred during transit.

Tips: Immediately report any shipping damage to both the incoming carrier and

Dionex. Shipping insurance will compensate for the damage only if reported

immediately.

Keep the original shipping container and packing material. They provide

excellent protection for the flow manager in case of future transit. Shipping the

instrument in any other packaging automatically voids the product warranty.

1. Place the shipping container on the floor. Remove the accessories kit and power cord.

2. Grasp the flow manager by the sides. Slowly and carefully, pull the instrument out of

the shipping container and place it on a stable surface.

Important: To prevent the flow manager from falling, only lift by the bottom

sides. Do not lift the unit by the packaging material or the front

panel door. When lifting or moving the flow manager, always lift it

by the bottom or sides of the unit.

Important: Afin d'empêcher l'instrument de tomber, saisissez-la par les côtés.

Ne soulevez l'instrument à l’aide du matériau d'emballage ou par la

porte du panneau avant. Lorsque vous soulevez ou déplacez

l'instrument, soulevez toujours par le bas ou les côtés.

3. Remove the foam inserts.

Operating Instructions Page 25

Page 32

UltiMate 3000 Series: Flow Managers and Column Thermostats

ger

r

4. Before connecting the flow manager to the power supply, wait approximately 4 hours

to allow the instrument to come to room temperature and to allow any condensation

that might have occurred during shipping to evaporate. After 4 hours, check the flow

manager; if condensation still exists, allow the flow manager to continue to warm up

(without connecting it to the power source) until the condensation is completely gone.

3.3 Positioning the Flow Manager in the UltiMate 3000 System

As the flow manager is part of an UltiMate 3000 system, Dionex recommends that you stack

the individual modules, for example, as shown in Fig. 14. However, the arrangement of the

system modules depends on the application. The UltiMate 3000 Proteomics MDLC system

manual in this manual binder provides more application examples and information about how

to arrange and/or connect the modules for these applications.

Solvent Rack

Detecto

Flow Mana

Autosampler

Pump

Fig. 14: Example for an UltiMate 3000 system

Page 26 Operating Instructions

Page 33

UltiMate 3000 Series: Flow Managers and Column Thermostats

3.4 Connecting the Flow Manager

3.4.1 USB

The Chromeleon Chromatography Management System can use a USB connection to

control the flow manager. Data is transferred digitally via the appropriate USB cable (part

no. 6911.0002, USB extension cable, part no. 6000.1005). To ensure trouble-free

operation, all USB cables (see above) should be ordered from Dionex.

Tip: If you want to operate the flow manager with Chromeleon, install the

Chromeleon software before connecting the flow manager to the USB port on

the Chromeleon server PC. When you install the Chromeleon software first, the

USB driver for the flow manager is automatically loaded and the Windows

operating system can detect the flow manager when the power is turned on.

Connect the flow manager to the server PC via the USB ports on the rear panel (→ Fig. 13,

page 21). To do so, select one of the following alternatives:

• Connect the flow manager directly to the USB port on the server PC.

• Connect the flow manager to the server PC via another UltiMate 3000 instrument that is

already connected to the server PC.

• Connect the flow manager to server PC via an external USB hub.

Tip: The USB standard limits the USB cable length to 5 meters. Each USB

device can be separated from the PC or next USB hub by no more than

5 meters.

Important: Dionex recommends using these USB ports for connections to Dionex

instruments only. Dionex cannot guarantee correct functioning if

instruments from other manufacturers are connected.

Important: Dionex recommande d'utiliser les ports USB uniquement pour les

raccordements aux instruments Dionex. Dionex ne peut garantir le bon

fonctionnement si les instruments d'autres fabricants sont raccordés.

3.4.2 Power Connection

Use the power cord shipped with the flow manager to connect the instrument to the main

power source. Connect the power cord from the main power receptacle on the rear panel to

the power source that is connected to a true ground. No adjustment is required to adapt the

line voltage to local voltage requirements.

Operating Instructions Page 27

Page 34

UltiMate 3000 Series: Flow Managers and Column Thermostats

3.4.3 Digital I/O

The two 6-pin Mini-DIN (→ Fig. 13, no. 5) ports can be used in Chromeleon to exchange

digital signals with external instruments. The accessories kit includes a 6-core Mini-DIN

signal cable (part no. 6000.1004). For information about the port and pin assignment, refer

to the technical appendix (→ page 91).

3.5 Opening the Front Panel Door

The front panel tilts downward to provide easy access to the components in the column

chamber. Tilting down the front panel automatically moves the valves and the column

carrier approximately 3.5 cm out of the enclosure, thus facilitating capillary connection.

