Page 1

© 2012 Thermo Fisher Scientific Inc.

UltiMate 3000 RSLCnano

Standard Applications

Revision: V1.0 R3

Date: January 2012

Doc.no. 4820.4103

Page 2

UltiMate 3000 RSLCnano – Standard Applications

1

Page 3

UltiMate 3000 RSLCnano – Standard Applications

Table of Contents

1 Introduction ................................................................................................................ 4

1.1 Additional Documents ............................................................................................... 5

2 Application Setup ....................................................................................................... 6

2.1 General Recommendations for Applications............................................................. 6

2.1.1 Connections ........................................................................................................ 6

2.1.2 Sample Preparation ............................................................................................. 7

2.1.3 Mobile Phases ..................................................................................................... 8

2.2 Installing the UltiMate 3000 RSLCnano system ....................................................... 9

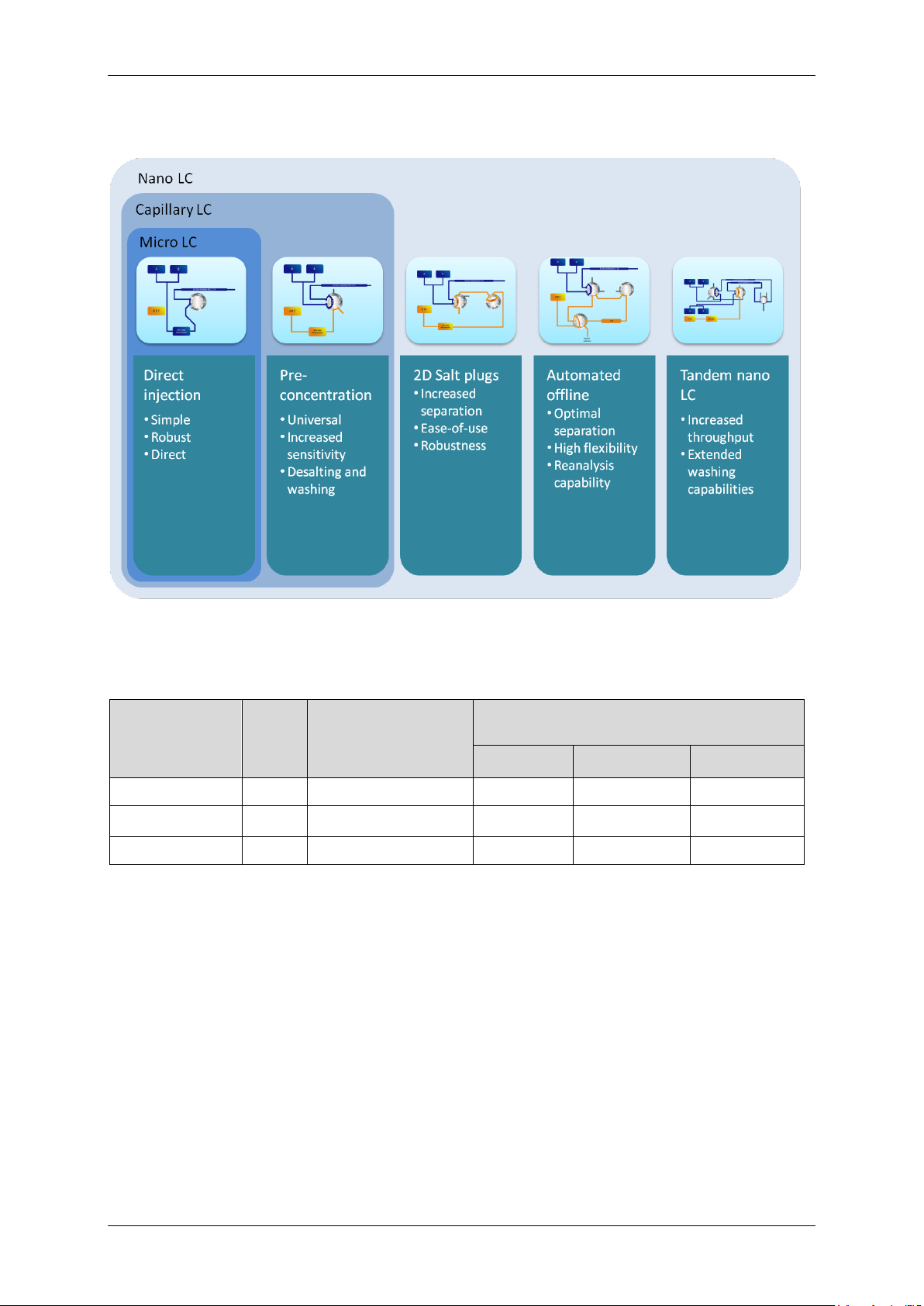

2.3 Application Overview ............................................................................................. 12

2.4 Direct Injection onto a Nano Column ..................................................................... 13

2.4.1 Hardware Layout .............................................................................................. 13

2.4.2 Fluidic Setup ..................................................................................................... 15

2.4.3 Installation Tips ................................................................................................ 15

2.4.4 Testing the Application .................................................................................... 16

2.4.5 Large Volume Injections .................................................................................. 16

2.5 Direct Injection onto a Capillary Column ............................................................... 18

2.5.1 Hardware Layout .............................................................................................. 18

2.5.2 Fluidic Setup ..................................................................................................... 19

2.5.3 Installation Tips ................................................................................................ 20

2.5.4 Testing the Application .................................................................................... 20

2.6 Pre-concentration onto a Nano Column .................................................................. 21

2.6.1 Hardware Layout .............................................................................................. 21

2.6.2 Fluidic Setup ..................................................................................................... 22

2.6.3 Installation Tips ................................................................................................ 23

2.6.4 Testing the Application .................................................................................... 23

2.7 Pre-concentration onto a 200 µm Monolithic Column ............................................ 25

2.7.1 Hardware Layout .............................................................................................. 25

2.7.2 Fluidic Setup ..................................................................................................... 26

2.7.3 Installation Tips ................................................................................................ 27

2.7.4 Testing the Application .................................................................................... 27

2.8 Pre-concentration on a Capillary Column ............................................................... 29

2.8.1 Hardware Layout .............................................................................................. 29

2.8.2 Fluidic Setup ..................................................................................................... 30

2.8.3 Installation Tips ................................................................................................ 31

2.8.4 Testing the Application .................................................................................... 31

2.9 2D Salt Steps with Nano Column ............................................................................ 32

2.9.1 Hardware Layout .............................................................................................. 32

2.9.2 Fluidic Setup ..................................................................................................... 33

2.9.3 Installation Tips ................................................................................................ 34

2.9.4 Testing the Application .................................................................................... 35

2.9.5 Salt Solutions Preparation ................................................................................ 36

2.10 Automated off-line 2D LC of Peptides, micro SCX x nano RP .............................. 37

2.10.1 Hardware Layout .............................................................................................. 37

2.10.2 Fluidic Setup ..................................................................................................... 39

2.10.3 Installation Tips ................................................................................................ 40

2.10.4 Testing the Application .................................................................................... 41

2.11 Automated off-line 2D LC, Cap RP (basic) x nan RP (acidic) ............................... 42

2.11.1 Hardware Layout .............................................................................................. 42

2.11.2 Fluidic Setup ..................................................................................................... 43

2

Page 4

UltiMate 3000 RSLCnano – Standard Applications

2.11.3 Installation tips ................................................................................................. 44

2.11.4 Testing the application ..................................................................................... 44

2.12 Tandem nano LC ..................................................................................................... 46

2.12.1 Hardware Layout .............................................................................................. 46

2.12.2 Fluidic Setup ..................................................................................................... 47

2.12.3 Installation Tips ................................................................................................ 48

2.12.4 Testing the Application .................................................................................... 48

3 FAQ ........................................................................................................................... 50

3.1 Interpreting a Chromatogram .................................................................................. 50

3.2 Troubleshooting nano LC peptide Applications...................................................... 50

3.3 The use of TFA and FA ........................................................................................... 52

3.4 Minimizing Baseline Noise ..................................................................................... 52

3.4.1 Drift .................................................................................................................. 52

3.4.2 Unstable Baseline ............................................................................................. 53

4 Appendix – Traditional Capillary Connections .................................................... 54

5 Appendix – Common Spare Parts in nano LC...................................................... 56

3

Page 5

UltiMate 3000 RSLCnano – Standard Applications

1 Introduction

This document describes the standard setup, recommended experimental conditions and

testing procedures to run standard applications on the Thermo Scientific Dionex UltiMate

3000 RSLCnano system.

Notes: This document is intended for Thermo Fisher Scientific (or authorized)

service personnel as well as customers to assist in the installation and

system test of UltiMate 3000 RSLCnano systems.

It is assumed that the individual using this manual has sufficient training in

the installation and usage of analytical instrumentation and is aware of the

potential hazards including (but not limited to) electrical hazards, chemical

solvent hazards, exposure to UV radiation and the exposure to pressurized

solvents.

At various points throughout the manual, messages of particular importance are indicated by

the following symbols:

Tip: Indicates general information intended to optimize the installation and

setup steps or the performance of the instrument.

Important: Indicates that failure to take note of the accompanying information may

result in damage to the instrument.

Warning: Indicates that failure to take note of the accompanying information may

result in personal injury.

This manual is provided "as is." Every effort has been made to supply complete and accurate

information and all technical specifications have been developed with the utmost care. The

information contained in this manual should not be construed as a commitment by Thermo

Fisher Scientific. Thermo Fisher Scientific assumes no responsibility for any errors that may

appear in this document. This document is believed to be complete and accurate at the time of

publication. In no event shall Thermo Fisher Scientific be liable for incidental or

consequential damages in connection with or arising from the use of this document.

The information contained in this document is subject to change without notice.

4

Page 6

UltiMate 3000 RSLCnano – Standard Applications

All rights reserved, including those for photomechanical reproduction and storage on

electronic media. No part of this publication may be copied or distributed, transmitted,

transcribed, stored in a retrieval system, or transmitted into any human or computer language,

in any form or by any means, electronic, mechanical, magnetic, manual, or otherwise, or

disclosed to third parties without the express written permission of Thermo Fisher Scientific

Inc.

Trademarks

Analyst is a registered trademark of AB Sciex.

Compass and Hystar are trademarks of Bruker Daltronics.

Nitronic is a registered trademark of AK Steel Corp.

PEEK is a trademark of Victrex PLC.

PharMed is a registered trademark of Saint -Gobain Performance Plastics.

Windows and Windows Vista are registered trademarks of Microsoft Corp.

All other trademarks are property of Thermo Fisher Scientific Inc. and its subsidiaries

1.1 Additional Documents

In addition to the information provided in this manual, the following documents are available:

• Operating Instructions of the individual modules

• Installation Qualification manual for installation of the UltiMate 3000 RSLCnano

• Micro Fraction Collection Option for the Thermo Scientific Dionex UltiMate WPS-

3000PL Nano/Cap Autosampler

• Application/technical notes to be published on the Dionex website

In addition to these documents, Chromeleon templates are available for these applications.

Please contact your local Thermo Scientific sales or service representative to obtain the

templates.

5

Page 7

UltiMate 3000 RSLCnano – Standard Applications

2 Application Setup

2.1 General Recommendations for Applications

The experimental conditions for each application are presented together with related

information such as schematics, installation tips and examples, results and interpretation.

2.1.1 Connections

All high-pressure fittings used in the applications on the UltiMate 3000 RSLCnano system are

made with nanoViper. nanoViper is a fingertight high-pressure fitting that is dead volume free

by design and back pressure resistant up to 1000 bar. The fittings are assembled in the factory

to ensure consistent fittings and prevent experimental failure due to bad connections.

