Page 1

LC20 CHROMATOGRAPHY ENCLOSURE

OPERATOR’S MANUAL

© 1993 Dionex Corporation

Document No. 034859

Revision 02

September 1993

Page 2

© 1993 Dionex Corporation

All rights reserved worldwide

Printed in the United States of America

This publication is protected by federal copyright law. No part of this publication

may be copi ed or distri buted, tr ansmitte d, tran scribe d, stor ed in a r etrieval sy stem,

or transmitted into any human or computer language, in any form or by any means,

electronic, mechanical, magnetic, manual, or otherwise, or disclosed to third parties

without the express written permission of Dionex Corporation, 1228 Titan Way,

Sunnyvale, California 94088-3603.

DISCLAIMER OF WAR RANTY AND LI MITED WARRANTY

THIS PUBLICATION IS PROVIDED “AS IS” WITHOUT WARRANTY OF

ANY KIND. DIONEX CORPORATION DOES NOT WARRANT,

GUARANTEE, OR MAKE ANY EXPRESS OR IMPLIED

REPRESENTATIONS REGARDING THE USE, OR THE RESULTS OF THE

USE, OF THIS PUBLICATION IN TERMS OF CORRECTNESS,

ACCURACY, RELIABILIT Y, CURRENTNESS, OR OTHERWISE.

FURTHER, DIONEX CORPORATION RESERVES THE RIGHT TO REVISE

THIS PUBLICATION AND TO MAKE CHANGES FROM TIME TO TIME

IN THE CONTENT HEREIN WITHOUT OBLIGATION OF DIONEX

CORPORATION TO NOTIFY ANY PERSON OR ORGANIZATION OF

SUCH REVISION OR CHANGES.

TRADEMARKS

DX-LAN, Self-Regen eratin g Suppr essor, SRS, and The rmoFlareare

trademarks of Dionex Corporation.

Teflon and Tefzel are registered trademarks of E.I. du Pont de Nemours and

Company.

PRINTING HISTORY

Revision 01, August 1993

Revision 02, September 1993

Page 3

1

2

Contents

•

Introduction

1.1 Ov ervie w . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.2 Ab out T his Manua l . . . . . . . . . . . . . . . . . 1- 3

1.3 Product Saf ety Information . . . . . . . . . . . . . 1-4

•

Description

2.1 Ov ervie w . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2 Front Panel . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.1 Rheodyn e In jection Valve . . . . . . . . . 2-3

2.3 Inte ri or Layout . . . . . . . . . . . . . . . . . . . 2-4

2.3.1 Component Panel . . . . . . . . . . . . . 2-5

Doc. 034859 -0 2 9/93

2.3.2 Rheodyn e In jection Valve . . . . . . . . . 2-6

2.3.3 Self-Regenerating Suppressor . . . . . . . 2-7

2.3.4 Leak Sensor . . . . . . . . . . . . . . . . 2-7

2.3.5 Separator Columns . . . . . . . . . . . . 2-7

2.3.6 Guard Columns . . . . . . . . . . . . . . 2-7

2.3.7 Column Select V alve . . . . . . . . . . . . 2-8

2.3.8 Detector C ells . . . . . . . . . . . . . . . 2-1 1

2.3.9 DS3 Detection Sta bilizer (Optional) . . . 2-11

2.4 Rear Panel . . . . . . . . . . . . . . . . . . . . . . 2-12

2.4.1 Cell Cables . . . . . . . . . . . . . . . . . 2- 13

2.4.2 Waste Line . . . . . . . . . . . . . . . . . 2-13

i

Page 4

Contents

3

4

2.4.3 So lenoid Interfa ce . . . . . . . . . . . . . 2-13

•

Service and Ma intenance

3.1 Routine Operation . . . . . . . . . . . . . . . . . . 3-3

3.1.1 Sample Loading . . . . . . . . . . . . . . 3-4

3.2 Shutdown . . . . . . . . . . . . . . . . . . . . . . 3-7

3.3 Routine Maintenance . . . . . . . . . . . . . . . . 3-7

•

Troubleshooting

4.1 Liquid Lea ks . . . . . . . . . . . . . . . . . . . . . 4- 3

4.2 Excessive System Backpressure . . . . . . . . . . 4-4

5

4.3 Inopera tive Column Sele ct Valve . . . . . . . . . 4-5

4.4 Column Select Valve Air Leaks . . . . . . . . . . 4-5

4.5 Peak Ghosting . . . . . . . . . . . . . . . . . . . . 4-6

4.6 Non-Repr oducible Peak Heig ht or Retention

Tim e . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.7 Abnormal Retention Time or Selectivity . . . . . 4-6

•

Service

5.1 Introduc tion . . . . . . . . . . . . . . . . . . . . . 5-3

5.2 Tube Fitting Installation . . . . . . . . . . . . . . 5-3

5.3 Restriction in the Hydraulic System . . . . . . . . 5-4

5.4 Injectio n or Column Select Va lve Liquid Leaks . 5-4

5.5 Column Select Valve Air Leaks . . . . . . . . . . 5-5

ii

Doc. 034859- 02 9/93

Page 5

A

B

Contents

5.6 Cleaning the Column Select Valve Slider . . . . . 5-6

5.7 Rep lacing Colum n Select Va lve Port Face . . . . 5-9

5.8 Servicing the Rheodyne Injection Valve . . . . . 5-9

•

Specifications

A.1 Environmental . . . . . . . . . . . . . . . . . . . . A-3

A.2 Ph ys ical . . . . . . . . . . . . . . . . . . . . . . . A-3

A.3 Hydraulics . . . . . . . . . . . . . . . . . . . . . . A-3

A.4 Insulation . . . . . . . . . . . . . . . . . . . . . . A-4

•

Installation

B.1 Facilities Required . . . . . . . . . . . . . . . . . B-3

B. 2 Inst allation Ins tr uctions . . . . . . . . . . . . . . . B-4

B. 2. 1 Stac king Modules . . . . . . . . . . . . . B-4

B. 2. 2 Waste Lines . . . . . . . . . . . . . . . . . B-5

B.2.3 Leak Control . . . . . . . . . . . . . . . . B-6

B.2.4 Liquid Line C onne ctions . . . . . . . . . B-6

B. 2. 5 Detector C ells . . . . . . . . . . . . . . . B-9

B.2.6 Column Installation . . . . . . . . . . . . B-12

B.2.7 SRS Installation (Optional) . . . . . . . . B-13

B.2.8 Solenoid Valve Connections

to the Pump . . . . . . . . . . . . . . . . B-14

Doc. 034859 -0 2 9/93

iii

Page 6

Contents

iv

Doc. 034859- 02 9/93

Page 7

1 • Introduction

1.1 Ov ervie w . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.2 Ab out T his Manua l . . . . . . . . . . . . . . . . . 1- 3

1.3 Produc t Safety Information . . . . . . . . . . . . . 1-4

Doc. 034859 -0 2 9/93

1-1

Page 8

LC20 Chromatography Enclosure

1-2

Doc. 034859- 02 9/93

Page 9

1 • Introduction

1.1 Overview

The LC20 Chromatog raphy Enclosure is an integral part of the

Dionex DX 500 Chr omatography Systems. It can house the

following system components, which must be ordered separately or

as part of anothe r module: Separator colu mns, optional guard

columns, SRS (Self-Regenerating Supp ressor), DS3 Detection

Stabilizer, and detector cell(s) for the ED40 Electrochemical

Detector and CD 20 Conductivity Detector.

The LC20 is available in two co nfigurations, depending o n

the type of injection valve installed:

•

LC30, PEEK automated inje ction valve (P/N 044088)

•

LC3 0, stainle ss steel automated injection valve (P/N 044171)

1.2 About This Manual

This manual describes the operation, mainte nance, and us e of the

L20 Chromatography E nclosure.

Chapter 1, Introduction, introduces the product a nd conventions

used in the manual, a nd provides safety information.

Chapter 2, Description, is a descriptio n of the physica l aspects of

the LC20 Chromato graphy Enclosure, followed by a functional

description of the operating features.

Chapter 3, Operation and Maintenance, discusses th e operating

features and routine maintenance.

Chapter 4, Troubleshooting, provides step-by -step procedures to

isolate problems and lists possible causes.

Chapter 5, Service, presents step-by-step p rocedures to perf orm

service an d parts replacemen t routines.

Doc. 034859 -0 2 9/93

1-3

Page 10

LC20 Chromatography Enclosure

Appendix A Specifications contains the LC2 0 specifications .

Appendix B, Installation, describes the installation a nd interface

necessary to place the LC20 i nto operation.

1.3 Product Safety Information

This instrument was designed in conformanc e with the safety

requirements set forth in IEC 1010 Safety R equirements for

Electrical Equipment for Measurement, Control, and Laboratory Use.

Section of this manual are flagged with key words and symbols to

denote the natu re of potential haza rds. These safety directives apply

to all operators an d service personnel.

The following safety reference symbols are marked in the instrument

and this manual where nec essary to alert the operator.

Indicates a potential hazard to the operator, or

damage to the instrument o r other property.

Example: Overtightening valve bolts may break them

off.

