Page 1

ICS-900 Ion Chromatography System

Operator’s Manual

Document No. 065215

Revision 02

September 2009

Page 2

©2009 by Dionex Corporation

All rights reserved worldwide.

Printed in the United States of America.

This publication is protected by federal copyright law. No part of this publication

may be copied or distributed, transmitted, transcribed, stored in a retrieval system, or

transmitted into any human or computer language, in any form or by any means,

electronic, mechanical, magnetic, manual, or otherwise, or disclosed to third parties

without the express written permission of Dionex Corporation, 1228 Titan Way,

Sunnyvale, California 94088-3603 U.S.A.

DISCLAIMER OF WARRANTY AND LIMITED WARRANTY

THIS PUBLICATION IS PROVIDED “AS IS” WITHOUT WARRANTY OF

ANY KIND. DIONEX CORPORATION DOES NOT WARRANT,

GUARANTEE, OR MAKE ANY EXPRESS OR IMPLIED

REPRESENTATIONS REGARDING THE USE, OR THE RESULTS OF THE

USE, OF THIS PUBLICATION IN TERMS OF CORRECTNESS, ACCURACY,

RELIABILITY, CURRENTNESS, OR OTHERWISE. FURTHER, DIONEX

CORPORATION RESERVES THE RIGHT TO REVISE THIS PUBLICATION

AND TO MAKE CHANGES FROM TIME TO TIME IN THE CONTENT

HEREINOF WITHOUT OBLIGATION OF DIONEX CORPORATION TO

NOTIFY ANY PERSON OR ORGANIZATION OF SUCH REVISION OR

CHANGES.

TRADEMARKS

AES, AMMS, Chromeleon, CMMS, and SRS are registered trademarks of Dionex

Corporation. MMS, MicroMembrane, and OnGuard are trademarks of Dionex

Corporation.

Teflon and Tefzel are registered trademarks of E.I. du Pont de Nemours and

Company.

Microsoft, Windows 2000, and Windows XP are registered trademarks of Microsoft

Corporation.

PRINTING HISTORY

Revision 01, March 2008

Revision 02, September 2009

Page 3

Contents

1 • Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Overview of the ICS-900 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 The ICS-900 Operator’s Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Safety and Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3.1 Safety Messages and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3.2 Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3.3 Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2•Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Operating Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.1 Front Door and Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.2 Component Mounting Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1.3 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 Fluid Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.3 System Component Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.3.1 Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.3.2 Pressure Transducer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.3.3 Injection Valve with Sample Loop . . . . . . . . . . . . . . . . . . . . . . 18

2.3.4 MMS 300 MicroMembrane Suppressor . . . . . . . . . . . . . . . . . . 19

2.3.5 Displacement Chemical Regeneration (DCR) . . . . . . . . . . . . . 20

Doc. 065215-02 9/09 i

Page 4

ICS-900 Operator’s Manual

2.3.6 Conductivity Cell and DS5 Detection Stabilizer . . . . . . . . . . . .21

2.4 Chromeleon and Chromeleon Xpress Software . . . . . . . . . . . . . . . . . . .23

2.4.1 The Panel Tabset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

2.4.2 Software Control Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

2.4.3 System Wellness and Predictive Performance . . . . . . . . . . . . .25

3 • Operation and Maintenance . . . . . . . . . . . . . . . . . . . . . . . .27

3.1 Operation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

3.2 Turning On the ICS-900 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

3.3 Connecting to Chromeleon or Chromeleon Xpress . . . . . . . . . . . . . . . .28

3.4 Preparing the Eluent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

3.5 Preparing the Regenerant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

3.6 Priming the Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

3.7 Equilibrating the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

3.8 Verifying Operational Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

3.9 Configuring Standby Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

3.10 Preparing Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

3.10.1 Collecting and Storing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

3.10.2 Pretreating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

3.10.3 Diluting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

3.11 Processing Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

3.11.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

3.11.2 Manually Processing Samples . . . . . . . . . . . . . . . . . . . . . . . . . .40

3.11.3 Automatically Processing Samples (Batch Processing) . . . . . .42

ii Doc. 065215-02 9/09

Page 5

Contents

3.11.4 Loading and Injecting Samples with an Autosampler . . . . . . . 44

3.11.5 Loading and Injecting Samples with a Syringe . . . . . . . . . . . . 46

3.11.6 Example Chromeleon Commands for Loading and

Injecting Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.12 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4 • Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.1 Alarms and Error Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.2 Liquid Leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.3 Pump Difficult to Prime or Loses Prime . . . . . . . . . . . . . . . . . . . . . . . . 58

4.4 Pump Does Not Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.5 No Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.6 Erratic Flow/Pressure Reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.7 Excessive System Backpressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.8 Peak “Ghosting” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.9 Nonreproducible Peak Height or Retention Time . . . . . . . . . . . . . . . . . 61

4.10 Abnormal Retention Time or Selectivity . . . . . . . . . . . . . . . . . . . . . . . 61

4.11 No Detector Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4.12 High Detector Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4.13 Baseline Noise or Drift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5•Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.1 Diagnostics and Calibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.1.1 Opening the Wellness Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Doc. 065215-02 9/09 iii

Page 6

ICS-900 Operator’s Manual

5.1.2 Wellness Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

5.1.3 Calibrating the Pressure Transducer . . . . . . . . . . . . . . . . . . . . .69

5.1.4 Calibrating the Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

5.1.5 Calibrating the Flow Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

5.2 Replacing Tubing and Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

5.3 Isolating a Restriction in the Liquid Plumbing . . . . . . . . . . . . . . . . . . . .74

5.4 Cleaning Eluent Bottles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

5.5 Changing the Sample Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

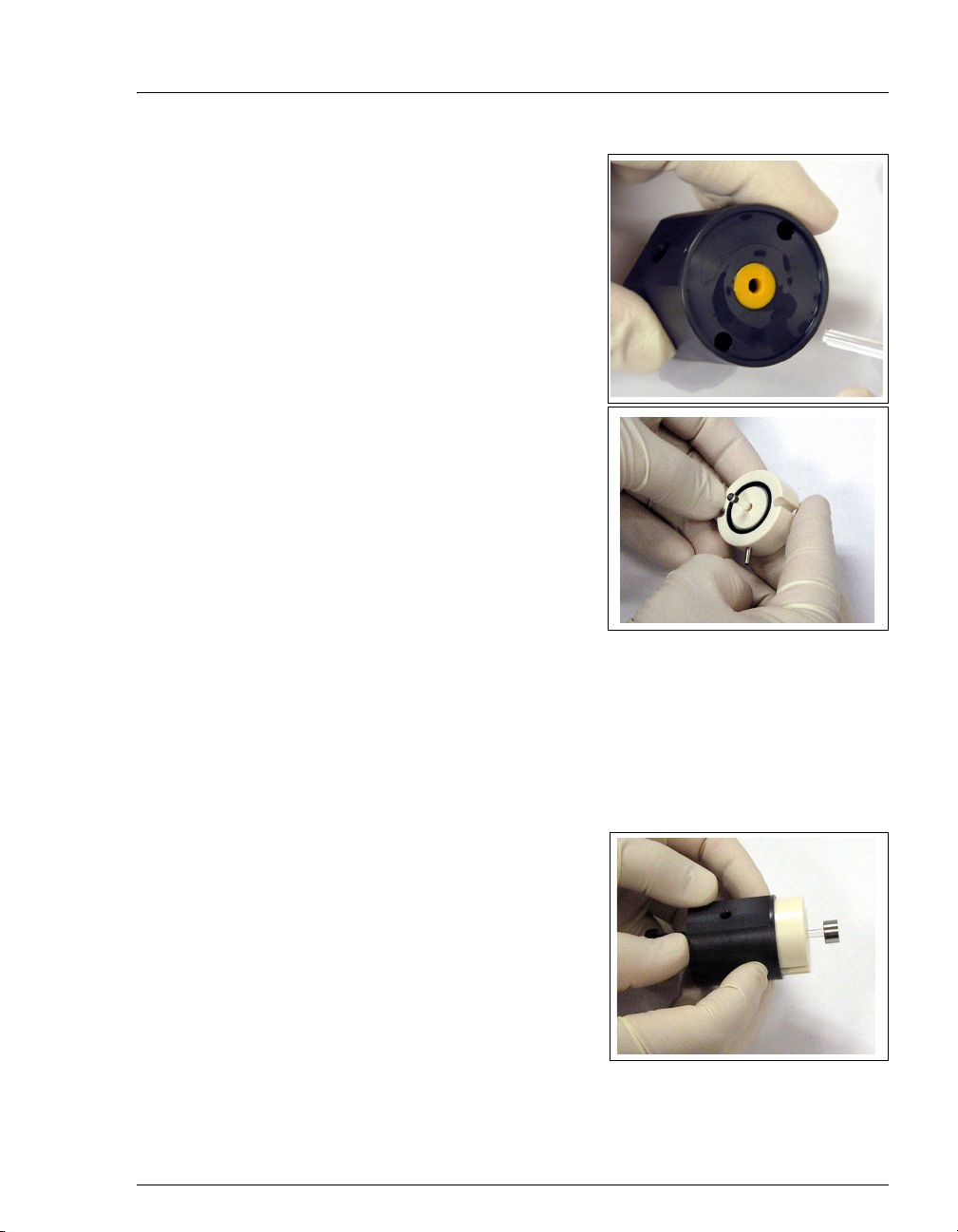

5.6 Cleaning and Replacing Pump Check Valves . . . . . . . . . . . . . . . . . . . .77

5.7 Replacing a Pump Piston Seal and Backup Seal . . . . . . . . . . . . . . . . . .80

5.8 Replacing a Pump Piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

5.9 Replacing the Waste Valve Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

5.10 Rebuilding the Injection Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

5.11 Replacing the Conductivity Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

5.12 Replacing the Suppressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

5.13 Changing the Main Power Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

A • Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

A.1 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

A.2 Physical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

A.3 Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

A.4 Front and Rear Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

A.5 Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

A.6 Injection Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

iv Doc. 065215-02 9/09

Page 7

Contents

A.7 Suppressors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

A.8 Column Heater/Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

A.9 Conductivity Detector and Flow Cell . . . . . . . . . . . . . . . . . . . . . . . . . . 96

A.10 Autosampler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

A.11 System Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

B • Reordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

C • TTL and Relay Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

C.1 Connecting a TTL or Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

C.2 Selecting TTL Input Control Modes and Functions . . . . . . . . . . . . . . 103

C.3 Configuring Relay Output 1 or 2 to Respond to the Pump Flow . . . . 106

C.4 Controlling TTL and Relay Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . 108

C.5 Controlling an AS40 Automated Sampler with a Relay . . . . . . . . . . . 110

D•FAQ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

D.1 How do I connect to an autosampler? . . . . . . . . . . . . . . . . . . . . . . . . . 113

D.2 How often should I perform calibrations? . . . . . . . . . . . . . . . . . . . . . . 113

D.3 Why are the retention times moving? . . . . . . . . . . . . . . . . . . . . . . . . . 113

D.4 How do I adjust retention times? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

D.5 When should I remake standards? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

D.6 When should I remake eluents? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

D.7 How do I start Chromeleon or Chromeleon Xpress? . . . . . . . . . . . . . 114

D.8 How do I back up data? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Doc. 065215-02 9/09 v

Page 8

ICS-900 Operator’s Manual

D.9 How do I delete data? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

D.10 How do I shut off the system? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

D.11 How do I store columns? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

D.12 How do I know when a column is dirty? . . . . . . . . . . . . . . . . . . . . . . .115

D.13 How do I clean a column? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

D.14 Why is the conductivity high? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

E • Introduction to Ion Chromatography (IC) . . . . .117

F • Glossary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

Index

vi Doc. 065215-02 9/09

Page 9

1.1 Overview of the ICS-900

The Dionex ICS-900 Ion Chromatography System (ICS-900) performs isocratic

ion analyses using suppressed conductivity detection. The ICS-900 is an

integrated ion chromatography system consisting of a pump, an injection valve,

and a conductivity cell. Other system components (guard column, separator

column, and suppressor) are ordered separately.

1 • Introduction

The ICS-900 is controlled with a PC running Windows

and the Chromeleon

later) or Chromeleon Xpress. The Chromeleon

System provides complete instrument control, data acquisition, and data

management. Chromeleon Xpress provides real-time control and monitoring of

Dionex chromatography instruments, but does not include data management

capabilities.

For communication between the ICS-900 and the PC on which Chromeleon or

Chromeleon Xpress is installed, the ICS-900 must be connected to a USB

(Universal Serial Bus) port on the PC or a USB hub. For details, refer to the

ICS-900 Ion Chromatography System Installation Instructions (Document No.

065214). The manual is provided on the Dionex Reference Library CD-ROM

(P/N 053891) and in the ICS-900 Ship Kit (P/N 067768).

NOTE For an introduction to basic ion chromatography

® Chromatography Management System (version 6.8 SP4 or

Chromatography Management

concepts, see Appendix E

.

® XP or Windows® 2000

Doc. 065215-02 9/09 1

Page 10

ICS-900 Operator’s Manual

1.2 The ICS-900 Operator’s Manual

1.2.1 Overview

The electronic version (i.e., PDF file) of the ICS-900 operator’s manual

contains numerous hypertext links that can take you to other locations

within the file. These links include:

• Table of contents entries

• Index entries

• Cross-references (underlined in blue) to sections, figures, tables, etc.

If you are not familiar with how to navigate PDF files, refer to the Help

system for Adob

e® Acrobat® or Adobe Reader® for assistance.

Chapter 1

Introduction

Chapter 2

Description

Chapter 3

Operation and

Maintenance

Chapter 4

Troubleshooting

Chapter 5

Service

Appendix A

Specifications

Appendix B

Reordering

Information

Introduces the ICS-900; explains the conventions

used in this manual, including safety-related

information.

Describes ICS-900 operating features, the

chromatographic flow path, and the software

required for ICS-900 control.

Provides operating instructions for the ICS-900

and describes routine preventive maintenance

procedures.

Lists problems and presents step-by-step

procedures for how to isolate and eliminate the

cause of each problem.

Provides step-by-step instructions for routine

service and parts replacement procedures that the

user can perform.

Provides specifications and installation site

requirements for the ICS-900.

Lists spare parts for the ICS-900.

2 Doc. 065215-02 9/09

Page 11

1 • Introduction

Appendix C

TTL and Relay

Control

Appendix D

FAQ

Appendix E

Introduction to Ion

Chromatography

Appendix F

Glossary

Describes the ICS-900 TTL and relay control

features.

Provides answers to frequently asked questions

about ICS-900 operation.

Describes basic ion chromatography concepts.

Provides definitions of terms commonly used in

ion chromatography.

1.3 Safety and Regulatory Information

The ICS-900 was manufactured by Dionex Corporation at the following location:

527 Lakeside Drive, Sunnyvale, CA 94088-3603 U.S.A. The ICS-900 is designed

for IC (ion chromatography) applications and should not be used for any other

purpose. Operation of an ICS-900 in a manner not specified by Dionex may result

in personal injury.

If there are questions regarding appropriate usage, contact Dionex Technical

Support. In the U.S., call 1-800-346-6390. Outside the U.S., call the nearest

Dionex office.

1.3.1 Safety Messages and Notes

This manual contains warnings and precautionary statements that can

prevent personal injury and/or damage to the ICS-900 when properly

followed. Safety messages appear in bold type and are accompanied by

icons, as shown below.

Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Doc. 065215-02 9/09 3

Page 12

ICS-900 Operator’s Manual

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury. Also used to identify a situation or

practice that may seriously damage the instrument, but will not cause

injury.

Indicates that the function or process of the instrument may be

impaired. Operation does not constitute a hazard.

Messages d'avertissement en français

Signale une situation de danger immédiat qui, si elle n'est pas évitée,

entraînera des blessures graves à mortelles.

Signale une situation de danger potentiel qui, si elle n'est pas évitée,

pourrait entraîner des blessures graves à mortelles.

Signale une situation de danger potentiel qui, si elle n'est pas évitée,

pourrait entraîner des blessures mineures à modérées. Également

utilisé pour signaler une situation ou une pratique qui pourrait

gravement endommager l'instrument mais qui n'entraînera pas de

blessures.

Warnhinweise in Deutsch

Bedeutet unmittelbare Gefahr. Mißachtung kann zum Tod oder

schwerwiegenden Verletzungen führen.

Bedeutet eine mögliche Gefährdung. Mißachtung kann zum Tod oder

schwerwiegenden Verletzungen führen.

Bedeutet eine mögliche Gefährdung. Mißachtung kann zu kleineren

oder mittelschweren Verletzungen führen. Wird auch verwendet, wenn

eine Situation zu schweren Schäden am Gerät führen kann, jedoch

keine Verletzungsgefahr besteht.

4 Doc. 065215-02 9/09

Page 13

Notes

Informational messages also appear throughout this manual. These are

labeled NOTE and are in bold type:

NOTE NOTES call attention to certain information. They

alert you to an unexpected result of an action,

suggest how to optimize instrument performance,

etc.