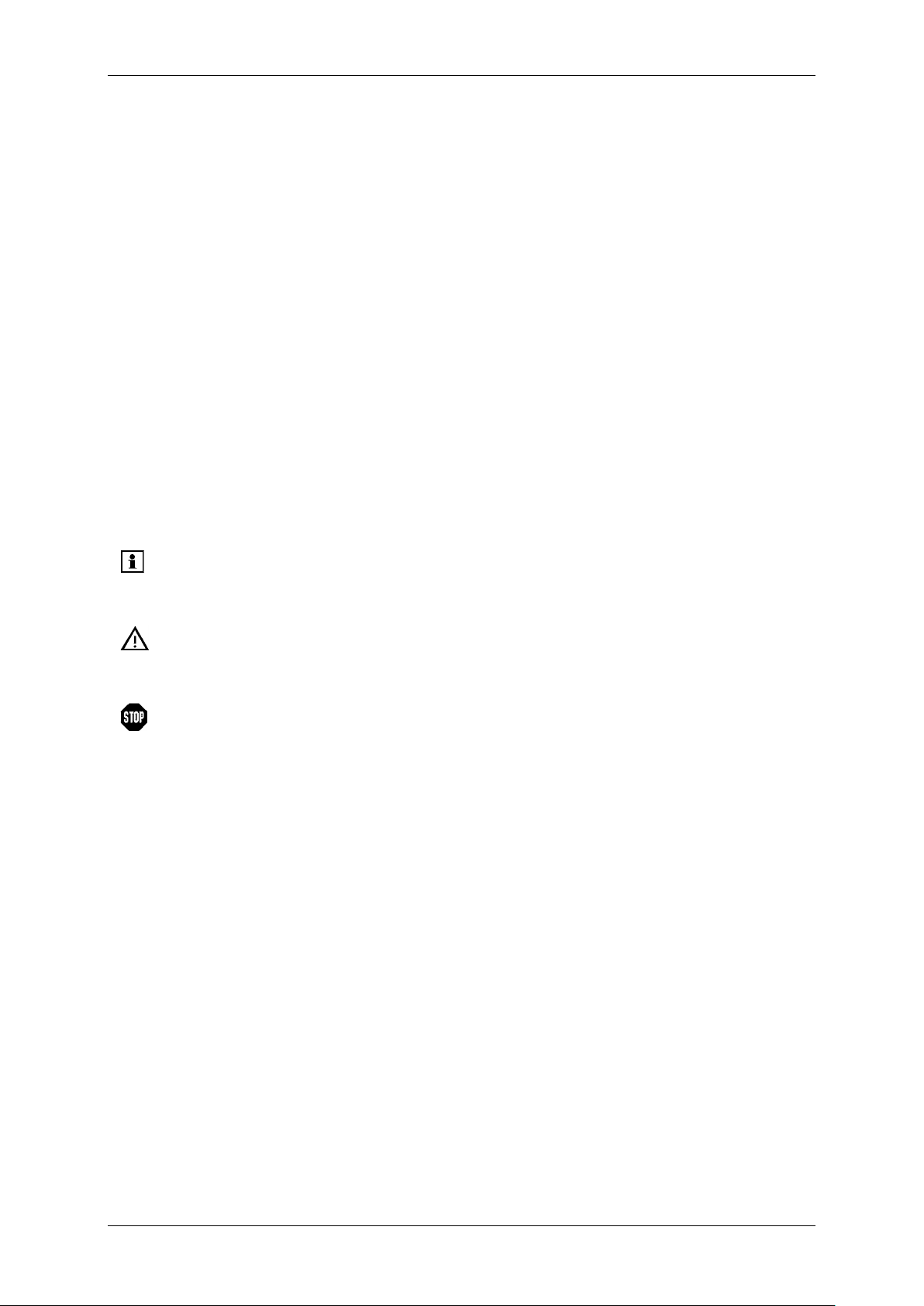

Figure 1: Example of a nanoViper fitting

1. Install nanoViper as any fingertight fitting.

2. Do not over-tighten connections (general guide line: finger-tight + maximum an

additional one eighth-turn).

3. Remove the black knurled screw.

The outlet of the nano columns is fitted with a nano connector. This is a dedicated connection

designed to offer maximum flexibility in connecting fused silica capillaries and offering

pressure stability up to 300 bars. The nano connector uses a special sleeve to ensure pressure

tightness. The assembly of a nano connector is described step by step below.

Figure 2: nano connector layout

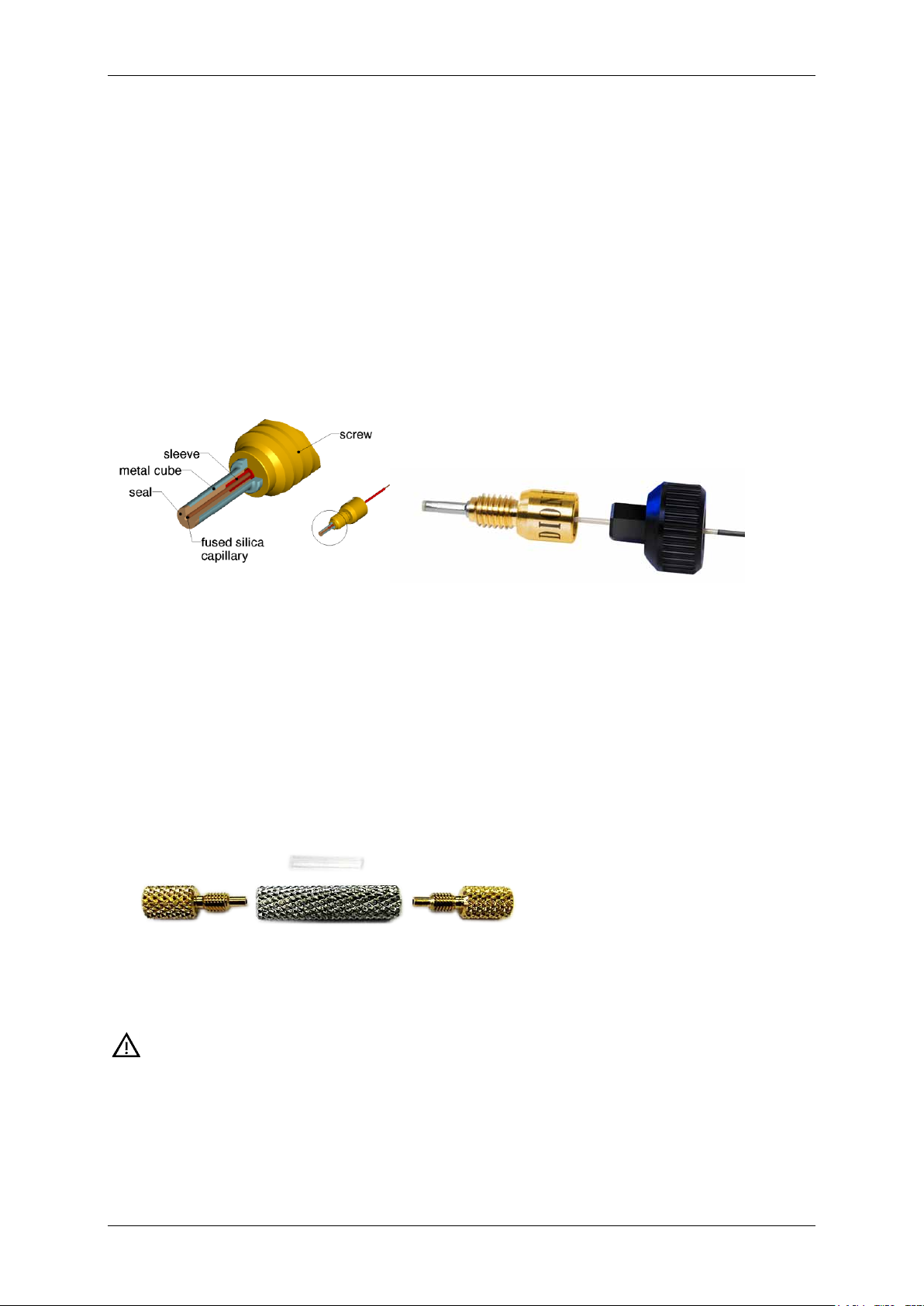

• Use a new nano connector sleeve (P/N 6720.0391) for each connection

Important: Do NOT use a PTFE sleeve. The size does not match the nano

connector and the pressure resistance is much lower.

6

Page 8

UltiMate 3000 RSLCnano – Standard Applications

Nano connector sleeve (~1.1 cm)

PTFE (1.8 cm)

Figure 3: nano connector (top) and PTFE (bottom) sleeve comparison

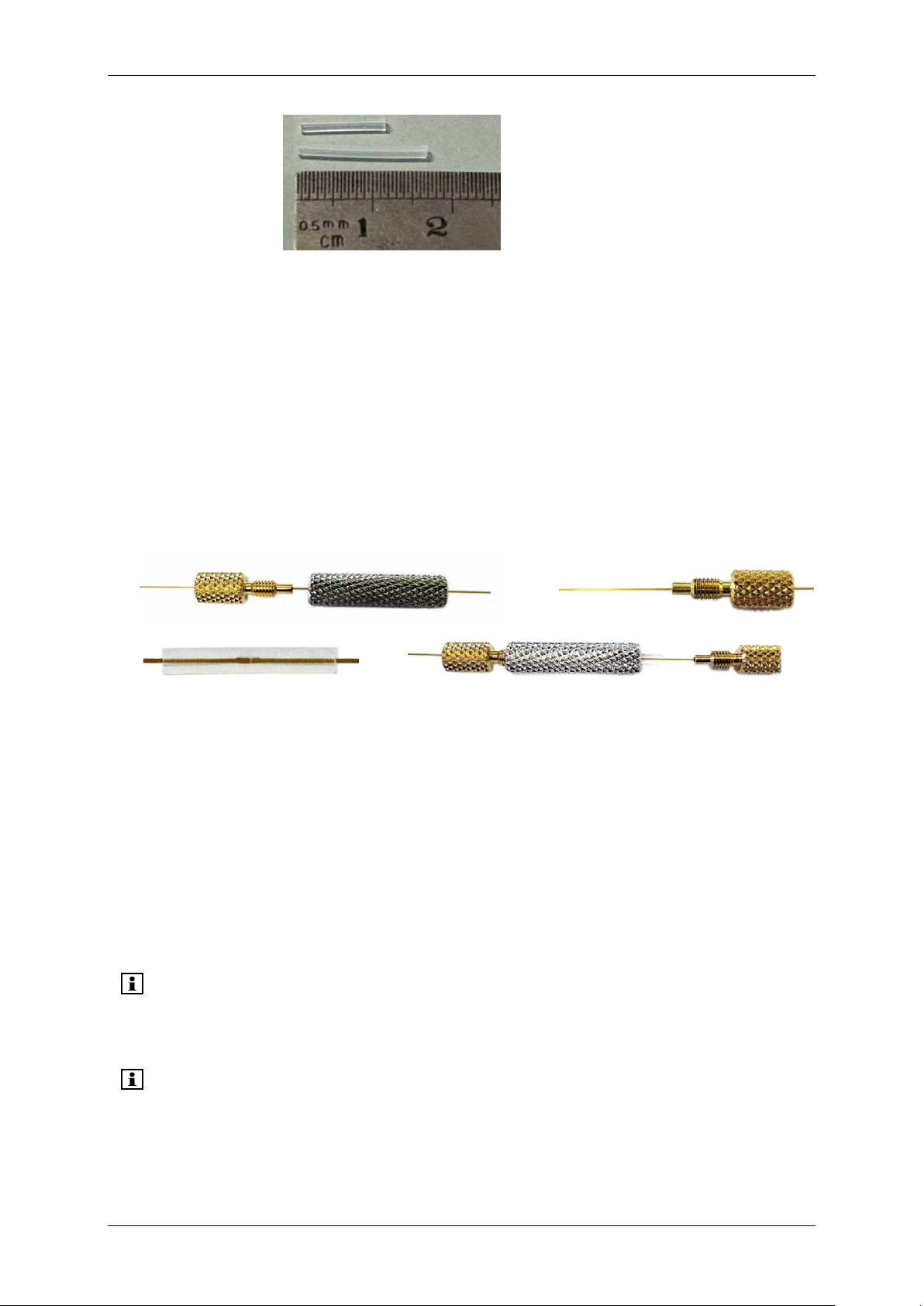

1. Slide the golden nut and silver union onto one of the fused silica outlets; slide the

second golden union on the other fused silica end. (→ Figure 4a and Figure 4b)

2. Slide the nano connector sleeve onto the fused silica, slide the other end of the fused

silica into the nano connector sleeve and make sure the connection is dead volume free.

Figure 4c

3. Tighten the golden nuts equally fingertight to ensure the nano connector sleeve is

centered in the silver union. Figure 4d

4. For traditional fittings, for example, PTFE sleeves see Appendix – Traditional Capillary

Connections (page 54)

a

b

c

Figure 4: Using the nano connector

d

2.1.2 Sample Preparation

• Follow the instructions provided with the test sample and use the solvents as indicated.

• After re-dissolving the sample wait at least 15 min before further diluting it.

o Use water with a minimum of 2 % ACN and appropriate ion-pairing agent to

dissolve.

o Dilution can be done in the same solvent or with water with appropriate ion-pairing

agent.

Tip: To limit the risks of peptides or proteins adsorption on the walls of the vials,

Thermo Fischer Scientific recommends using glass inserts (Polypropylene vials

for WPS with glass insert, 250 µL, set of 25, P/N 6820.0027).

Tip: When using IEX columns, make sure that the sample solvent contains a very

limited amount of salt and is at the right pH level (for example, adjust to pH 3

when using a SCX column to separate peptides).

7

Page 9

UltiMate 3000 RSLCnano – Standard Applications

2.1.3 Mobile Phases

• Always use fresh solvents.

• When running online multidimensional approaches, make sure that the mobile phase of

the first dimension will allow for trapping the sample on the (trap) column used on the

second dimension.

• For example, do not use phosphate buffers from SCX separations as loading solvent in

RP separations.

• Thermo Fischer Scientific recommends replacing (aqueous) solvents at least once every

two weeks.

Tip: Replace solvents completely; do not ’top up’ to avoid unwanted components

building up in the mobile phases.

