Page 1

MSQ

Document No. 031871

Hardware

Revision 02

October 2003

™

Page 2

©2003 by Dionex Corporation

All rights reserved worldwide.

Printed in the United States of America.

This publication is protected by federal copyright law. No part of this publication may be copied or

distributed, transmitted, transcribed, stored in a retrieval system, or transmitted into any human or computer

language, in any form or by any means, electronic, mechanical, magnetic, manual, or otherwise, or disclosed

to third parties without the express written permission of Dionex Corporation, 1228 Titan Way, Sunnyvale,

California 94088-3603 U.S.A.

DISCLAIMER OF WARRANTY AND LIMITED WARRANTY

THIS PUBLICATION IS PROVIDED “AS IS” WITHOUT WARRANTY OF ANY KIND. DIONEX

CORPORATION DOES NOT WARRANT, GUARANTEE, OR MAKE ANY EXPRESS OR

IMPLIED REPRESENTATIONS REGARDING THE USE, OR THE RESULTS OF THE USE, OF

THIS PUBLICATION IN TERMS OF CORRECTNESS, ACCURACY, RELIABILITY,

CURRENTNESS, OR OTHERWISE. FURTHER, DIONEX CORPORATION RESERVES THE

RIGHT TO REVISE THIS PUBLICATION AND TO MAKE CHANGES FROM TIME TO TIME IN

THE CONTENT HEREINOF WITHOUT OBLIGATION OF DIONEX CORPORATION TO

NOTIFY ANY PERSON OR ORGANIZATION OF SUCH REVISION OR CHANGES.

TRADEMARKS

Chromeleon is a registered trademark of Dionex Corporation.

Cone Wash, M-Path, MSQ, and Xcalibur are trademarks of Thermo Electron Corporation.

Microsoft is a registered trademark of Microsoft Corporation.

Q-tip is a trademark of Chesebrough-Pond’s, Inc.

Teflon, Vespel, and Viton are registered trademarks of E.I. du Pont de Nemours and Company.

PRINTING HISTORY

Revision 01, July 2002

Revision 02, October 2003

The products of Dionex Corporation are produced under ISO 9001 accredited quality management systems.

Published by Technical Publications, Dionex Corporation, Sunnyvale, CA 94086.

Page 3

Chapter 1

Introducing the MSQ 1.

Introducing the MSQ.................................................................................................................1-i

Introduction ....................................................................................................................................1-1

System Overview............................................................................................................................1-2

What Is Mass Detection?...................................................................................................1-4

Exterior Features of the MSQ............................................................................................1-5

The Source–An Introduction to API Techniques ...........................................................................1-8

Electrospray.......................................................................................................................1-9

Atmospheric Pressure Chemical Ionization.....................................................................1-13

Source Fragmentation......................................................................................................1-16

Cone Voltage Ramping ...................................................................................................1-18

Polarity Switching ...........................................................................................................1-19

Application of API Techniques .......................................................................................1-20

The Self-Cleaning Source: Cone Wash ........................................................................................1-23

Introduction .....................................................................................................................1-23

Functional Description ....................................................................................................1-24

The Reference Inlet System..........................................................................................................1-25

Introduction .....................................................................................................................1-25

Functional Description ....................................................................................................1-25

The Mass Analyzer and Detector .................................................................................................1-26

The Vacuum System.....................................................................................................................1-27

The Data System...........................................................................................................................1-28

Software...........................................................................................................................1-28

Raw Data .........................................................................................................................1-30

Raw Data Types...............................................................................................................1-31

____________________________MSQ Hardware Manual _____________________________ 1-i

Page 4

Introducing the MSQ

Introduction ____________________________________________________________________________

1-ii____________________________ MSQ Hardware Manual ____________________________

Page 5

Introducing the MSQ

___________________________________________________________________________ Introduction

Introduction

The MSQ™ MS detector has been specifically designed and engineered for

liquid chromatographic detection using Atmospheric Pressure Ionization

(API) and Mass Spectrometry (MS) technology. These technologies can

provide sensitive and selective detection of organic molecules.

Interfacing High Performance Liquid Chromatography (HPLC or LC) and

MS provides the separation scientist with one of the most powerful

analytical tools available. Both LC and MS have developed to a point

whereby they represent two of the most important techniques in

characterizing and detecting organic compounds. Although the potential

benefits of interfacing LC to MS have been clearly recognized for many

years, producing a truly automated “connect-and-use” interface has proven

to be a challenging task.

Atmospheric Pressure Ionization (API) techniques now provide highly

sensitive detection using conventional to capillary LC flow rates on benchtop MS detector systems. LC/MS works with typical solvent compositions,

whether the separation is achieved by isocratic or gradient elution.

Historically, LC/MS has been compatible only with volatile buffer systems

using modifiers such as trifluoroacetic acid, formic acid, and acetic acid.

Phosphate buffers, although extensively used in LC separations, were not

suited to LC/MS due to rapid blocking of the ion sampling region caused by

the deposition of involatile phosphate salts. The self-cleaning API source

allows for extended periods of operation in LC/MS with chromatographic

buffers such as phosphates or ion-pairing agents and samples in dirty

matrices.

API using Electrospray (ESI) or Atmospheric Pressure Chemical Ionization

(APCI) interfaces has proved to be invaluable in meeting sensitivity

requirements in quantitative methods. It can also provide structural

information, which is complementary to techniques such as NMR and infra

red spectroscopy.

This introduction focuses on the principal components of the system.

___________________________MSQ Hardware Manual ____________________________ 1-1

Page 6

Introducing the MSQ

System Overview ________________________________________________________________________

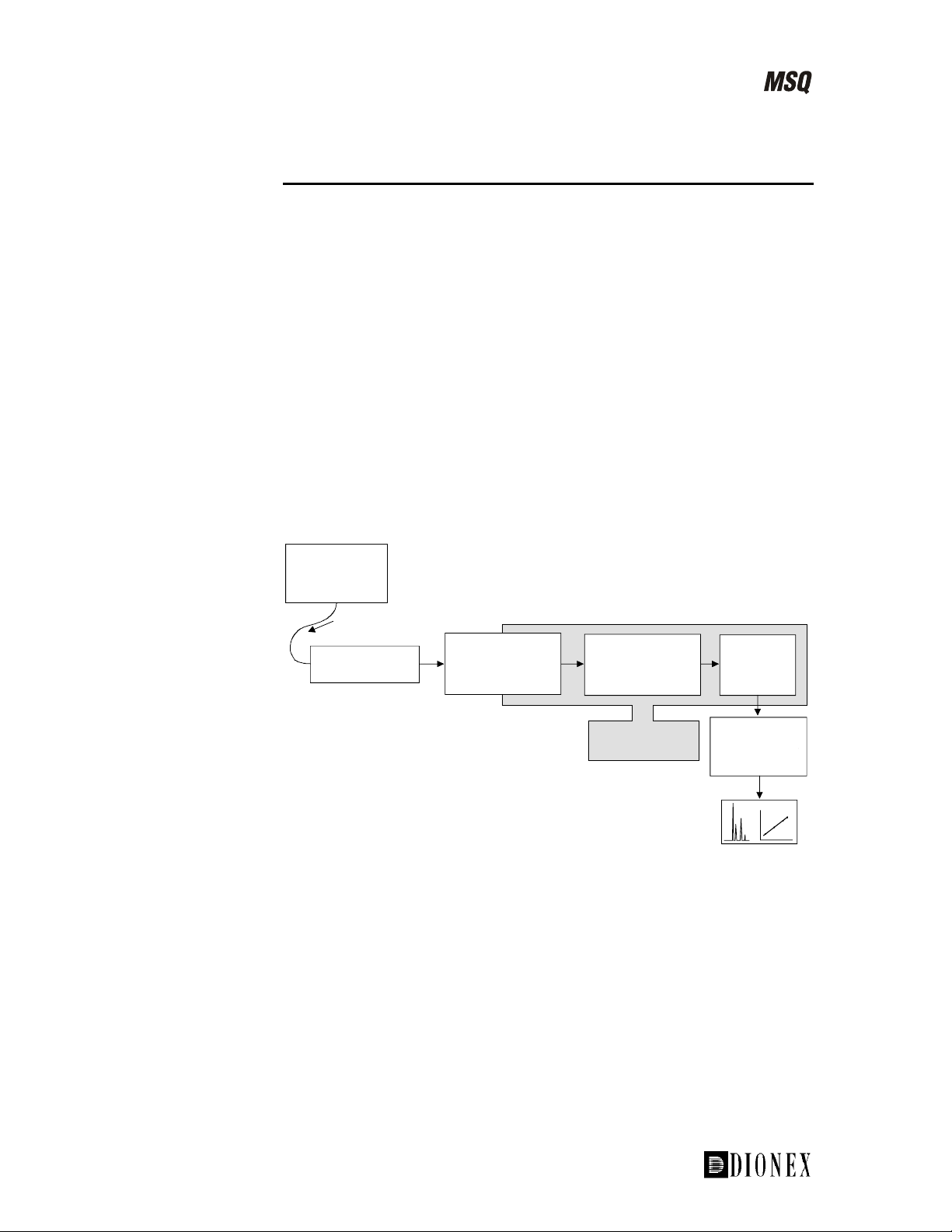

System Overview

The MSQ MS detector is an integral part of the LC detection system. Key

points of the system are:

The sample is introduced into the ion source using an LC system,

•

possibly through a column.

•

In an API MS detector, the part of the source where ionization takes

place is held at atmospheric pressure, giving rise to the term

Atmospheric Pressure Ionization (API).

•

In ESI, the sample is ionized in the liquid phase, while in APCI,

ionization occurs in the gas phase. In both cases, efficient desolvation is

needed to remove the solvents from the sample.

•

Ions, now in the gas phase, are passed through the mass analyzer and are

collected at the detector.

•

The detected signal is sent to the data system and stored ready for

processing.

LC System

Sample

introduction

LC Column

Separation

Figure 1-1. The key components of the MSQ API LC detection system

Ion Source

Ionization &

transmission

Mass Analyzer

Sorting of ions

Turbomolecular

& rotary pumps

Molecular weight information

Structural information

Positive identification

Quantitative information

Detector

Detection

of ions

Data System

Windows NT

1-2 ___________________________ MSQ Hardware Manual ____________________________

Page 7

Introducing the MSQ

_______________________________________________________________________System Overview

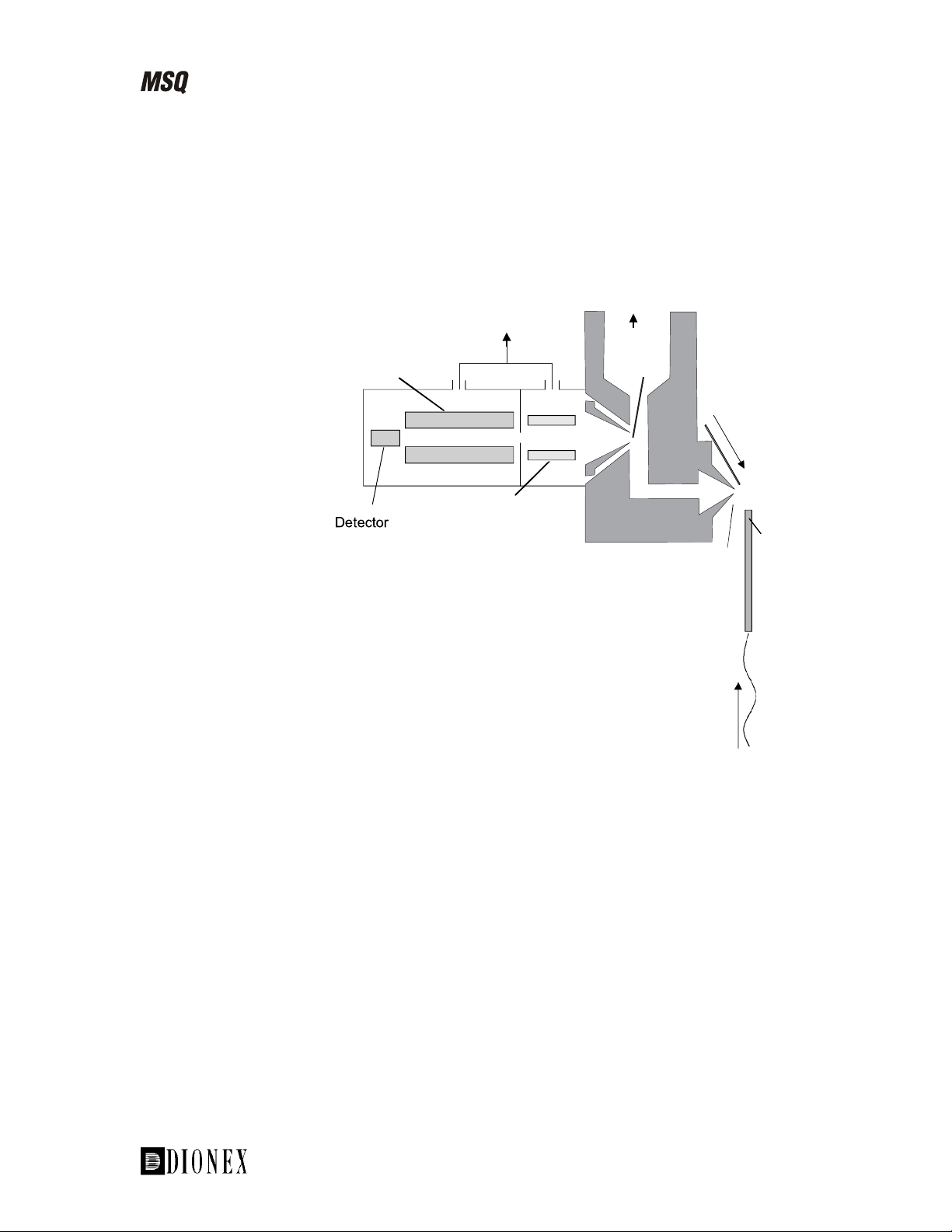

The main features of the MSQ MS detector are:

Dual ESI/APCI orthogonal probe •

• • Self-cleaning API-LC/MS interface

M-Path™ triple orthogonal source

Quadrupole

mass analyzer

Split flow

turbomolecular

pump

Square

quadrupole

RF lens

Rotary

pump

Exit cone

Entrance cone

From HPLC

Cone wash

Orthogonal sample

introduction probe

Figure 1-2. Schematic diagram of the MSQ API inlet, analyzer, and

detector system

The LC eluent is ionized at the API probe and the resulting ions are focused

into a square quadrupole RF lens. The quadrupole mass analyzer filters the

ions before detection.

___________________________MSQ Hardware Manual ____________________________ 1-3

Page 8

Introducing the MSQ

System Overview ________________________________________________________________________

What Is Mass Detection?

Mass detection is a very powerful analytical technique used in a number of

fields, including:

Identification of unknown compounds •

• • Quantitation of known compounds

Determination of chemical structure

The basic function of an MS detector is to measure the mass-to-charge ratio

of ions.

The unit of mass used is the Dalton (Da). One Dalton is equal to 1/12 of the

mass of a single atom of carbon-12. This follows the accepted convention

that an atom of carbon-12 has exactly 12 atomic mass units (amu). The MS

detector does not directly measure molecular mass, but the mass-to-charge

ratio of the ions. Electrical charge is a quantized property and so can exist

only as an integer; that is, 1, 2, 3, and so on. The unit of charge used here (z)

is that which is on an electron (negative) or a proton (positive). Therefore,

the mass-to-charge ratio measured can be denoted by m/z. Most ions

encountered in mass detection have just one charge. In this case, the massto-charge ratio is often spoken of as the “mass” of the ion.