1.3.2 Safety Symbols

These symbols appear on the ICS-900 or on ICS-900 labels:

Alternating current

Primary protective conductor terminal

1 • Introduction

Secondary protective conductor terminal

Power supply is on

Power supply is off

Indicates a potential hazard. Refer to this operator’s

manual for an explanation of the hazard and how to

proceed.

Doc. 065215-02 9/09 5

Page 14

ICS-900 Operator’s Manual

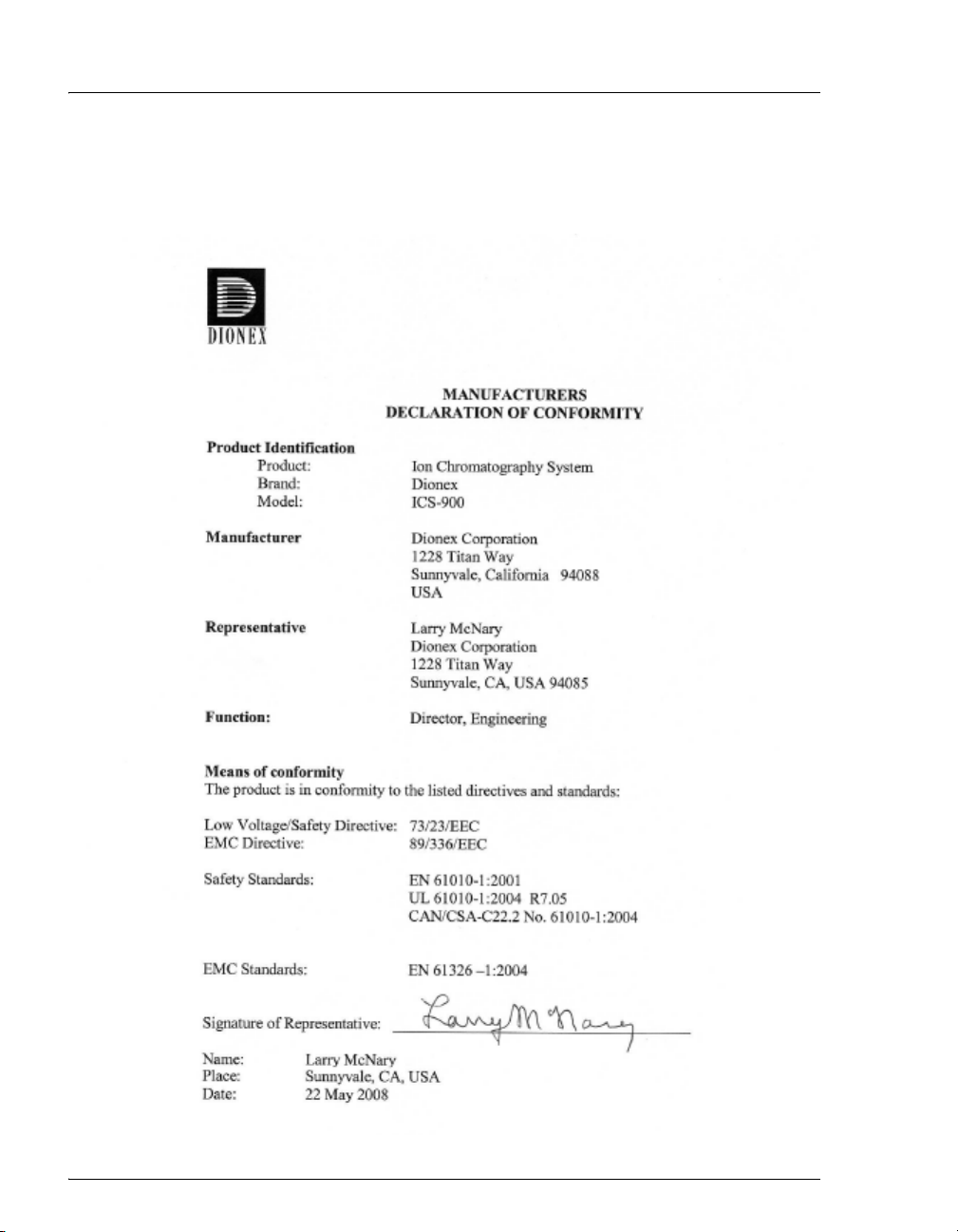

1.3.3 Declaration of Conformity

The cETLus and CE marks on the ICS-900 model/data label indicate that

the ICS-900 is in compliance with the following standards.

6 Doc. 065215-02 9/09

Page 15

2.1 Operating Features

2.1.1 Front Door and Top Cover

Figure 2-1 illustrates the front door and top cover of the ICS-900 Ion

Chromatography System (ICS-900).

2 • Description

Status LEDs

Injection

Port

Figure 2-1. ICS-900 Ion Chromatography System

Eluent Bottle

Regenerant

Bottle

Doc. 065215-02 9/09 7

Page 16

ICS-900 Operator’s Manual

LEDs

Three status LEDs (described below) are on the ICS-900 front door.

LED Label If On (Green) If Flashing

Power ICS-900 power is on Does not flash

Ready System check passed, but

sequence not yet started

(LED stays on until run starts

or sequence is aborted)

Run Running/acquiring data Error/alarm/fault (including

System check failed (occurs if

system check executes for

10 minutes without success)

injection valve position)

Other status information and alarm messages are displayed in the Audit

Trail in Chromeleon or Chromeleon Xpress. For a description of these

messages, see Section 4.1

Injection Port

The injection port can be connected to the injection valve inside the

ICS-900. The sample to be analyzed is injected into the injection port

using a syringe. For automated sample injections, the ICS-900 injection

valve can be connected to an autosampler, instead of to the injection port.

For more information about sample injection, see Section 3.11.5

Eluent and Regenerant Bottles

.

The ICS-900 top cover is molded to hold one eluent bottle assembly

(P/N 062510) and one regenerant bottle assembly (anion, P/N 068222;

cation, P/N 068223).

• Eluent carries the sample through the ICS-900 and facilitates the ion

separation process. The type of eluent used depends on the analyses

8 Doc. 065215-02 9/09

Page 17

performed. For example, an ICS-900 configured for anion analyses

r

uses carbonate eluent, while an ICS-900 configured for cation

analyses uses methanesulfonic acid (MSA) eluent.

• Regenerant renews the suppressor’s ability to suppress eluent

conductivity. An ICS-900 configured for anion analyses uses dilute

sulfuric acid regenerant. An ICS-900 configured for cation analyses

uses tetrabutylammonium hydroxide (TBAOH) regenerant. For more

information about suppressor regeneration, see Section 2.3.5

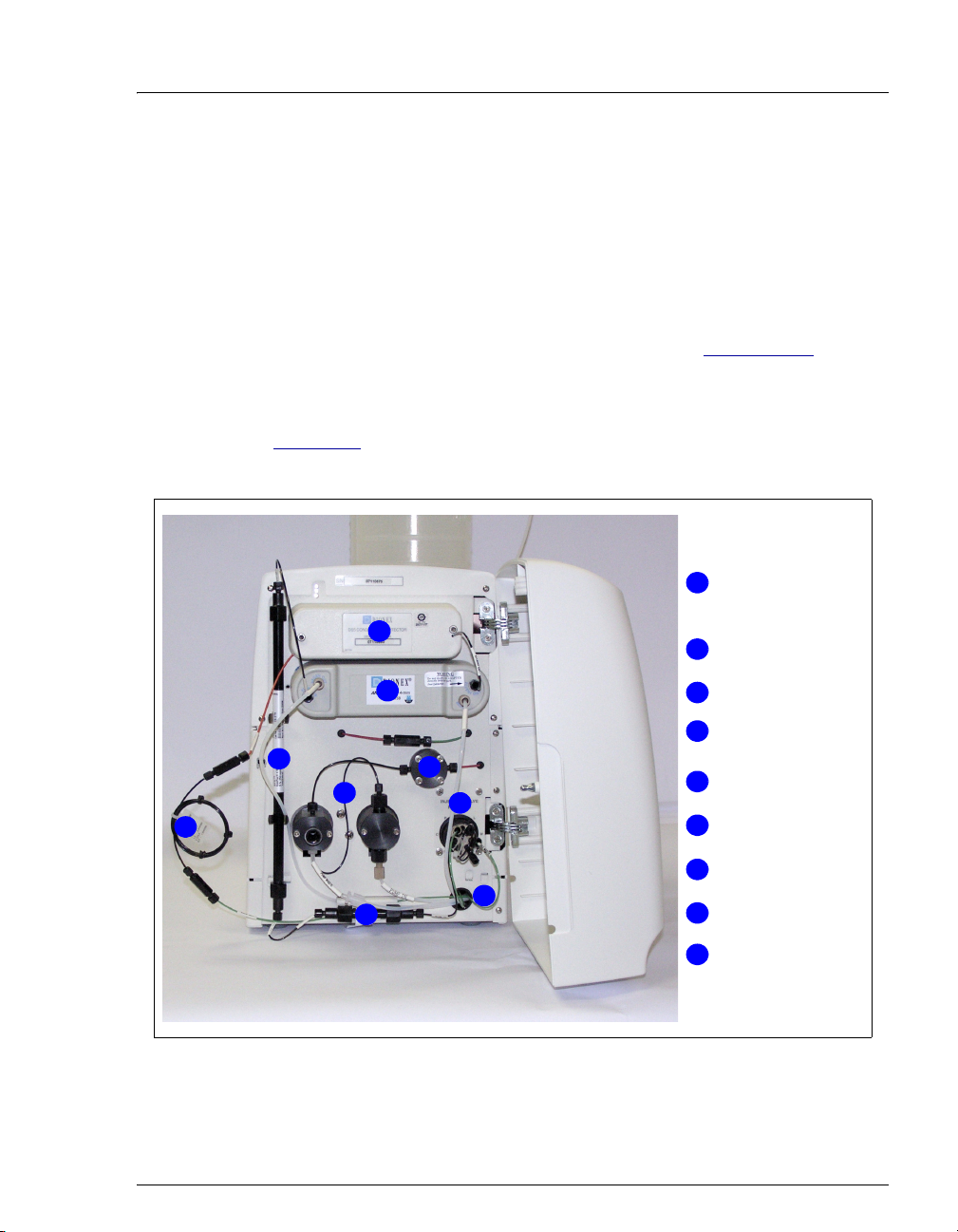

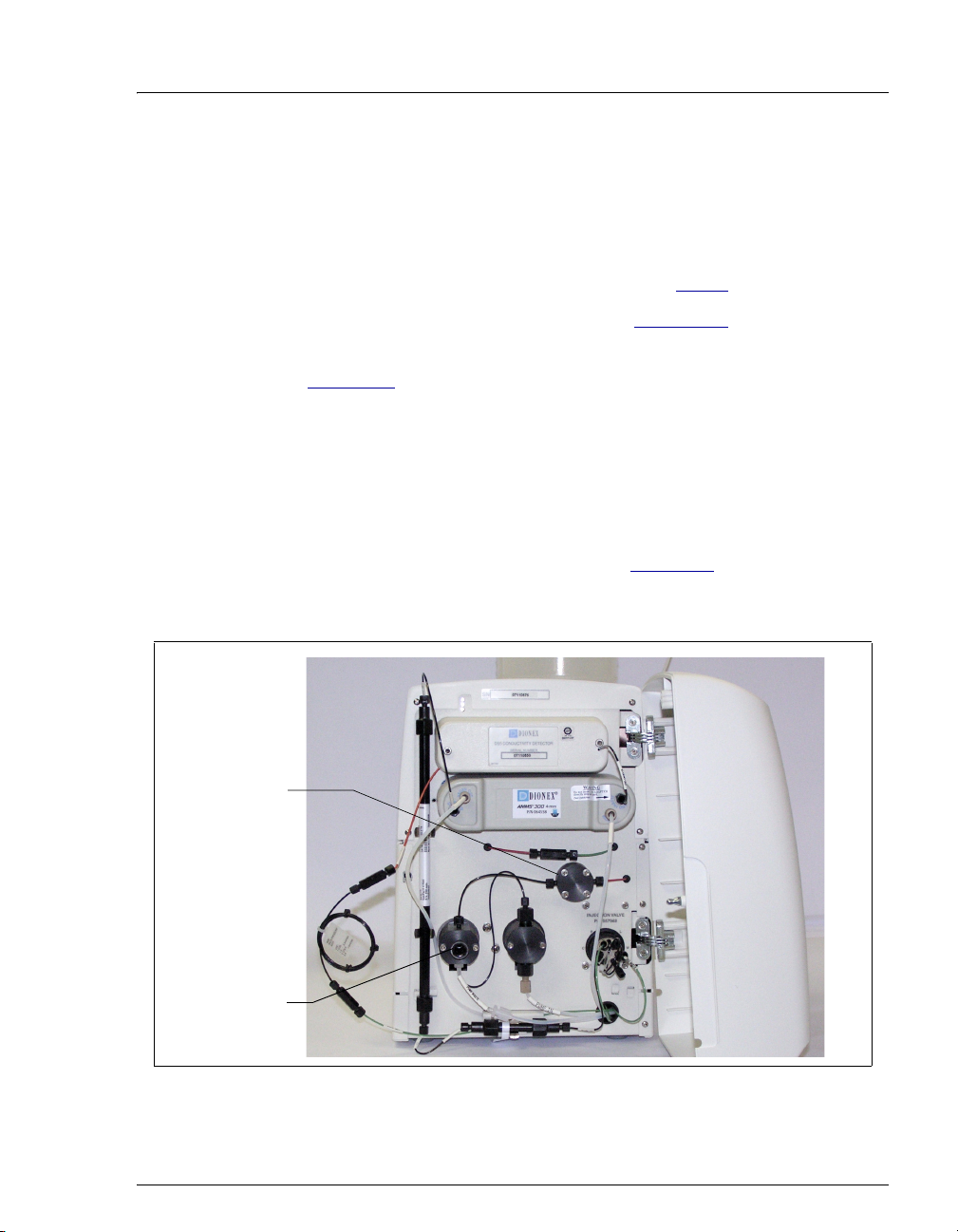

2.1.2 Component Mounting Panel

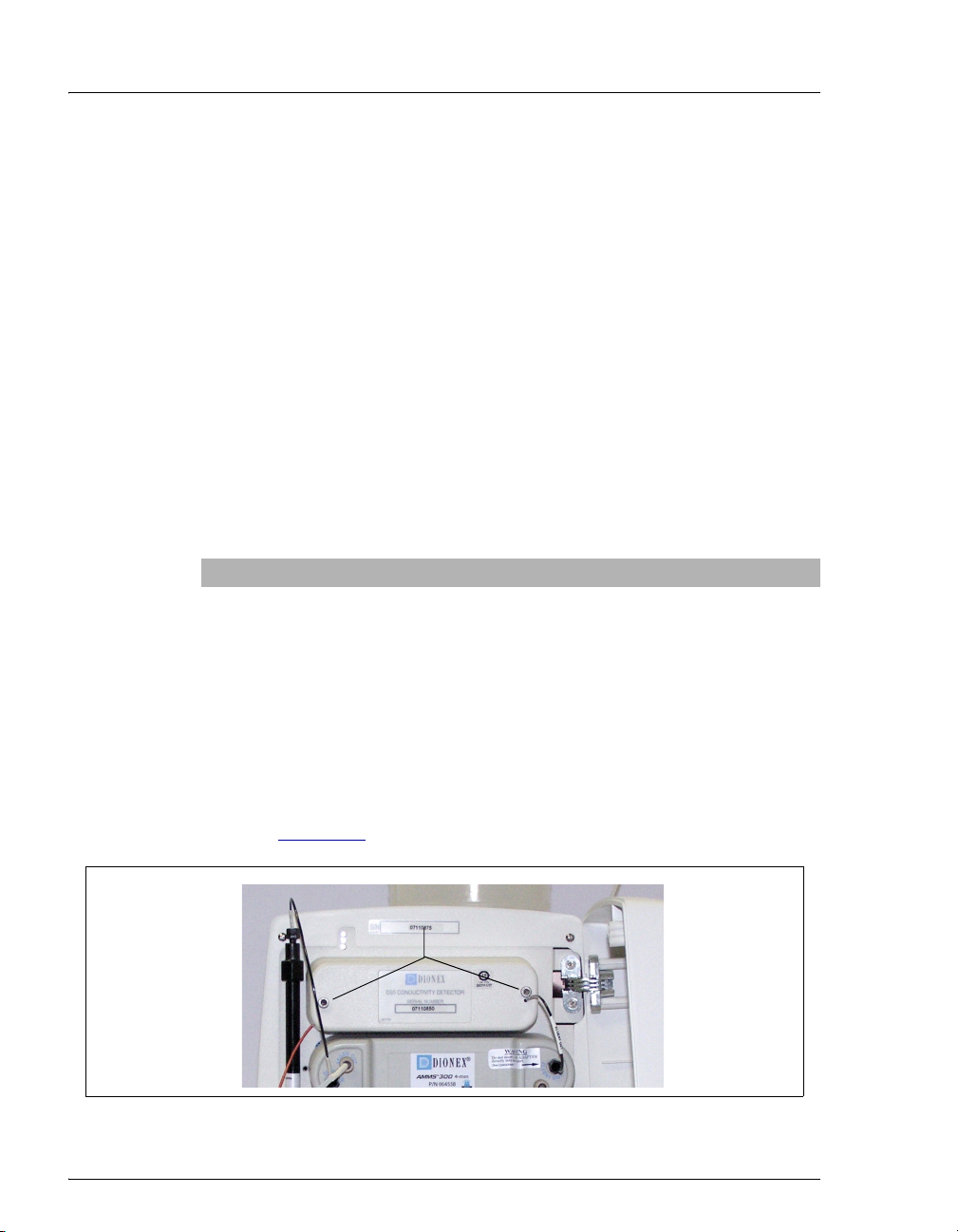

Figure 2-2 shows the components installed on the component panel

behind the ICS-900 front door.