8

Page 10

UltiMate 3000 RSLCnano – Standard Applications

SRD-3400, SRD-3200 with degassing or

NCS-3500RS module featuring

VWD-3400RS with flow cells for

WPS-3000TPL RS

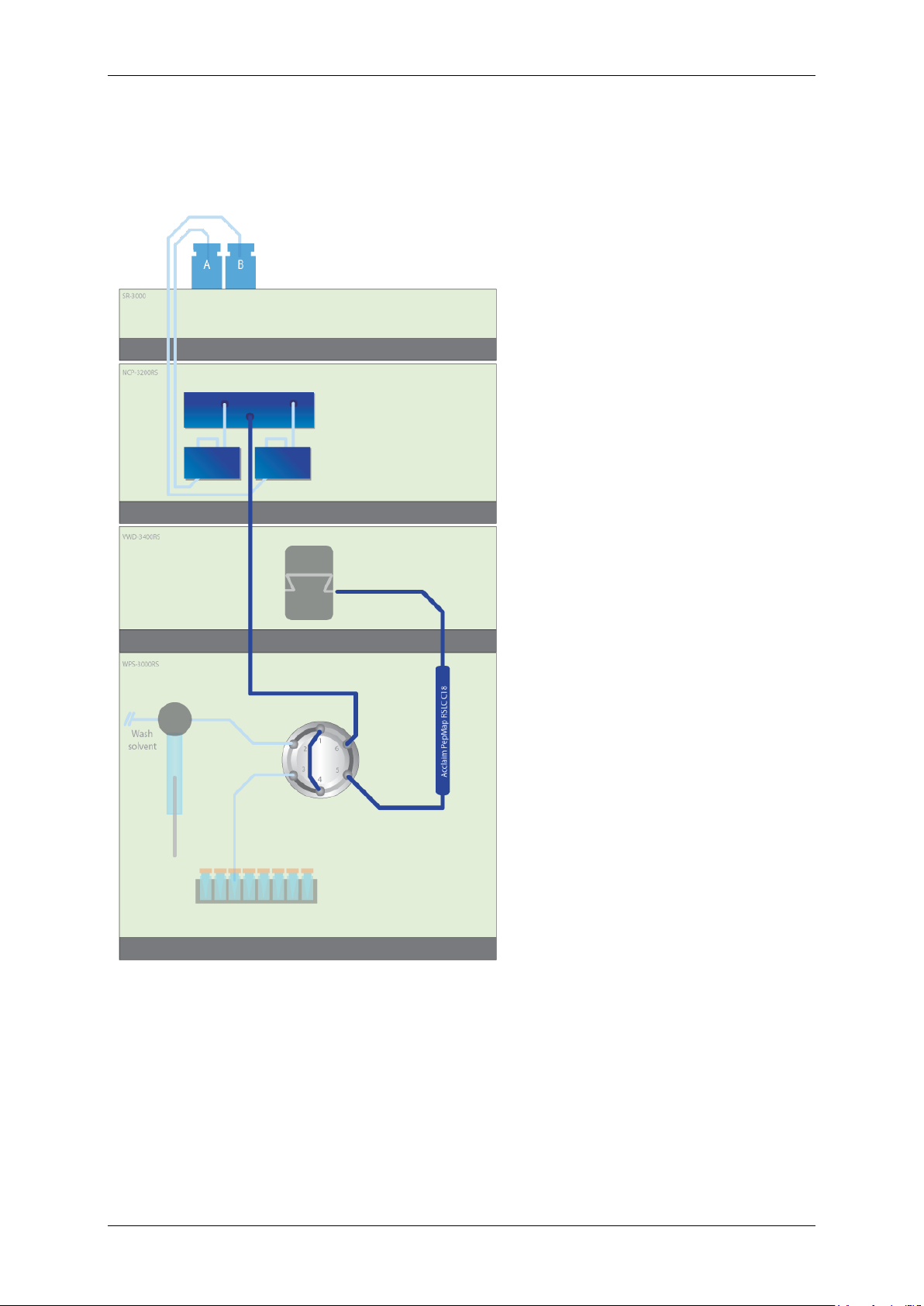

2.2 Installing the UltiMate 3000 RSLCnano System

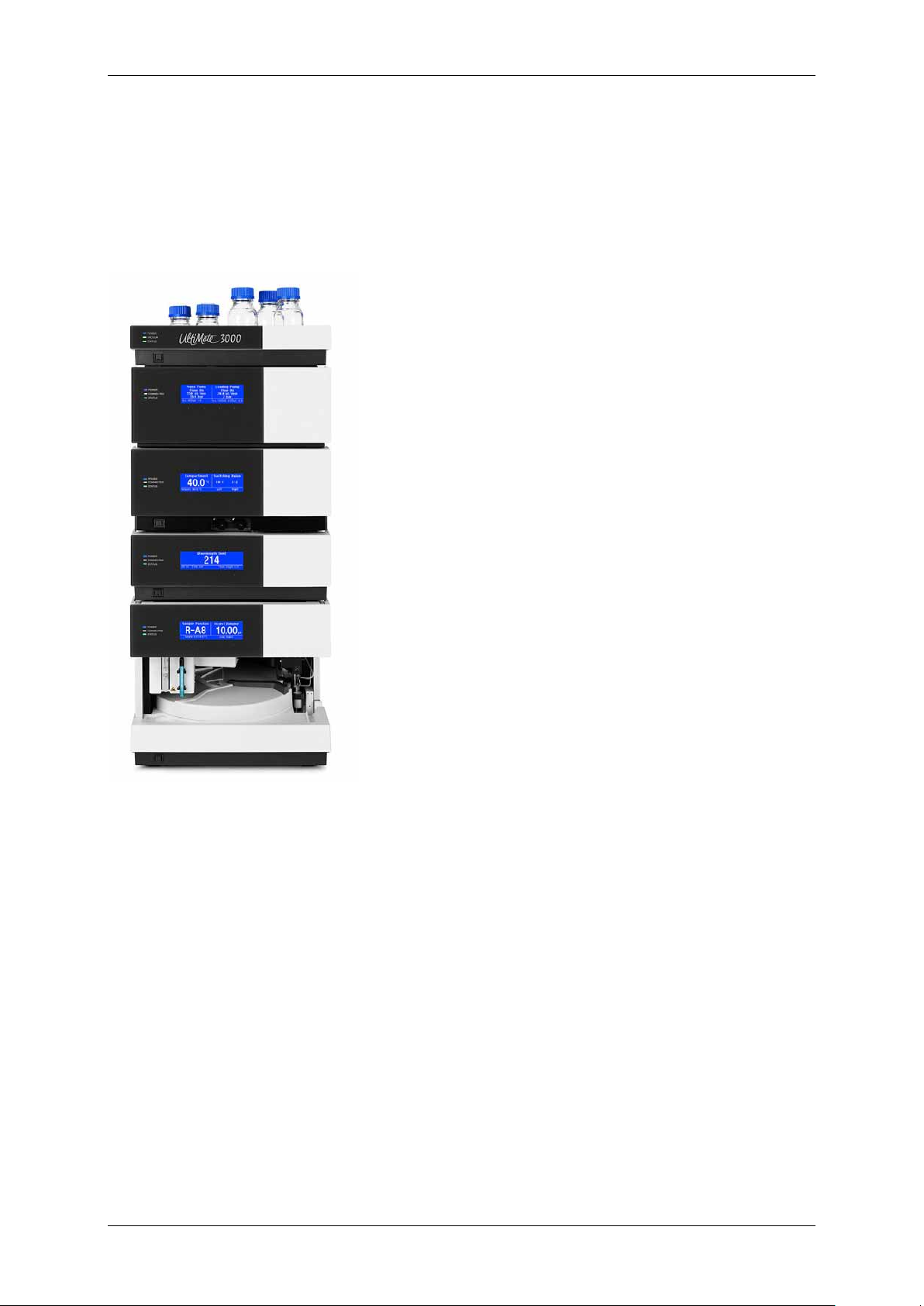

The general UltiMate 3000 RSLCnano system overview is shown in Figure 5. The modular

nature of the Thermo Scientific Dionex UltiMate 3000 platform does allow modifications to

this layout.

SR-3000 without degassing.

- NC pump, up to 800 bar

- Loading pump, micro Titanium up to 500 bar

- Column compartment with up to two switching valves

Optional:

- NCP-3200RS

- PAEK valve

Figure 5: RSLCnano system overview

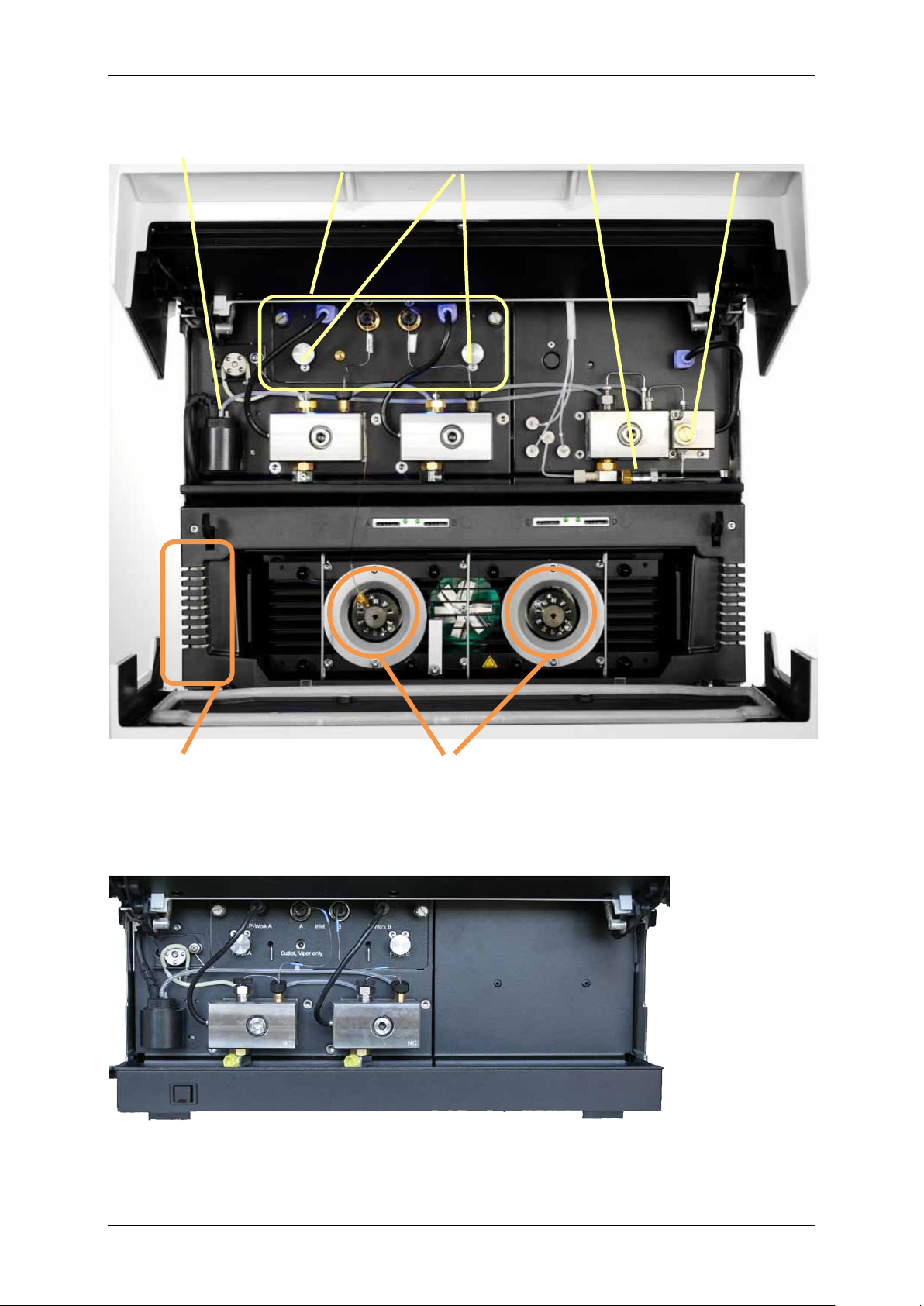

Figure 6 shows the interior of the NCS-3500RS module. The module consists of two pumps

and an integrated column compartment. The most important elements required for system

setup are indicated in the picture.

Figure 7 shows the interior of the NCP-3200RS module. This module contains only the

NC_Pump, but is identical in capabilities and performance as the NC_Pump in the NCS3500RS.

- nano (3nL),

- capillary (45 nL)

- micro (180 nL) LC

- Temperature controlled autosampler equipped with a

1000 bar switching valve

- Optional:

8-port valve (350 bar) for automated off-line

applications

9

Page 11

UltiMate 3000 RSLCnano – Standard Applications

NC_Pump

Loading pump

Rear seal wash system

Flow meter

Purge screws

Inline filter

Purge screw

Tubing guides

Snap-in valves

Column compartment

Figure 6: Detailed overview of the NCS-3500RS interior

Figure 7: Detailed overview of the NCP-3200RS interior, components are identical to the NC_Pump in the NCS3500RE

10

Page 12

UltiMate 3000 RSLCnano – Standard Applications

1

To control the module, Thermo Scientific Dionex Chromeleon 6.80 SR8 (or later) or

2

Prepare electrical and USB connections, power up modules, and then prepare server

3

Prepare solvents and install them according to the application.

Important

Use the PEEK solvent inlet filter frits in both, the NC pump and loading pump

Degassing of the loading pump solvents is required when the loading pump is

4

Purge both blocks of the NC pump (min 30 min.), while assisting with a syringe until

Make sure that the purge screws of the NC_Pump are entirely opened.

5

Purge flow meter for 30 min.

The purge time with a nano flow selector is 30 minutes. For capillary and micro

6

Perform pressure sensor offset calibration, using Chromeleon Diagnostics. To do so, open

7

Perform viscosity calibration using Chromeleon Diagnostics or select default viscosities

To see the solvent list for which default viscosities are available, use the

8

Prepare all fluidics using the provided nanoViper connection tubing.

Do not overtighten the fingertight connection!

Before the parts of the application kit are installed, the UltiMate 3000 RSLCnano system has

to be prepared and primed. To prepare the system, the following steps are required. For more

details, see the operating instructions for the respective module.