1-4

Doc. 034859- 02 9/93

Page 11

2 • Description

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2 Front Panel . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.1 Rheodyne Injection Valve . . . . . . . . . 2-3

2.3 Interior Layout . . . . . . . . . . . . . . . . . . . 2-4

2.3.1 Component Panel . . . . . . . . . . . . . 2-5

2.3.2 Rheodyne Injection Valve . . . . . . . . . 2-6

2.3.3 Self-Regenerating Suppressor . . . . . . . 2-7

2.3.4 Leak Sensor . . . . . . . . . . . . . . . . 2-7

2.3.5 Separator Columns . . . . . . . . . . . . 2-7

2.3.6 Guard Columns . . . . . . . . . . . . . . 2-7

2.3.7 Column Select V alve . . . . . . . . . . . . 2-8

2.3.8 Detector Cells . . . . . . . . . . . . . . . 2-11

2.3.9 DS3 Detection Stabilizer (Optional) . . . 2-11

Doc. 034859 -0 2 9/93

2.4 Rear Panel . . . . . . . . . . . . . . . . . . . . . . 2-12

2.4.1 Cell Cables . . . . . . . . . . . . . . . . . 2-13

2.4.2 Waste Line . . . . . . . . . . . . . . . . . 2-13

2.4.3 Solenoid Interface . . . . . . . . . . . . . 2-13

2-1

Page 12

LC20 Chromatography Enclosure

2-2

Doc. 034 859-02 9/93

Page 13

2 • Description

2.1 Overview

Eluent from the grad ient pump enters the R heodyne injection valve

port inside the enclosure. From the inje ction valve, eluent and

sample flow through the g uard column (if used ), the separator

column, the supp ressor or other post-column device, and finally

through the detec tor cells.

The LC20 may be configured for optional dual-channel opera tion. It

will then include a secon d Rheodyne injection valve and component

panel. There is eno ugh tubing in th e LC20 Ship Kit (P/N 046 300) to

plumb two systems.

The LC20 do es not req uire power. Internal compon ents are operat ed

by the GP40/IP20 p ump.

2.2 Front Panel

The front panel of the enclosur e is the door. It contains access to

one or two Rheodyne injection valves.

2.2.1 Rheodyne Injection Valve

Doc. 034859 -0 2 9/93

The Rheodyne injection valve is mounted on th e component

panel in a manner that allows its control knob to extend

through the fron t door for acce ss. If the LC20 is configured

as a dual-chan nel module, a second Rheodyne in jection valve

will be installed on th e left-side compone nt panel and extend

through the adjac ent port.

2-3

Page 14

LC20 Chromatography Enclosure

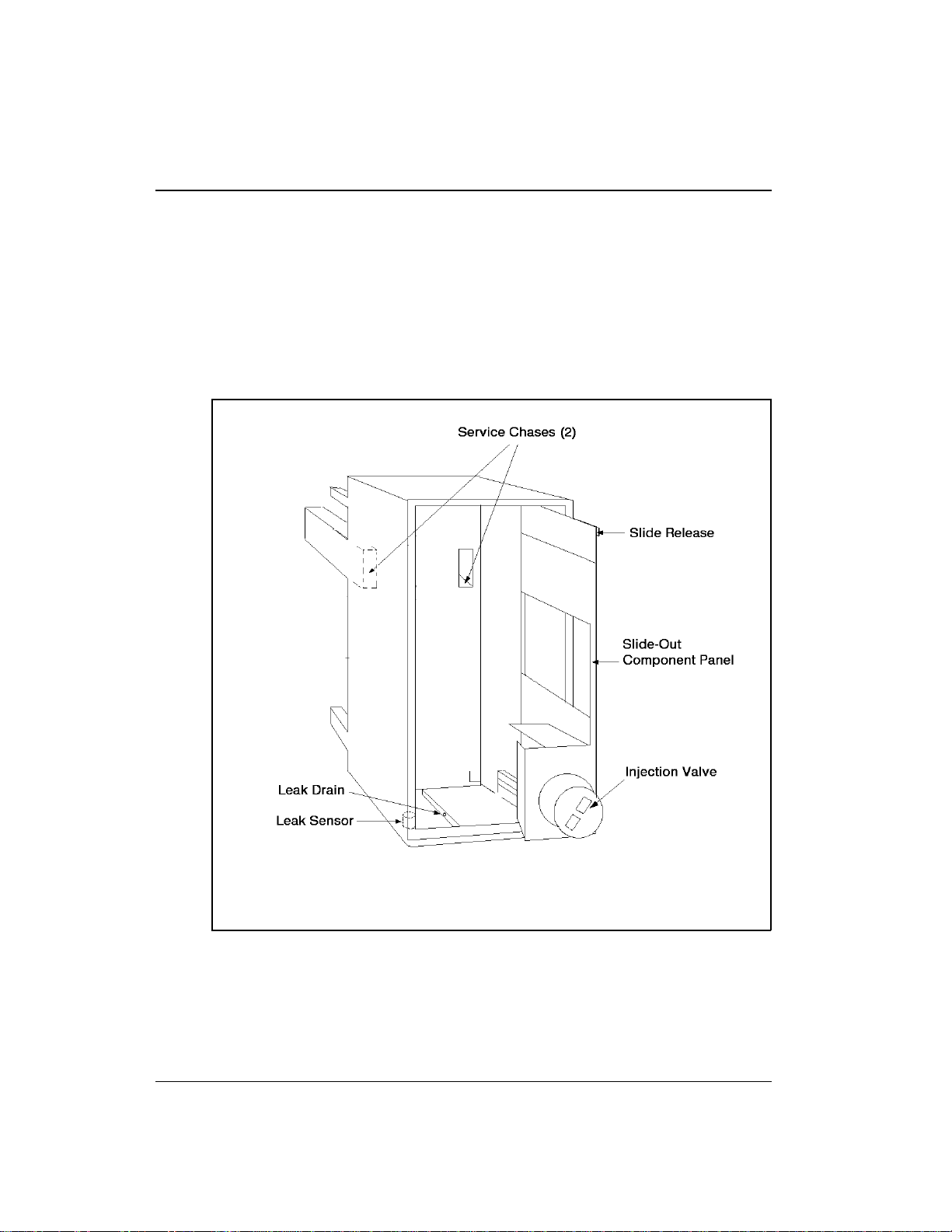

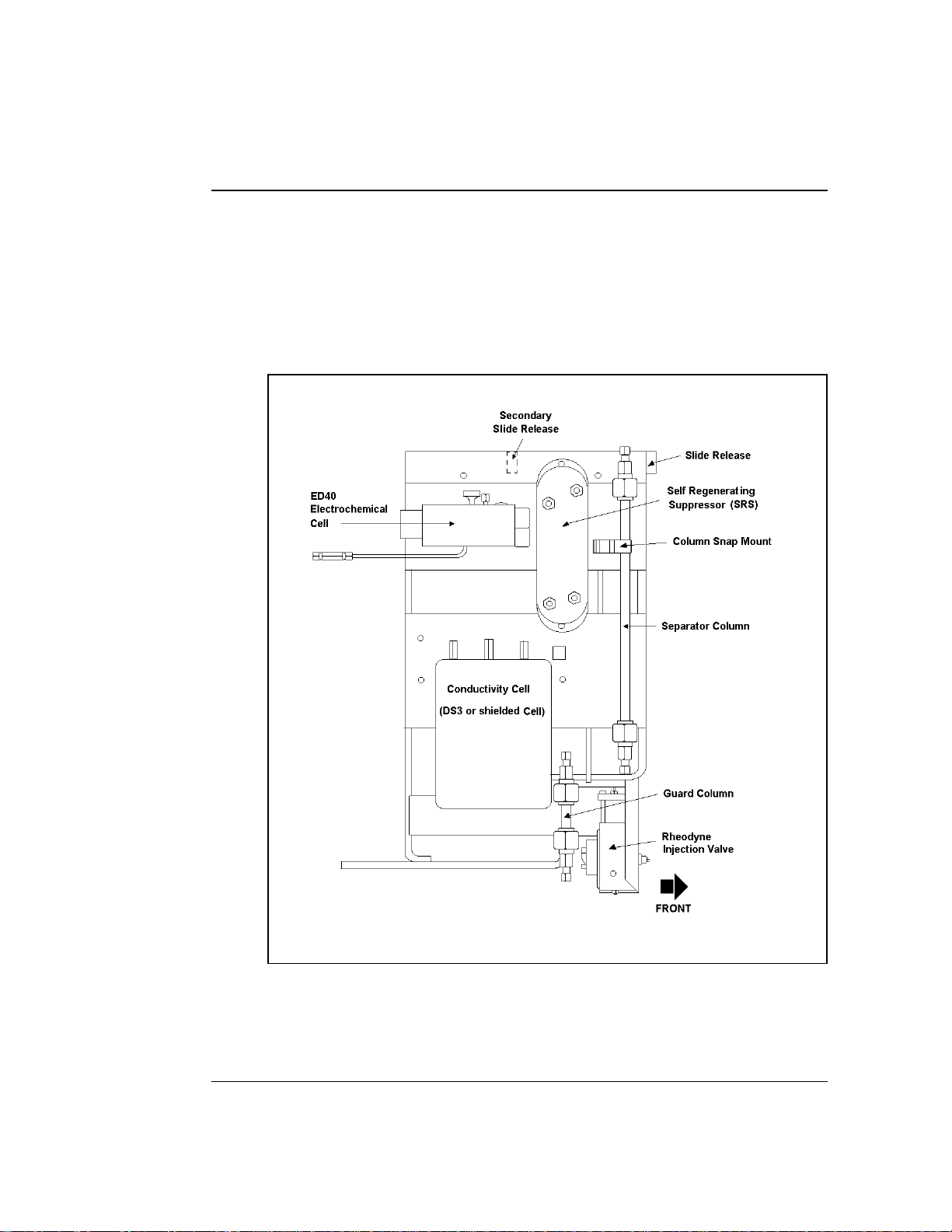

2.3 Interior Layout

The interior of the LC20 is a n insulated, passive chamber. It

contains a slide-out panel for mounting components. Figure 2-1

illustrates the LC20 chassis. See Section B.2. 1 for recommended

stacking configurations. See Figure 2-2 for an illustration of the

slide-out component pa nel.