1

2 • Description

.

Conductivity Cell

1

(Housed in DS5

Detection Stabilize

MMS 300

2

Suppressor

2

3

4

9

8

5

6

7

3

Separator Column

Pump Heads

4

Pressure

5

Transducer

Injection Valve

6

Tubing Chase

7

Guard Column

8

Backpressure

9

Tub ing

Figure 2-2. ICS-900 Component Mounting Panel

Doc. 065215-02 9/09 9

Page 18

ICS-900 Operator’s Manual

Conductivity Cell

The flow-through heated conductivity cell measures the electrical

conductance of analyte ions as they pass through the cell. A heat

exchanger inside the cell regulates the temperature to 40 °C (104 °F). The

cell is housed inside a DS5 Detection Stabilizer (P/N 067761). For details

about the conductivity cell and DS5 Detection Stabilizer, see

Section 2.3.1

MMS™ 300 MicroMembrane Suppressor

The MMS 300 suppressor reduces the eluent conductivity and enhances

the conductivity of the sample ions, thereby increasing detection

sensitivity. For details about the MMS 300 suppressor, see Section 2.3.4

Separator and Guard Columns

Both the separator and guard columns are packed with resin and perform

the separation of the sample ions. The main function of the guard column

is to trap contaminants and remove particulates that might damage the

separator column.

.

.

Pressure Transducer

The pressure transducer measures the system backpressure. See

Section 2.3.2

Pump Heads

for details about the pressure transducer.

The ICS-900 includes a dual-piston serial pump. The flow rate can be set

from 0.01 mL/min to 5.00 mL/min. However, for optimum performance,

set the flow rate to between 0.20 and 3.00 mL/min. Setting the flow rate

to 0.00 mL/min turns off the pump. For details about the pump, see

Section 2.3.1

Injection Valve

.

The injection valve is a six-port, electrically-activated valve. For details

about the injection valve, see Section 2.3.3

10 Doc. 065215-02 9/09

.

Page 19

Tubing Chase

The tubing chase routes tubing from the component panel, through the

ICS-900 interior, to the rear panel.

2.1.3 Rear Panel

Figure 2-3 illustrates the ICS-900 rear panel.

2 • Description

USB Connector

1

1

2

3

4

5

Link LED

2

TTL and Relay

3

Connector

Fuse Holder,

4

Power Switch, and

Power Receptacle

Plumbing and

5

Waste Lines

Figure 2-3. ICS-900 Rear Panel

USB Connector

The USB connector connects the ICS-900 to the PC on which

Chromeleon or Chromeleon Xpress is installed. For the standard system

configuration of one ICS-900 connected to a PC, connect a USB cable

between the USB connector on the ICS-900 and a USB port on the PC.

For detailed connection instructions, refer to the ICS-900 Ion

Chromatography System Installation Instructions (Document

Doc. 065215-02 9/09 11

Page 20

ICS-900 Operator’s Manual

No. 065214), provided on the Dionex Reference Library CD-ROM

(P/N 053891) and in the ICS-900 Ship Kit (P/N 067768).

Link LED

The Link LED indicates the communication status

between the ICS-900 and the PC on which

Link

Chromeleon or Chromeleon Xpress is installed.

LED Status Description

On The ICS-900 and the PC are linked, but no data is currently

being transmitted or received

Flashing The ICS-900 and the PC are linked and data is being

transmitted

Off The ICS-900 and the PC are not currently linked

TTL and Relay Connector

The TTL and Relay connector strip provides two TTL outputs, two relay

outputs, and four TTL inputs. The outputs can be used to control

functions in other TTL- or relay-controllable devices. The inputs can be

used to switch the injection valve position, turn the pump on and off, and

perform an autozero command. For connection instructions, see

Appendix C

Fuse Holder, Power Switch, and Power Receptacle

.

• The fuse holder contains two fast-blow IEC 127 fuses rated 3.15 A

(P/N 954745). For instructions on how to change the fuses, see

Section 5.13

.

• The power switch provides on/off control of power to the ICS-900.

• The power cord plugs into the IEC 320 three-prong receptacle.

The power supply cord is used as the main disconnect device. Make

sure the socket-outlet is located near the ICS-900 and is easily

accessible.

Le cordon d'alimentation principal est utilisé comme dispositif

principal de débranchement. Veillez à ce que la prise de base soit

située/installée près du module et facilement accessible.

12 Doc. 065215-02 9/09

Page 21

2 • Description

Das Netzkabel ist das wichtigste Mittel zur Stromunterbrechung.

Stellen Sie sicher, daß sich die Steckdose nahe am Gerät befindet und

leicht zugänglich ist.

Plumbing and Waste Lines

The following lines exit the ICS-900 through the tubing chase on the

lower left corner of the rear panel.

• Eluent

• Regenerant

• Cell outlet

• Waste (sample, regenerant, and pump priming)

Doc. 065215-02 9/09 13

Page 22

ICS-900 Operator’s Manual

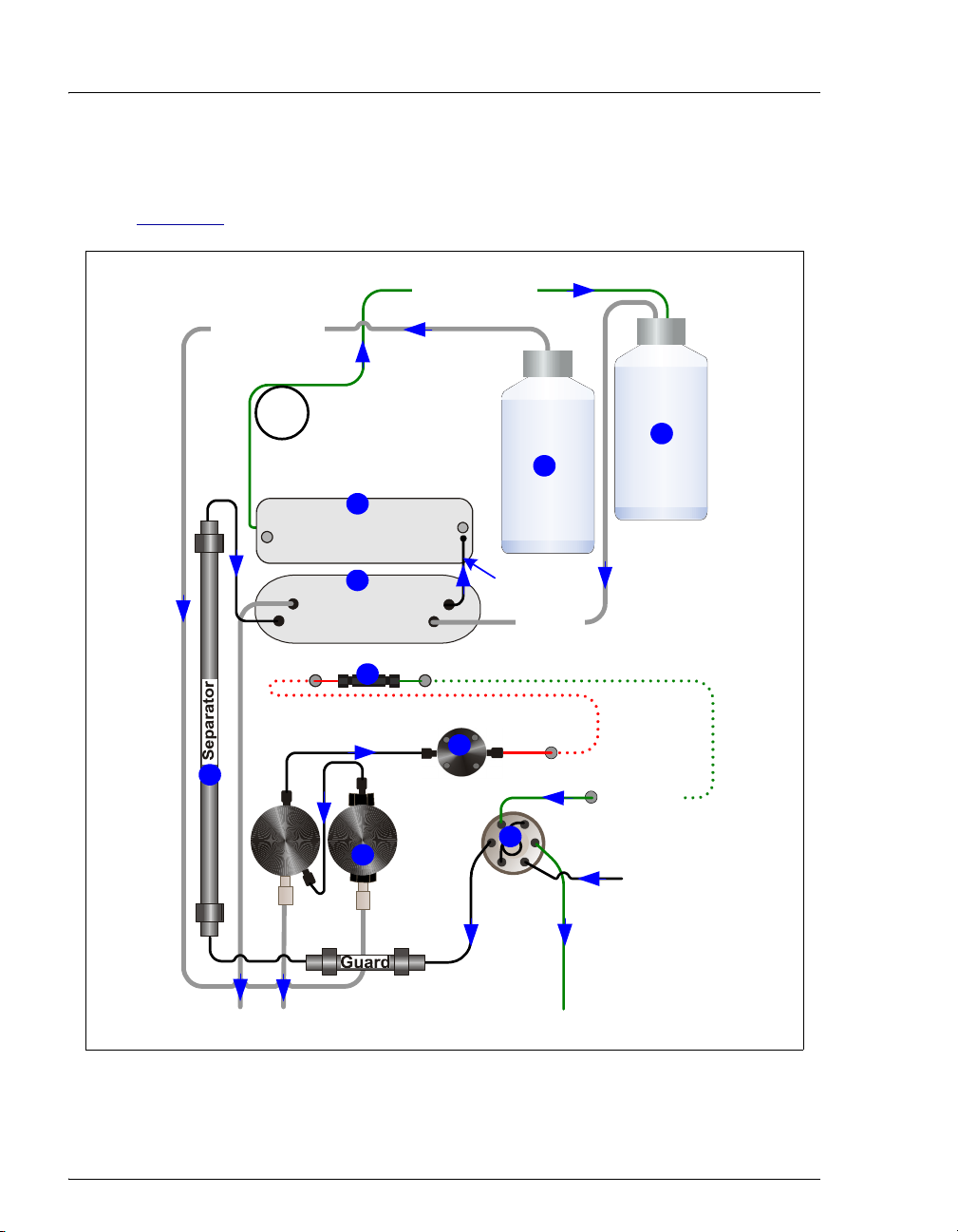

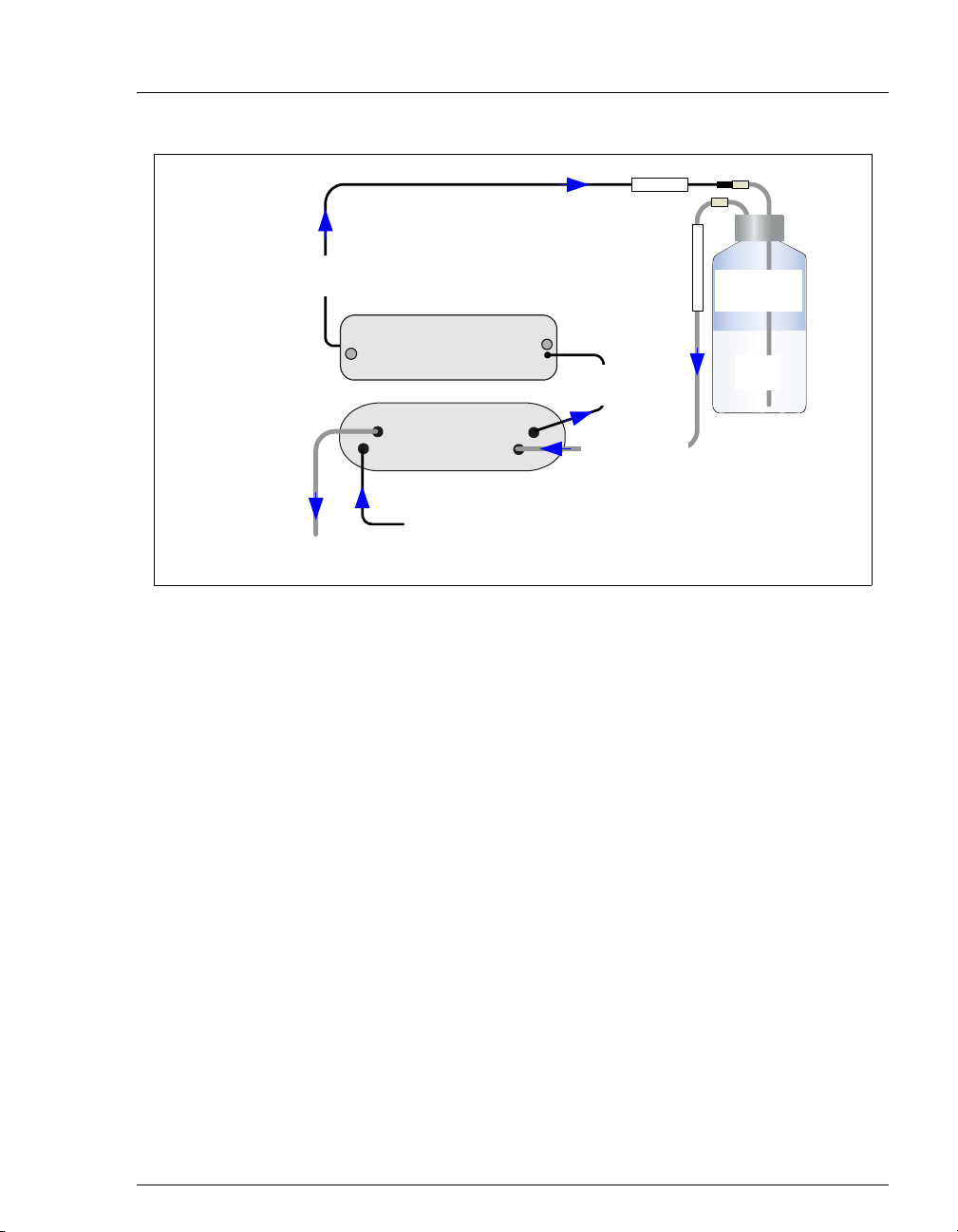

2.2 Fluid Schematic

Figure 2-4 shows the flow path through the ICS-900.

To pump inlet

From cell outlet

6

Backpressure Coil

(1 or 2, depending on

flow rate)

8

Conductivity Cell

(in DS5 Detection Stabilizer)

Regen Out Eluent Out

Eluent In

Secondary

7

MMS 300

Pulse Damper

4

Primary

2

Pump

Heads

Regen In

Transducer

Eluent

To cell inlet

To MMS

Regen In

Pressure

3

LP

5

CW

L

S

Injection

Valve

Regenerant

9

1

Eluent in

from pulse

damper

Sample in

To Waste

To Waste

Figure 2-4. ICS-900 Flow Schematic

14 Doc. 065215-02 9/09

Page 23

2 • Description

Liquid flows through the ICS-900 along the following flow path. Refer to

Figure 2-4

for the flow path number locations.

• Eluent from the eluent bottle is drawn into the pump . The pump pushes

the eluent through the pressure transducer , which measures the system

pressure, and through a pulse damper , which smooths minor pressure

1 2

3

4

variations from the pump to minimize baseline noise.

• The eluent then flows into the injection valve . After sample is loaded into

5

the sample loop and the injection valve is toggled to the Inject position, eluent

passes through the sample loop pushing the sample into the eluent stream.

• The eluent/sample mixture is pumped through the guard and separator

columns , where the ions are separated by the ion exchange process.

• The eluent/sample mixture then flows through the suppressor , which

suppresses the conductivity of the eluent and enhances the conductivity of the

analyte. Regenerant flows continuously through the suppressor, restoring the

ion exchange sites to their original state.

• The eluent/sample mixture then flows through the conductivity cell , where

the analytes are detected. A signal is produced and sent to Chromeleon or

Chromeleon Xpress software.

• Finally, the eluent flows out of the cell and into the regenerant bottle , where

it pressurizes the regenerant and forces it into the suppressor.

6

7

8

9

Doc. 065215-02 9/09 15

Page 24

ICS-900 Operator’s Manual

2.3 System Component Details

2.3.1 Pump

The ICS-900 pump is a microprocessor-based isocratic eluent delivery

system. Its variable speed, dual-piston series design ensures pulse-free

pumping for the most demanding applications.