DCMSLink version 2.8 (or later) and appropriate license are required.

configuration.

- NC pump channels A and B

- Loading pump channels A, B, and C (10-50% isopropanol in water for unused

channels)

- Rear seal wash solvent (~10% isopropanol in water)

- Autosampler wash solvent (~10% isopropanol 0.1% FA in water).

solvent lines.

Tip

used for gradient formation or the flow rate is above 20 µL/min.

liquid exits the purge lines. Purge all channels of the loading pump (minimum 10 min).

Tip

Tip

flow selectors purge times may be shorter. Please refer to the NCS-3500RS or

NCP-3200RS manual for details.

the More options panel of the NC_Pump and click the related button.

from the available viscosity list.

Tip

Commands dialog (F8) and scroll to Pump module NC_Pump

%A_Viscosity (%B_Viscosity).

Tip

11

Page 13

2.3 Application Overview

UltiMate 3000 RSLCnano – Standard Applications

Table 1: Property overview of different flow selectors

Flow Selector

Type

Nano Nan 6041.0002 500 nL/min 50 nL/min* 1000 nL/min

Capillary Cap 6041.0003 5 µL/min 500 nL/min 10 µL/min

Micro Mic 6041.0014 25 µL/min 2.5 µL/min 50 µL/min

*Lower flow rates are available upon request

I.D. P/N Total Flow Rate

(Sum of channel A and B)

Nominal Minimum Maximum

12

Page 14

UltiMate 3000 RSLCnano – Standard Applications

2.4 Direct Injection onto a Nano Column

2.4.1 Hardware Layout

The preferred setup is presented in

Figure 8 and consists of:

SR-3000 5035.9200

NCP-3200RS 5041.0030

VWD-3400RS 5074.0010

3 nL flow cell 6074.0270

WPS-3000TPL RS 5826.0020

Application kit: 6720.0300

Figure 8: Setup for a Direct Injection experiment onto a

nano column

13

Page 15

UltiMate 3000 RSLCnano – Standard Applications

The alternative setup is presented in

Figure 9 and consists of:

SRD-3400 5035.9245

NCS-3500RS 5041.0010

VWD-3400RS 5074.0010

3 nL flow cell 6074.0270

WPS-3000TPL RS 5826.0020

Application kit: 6720.0300

Figure 9: Setup for a Direct Injection experiment onto a

nano column

14

Page 16

UltiMate 3000 RSLCnano – Standard Applications

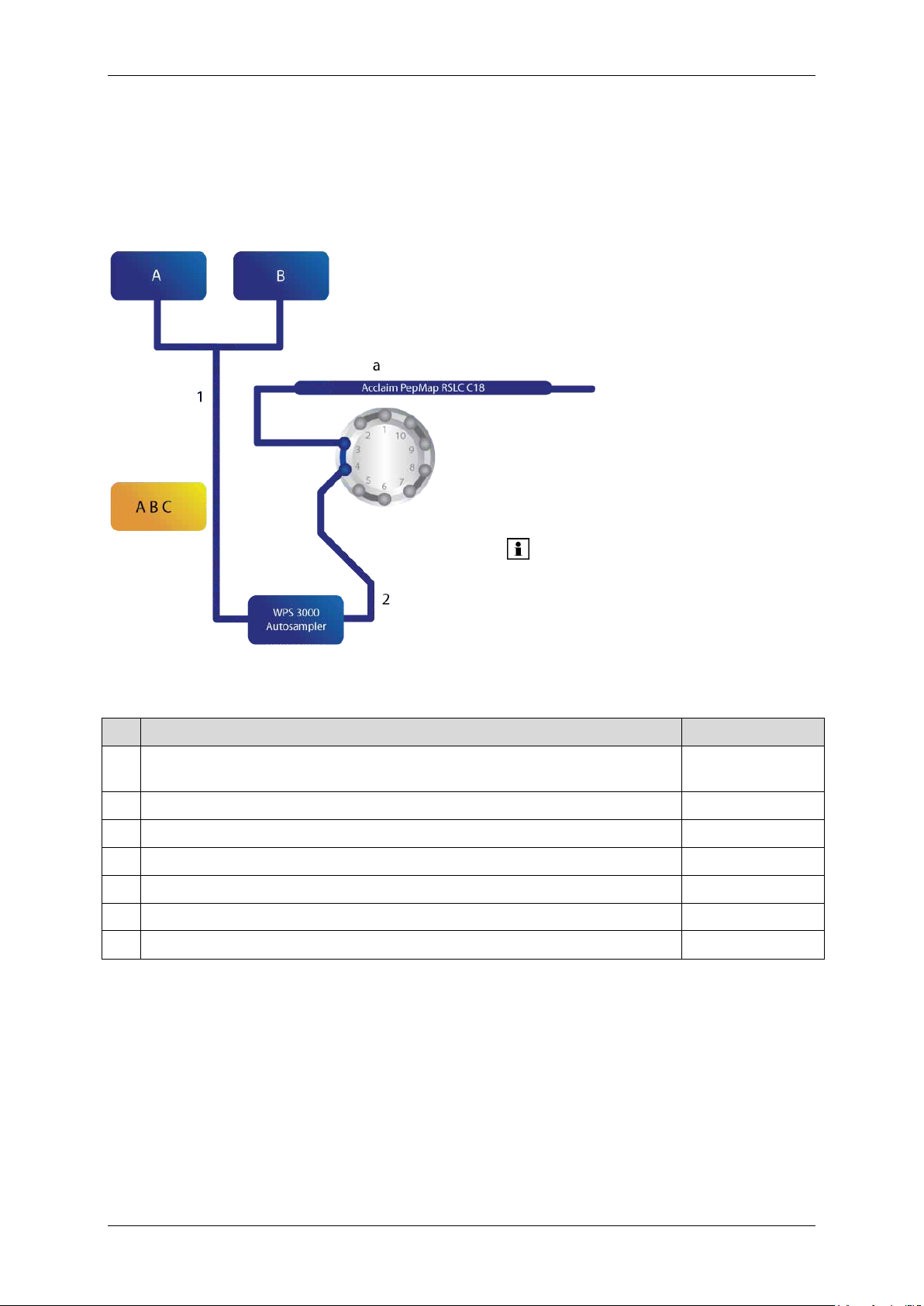

2.4.2 Fluidic Setup

Figure 10 presents the setup using the parts of the Direct Injection application kit. Columns

are marked with letters, tubing with digits, and the sample loop is installed in the WPS3000PL Autosampler

Tip: When no valve is

available, a union can be used to

connect the capillary column

(P/N 6040.2304)

Figure 10: Fluidic connections for a Direct Injection experiment onto a nano column

Table 2: UltiMate 3000 RSLCnano Direct Injection nano LC kit (P/N 6720.0300) contents

# Item Replacement P/N

75 µm I.D. x 15 cm, packed with Acclaim PepMap RSLC C18, 2 µm,

a

100Å, nanoViper

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 20 µm x 750 mm 6041.5280

1

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 20 µm x 550 mm 6041.5260

2

nanoViper sample loop 1 µL, FS/PEEK sheathed I.D. x L 100 µm x 127 mm 6826.2401

Polypropylene vials for WPS with glass insert, 250 µL, 25 pcs. 6820.0027

Polypropylene caps for WPS vials, 25 pcs. 6820.0028

Cytochrome C digest, 1.6 nmol, Lyophilized 161089

164534

2.4.3 Installation Tips

• Follow the General Recommendations for Applications (→ page 6).

• The impact of dwell (dead) volumes on reproducibility is very important. Improper

connections of the different elements are the most likely cause of failure for this

application.

15

Page 17

UltiMate 3000 RSLCnano – Standard Applications

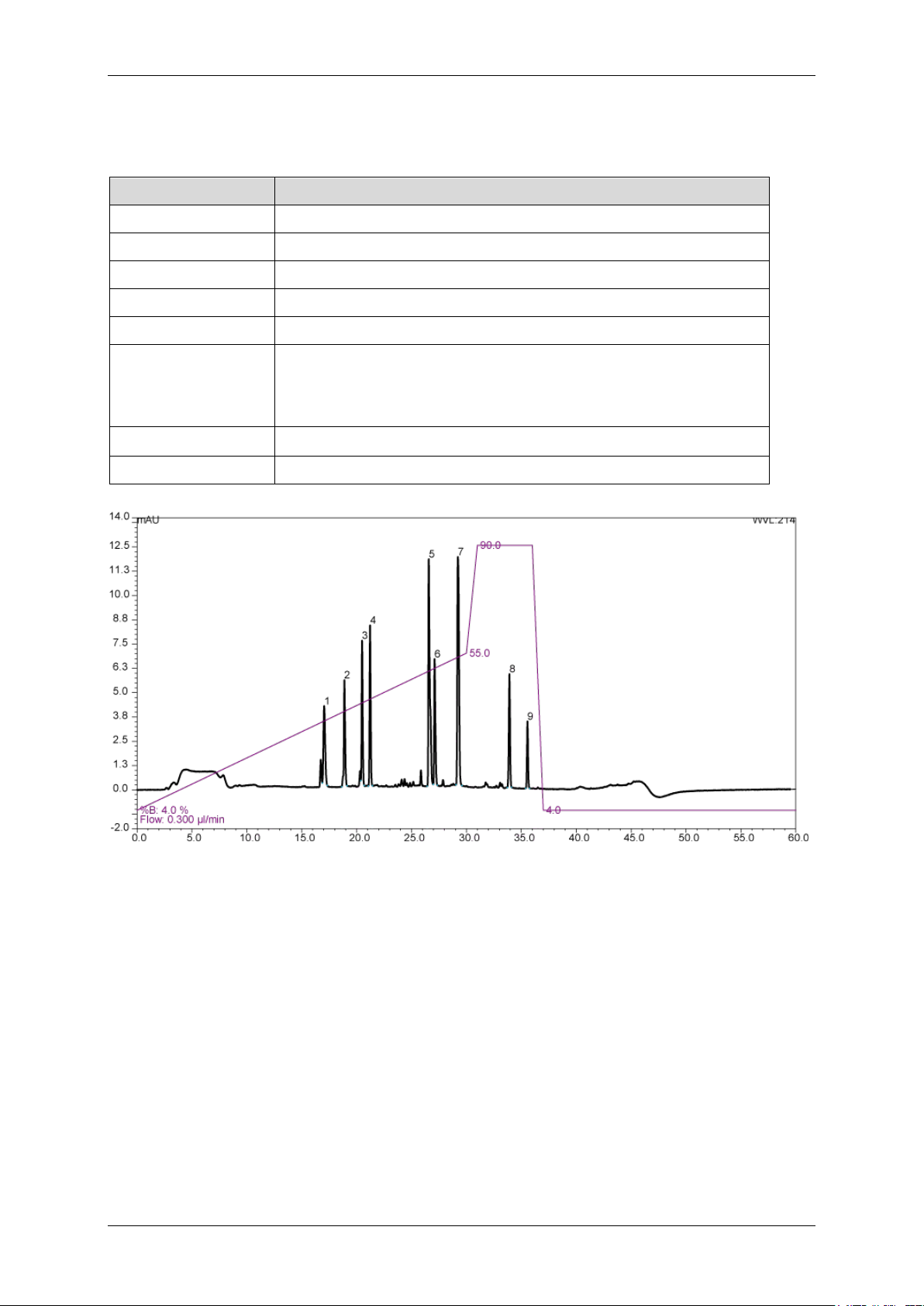

2.4.4 Testing the Application

The direct injection can be tested using the following conditions:

Property Setting

Mobile phase A 100% water + 0.05% TFA

Mobile phase B 20%/80% (v/v) water/ACN + 0.04% TFA

Sample Cytochrome C digest 1 pmol/μL, prepared according to the instruction sheet

Injection volume 1 μL

UV detection 214 nm

Gradient 4% to 55% B in 30 min

90% B for 5 min

25 min equilibration

WPS temperature

Flow rate 300 nL/min (nano flow selector)

5°C (WPS-3000(B)T only)

Figure 11: Typical chromatogram for a Direct Injection of 1 pmol Cyt C onto a nano column

For details on interpretation and troubleshooting of the Cytochrome C nano LC separation,

see the FAQ section on page 50.

2.4.5 Large Volume Injections

Typically direct injections in nano LC are performed with 1 µL loop sizes to minimize the

gradient delay. Larger volume injections are performed with a pre-concentration setup. The

WPS-3000PL autosampler series allows for a custom injection program (UDP) to switch back

the injection valve after sample loading to bypass the loop. This way a larger sample volume

can be injected and pre-concentrated directly onto the nano column, without using a preconcentration setup.

16

Page 18

UltiMate 3000 RSLCnano – Standard Applications

The advantage of such a setup is the ease of use and a minimum loss of peptides, especially

hydrophilic ones. The prerequisites of this setup are desalted samples, since all that is injected

will enter the MS, and an investment of extra analysis time to accommodate the loading of

sample with nano flow.

17

Page 19

2.5 Direct Injection onto a Capillary Column

The recommended setup is

2.5.1 Hardware Layout

UltiMate 3000 RSLCnano – Standard Applications

presented in Figure 12 and consists

of:

SRD-3400 5035.9245

NCS-3500RS 5041.0020

VWD-3400RS 5074.0010

45 nL flow cell 6074.0280

WPS-3000TPL RS 5826.0020

Application kit: 6720.0305

Figure 12: Setup for a Direct Injection experiment onto a

capillary column

18

Page 20

UltiMate 3000 RSLCnano – Standard Applications

(P/N 6040.2304)

2.5.2 Fluidic Setup

Figure 13 presents the setup using the parts of the Direct Injection application kit. Columns

are marked with letters, tubing with digits, and the sample loop is installed in the

WPS-3000PL Autosampler.