1-4 ___________________________ MSQ Hardware Manual ____________________________

Page 9

Introducing the MSQ

_______________________________________________________________________System Overview

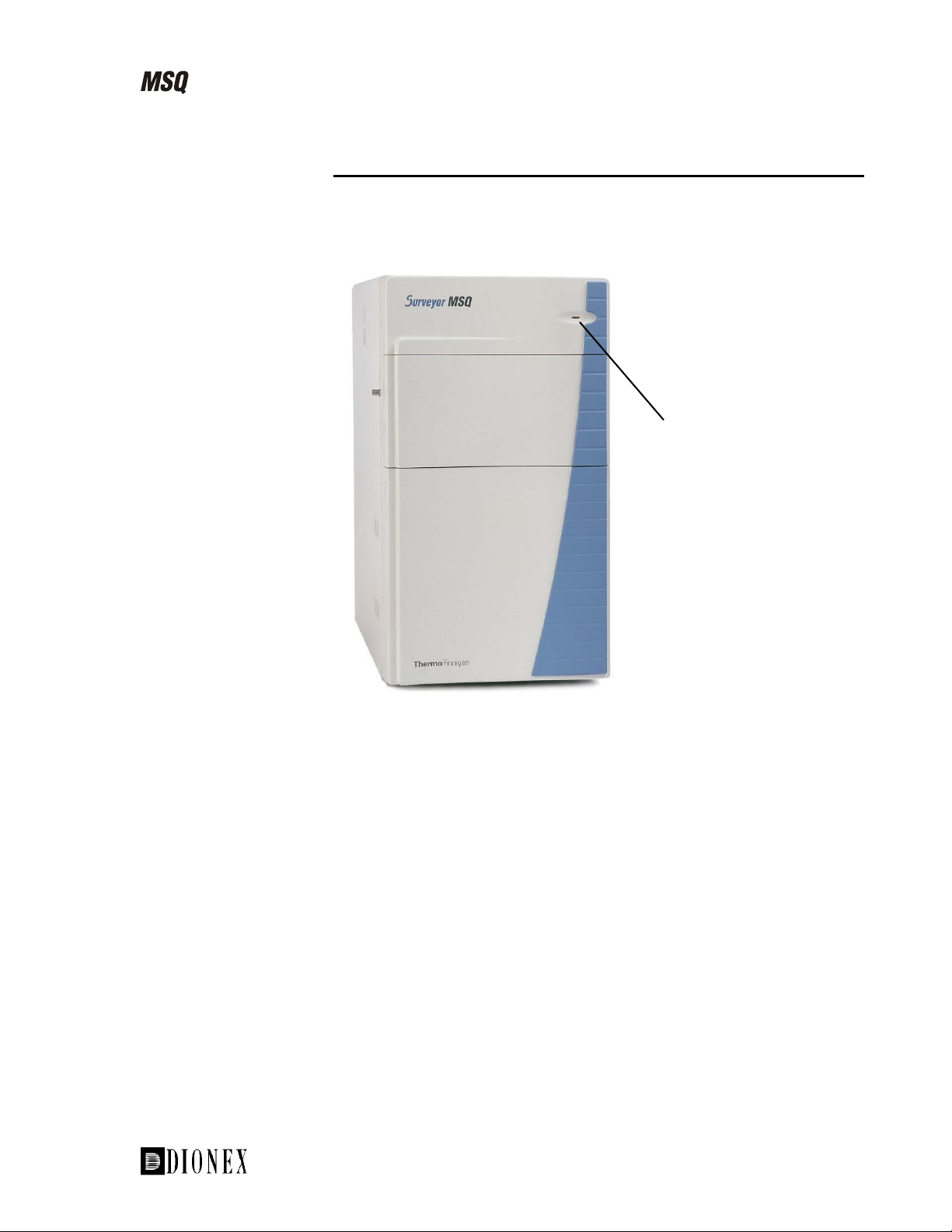

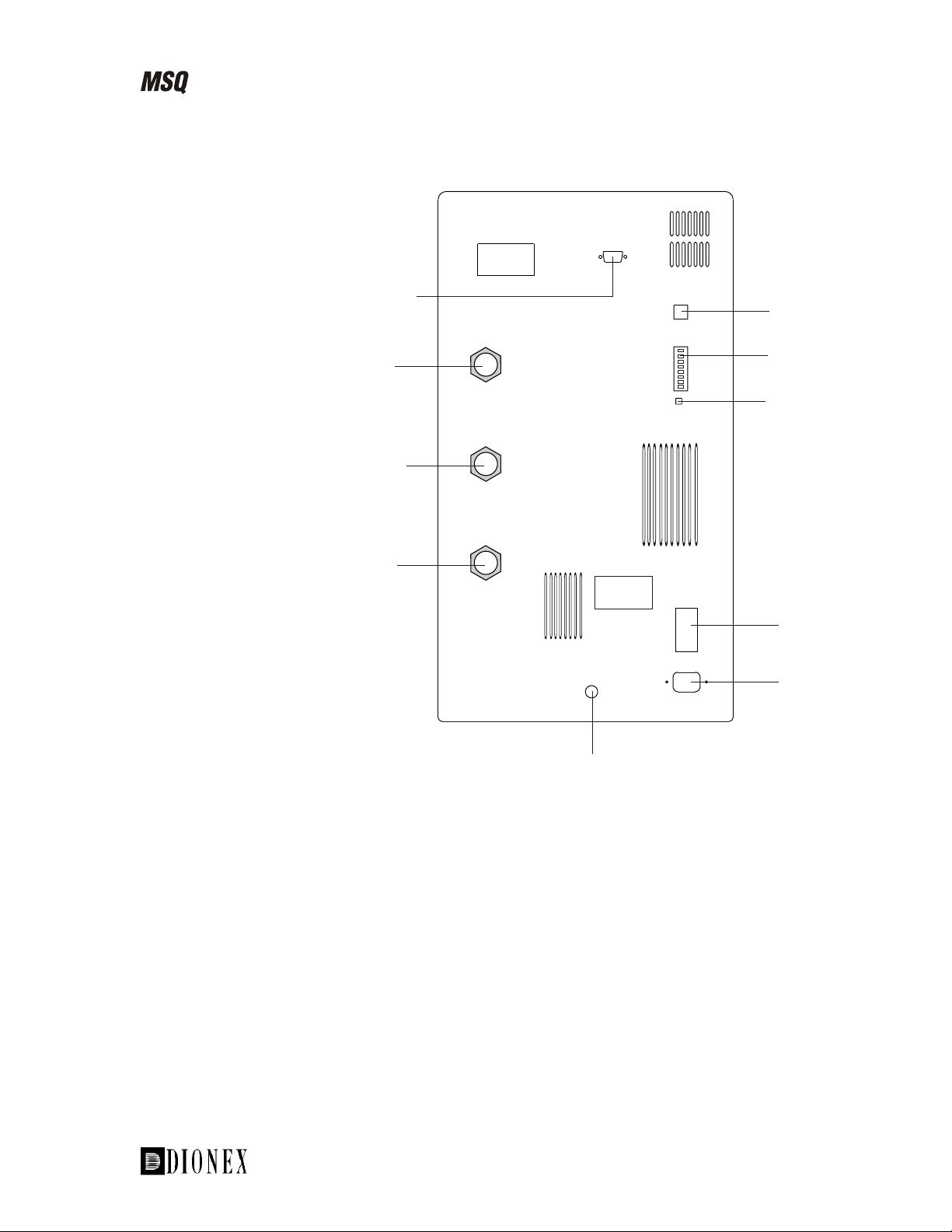

Exterior Features of the MSQ

This section highlights the exterior features of the MSQ. The parts labeled

here may be referred to in later chapters of this manual or other manuals

supplied with the MSQ.

Status light

Figure 1-3. Front view of the MSQ

Figure 1-3 shows the front view of the MSQ. The main feature is the status

light.

___________________________MSQ Hardware Manual ____________________________ 1-5

Page 10

Introducing the MSQ

System Overview ________________________________________________________________________

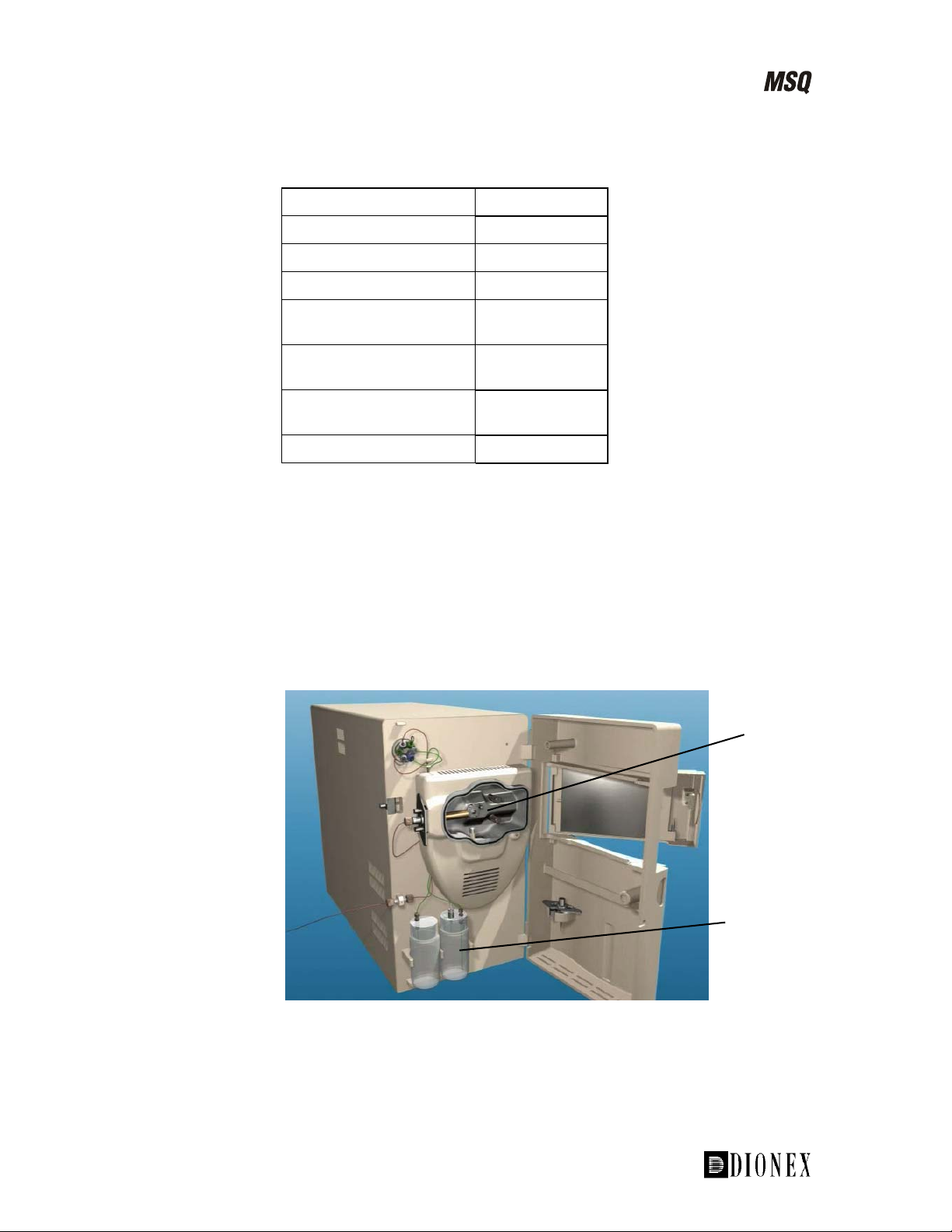

Table 1-1. Instrument status light

Instrument Status Light

Vented Red

Venting Red

Pumping down Flashing yellow

Under vacuum (above

vacuum trip)

Under vacuum (ready

for use)

Operate on (MSQ in

use)

Source enclosure open Red

Red

Yellow

Green

The vacuum trip is the pressure below which it is safe to switch on the

voltages in the source. When the instrument is functioning normally, the

status light will go from flashing yellow to solid yellow and Operate can be

switched On. If the pressure in the instrument rises above the operating

pressure, the status light turns red to indicate that the pressure is above a

safe level. See the chapter Shutting Down and Restarting the System for

information on pumping down the MSQ.

Figure 1-4 shows the MSQ with the doors open. The source enclosure and

reference inlet are now visible.

Source

enclosure

Figure 1-4. The MSQ with the doors open

1-6 ___________________________ MSQ Hardware Manual ____________________________

Reference

inlet

Page 11

Introducing the MSQ

_______________________________________________________________________System Overview

Figure 1-5 is a schematic of the rear view of the MSQ.

PUMP RELAY

Rotary pump power

To P C

Contact closure and

analog inputs

To rotary pump

USB

SOURCE

USER I/O

EXHAUST

Exhaust from API

source

BACKING

To rotary pump

Figure 1-5. Rear view of the MSQ

RESET

MODEL:

RATING: 220-240v

GAS IN

6 BAR MAX

50/60 Hz

1000 VA

MAINS ON/OFF

Gas inlet for nebulizer

and sheath gas

Reset communications

Power switch

MAINS IN

Power supply

___________________________MSQ Hardware Manual ____________________________ 1-7

Page 12

Introducing the MSQ

The Source–An Introduction to API Techniques ________________________________________________

The Source–An Introduction to API Techniques

The source, or interface, performs four main functions:

Separates the analytes from the solvent and buffer systems used in LC •

• • Ionizes the analyte molecules

Allows efficient transfer of ions into the mass analyzer for detection

LC eluent enters the source through the orthogonal sample introduction

probe. The primary objective of an orthogonal probe is to direct any

involatile components present in the LC eluent, such as those from buffers,

ion-pairing agents, or matrices, away from the entrance orifice. Under

operating conditions, however, both the sample ions and the charged liquid

droplets (containing any involatile components, if they are present) are

deflected by the electric field towards the entrance orifice. This leads to a

gradual buildup of involatiles and a concomitant loss in sensitivity with

time. The self-cleaning source delivers a constant, low flow of solvent (the

cone wash™) to the edge of the inlet orifice, helping to prevent a buildup of

involatiles during an LC/MS run.

1-8 ___________________________ MSQ Hardware Manual ____________________________

Page 13

Introducing the MSQ

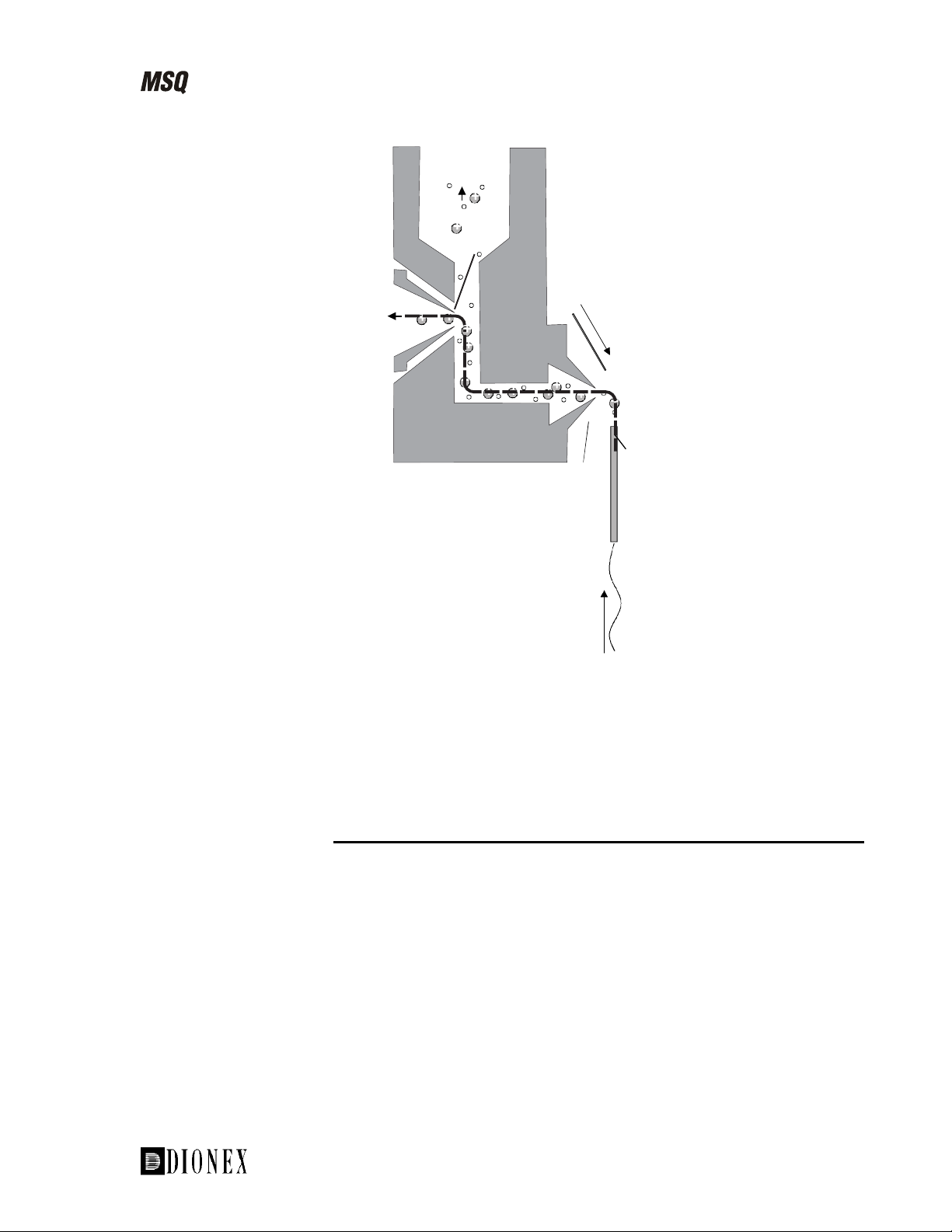

_______________________________________________ The Source–An Introduction to API Techniques

Rotary

pump

Exit cone

To the mass

analyzer

Entrance cone

From HPLC

Figure 1-7. Schematic of the MSQ source showing the cone wash

Cone wash

Orthogonal sample

introduction probe

Two types of API are commonly encountered. These are Electrospray

Ionization (ESI) and Atmospheric Pressure Chemical Ionization (APCI).