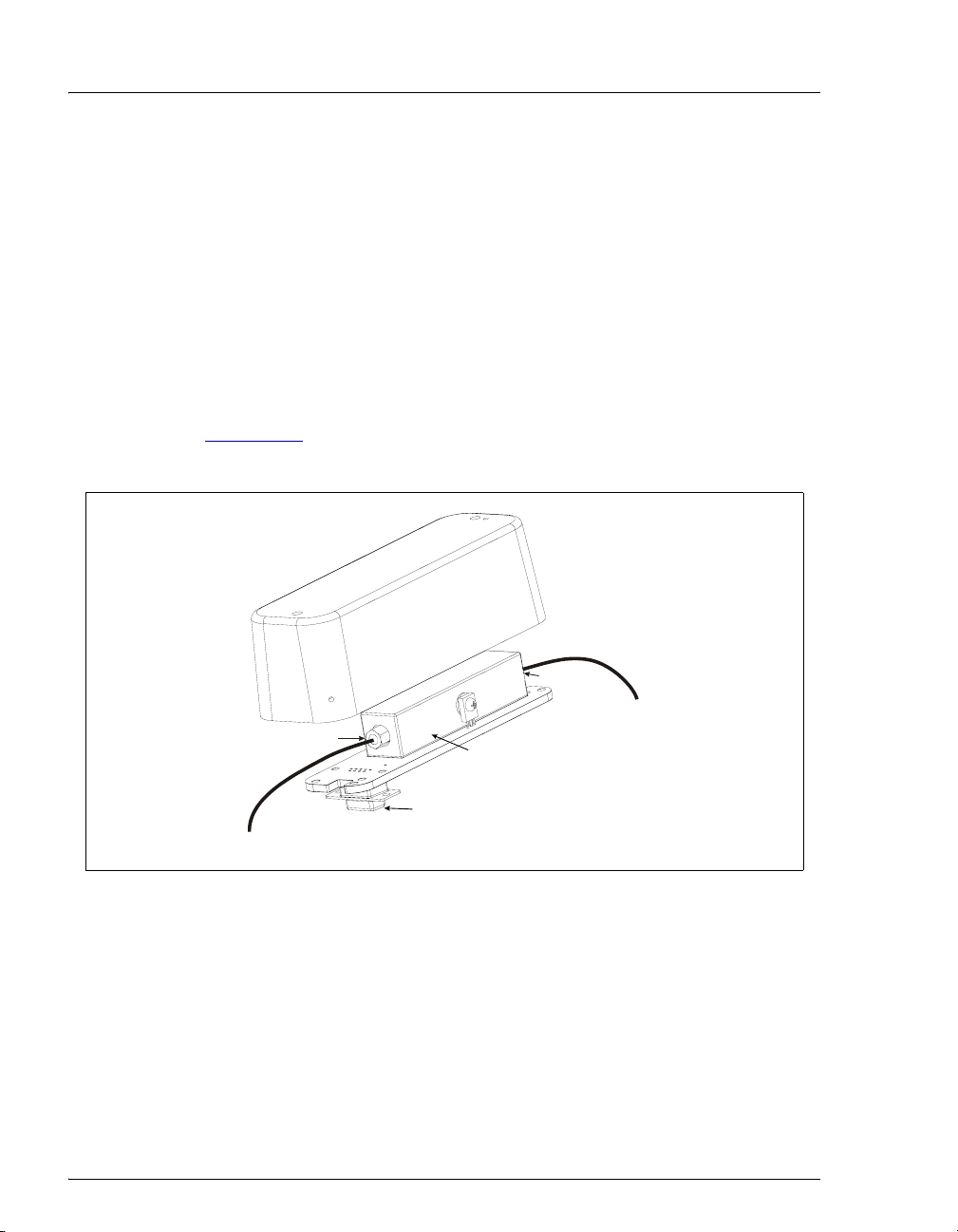

Primary Pump Head

The primary pump head pumps eluent into the secondary head (see

Figure 2-5

pump, are located on the bottom (inlet) and top (outlet) of the primary

pump head.

Secondary

Pump Head

). The check valves, which prevent reverse flow through the

Outlet Check

Valve

Primary Pump

Head

Waste Valve

Inlet Check

Valve

Figure 2-5. ICS-900 Pump Components

Secondary Pump Head

The secondary pump head delivers eluent to the pressure transducer. The

waste valve is located on the front of the secondary pump head (see

Figure 2-5

).

To open the waste valve, turn the knob one-half turn counterclockwise.

When the waste valve is in the open position, all output is directed to

waste.

16 Doc. 065215-02 9/09

Page 25

2.3.2 Pressure Transducer

The pressure transducer measures the system pressure at the point that the

eluent flows from the pump head outlet check valve. Pressure readings

indicate that the pumping system is delivering smooth, accurate flow.

Pressure readings can be monitored from Chromeleon or Chromeleon

Xpress.

The system pressure should remain consistent (no more than a 3%

difference from one pressure reading to the next). High and low pressure

limits can be used to stop the pump flow if a limit is exceeded. The

pressure limits can be set from Chromeleon (in the Server Configuration

Properties dialog box or in the Chromeleon or Chromeleon Xpress

program). For troubleshooting information if a pressure limit is exceeded,

see Section 4.7

Pulse Damper

Flow output from the pressure transducer continues to the pulse damper,

which smooths minor pressure variations. From there, flow is directed to

the injection valve and then to the remainder of the chromatography

system.

.

2 • Description

Doc. 065215-02 9/09 17

Page 26

ICS-900 Operator’s Manual

C

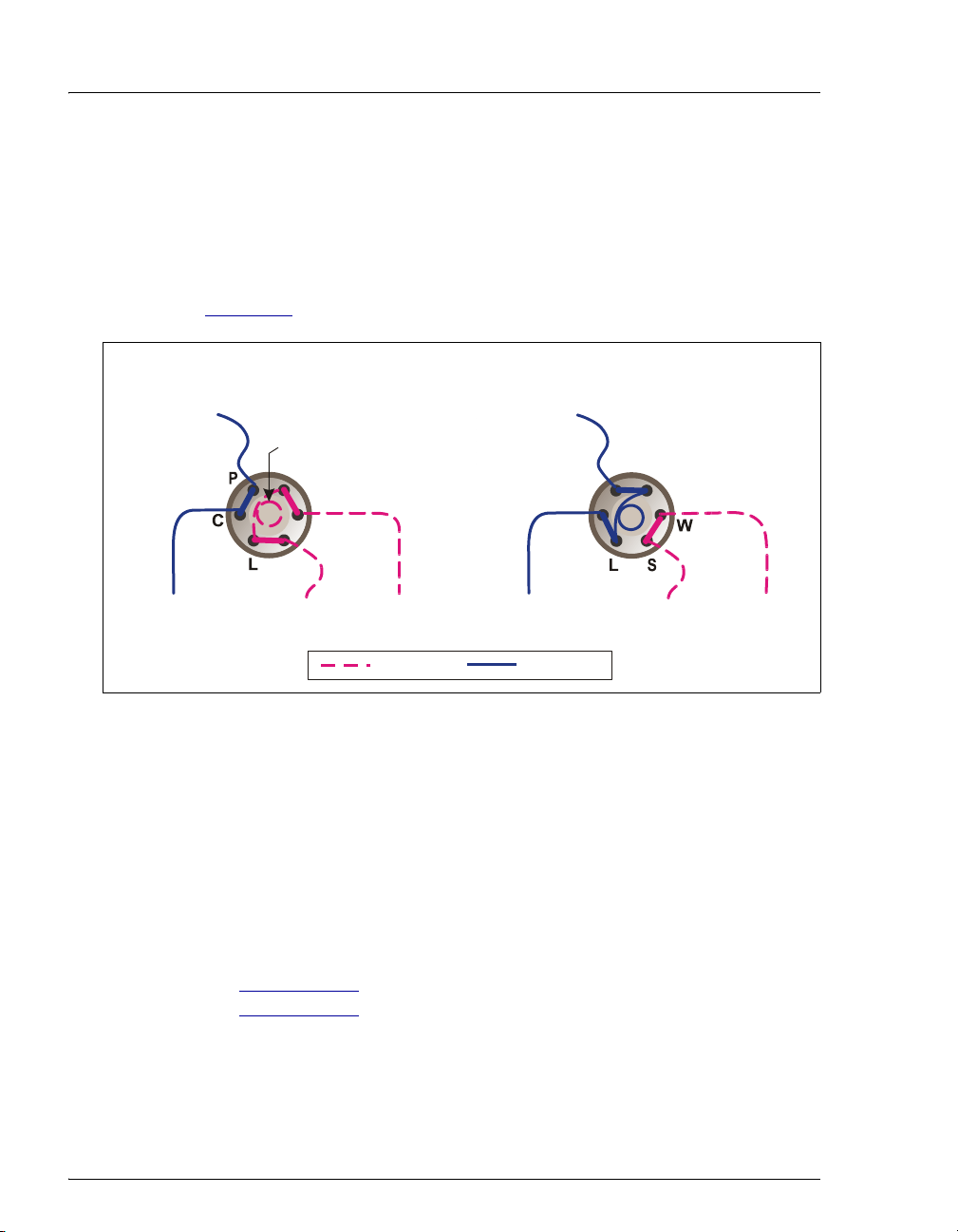

2.3.3 Injection Valve with Sample Loop

The injection valve is a six-port, electrically-activated Rheodyne valve. A

10 μL sample loop (P/N 042949) is installed on the valve at the factory.

The valve has two operating positions: Load and Inject. Eluent flows

through either the Load or Inject path, depending on the valve position.

From Pump

To Column

Figure 2-6

LOAD POSITIONINJE

shows flow schematics for the valve.

T POSITION

From Pump

Sample Loop

L

W

S

Sample In

Figure 2-6. Injection Valve Flow Schematics

To Waste

= Sample

= Eluent

P

C

L

Sample InTo Column

To Waste

• In the Load position, sample is loaded into the sample loop, where it

is held until injection. Eluent flows from the pump, through the valve,

and to the column, bypassing the sample loop. Sample flows from the

syringe or autosampler line (if installed), through the valve, and into

the sample loop. Excess sample flows out to waste.

• In the Inject position, sample is swept to the column for analysis.

Eluent flows from the pump, through the sample loop, and on to the

column, carrying the contents of the sample loop with it.

Section 3.11.2

Section 3.11.3

18 Doc. 065215-02 9/09

describes how to inject samples manually;

describes how to inject samples with an autosampler.

Page 27

2.3.4 MMS 300 MicroMembrane Suppressor

E

T

The MMS 300 suppressor reduces the eluent conductivity and enhances

the conductivity of the sample ions, thereby increasing detection

sensitivity.

2 • Description

As illustrated in Figure 2-7

,

a constant flow of

regenerant over the

membrane continually

restores the suppression

ability of the MMS 300.

A process called

Displacement Chemical

Regeneration (DCR)

pushes regenerant from the

regenerant bottle through

the suppressor. See

Section 2.3.5

for details.

N

I

T

N

E

U

L

N

E

G

E

R

R

For more information about

the MMS 300, refer to the

suppressor manual.

Suppressor manuals are

included on the Dionex

Reference Library CDROM (P/N 053891).

m

m

-

4

U

O

T

N

E

U

L

E

N

I

N

E

G

E

R

T

U

O

n

e

e

r

c

S

t

n

a

r

e

n

e

g

e

n

a

h

c

x

E

n

o

I

n

e

u

l

E

n

a

h

c

x

E

n

o

I

a

r

e

n

e

g

e

R

e

n

a

r

b

m

e

M

e

g

n

e

e

r

c

S

t

e

n

a

r

b

m

e

M

e

g

n

e

e

r

c

S

t

n

Figure 2-7. MMS 300 Suppressor Flow

Doc. 065215-02 9/09 19

Page 28

ICS-900 Operator’s Manual

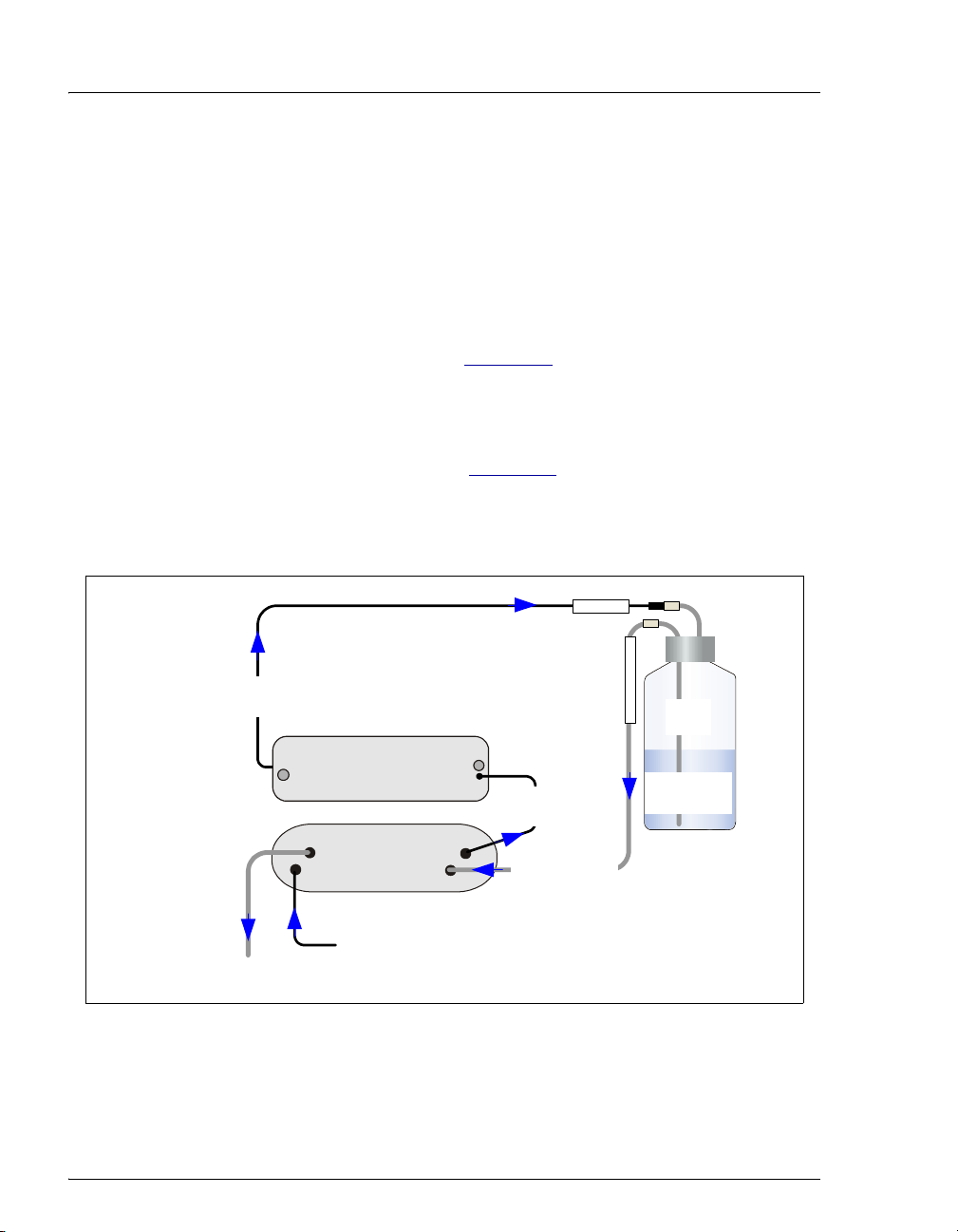

2.3.5 Displacement Chemical Regeneration (DCR)

Displacement Chemical Regeneration (DCR) is the process that restores

the ability of the MMS 300 suppressor to suppress eluent. In DCR, the

eluent that exits the cell is pumped into the regenerant bottle. The eluent

pressurizes the bottle and pushes the regenerant into the suppressor.

However, because the eluent is a different density than the regenerant, it

remains separate.

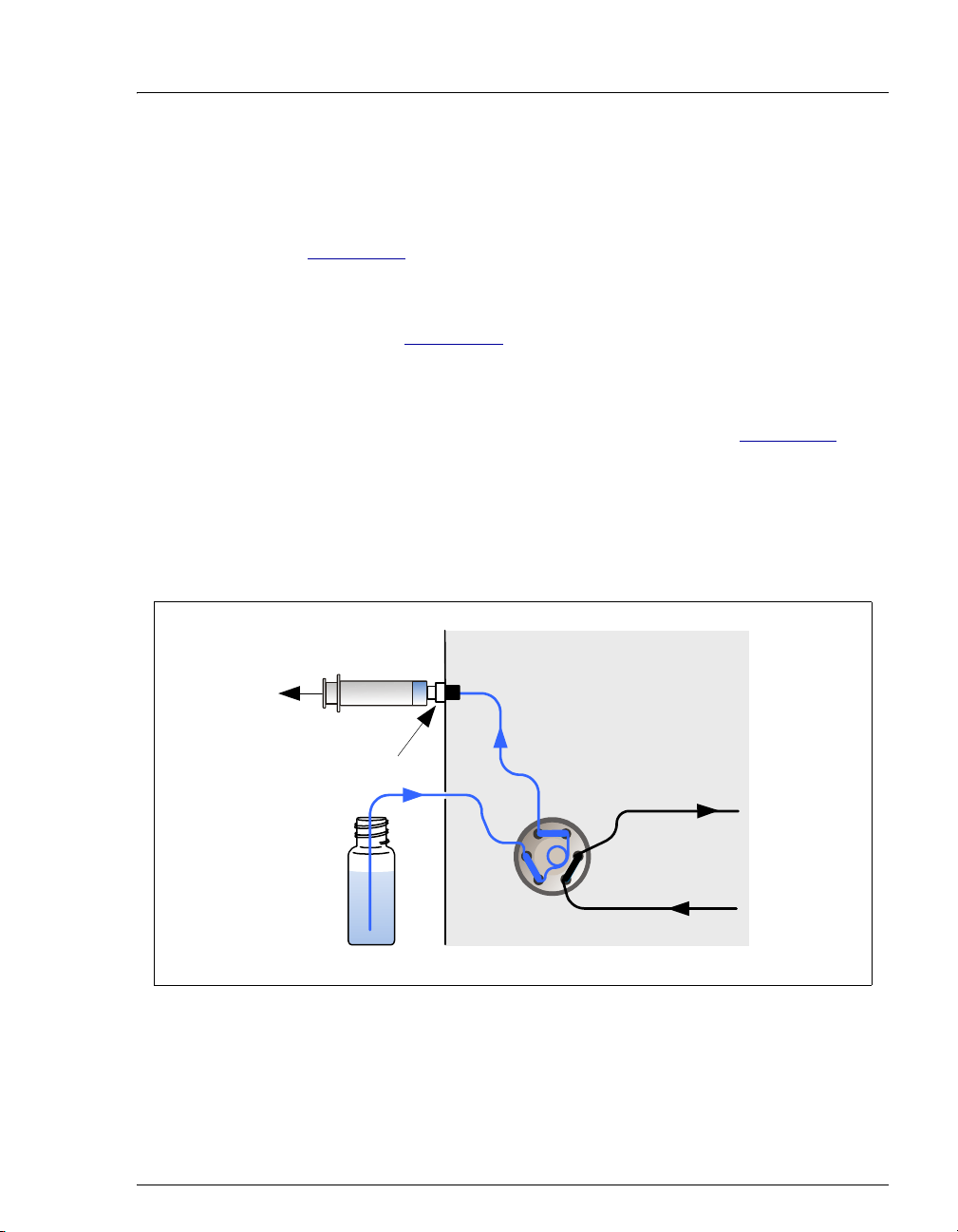

In the anion DCR process (see Figure 2-8

), the eluent is less dense than

the regenerant and it remains on the top of the bottle, forcing the

regenerant into the regenerant line at the bottom of the bottle and out into

the suppressor.