2-4

Figure 2-1. LC20 Interior Chassis

Doc. 034 859-02 9/93

Page 15

2.3. 1 Component Panel

Components are mounted o n the slide-out panel. The panel

on the right side is standard in all LC20 enclos ures. When a

dual-channel modu le is ordered, an o pposite panel is

factory-installed on the left side (see Figure 2- 2).

2 • Description

Doc. 034859 -0 2 9/93

Figure 2-2. Component Panel Layout

2-5

Page 16

LC20 Chromatography Enclosure

The component pa nel has two slide releases to lock it in a

fully closed (in) or op en (out) posi tion. Press th e slide rele ase

at the upper horizontal edge of the panel to release the detent.

The panel will lock at about three q uarters of its total travel

when you pull it out. This prevents it from being pulled

entirely out of the tracks and possibly damaging the

components. To reinsert the panel, press th e second slide

release and push it back into its closed position. The fully

closed position locks the panel and prevents it from being

forced outward by pressure from the vario us tubing

arrangements.

The panel can b e pulled completely out by pressing the

second slide release a nd pulling the panel until it clears the

top and bottom tracks. H old the panel securely when it

disengages the tracks. To replace the panel, align it with the

top and bottom tracks and push inward until it engages the

second detent. Pre ss the second slide release a nd push the

panel to its closed and locked position.

2-6

Various component arrang ements are made pos sible by

multiple mounting ho les and slots. The configuration s hown

here is only on e of many offered by the enclos ure.

2.3.2 Rheodyne Injection Valve

The Rheodyne injection valve is mounted at the bottom of the

component pane l. Its control knob exten ds through the door

to allow manual operation with the doo r closed. The valve

has two operating positions:

The injection valve is a low-volume, metal-free, 35 MPa

(5000 psi) rotary injec tion valve. It accommodates syr inge

injections or pressurized sample loading.

The Rheodyne injection valve is equippe d with a microswitch

for detection of the valve position. The microswitch can be

wired to a module that can p rocess the signal to verify the

position of the valve.

INJECT

and

LOAD

.

Doc. 034 859-02 9/93

Page 17

The LC20 S hip Kit in cludes two acce ssories fo r the

Rheodyne injection valves: a 25 µL gas-t ight syrin ge

(P/N 041389) and a 25 µL sample loop (P/N 0 42857). For

more information about the valve, including important

operating precautions, refer to the

Manual

(Document No . 034468), inclu ded in the LC20 Ship

Kit.

2.3. 3 Self-Regenerating Suppressor

The Self-Regenerating Suppresso r (SRS) is held in place

by a special support pla te. Align the two slots on the botto m

of the SRS case with the tabs on the suppo rt plate. Press

and then

down

to lock the SRS in place. Pull up and then

to remove (see Figure B-8 in Appendix B).

2.3.4 Leak Sensor

This sensor detects leaks and spills in th e bottom of the

enclosure, a nd generates a signal wh en a leak occurs . The

sensor is located at the lower front corner of the left wall in

the bottom tray. Its cable exits through the rear service ch ase,

and must be conne cted to the GP40 pump .

2 • Description

Rheodyne Valve Operator’s

in

out

2.3. 5 Separator Columns

2.3.6 Guard Columns

Doc. 034859 -0 2 9/93

The column mount n ear the front of th e component panel c an

accommodate up to two separato r columns. The colu mn

mount supports 4-mm columns on one side and 2-mm

columns on the other. The column mount can be removed by

pressing on each side of its mounting ta b and pulling away

from the slot in the panel. Yo u can then reverse it and press it

back into the panel to ch ange column size and maintain the

columns at the outer positio n (see Figure B-7 in Appendix B).

The smaller gu ard columns (if used) are held in pl ace by the

tubing below the separator columns.

2-7

Page 18

LC20 Chromatography Enclosure

2.3.7 Col umn Select Valve

The column selec t valve (P/N 044858), when included, will

be supported o n the component pan el by a mounting plate .

The column select valve is controlled by the pump through a

pair of air solenoids on the back of the LC20.

The column select valve is not normally plumbe d into the

system. However, enough tubing is provided in the LC20

Ship Kit to plumb u p to two column select valves into two

systems. When plumb ed, the optional 28 MKa (400 0 psi)

column sel ect valve directs the flow of eluent a nd sample

from the Rheodyne injection valve to either column A or B.

The column select valve can alternatively be used to switch in

and out a separator c olumn.

The column select valve is actuated by a pair o f solenoids

mounted on the rear panel, which will be included only wh en

the column select valve is installed. The solenoids are

electrically co nnected to and controlled b y the GP40 or IP20

pump. Refer to the pump manual for operating instructions.

2-8

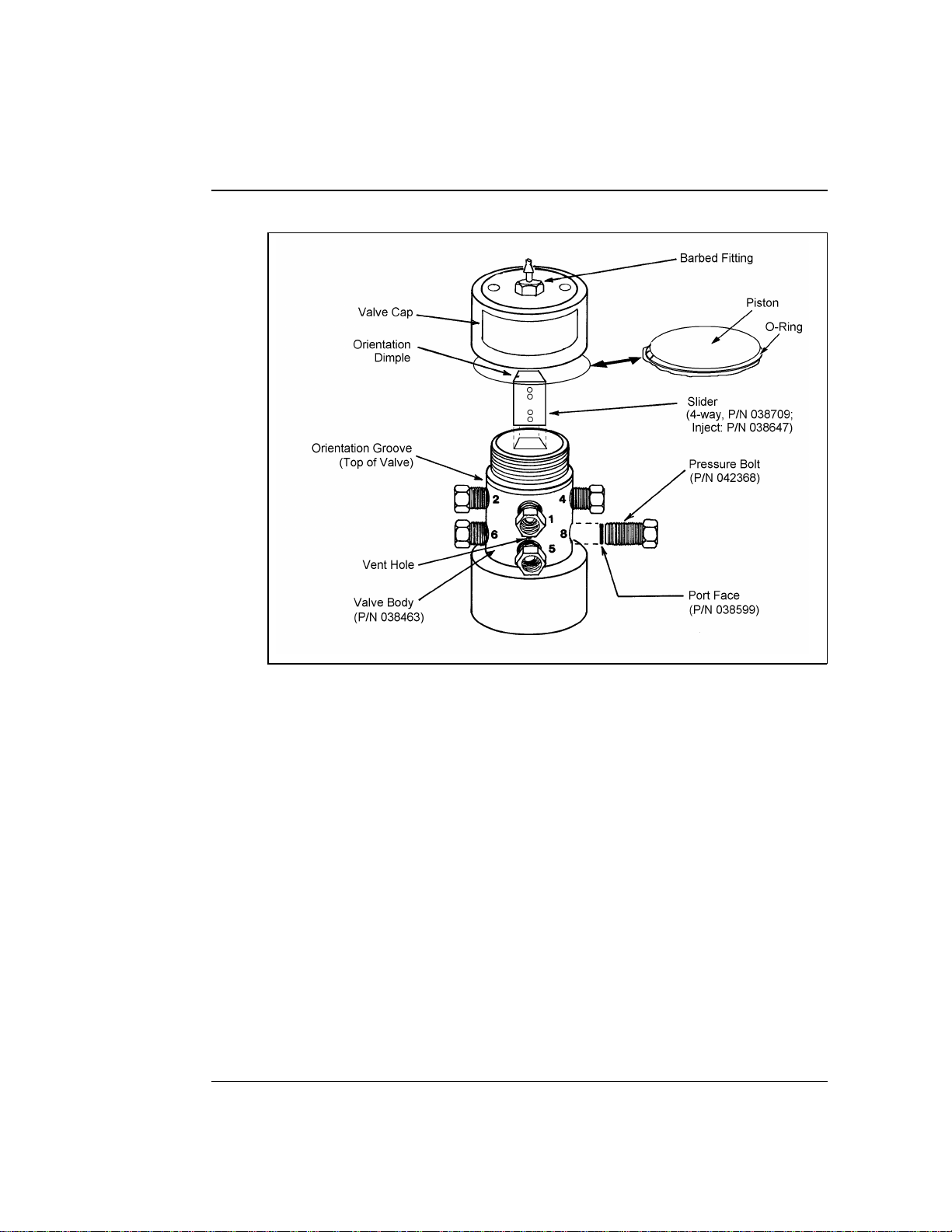

Figure 2-3 shows the assembly of the column select valve.

Doc. 034 859-02 9/93

Page 19

2 • Description

Doc. 034859 -0 2 9/93

Figure 2-3. Column Select Valve

The groove around the valve body in dicates the top of the

valve. The ports are numbe red clockwise aroun d the valve

body. The small vent hole is between ports 1 a nd 5. Pressure

bolts provide an intermediate conn ection between the valve

slider and all tube fittings.

These bolts must be tightened

evenly to provide uniform sealing pressure against the

valve slider and ensure leak-free operation.

maintenance information, refer to the

Installation and

Maintenance of the Dionex High Pressure Valve

. For valve

(Document

No. 032678).