The following sections discuss the mechanism of ion generation in each.

Electrospray

Electrospray Ionization (ESI) is regarded as a soft ionization technique

providing a sensitive means of analyzing a wide range of polar molecules.

Since the first combined ESI LC/MS results were announced in 1984, and

its first application to protein analysis four years later, the technique has

become an established analytical tool in separation science.

When applied to smaller molecules up to 1000 Daltons in molecular mass,

electrospray ionization results in either a protonated, [M+H]

1-8) or deprotonated, [M-H]

-

, molecule. Choice of ionization mode is

governed by the functional chemistry of the molecule under investigation. In

ESI, fragmentation is generally not apparent; however, increased source

voltages can induce fragmentation to provide structural information.

___________________________MSQ Hardware Manual ____________________________ 1-9

+

(see Figure

Page 14

Introducing the MSQ

z

The Source–An Introduction to API Techniques ________________________________________________

100

240

OH

NH

tBu

HO

%

HO

Chemical structure of salbutamol,

(molecular weight 239)

0

60 80 100 120 140 160 180 200 220 240 260 280 300

241

m/

Figure 1-8. Electrospray mass spectrum of salbutamol in positive ion

mode

The base peak at m/z 240 (see Figure 1-8) corresponds to the protonated

salbutamol molecule. It is notable that ESI results in a prominent base peak

with minimal fragmentation, quite dissimilar from the results often achieved

with GC/MS.

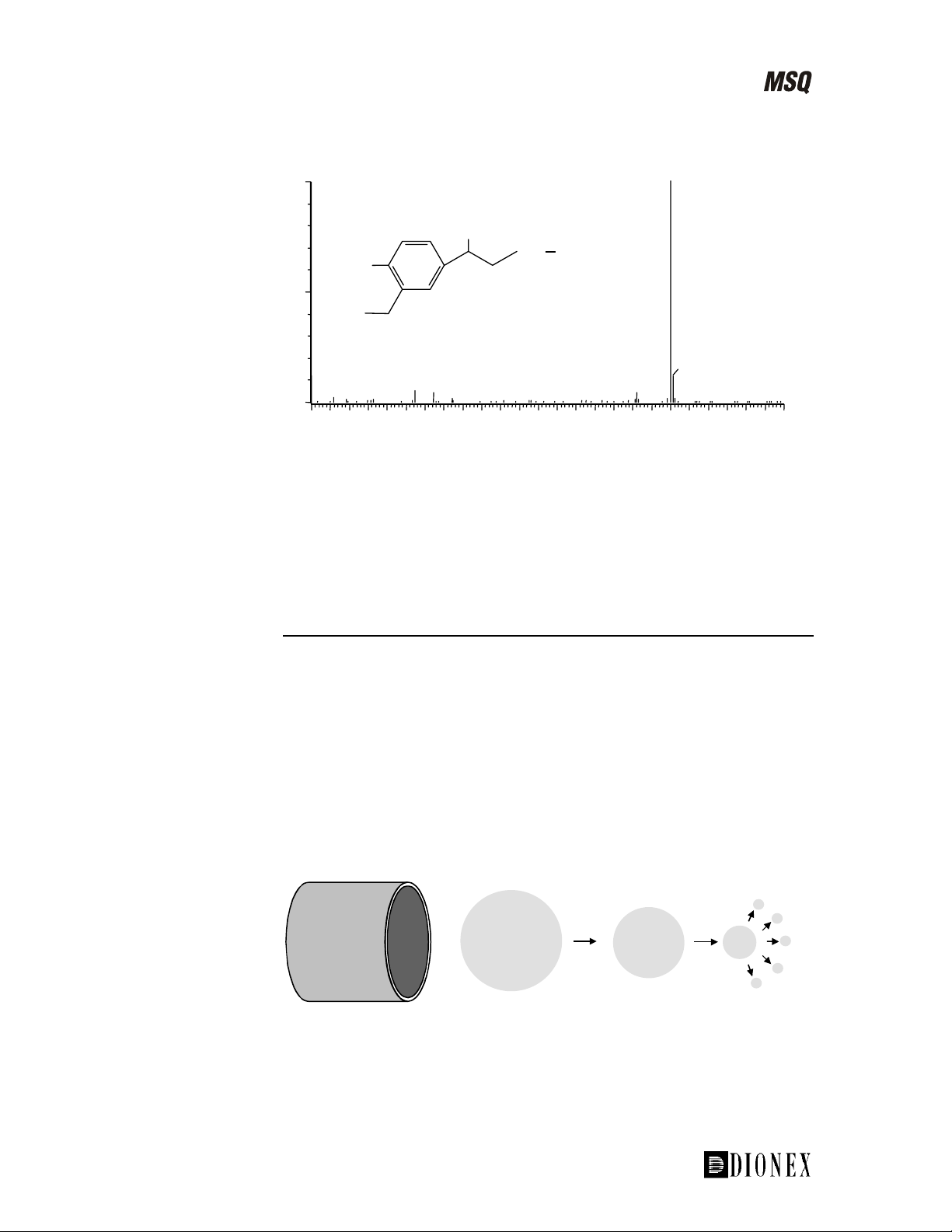

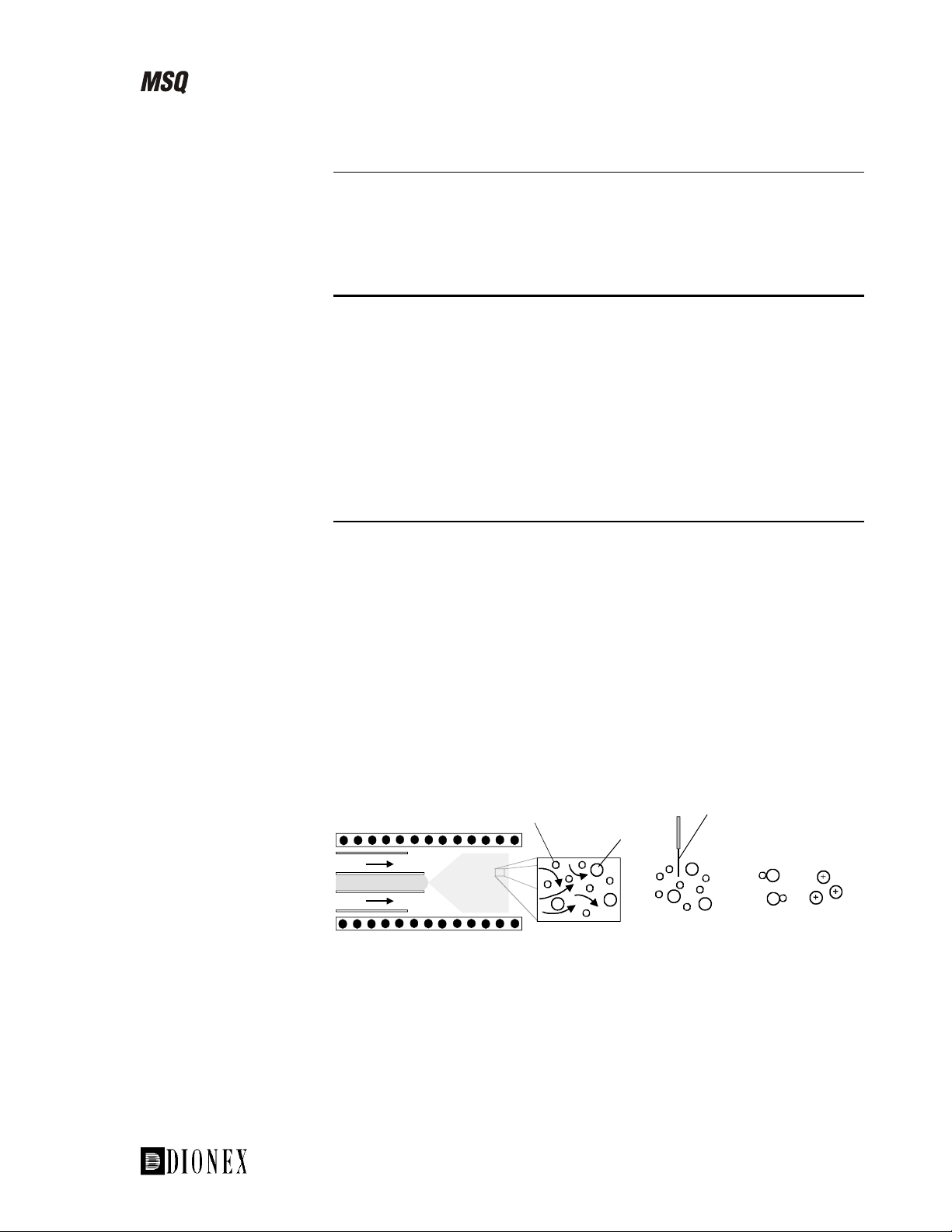

Mechanism of Ion Generation

Electrospray ionization operates by the process of emission of ions from a

droplet into the gas phase, a process termed Ion Evaporation. A solvent is

pumped through a stainless steel insert capillary that carries a high potential,

typically 3 to 5 kV (see Figure 1-9). The strong electric field generated by

this potential causes the solvent to be sprayed from the end of the insert

capillary (hence, electrospray), producing highly charged droplets. As the

solvent is removed by the desolvation process, the charge density on the

surface of the droplets increases until the Rayleigh limit is exceeded; after

this, a multitude of smaller droplets are formed by coulombic explosion.

This process is repeated until charged sample ions remain. These ions are

then available for sampling by the ion source.

-

+

Insert capillary +3-5 kV

+

+

+

+

+

Droplet

containing

ions

+

+

+

+

-

+

+

+

+

-

+

+

+

+

+

+

+

As the droplet

evaporates, the

electric field

increases and ions

move towards

the surface

Figure 1-9. Positive ion electrospray mechanism

-

+

+

+

-

+

+

+

+

+

-

+

-

+

+

+

-

+

+

++

+

+

+

Ions evaporate

from the surface

1-10 __________________________ MSQ Hardware Manual ____________________________

Page 15

Introducing the MSQ

_______________________________________________ The Source–An Introduction to API Techniques

Electrospray Ionization Using the MSQ Source

The sample, in solution, enters the source via a stainless steel insert capillary

held at a voltage of 3 to 5 kV. The insert capillary is surrounded by a tube

that directs a concentric flow of nitrogen nebulizing gas past the droplets of

liquid forming at the probe tip. The action of the nebulizing gas, high

voltage, and heated probe produces an aerosol of liquid droplets containing

ions of the sample and solvent. The ion evaporation process is assisted by a

second concentric flow of heated nitrogen gas. This is the sheath gas. This

highly efficient evaporation process close to the entrance cone enables the

routine use of high LC flow rates (up to 2.0 mL/min) in ESI mode.

The newly formed ions then enter the focusing region through the entrance

cone. This is due to the following:

The high electric field. The insert capillary is at 3 to 5 kV with respect

•

to the rest of the source, which is typically at 20 to 30 V.

• The gas flow into the focusing region.

Ions then exit the focusing region and pass into the RF lens. The RF lens

(square quadrupole) helps to focus the ions before they enter the mass

analyzer region.

Region

Intermediate

Pressure

Region

Exit cone

Entrance cone

Probe

Insert capillary

LC eluent

Nebulizing gas, N

Sheath gas, N

2

2

Insert

Cone Wash

Atmospheric

Pressure

Region

Figure 1-10. Schematic of the ESI source on the MSQ, showing the

principal components and pressure regions

Rotary

pump

___________________________MSQ Hardware Manual ___________________________ 1-11

Page 16

Introducing the MSQ

The Source–An Introduction to API Techniques ________________________________________________

Spectral Characteristics

Polar compounds of low molecular weight (<1000 amu) typically form

singly charged ions by the loss or gain of a proton. Basic compounds (for

example, amines) can form a protonated molecule [M+H]

analyzed in positive ion mode to give a peak at m/z M+1. Acidic

compounds (for example, sulphonic acids) can form a deprotonated

molecule [M-H]

-

, which can be analyzed in negative ion mode to give a

peak at m/z M-1. As electrospray is a very soft ionization technique, there is

usually little or no fragmentation and the spectrum contains only the

protonated or deprotonated molecule.

Some compounds are susceptible to adduct formation if ionization takes

place in the presence of contamination or additives such as ammonium or

sodium ions. The spectra will show other ions in addition to, or instead of,

the quasi-molecular ion. Common adducts are ammonium ions NH

[M+18]

100

+

, sodium ions Na+ [M+23]+, and potassium ions K+ [M+39]+.

+

, which can be

+

4

[M+H]

322

+

%

+

100

103

80

99

0

60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360

141

145

181

187

241

244

261

279

282

[M+Na]

344

363

m/z

Figure 1-11. Electrospray spectrum showing a sodium adduct

The singly charged ions arising from samples of relatively low molecular

masses can be interpreted directly, as they represent the protonated or

deprotonated molecule. Electrospray, however, can produce multiply

charged ions for analytes that contain multiple basic or acidic sites, such as

proteins and peptides. As an MS detector measures mass-to-charge ratio

(m/z), these ions appear at a m/z value given by the mass of their protonated

molecule divided by the number of charges:

n

+

nHM

+

n

zm

=

Where, M = actual mass, n = number of charges, and H = mass of a proton.

Electrospray allows molecules with molecular weights greater than the mass

range of the MS detector to be analyzed. This is a unique feature of

electrospray.

1-12 __________________________ MSQ Hardware Manual ____________________________

Page 17

Introducing the MSQ

_______________________________________________ The Source–An Introduction to API Techniques

Flow Rate

The electrospray source can be used with flow rates from 5.0 µL/min to

2.0 mL/min.

Atmospheric Pressure Chemical Ionization

Atmospheric Pressure Chemical Ionization (APCI) is also a very soft

ionization technique and has many similarities to electrospray ionization.

Ionization takes place at atmospheric pressure and the ions are extracted into

the MS detector in the same way as in electrospray.

Similarly, as observed in ESI, [M+H]

providing molecular weight information. Fragmentation can be induced in

the source by increasing the source voltage to give structural information.