To open the front panel door, press the release button on top of the enclosure. If the door lock

is not released immediately, press the front panel against the enclosure.

If necessary, press

here against the

Press the release

button.

Locking mechanism for the front panel door

Fig. 15: Tilting the front panel downward

To close the column chamber, tilt the front panel upward until you hear the locking

mechanism engage.

Important: When lifting or moving the flow manager, always lift the unit by the

bottom sides or the sides. Lifting the flow manager by the bottom front

or by the front panel may damage the door.

Do not place any heavy objects on the open front panel door. This may

damage the door.

Important: Lorsque vous soulevez ou l’instrument, tenez-le toujours par le dessous

ou par les côtés de l'unité. Soulever l’instrument par la partie avant

inférieure ou par le panneau avant peut endommager la porte.

Ne placez aucun objet lourd sur la porte ouverte du panneau avant. Ceci

pourrait endommager la porte.

Page 28 Operating Instructions

Page 35

UltiMate 3000 Series: Flow Managers and Column Thermostats

3.6 Preparing the Flow Manager

Important: The flow manager is filled with a mixture of isopropanol and water

(20:80) when being shipped from the factory. During initial operation,

make sure that the solvents used are miscible. Otherwise, use an

appropriate intermediate solvent.

When you operate a biocompatible flow manager, observe the

instructions for connecting the capillaries to the switching valve and/or

flow splitter (→ Biocompatible Flow Managers, page 13).

Important: L'instrument est stocké sous isopropanol et eau. Au cours démarrage de

l'instrument, assurez-vous que les solvants utilisés soient miscibles.

Sinon, suivez les étapes intermédiaires appropriées.

Afin de raccorder les capillaires à la vanne d'injection ou au diviseur de

débit biocompatible, veuillez respecter les instructions d'installation

(→ Biocompatible Flow Managers, page 13).

After you have unpacked, positioned and connected the flow manager as described in

sections 3.1 through 3.4, follow the steps below to prepare the flow manager for operation.

1. Connect a drain tubing to the two ports at the bottom right of the instrument (→ Fig.

16) to direct condensing water and/or liquid leaks to an appropriate waste container.

Drain port

(2 ports at the bottom right

of the flow manager)

Fig. 16: Drain port

Important: The drain tube must remain below the drain port. If the drain tube is

above the drain port, the liquid may flow back into the interior and

cause damage to the instrument. Also, be careful not to use tubing

that is bent.

Important: Afin d'éviter d'endommager l'instrument, assurez-vous qu'aucune

pièce des tubes n'est placée plus haute que le port de raccordement.

Operating Instructions Page 29

Page 36

UltiMate 3000 Series: Flow Managers and Column Thermostats

Wrong Correct

Fig. 17: Connecting the drain tubing

Tip: As the flow manager is part of an UltiMate 3000 system for nano

and cap HPLC applications, you may connect the drain tubing of the

system modules with the connecting pieces from the devices'

accessories kits. For more information, refer to the UltiMate 3000

Proteomics MDLC system manual.

2. Connect a waste tubing to the waste port on the instrument's rear panel (→ Fig. 18) to

direct any liquid from the waste path of the flow splitter to an appropriate waste

container. Dionex recommends connecting, for example, PTFE tubing with an inner

diameter of 1 mm (minimum 0.5 mm). Make sure that the tubing is long enough to

reach the bottom of the waste container.

Waste port

Fig. 18: Waste port

(on the rear panel)

Important: Make sure the waste port and waste tubing are not blocked during

operation of the flow manager and that the tubing is not bent.

For optimum chromatographic results, you should not change the

position of the tubing and/or the waste container during the analysis

or direct the liquid to a capped waste container because this might

impair flow control performance.

Important: Assurez-vous que la tubulure d’évacuation (Waste) est libre en

toutes circonstances. Vérifiez que les tubes ne sont ni pliés, ni

bouchés.

Pour des résultats chromatographiques optimaux, vous ne devez ni

modifier les positions de la tubulure d’évacuation et du flacon egout

pendant l'analyse, ni diriger le liquide dans un récipient

hermétiquement clos; ceci risque d'affecter les performances du

contrôle du débit.

Page 30 Operating Instructions

Page 37

UltiMate 3000 Series: Flow Managers and Column Thermostats

3. Install the column(s) as described in Installing a Separation Column (→ page 31).

4. Install the column(s) as described in Installing a Trap Column (→ page 36).

5. Establish the fluid connections between the column(s), switching valve(s), and flow

splitter according to your application. For information about the connections on the

column switching valves, refer to section 3.6.2 (→ page 35). For information about the

connections on the flow splitter, refer to section 3.6.4 (→ page 37).