2-9

Page 20

LC20 Chromatography Enclosure

The valve is operated by a ir pressure push ing against pistons

inside the valve cap. The p iston pushes a slider up and down

inside the valve body. Applying pressure to the top piston

pushes the slider down; applying pressure to the bottom

piston pu shes the sl ider up. T he slider con nects the valve

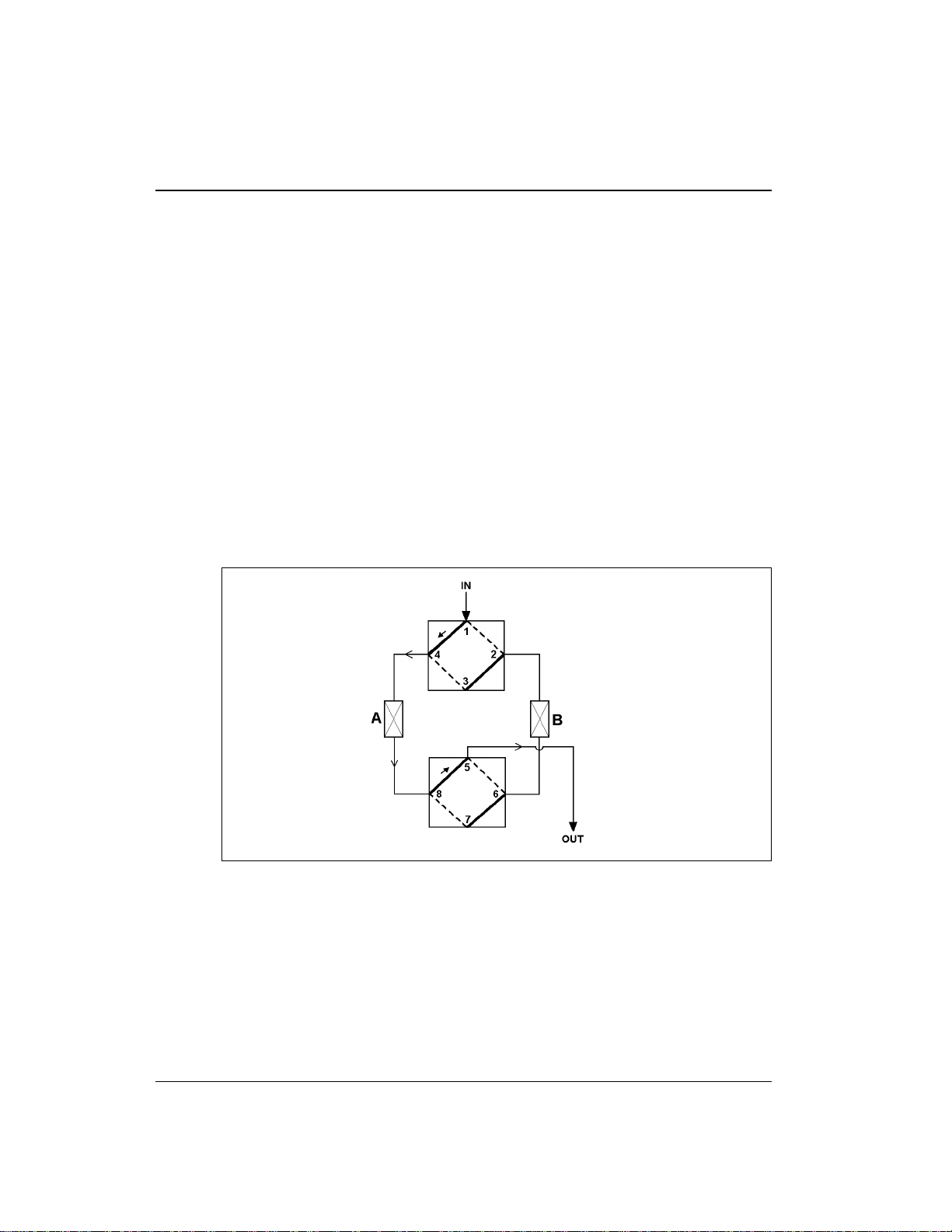

ports as follows (see Figure 2-4 ).:

Switch in OFF position, selecting column A (slider down):

1 → 4 and 2 → 3,

5 → 8 and 6 → 7

Switch in ON position, s electing column B (slider up):

1 → 2 and 3 → 4,

5 → 6 and 7 → 8

2-10

Figure 2-4. Column Select Valve Slider Connections

The valve is tested to op erate leak-free at 28 M Pa (4000 psi).

After testing, the valve pressure bolts are loosened to reduce

stress on critical parts during storage. Before shipment, the

pressure b olts are tigh tened to provide leak-free oper ation at

pressures up to 17 MPa (2500 psi) or 90 in-oz torque. If yo u

Doc. 034 859-02 9/93

Page 21

need to o perate at hig her pressu res (up to 2 8 MPa, or

4000 psi), first torque the bolts to 128 in-oz . If the valve is to

be unused for mo re than two days, red uce the torque o n the

bolts to 90 in-oz while ins talling or removing the fittings.

Use a wrench on the valve pressure bolt to prevent it from

turning while loosening the fitting. Refer to

Maintenance of the Dionex High-Pressure Valve

No. 032678) for additional information.

2.3.8 Detector Cells

Detector cells for the CD20 Conductivity Detector or the

ED40 Electrochemical De tector are mounted o n the

component pane l. Their cables exit thr ough one of the serv ice

chases on the r ear panel.

2.3. 9 DS3 Detection Stabilizer (Optional)

The DS3 improves baseline stability by da mping fluctuations

in temperature, thus improving detection at trace levels. Refer

to the

DS3 Detection Stabilizer Installation Instructions

(Document No. 0348 50).

2 • Description

Installation and

(Document

Doc. 034859 -0 2 9/93

2-11

Page 22

LC20 Chromatography Enclosure

2.4 Rear Panel

The rear panel provides installation space for air and valve

connectors (see Figure 2-5).

2-12

Figure 2-5. LC20 Rear Panel

Doc. 034 859-02 9/93

Page 23

2.4.1 Cell Cables

The cables ins ide the LC20 , which connec t the detector cel l

to the CD20 Cond uctivity Detector or the ED40

Electrochemical Detector normally exit through service chase

in the rear panel ( see Figure 2-5).

2.4 .2 Waste Line

The cell and suppressor waste lines from insid e the LC20

normally exit through the service chase in th e rear panel (see

Figure 2-5). The injection valve waste lines should exit

through the lower side s lots of the enclosure .

2.4.3 Solenoid Interface

The air-actuated solenoid valves used to control the inje ction

valve and the column select valves (if installed) are

controlled directly by the pump. The solenoids are installed

as pairs; one pair is shown in Figure 2-5.

2 • Description

Doc. 034859 -0 2 9/93

Refer to the GP40 Gradient Pump or IP20 Isocratic Pump

manual for connection details.

2-13

Page 24

LC20 Chromatography Enclosure

2-14

Doc. 034 859-02 9/93

Page 25

3 • Operation and Maintenance

3.1 Routine Operation . . . . . . . . . . . . . . . . . . 3-3

3.1.1 Sample Loading . . . . . . . . . . . . . . 3-4

3.2 Shutdown . . . . . . . . . . . . . . . . . . . . . . 3-7

3.3 Routine Maintenance . . . . . . . . . . . . . . . . 3-7

Doc. 034859 -0 2 9/93

3-1

Page 26

LC20 Chromatography Enclosure

3-2

Doc. 034 859-02 9/93

Page 27

3 • Operation and Maintenance

3.1 Routine Operatio n

Inside the Rheodyn e injection valve, eluent flows through one of

two paths depending on the position of the injection valve knob (see

Figure 3-6).

Figure 3-6. Injection Valve Schematic

In th e

column without en tering the sample loop. Sample flows from the

syringe into the valve and through the sa mple loop, and excess

sample flows out to waste.

In th e

sample loop, and out to the column (carrying the contents of the

sample loop with it).

Doc. 034859 -0 2 9/93

position, eluent flows in from the pump and out to the

LOAD

INJECT

position, eluent flows in from the pump, thro ugh the

3-3

Page 28

LC20 Chromatography Enclosure

3.1. 1 Sample Loading

The Rheodyne injection valve may be filled completely or

partially. These techniques differ in accuracy, precision, and

the amount of sample r equired. Refer to th e Rheodyne valve

Operating Instructions

selecting a method for your application.

Before filling the injection valve sample loop, set the

Rheodyne injection valve knob to

There are fo ur methods for plumbin g the Rheodyne valve

sample loop:

When inserting needles into the needle port, use only

0.028-inch OD (22 gauge) x 2-in. long needles with 90

degree point style (square end). Using the incorrect needle

size can damage the injector.

Direct injection into the valve:

1.

LOAD

its

position. Insert the syringe into the needle port

on the injection valve (see Figure 3-6). Overfill the

sample loop with several sample loop volumes. Excess

sample will flow out thro ugh the waste line. L eave the

syringe in th e needle port until the injection valve knob is

turned to

INJECT

.

included in the LC20 Ship Kit before

LOAD

(see Figure 3-6)

Set the injection valve to

3-4

Drawing sample through the waste line:. Place the

2.

injection valve into its

LOAD

position. Insert the syringe

into the need le port on the Rheo dyne valve, place the

valve waste line (port #6) into the sample container (see

Figure 3-7). Draw sample into the loop throu gh the

injection valve waste line. No sample will c ome into

contact with the metal ne edle of the loading syringe.