Mechanism of Ion Generation

+

and [M-H]- ions are usually formed

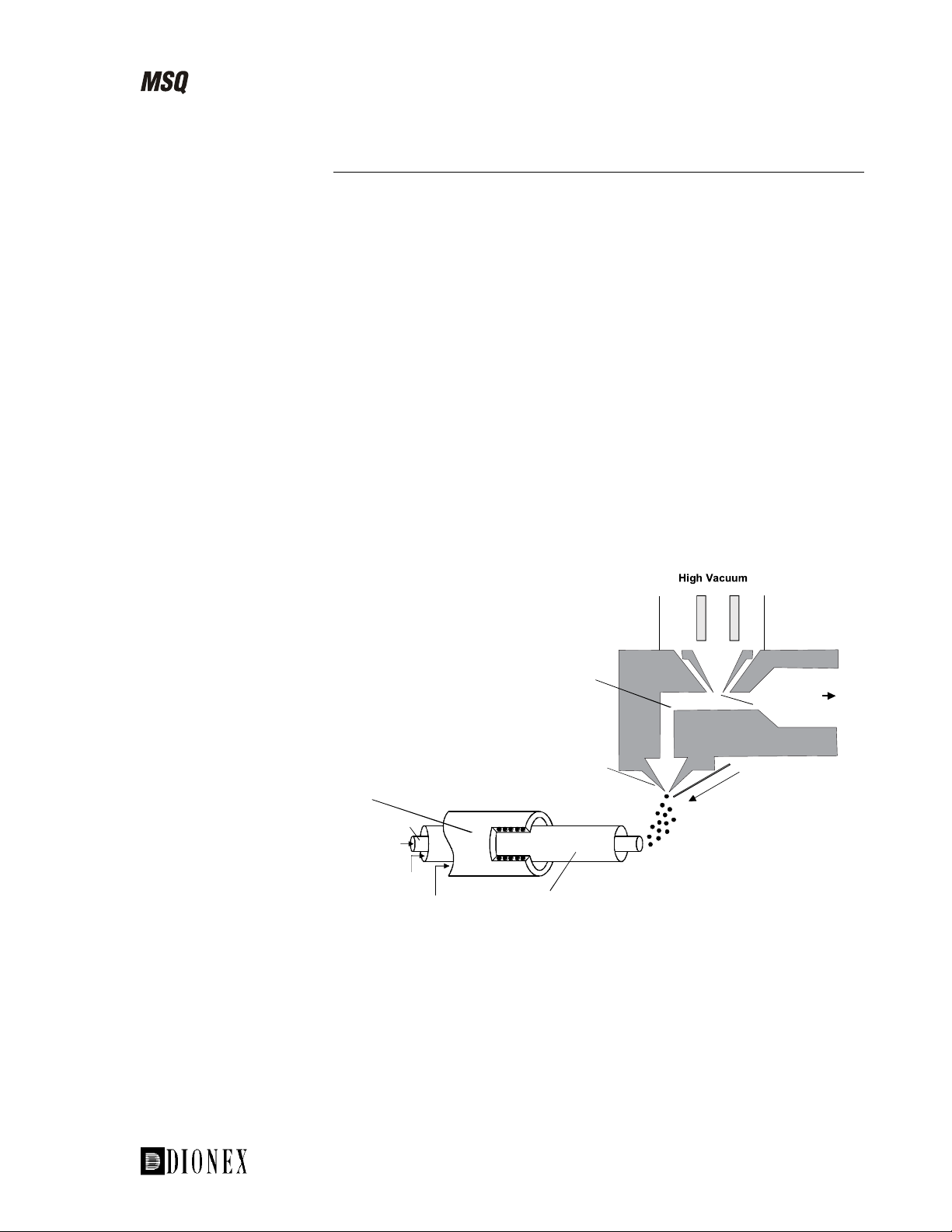

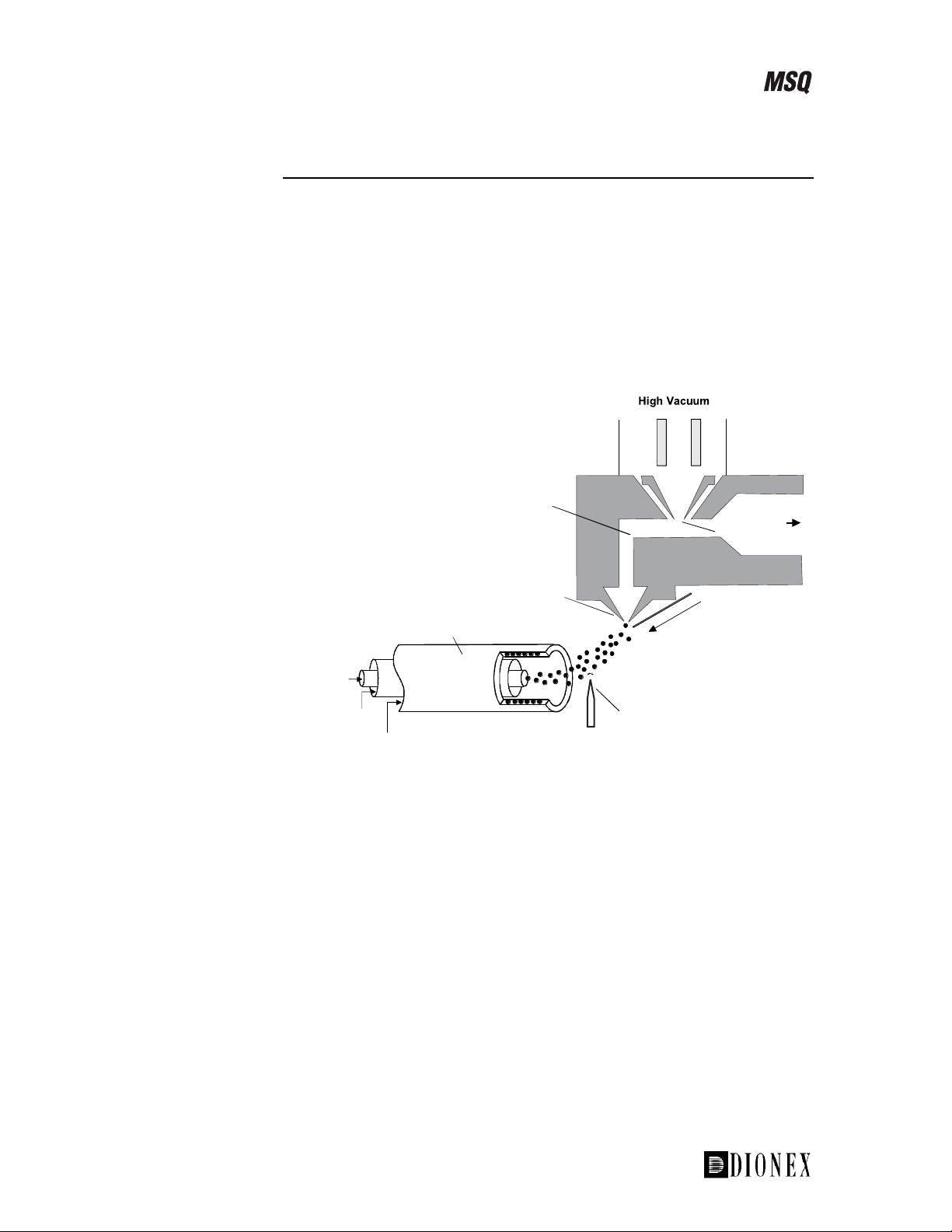

In APCI, the liquid elutes from an insert capillary, surrounded by a coaxial

flow of nitrogen nebulizing gas into a heated region. The combination of

nebulizing gas and heat form an aerosol that evaporates quickly to yield

desolvated neutral molecules (see Figure 1-12).

At the end of the probe is a corona pin held at a high potential (typically 2.0

to 3.5 kV). This produces a high-field corona discharge that causes solvent

molecules eluting into the source to be ionized. In the atmospheric pressure

region surrounding the corona pin, a series of reactions occur that give rise

to charged reagent ions. Any sample molecules, which elute and pass

through this region of reagent ions, can be ionized by the transfer of a proton

to form [M+H]

+

or [M-H]-. This is a form of chemical ionization; hence the

name of the technique, Atmospheric Pressure Chemical Ionization.

Heated nebuliser

N

2

Liquid

N

2

Solvent molecules

An aerosol

is formed

Sample molecules

Solvent and

sample molecules

are desolvated

Corona pin

Collisions and

+

+

+

proton transfer

+

+

+

+

Solvent molecules

are ionized

+

+

Sample

+

[M+H]

ions formed

Figure 1-12. Positive ion APCI mechanism

___________________________MSQ Hardware Manual ___________________________ 1-13

Page 18

Introducing the MSQ

The Source–An Introduction to API Techniques ________________________________________________

APCI Using the MSQ Source

The sample is carried to a spray region via a stainless steel insert capillary.

The action of both the nebulizing gas and the heated probe leads to the

formation of an aerosol. The desolvation process is assisted by a second

concentric flow of nitrogen gas, the sheath gas.

In contrast to electrospray, APCI is a gas phase ionization technique.

Ionization occurs as the aerosol leaves the heated nebulizer region. A corona

pin, mounted between the heated region and the entrance cone, ionizes the

sample molecules with a discharge voltage of approximately 3.0 to 3.5 kV

in positive ion mode and 2.0 to 3.0 kV in negative ion mode.

Region

Intermediate

Pressure

Region

Exit cone

Rotary

pump

Entrance cone

Pressure

Region

Cone Wash

LC eluent

Nebulizing gas, N

Sheath gas, N

Probe

2

2

Atmospheric

Corona pin

Figure 1-13. Schematic of the APCI source on the MSQ, showing the

principal components and pressure regions

The newly formed ions then enter the focusing region through the entrance

orifice and pass into the RF lens region. The RF lens (square quadrupole)

helps to focus the ions before they enter the mass analyzer region.

1-14 __________________________ MSQ Hardware Manual ____________________________

Page 19

Introducing the MSQ

_______________________________________________ The Source–An Introduction to API Techniques

Spectral Characteristics

Like electrospray, APCI is a soft ionization technique and forms singly

charged ions–either the protonated, [M+H]

+

, or deprotonated, [M-H]-,

molecule–depending on the selected ionization mode. Unlike electrospray,

however, APCI does not produce multiply charged ions and so is unsuitable

for the analysis of high molecular weight compounds such as proteins or

peptides.

Although a high temperature is applied to the probe, most of the heat is used

in evaporating the solvent, so the thermal effect on the sample is minimal. In

certain circumstances (for example, with very thermally labile (unstable)

compounds), the heated probe may cause some thermal fragmentation.

Flow Rate

Flow rates of 0.2 to 2.0 mL/min can be used with APCI.

___________________________MSQ Hardware Manual ___________________________ 1-15

Page 20

Introducing the MSQ

The Source–An Introduction to API Techniques ________________________________________________

Source Fragmentation

Both electrospray and APCI are regarded as soft ionization techniques.

Ionization generally results in spectra dominated by either the protonated

molecule [M+H]

(negative ion mode), depending on whether positive or negative ionization

mode has been selected. Choice of ionization mode is governed by the

functional chemistry of the molecule under investigation.

Source fragmentation can be induced to give additional information on a

compound, such as diagnostic fragment ions for structural determination or

an increased response on a particular confirmatory ion for peak targeting.

Formation of Diagnostic Fragment Ions

The MSQ allows the simultaneous acquisition of MS data at a number of

different source voltages. For example, the MSQ can be programmed to

acquire data at source voltages of 20, 40, and 60 V on an alternating scan

basis within a single acquisition. The benefits of setting up acquisitions in

this way are:

+

(positive ion mode) or deprotonated molecule [M-H]-

The optimum source voltage for a particular ion can be determined in

•

one acquisition for compounds where sample volume is at a premium.

• The intensity of fragment ions can be maximized to gain structural

information.

Fragmentation at increased source voltages is useful for most compounds.

For example, using source fragmentation of salbutamol in electrospray

ionization, a number of confirmatory fragment ions can be generated and

their intensity maximized (see Figure 1-14).

The mechanism for the formation of the fragment ions is characteristic for

not only salbutamol, but also for related β-agonists such as clenbuterol,

terbutaline, and metaproterenol. It involves loss of water (-18 amu; resulting

in the fragment ion at m/z 222 (middle trace)) and an additional loss of the

tert-butyl group (-56 amu; resulting in the fragment at m/z 166 (lower

trace)).

Note. The MSQ uses the term “cone voltage” to represent source voltage.