Tip: When no valve is

available, a union can be used to

connect the capillary column

Figure 13: Fluidic connections for a Direct Injection experiment onto a capillary column

Table 3: UltiMate 3000 RSLCnano Direct Injection capillary LC Kit (P/N 6720.0305) contents

# Item Replacement P/N

300 µm I.D. x 15 cm, packed with Acclaim PepMap RSLC C18, 2 µm,

a

100Å, nanoViper

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 50 µm x 750 mm 6041.5580

1

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 50 µm x 550 mm 6041.5560

2

nanoViper sample loop 5 µL, FS/PEEK sheathed I.D. x L 200 µm x 159 mm 6826.2405

Polypropylene vials for WPS with glass insert, 250 µL, 25 pcs. 6820.0027

Polypropylene caps for WPS vials, 25 pcs. 6820.0028

Cytochrome C digest, 1.6 nmol, Lyophilized 161089

164537

19

Page 21

UltiMate 3000 RSLCnano – Standard Applications

2.5.3 Installation Tips

Follow the General Recommendations for Applications (→ page 6).

2.5.4 Testing the Application

The direct injection can be tested using the following conditions:

Property Setting

Mobile phase A 100% water + 0.05% TFA

Mobile phase B 20%/80% (v/v) water/ACN + 0.04% TFA

Sample Cytochrome C digest 8 pmol/μL, prepared according to the instruction sheet

Injection volume 1 μL

UV detection 214 nm

Gradient 4% to 55% B in 30 min

90% B for 5 min

25 min equilibration

WPS temperature

Flow rate 4 μL/min (capillary flow selector)

5°C (WPS-3000(B)T only)

Figure 14: Typical chromatogram for a Direct Injection of 8 pmol Cyt C onto a capillary column

20

Page 22

UltiMate 3000 RSLCnano – Standard Applications

2.6 Pre-concentration onto a Nano Column

2.6.1 Hardware Layout

The recommended setup is

presented in Figure 15 and consists

of:

SRD-3400 5035.9245

NCS-3500RS 5041.0010

10-port sw. valve 6041.0001

VWD-3400RS 5074.0010

3 nL flow cell 6074.0270

WPS-3000TPL RS 5826.0020

Application kit: 6720.0310

Figure 15: Setup for a Pre-concentration experiment onto a

nano column

21

Page 23

UltiMate 3000 RSLCnano – Standard Applications

2.6.2 Fluidic Setup

Figure 16 presents the setup using the parts of the Pre-concentration application kit. Columns

are marked with letters, tubing with digits, and the sample loop is installed in the

WPS-3000PL Autosampler

Tip: The schematic shows a 10-port switching valve, but this application can be

performed on a 6-port valve. Ensure that the relative positions of the connections

are correct, and update the valve switching in the Chromeleon templates if

necessary.

Figure 16: Fluidic connections for a Pre-concentration experiment onto a nano column

Table 4: UltiMate 3000 RSLCnano Pre-concentration nano LC kit (P/N 6720.0310) contents

# Item Replacement P/N

75 µm I.D. x 15 cm, packed with Acclaim PepMap RSLC C18, 2 µm, 100Å,

a

nanoViper

Nano Trap Column, 75 µm I.D. x 2 cm, packed with Acclaim PepMap100 C18,

b

3 µm, 100Å (set of 2) nanoViper

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 20 µm x 350 mm 6041.5240

1

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 75 µm x 650 mm 6041.5775

2

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 75 µm x 550 mm 6041.5760

3

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 20 µm x 750 mm 6041.5280

nanoViper sample loop 20 µL, FS/PEEK sheathed I.D. x L 250 µm x 408 mm 6826.2420

PTFE tubing, 500 µm I.D. 100 cm, used as waste tubing 6720.0077

4

Polypropylene vials for WPS with glass insert, 250 µL, 25 pcs. 6820.0027

Polypropylene caps for WPS vials, 25 pcs. 6820.0028

Cytochrome C digest, 1.6 nmol, Lyophilized 161089

164534

164535

1/16" Universal Fingertight Fitting, one-piece design, extra long thread, 4 pcs. 6720.0015

22

Page 24

UltiMate 3000 RSLCnano – Standard Applications

2.6.3 Installation Tips

• Follow the General Recommendations for Applications (→ page 6).

• The design of the nano trap column provides the easiest connections, but must only be

used in forward flush operation. Please check the indicated flow direction when

installing a nano trap column.

• If the loss of hydrophilic peptides is observed, the concentration of acetonitrile in the

loading solvent can be decreased down to 99/1 Water/ACN + 0.05% TFA or the use of

a stronger ion-pairing agent such as heptafluorobutyric acid (HFBA) can be considered.

2.6.4 Testing the Application

The pre-concentration setup can be tested using the following conditions:

Property Setting

Mobile phase A 100% water + 0.05% TFA

Mobile phase B 20%/80% (v/v) water/ACN + 0.04% TFA

Loading solvent 98%/2% (v/v) water/ACN + 0.05% TFA

Sample Cytochrome C digest 1 pmol/μL, prepared according to the instruction sheet

Injection volume 1 μL (partial loop fill of a 20µL loop)

UV detection 214 nm

Loading time 3 min (may vary with different injection volume/routine)

Gradient 4% to 55% B in 30 min

90% B for 5 min

25min equilibration

WPS temperature

Loading flow 5 μL/min

Flow rate 300 nL/min (nano flow selector)

5°C (WPS-3000(B)T only)

Figure 17: Typical chromatogram for Pre-concentration of 1 pmol Cyt C onto a nano column

23

Page 25

UltiMate 3000 RSLCnano – Standard Applications

To evaluate the result of the experiment, the chromatogram should look very similar to the

one obtained with direct injection.

For details on interpretation and troubleshooting of the Cytochrome C nano LC separation,

see the FAQ section on page 50.

Tip: The example chromatogram provided (Figure 17) has been obtained under optimal

conditions. When having difficulties to obtain a similar result, focus on the delay of

the 'injection peak' and 'wash peak'; for example, check for any dwell (dead)

volume.

24

Page 26

UltiMate 3000 RSLCnano – Standard Applications

2.7 Pre-concentration onto a 200 µm Monolithic Column

2.7.1 Hardware Layout

The recommended setup is

presented in Figure 18 and consists

of:

SRD-3400 5035.9245

NCS-3500RS 5041.0020

10-port sw. valve 6041.0001

VWD-3400RS 5074.0010

3 nL flow cell 6074.0270

WPS-3000TPL RS 5826.0020

Application kit: 6720.0320

Figure 18: Setup for a Pre-concentration experiment onto a

monolithic column

25

Page 27

UltiMate 3000 RSLCnano – Standard Applications

2.7.2 Fluidic Setup

Figure 19 presents the setup using the parts of the Pre-concentration application kit. Columns

are marked with letters, tubing with digits, and the sample loop is installed in the

WPS-3000PL Autosampler.

Tip: The schematic shows a 10-port switching valve, but this application can be

performed on a 6-port valve. Ensure that the relative positions of the connections

are correct, and update the valve switching in the Chromeleon templates if

necessary.

Figure 19: Fluidic connections for a Pre-concentration experiment onto a monolithic column

Table 5: UltiMate 3000 RSLCnano Pre-concentration monolithic LC kit (P/N 6720.0320) contents

# Item Replacement P/N

PepSwift Monolithic Capillary Column, 200 µm I.D. x 5 cm (PS-DVB), nanoViper 164557

a

PepSwift Monolithic Trap Column, 200 µm x 5 mm (PS-DVB), set of 2, nanoViper 164558

b

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 50 µm x 350 mm 6041.5540

1

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 75 µm x 650 mm 6041.5775

2

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 75 µm x 550 mm 6041.5760

3

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 50 µm x 750 mm 6041.5580

nanoViper sample loop 20 µL, FS/PEEK sheathed I.D. x L 250 µm x 408 mm 6826.2420

PTFE tubing, 500 µm I.D. 100 cm, used as waste tubing 6720.0077

4

Polypropylene vials for WPS with glass insert, 250 µL, 25 pcs. 6820.0027

Polypropylene caps for WPS vials, 25 pcs. 6820.0028

Cytochrome C digest, 1.6 nmol, Lyophilized 161089

1/16" Universal Fingertight Fitting, one-piece design, extra long thread, 4 pcs. 6720.0015

26

Page 28

UltiMate 3000 RSLCnano – Standard Applications

2.7.3 Installation Tips

• Follow the General Recommendations for Applications (→ page 6).

• Using a stainless steel loop (on a standard system) instead of a PEEK loop is

recommended in case of injecting highly diluted samples.

• With column oven temperatures below 45°C, TFA can be used instead of HFBA in the

loading solvent to load the sample onto the trap column.

• Due to the speed of the separation, the value for the detector's time constant (response)

must be reduced to 0.1s.

• Concentration of HFBA in the loading solvent can be increased to 0.1% in case trapping

problems are observed.

• The loss of hydrophilic peptides (for example, peaks 1 and 2 are lower than expected)

may (partially) be decreased by lowering the oven temperature.

2.7.4 Testing the Application

The pre-concentration setup can be tested using the following conditions:

Property Setting

Mobile phase A 100% water + 0.05% TFA

Mobile phase B 50%/50% water/ACN + 0.04% TFA

Loading solvent 100% water + 0.05% HFBA

Sample Cytochrome C digest 1 pmol/μL, prepared according to the instruction sheet

Note: The sample must be diluted in the loading solvent.

Injection volume 0.5 μL (partial loop)

UV detection 214 nm

Loading time 3 min (may vary with different injection volume/routine)

Gradient 1% to 70% B in 8 min

90% B for 2 min

8.5 min equilibration

Oven temperature

WPS temperature

Loading flow 10 μL/min

Flow rate 3.0 μL/min (capillary flow selector)

60°C

5°C (WPS-3000(B)T only)

27

Page 29

UltiMate 3000 RSLCnano – Standard Applications

Figure 20: Typical chromatogram for Pre-concentration of 0.5 pmol Cyt C onto a monolithic column

Tip: When the trap column is switched in line with the analytical column, a large

positive peak is detected at 214 nm. This is due to the different UV absorbance of

the ion-pairing agents used in the loading and analytical solvent.

28

Page 30

UltiMate 3000 RSLCnano – Standard Applications

2.8 Pre-concentration on a Capillary Column

2.8.1 Hardware Layout

The recommended setup is

presented in Figure 21 and consists

of:

SRD-3400 5035.9245

NCS-3500RS 5041.0020

10-port sw. valve 6041.0001

VWD-3400RS 5074.0010

45 nL flow cell 6074.0280

WPS-3000TPL RS 5826.0020

Application kit: 6720.0315

Figure 21: Setup for a Pre-concentration experiment onto a

capillary column

29

Page 31

UltiMate 3000 RSLCnano – Standard Applications

2.8.2 Fluidic Setup

Figure 22 presents the setup using the parts of the pre-concentration application kit. Columns

are marked with letters, tubing with digits, and the sample loop is installed in the

WPS-3000PL Autosampler.

Tip: The schematic shows a 10-port switching valve, but this application can be

performed on a 6-port valve. Ensure that the relative positions of the connections

are correct, and update the valve switching in the Chromeleon templates if

necessary.

Figure 22: Fluidic connections for a Pre-concentration experiment onto a capillary column

Table 6: UltiMate 3000 RSLCnano Pre-concentration capillary LC kit (P/N 6720.0315) contents

# Item Replacement P/N

300 µm I.D. x 15 cm, packed with Acclaim PepMap RSLC C18, 2 µm, 100Å,

a

nanoViper

Nano Trap Column, 100 µm I.D. x 2 cm, packed with Acclaim PepMap100 C18,

b

5 µm, 100Å (set of 2) nanoViper

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 50 µm x 350 mm 6041.5540

1

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 75 µm x 650 mm 6041.5775

2

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 75 µm x 550 mm 6041.5760

3

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 50 µm x 750 mm 6041.5580

nanoViper sample loop 20 µL, FS/PEEK sheathed I.D. x L 250 µm x 408 mm 6826.2420

PTFE tubing, 500 µm I.D. 100 cm, used as waste tubing 6720.0077

4

Polypropylene vials for WPS with glass insert, 250 µL, 25 pcs. 6820.0027

Polypropylene caps for WPS vials, 25 pcs. 6820.0028

Cytochrome C digest, 1.6 nmol, Lyophilized 161089

164537

164564

1/16" Universal Fingertight Fitting, one-piece design, extra long thread, 4 pcs. 6720.0015

30

Page 32

UltiMate 3000 RSLCnano – Standard Applications

2.8.3 Installation Tips

• Follow the General Recommendations for Applications (→ page 6).

• The design of the nano trap column provides the easiest connections, but must only be

used in forward flush operation. Please check the indicated flow direction when

installing a nano trap column.