Remove the sample from the sample container. Leave the

syringe in the needle port until the injection valve knob

has been switched to

INJECT

.

Doc. 034 859-02 9/93

Page 29

3 • Operation and Maintenance

Figure 3-7. Drawing Sample

Doc. 034859 -0 2 9/93

3-5

Page 30

LC20 Chromatography Enclosure

Loading sample through the waste line:

3.

possible outgassin g effects of using suction to draw the

sample through the waste line, connect a luer fitting and

sample-filled syringe in the end of the waste line. Connect

the other end of the waste line into injection valve port

#6. Place the valve in its

adaptor shipped with the Rheodyne valve into the needle

port. Push sa mple through the waste line. Waste will exit

the valve through the n eedle adaptor. No sample to be

analyzed will come into contact with the metal needle of

the needle adaptor (see F igure 3-8).

To avoid the

LOAD

position. Insert the needle

3-6

Figure 3-8. Loadng Sample

Loading from an automate d sampler:

4.

See the

autosampler operator’s manual for instructions.

Doc. 034 859-02 9/93

Page 31

3.2 Shutdown

If the LC20 will not be us ed for more than three days and if the

column select valve is torqued for high pressure, reduce the torqu e

on the pressure bolts to 90 in-oz to prevent possible damage to the

valve .

If other modules are connected to the rear panel power s trip, make

sure the fr ont panel doo r is fully clos ed. Press the power actuator

switch on the fron t panel to shut off power to other modu les. The

power actuator rod leading the power switch at the rear of the

module will not op erate if the door is open.

3.3 Routine Maintenance

•

Periodically check for leaks or spills inside th e LC20. Locate and

repair leaks and clean up spills. Rinse all dried eluents

(especially when they include salt solutions) o r reagents off

system compone nts with deionized wate r or, in the case of

spilled ninhydrin, with isopropyl alcohol.

3 • Operation and Maintenance

•

Periodically check all air and liquid lin es for crimping. Move or

reroute pin ched lines; replace d amaged lines.

Doc. 034859 -0 2 9/93

3-7

Page 32

LC20 Chromatography Enclosure

3-8

Doc. 034 859-02 9/93

Page 33

4 • Troubleshooting

4.1 Liquid Lea ks . . . . . . . . . . . . . . . . . . . . . 4- 3

4.2 Excessive System Backpressure . . . . . . . . . . 4-4

4.3 Inopera tive Column Sele ct Valve . . . . . . . . . 4-5

4.4 Column Select Valve Air Leaks . . . . . . . . . . 4-5

4.5 Peak Ghosting . . . . . . . . . . . . . . . . . . . . 4-6

4.6 Non-Repr oducible Peak Heig ht or Retention

Tim e . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.7 Abnormal Retention Time or Selectivity . . . . . 4-6

Doc. 034859 -0 2 9/93

4-1

Page 34

LC20 Chromatography Enclosure

4-2

Doc. 034859- 02 9/93

Page 35

4 • Troubleshooting

Use this troubleshooting guide to isolate and solve problems that

may occur while using the LC20. If the re is more than one possible

cause, read the potential sources of the prob lem to determine which

may be the most applicable. If th e problem persists, call the nearest

Dionex Regional Office.

For troubleshooting pr ocedures specific to the Rheodyne injection

valve, re fer to the Rheodyne Valve Operator’s Manual (Document

No. 034468).

4.1 Liquid Leaks

•

Leak ing fitt ing.

Locate the source of the leak. Make sure all liqu id line

connections are tight:

1. If the con nections are made with Dionex ferrule fittings,

see Installation o f Dionex Ferrule Fittings (Document

No. 034213) f or instructions.

•

Broken liquid line.

•

Blocked or improperly installed waste line.

Doc. 034859 -0 2 9/93

2. If the colu mn select valve is plumbed into the system,

remove the valve from its mounting clip to improve

access t o all valve ports. Use a wrench on the valve

pressure bolt to prevent it from turning while tighte ning

the fitting.

Replace the f errule or r eplace the tubin g.

Make sure th e waste lines from the valves and ce lls are not

crimped or otherwis e blocked. Also make sure they are not

elevated at any point after they exit the modu le.

4-3

Page 36

LC20 Chromatography Enclosure

• Pressure bolt(s) on c olumn switching valve are too loose.

Follow the procedure below to tighten the pressure bolts:

1. Turn off the liquid flow.

2. Tighten each pressure bolt fingertight, the n use an

open-end wren ch to tighten an additional one-eighth tu rn.

NOTE

All eight pressure bolts must be evenly tightened

against the slider for optimum leak-free operation.

3. Turn on the liquid flow evenly and check for leak s.

Tighten pressure bolts further if leaks appear.

NOTE

Use a torque wren ch to evenly tight en pressure bolts

for optimum l eak-free operati on. Refer to

and Mainte nance of the Dionex Ine r t H ig h P ressu re Valve

(Document No. 032678) for torque requirements.

Installation

• A co lumn select valve port is scra tched.

Replace t he port face.

4.2 Excessive System Backpressure

• Restriction in the hydraulic system.

1. Chec k all liquid lines and valves for crimping or

blockage. Make sure ferrule fittings are not overtightened

into Tefzel tubing. Refer to

Fittings

(Document No. 034 213) for details.

2. Verify that valves are being fully activated (not between

positions).

• Flow rate through the columns is too high.

Reduce the flow rate.

4-4

Installation of Dionex Ferrule

Doc. 034859- 02 9/93

Page 37

• Clogged co lumn bed supports.

Replace th e bed support s as instructe d in the col umn manual.

• Columns are contaminated.

Clean the columns (see Column Rejuvena tion Procedures,

Technical Note 2 R, Document No. 032036).

4.3 Inoperative Column Select Valve

• Air is not reaching t he valve.

Check that the air s upply is turned on a nd is supplying 550 to

820 KPa (80 to 120 psi).

• Air tubing harness is crimped or blocked.

Check the air tu bing for blockage. R emove and replace any

blocked tubing. Re position crimped or pinch ed tubes.

• Air le ak.

4 • Troubleshooting

Air leaks are usually audible; isolate and eliminate leaks.

• Valve is incorrectly plumbed.

Check that the system is correctly plumbed . Re-plumb the

system if n ecessary.

• Pressu re bolts on th e column sele ct valve are too tig ht.

Follow the procedure in Section 4.1 to loosen the pressure

bolts if the column select valve is plumbed into the system:

4.4 Column Select Valve Air Leaks

• Air le ak.

Air leaks are us ually audible and f requently cause excessive

cylinder gas/air consu mption. Locate and rep air the leak.

Doc. 034859 -0 2 9/93

4-5

Page 38

LC20 Chromatography Enclosure

4.5 Peak Ghosting

Ghosting is the appear ance of extraneous peaks in a

chromatogram. These may be late-eluting peaks from a previous

injection or result from a contaminated valve or a poor sample

loading technique. These peaks may co-elute with peaks of

interest, resulting in non-reproducible peak heights.

• Insufficient time between sample injections.

Wait until the previous sample has been completely eluted

before making anoth er injection.

• Insufficient flush between samples.

Flush the sample loop with at least 10 loop volumes of

deionized water or sample between sample injec tions.

4.6 Non-Reproducible Peak Height or Retention Time

• Column overloa ding.

1. Chan ge to a sample loop with a sm aller volume.

2. Dilute th e sample.

• Liquid leaks.

Locate and eliminate the leaks.

Also see “Peak ghosting” in Section 4.5 above.

4.7 Abnormal Retention Time or Selectivity

• System is not equilibrated following an eluent change .

Allow the system to equilibrate with at least 2 0 column

volumes of eluent (for example, 30 minutes at 2. 0 mL/min

for 4 mm anion separator columns).

• Flow rate through s ystem is inco rrect.

1. Ch eck that the correct flow ra te is selected .

4-6

Doc. 034859- 02 9/93

Page 39

2. Loc ate and eliminate any liquid leaks.

• Cont aminated or in correct eluent.

Remake the elu ent using reagent grad e chemicals an d ASTM

filtered Ty pe I (18 megohms or 1 µS) grade deion ized water.

• Contaminat ed or degraded sample.

Take appropriate precautions when preparing and storing

samples to prevent contamination and degradation.

• Column is contaminated.

1. Cl ean the column (see Col umn Rejuvenation Procedures,

Technical Note 2R , Document No. 03 2036).

2. If cle aning is unsuccess ful, replace the column .

4 • Troubleshooting

Doc. 034859 -0 2 9/93

4-7

Page 40

LC20 Chromatography Enclosure

4-8

Doc. 034859- 02 9/93

Page 41

5 • Service

5.1 Introduc tion . . . . . . . . . . . . . . . . . . . . . 5-3

5.2 Tube Fitting Installation . . . . . . . . . . . . . . 5-3

5.3 Restriction in the Hydraulic System . . . . . . . . 5-4

5.4 Injectio n or Column Select Va lve Liquid Leaks . 5-4

5.5 Column Select Valve Air Leaks . . . . . . . . . . 5-5

5.6 Cleaning the Column Select Valve Slider . . . . . 5-6

5.7 Rep lacing the Col umn Select Valve Port Face . . 5-9

5.8 Servicing the Rheodyne Injection Valve . . . . . 5-9

Doc. 034859 -0 2 9/93

5-1

Page 42

LC20 Chromatography Enclosure

5-2

Doc. 034859- 02 9/93

Page 43

5 • Service

5.1 Introduction

This section describes service and repair procedures for the LC20.