1-16 __________________________ MSQ Hardware Manual ____________________________

Page 21

Introducing the MSQ

+

+

+

u

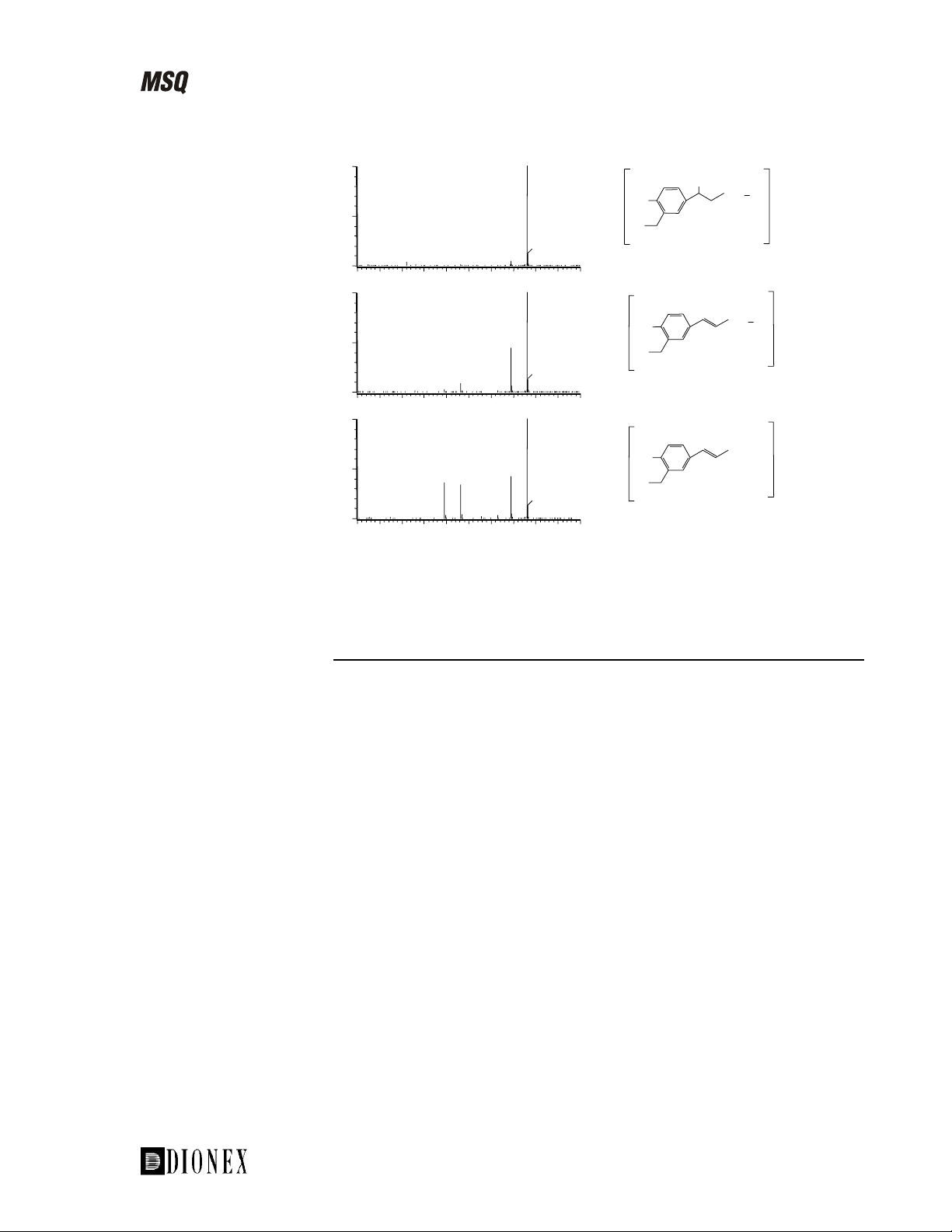

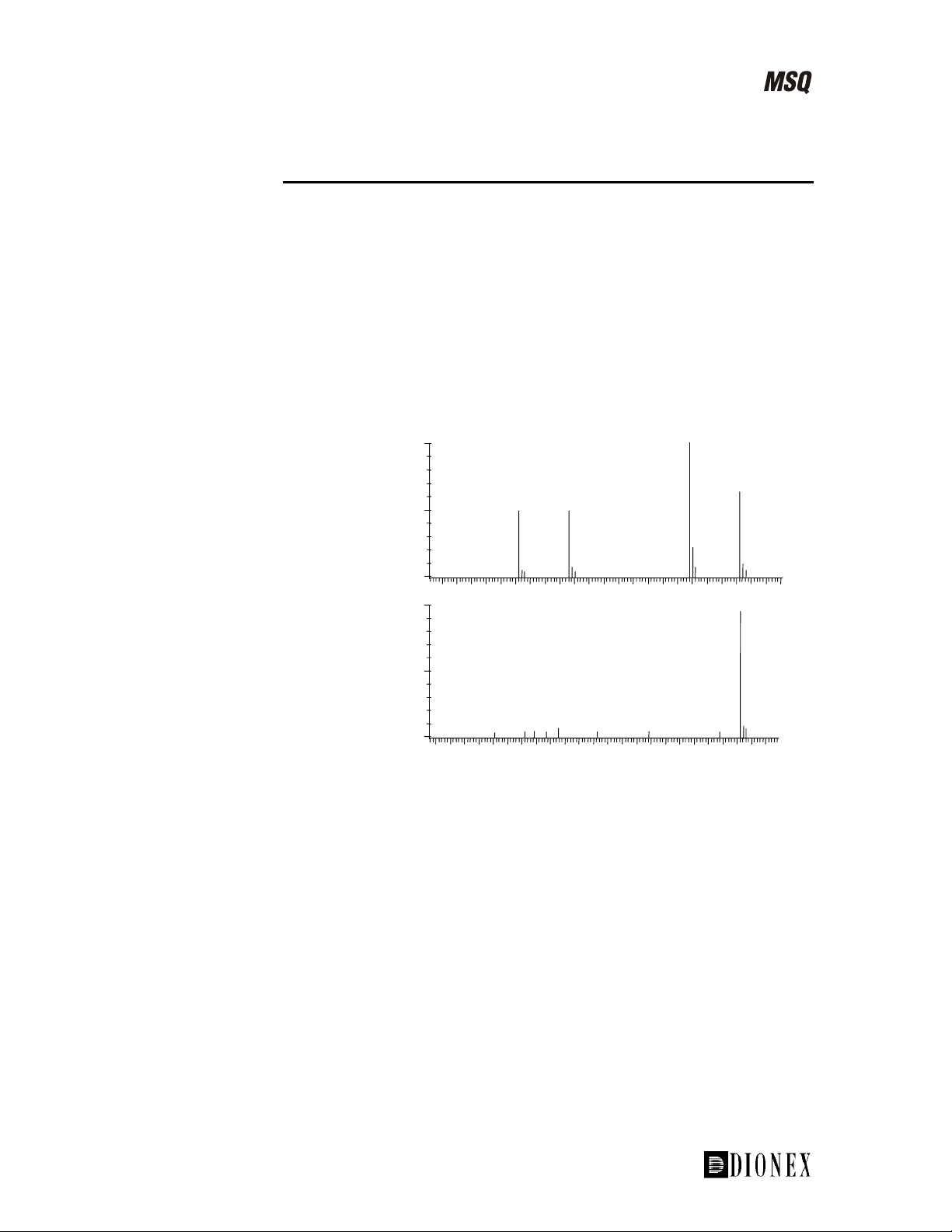

_______________________________________________ The Source–An Introduction to API Techniques

100

Source voltage 10V

%

0

50 75 100 125 150 175 200 225 250 275 300

100

Source voltage 25V

%

0

50 75 100 125 150 175 200 225 250 275 300

100

Source voltage 35V

%

0

50 75 100 125 150 175 200 225 250 275 300

148

166

240

241

240

222

241

240

222

241

m/z

m/z

m/z

Protonated molecule at m/z 240

OH

+

tBu

NH

HO

HO

2

Fragment ion at m/z 222

NH

tBu

HO

HO

2

Fragment ion at m/z 166

NH

HO

HO

3

[M+H]

[M+H]+-H2O

[M+H]+-H2O-tB

Figure 1-14. Source fragmentation of salbutamol in electrospray

ionization

Optimum Response for Confirmatory Ions

When acquiring fragment ions for confirmation purposes, the applied source

voltage per compound would require some optimization to maximize the

intensity of these ions. It is generally observed that small changes to the

source voltage result in only small intensity changes; thus, fine-tuning of

this voltage is usually not critical (typically +/- 5 V is adequate).

___________________________MSQ Hardware Manual ___________________________ 1-17

Page 22

Introducing the MSQ

The Source–An Introduction to API Techniques ________________________________________________

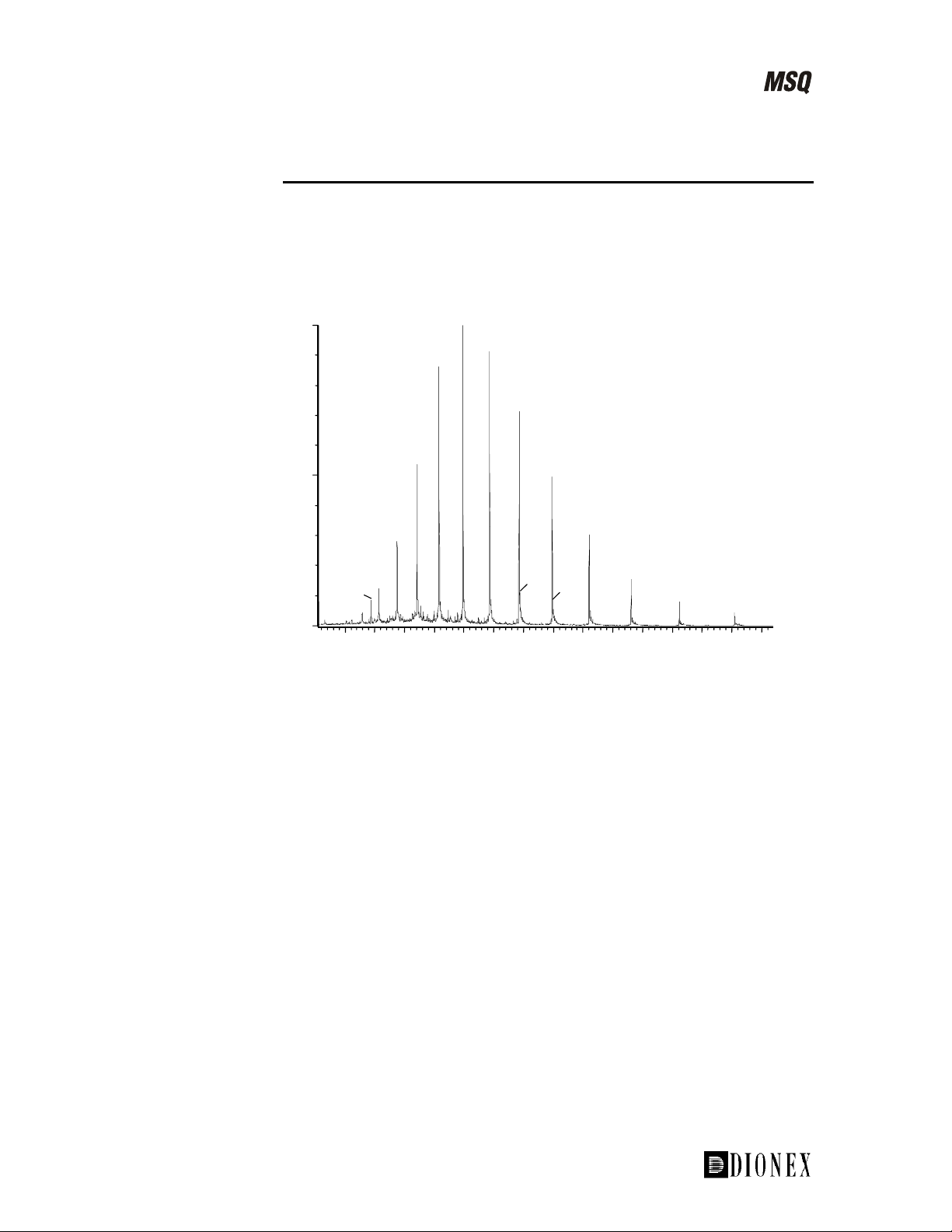

Cone Voltage Ramping

Source voltage ramping can be used in Full Scan operation (see page 1-32)

in electrospray when the compound of interest forms multiply charged ions.

A spectrum similar to that in Figure 1-15 will be produced, showing the

multiply charged envelope.

771

808

848

893

942

944

998

999

1060

1131

1212

1305

m/z

100

%

738

707

694

0

700 800 900 1000 1100 1200 1300

Figure 1-15. Electrospray spectrum of horse heart myoglobin

This envelope is represented in diagrammatic form in Figure 1-16. The first

diagram shows the envelope at a source voltage of 30 V. Next, the envelope

is shown at 60 V. There is no ramping applied here. The envelope has the

same shape but has moved to a higher m/z value. This is due to the charge

stripping that occurs at high source voltages, which lowers the charge state

and produces an apparent higher mass distribution. If the source voltage is

ramped between 30 and 60 V, the charge distribution envelope is extended

and it resembles the lower diagram.

1-18 __________________________ MSQ Hardware Manual ____________________________

Page 23

Introducing the MSQ

f

_______________________________________________ The Source–An Introduction to API Techniques

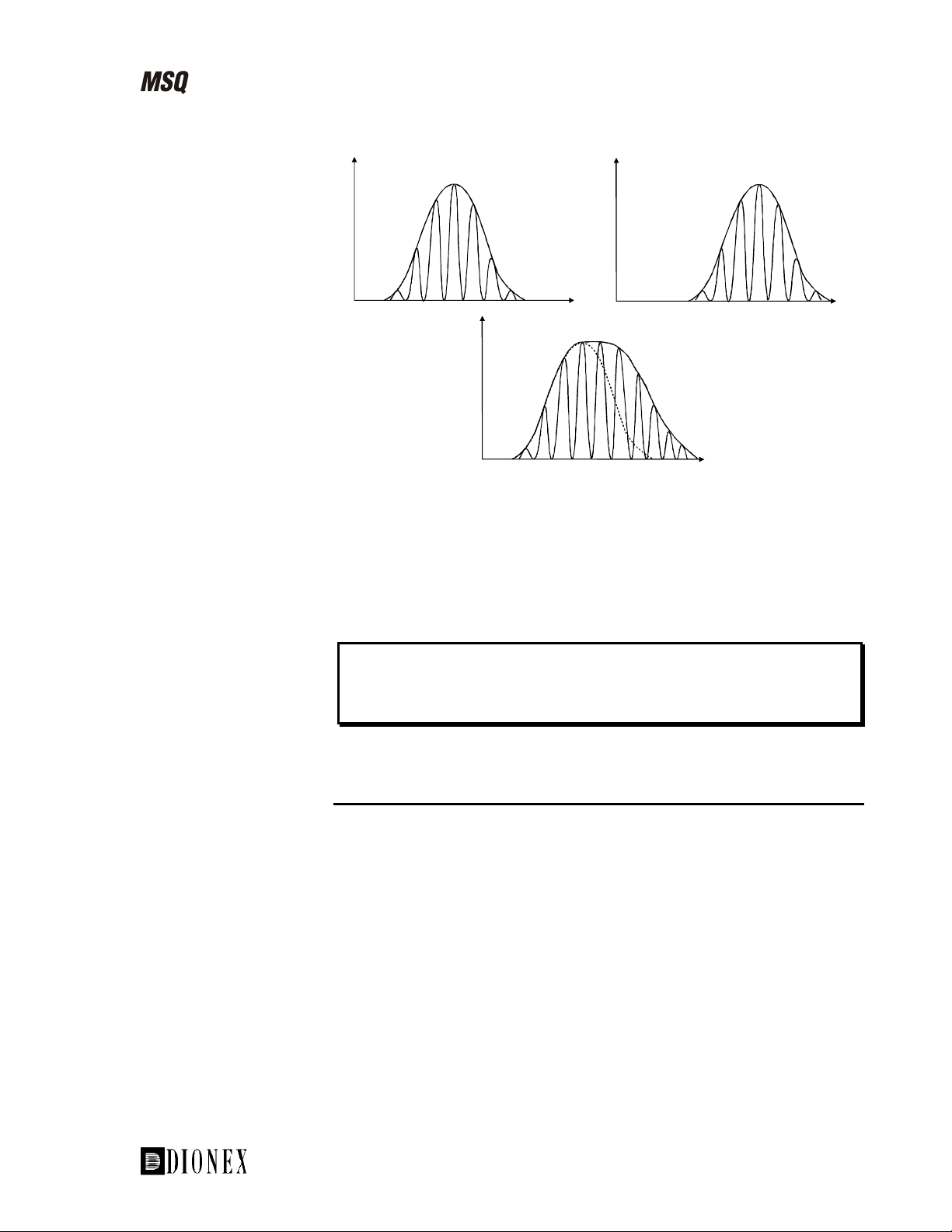

Intensity

Without s ource voltage ramping

Source voltage 30V

Increasing

number of

charges

Intensity

Decreasing

number o

charges

With source voltage ramping 30-60V

m/z

Intensity

Without s ource voltage ramping

Source voltage 60V

m/z

Figure 1-16. Cone voltage ramping

Cone voltage ramping is often used for proteins and peptides during:

Calibration (to extend the calibration range) •

• Analysis (to increase the number of charge states leading to greater

accuracy of molecular weight determination)

m/z

Note. Cone voltage ramping will not perform source fragmentation because

the same cone voltage corresponds to the same m/z value each time.

Polarity Switching

Switching between positive and negative ionization modes in a single

analytical run is supported by the MSQ. Rapid polarity switching is a

technique that is applied to several important areas of MS analysis; for

example:

Quantitation of different chemistries within the same run. In drug

•

metabolism studies, certain compounds preferentially ionize in positive

ion mode because they may contain a primary amino group. Other

metabolites, such as glucuronide metabolites, are likely to lose a proton

and respond in the negative ion mode.

• Rapid screening of unknown analytes; for example, in combinatorial

chemistry. If the compound has a carboxylic acid group that is sterically

unhindered, it is likely that the compound will lose a proton in negative

ion mode and not respond in positive ion mode.

___________________________MSQ Hardware Manual ___________________________ 1-19

Page 24

Introducing the MSQ

A

The Source–An Introduction to API Techniques ________________________________________________

Application of API Techniques

Both electrospray and APCI are ideal for online liquid chromatography

detection, providing an additional dimension of information. With many

compounds, it is possible to analyze them by both APCI and electrospray. It

may be difficult to decide which is the more appropriate technique,

especially when the compounds of interest lack polar functionalities.

Points to note:

Electrospray is one of the softest ionization methods available, whereas

•

APCI, although also a soft ionization technique, may not be suitable for

some very thermally labile compounds as there may be thermal

fragmentation (see Figure 1-17).

214

231

231

PCI mass spectrum,

source voltage 25V.

Electrospray mass

spectrum, source

voltage 25V.

100

%

0

130 140 150 160 170 180 190 200 210 220 230 240

100

%

0

130 140 150 160 170 180 190 200 210 220 230 240

156

173

Figure 1-17. Thermal fragmentation of the herbicide asulam in APCI

APCI does not yield multiply charged ions like electrospray, and so is

•

unsuitable for the analysis of high molecular weight compounds such as

proteins.

m/z

m/z

• Both APCI and electrospray generally provide data from which it is

simple to infer molecular weight values.

In many cases, with the correct conditions, only one major peak is

observed in the spectrum: either the protonated molecule [M+H]

ion) or deprotonated molecule [M-H]

-

(-ve ion). However, some

+

(+ve

compounds are more susceptible to fragmentation than others, so

different degrees of fragmentation may be seen from compound to

compound. When determining molecular weights, always take account

of possible adduct ions. Common adducts are [M+18]

+

NH

+

4

(ammonium adducts seen in the presence of buffers such as ammonium

acetate), [M+23]+ Na+ (sodium adducts), and [M+39]+ K+ (potassium

adducts).

1-20 __________________________ MSQ Hardware Manual ____________________________

Page 25

Introducing the MSQ

_______________________________________________ The Source–An Introduction to API Techniques

Source fragmentation is used in both APCI and electrospray to give

•

structural information.