• If the loss of hydrophilic peptides is observed, the concentration of acetonitrile in the

loading solvent can be decreased down to 99/1 water/ACN + 0.05% TFA

2.8.4 Testing the Application

The pre-concentration setup can be tested using the following conditions:

Property Setting

Mobile phase A 100% water + 0.05% TFA

Mobile phase B 20%/80% (v/v)water/ACN + 0.04% TFA

Loading solvent 98%/2% (v/v) water/ACN + 0.05% TFA

Sample Cytochrome C digest 8 pmol, prepared according to instruction sheet

Injection volume 1 μL (partial loop fill of a 20 µL loop)

UV detection 214 nm

Loading time 3 min (may vary with different injection volume/routine)

Gradient 4% to 55% B in 30 min

90% B for 5 min

25min equilibration

WPS temperature

Loading flow 20 μL/min

Flow rate 4 μL/min (capillary flow selector)

5°C (WPS-3000(B)T only)

31

Page 33

UltiMate 3000 RSLCnano – Standard Applications

2.9 2D Salt Steps with Nano Column

2.9.1 Hardware Layout

The recommended setup is

presented in Figure 23 and consists

of:

SRD-3400 5035.9245

NCS-3500RS 5041.0010

2x 10-port sw.valve 6041.0001

VWD-3400RS 5074.0010

3 nL flow cell 6074.0270

WPS-3000TPL RS 5826.0020

Application kit: 6720.0325

Figure 23: Setup for a 2D Salt Plugs experiment

32

Page 34

UltiMate 3000 RSLCnano – Standard Applications

2.9.2 Fluidic Setup

Figure 24 presents the setup using the parts of the 2D-LC Salt Plugs application kit. Columns

are marked with letters, tubing with digits, and the sample loop is installed in the

WPS-3000PL Autosampler.

Tip: The schematic shows 10-port switching valves, but this application can be

performed on 6-port valves. Ensure that the relative positions of the connections

are correct, and update the valve switching in the Chromeleon templates if

necessary.

Figure 24: Fluidic connections for a 2D LC Salt Plugs experiment

Table 7: UltiMate 3000 RSLCnano 2D salt plugs kit (P/N 6720.0325) contents

# Item Replacement P/N

300 µm I.D. x 10 cm, packed with Poros 10 S with connections, 130 µm I.D.

a

FS sheathed inlet and outlet, nanoViper

75 µm I.D. x 15 cm, packed with Acclaim PepMap RSLC C18, 2 µm, 100Å,

b

nanoViper

Nano Trap Column, 100 µm I.D. x 2 cm, packed with Acclaim PepMap100 C18,

c

5 µm, 100Å (set of 2) nanoViper

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 20 µm x 350 mm 6041.5240

1

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 75 µm x 650 mm 6041.5775

2

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 75 µm x 550 mm 6041.5760

3

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 75 µm x 250 mm 6041.5730

4

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 20 µm x 750 mm 6041.5280

nanoViper sample loop 20 µL, FS/PEEK sheathed I.D. x L 250 µm x 408 mm 6826.2420

PTFE tubing, 500 µm I.D. 100 cm, used as waste tubing 6720.0077

5

164565

164534

164564

Polypropylene vials for WPS with glass insert, 250 µL, 25 pcs. 6820.0027

Polypropylene caps for WPS vials, 25 pcs. 6820.0028

Protein mixture digest, 100 pmol, Lyophilized 161088

1/16" Universal Fingertight Fitting, one-piece design, extra long thread, 4 pcs. 6720.0015

33

Page 35

UltiMate 3000 RSLCnano – Standard Applications

2.9.3 Installation Tips

• Follow the General Recommendations for Applications (→ page 6).

• The design of the nano trap column provides the easiest connections, but must only be

used in forward flush operation. Please check the indicated flow direction when

installing a nano trap column.

• If the loss of hydrophilic peptides is observed, the concentration of acetonitrile in the

loading solvent can be decreased down to 99/1 water/ACN + 0.025% TFA.

• If too much hydrophobic secondary interaction is observed on the IEX column, the

amount of ACN can be increased up to 5% or 10%. This will be at the expense of the

loading efficiency for hydrophilic peptides on the trap column.

• The loading time and desalting time are highly dependent on the sample quantity and

purity. They can be adjusted to meet customer needs. However the desalting step must

be kept long enough to avoid the formation of adducts between salt and sample.

• To limit the breakthrough on the SCX column, the loading solvent must contain as little

TFA as possible (for example, max. 0.025%) or FA should be used.

• The salt plugs listed here have been chosen to check the system and work fine for the

separation of the protein mix digest. The best sequence of plugs will highly depend on

the affinity of the peptides present in the sample with the IEX column.

• It is useful to inject several times the last salt plug or to prepare one with a higher salt

concentration in order to make sure that the column is clean before repeating an

experiment.

• After each series of injection, it is useful to wash the column with consecutive 2M salt

injections. When the salt is washed out from the column, a 60/40 water/ACN solution

can also be used to wash out peptides which might be bound to the column due to

hydrophobic interactions.

• SCX column regeneration can be performed by flushing the column overnight with a

10 mM phosphate buffer pH 3, 20% ACN and 600 mM NaCl salt solution. Please

ensure that the column is conditioned with loading solvent before using it in the 2D salt

plug application.

Tips: The combination of salts, buffers and organic solvents can result in precipitation.

When preparing the solution described above, carefully evaluate if salts precipitate.

Dilute or remove precipitation before using the wash solvent, to prevent system

damage.

34

Page 36

UltiMate 3000 RSLCnano – Standard Applications

2.9.4 Testing the Application

The 2D salt plug setup can be tested using the following conditions:

Property Setting

Mobile phase A 100% water + 0.05% TFA

Mobile phase B 20%/80% (v/v) water/ACN + 0.04% TFA

Loading solvent 95%/5% (v/v) water/ACN + 0.025% TFA

Sample Protein mix digest, prepared according to the included instruction sheet

Salt plugs

concentration (mol/L)

Injection volume Sample: 10 μL

UV detection 214 nm

Loading time 5 min (may vary with different injection volume/routine)

Desalting time 7 min (started after loading time has passed)

Gradient Isocratic 4% for 10min

1 mmol NaCl

2 mmol NaCl

5 mmol NaCl

10 mmol NaCl

20 mmol NaCl

50 mmol NaCl

100 mmol NaCl

200 mmol NaCl

500 mmol NaCl

1000 mmol NaCl

2000 mmol NaCl

Salt plugs: 20 μL

4% to 55% B in 30 min

90% B for 5 min

18 min equilibration

WPS temperature

Loading flow 10 μL/min

Flow rate 300 nL/min (nano flow selector)

5°C

To evaluate the result of the experiment, focus on the following points:

• Injection profile should be reproducible.

• The peptides should be well distributed over the different fractions and among the

fractions (orthogonal separation).

35

Page 37

UltiMate 3000 RSLCnano – Standard Applications

2.9.5 Salt Solutions Preparation

The following protocol can be used to prepare the salt plugs:

• Prepare two stock solutions using the loading solvent:

1) 2000 mM NaCl (for example, 467.5 mg of NaCl in 4 ml of loading solvent)

2) 100 mM NaCl (for example, prepare the 100 mM solution of the first table

two times)

• Dilute the stock according to the tables below: Use standard 1.5 mL vials (for example,

do not use inserts).

Concentration of

NaCl

2000 mM 1000 μL 0 μL 1000 μL

1000 mM 500 μL 500 μL 1000 µL

500 mM 250 μL 750 μL 1000 µL

200 mM 100 μL 900 μL 1000 µL

100 mM

Volume of 2000 mM NaCl

stock solution

50 μL 950 μL 1000 µL

Volume of loading

solvent

Total volume

Concentration of

NaCl

50 mM 500 μL 500 μL 1000 µL

20 mM 200 μL 800μL 1000 µL

10 mM 100 μL 900 μL 1000 µL

5 mM 50 μL 950 μL 1000 µL

2 mM 20 μL 980 μL 1000 µL

1 mM 10 μL 990 μL 1000 µL

Volume of 100 mM NaCl

stock solution

Volume of

loading solvent

Total volume

36

Page 38

UltiMate 3000 RSLCnano – Standard Applications

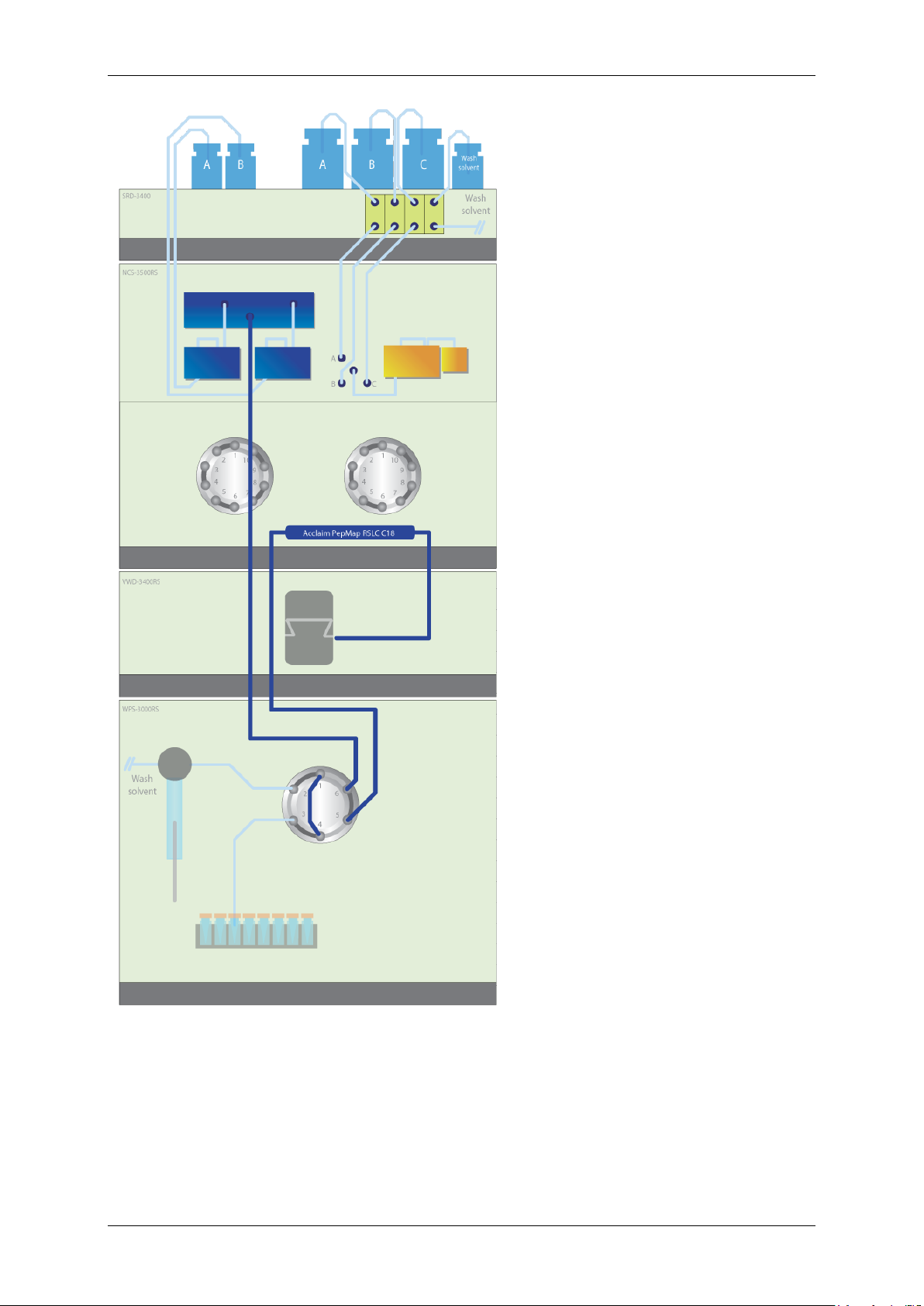

2.10 Automated off-line 2D LC of Peptides, micro SCX x nano RP

2.10.1 Hardware Layout

The recommended setup with one

detector is presented in Figure 25,

when using two detectors a dual

stack, as shown in Figure 26, is

recommended. The single detector

setup consists of:

SRD-3400 5035.9245

NCS-3500RS 5041.0010

2x 10-port sw.valve 6041.0001

VWD-3400RS 5074.0010

3 nL flow cell 6074.0270

or

180 nL flow cell 6074.0290

WPS-3000TPL RS 5820.0010

µFC option 6820.0051

Application kit: 6720.0330

Tip: The µFC option limits

the upper pressure of the

first dimension to

350 bar, due to the

applied 8-port valve.

Figure 25: Setup for an Automated Off-line 2D Mic Nan

experiment

A second UV detector is

used when the nano

column is not directly

interfaced with the mass

spectrometer.

37

Page 39

UltiMate 3000 RSLCnano – Standard Applications

Figure 26: Setup for an Automated Off-line 2D Mic Nan experiment using two detectors

The recommended setup using 2 detectors is

presented in Figure 26 and consists of:

SRD-3400 5035.9245

NCS-3500RS 5041.0010

2x 10-port sw.valve 6041.0001

2x VWD-3400RS 5074.0010

3 nL flow cell 6074.0270

180 nL flow cell 6074.0290

Tip: The µFC option limits

the upper pressure of the

first dimension to

350 bar, due to the

applied 8-port valve.

WPS-3000PL 5820.0010

µFC option 6820.0051

Application kit: 6720.0330

38

Page 40

UltiMate 3000 RSLCnano – Standard Applications

2.10.2 Fluidic Setup

Figure 27 presents the setup using the parts of the Automated Off-line Mic Nan SCX RP

application kit. Columns are marked with letters, tubing with digits.