In the cation DCR process (see Figure 2-9

), the eluent is denser than the

regenerant and it flows to the bottom of the bottle. This displaces the

regenerant, pushing regenerant out of the regenerant line at the top of the

bottle and out into the suppressor.

Regen In

Used eluent out to

regenerant reservoir

(in DS5 Detection Stabilizer)

Regen Out Eluent Out

Eluent In

Conductivity Cell

AMMS 300

Regen In

Eluent

out to cell

Regenerant in

from reservoir

Used

Regen Bottle Out

Eluent

Anion

Regenerant

Eluent in from column

Regenerant out to waste

Figure 2-8. Anion ICS-900 Displacement Chemical Regeneration (DCR)

20 Doc. 065215-02 9/09

Page 29

Regen In

2 • Description

Used eluent out to

regenerant reservoir

Conductivity Cell

(in DS5 Detection Stabilizer)

Regen Out Eluent Out

Eluent In

Regenerant out to waste

CMMS 300

Regen In

Eluent in from column

Eluent

out to cell

Regenerant in

from reservoir

Cation

Regenerant

Regen Bottle Out

Used

Eluent

Figure 2-9. Cation ICS-900 Displacement Chemical Regeneration (DCR)

Connections to the regenerant bottle differ depending on whether the

system will run an anion or a cation application. Regenerant bottles for

each type of application are available (anion regenerant bottle assembly,

P/N 068222; cation regenerant bottle assembly, P/N 068223). For detailed

installation instructions, refer to the DCR Kit Installation Instructions

(Document No. 031664), provided on the Dionex Reference Library CDROM (P/N 053891).

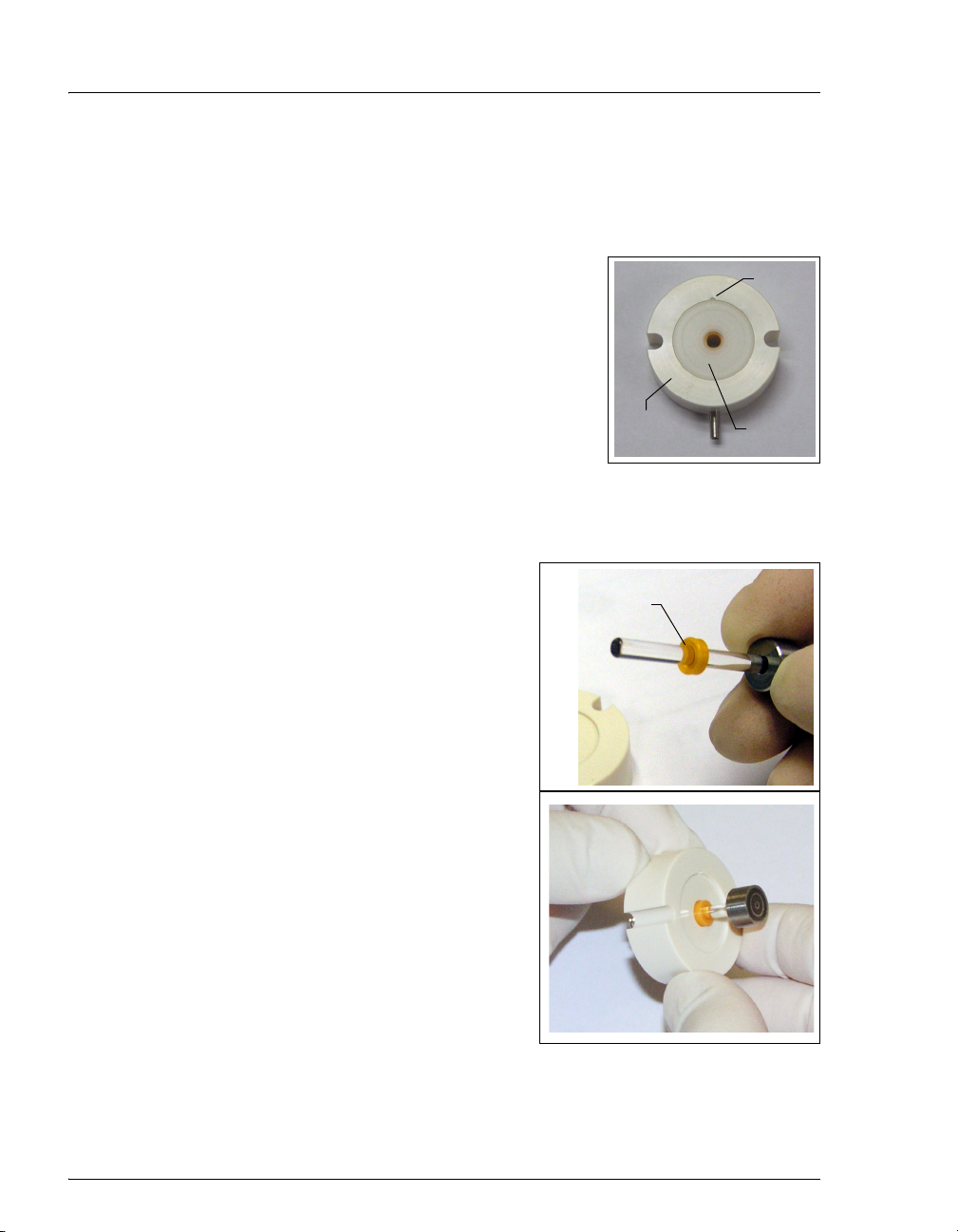

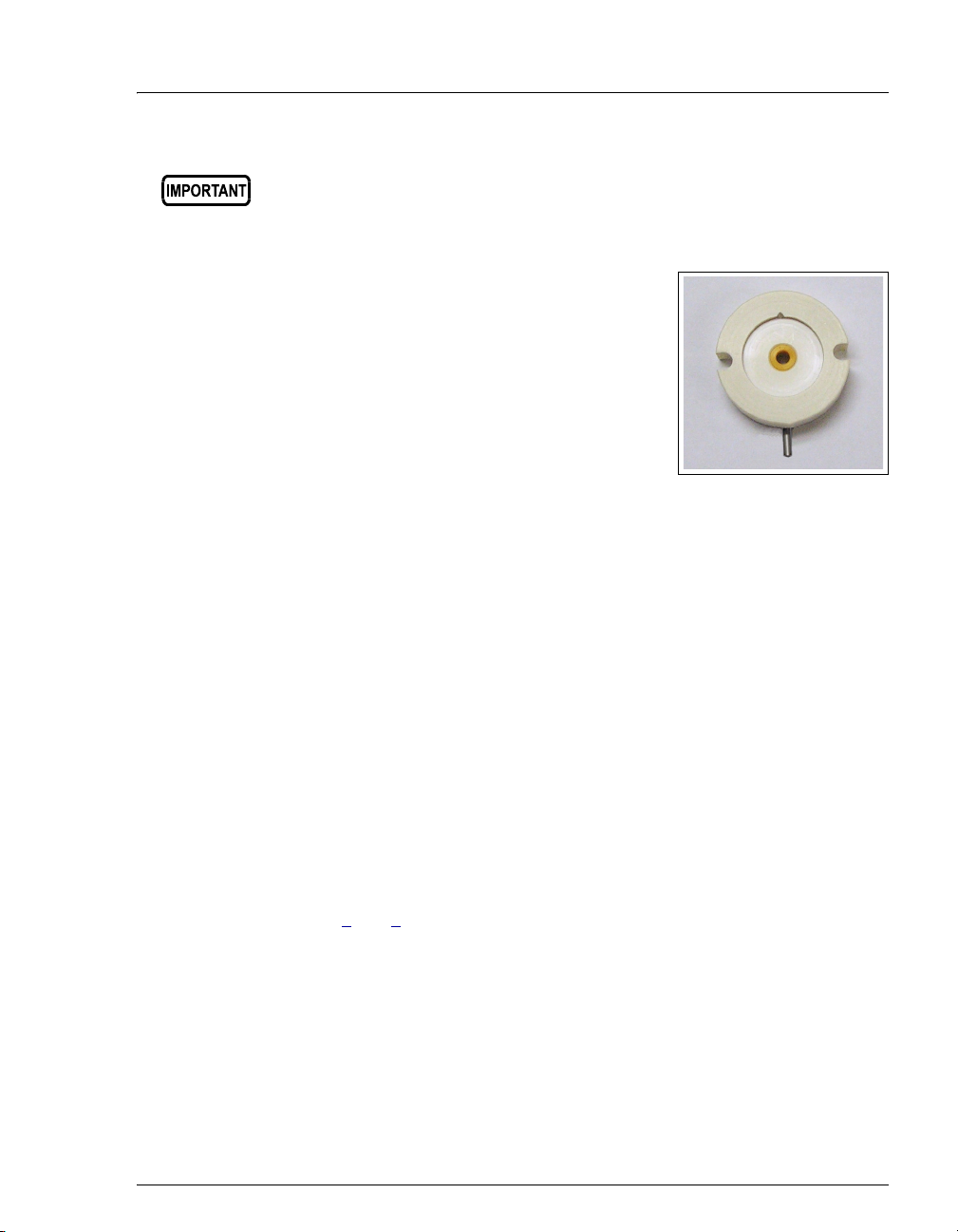

2.3.6 Conductivity Cell and DS5 Detection Stabilizer

The flow-through heated conductivity cell contains two 316 stainless steel

electrodes that are permanently sealed into the PEEK cell body. The cell

measures the electrical conductance of analyte ions as they pass through

the cell.

Temperature directly affects the conductivity of a solution. For example,

laboratory heating and air conditioning systems can cause a regular slow

cycling in the baseline. This, in turn, can affect the reproducibility of an

analysis. The higher the conductivity, the more pronounced the effect.

Doc. 065215-02 9/09 21

Page 30

ICS-900 Operator’s Manual

t

In ion analysis, the effect of temperature variation is minimized by

suppressing eluent conductivity. Built-in preset temperature

compensation also ensures that there is no major change in the baseline or

in peak heights. Temperature compensation

stability.

Direct conductive heating is used in the ICS-900 conductivity cell to

provide temperature control and compensation. A heat exchanger inside

the ICS-900 cell regulates the temperature. All data is collected at 40 °C

(104 °F).

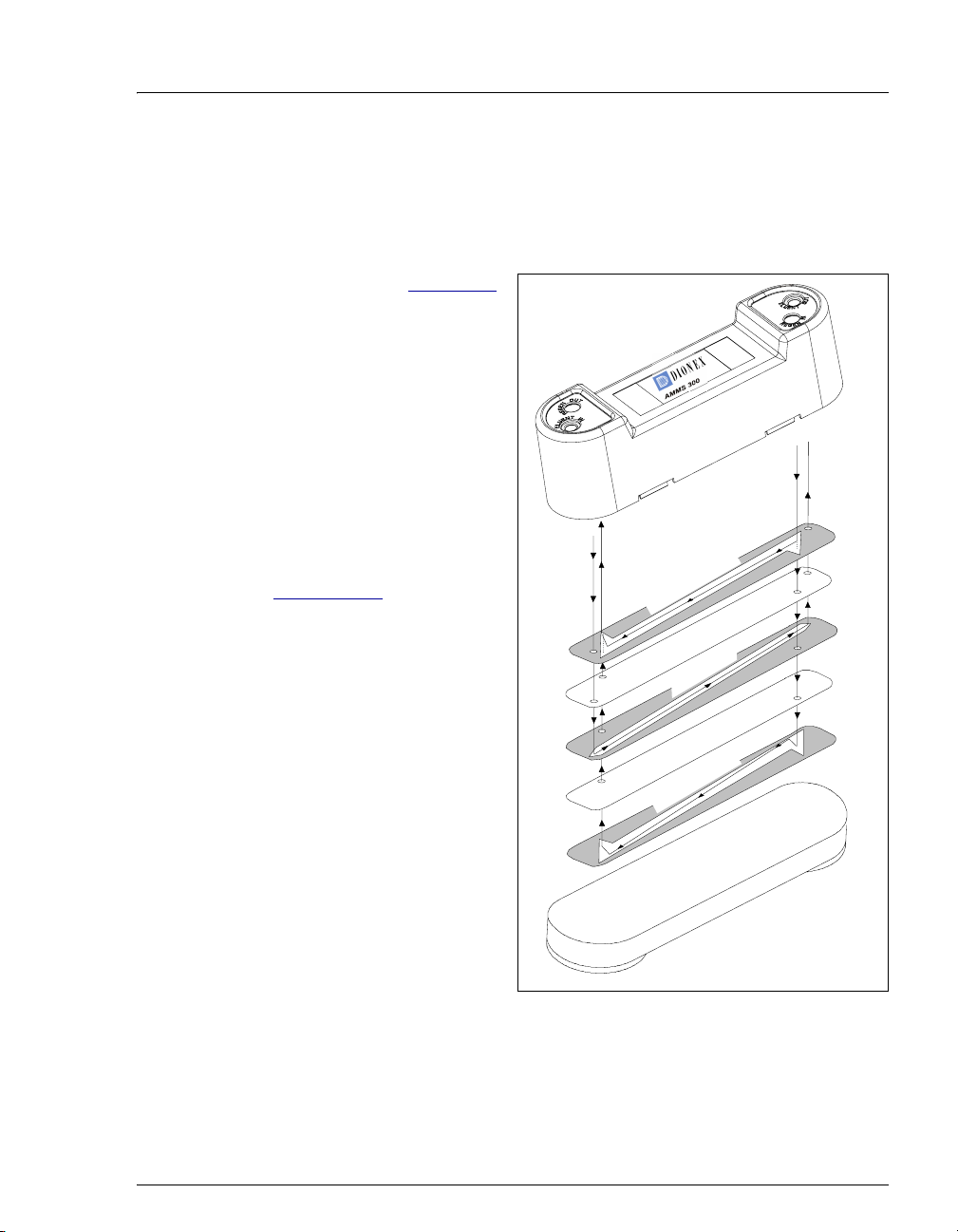

The cell is housed inside a DS5 Detection Stabilizer (P/N 067761) (see

Figure 2-10

temperature.

), which helps to insulate the cell from fluctuations in ambient

further improves baseline

r

e

z

i

l

i

b

a

t

S

n

o

i

t

c

e

t

e

D

5

S

D

Cell Inlet

From suppressor

Cell Outlet

To r egenerant reservoir

Conductivity Cell

Connector to component

mounting panel

ELUENT OUT por

Figure 2-10. Conductivity Cell and DS5 Detection Stabilizer

The conductivity cell has two detection limit ranges: 0 to 500

10,000

for the application. The default range of 0 to 500

μS. Select the range depending on the expected detector readings

μS is appropriate for

μS or 0 to

most applications. The detection limit range is set in the Properties dialog

box of the Chromeleon Server Configuration program. For details, refer

to the ICS-900 Ion Chromatography System Installation Instructions

(Document No. 065214), provided on the Dionex Reference Library CDROM (P/N 053891) and in the ICS-900 Ship Kit (P/N 067768).

22 Doc. 065215-02 9/09

Page 31

2 • Description

2.4 Chromeleon and Chromeleon Xpress Software

The ICS-900 is controlled by a PC configured with Chromeleon Chromatography

Management System or Chromeleon Xpress. Chromeleon

Management System provides complete instrument control, data acquisition, and

data management. Chromeleon Xpress provides real-time control and monitoring

of Dionex chromatography instruments, but does not include data management

capabilities.