In general, increasing the voltage applied to the source block (the cone

voltage) yields increasing amounts of fragmentation, depending on the

nature of the compound. The optimum source voltage required to give

the maximum intensity of the protonated or deprotonated molecule is

compound-dependent, as is the source voltage required for

fragmentation. The energies involved in source fragmentation are low,

so usually only weaker bonds such as C-N and C-O are broken.

Since there are many similarities between electrospray and APCI, there are

many applications common to both.

Compounds suitable for analysis by electrospray are polar and of molecular

weight less than 100,000 amu. The higher molecular weight compounds,

such as proteins, can produce multiply charged ions. As it is the mass-tocharge ratio (m/z) that is measured by the MS detector, these can often be

seen at lower masses. For example, if the molecular weight is 10,000, a

doubly charged ion (2+ in +ve ion) would be seen at m/z 5001, 10+ at m/z

1001, etc.

Typical electrospray applications are: peptides, proteins, oligonucleotides,

sugars, drugs, steroids, and pesticides.

Compounds suitable for analysis by APCI are generally polar (although less

polar than electrospray) and of molecular weight <1000 amu.

Typical APCI applications are: pesticides, drugs, azo dyes, and steroids.

A summary comparing electrospray and APCI is shown in Table 1-2.

___________________________MSQ Hardware Manual ___________________________ 1-21

Page 26

Introducing the MSQ

The Source–An Introduction to API Techniques ________________________________________________

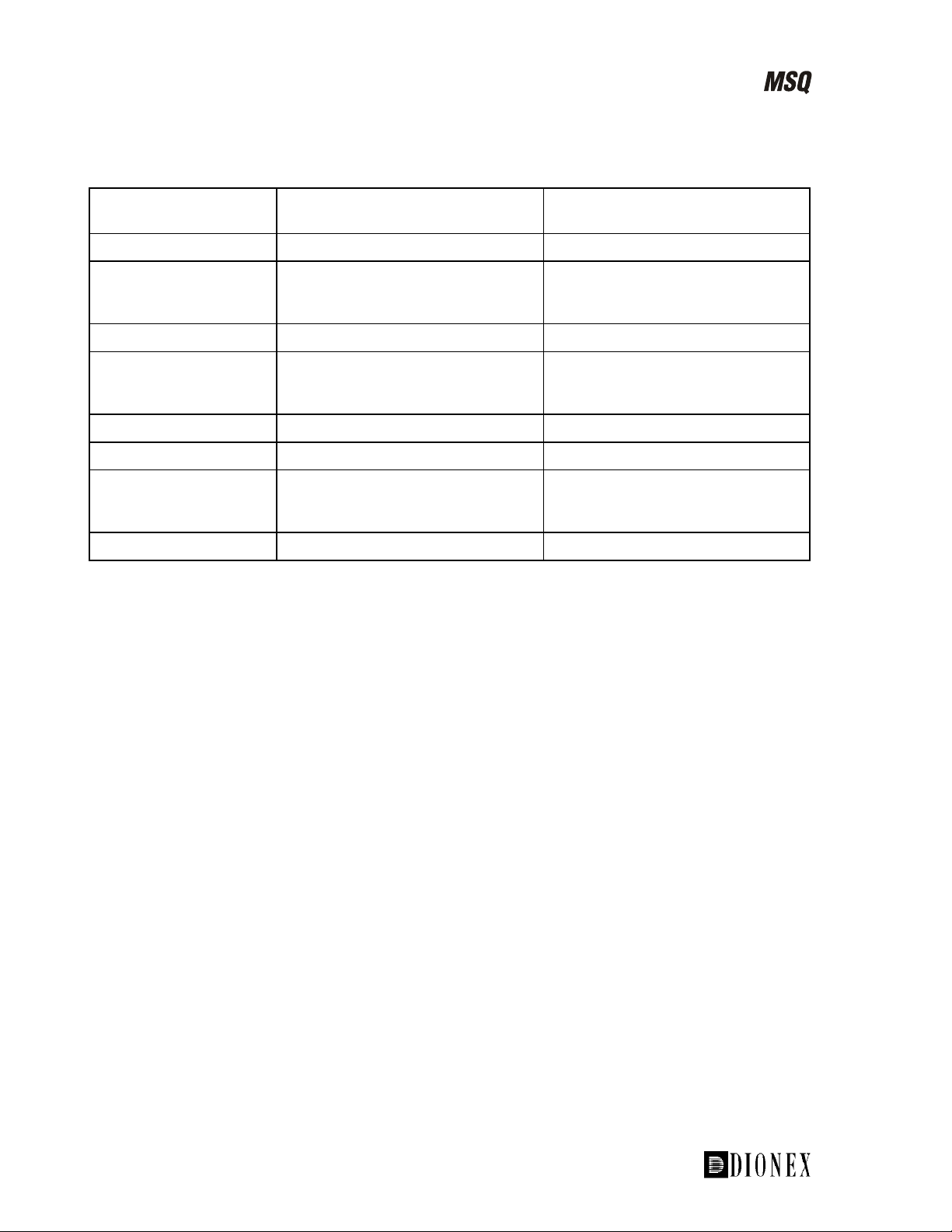

Table 1-2. Comparison of ESI and APCI

LC/MS technique Electrospray (ESI) Atmospheric Pressure Chemical

Ionization (APCI)

Compound polarity Polar Polar, some non-polar

Examples Drugs, proteins, biopolymers,

oligonucleotides, steroids, and

pesticides

Pesticides, azo dyes, drugs,

metabolites, agrochemicals, and

steroids

Sensitivity fg to pg (compound-dependent) fg to pg (compound-dependent)

Type of spectra [M+H]+ for +ve ion mode, [M-H]- for

-ve ion mode, fragmentation via

source voltage

+

[M+H]

for +ve ion mode, [M-H]- for

-ve ion mode, fragmentation via

source voltage

Flow rates 2.0 µL/min to 2.0 mL/min 0.2 to 2.0 mL/min

LC columns Capillary to 4.6-mm ID columns 2.1- to 4.6-mm ID columns

Mobile phases H2O, CH3CN, CH3OH are most

frequently used.

H2O, CH3CN, CH3OH are most

frequently used. Non-polar

solvents can be used.

Typical mass range <100,000 <1000

1-22 __________________________ MSQ Hardware Manual ____________________________

Page 27

Introducing the MSQ

______________________________________________________The Self-Cleaning Source: Cone Wash

The Self-Cleaning Source: Cone Wash

This section introduces the cone wash. Information on how and when to use

it is provided in the chapter LC/MS and the Cone Wash.

Introduction

The API source on the MSQ includes a self-cleaning solvent delivery

system (the cone wash). This makes the source extremely robust and

productive and greatly increases the number of samples that can be analyzed

before maintenance is required.

The orthogonal API probe serves to direct the LC eluent away from the inlet

orifice. However, under typical LC/MS conditions, both the ions and the

charged liquid droplets (containing involatile components) are deflected by

the electric field towards the inlet orifice. This effect leads to a gradual

buildup of involatile components and an associated loss in sensitivity with

time.

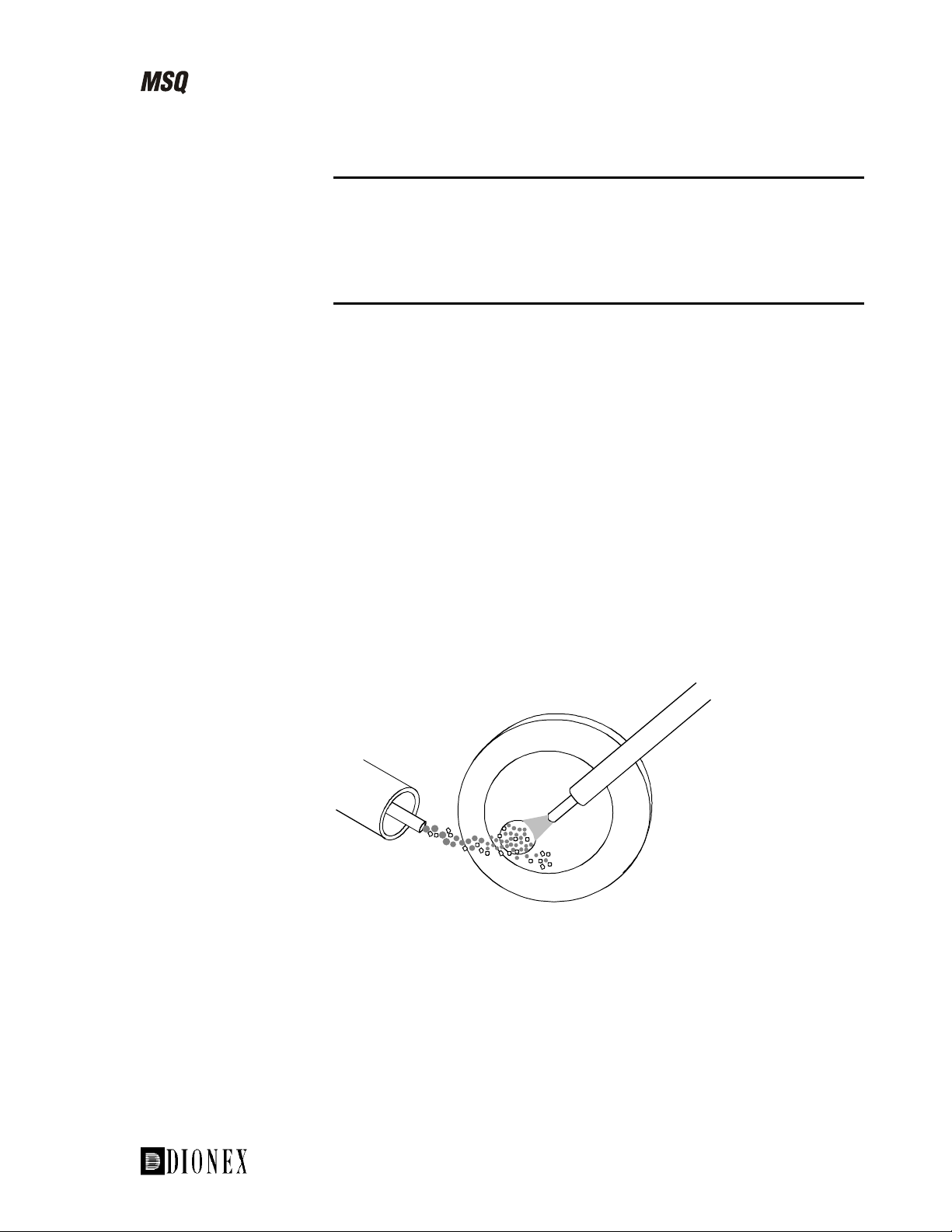

The self-cleaning API source delivers a constant, low flow of solvent to the

edge of the inlet orifice (see Figure 1-18). This prevents the buildup of

involatile components during LC/MS analysis with typical chromatographic

buffers (for example, phosphates and ion-pairing agents). This greatly

improves the quantitation precision of analysis without the need to

compromise the LC method, and more importantly, dramatically extends the

length of time possible for analysis.

Figure 1-18. Dispersion of involatile components from the inlet orifice

___________________________MSQ Hardware Manual ___________________________ 1-23

Page 28

Introducing the MSQ

The Self-Cleaning Source: Cone Wash _______________________________________________________

Functional Description

As shown in Figure 1-18, the cone wash nozzle consists of a stainless steel

capillary, which is fed to the edge of the inlet orifice of the entrance cone.

The capillary is attached to PEEK tubing, internal to the instrument, which

when connected to an LC pump delivers the solvent (typically HPLC-grade

water or organic solvents such as methanol) at a controlled flow rate.

Note. It is necessary to use the cone wash only for compounds in dirty

matrices or when involatile buffers are used. Choose the cone wash solvent

to give the most effective solubility for the expected contaminants.

1-24 __________________________ MSQ Hardware Manual ____________________________

Page 29

Introducing the MSQ

______________________________________________________________ The Reference Inlet System

The Reference Inlet System

This section introduces the reference inlet system. Information on how to set

up the system is provided in the chapter Reference Inlet System.

Introduction

The recommended way to introduce a sample for tuning and mass

calibration in electrospray is to use the reference inlet system.

Functional Description

As shown in Figure 1-20, the reference inlet system consists of a pressurized

reservoir containing the reference sample and a PEEK delivery tube. One

end of the PEEK delivery tube is inserted into the reference inlet reservoir,

while the other end is attached to the switching valve. When the pressure in

the reservoir is increased, the sample is forced through the PEEK tube and

infused directly into the 100 µL sample loop.

Figure 1-20. The reference inlet system

___________________________MSQ Hardware Manual ___________________________ 1-25

Page 30

Introducing the MSQ

The Mass Analyzer and Detector____________________________________________________________

The Mass Analyzer and Detector

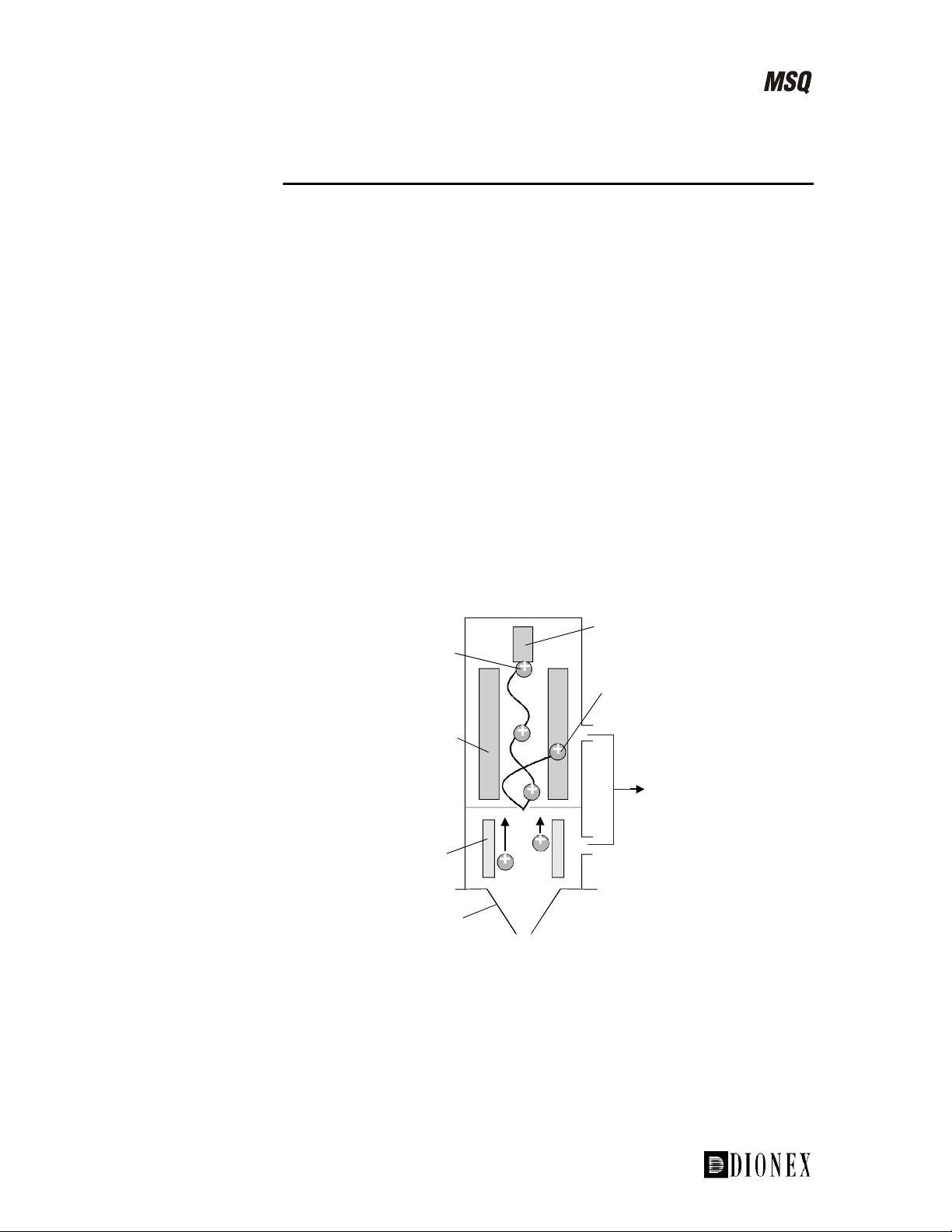

The mass analysis and detection system comprises two main components:

A quadrupole mass analyzer •

• A detector whose main component is a channeltron electron multiplier

The square quadrupole RF lens helps to focus the ions before they are

filtered, according to their mass-to-charge ratio in the mass analyzer.