6. Connect the flow manager to the other components of your UltiMate 3000 system, as

required by your specific application.

Tip: For information about how to connect the system modules and for

application examples, refer to the UltiMate 3000 Proteomics MDLC

system manual.

7. Turn on the instrument by pressing the power switch on the rear panel.

Tip: The noise that is heard for a few seconds after turning on the flow manager

is normal and does not impair the flow manager's performance.

When the flow manager is powered up, the following information appears on the front

panel display: Device type, serial number, and firmware version. After some seconds, the

initial screen changes to the status screen (→ page 41).

8. Install the flow manager in Chromeleon as described in section 5 (→ page 49).

3.6.1 Installing a Separation Column

Warning: Before carrying out any work in the column chamber, wait for the

column chamber to cool down. Do not touch any metal parts inside

the column chamber while the temperature set point is > 50 °C (122

°F).

Avertissement: Avant de procéder à toute modification dans le compartiment de

colonne, attendez que celui-ci refroidisse. Ne touchez aucune partie

en métal à l'intérieur du four, tant que l’affichage de la température

est > 50 °C (122 °F).

Four column brackets are installed in the column chamber at the factory. Attach the

columns to the brackets using the special column clips from the accessories kit.

1. The column clip consists of two pieces.

To remove the ring from the bottom part, slightly press the ring in the direction of the

arrows, which are printed on the ring.

Operating Instructions Page 31

Page 38

UltiMate 3000 Series: Flow Managers and Column Thermostats

Press the ring in the

direction indicated by the

arrows on the ring.

Fig. 19: Two-piece column clip

2. When installing the column clips for the first time: the kit includes self-adhesive foam

pads to protect the column. Place one pad on the inner side of the bottom part of each

clip.

3. Attach the bottom part of the clip to the bracket and turn it 90° clockwise.

Attach the bottom part of the

clip to the bracket and turn it

90° clockwise.

Fig. 20: Installing the bottom part

4. If you want to use column identification

Attach the column ID chip card to the column. Two chip cards are provided in the

accessories kit. Wrap the ribbon around the column, pass the shank of the rivet

through a hole, and press down to unite the two parts (→ section 5.5, page58).

Page 32 Operating Instructions

Page 39

UltiMate 3000 Series: Flow Managers and Column Thermostats

5. Press the column into the clip and reinstall the ring.

Fig. 21: Installing a column in the clip

6. Connect the capillaries to column.

Tip: For information about the connections on the column switching

valve(s), refer to section 3.6.2 (→ page 35). For information about the

connections on the flow splitter, refer to section 3.6.4 (→ page 37).

You can guide the capillaries out of the interior at any position between the enclosure

and the front panel door. To thread the capillaries out of the interior on the left or right

side of the enclosure, direct them through the respective capillary guide.

Capillary guide

Fig. 22: Capillary guide installed on the carrier

Dionex recommends guiding the capillaries out of the interior in such a way that the

connections are as short as possible.

Operating Instructions Page 33

Page 40

UltiMate 3000 Series: Flow Managers and Column Thermostats

Tip: Place the capillaries in such a manner (i.e., preferably 90-degree angle

related to the door seal) that they do not open a small path for ambient

air into the column chamber. This will prevent a proper seal and thus,

impair the heating and cooling performance of the flow manager. When

cooling, an improper seal may lead to a considerable amount of

condensed water.

An electronic column identification module allows GLP-compliant

documentation of the column type and the most important column

parameters. For more information, refer to section 5.5 (→ page 58).

You may move the preinstalled brackets as required by your application:

• The bracket for the column clips is installed in the column carrier as shown in Fig. 23. To

remove the bracket, slightly push it downward. You can now remove the bracket at the

top. Then, remove it at the bottom of the carrier. To install the bracket at the new position,

proceed in the reverse order.

Bracket installed in

the column carrier.

Slightly push the bracket

downward.

Fig. 23: Bracket installed in the column carrier

Page 34 Operating Instructions

Page 41

UltiMate 3000 Series: Flow Managers and Column Thermostats

3.6.2 Connecting the Capillaries to the Column Switching Valve

Depending on the instrument configuration, the flow manager is fitted with one or two

column switching valves (2-position/10-port or 2-position/6-port). Valve switching is

programmed and controlled via Chromeleon. (For more information, refer to the

Chromeleon online Help.) Establish the fluid connections:

1. Remove the plastic cap that protects the switching valve during shipment.

2. Connect the capillaries, using an appropriate tool. For an example, refer to Fig. 24.

Important: When you operate a biocompatible flow manager, observe the

instructions for connecting the capillaries to the switching valve

(→ page 13).