Tip: The schematic shows 10-port switching valves, but this application can be

performed on 6-port valves. Ensure that the relative positions of the connections

are correct, and update the valve switching in the Chromeleon templates if

necessary.

Figure 27: Fluidic connections for an Automated Off-line 2D experiment

Table 8: UltiMate 3000 RSLCnano Automated Off-line SCX-RP peptides kit (P/N 6720.0330) contents

# Item Replacement P/N

1.0 mm I.D. x 15 cm, packed with Polysulfoethyl ASP, 5 µm, 300Å, nanoViper 164566

a

75 µm I.D. x 15 cm, packed with Acclaim PepMap RSLC C18, 2 µm, 100Å,

b

nanoViper

Nano Trap column, 75 µm I.D. x 2 cm, packed with Acclaim PepMap100 C18,

c

3 µm, 100Å (set of 2) nanoViper

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 20 µm x 350 mm 6041.5240

1

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 75 µm x 650 mm 6041.5775

2

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 75 µm x 550 mm 6041.5760

3 (4)

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 75 µm x 250 mm 6041.5730

5

164534

164535

39

Page 41

UltiMate 3000 RSLCnano – Standard Applications

Table 8: UltiMate 3000 RSLCnano Automated Off-line SCX-RP peptides kit (P/N 6720.0330) contents Continued

# Item Replacement P/N

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 20 µm x 750 mm 6041.5280

nanoViper sample loop 50 µL, FS/PEEK sheathed I.D. x L 250 µm x 408 mm 6826.2450

6

PTFE tubing, 500 µm I.D. 100 cm, used as waste tubing 6720.0077

7

Protein mixture digest, 100 pmol, Lyophilized 161088

Cytochrome C digest, 1.6 nmol, Lyophilized 161089

Polypropylene vials for WPS with glass insert, 250 µL, 25 pcs. 6820.0027

Polypropylene caps for WPS vials, 25 pcs. 6820.0028

96 Well Microplate, PP, V-Bottom 6820.4113

1/16" Universal Fingertight Fitting, one-piece design, extra long thread, 4 pcs. 6720.0015

Buffer tubing 500 µL, WPS-3000PL 6820.0020

LCi Solutions Library CD 6830.0400

Operating Instructions for automated off-line 2D-LC of peptides and proteins 164208

2.10.3 Installation Tips

• Follow the General Recommendations for Applications (→ page 6).

• The design of the nano trap column provides the easiest connections, but must only be

used in forward flush operation. Please check the indicated flow direction when

installing a nano trap column.

• If the loss of hydrophilic peptides is observed, the concentration of acetonitrile in the

loading solvent can be decreased down to 99/1 water/ACN + 0.05% TFA

• If too much hydrophobic secondary interaction is observed on the IEX column, the

amount of ACN can be increased up to 5% or 10%.

• The loading time and desalting time are highly dependent on the sample quantity and

purity. They can be adjusted to meet customer needs. However, the desalting step must

be kept long enough to avoid the formation of adducts between salt and sample.

• Optimal trapping in the second dimension is achieved by adding a strong ion-pairing

agent to the fractions, prior to reinjection.

40

Page 42

UltiMate 3000 RSLCnano – Standard Applications

2.10.4 Testing the Application

The Mic Nan SCX – RP application setup can be tested using the following conditions:

Property Setting

Mobile phase A 100% water + 0.05% TFA

Mobile phase B 20%/80% (v/v) water/ACN + 0.04% TFA

Loading pump A 5 mM HxPO4 pH 3 + 5% ACN

Loading pump B Loading pump A with 1 M NaCl

Loading pump C 98%/2% (v/v) water/ACN + 0.05% TFA

Sample Protein mix digest, prepared according to the included instruction sheet

Injection volume Sample: 10 μL

Fractions: 20 μL

Gradient SCX 0-50% B in 20 min

90%B for 5 min

10 min equilibration

SCX flow rate 50 µL/min

UV detection 214 nm

Fractions Every minute for 20 minutes

Loading time 7 min (may vary with different injection volume/routine)

Desalting time 5 min (counted after loading time has passed)

Gradient RP Isocratic 4% for 10min

4% to 55% B in 30 min

90% B for 5 min

15 min equilibration

WPS temperature

Loading flow 5 μL/min

Flow rate 300 nL/min (nano flow selector)

5°C

The automated off-line application allows, as any off-line application, optimization of the

individual separation dimensions. Thermo Fisher Scientific recommends testing and

optimizing the performance of each separation dimension (SCX and RP) individually in a

one-dimensional application.

This means that, for a nano RP second dimension, the test criteria are identical as described in

the part of Pre-concentration onto a Nano Column on page 21.

41

Page 43

UltiMate 3000 RSLCnano – Standard Applications

2.11 Automated off-line 2D LC, Cap RP (basic) x nan RP (acidic)

2.11.1 Hardware Layout

Figure 28: Setup for an Automated Off-line 2D Cap Nan experiment

The recommend setup is presented in

Figure 28 and consists of:

SRD-3400 5035.9245

Tip: The µFC option limits

the upper pressure of the

first dimension to

350 bar, due to the

NCS-3500RS 5041.0010

applied 8-port valve.

NCP-3200RS 5041.0030

2x 10-port sw. valve 6041.0001

The NCP-3200RS spare

parts kit has two 130 cm

VWD-3400RS 5074.0010

3 nL flow cell 6074.0270

45 nL flow cell 6074.0280

WPS-3000PL 5820.0010

µFC option 6820.0051

long solvent inlet tubing

to place the bottles on

top of the system.

Application kit: 6720.0340

42

Page 44

UltiMate 3000 RSLCnano – Standard Applications

2.11.2 Fluidic Setup

Figure 29 presents the setup using the parts of the Automated Off-line Cap Nan application

kit. Columns are marked with letters, tubing with digits.

Tip: The schematic shows 10-port switching valves, but this application can be

performed on 6-port valves. Ensure that the relative positions of the connections

are correct, and update the valve switching in the Chromeleon templates if

necessary.

Figure 29: Fluidic connections for an Automated Off-line 2D experiment

Table 9: UltiMate 3000 RSLCnano Automated Off-line RP-RP peptides kit (P/N 6720.340) contents

# Item Replacement P/N

75 µm I.D. x 15 cm, packed with Acclaim PepMap RSLC C18, 2 µm, 100Å,

a

nanoViper

Nano Trap Column, 75 µm I.D. x 2 cm, packed with Acclaim PepMap100 C18,

b

3 µm, 100Å (set of 2) nanoViper

0.3 mm I.D. x 15 cm, packed with Acclaim PA2, nanoViper 164592

c

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 20 µm x 350 mm 6041.5240

1

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 50 µm x 350 mm 6041.5540

2

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 50 µm x 650 mm 6041.5575

3

nanoViper outlet tubing 50 um I.D. x 30 cm 6041.4573

4

Nano connector including connection sleeves 6720.0390

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 75 µm x 350 mm 6041.5735

5

164534

164535

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 75 µm x 250 mm 6041.5730

6

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 20 µm x 750 mm 6041.5280

nanoViper sample loop 20 µL, FS/PEEK sheathed I.D. x L 250 µm x 408 mm 6826.2420

43

Page 45

UltiMate 3000 RSLCnano – Standard Applications

100% water, 1% (72 mM) triethylamine (TEA) titrated to pH = 9.6 with acetic

19%/80% (v/v) water/ACN, 1% (72 mM) triethylamine (TEA), titrated to pH =

Table 9: UltiMate 3000 RSLCnano Automated Off-line RP-RP peptides kit (P/N 6720.340) contents - Continued

# Item Replacement P/N

PTFE tubing, 500 µm I.D. 100 cm, used as waste tubing 6720.0077

1/16" Universal Fingertight Fitting, one-piece design, extra long thread, 4 pcs. 6720.0015

Protein mixture digest, 100 pmol, Lyophilized 161088

Cytochrome C digest, 1.6 nmol, Lyophilized 161089

Polypropylene vials for WPS with glass insert, 250 µL, 25 pcs. 6820.0027

Polypropylene caps for WPS vials, 25 pcs. 6820.0028

96 Well Microplate, PP, V-Bottom 6820.4113

LCi Solutions Library CD 6830.0400

Operating Instructions for automated off-line 2D-LC of peptides and proteins 164208

2.11.3 Installation tips

• Follow the General Recommendations for Applications (→ page 6).

• The design of the nano trap column provides the easiest connections, but must only be

used in forward flush operation. Please check the indicated flow direction when

installing a nano trap column.

• If the loss of hydrophilic peptides is observed, the concentration of acetonitrile in the

loading solvent can be decreased down to 99/1 water/ACN + 0.05% TFA.

• Optimal trapping in the second dimension is achieved by adding a strong, acidic ion-

pairing agent to the fractions and a combination of evaporating and diluting the ACN

from the first dimension.

• When two VWD-3400RS detectors are available, they should be placed on top of each

other.

• Depending on the location of the MS outlet and the application of UV detection (1st or

2nd Dimension), the WPS can be placed on the left side of the system.

2.11.4 Testing the application

The automated off-line application allows, as any off-line application, optimization of the

individual separation dimensions. Thermo Fisher Scientific recommends testing and

optimizing the performance of each separation dimension (RP basic and RP acidic)

individually in a one-dimensional application.

This means that the test criteria for a nano RP second dimension are identical as described in

the part of Pre-concentration onto a Nano Column on page 21.

Property Setting

NCS NC_Pump A

NCS NC_Pump B

Loading pump A 98%/2% (v/v) water/ACN + 0.05% TFA

NCP NC_Pump A 100% water + 0.05% TFA

NCP NC_Pump B 20%/80% (v/v) water/ACN + 0.04% TFA

acid

9.6 with

acetic acid

44

Page 46

UltiMate 3000 RSLCnano – Standard Applications

Property Setting

Sample Protein mix digest, prepared according to the included instruction sheet

Injection volume Sample: 10 μL

Fractions: 20 μL

Gradient RP basic 4-60% B in 15 min,

90% B for 5 min,

25 min equilibration

UV detection 214 nm

Fractions Every minute for 20 minutes

Loading time 7 min (may vary with different injection volume/routine)

Gradient RP acidic Isocratic 4% for 10min

4% to 55% B in 30 min

90% B for 5 min

15 min equilibration

WPS temperature

Flow rate cap 6 µL/min

Loading flow 5 μL/min

Flow rate nano 300 nL/min

5°C

45

Page 47

2.12 Tandem nano LC

2.12.1 Hardware Layout

UltiMate 3000 RSLCnano – Standard Applications

Figure 30: Setup for a Tandem nano LC experiment

The recommended setup is presented in Figure 30

and consists of:

SRD-3400 5035.9245

NCS-3500RS 5041.0010

NCP-3200RS 5041.0030

2x 10-port sw.valve 6041.0001

VWD-3400RS 5074.0010

3 nL flow cell 6074.0270

WPS-3000FC 5824.0020

Application kit: 6720.0335

Tip: The components to

convert the WPS3000FC are included in

the application kit.

The NCP-3200RS spare

parts kit has two 130 cm

long solvent inlet tubing

to place the bottles on

top of the system.

46

Page 48

UltiMate 3000 RSLCnano – Standard Applications

2.12.2 Fluidic Setup

Figure 31 presents the setup using the parts of the Tandem nano LC application kit. Columns

are marked with letters, tubing with digits.

Tip: The schematic shows 10-port switching valves, but this application can be

performed on 6-port valves. Ensure that the relative positions of the connections

are correct, and update the valve switching in the Chromeleon templates if

necessary.

Figure 31: Fluidic connections for a Tandem nano LC experiment

A field upgrade to the WPS-3000FC needs to be performed to make the autosampler suitable

for this application. First, the nano injection kit (P/N 6824.0030) should be installed and

secondly the lower valve must be replaced with the nano switching valve (P/N 6825.0020).

All necessary parts are included in the kit. For further information, refer to the operating

instructions for the module.

Table 10: UltiMate 3000 RSLCnano Tandem nano LC kit (P/N 6720.0335) contents

#

Item Replacement P/N

75 µm I.D. x 15 cm, packed with Acclaim PepMap RSLC C18, 2 µm, 100Å,

a

nanoViper

Nano Trap Column, 75 µm I.D. x 2 cm, packed with Acclaim PepMap100 C18,

b

3 µm, 100Å (set of 2) nanoViper

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 20 µm x 350 mm 6041.5240

1

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 75 µm x 650 mm 6041.5775

2,3

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 75 µm x 250 mm 6041.5730

4

nanoViper capillary FS/PEEK sheathed 1/32" I.D. x L 20 µm x 750 mm 6041.5280

164534

164535

PTFE tubing, 500 µm I.D. 100 cm, used as waste tubing 6720.0077

5

nanoViper sample loop 20 µL, FS/PEEK sheathed I.D. x L 250 µm x 408 mm 6826.2420

Fused silica tubing I.D. 20µm O.D. 280µm, 5 meters for nano LC connections 160475

47

Page 49

UltiMate 3000 RSLCnano – Standard Applications

Table 10: UltiMate 3000 RSLCnano Tandem nano LC kit (P/N 6720.0335) contents - Continued

#

Item Replacement P/N

Cleaving stone 160483

Upgrade kit nano/cap WPS-3000TFC 6824.0030

1/32” 2 pos 6 port nano switching valve 6825.0020

Fittings for nano valve 6720.0080

Polypropylene vials for WPS with glass insert, 250 µL, 25 pcs. 6820.0027

Polypropylene caps for WPS vials, 25 pcs. 6820.0028

Cytochrome C digest, 1.6 nmol, Lyophilized 161089

1/16" Universal Fingertight Fitting, one-piece design, extra long thread, 4 pcs. 6720.0015

2.12.3 Installation Tips

• Follow the General Recommendations for Applications (→ page 6).