The analyzer in the MSQ is a quadrupole. This is one of the most widely

used types of analyzer and can be easily interfaced to various inlet systems.

By applying carefully controlled voltages to the four rods in the quadrupole,

only ions of a specific mass-to-charge ratio are allowed to pass through at

any one time.

The ions then reach the detector, whose main component is a channeltron

electron multiplier. In positive ion mode, the ions exit the analyzer and

strike a conversion dynode, which results in the emission of electrons. The

electrons are accelerated towards the channeltron electron multiplier, which

then creates an electron cascade. The current is then converted and amplified

into a voltage signal that is analyzed and processed by the MSQ’s on-board

data acquisition system. The resultant peak information is sent to the data

system.

Ion successfully transmitted

by the mass analyzer

Quadrupole

mass analyzer

Square

quadrupole

RF lens

Source exit cone

Figure 1-21. Schematic of the MSQ analyzer and detector

Detector

Ion trajectory incorrect

for transmission trough

the mass analyzer

Split flow

turbomolecular

pump

1-26 __________________________ MSQ Hardware Manual ____________________________

Page 31

Introducing the MSQ

____________________________________________________________________ The Vacuum System

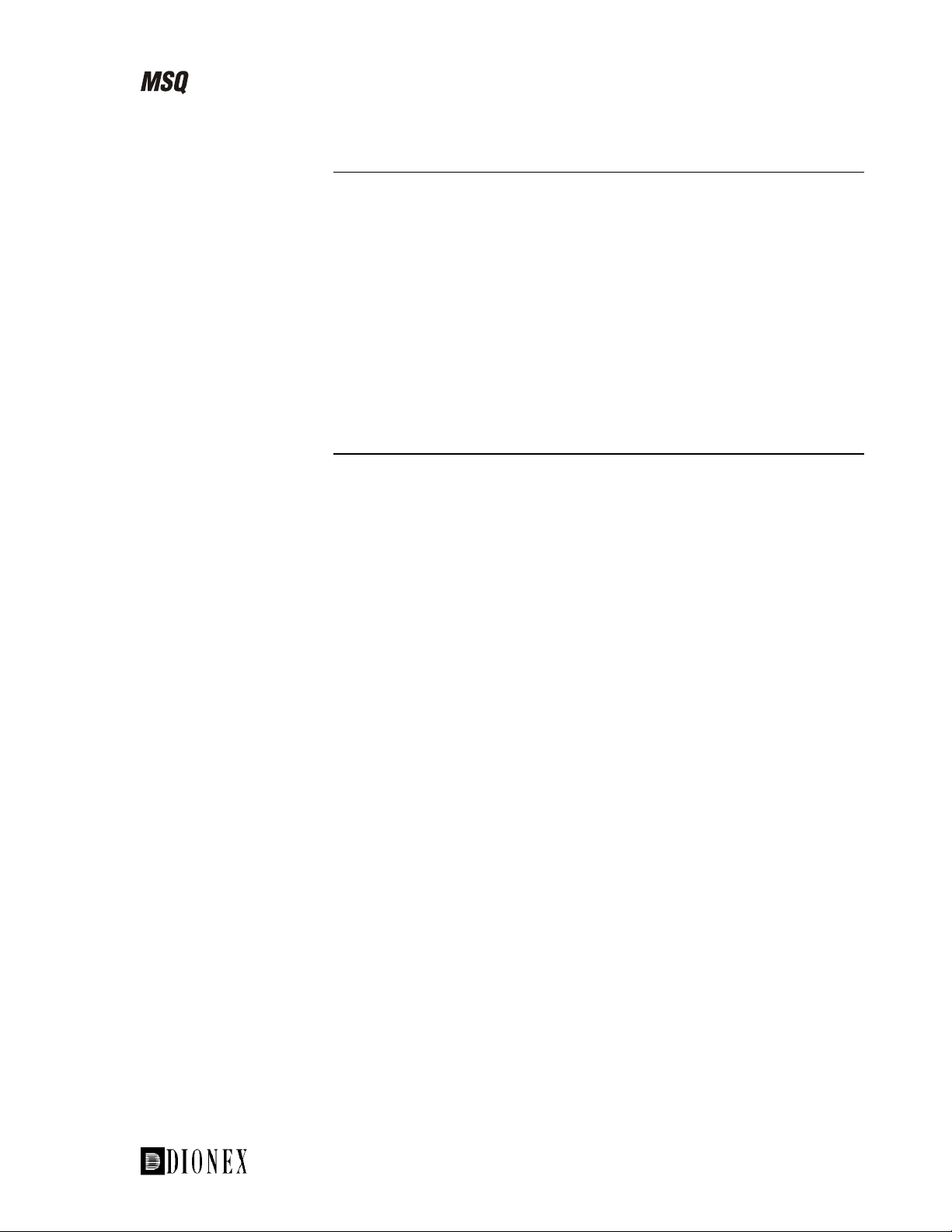

The Vacuum System

The main challenge in interfacing MS with LC is the introduction of a liquid

mobile phase at flow rates of up to 2.0 mL/min into a system that operates

under vacuum. The transition between atmospheric pressure and high

vacuum is achieved by using several different stages of pressure controlled

by the vacuum system. This arrangement effectively removes the mobile

phase, leaving the analytes to travel as ions through the mass analyzer.

It is important to remember that an MS detector must be under high vacuum

in order to operate. In the case of the MSQ system, not all of the MS

detector is under high vacuum. The ion source is held at atmospheric

pressure, while the region between the entrance and exit cones is held at an

intermediate pressure to step down to the high vacuum region in the mass

analyzer and detector. The intermediate pressure region is pumped by one

rotary pump. The high vacuum in the mass analyzer and detector region is

achieved by using a split-flow turbomolecular pump. All the pumps are

controlled by the data system.

___________________________MSQ Hardware Manual ___________________________ 1-27

Page 32

Introducing the MSQ

The Data System ________________________________________________________________________

The Data System

The data system has complete control of the MSQ system and runs on a

Microsoft® Windows platform.

Software

Xcalibur™ software controls the MSQ MS detector. When Xcalibur is run,

the Home page is displayed (see Figure 1-22). Xcalibur also runs the MSQ

server (see Figure 1-23).

The Home Page

The Home page opens to show a ‘road map’ view of the data system.

Figure 1-22. The Xcalibur Home page “road map” view

1-28 __________________________ MSQ Hardware Manual ____________________________

Page 33

Introducing the MSQ

_______________________________________________________________________The Data System

The icons shown on the road map provide an easy way to access all the

major modules of the data system. These modules are:

Instrument Setup •

Use Instrument Setup to configure the MSQ and all your LC equipment for

acquisition. This information is saved as an instrument method.

•

Processing Setup

Use Processing Setup to specify all parameters for processing, reporting,

and manipulation of acquired data. This information is saved as a processing

method.

•

Sequence Setup

Use Sequence Setup to enter the details of the samples to be examined,

including instrument and processing methods, and to control the acquisition

of data.

•

Qual Browser

Use Qual Browser to examine acquired data, both chromatograms and

spectra, in order to obtain more information about the compounds in the

sample.

•

Quan Browser

Use Quan Browser to examine acquired data in order to obtain an accurate

determination of the amounts of individual components present in a sample.

•

Library Browser

Use Library Browser to create your own libraries of spectra and to perform

searches of those libraries.

The Server

The server is displayed as an icon on the Windows taskbar. In Figure 1-23,

it is shown just to the left of the time display. The light will be red, yellow,

or green, depending on the status of the system.

Figure 1-23. The taskbar showing the Xcalibur Home page and server

The server is shown as one light. When the light is green, the MSQ is under

vacuum with Operate On and the API gas flowing. When the MSQ is

pumping down, the light is yellow and flashing.

Use the server to tune and calibrate the MSQ and to pump or vent the

system.

___________________________MSQ Hardware Manual ___________________________ 1-29

Page 34

Introducing the MSQ

The Data System ________________________________________________________________________

Right-click on the server to display a menu:

Choose Instrument Tune and Calibration to display the Instrument

•

Tuning and Calibration Wizard.

Figure 1-24. The MSQ Instrument Tuning and Calibration Wizard

Choose Tune to display the Tune page. •

• • Choose Pump to pump down the MSQ or Vent to vent the MSQ.

Choose Exit to close the server. If Xcalibur is still running, this will not

be allowed and an error message will be displayed.

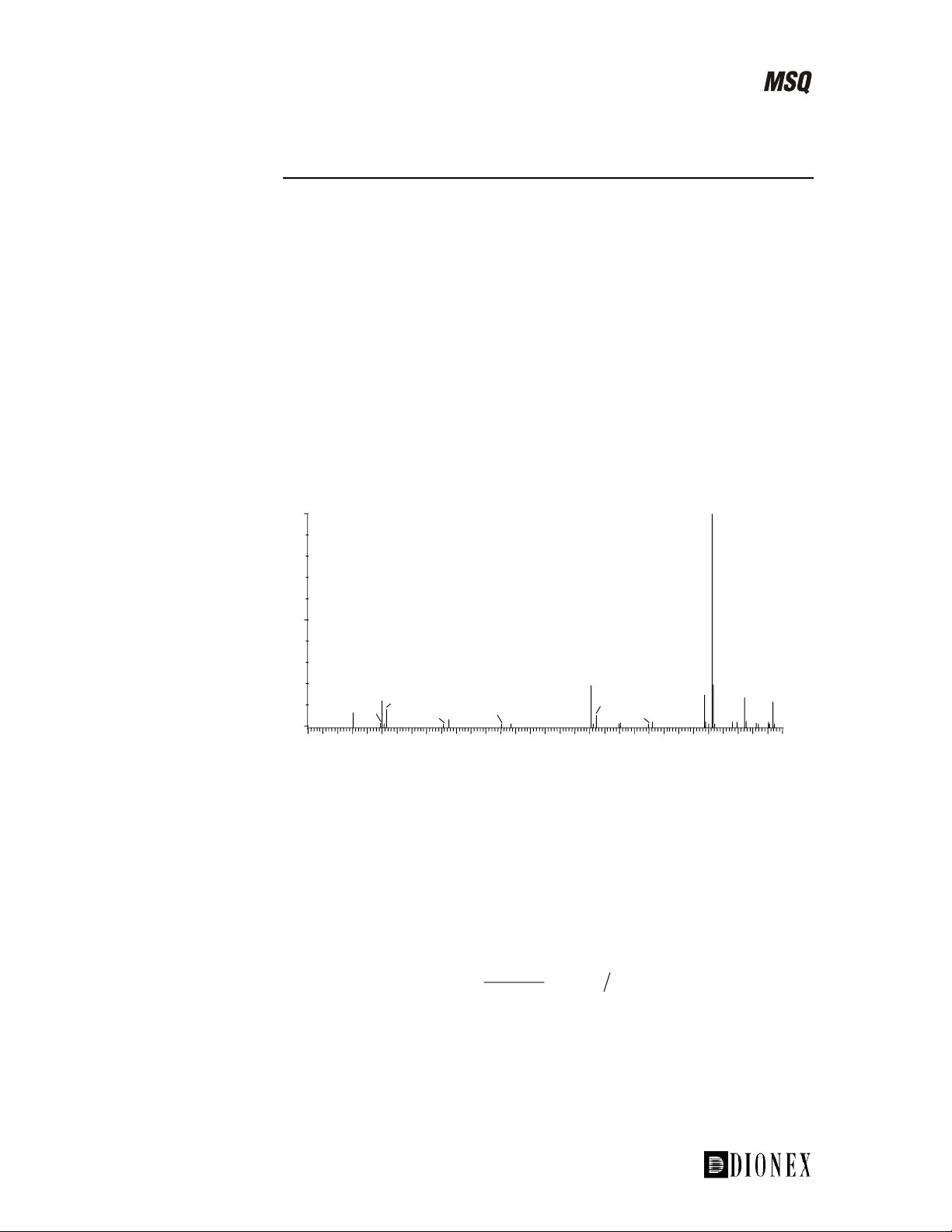

Raw Data

Xcalibur acquires data in a “raw” file. Raw data can be viewed as

chromatograms and mass spectra (see Figure 1-25).

The term mass spectrum refers to a plot of mass-to-charge ratio (m/z)

versus relative abundance information. The mass spectrum at a particular

time in an analytical run will reveal a “snapshot” of the data at that time.

The chromatogram is a plot of relative abundance versus time. Xcalibur

produces the following types of chromatograms: total ion current (TIC)

chromatogram, base peak chromatogram, mass range chromatogram, and

analog UV chromatogram.

1-30 __________________________ MSQ Hardware Manual ____________________________

Page 35

Introducing the MSQ

_______________________________________________________________________The Data System

RT: 1.09 - 6.11

10 0

80

60

40

1. 2 4 1. 5 5 2 . 2 5

Relat ive Abundanc e

20

0

1. 5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0

carb mix pmix03#102 RT: 2.66 AV: 1 SB: 38 1.42-2.07, 2.87-3.15 NL: 1.02E5

T: + c ESI Ful l ms [ 150.00-500.00]

100

80

60

40

20

Relative Abundance

181.5 387.0

0

150 200 250 300 350 400 450 500

2.35

229.4

2.66

240.3

2.82

3.28

281.2

3.59

Time (min)

282.5

3.72

3.87

346.8 403.2

m/z

4.75

5.174.18 5.32

454.1

5.42

459.1

NL:

2.49E5

TIC carb

mix pmix03

461.0256.2

482.1

Figure 1-25. A mass spectrum taken at retention time 2.66 minutes

(lower trace) from a TIC chromatogram (upper trace)

Raw Data Types

The data can be collected and stored by the data system in two different

ways: Full Scan and Selected Ion Monitoring (SIM). The main difference

between these two modes is:

In Full Scan mode, data is collected across the whole scan range. •

• In SIM mode, data is acquired only at specific mass-to-charge ratios.

___________________________MSQ Hardware Manual ___________________________ 1-31

Page 36

Introducing the MSQ

The Data System ________________________________________________________________________

Full Scan Mode

There are three different types of Full Scan acquisition. These are:

Centroid •

• • Profile

MCA (Multi Channel Analysis)

In all full scan acquisitions, raw data is collected over the whole scan range

defined by the start and end mass.

Centroid

During centroid acquisitions, Xcalibur automatically determines and saves

the mass center of the acquired profile peak returned from the detector.

Hence, the previously large number of points that described the mass

spectral peak are reduced to a single centroid stick (see Figure 1-26) for

each ion mass recorded. This has the advantage of reducing the quantity of

data recorded to the hard disk and improving processing speeds.

100

%

0

120 140 160 180 200 220 240 260 280

265

267

263

Figure 1-26. Full scan centroid spectrum of pentachlorophenol

m/z

1-32 __________________________ MSQ Hardware Manual ____________________________

Page 37

Introducing the MSQ

_______________________________________________________________________The Data System

Profile

With profile acquisition, data is not “centroided” into sticks. Instead, the

signal received by the interface electronics is stored to give an analog

intensity profile of the data being acquired for every scan (see Figure 1-27).

Profile acquisition enables mass spectral peak width and resolution to be

examined and measured. For example, the resolution between an ion and its

isotope(s) or multiply charged ions can be seen and measured, if necessary.

This is most useful in the case of protein and peptide analysis, where

multiply charged ions are formed.

As data is being written to disk at all times (even when there are no peaks

being acquired), profile data acquisition places an extra burden on the

acquisition system in comparison to centroided acquisition. Profile data files

tend to be significantly larger than centroided ones and the scan speeds used

tend to be slower than when acquiring centroided data.

100

%

281

283

0

275 300 325 350 375 400 425 450 475 500 525

325

Figure 1-27. Full scan profile spectrum of D-raffinose

503

504

m/z

___________________________MSQ Hardware Manual ___________________________ 1-33

Page 38

Introducing the MSQ

The Data System ________________________________________________________________________

MCA

The third type of full scan acquisition is MCA. Such data can be thought of

as “summed profile,” with only one intensity-accumulated scan being

written to disk for a given experiment (see Figure 1-28). As each scan is

acquired, its intensity data is added to the accumulated summed data of

previous scans.