These services are required rarely, but some wear of the fittings and

tubing is to be expecte d during the life of th e enclosure. Be fore

repairing or replac ing any part, refer to Chap ter 4 to isolate th e

source of the prob lem. For service and maintenance procedures for

the Rheodyne injec tion valve, refer to the Rhe odyne manual

supplied in the LC20 Ship Kit.

When ordering replacement parts, pleas e include the mo del and

serial number of you r LC20. If poss ible, also provide the par t

numbers and, whe re applicable, the revision number of the items

you are ordering.

5.2 Tube Fitting Installation

The LC20 is plumbed with Dio nex 10-32 ferrule fittings. PEEK

tubing is recommended for use throughout the system. However,

ThermoFlare tu bing may b e installed whe re pressures are below

7 MPa (1000 psi); this includes waste line s, tubing from an

autosampler to the Rheody ne valve injection port, or tubing from the

separator column to the suppressor. Use 1.6-mm (0.063-in) ID

Teflon tubing for regenerant lines for both the 2-mm and 4-mm

suppr e ss o rs.

For instructions on how to install ferrule fittings on PEEK or Tefzel

tubin g, refe r to Installation of Dionex Ferrule Fittings (Document

No. 034213), p rovided in the LC20 Sh ip Kit.

Doc. 034859 -0 2 9/93

5-3

Page 44

LC20 Chromatography Enclosure

5.3 Restriction in the Hydraulic System

A restriction in the hydraulic system will cause excessive system

backpressure.

1. Begin pump ing eluent through the system (including the

columns) at the flow rate normally used.

2. Follow the appropriate hydraulic schematic (see Figures B-4

through B-6) and work backward th rough the system, beginnin g

at the cell exit. One at a time, loo sen each fitting and observe the

pressure. Th e connection at whic h the pressure drops indic ates

the point of po int of restriction.

3. Remove the res triction either by bac k flushing or by replacing

the section of tubin g.

4. If the restriction is caused by the column select valve,

disassemble t he valve and clean th e slider (see S ection Figur e

2-4. Column Select Valve Slider Connections

5.4 Injection or Column Select Valve Liquid Leaks

A poor seal be tween the fe rrule sealin g surface and t he valve

pressure bolt or b etween the po rt face an d the valve slider may

cause the co lumn select valve t o leak (see F igure 2-3). The flow

rate through the system may be low, producing chromatograms

with longer than normal retention times and poor reproducibility.

1. Tighten any loose fittings fingertight, then an additional

one-eighth turn. Tighten further only if a leak co ntinues.

DO NOT OVERTIGHTEN. Use an open end wrenc h to hold

the valve pressure bolts to prevent them from turning

when tightening connections to the valves.

5-4

Doc. 034859- 02 9/93

Page 45

5 • Service

2. If tightening the fitting does not stop the leak, disconnect the

fitting from the valve. Occasionally, fittings stop leaking if

simply disconnected and th en immediately reconnected. If the

leak continues, install a sh ort length of tubing, with fittings,

between the pressure bolt and the suspect fitting. Connect the

fitting to the tubing with a union. A leaking fitting will also leak

inside the union. If necessary, replace the fitting.

If you replace

the fitting , also replace t he ferrule.

NOTE

When connecting or disconnecting fittings from the valve

pressure bolts, use a wrench to hold the bolt and prevent it from

turning.

3. Make sure all valve pressure bolts are evenly tightened. Refer to

Installation and Mainten ance of the Dionex Inert High-Pressure

Valve

(Document No. 032678) for the torqu e requirements.

Use caution as overtightening may break off the bolt in the

valve body.

4. If tighte ning the pressure bo lts does not stop the leak, refer to

Section 5.7 for instructions to replace the port face.

5.5 Column Select Valve Air Leaks

An air leak around the valve piston or cap results in excessive

air consumption and may cause the valve to operate sluggishly

or not at all.

1. Remove the column switch ing valve from its mounting clip.

2. Make s ure that the top and b ottom caps are tight. If necessary,

tighten them fingertight.

3. If the leak contin ues, determine which end of th e valve leaks by

activating the corresponding switch. Air will escape through the

vent hole wh en the leaking end is press urized.

4. Dis connect the a ir line from th e leaking cap. I f necessary, use

the valve switch to turn off the air th rough the disco nnected line.

Doc. 034859 -0 2 9/93

5-5

Page 46

LC20 Chromatography Enclosure

5. Un screw the leaking cap from the valve body (Figure 2-3) .

Inspect the cap O-ring for crack s and replace if necessar y

(P/N 038650) .

6. Pres s the discon nected air lin e (Step 4) again st the small vent

hole between ports 1 and 5. Ac tivate the valve switch to apply

air pressure against the slider. The piston will pop out of the

valve body.

7. Ins pect the pi ston O-ring for cracks and r eplace if neces sary

(P/N 038651) .

8. Carefully lubricate the p iston O-ring with a small amount of

silicone grease.

Use the grease sparingly . Excess grease may co ntaminate

the eluent.

9. Press th e piston back into the valve body.

10. Make s ure that the cap O- ring is inside the c ap. Screw the cap

back onto the valve body. Tighten it only fingertight.

11. Reconnec t the air line to the valve.

5.6 Cleaning the Column Select Valve Slider

A dirty or plugged valve slider cau ses excessive system

backpressure and may cause poor chromatographic

performance.

1. Turn off the pump and th e eluent selector valves.

2. Remove the plu gged valve from its mounting clip (se e Figure 2-3

3. Dis connect the a ir line from o ne cap. If necessary, use the valve

switch to turn off the air through the d isconnected line.

5-6

Doc. 034859- 02 9/93

Page 47

5 • Service

4. Un screw one cap from the valve body. Be careful not to lose the

cap O-ring.

5. Pres s the discon nected air lin e (Step 3) again st the small vent

hole between ports 1 and 5. Ac tivate the valve switch to apply

air pressure against the slider. The piston will pop out of the

valve body.

6. Turn off the ai r sup ply.

7. Carefully loosen ea ch of the pressure bolts one-eighth turn to

disengage the po rt faces from the slider. Do not loose n any

further.

8. Rem ove the other cap . Push on t he slider to force the oth er

piston out of the valve body.

9. Carefully p ush the slider out o f the valve body with a blu nt rod.

10. Ins pect the slider surfa ce. If there are scratches i n the sur face,

replace the s lider (P/N 038709) .

11. Pla ce the slider in a small co ntainer of deio nized water or

methanol. Sonicate or agitate vigorou sly for several minutes.

12. Rins e the slider with deionized water. Blow any water out of the

holes and inspect them f or blockage. Use a fine piece of wire

(0.025 in) to dislodge any remaining b lockage. Be carefu l not to

scratch the slider surface. If the blockage cannot be removed,

replace the sli der.

13. Push the slider back into the valve body. Orient the dimple on

the top of the slider between por ts 1 and 2 of the valve body (see

Figure 2-3).

The valve operates properly on ly if the sli der is corr ectly

oriented in the valve body. The groove around the valve body

indicates the top of the valve body. The small vent hole is

between ports 1 and 5. The ports a re numbered clockwise fro m

the top around th e valve body. The slider co nnects the ports as

follows:

Doc. 034859 -0 2 9/93

5-7

Page 48

LC20 Chromatography Enclosure

Switch in OFF or LOAD position (slider d own):

1 → 4 and 2 → 3

5 → 8 and 6 → 7

Switch in ON or INJECT pos ition (slider up):

1 → 2 and 3 → 4

5 → 6 and 7 → 8

14. Ins pect the piston O-ri ngs (P/N 038651) and replace them if

necessa ry.

15. Carefully lubricate the pisto n O-rings with a small a mount of

silicone grease and reassemble the valve (see Section 5.5 for

instructions to correct Column Select Valve air leaks).

16. Tighten each pressure bolt fingertight, the n use an open e nd

wrench to tighten a n additional one-eighth turn.

For optimal leak-free operation a t 28 MPa (4000 psi), a ll eight

pressure bolts must be evenly tightened against the slider

(128 in-oz). A spec ial torque wrench kit (P/N 03894 3) is

available from Dionex.

17. Turn on the liquid flow and check for lea ks. Tighten the pressure

bolts further if leaks appear.

Use cauti on as overtighteni ng may

break off the bolt in the valve body.

18. If cleaning the valve slider does not eliminate the backpressure

problem, see the next section for instruction s to replace the port

face.

5.7 Replacing the Column Select Valve Port Face

A scratched port face may cause a leak around the pressure bolt.

A plugged port face will cause excessive system backpressure

and may cause poor chromatographic performance.

1. Turn off the liquid flow.

2. Remove the valve from its mounting clip.

5-8

Doc. 034859- 02 9/93

Page 49

5 • Service

3. Disconnect the tube fitting from the pressure bolt that shows

evidence of leaking, then unscrew the pressure bolt from the

valve body.

4. Inspect the port face. If it is scratched or plugged, c arefully pry

it out of the pres sure bolt, using the extractor tool (P/N 038930)

designed for th is. Press a new port face (P/N 038599) into the

pressure bolt.

Be careful to not scratch the sealing surfaces!

5. Screw the pressure bolt into the valve body. Tighten each

pressure bol t fingertight, th en use an o pen end wrench to tighten

an additional one-eighth turn.

For optimal leak-free operation a t 28 MPa (4000 psi), a ll eight

pressure bolts must be evenly tightened against the slider

(128 in-oz). A spec ial torque wrench kit (P/N 03894 3) is

available from Dionex.