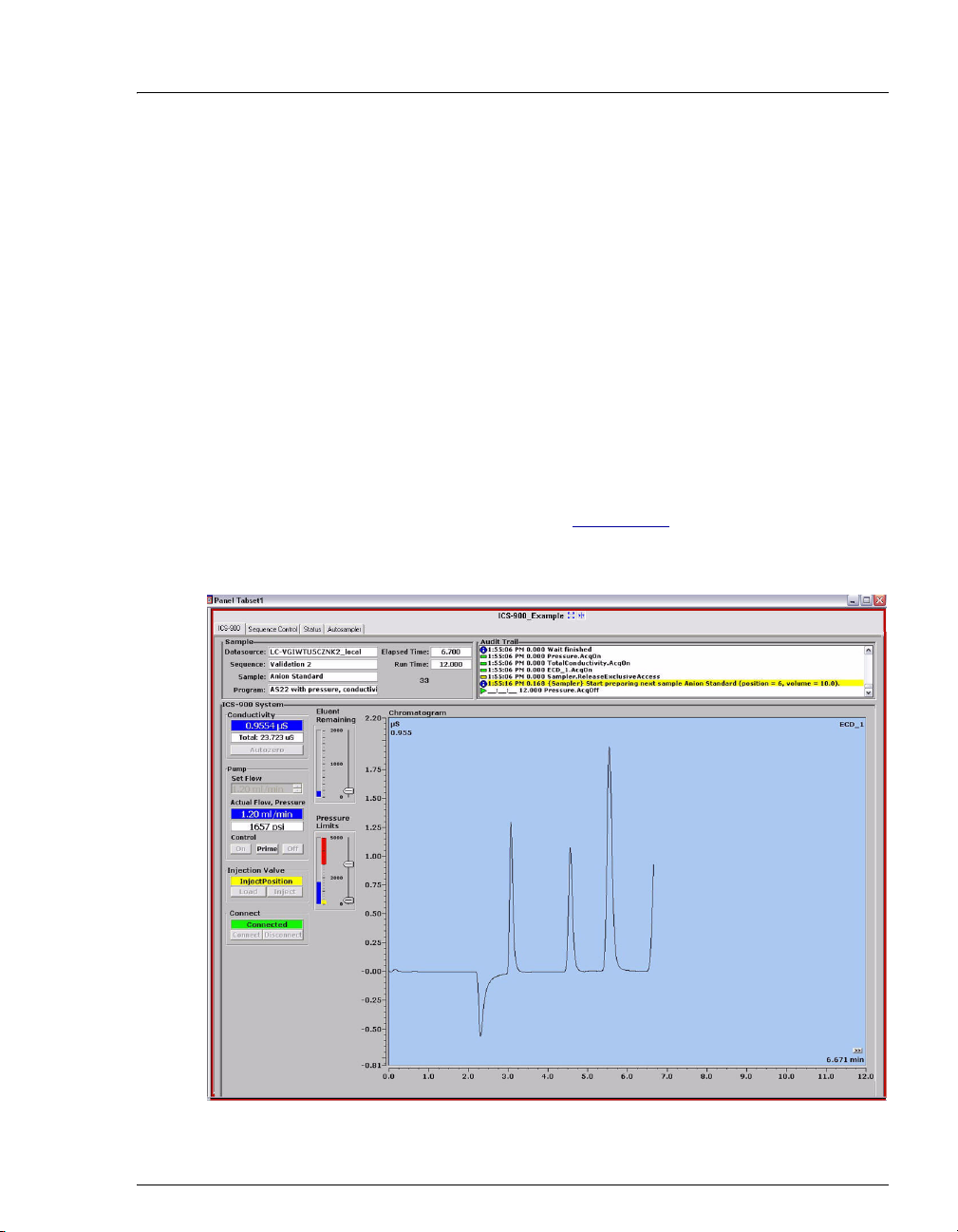

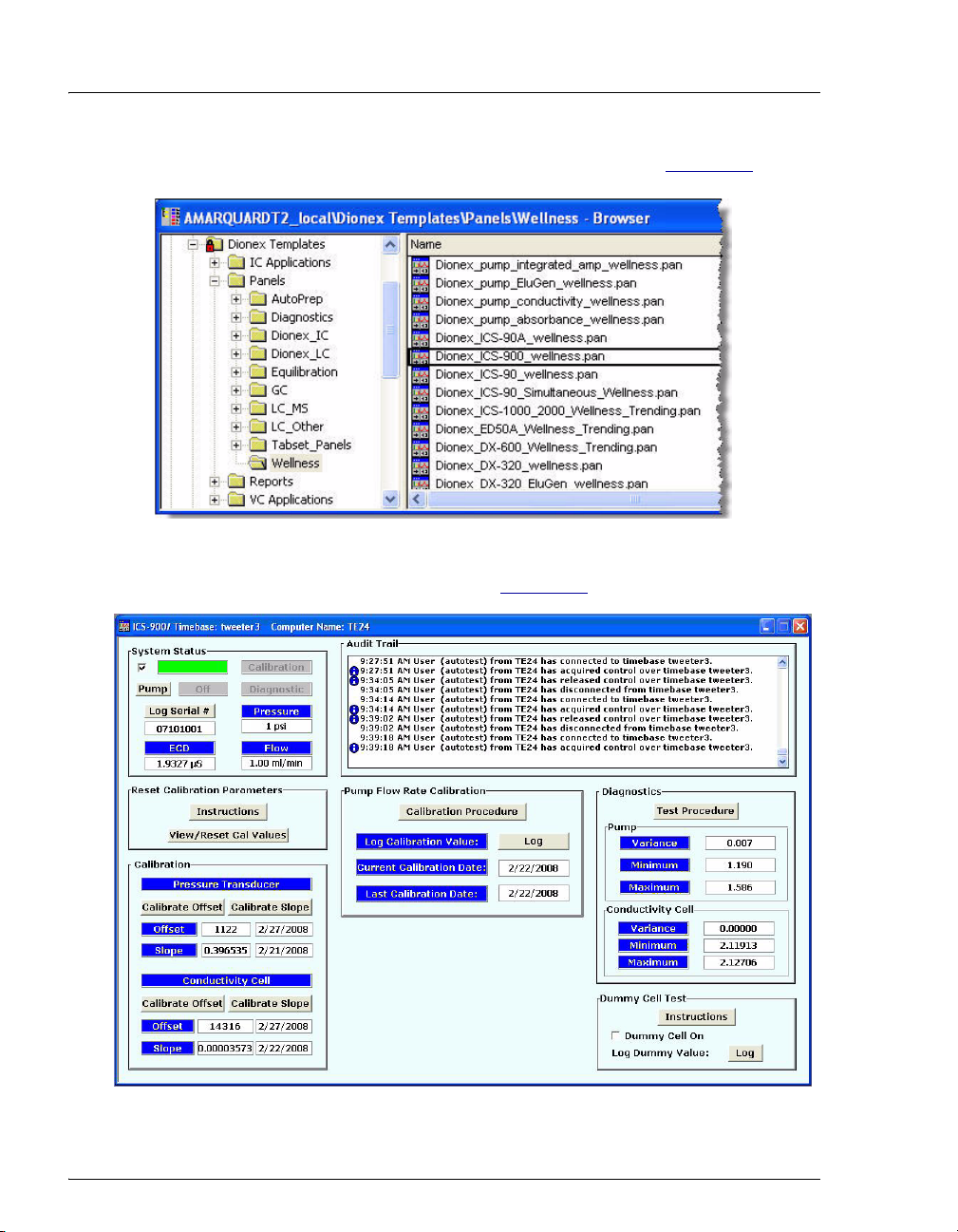

2.4.1 The Panel Tabset

The Chromeleon and Chromeleon Xpress panel tabset provides a

centralized location for controlling system functions. A panel tabset for

an ICS-900 system typically includes the following Control panels:

• An ICS-900 Control panel (see Figure 2-11) provides access to

ICS-900 functions. The label on the tab for this panel is the name of

the timebase in which the ICS-900 is configured.

Chromatography

Figure 2-11. ICS-900 Panel on the Panel Tabset

Doc. 065215-02 9/09 23

Page 32

ICS-900 Operator’s Manual

• A Sequence Control provides controls for defining and running

sequences (groups of sample injections to be analyzed in the order in

which they are listed).

• A Status panel shows the overall system status.

• An autosampler panel provides access to autosampler functions.

This panel is present only if the timebase in which the ICS-900 is

configured includes an autosampler.

To open the panel tabset, use one of the methods below:

• If Chromeleon is installed,

start Chromeleon and click

the Default Panel Tabset

toolbar button, or select

View > Default Panel

Tab se t.

• If Chromeleon Xpress is

installed, start the application; this automatically displays the

ICS-900 panel tabset.

2.4.2 Software Control Modes

Two modes of software control are available: direct control and

programmed control.

• With direct control, you select operating parameters and commands

from the Control panels. Direct control commands are executed as

soon as they are entered. See Section 3.11.2

control.

for details about direct

• With programmed control, you create a list of control commands to

be executed in chronological order. Programs can be created

automatically (with the help of a software wizard). See Section 3.11.3

for details about programmed control.

24 Doc. 065215-02 9/09

Page 33

2 • Description

2.4.3 System Wellness and Predictive Performance

System Wellness monitors the overall “health” of a chromatographic

system. It provides built-in diagnostic and calibration features that help

prevent unscheduled system shutdowns and assure reliable operation of

system devices. For details about System Wellness, see Section 5.1

Predictive Performance provides functions for monitoring the usage of

replaceable parts and for planning service procedures. Predictive

Performance lets you monitor the following functions:

• The number of hours the ICS-900 has been in use

• The number of times the injection valve has cycled

• The number strokes performed by the pump pistons

• The estimate of the amount of wear to the piston seal

• The volume of eluent pumped through the suppressor and column

You can set limits for injection valve cycles, piston strokes, piston seal

wear, suppressor usage, and column usage. Two limits can be set for each

parameter. When the first limit is reached, a warning message is displayed

in the Chromeleon or Chromeleon Xpress Audit Trail. When the second

limit is reached, an error message is displayed in the Audit Trail. After

replacing a part, reset the limit counters to zero.

.

Different applications cause different rates of wear on the consumable

parts in your instrument. Experience will help you determine the

appropriate limits to set to predict when the next maintenance will be

required.

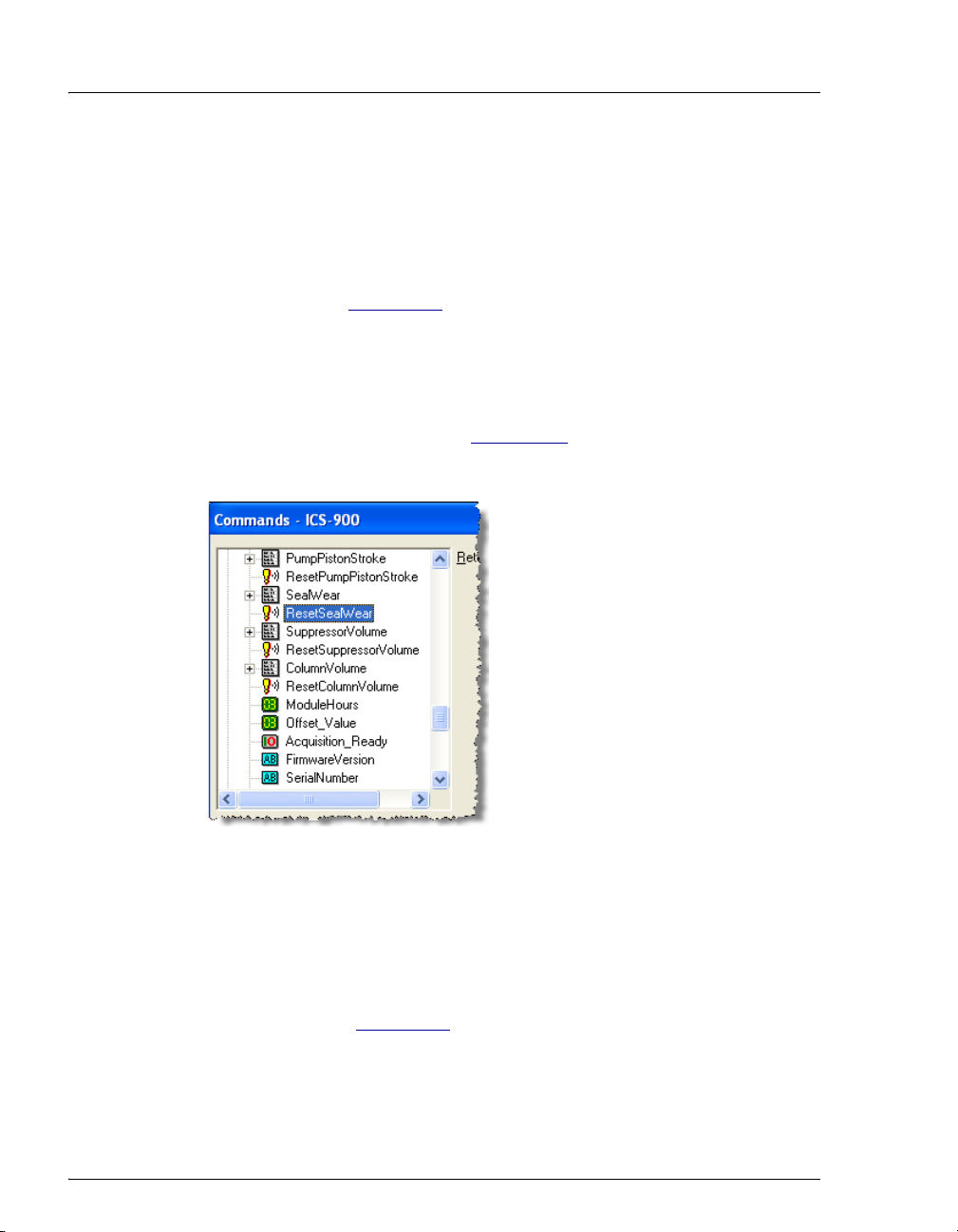

Predictive Performance commands and parameters are available in the

Commands dialog box in Chromeleon or Chromeleon Xpress. To open

the Commands dialog box, press F8. Expand the list of commands under

Pump_ECD and scroll to the Predictive Performance commands

Doc. 065215-02 9/09 25

Page 34

ICS-900 Operator’s Manual

(InjectValveCycles, PumpPistonStrokes, SealWear,

SuppressorVolume, ColumnVolume) (see Figure 2-12

).

Figure 2-12. Predictive Performance Commands: InjectValveCycles

If you do not wish to receive these warning or error messages, you can

disable them by setting the Warning and Limit parameter for each

Predictive Performance function to Off.

26 Doc. 065215-02 9/09

Page 35

3 • Operation and Maintenance

This chapter describes routine operating and maintenance procedures for the ICS900 Ion Chromatography System (ICS-900).

3.1 Operation Overview

Figure 3-1 illustrates the basic steps for routine operation of the ICS-900.

Turn on the ICS-900

power

Connect to

Chromeleon

Prepare the eluent

and regenerant

Prime the pump

Equilibrate the

system

Prepare samples

Process samples

Figure 3-1. ICS-900 Operation Flow Chart

Doc. 065215-02 9/09 27

Page 36

ICS-900 Operator’s Manual

3.2 Turning On the ICS-900 Power

Press the power switch on the ICS-900 rear panel (see Figure 2-3) to turn on the

system power. These are the conditions at power-up:

• The pump is off.

• The injection valve is in the Load position.

• The conductivity detector begins reading the current conductivity.

3.3 Connecting to Chromeleon or Chromeleon Xpress

1. Turn on the PC.

2. Start the Chromeleon Server, if it is not already running.

a. Check the Chromeleon Server Monitor icon on the Windows taskbar.

• When the server is running, the icon is gray .

• When the Server is not running, the icon is crossed out in red . To

start the server, right-click the icon and select Start Server.

b. If the Server Monitor icon is not on the Windows taskbar, click Start and

select All Programs (or Programs) > Chromeleon > Server Monitor.

The Server Monitor opens. Click Start to start the server.

3. To start the Chromeleon client, click Start and select All Programs (or

Programs) > Chromeleon > Chromeleon.

4. If Chromeleon is installed, display

the panel tabset by selecting View >

Default Panel Tabset or by

clicking the Default Panel Tabset

toolbar button.

If Chromeleon Xpress is installed,

starting the application

automatically displays the panel tabset.

5. To display the ICS-900 Control panel, select the tab labeled with the ICS-900

timebase name (see Figure 3-2

28 Doc. 065215-02 9/09

).

Page 37

3 • Operation and Maintenance

Figure 3-2. ICS-900 Control Panel on Panel Tabset

3.4 Preparing the Eluent

1. Prepare the eluent. For instructions refer to the column manual. Column

manuals are included on the Dionex Reference Library CD-ROM (P/N

053891).

2. Fill the eluent bottle with the prepared eluent, insert the stopper assembly

tubing into the bottle, and hand tighten the cap.

Set the Eluent Level

After filling the bottle, move the Eluent Remaining slider on the ICS-900

Control panel (see Figure 3-3) to indicate the volume of liquid in the bottle.

The ICS-900 determines the eluent usage by monitoring the flow rate and the

length of time the pump is on. As the eluent is used up, the ICS-900 updates the

Eluent Remaining slider and gauge. A warning appears in the Audit Trail when

the level falls below 200 mL, and then again when the level falls bellow 100 mL.

Doc. 065215-02 9/09 29

Page 38

ICS-900 Operator’s Manual

For the eluent level to be accurate, you must enter the level each time

the bottle is filled.

Figure 3-3. Setting the Eluent Level

3.5 Preparing the Regenerant

After filling the eluent

bottle, move the slider to

indicate the volume of

liquid in the bottle

Note: The Eluent

Remaining slider and

gauge are updated as the

liquid is used up.