An advantage of MCA is that although noise will accumulate at the same

rate as sample-related data, noise is random, and therefore its effects will be

reduced over a number of scans. This will emphasize the sample-related

data and improve signal to noise. A further advantage of MCA is that data is

written to disk only at the end of an experiment; therefore, significantly less

storage space is required.

MCA cannot be used for time-resolved data because an MCA raw file

contains only one scan. Therefore, MCA is not used during a

chromatographic run. Generally, it is used to acquire infusion or loop

injected samples of fairly weak concentration (the signal can then be

enhanced). The real-time spectrum can be viewed and the acquisition

stopped when the required results are obtained. MCA is often used to

acquire raw data from the infusion of proteins and peptides.

771

808

848

893

942

944

998

999

1060

1131

1212

1305

100

%

738

707

694

0

700 800 900 1000 1100 1200 1300

Figure 1-28. Full scan MCA spectrum of horse heart myoglobin

m/z

1-34 __________________________ MSQ Hardware Manual ____________________________

Page 39

Introducing the MSQ

_______________________________________________________________________The Data System

SIM Mode

This acquisition mode is used when only one or a few specific masses are to

be monitored during the acquisition. Since most of the acquisition time is

spent on these masses, the SIM technique is far more sensitive (typically

greater than a factor of ten) than full scan techniques. However, this

sensitivity does depend on the number of masses being monitored

simultaneously.

SIM is also a highly selective technique. Impurities present in the sample

that co-elute with the compound of interest will not affect the analysis as

long as they do not produce ions at the same m/z value being monitored.

SIM does not produce spectra that can be used for library searching routines.

___________________________MSQ Hardware Manual ___________________________ 1-35

Page 40

Introducing the MSQ

The Data System ________________________________________________________________________

1-36 __________________________ MSQ Hardware Manual ____________________________

Page 41

Chapter 2

Changing Ionization Modes 2.

Changing Ionization Modes ......................................................................................................2-i

Introduction ....................................................................................................................................2-1

Switching from ESI to APCI ..........................................................................................................2-2

Switching from APCI to ESI ..........................................................................................................2-4

____________________________MSQ Hardware Manual _____________________________ 2-i

Page 42

Changing Ionization Modes

Introduction ____________________________________________________________________________

2-ii ____________________________ MSQ Hardware Manual ____________________________

Page 43

Changing Ionization Modes

____________________________________________________________________________ Introduction

Introduction

Use the information in this chapter in conjunction with the animations on

the MSQ CD shipped with your system. The chapter is divided into the

following sections:

Switching from ESI to APCI •

• Switching from APCI to ESI

____________________________MSQ Hardware Manual ____________________________ 2-1

Page 44

Changing Ionization Modes

Switching from ESI to APCI ________________________________________________________________

Switching from ESI to APCI

The starting point for this procedure is the source setup for ESI operation,

with the LC and gas flows off, and the probe cooled.

WARNING. Allow the source block and probe heater assembly to cool

before changing ionization modes.

1.

Unscrew and remove the PEEK finger-tight fitting from the ESI probe

assembly (P/N FM102595).

2.

Turn the locking plate clockwise to the open position, and remove the

ESI probe assembly (P/N FM102595).

PEEK fitting

Figure 2-5. ESI probe assembly

3.

Swap the ESI probe assembly (P/N FM102595) with the APCI probe

Locking plate

assembly (P/N FM102587), located in the holder in the door.

4.

Turn the locking plate on the APCI probe assembly clockwise into the

open position, insert the APCI probe assembly (P/N FM102587), and

turn the locking plate counterclockwise into the closed position.

5.

Change the APCI blank plug (P/N FM101437) with the APCI corona

pin (P/N FM101433), located in the holder in the source enclosure door.

2-2 ___________________________ MSQ Hardware Manual ____________________________

Page 45

Changing Ionization Modes

________________________________________________________________Switching from ESI to APCI

Figure 2-6. APCI corona pin and APCI blank plug

6. Insert the PEEK finger-tight fitting into the APCI probe assembly (P/N

FM102587) and screw it into place.

____________________________MSQ Hardware Manual ____________________________ 2-3

Page 46

Changing Ionization Modes

Switching from APCI to ESI ________________________________________________________________

Switching from APCI to ESI

The starting point for this procedure is the source setup for APCI operation,

with the LC and gas flows off, and the probe cooled.

WARNING. Allow the source block and probe heater assembly to cool

before changing ionization modes.

1.

Unscrew and remove the PEEK finger-tight fitting from the APCI probe

assembly (P/N FM102587).

2.

Change the APCI blank plug (P/N FM101437) with the APCI corona

pin (P/N FM101433), located in the holder in the source enclosure door.

Figure 2-7. APCI blank plug and APCI corona pin

3. Turn the locking plate clockwise to the open position, and remove the

APCI probe assembly (P/N FM102587).

2-4 ___________________________ MSQ Hardware Manual ____________________________

Page 47

Changing Ionization Modes

________________________________________________________________Switching from APCI to ESI

PEEK fitting

Figure 2-5. ESI probe assembly

4.

Swap the APCI probe assembly (P/N FM102587) with the ESI probe

Locking plate

assembly (P/N FM102595), located in the holder in the door.

5.

Turn the locking plate on the ESI probe assembly clockwise into the

open position, insert the ESI probe assembly (P/N FM102595), and turn

the locking plate counterclockwise into the closed position.

6.

Insert the PEEK finger-tight fitting into the ESI probe assembly (P/N

FM102595) and screw it into place.

____________________________MSQ Hardware Manual ____________________________ 2-5

Page 48

Changing Ionization Modes

Switching from APCI to ESI ________________________________________________________________

2-6 ___________________________ MSQ Hardware Manual ____________________________

Page 49

Chapter 3

LC/MS and the Cone Wash 3.

LC/MS and the Cone Wash ......................................................................................................3-i

Introduction ....................................................................................................................................3-1

LC/MS Considerations ...................................................................................................................3-2

Flow Rates .........................................................................................................................3-2

HPLC Solvents and Mobile Phase Additives ....................................................................3-3

Setting Up the Cone Wash..............................................................................................................3-7

Flow Splitting .................................................................................................................................3-9

___________________________ MSQ Hardware Manual _____________________________ 3-i

Page 50

LC/MS and the Cone Wash

Introduction ____________________________________________________________________________

3-ii____________________________ MSQ Hardware Manual ____________________________

Page 51

LC/MS and the Cone Wash

____________________________________________________________________________ Introduction

Introduction

Historically, LC/MS has been compatible only with volatile buffer systems

using modifiers such as trifluoroacetic acid, formic acid, and acetic acid.

Phosphate buffers, although extensively used in LC separations, were not

suited to LC/MS due to the rapid blocking of the ion sampling region caused

by the deposition of involatile phosphate salts. The self-cleaning API source

allows routine LC/MS with chromatographic buffers such as phosphates or

ion-pairing agents and samples in dirty matrices.

This chapter contains the following information:

Details of HPLC solvents and mobile phase additives that focus on

•

LC/MS applications using the MSQ.

• • Instructions on how to set up the cone wash and information on when to

use it.

Instructions on flow splitting for use with hyphenated detection

applications.

____________________________MSQ Hardware Manual ____________________________ 3-1

Page 52

LC/MS and the Cone Wash

LC/MS Considerations ____________________________________________________________________

LC/MS Considerations

This section discusses the considerations to be taken into account when

choosing solvents and additives. It also provides guidance on how to

optimize LC/MS analyses to produce high quality data using the MSQ.

Flow Rates

In general, the column in use determines the flow rate. Each column has an

optimum flow rate. The guidelines in Table 3-1 apply.

Table 3-1. LC columns and flow rates

Column ID Flow Rate

4.6 mm 1.0 mL/min

3.9 mm 0.5 mL/min

2.1 mm 0.2 mL/min

1.0 mm 40-50 µL/min

Capillary <10 µL/min

The different ionization modes require different flow rates and column IDs.

The following guidelines apply when using the MSQ:

Electrospray can operate at all the flow rates described in Table 3-1.

•

Therefore, the full range of column IDs can be used without splitting the

flow.

• APCI cannot operate at flow rates below 0.2 mL/min; therefore, suitable

column IDs are 2.1 mm, 3.9 mm, and 4.6 mm.

3-2 ___________________________ MSQ Hardware Manual ____________________________

Page 53

LC/MS and the Cone Wash

____________________________________________________________________LC/MS Considerations

HPLC Solvents and Mobile Phase Additives

The following section is a guide for the choice of solvent and mobile phase

additives to use. The choice of solvents for LC will be dictated primarily by

the separation requirements, but there are some guidelines that need to be

followed. These guidelines take the form of selected examples, which have

been divided into three categories: most compatible, least suitable, and other

less common ones. In all cases, degassed solvents are necessary for LC/MS

operation. Sonication, helium sparging, or vacuum membrane degassing

achieves this. Helium sparging and vacuum membrane degassing are the

more efficient techniques.

Most Compatible Solvents

Most compatible solvents are:

Water •

• • Acetonitrile

Methanol

These common reverse phase LC solvents are ideal for LC/MS. When using

high percentages of water, the probe temperature usually needs to be raised

to aid desolvation in the source.

Most Compatible Additives

The most compatible additives are:

Acetic acid or formic acid •

LC separations can be enhanced by reducing the pH of the mobile phase.

Suitable additives for this are acetic acid or formic acid. (Formic acid is

stronger than acetic acid and therefore, less needs to be added to reach a

required pH.) Addition of acids can suppress ionization in negative ion

analysis and weakly acidic compounds may not form [M-H]- ions in acidic

conditions.

•

Ammonium hydroxide

Ammonium hydroxide (ammonia solution) is suitable for increasing the pH

of the mobile phase, which can enhance LC separations. When analyzing

weakly acidic compounds, in negative ion mode, it is unlikely that there will

be any suppression of ionization.

____________________________MSQ Hardware Manual ____________________________ 3-3

Page 54

LC/MS and the Cone Wash

LC/MS Considerations ____________________________________________________________________

Ammonium acetate or ammonium formate •

These volatile salts are often used to buffer mobile phases. Use as little

ammonium acetate or ammonium formate as possible, keeping the

concentration below 100 mM. Ensure that the cone wash is running when

using high concentrations.

•

Non-volatile salts

When using non-volatile salts, ensure that the cone wash is running as they

can crystallize in the source, block the entrance cone, and prevent the mass

spectrometer from functioning. The most common non-volatile salts used

are phosphates.

•

Ion pairing agents

Ensure that the cone wash is running when using ion-pairing agents (for

example, sodium octanesulfonic acid). Many ion-pairing agents suppress

electrospray ionization.

Least Suitable Additives

Least suitable additives are surface-active agents/detergents.

These can suppress the ionization of other compounds. Detergents, by their

very nature, are concentrated at the surface of a liquid. This causes problems

with electrospray, as the ionization relies on the evaporation of ions from the

surface of a droplet. The detergent therefore suppresses the evaporation of

other ions. Use surfactants only when they are being analyzed themselves,

not as additives to HPLC mobile phases.

Other Solvents

Other solvents are:

Normal phase solvents •

Normal phase solvents such as dichloromethane, hexane, and toluene are

most suitable for use in APCI.

•

Propan-2-ol (IPA), 2-methoxyethanol, ethanol, and so on

These have all been used with LC/MS, but their use tends to be applicationspecific.

•

Dimethyl sulfoxide (DMSO)

This solvent is commonly used by synthetic chemists for primary dilution.

3-4 ___________________________ MSQ Hardware Manual ____________________________

Page 55

LC/MS and the Cone Wash

____________________________________________________________________LC/MS Considerations

Other Additives

•

Trifluoroacetic acid (TFA)

This is frequently used for peptide and protein analysis. High levels,

>0.1% v/v, can cause suppression of sensitivity in positive ion mode. TFA

may completely suppress ionization in negative ion mode.

•

Triethylamine (TEA)

This may suppress the ionization of less basic compounds in positive ion

mode (as it also is readily ionized to give a [M+H]

+

ion at m/z 102). TEA

enhances ionization of other compounds in negative ion mode because it is

basic. This is a particularly useful additive for the analysis of nucleic acids.

•

Tetrahydrofuran (THF)

In ESI, use of THF can reduce sensitivity. This effect can be counteracted

by post-column addition of ammonium acetate. It has no effect in APCI.

Caution. Do not use a concentration of THF greater than 5% with PEEK

tubing. THF causes swelling in the PEEK tubing and consequently presents

a risk of the LC tubing bursting.

• Inorganic acids

Inorganic acids (for example, sulfuric acid or phosphoric acid) can be used.

Check the suitability of the LC column to low pHs.

Caution. After using phosphoric acid, thoroughly clean the source, source

enclosure, and hexapole RF lens to minimize the physical damage.

____________________________MSQ Hardware Manual ____________________________ 3-5

Page 56

LC/MS and the Cone Wash

LC/MS Considerations ____________________________________________________________________

Summary of Additives

Table 3-2. Summary of additive use

Avoid

Use

Positive ion Trifluoroacetic acid (TFA) (>0.1% v/v),

surfactants.

Negative ion Surfactants, organic acids; for example,

acetic acid, formic acid, trifluoroacetic

acid (TFA).

Positive ion Acetic acid, formic acid, ammonium

acetate (<0.1M).

Negative ion Triethylamine (TEA), ammonium

hydroxide (ammonia solution),

ammonium acetate (<0.1M).

3-6 ___________________________ MSQ Hardware Manual ____________________________

Page 57

LC/MS and the Cone Wash

________________________________________________________________ Setting Up the Cone Wash

Setting Up the Cone Wash

Use the following information in conjunction with the setup and

maintenance animations on the MSQ CD shipped with the instrument.

Note. It is necessary to use the cone wash only for dirty matrices or with

involatile buffers. Choose the cone wash solvent to give the most effective

solubility for the expected contaminants.

A pump (such as the optional AXP-MS pump) delivers solvent to the cone

wash. The PEEK tubing (green stripe is recommended) is fed through the

door and attached to a PEEK fitting which screws into the instrument on the

right of the source block cover (see Figure 3-1). The recommended flow rate

is 100 µl/min with 50:50 methanol:water.

From LC pump

to cone wash

Figure 3-1. Cone wash solvent delivery

Turn the cone wash nozzle counterclockwise until the tip of the nozzle just

touches the top of the entrance cone, and then turn on the LC pump.

____________________________MSQ Hardware Manual ____________________________ 3-7

Page 58

LC/MS and the Cone Wash

Setting Up the Cone Wash_________________________________________________________________

Figure 3-2. Cone wash nozzle in the on position

Caution. Do not leave the cone wash running when the source heater is

turned off; this could lead to cone wash solvents condensing on the RF

lens.

3-8 ___________________________ MSQ Hardware Manual ____________________________

Page 59

LC/MS and the Cone Wash

___________________________________________________________________________ Flow Splitting

Flow Splitting

Due to the MSQ’s source design, flow splitting of the LC eluent is not

usually required. However, if hyphenated detection is required, flow

splitting can be achieved in the following way.

Zero dead volume

T-piece

HPLC column

PEEK LC tubing

PTFE sleeve

Fused silica

to waste or UV

Figure 3-7. Schematic of a split

Fused silica

to insert

and source

PTFE sleeve

A simple and effective way to make a post-column split for use with the

MSQ is shown in Figure 3-7.

1.

Connect a zero dead volume T-piece to the exit of the column, using the

normal PEEK or stainless steel LC tubing (PEEK tubing is used in the

figure).

2.

Connect one of the exits of the T-piece to the source enclosure, using

narrow bore PEEK tubing or, as shown in the diagram, fused silica. Use

a PTFE, or orange stripe PEEK tubing, sleeve to secure the fused silica

into the T-piece.

3.

Connect a length of the same tubing to the other exit (the split stream).

The amount of liquid directed through the split stream is determined by the

backpressure exerted at this exit, and hence by the internal diameter and the

length of the tubing attached. As a general rule, the longer the piece of

tubing attached to the split, the greater the flow to the source and the smaller

the split. To reduce the flow to the source and increase the split, shorten the