• The standard column outlets are 30 cm fused silica capillaries. 20 µm I.D. fused silica

tubing is provided in the kit to extend the column outlets if necessary. Replacing the

attached fused silica by the appropriate length using the nano connector on the column

will give the best result.

• The design of the nano trap column provides the easiest connections, but must only be

used in forward flush operation. Please check the indicated flow direction when

installing a nano trap column.

• If the loss of hydrophilic peptides is observed, the concentration of acetonitrile in the

loading solvent can be decreased down to 99/1 water/ACN + 0.05% TFA

• The WPS-3000FC is normally used for fraction collection. By replacing the divert valve

by a nano valve, the autosampler is fitted for tandem nano LC. Controlling the divert

valve position is performed with the commands Collect and Drain.

2.12.4 Testing the Application

The tandem nano LC setup consists of two pre-concentration nano setups that can be operated

individually; therefore, the system can be tested and evaluated using the conditions in the

table below, as also described in the part of Pre-concentration onto a Nano Column on page

21.

Property Setting

Mobile phase A 100% water + 0.05% TFA

Mobile phase B 20%/80% (v/v) water/ACN + 0.04% TFA

Loading pump A 98%/2% (v/v) water/ACN + 0.05% TFA

Sample Cytochrome C 1 pmol/µL, prepared according to instruction sheet

Injection volume Sample: 1 μL

UV detection 214 nm

Loading time 3 min (may vary with different injection volume/routine)

48

Page 50

UltiMate 3000 RSLCnano – Standard Applications

Property Setting

Gradient RP 4% to 55% B in 30 min

90% B for 5 min

15 min equilibration

WPS temperature

Loading flow 5 μL/min

Flow rate 300 nL/min (nano flow selector)

5°C

49

Page 51

UltiMate 3000 RSLCnano – Standard Applications

3 FAQ

3.1 Interpreting a Chromatogram

A typical Cytochrome C separation is shown in Figure 32. The different areas of a

chromatographic separation are marked inside the figure.

Figure 32: Example Cytochrome C separation with different parts of the run identified.

The finite volume of an HPLC system requires a certain time between the formation of a

gradient and detecting the gradient change. This so-called gradient delay can be seen by

comparing the programmed gradient with the detected signal. Figure 32 shows the gradient

delay between pump and UV detector.

The ‘inject peak’ really corresponds to the inject peak in direct injection setups, in preconcentration setups a similar baseline can be observed, but then the area marked as inject

peak resembles the trapping column being placed in line with the nano column.

The dwell volume represents the volume between the autosampler and the nano columns,

since there are usually one (direct injection) or two (pre-concentration) valve switches

involved in the application, which introduce addition fluidics, the dwell volume and gradient

delay are not the same volume.

3.2 Troubleshooting nano LC peptide Applications

The above chromatogram Figure 32 shows the separation of a Cytochrome C digest on a nano

column. The Cytochrome C standard appears relatively simple compared to a typical

proteomics sample, but is ideal for troubleshooting a direct injection and pre-concentration

setup.

Tip: When troubleshooting a pre-concentration setup, Thermo Fisher Scientific

recommends switching back to direct injection if the tips below do not provide

remedy.

In assessing the separation performance of a system several points are evaluated, which are

organized in the flow chart below. The values in the flowchart are based on a Cytochrome C

digest separation; when working with a different standard use a reference chromatogram for

the expected values for number of peaks, intensity and elution window.

50

Page 52

UltiMate 3000 RSLCnano – Standard Applications

51

Page 53

UltiMate 3000 RSLCnano – Standard Applications

3.3 The use of TFA and FA

The separation of peptides by reversed phase is typically done in the presence of an ion

pairing agent. The typical ion pairing agents serve a double function. First, these weak acids

bring the pH of the solvents down to pH 2-3, causing almost all peptides to have an overall

positive charge. Secondly, the negative counterion of the acid will serve as the ion pairing

agent with the peptides to create an overall neutral analyte that is separates on the RP column.

The double function of the ion pairing agent allows having an efficient separation with

minimal additives added to the solvents. Nonetheless, there is a choice of ion pairing agents,

where the most common choice is between Trifluoro Acetic Acid (TFA) and Formic Acid

(FA). In this manual, TFA is used in the application as this is the stronger ion pairing agent

and results in better chromatography. However, in LC-MS applications, often FA is preferred

to minimize the effects of ion suppression. When performing the applications mentioned in

this manual with FA, replace the volume (%) of TFA by double the volume (%) of FA; e.g.

0.05% TFA becomes 0.1% FA.

3.4 Minimizing Baseline Noise

The 3 nL flow cell (P/N 6074.0270) and 45 nL flow cell (P/N 6074.0280) are designed to

function in the same way as transfer tubing normally used to connect a column outlet to a

mass spectrometer. This allows UV detection in nano and capillary LC without introducing

post column band broadening.

Typically peptide UV detection is performed at a wavelength of 214 nm, in which most

organic compounds absorb quite strongly. There are some actions that can be taken to

minimize baseline drift and noise for optimal use of the UV detection.

3.4.1 Drift

Ensure that the UV lamp has been switched on for sufficient time in order to have it running

at a stable temperature. Chromeleon can detect this and will give a warning during the ‘Ready

Check‘ if the UV lamp temperature is not stable yet. The UV detector can be used, but it is

not at its optimal performance.

Gradient RP nano LC typically involves a significant change in solvent composition. The

higher absorption from the organic modifier in the B solvent will result in a rise of the

baseline. The ion pairing agent (typically FA or TFA) in the A and B solvent can be used to

compensate the baseline rise. As a rule of thumb, the compositions as indicated in Table 11

can be used to obtain a straight baseline.

Table 11: Ion pairing agent addition

A B

FA 0.1% 0.08%

TFA 0.05% 0.04%

Lamp and flow cell age can have a significant influence on baseline drift. New lamps and

flow cells may show some drift during the so-called ‘burn in’ period.

Lamps should be replaced after approximately 2000 hours and older flow cells can be cleaned

by flushing overnight with organic solvent or for a shorter period with a strong acidic

solution; see operating instructions for details.

52

Page 54

UltiMate 3000 RSLCnano – Standard Applications

3.4.2 Unstable Baseline

Unstable baselines can have various causes. The UltiMate 3000 RSLCnano pumps are

designed to provide the best gradient precision, but solvent miscibility can present a problem.

Therefore, Thermo Fisher Scientific recommends using a minimum of 5% water in the

organic mobile phase.

Baseline artifacts in pre-concentration applications using low loading flows (< 10 µL/min)

may occur. These artifacts are only observed in the UV signal and have no effect on the

performance of the analysis. If artifacts in the baseline are observed, Thermo Fisher Scientific

recommends bypassing the degasser in pre-concentration applications where no gradient

formation is required and loading flows are below 20 µL/min. If bypassing the degasser is

undesired or impossible an alternative is to maintain degassing, but to increase the loading

flow during the elution phase to values between 30 and 100 µL/min.

53

Page 55

UltiMate 3000 RSLCnano – Standard Applications

PEEK Tubing

Nut

Ferrule

Injection Port/Union

Fused Silica Capillary

PTFE Connec t or

4 Appendix – Traditional Capillary Connections

• When installing fused silica tubing (for example, the capillary column):

o Insert the PEEK sleeve with the stainless steel nut (standard) or PEEK nut

(biocompatible system) and the appropriate ferrule in a port (or the preassembly

tool, when working on a biocompatible system!).

o Push the sleeve all the way into the port. It is essential for a zero dead volume

connection that the assembly seats firmly.

o Tighten the nut by two or three turns to make certain that the ferrule grabs the

sleeve.

o Remove the pre-assembled fitting, and then slide the capillary (column) into the

sleeve.

o When re-installing the fitting together with the capillary (column), make certain

that the tip of the tubing does not extend the tip of the sleeve. Tighten the nut

finger-tight.

o Push the capillary (column) all the way into the sleeve (port) to minimize dead

volume. It is essential for a zero dead volume connection that the assembly seats

firmly.

• To prepare connections with PTFE sleeves:

o Start flow delivery.

o Slide the fused silica capillary (for example, the column) approximately 1- 2 mm

into the sleeve.

o Wait until a droplet is formed at the outlet. Remove the droplet (together with

potential dirt in the tubing).

o Now push the capillary (column) half-way into the sleeve. Wait again until a

droplet is formed and remove it.

o Connect the second capillary (for example, the inlet capillary of the flow cell).

54

Page 56

UltiMate 3000 RSLCnano – Standard Applications

PEEK Sleeve (o range)

Nut

Fused Silica Capillary

280 ∝m O.D.

Microt ight

Union

Gauge Plug

• When using a micro tight union, always use the gauge plug provided with the union to

make sure that the connection is well centered.

55

Page 57

UltiMate 3000 RSLCnano – Standard Applications

164567

164568

164569

164570

164571

164572

164561

164562

164563

164534

164536

164540

164560

164537

164564

164535

164584

164543

164557

164542

164585

164586

164558

5 Appendix – Common Spare Parts in nano LC

The three tables below list the most common parts to be used with the UltiMate 3000

RSLCnano system. They are divided by columns (Table 12), tubing (Table 13, Table 14), and

hardware (Table 15).

Table 12: List of columns available for the UltiMate 3000 RSLCnano system

Item P/N

Acclaim PepMap Columns

Acclaim PepMap100, C18, 3 μm, 100 Å, 75 μm I.D. × 5 cm, nanoViper

Acclaim PepMap100, C18, 3 μm, 100 Å, 75 μm I.D. × 15 cm, nanoViper

Acclaim PepMap100, C18, 3 μm, 100 Å, 75 μm I.D. × 25 cm, nanoViper

Acclaim PepMap100, C18, 3 μm, 100 Å, 75 μm I.D. × 50 cm, nanoViper

Acclaim PepMap100, C18, 3 μm, 100 Å, 300 μm I.D. × 15 cm, nanoViper

Acclaim PepMap100, C18, 3 μm, 100 Å, 1 mm I.D. × 15 cm, nanoViper

Acclaim PepMap RSLC Columns

Acclaim PepMap RSLC C18, 2 μm, 100 Å, 50 μm I.D. x 5 cm, nanoViper

Acclaim PepMap RSLC C18, 2 μm, 100 Å, 50 μm I.D. x 15 cm, nanoViper

Acclaim PepMap RSLC C18, 2 μm, 100 Å, 75 μm I.D. x 5 cm, nanoViper

Acclaim PepMap RSLC C18, 2 μm, 100 Å, 75 μm I.D. x 15 cm, nanoViper

Acclaim PepMap RSLC C18, 2 μm, 100 Å, 75 μm I.D. x 25 cm, nanoViper

Acclaim PepMap RSLC C18, 2 μm, 100 Å, 75 μm I.D. x 50 cm, nanoViper

Acclaim PepMap RSLC C18, 2 μm, 100 Å, 300 μm I.D. x 5 cm, nanoViper

Acclaim PepMap RSLC C18, 2 μm, 100 Å, 300 μm I.D. x 15 cm, nanoViper

Nano Trap Columns

Nano Trap Column, 100 μm I.D. x 2 cm, packed with Acclaim PepMap100 C18, 5 μm

Nano Trap Column, 75 μm I.D. x 2 cm, packed with Acclaim PepMap100 C18, 3 μm

Cartridge based trap columns.

μ-Precolumn™ holder, 5 mm, with 30 μm i.d. connecting tubing, nanoViper fittings 164649

300 µm i.d. x 5 mm, packed with Acclaim PepMap100 C18, 5 µm, 100Å (set of 5 cartridges) 160454

PepSwift and ProSwift Monolithic Columns

PepSwift Monolithic Nano Column, 100 μm I.D. × 5 cm, nanoViper

PepSwift Monolithic Nano Column, 100 μm I.D. x 25 cm, nanoViper

PepSwift Monolithic Capillary Column, 200 μm I.D. x 5 cm, nanoViper

PepSwift Monolithic Capillary Column, 200 μm I.D. x 25 cm, nanoViper

PepSwift Monolithic Capillary Column, 500 μm I.D. × 5 cm, nanoViper

ProSwift RP-10R Monolithic Capillary Column, 1 mm I.D. × 5 cm, nanoViper

PepSwift Trap Columns

PepSwift Monolithic Trap Column, 200 μm x 5 mm, set of 2, nanoViper

56

Page 58

UltiMate 3000 RSLCnano – Standard Applications

Table 13: Matrix for connection tubing for the UltiMate 3000 RSLCnano system

ID

Length (mm)

70 6041.5120 6041.5123 6041.5126 6041.5810 6041.5817

150 6041.5121 6041.5124 6041.5127 6041.5811 6041.5818

250 - - 6041.5730 6041.5812 6041.5819

350 6041.5240 6041.5540 6041.5735 6041.5813 6041.5820

450 - - - 6041.5814 6041.5821

550 6041.5260 6041.5560 6041.5760 6041.5815 6041.5822