The type of regenerant used with the ICS-900 depends on the type of analysis to

be run. A dilute sulfuric acid regenerant is used for anion analyses; a

tetrabutylammonium hydroxide (TBAOH) regenerant is used for cation analyses.

Follow the instructions below to prepare either anion or cation regenerant.

Use ASTM Type I (18 megohm-cm) filtered and deionized water to prepare the

regenerant.

1. Verify that you have the correct regenerant bottle assembly (P/N 068222 for

anion analyses; P/N 068223 for cation analyses):

• For anions, verify that the cap is labeled ANION and the REGEN BOTTLE

line extends to the bottom of the bottle.

OUT

• For cations, verify that the cap is labeled CATION and the REGEN BOTTLE

OUT line extends only about 1 cm (0.4 in) into the bottle.

2. Rinse the regenerant bottle with deionized water.

3. Fill the bottle about halfway with deionized water.

30 Doc. 065215-02 9/09

Page 39

3 • Operation and Maintenance

4. Determine the regenerant concentration required for the application. To

estimate the regenerant concentration required for an eluent strength, use the

following formulas:

Anion Regenerant Concentration = (mM eluent) x 2

Cation Regenerant Concentration = (mM eluent) x 5

For example, if you are using 20 mM methanesulfonic acid (MSA) as the

eluent for cation analysis, use a regenerant concentration of 100 mM

tetrabutylammonium hydroxide (TBAOH).

For additional details, refer to the Displacement Chemical Regeneration

(DCR) kit installation instructions and the suppressor manual.

5. Empty the required amount of concentrate (sulfuric acid for anions; TBAOH

for cations) into the bottle.

For acid concentrates (such as the anion regenerant), always pour the

concentrate into deionized water, not into the empty bottle.

Pour les concentrés acides (comme le régénérant anionique), versez toujours le

concentré dans de l'eau désionisée et non dans le réservoir vide.

Gießen Sie säurehaltige Konzentrate (beispielsweise den Anionregenerenten)

das Konzentrat immer in entionisiertes Wasser und nicht in den leeren Behälter.

6. Fill the bottle almost to the top with deionized water and then place the bottle

in the tray on the top of the ICS-900.

NOTE To avoid staining the ICS-900, be careful not to spill

TBAOH on the instrument.

7. Using the concentrate bottle, pour additional deionized water into the bottle

until it is completely filled to the top. If a few drops spill over, then it is full

enough.

The regenerant bottle must be filled all the way to the top at all times.

8. Insert the stopper assembly tubing into the bottle and hand-tighten the cap.

9. Invert the bottle three or four times to disperse the concentrate.

Doc. 065215-02 9/09 31

Page 40

ICS-900 Operator’s Manual

After the analysis begins, do not mix the contents of the regenerant bottle.

10.Verify that the liquid lines from the ELUENT and REGEN bottles are

connected to the corresponding lines from the ICS-900 (see Figure 3-4

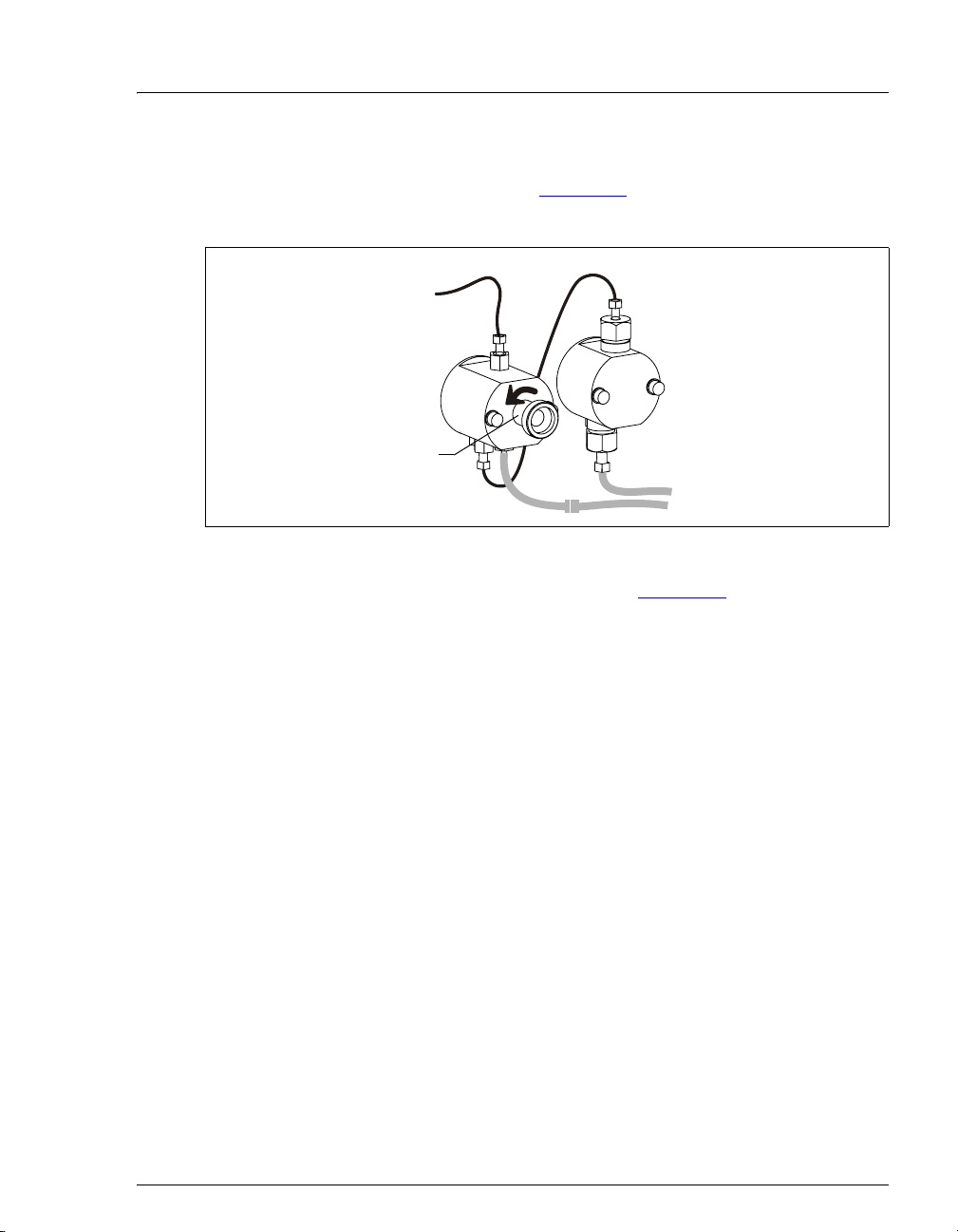

ELUENT Bottle Out

).

Figure 3-4. Eluent and Regenerant Bottle Liquid Line Connections

3.6 Priming the Pump

Prime the pump if the eluent has been changed, the eluent line contains air, or the

pump heads are dry (for example, after servicing).

NOTE If the eluent line is empty or the pump heads are

completely dry, you can use a 10 cc syringe (P/N 054578)

to prime the pump (see page 34

REGEN

Bottle In

REGEN Bottle Out

).

1. Verify that the ELUENT and REGEN bottles are filled, the bottle caps are

installed and hand-tightened, and the liquid lines are connected to the bottles.

2. Verify that the waste lines are directed to a waste container.

32 Doc. 065215-02 9/09

Page 41

3 • Operation and Maintenance

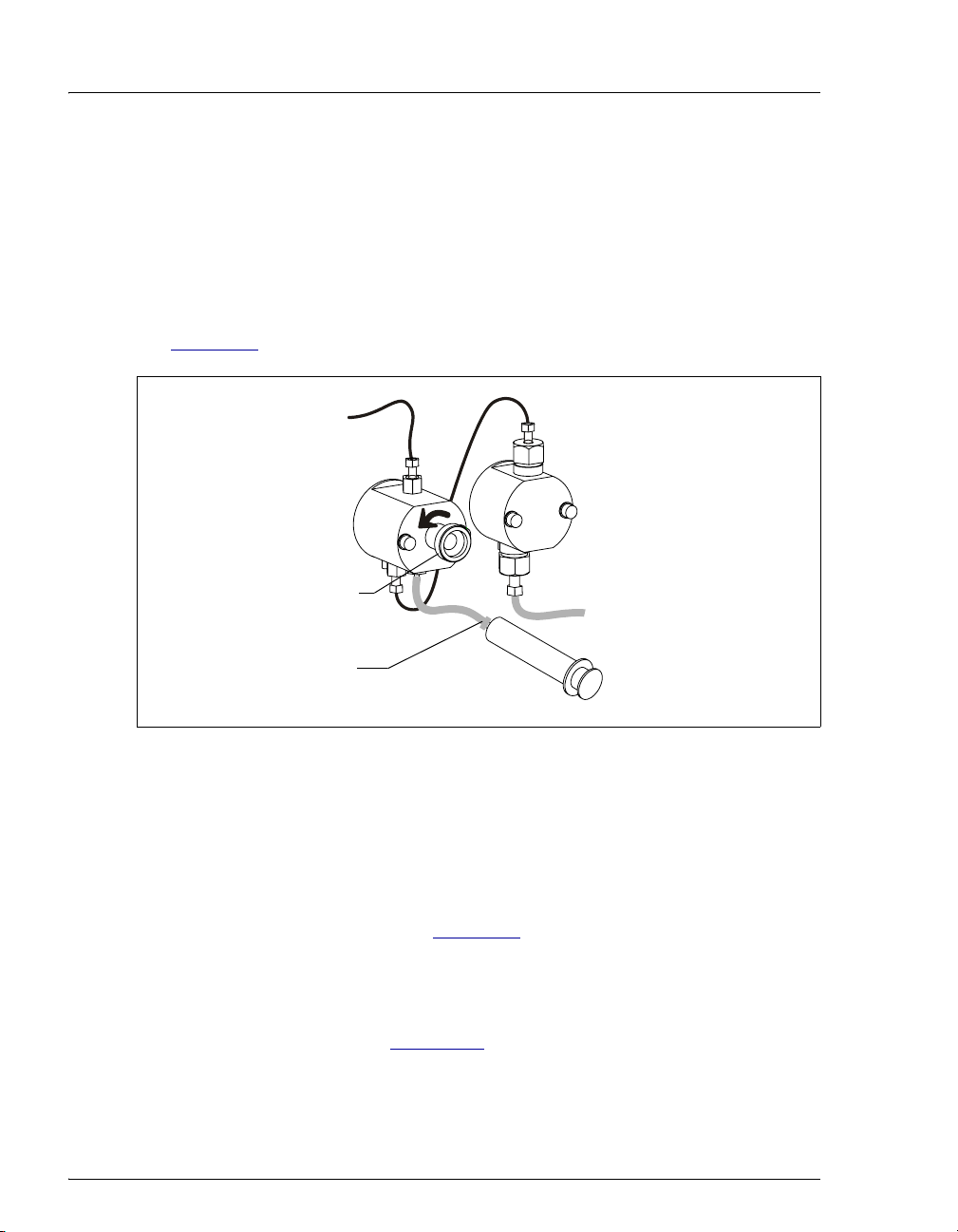

3. Open the waste valve on the secondary (left) pump head by turning the knob

one-half turn counterclockwise (see Figure 3-5

eluent flow path to waste and eliminates backpressure.

Secondary

Pump Head

Waste Valve

(Open)

Figure 3-5. Priming the Pump

). Opening the valve directs the

4. Click

Prime on the ICS-900 Control panel (see Figure 3-2), or open the

Commands dialog box (press F8), select the Pump command, and select the

Prime option. The pump will begin pumping at approximately 3 mL/min.

5. Continue priming the ICS-900 until no air bubbles are exiting the pump waste

line.

6. Click

Pump Off.

7. Close the waste valve. Do not overtighten. The pump is now ready for

operation.

NOTE A convenient way to verify that the waste valve is closed

is to select the pump flow rate required for your

application, turn on the pump, and then close the valve.

The pressure should rise to the value expected for the

application and quickly stabilize.

Doc. 065215-02 9/09 33

Page 42

ICS-900 Operator’s Manual

Priming the Eluent Line with a Syringe (Optional)

A syringe can be used to facilitate priming when the eluent line is empty or the

pump heads are completely dry.

1. Verify that the pump is turned off.

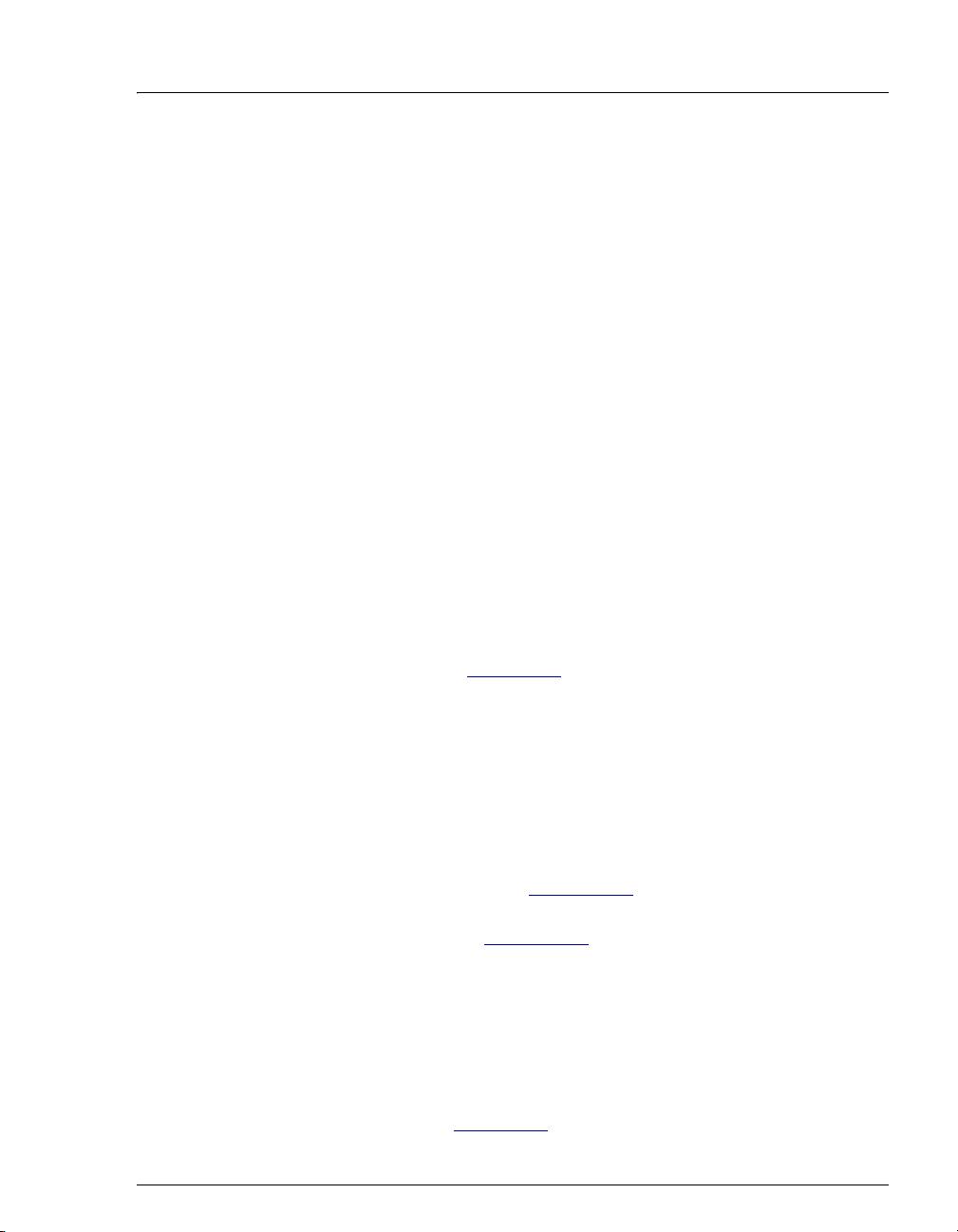

2. Disconnect the waste line from the luer fitting on the secondary (left) pump

head and connect a 10 mL syringe (P/N 054578) to the luer fitting (see

Figure 3-6

).

Secondary

Pump Head

Waste Valve

(Open)

Luer Fitting

Figure 3-6. Priming the Eluent Lines

10 mL Syringe

(P/N 054578)

3. Open the waste valve by turning it one-half turn counterclockwise.

4. Draw the syringe back to begin removing air from the flow path.

NOTE When the line already contains liquid, the syringe will be

difficult to draw back. In this case, prime with the prime

command only (see Section 3.6

).

5. When a small amount of liquid enters the syringe, remove the syringe from

the luer fitting, and reconnect the waste line to the luer fitting.

6. Follow the instructions in Section 3.6

34 Doc. 065215-02 9/09

to finish priming.

Page 43

3.7 Equilibrating the System

1. Turn on the pump and run at the flow rate recommended for the column.

2. Allow the system to equilibrate. The ICS-900 Control panel displays the

background conductivity (the conductivity of the eluent without the offset

performed by the autozero command).