6. Turn on the liq uid flow and check for leaks . Tighten pressure

bolts further if leaks appear.

For optimal leak-free operation, a torque wrench can be used to

evenly tighten pressure bolts. Refer to

Installation and

Maintenance of the Dionex Inert High-Pressure Valve

No. 032678) for torque requirements.

Use caution as

overtightening may break off the bolt in the valve body.

7. Reconnect the tube fitting to the pressure bolt. Use a wren ch to

prevent the pressure bolt from turning while tightening the

fitting. Tighten the fitting fingertight, then an additional

one-eighth tur n. Tighten further only if leak s appear.

5.8 Servicing the Rheodyne Injection Valve

The Rheodyne injection valve requires infrequent servicing. See the

Rheodyne Valve Operator’s Manual

specific maintenance and service requirements. For major

disassembly, contact th e nearest Di onex Regional Office for

assistan ce.

Doc. 034859 -0 2 9/93

(Document No. 0 34468) for

(Document

5-9

Page 50

LC20 Chromatography Enclosure

5-10

Doc. 034859- 02 9/93

Page 51

A • Specifications

A.1 Environmental . . . . . . . . . . . . . . . . . . . . A-3

A.2 Physical . . . . . . . . . . . . . . . . . . . . . . . A-3

A.3 Hydraulics . . . . . . . . . . . . . . . . . . . . . . A-3

A.4 Insulation . . . . . . . . . . . . . . . . . . . . . . A-4

Doc. 034859 -0 2 9/93

A-1

Page 52

LC20 Chromatography Enclosure

A-2

Doc. 034 859-02 9/93

Page 53

A.1Environmental

A • Specifications

Ambient

Temperature:

Humidity: 5-95% relative (non-condensing)

Air Pressure: 400 to 800 KPa (60 to 120) psi for the Rheodyne injection

Operating

Pressure:

A.2Physical

Dimensions: 50 cm high x 22.5 cm wide x 49 cm deep

Weight: 12 kg (25 lbs)

A.3Hydraulics

4 °C to 75 °C

(40 °F to 167 °F)

valve and column select valve;

Use laboratory-quality air or regulated compressed air,

nitrogen, or helium.

35 MPa (5000 psi) maximum liquid path (tubing, valves,

columns, etc.)

(20.8 in x 8.9 in x 20.4 in)

6 cm clearance required in back of the module

Rheodyne

Injection Valve:

Column Select

Valve:

Doc. 034859-02 9/93

35 MPa (5000 psi) metal-free or stainless steel rotary valve

for low-volume injections.

28 MPa (4000 psi) metal-free column select valve to direct

eluent and sample to one of two columns. The column select

valve option is installed at the factory but i s not plumbed into

the system. Tubing to plumb the LC20 for column select

applications is included in the LC20 Ship Kit (P/N 046300).

A-3

Page 54

LC20 Chromatography Enclosure

A.4 Insulation

Dampening Dampens o utsi de temper ature vari ations by a fa ctor of

–5 to 10 over 10 minutes

–2 to 4 ove r 60 m in utes

A-4

Doc. 034 859-02 9/93

Page 55

B • Installation

B.1 Facilities Required . . . . . . . . . . . . . . . . . B-3

B. 2 Inst allation Ins tr uctions . . . . . . . . . . . . . . . B-4

B. 2. 1 Stac king Modules . . . . . . . . . . . . . B-4

B. 2. 2 Waste Lines . . . . . . . . . . . . . . . . . B-5

B.2.3 Leak Control . . . . . . . . . . . . . . . . B-6

B.2.4 Liquid Line C onne ctions . . . . . . . . . B-6

Injection Valve Connections . . . . . . B-7

B. 2. 5 Detector C ells . . . . . . . . . . . . . . . B-9

External Cell . . . . . . . . . . . . . . . B-9

Inte rn al Ce ll . . . . . . . . . . . . . . . B- 10

B.2.6 Column Installation . . . . . . . . . . . . B-12

B.2.7 SRS Installation (Optional) . . . . . . . . B-13

B.2.8 Solenoid Valve Connections to the

Pump . . . . . . . . . . . . . . . . . . . . B-14

Doc. 034859 -0 2 9/93

B-1

Page 56

LC20 Chromatography Enclosure

B-2

Doc. 034859- 02 9/93

Page 57

B • Installation

B.1 Facilities Required

Appendix A of this manual co ntains the complete LC20

specifications. The location selected to install the L C20 should also

meet the following requirements:

•

A sturdy table o r work bench with at least 15 cm (6 in) free

space behind the mo dule for connections and ventila tion.

Maximum horizontal slope is 2-cm pe r lateral meter (0.25-inch

per lateral foot).

•

Nitrogen, argon, or helium gas cylinder for reservoir pressure.

•

As the enclosure d oes not have temperature c ontrol, the

environment will affect the enclosure operation. The system

should be installed with adequate ventilation and in an

environment that provides maximum consistency in ambient

temperature and humidity. In general, y ou should

— avoid sun and proximity to hot equipment.

— avoid heavy air drafts and sudden temperatu re changes

— not operate the enclosure in conden sing atmospheres

— maintain s pecified ambient temperatures.

Connect gas/air pressure to the solenoids on the rear pan el (see

Figure 2-5). The gas/air pressure is route d to the enclosure valves

through air valves, which are actuated electrically by the pump.

Connect th e wiring to the proper co nnector on th e pump accordi ng

to the plumbing schematics further in this chapter.

Doc. 034859 -0 2 9/93

To avoid contamination and possi ble deter ioration of the

valves, make sure laboratory pneumatic air, if used, is

oil-free, dry, and filtered, and maintained within the

pressure limits specified above.

B-3

Page 58

LC20 Chromatography Enclosure

B.2 Installation Instructions

A Dionex-trained representative will install the LC20 and other

system modules for yo u. The instructio ns given here are for your

reference. Conta ct the nearest Dionex Regional O ffice for assistance

if you experience any difficulties durin g or after installation that a re

not addressed in this manual.

B. 2. 1 Sta cking Mo dules

Dionex DX-500 Chroma tography Syst em modules are d esigned

to be stacked on top of each ot her up to a maximu m height of

four units. The e nclosure is three units high and should not be

stacked on any other unit. The enclosu re should not have more

than one single- unit module on to p of it, such as a CD20

Conductivity Detector, ED40 Electrochemic al Detector, or the

EO1 Eluent Organizer (P /N 044125). Fig ure B-1 illustrates the

recommended stacking configuration.

B-4

Figure B-1. Recommended Stacking Configuration

Lift the module only from the bottom surface. Do not lift

it with the panel doors as this will damage the door hinges.

Doc. 034859- 02 9/93

Page 59

B.2. 2 Waste Lines

Install the piece of 12.5-mm (0.5-in) O D tubing (P/N 0357 59)

over the waste nipple in the lower left corner of the LC20

rear panel (see Figu re 2-5). Make sure the opposite end of the

line is inserted into a waste container below the level of the

enclosure and that it is not bent, pinc hed, or elevated at any

point (see Figure B-2).

Minor leaks do not generally present a serious situation, but

they should be thorough ly rinsed with de ionized water and

dried to prevent salt solutions from crystallizing on the

enclosure surfaces .

B • Installation

Doc. 034859 -0 2 9/93

Figure B-2. Waste Lines Installation

Neutralize acidic and caustic waste before disposal.

Dispose of wastes containing organic solvents in

accordance with local regulations.

B-5

Page 60

LC20 Chromatography Enclosure

B.2. 3 Leak Control

If a leak occur s, waste liquid will accu mulate in the botto m

of the enclosure. The bottom is slanted to collect the liquid in

the trough on the lef t side. A line at the rear o f the trough

drains the liquid from the enclosure a nd into a waste

container. A leak detector cell is located on th e sidewall of

the trough to dete ct and report any leak s. The output of the

sensor should be connected to any modu le that can proce ss

the signal and report it as a fault.

A leak is generally not a serious event. However, all leaks

should be stoppe d and the floor should be dried and r insed

with deionized water to prevent formation of salt crystals.

B. 2. 4 Liqu id Line Con nection s

The LC20 Ship Kit c ontains PEEK tubing in three different

IDs. After selecting the appropriate tubing size (see below),

you will need to cut the tubing to the lengths required to

plumb the system. However, before cutting any tubin g, be

sure that it is long e nough to allow servicing the sy stem (e.g.,

you should be ab le to open the front door of the LC20 and

slide the component panel out of the enclosure to its detent

without putting stress on the tubing).

B-6

•

For 4-mm column systems:

Use 0.25 -mm (0.010-in) ID

PEEK tubing (P/N 042690) for conne ctions between

system compone nts.

•

For 2-mm column systems:

Use 0.12 5-mm (0.005-in)

ID PEEK tubing (P/N 044221) for connections betwee n

system compone nts.

•

For both systems:

Use 0.5-mm (0. 020-in) ID PEE K

tubing (P/N 042 885) for valve waste lines and 0.25-mm

(0.010-in) I D PEEK tubing (P/N 0426 90) for detector c ell

waste lin es.

If preferred, ThermoFlare tubing can be in stalled where

pressures are b elow 7 MPa (1000 psi). This may inc lude

Doc. 034859- 02 9/93

Page 61

B • Installation

waste lines, tubing from an autosampler to the Rheodyne

injection valve port, and tubing from the separator column to

the SRS.

The system plumbi ng depends primarily on the detection

mode. Consult the pr oper fluid schematic in Section B.2.5.