Important: Afin de raccorder les capillaires à la vanne d'injection biocompatible,

veuillez respecter les instructions d'installation (→ page 13).

from

pump

to

detector

2

3

4

5

1

1-2

1-10

6

Wast e

FLM-3100

10

9

8

7

Waste

from

autosampler

n

1

2

10

3

4

5

1-2

1-10

6

9

8

7

Separation column

Flow splitter

m

u

l

o

c

e

r

p

Port Connect the capillary ….

1 from the autosampler

2 to the trap column

3 to the separation column

4 from the flow splitter

5 from the trap column

6 to the waste

7-9 Not used

10 To the waste

Fig. 24: Example for the connections on a 2-position/10-port column switching valve

Operating Instructions Page 35

Page 42

UltiMate 3000 Series: Flow Managers and Column Thermostats

Important: To connect the capillaries to the switching valve, install only the

ferrules and fitting screws provided in the flow manager's accessories

kit.

Important: Pour raccorder les capillaires à la vanne d'injection, installez

uniquement les ferrules et les raccords fournis dans le kit d'accessoires.

3.6.3 Installing a Trap Column

Warning: Before carrying out any work in the column chamber, wait for the

column chamber to cool down. Do not touch any metal parts inside

the column chamber while the temperature set point is > 50 °C (122

°F).

Avertissement: Avant de procéder à toute modification dans le compartiment de

colonne, attendez que celui-ci refroidisse. Ne touchez aucune partie

en métal à l'intérieur du four, tant que l’affichage de la température

est > 50 °C (122 °F).

Follow the steps below if your application includes a trap column:

1. To install the trap column a column holder is required.

The application kits for the UltiMate 3000 nano and cap system include a trap column

holder with the appropriate capillaries.

2. Insert the trap column in its holder and connect the capillaries directly to the column

switching valve, e.g., to ports 2 and 5 (→ Fig. 24, page 35) as described in the

UltiMate 3000 Proteomics MDLC system manual in this manual binder.

Important: When you operate a biocompatible flow manager, observe the

instructions for connecting the capillaries to the switching valve

(→ page 13).

Important: Afin de raccorder les capillaires à la vanne d'injection biocompatible,

veuillez respecter les instructions d'installation (→ page 13).

Page 36 Operating Instructions

Page 43

UltiMate 3000 Series: Flow Managers and Column Thermostats

3.6.4 Connecting the Flow Splitter

Important: The flow sensor connectors (→ Fig. 11, no. 2) and the flow control

valve connector (→ Fig. 11, no. 3) are installed in the factory. They

should not be opened by the user.

Important: Les raccordements au capteur de débit (→ Fig. 11, no. 2) et à la vanne

de régulation de débit (→ Fig. 11, no. 3) sont effectués en usine. Ils ne

doivent pas être modifiés par l'utilisateur.

Follow the steps below to connect the capillaries to the flow splitter:

Warning: Before carrying out any work in the column chamber, wait for the

column chamber to cool down. Do not touch any metal parts inside

the column chamber while the temperature set point is > 50 °C (122

°F).

Avertissement: Avant de procéder à toute modification dans le compartiment de

colonne, attendez que celui-ci refroidisse. Ne touchez aucune partie

en métal à l'intérieur du four, tant que l’affichage de la température

est > 50 °C (122 °F).

Important: When connecting the capillaries, make sure that the connectors are

free from contaminants. Even minute particles may cause damage to

the flow splitter, flow control valve, and column.

When you operate a biocompatible flow manager, observe the

instructions for connecting the capillaries (→ page 13).

Important: Lorsque vous connectez les capillaires, assurez-vous que les

raccords sont exempts de tout contaminant. Même d'infimes

particules peuvent causer des dommages au système (ex. diviseur de

débit, vanne de régulation de débit et colonne).

Afin de raccorder les capillaires à la vanne d'injection

biocompatible, veuillez respecter les instructions d'installation

(→ page 13).

Operating Instructions Page 37

Page 44

UltiMate 3000 Series: Flow Managers and Column Thermostats

1. Use the special capillary that is shipped with the Application Kit to connect the flow

manager to the pump (→ Fig. 11, page 19).

Description Part No.

Long capillary for connecting the pump to the flow splitter

(including the appropriate fittings and ferrules)

Standard version

Biocompatible version

Use this capillary, for example, when the system modules are stacked

as shown in Fig. 14 (→ page 26).