3. Offset the background and zero the conductivity reading by clicking the

Autozero

4. Monitor the system pressure to make sure it is at the expected pressure for the

installed column (refer to the column manual for details) and is stable.

Column manuals typically provide pressure specifications for systems that do

not include a guard column. Expect the ICS-900 system pressure (with a

guard column) to be 15% to 20% higher than the specification in the column

manual.

• If the pressure is less than expected, air may be trapped in the system.

button on the ICS-900 Control panel.

Release the air by temporarily removing the pump fitting (P) on the

injection valve. Allow the air to escape, and then reconnect the fitting.

3 • Operation and Maintenance

• If the pressure is too high, there may be a restriction in the system

plumbing. Refer to the Section 4.7

5. Check for leaks in the regenerant bottle.

6. Check that liquid is flowing out of the suppressor

7. Monitor the baseline conductivity. In general, it should be <30

set up for anion analyses, and <2

Equilibration time varies and it can take some time to reach these expected

values.

If the conductivity is too high, see Section 4.12

information. If the baseline is drifting or has excessive “noise” (large

fluctuations in readings), see Section 4.13

μS for a system set up for cation analyses.

3.8 Verifying Operational Status

After the system has equilibrated, verify the actual pump pressure and stability by

monitoring the pump pressure. Record the short-term pressure fluctuations; they

should be less than 0.13 MPa (20 psi). If the pressure fluctuates by more than this

amount, prime the pump (see Section 3.6

for troubleshooting information.

REGEN OUT waste line.

μS for a system

for troubleshooting

.

).

Doc. 065215-02 9/09 35

Page 44

ICS-900 Operator’s Manual

3.9 Configuring Standby Mode

You can configure the ICS-900 to enter standby mode after a period of inactivity

(a period of time in which no data collection and no input from Chromeleon or

Chromeleon Xpress has occurred). In standby mode, the pump flow rate is

reduced.

To configure standby mode:

1. Start the Chromeleon Server Configuration program (click Start on the

Windows taskbar and select All Programs (or Programs) > Chromeleon >

Server Configuration).

2. Right-click the ICS-900 device in the timebase and select Properties.

3. Click Options (see Figure 3-7

Figure 3-7. ICS-900 Properties Dialog Box: Options Tab Page

4. Enter the desired Standby Flow Rate and select the Inactivity Time Out

Period. If you select (0, Off), the ICS-900 does not enter standby mode when

it is idle.

To cancel standby mode and return the pump to the normal flow rate, either turn

on the pump from the ICS-900 Control panel or start a new sequence.

).

36 Doc. 065215-02 9/09

Page 45

3.10 Preparing Samples

NOTE Sample preparation can be performed while the system

is equilibrating.

3.10.1 Collecting and Storing

Collect samples in high density polyethylene containers that have been

thoroughly cleaned with ASTM Type I (18 megohm-cm) filtered and

deionized water. Do not clean containers with strong acids or detergents

because these will leave traces of ions on the container walls. The ions

may interfere with the analysis.

If samples will not be analyzed on the day they are collected, filter them

through clean 0.45 μm filters immediately after collection; otherwise,

bacteria in the samples may cause the ionic concentrations to change over

time. Refrigerating the samples at 4

eliminate, bacterial growth.

Analyze samples containing nitrite or sulfite as soon as possible. Nitrite

oxidizes to nitrate, and sulfite to sulfate, thus increasing the measured

concentrations of these ions in the sample. In general, samples that do not

contain nitrite or sulfite can be refrigerated for at least one week with no

significant changes in anion concentrations.

3 • Operation and Maintenance

°C (39 °F) will reduce, but not

3.10.2 Pretreating

Analyze rainwater, drinking water, and air particulate leach solutions

directly with no sample preparation (other than filtering and possibly

diluting).

Filter groundwater and wastewater samples through 0.45 μm filters

before injection, unless samples were filtered after collection.

A Dionex High Pressure Inline Filter (P/N 044105) is available for

removing particulates down to 0.45 micron from samples. Connect the

inline filter between the autosampler outlet and the sample inlet port on

the injection valve. For details, see the printed installation instructions

provided with the inline filter.

Before injection, pretreat samples that may contain high concentrations of

interfering substances by putting them through Dionex OnGuard™

Doc. 065215-02 9/09 37

Page 46

ICS-900 Operator’s Manual

cartridges. For instructions, refer to Installation and Troubleshooting

Guide for OnGuard Cartridges (Document No. 032943). The manual is

included on the Dionex Reference Library CD-ROM (P/N 053891).

3.10.3 Diluting

Because the concentrations of ionic species in different samples can vary

widely from sample to sample, no single dilution factor can be

recommended for all samples of one type. In some cases (for example,

many water samples), concentrations are so low that dilution is not

necessary.

Use eluent or ASTM Type I (18 megohm-cm) filtered and deionized

water to dilute the sample. When using carbonate eluents, diluting with

eluent minimizes the effect of the water dip at the beginning of the

chromatogram. If you dilute the sample with eluent, also use eluent from

the same lot to prepare the calibration standards. This is most important

for fluoride and chloride, which elute near the water dip.

To improve the accuracy of early eluting peak determinations, such as

fluoride, at concentrations below 50 ppb, dilute standards in eluent or

spike the samples with concentrated eluent to minimize the water dip. For

example, spike a 100 mL sample with 1.0 mL of a 100 X eluent

concentrate.

38 Doc. 065215-02 9/09

Page 47

3.11 Processing Samples

3.11.1 Overview

Samples can be run manually (one at a time), or they can be grouped and

run automatically in batches. Figure 3-8

manual and batch sample processing.

3 • Operation and Maintenance

shows the typical steps for

Manual Sample

Processing

Load the sample

Autozero

Start data

acquisition

Inject the sample

Monitor

chromatogram

Stop data

acquisition

Batch Sample

Processing

Create a program*

Create a sequence

Load the

sequence

Start the batch

*Includes commands

for sample loading,

autozero, injection,

and data acquisition.

Figure 3-8. Sample Processing Overview

Doc. 065215-02 9/09 39

Page 48

ICS-900 Operator’s Manual

3.11.2 Manually Processing Samples

To manually process a sample, select operating parameters and

commands from the Chromeleon or Chromeleon Xpress panel tabset.

Commands are executed as soon as they are entered.

Summary of Manual Sample Processing

1. Complete the instructions in Section 3.2 through Section 3.10 to

prepare the ICS-900 for operation and to prepare the sample for

processing.

2. Load the sample into the injection valve sample loop with an

autosampler (see Section 3.11.4

) or a syringe (see Section 3.11.5).

3. On the ICS-900 Control panel, click the Autozero

button.

4. On the Sequence Control panel, click the Acq On button (or click

the Acquisition On/Off button on the Chromeleon toolbar).

5. Switch the injection valve to the Inject position. The method used to

switch the injection valve depends on whether you are using an

autosampler (see Section 3.11.4

) or a syringe (see Section 3.11.5).

6. The signal plot is displayed on the ICS-900 Control panel (see

Figure 3-9

). Monitor the chromatogram and when sample data has

been collected, click the Acq Off button on the Sequence Control

40 Doc. 065215-02 9/09

Page 49

3 • Operation and Maintenance

panel (or click the Acquisition On/Off button on the Chromeleon

toolbar).

Figure 3-9. Manual Data Acquisition

Saving Manual Data

NOTE Chromeleon Xpress does not allow data to be saved.

If you are using Chromeleon, data from manual processing is saved in the

manual sequence under the timebase folder in the local datasource.

To save the data from a manual run:

1. Select the manual folder and select File>Save As.

2. Enter a new name for the sequence.

3. Select the Save raw data check box.

Doc. 065215-02 9/09 41

Page 50

ICS-900 Operator’s Manual

4. Click Save.

3.11.3 Automatically Processing Samples (Batch Processing)

You can use Chromeleon or Chromeleon Xpress to create a list of samples

(a sequence) to be processed automatically. For each sample, the

sequence includes the following:

• A program with commands and parameters for controlling the

ICS-900 and autosampler (if installed), and for acquiring sample data.

• A quantification method for peak identification and area

determination. The quantification method is not included with

Chromeleon Xpress.

• Additional sample processing parameters (sample name, sample type,

injection volume, etc.).

After creating the sequence, you can start batch processing.

Summary of Automatic Sample Processing

1. Complete the instructions in Section 3.2 through Section 3.10 to

prepare the ICS-900 for operation and to prepare the samples for

processing.

2. If an autosampler is installed, prepare and fill the sample vials and

place them in the autosampler tray or cassette. Refer to the

autosampler manual for detailed instructions. Autosampler manuals

are provided on the Dionex Reference Library CD-ROM

(P/N 053891).

3. If an autosampler is not installed, load the sample into the injection

valve sample loop through the sample port on the ICS-900 front door

(see Section 3.11.5

4. Use the Application Wizard to specify a program and quantitation

method, and create a sequence:

a. On the Sequence Control panel, click Application Wizard.

).

42 Doc. 065215-02 9/09

Page 51

3 • Operation and Maintenance

b. Select an application template from the list (see Figure 3-10).

Figure 3-10. Application Wizard

c. Click Next> and select the in a new sequence via Sequence

Wizard option.

d. Click Next> to go to the Sequence Wizard.

e. Complete the steps in the Sequence Wizard, adding the desired

number of samples and standards to the list. For help, click the

Help button on the Sequence Wizard page.

After you click Finish, a sequence is created and a program

appropriate for the selected application is copied to the sequence. If

you are using Chromeleon, a quantification method is also copied to

the sequence

.

5. Load the sequence and start batch processing:

a. On the Sequence Control panel, click Load Sequence.

b. Select the sequence created in Step 4

and click Open.

c. Click Start Batch.

Doc. 065215-02 9/09 43

Page 52

ICS-900 Operator’s Manual

3.11.4 Loading and Injecting Samples with an Autosampler

1. Verify that the autosampler output line is connected to port S (5) on

the injection valve. Direct the injection valve waste line as required

for the installed autosampler model.

For details about connecting an autosampler, refer to the ICS-900

Installation Instructions (Document No. 065214) and the autosampler

operator’s manual. The manuals are included on the Dionex

Reference Library CD-ROM (P/N 053891). The ICS-900 Installation

Instructions are also included in the ICS-900 Ship Kit (P/N 067768).

2. Prepare and fill the sample vials and place them in the autosampler

tray or cassette. Refer to the autosampler manual for detailed

instructions.

3. Use one of the following methods to load sample into the injection

valve sample loop and inject it onto the column:

• Automatically: Include the Load and Inject commands in a

Chromeleon or Chromeleon Xpress program. See the examples in

Section 3.11.6

processing samples.

. See Section 3.11.3 for details about automatically

• Manually with an AS40: Start the AS40 load cycle (either

manually or with a relay). When the AS40 load cycle is complete,

click the Inject button on the ICS-900 Control panel (see

Figure 3-11

processing samples.

Figure 3-11. ICS-900 Control Panel Load and Inject Buttons

). See Section 3.11.2 for details about manually

• Manually with an AS or AS-DV: Click the Inject icon on the

Chromeleon tool bar or select Control>Inject. On the Inject

dialog box, enter the Position and Vo lu me and click OK.

44 Doc. 065215-02 9/09

Page 53

3 • Operation and Maintenance

Autosampler Setup Notes

Follow the steps below to verify that the ICS-900 injection valve is

controlled by the correct device.

1. Open the Chromeleon Server Configuration program.

2. Open the ICS-900 Properties dialog box and click Inject Valve.

3. Under Controlled by, check the device selected for

Pump_InjectValve:

• For an AS or AS-DV, verify that the AS is shown (see

Figure 3-12

).

Figure 3-12. ICS-900 Properties: Inject valve controlled by AS

• For an AS40, verify that the ICS-900 is shown (see Figure 3-13).

Figure 3-13. ICS-900 Properties: Inject Valve Controlled by ICS-900

4. To change the controlling device, select the Pump_InjectValve name

and press the F2 key. On the Device Configuration dialog box, select

the correct device from the Controlled By list. Click OK.

5. For an AS40, also verify that there is a relay connection from the

AS40 Load relay to the ICS-900 RELAY OUT 1. Refer to the

connection instructions in Section C.5

Doc. 065215-02 9/09 45

for details.

Page 54

ICS-900 Operator’s Manual

3.11.5 Loading and Injecting Samples with a Syringe

This section describes two methods for loading sample into the injection

valve sample loop with a syringe:

• Loading sample with a syringe through the sample loading port on the

front of the ICS-900 (push method)

• Loading sample with a vacuum syringe through the sample loading

port on the front of the ICS-900 (pull method)

NOTE For instructions on how to load and inject

samples with an autosampler, see Section 3.11.4

Loading Samples with a Syringe (Push Method)

1. Verify that the sample loading port on the front of the ICS-900 is

connected to sample port

Figure 3-14

).

2. Fill a syringe with a calibration standard or sample.

S (5) on the injection valve (see

.

3. Insert the syringe into the sample loading port on the front of the

ICS-900.

4. Verify that the injection valve is in the Load position. If it is not, click

the Load button on the ICS-900 Control panel (see Figure 3-11

).

5. Overfill the sample loop with five sample loop volumes. Remember

that the line from the syringe to the valve must be filled first before

the sample loop can be filled. Excess sample will exit through the

injection valve waste line.

6. Leave the syringe in the port. This prevents the sample from

siphoning out of the loop before injection.

7. Use one of the following methods to inject the sample onto the

column:

• Manually: Click the Inject button on the ICS-900 Control panel.

See Section 3.11.2

for details about manually processing samples.

• Automatically: Include the Inject command in a Chromeleon or

Chromeleon Xpress program. See the examples in Section 3.11.6

See Section 3.11.3

samples.

for details about automatically processing

.

46 Doc. 065215-02 9/09

Page 55

3 • Operation and Maintenance

Loading Samples with a Vacuum Syringe (Pull Method)

1. Verify that the sample loading port on the front of the ICS-900 is

connected to sample port

Figure 3-14

).

S (5) on the injection valve (see

2. Disconnect the waste line from port

W (6) on the injection valve and

attach a shorter line: 25 to 30 cm (10 to 12 in) of PEEK or Teflon®

tubing (see Figure 3-14

).

3. Place the free end of this line into the sample.

4. Verify that the injection valve is in the Load position. If it is not, click

the Load button on the ICS-900 Control panel (see Figure 3-11

).

5. Insert a syringe into the sample loading port on the front door and pull

out the plunger to draw the sample into the injection valve. Draw at

least five times the sample loop volume. Remember that the line from

the sample to port

W (6) on the injection valve must be filled first

before the sample loop can be filled.

Syringe

Sample

Loading Port

(on front door)

(4)(5)

L

S

C

(3)

(2)

P

Sample

W

(6)

(1)

L

Injection Valve

Figure 3-14. Loading Sample with a Vacuum Syringe (Pull Method)

Doc. 065215-02 9/09 47

Page 56

ICS-900 Operator’s Manual

6. Use one of the following methods to inject the sample onto the

column:

• Manually: click the Inject button on the ICS-900 Control panel.

See Section 3.11.2

for details about manually processing samples.

• Automatically: Include the Inject command in a Chromeleon or

Chromeleon Xpress program. See the examples in Section 3.11.6

See Section 3.11.3

for details about automatically processing

samples.

3.11.6 Example Chromeleon Commands for Loading and Injecting Samples

The following examples show commands for loading and injecting

samples using an AS, AS-DV, or AS40 autosampler.

Example AS Program Commands

0.000 Pump_ECD.Autozero ;Zero the baseline.

.

Load ;Switch the valve to Load.

Wait CycleTimeState ;Wait for cycle time (if any).

Inject ;Switch the valve to Inject.

Wait InjectState ;Wait for injection to complete.

ECD_1.AcqOn ;Start data acquisition.

14.000 ECD_1.AcqOff ;Stop data acquisition.

Example AS-DV Program Commands

Sampler.LoadPosition ;Switch the valve to Load.

DeliverSample ;Deliver sample to the valve.

0.000 Autozero ;Zero the baseline.

Wait CycleTimeState ;Wait for cycle time (if any).

Inject ;Switch the valve to Inject.

ECD_1.AcqOn ;Start data acquisition.

14.000 ECD_1.AcqOff ;Stop data acquisition.

48 Doc. 065215-02 9/09

Page 57

3 • Operation and Maintenance

Example AS40 Program Commands

-2.300 Pump_ECD_Relay_1.Closed Duration=138.00 ;Note 1

0.000 Pump_ECD.Autozero ;Note 2

ECD_1.AcqOn ;Note 3

Pump_InjectValve.InjectPosition Duration=30.00 ;Note 4

30.00 ECD_1.AcqOff ;Note 5

AS40 Program Command Notes:

1. Close the ICS-900 RELAY OUT 1, which is connected to the AS40

LOAD relay. This signals the AS40 to load the sample.

2. Zero the baseline.

3. Start data acquisition.

4. Switch the valve to Inject for 30 seconds.

5. Stop data acquisition.

3.12 Maintenance

This section describes routine maintenance procedures for the ICS-900 that users