The LC20 is plumbed with Dio nex 10-32 ferrule fittings. If

you need instru ctions on how to install ferrule fittings, refer

Installation of Dionex Ferrule Fittings

to

(Document

No. 034213), p rovided in the LC20 Sh ip Kit.

Injection Valve Connections

Doc. 034859 -0 2 9/93

Figure B-3. Injection Valve Ports

1. Conn ect the eluent lin e from the pump pres sure

transducer to port #2 on th e Rheodyne injection valve. A

label on top of the valve identifies ports #1 and # 2. Ports

#3 through # 6 follow in sequence, with po rt #6 close to

port #1 on th e opposite side fr om port #2 (see Figure B-).

2. Conn ect a piece of PEE K tubing with ferrule

(P/N 043276) and fitting (P/N 043275) to port #3 on the

Rheodyne valve.

B-7

Page 62

LC20 Chromatography Enclosure

3. Conn ect the other end of the tubing to the separator

column (or guard column, if installed). Refer also to

Installation of Dionex Ferrule Fittings

No. 034213) in cluded in the LC 20 Ship Kit.

4.

Connect th e 25 µL sample loop (P/N 042857) between

ports #1 an d #4 of the Rheody ne injection valve. Other

sample loop sizes ar e available, contact t he nearest

Dionex Regional Office for infor mation.

5. Cut two pieces of tubing for waste lines. Install a ferrule

(P/N 043276) and fitting (P/N 043275) o n one end of

each of the pieces of tubing.

6. Conn ect the ferrule fitting end of one of the waste lines to

port #5 on the Rheodyne valve. Connect the ferrule fitting

end of the s econd waste line to port #6. Route the waste

lines out through the chases and place the ends of the

lines in a waste conta iner.

(Document

B-8

Doc. 034859- 02 9/93

Page 63

B.2.5 Detector Cells

Exter nal Cell

When using a detector with a c ell external to the LC20

(normally an optical detector), connect the outlet of the

separator column or suppressor to the detector cell inlet (see

Figure B-4). Rou te the tubing exiting the s eparator column or

suppressor throu gh one of the side slots on the LC20.

B • Installation

Doc. 034859 -0 2 9/93

Figure B-4. External Detector Cell Plumbing Schematic

B-9

Page 64

LC20 Chromatography Enclosure

Internal C ell

Refer to the appropriate plumbing sch ematic in the following

series (Figures B-4 through B-6) when installing a cell in the

LC20. If the conductivity cell is installed inside the optional

DS3 Detection Stabilizer, see the

Operator’s Manual

(Document No. 034850).

DS3 Detection Stabilizer

B-10

Figure B-5. Conductivity Cell Plumbing Schematic

Doc. 034859- 02 9/93

Page 65

B • Installation

Doc. 034859 -0 2 9/93

Figure B-6. Electrochemical Cell Plumbing Schematic

B-11

Page 66

LC20 Chromatography Enclosure

B. 2. 6 Colum n Instal lation

The separator columns are purchased separately from the

LC20.

1. Before installing the separator columns, pump deionized

water through the LC20 at 3 mL/min for 1 to 2 minutes to

clear any air from the liquid lines. Activate injection each

valve several times to make sure that no air is trapped in

the hydraulic system. Trapped air will reduce efficiency.

2. Redu ce the flow rate to 2.0 mL/min and verify that the

pressure through the system, with no columns installed, is

less than 690 KPa (100 psi).

3. Install th e separator column mounting clip by inserting it

into one of th e square holes at the front edge of the

component panel (see Figure B-7. If you are using the

4-mm suppressor columns, orient the clip so the larger

clips are toward the front. If you are using the 2-mm

columns, orient the clip s o the smaller clips are nearer the

front.

B-12

Figure B-7. Separator Column Mounting Clip

Doc. 034859- 02 9/93

Page 67

B • Installation

4. Eac h column is accompanied by a manual co ntaining

specialized installation and start-up instructions. After

consulting your c olumn manual for any s pecial requirements,

install the columns in the LC20:

a. Remove the end plugs from the separator column and

store them in a s afe place. You must reinstall the end

plugs in the columns before placing the columns in

storage.

b. Use PEEK tubing with ferrule fittings to co nnect the inlet

of the guar d column to the #3 p ort of the Rheody ne valve.

c. Conn ect the outlet of the guard column to the inlet

(bottom) of the separator column.

d. For suppr essed conductivity detection, c onnect the outlet

(top) of the separator column to the

ELUENT INLET

SRS. Otherwise, c onnect the separator outlet d irectly to

the detector inlet.

of the

5. Snap th e separator columns into the column clips o n the

B.2. 7 SRS Installation (Optional)

Doc. 034859 -0 2 9/93

component panel. See Figu re 2-2 for an illustration of the

columns mounted in the clips. The guard columns are held in

place only by the connec ting tubing.

1 For complete SRS technical de tails, refer to the SRS

manual.

2. If yo u are using an external regenerant:

a. Assemble and fill the regenerant reservoir as described

in the instructions shipped with the reservoir.

b. Locate the 75-mm (30 -in) tubing (P/N 03 5727) in the

SRS Ship Kit. Use this tub ing to connect the reservoir

to the

REGENERANT INLET

of the SRS.

c. Adjust the regenerant flow rate as instructed in th e

SRS manual.

B-13

Page 68

LC20 Chromatography Enclosure

3. D irect the line connected to t he SRS

OUTLET

through the service ch ase and to a was te

REGENERANT

container.

4. Moun t the SRS on the comp onent panel (see Figure B-8).

The SRS has a special mou nting bracket th at can be

installed in several positions on the componen t panel,

depending on your application. After mounting the

bracket, align the slots on the back of the SRS with th e

tabs on the mou nting bracket. Press in and then

lock th e SRS in pl ace. Lift up and pull

out

down

to

to remove the

SRS, if necessary.

B-14

Figure B-8. SRS Installation

B.2. 8 Solenoid Valve Connections to the Pump

Connect air-actuated solenoid valves between pump and the

LC20 for control of the column select and injection valves.

Refer to the pump operator’s manual for installation

instructions.

Doc. 034859- 02 9/93

Page 69

Index

A

Abnormal retention time, 4-6

Abnormal selectivity, 4-6

Air leaks, 4-5

C

Cell cable connectors, 2-13

Column installation, B-12

Column select valve, 2-8

Colum n s

Guard col umns, 2 -7

Separator columns, 2-7

Connectors

Cell cable connectors, 2-13

D

Description

Cell cable connectors, 2-13

Column select valve, 2- 8

Detector cell s, 2 -11

Guard col umns, 2 -7

Leak sensor, 2-7

Overview, 2-3

Physical , A-3

Rheodyne injectio n valve, 2- 3, 2-6

Self-Regen erating Suppresso r, 2-7, B-13

Separator columns, 2-7

Solenoid interface, 2-13, B-14

Detector cell plumbing, B-9

Detector cell s, 2- 11

DS3 Detection Stabilizer, 2-11

E

Environmental specifications, A-3

F

Facilities required, B-3

Front panel, 2-3

G

Guard colu mns, 2- 7

H

Hydraulic specifications, A-3

I

Injection valve, 2 -3, 2-6

Sample loading, 3-4

Solenoid interface, 2-13, B-14

Injection valve connections, B -7

Installation, B-3

Column installation, B-12

Detector cell plumbing, B-9

Facilities required, B-3

Injection valve connections, B-7

Leak Control, B-6

Liquid Line Connections, B-6

Rear Panel, 2-12

Solenoid interface, 2-13, B-14

SRS installation, B-13

Stacking modules, B-4

Waste line, 2-13, B-5

Interior c ompo ne nts, 2- 4

Column select valve, 2- 8

Detector cell s, 2 -11

DS3 Detection Stabilizer, 2-11

Guard col umns, 2 -7

Leak sensor, 2-7

Self-Regen erating Suppresso r, 2-7, B-13

Separator columns, 2-7

Doc. 034859 -0 2 9/93

Index-1

Page 70

LC20 Chromatography Enclosure

L

Leak Control, B-6

Leak sensor, 2-7

Liquid leaks, 4-3

Liquid L ine Co nnect io ns, B -6

M

Maintenance

Abnormal retention time, 4-6

Abnormal se lectivity, 4-6

Air leaks, 4-5

Liquid leaks, 4-3

Peak ghosting, 4-6

Routine maintenance, 3-7

O

Operation

Sample loading, 3-4

Shutdown, 3-7

Options

DS3 Detection Stabilizer, 2-11

Self-Regen erating Suppresso r, 2-7, B-13

P

R

Rear Pa nel, 2- 12

Routine maintenance, 3-7

S

Sample loading, 3-4

Separat or colu mns, 2-7

Service, 5-1

Shutdown, 3-7

Solenoid interf ace, 2- 13, B-14

Specifications, A-3

Environmental, A-3

Hydraulic, A-3

SRS

seeSelf- Regener ating Su ppressor

SRS installation, B-13

Stacking modules, B-4

T

Troublesho otin g, 4-3 , 4-5, 4-7

Abnormal retention time, 4-6

Abnormal selectivity, 4-6

Air lea ks, 4- 5

Liquid l eaks, 4-3

Peak ghos ting, 4-6

Peak ghos ting, 4-6

Physical de scrip ti on, A-3

Front panel, 2-3

Interior components, 2-4

Rear Panel, 2-12

Index-2

W

Waste line installation, 2-13, B-5

Doc. 034 859-02 9/93

Loading...

Loading...