Page 1

ICS-3000 Ion Chromatography System

Operator's Manual

Document No. 065031

Revision 04

January 2008

Page 2

© 2008 by Dionex Corporation

All rights reserved worldwide.

Printed in the United States of America.

This publication is protected by federal copyright law. No part of this publication

may be copied or distributed, transmitted, transcribed, stored in a retrieval system, or

transmitted into any human or computer language, in any form or by any means,

electronic, mechanical, magnetic, manual, or otherwise, or disclosed to third parties

without the express written permission of Dionex Corporation, 1228 Titan Way,

Sunnyvale, California 94088-3603 U.S.A.

DISCLAIMER OF WARRANTY AND LIMITED WARRANTY

THIS PUBLICATION IS PROVIDED “AS IS” WITHOUT WARRANTY OF

ANY KIND. DIONEX CORPORATION DOES NOT WARRANT,

GUARANTEE, OR MAKE ANY EXPRESS OR IMPLIED

REPRESENTATIONS REGARDING THE USE, OR THE RESULTS OF THE

USE, OF THIS PUBLICATION IN TERMS OF CORRECTNESS, ACCURACY,

RELIABILITY, CURRENTNESS, OR OTHERWISE. FURTHER, DIONEX

CORPORATION RESERVES THE RIGHT TO REVISE THIS PUBLICATION

AND TO MAKE CHANGES FROM TIME TO TIME IN THE CONTENT

HEREINOF WITHOUT OBLIGATION OF DIONEX CORPORATION TO

NOTIFY ANY PERSON OR ORGANIZATION OF SUCH REVISION OR

CHANGES.

TRADEMARKS

AES, Atlas, Chromeleon, EluGen, IonPac, OnGuard, and SRS are registered

trademarks of Dionex Corporation. CarboPac, MicroMembrane, MMS, ReagentFree, and RFIC are trademarks of Dionex Corporation.

Adobe, Adobe Reader, and Acrobat are registered trademarks of Adobe Systems,

Incorporated.

Kel-F is a registered trademark of 3M Corporation.

FastLock and MSQ Plus are trademarks of Thermo Electron Corporation.

PEEK is a trademark of Victrex PLC.

PharMed and Tygon are registered trademarks of Saint-Gobain Performance Plastics.

Teflon is a registered trademark of E.I. duPont de Nemours & Company.

TitanHP is a trademark of Rheodyne LLC

Ultem is a registered trademark of General Electric Company

PRINTING HISTORY

Revision 01, May 2005

Revision 02, July 2006

Revision 03, September 2006

Revision 04, January 2008

Page 3

1 • Introduction

1.1 ICS-3000 System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.1 ICS-3000 System Components . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1.2 ICS-3000 System Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2 ICS-3000 System Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3 The ICS-3000 System Operator’s Manual . . . . . . . . . . . . . . . . . . . . . . 11

1.3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3.2 Safety Messages and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.4 Safety and Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.4.1 Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Contents

2•Description

DP/SP Description

2.1 DP/SP Front Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.2 DP/SP Interior Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.2.1 Pump Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.2.2 Pressure Transducer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.2.3 Proportioning Valves (Gradient pump only) . . . . . . . . . . . . . . 20

2.2.4 Vacuum Degassing Module . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.2.5 Piston Seal Wash System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.2.6 Static Mixer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Doc. 065031-04 1/08 i

Page 4

ICS-3000 Ion Chromatography System

2.3 DP/SP Flow Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

2.3.1 Isocratic Pump Flow Schematic . . . . . . . . . . . . . . . . . . . . . . . .23

2.3.2 Gradient Pump Flow Schematic . . . . . . . . . . . . . . . . . . . . . . . .24

2.4 DP/SP Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

2.5 Eluent Reservoirs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

2.6 EO (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

EG Description

2.7 EG Front Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

2.8 EG Interior Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

2.9 EG Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

2.10 EG Flow Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

DC Description

2.11 DC Front Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

2.12 DC Interior Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

2.13 DC Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

2.14 Injection Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

2.14.1 Injection Valve Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

2.14.2 Injection Valve Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

2.15 CD Conductivity Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

2.15.1 Heated Conductivity Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

2.15.2 Suppressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

2.15.3 System Flow Schematic for Conductivity Detection . . . . . . . .56

2.16 ED Electrochemical Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

2.16.1 Amperometry Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

ii Doc. 065031-04 1/08

Page 5

Contents

2.16.2 Combination pH–Ag/AgCl Reference Electrode . . . . . . . . . . . 58

2.16.3 DC Amperometric Detection . . . . . . . . . . . . . . . . . . . . . . . . . . 60

2.16.4 Integrated and Pulsed Amperometric Detection . . . . . . . . . . . 61

2.16.5 Cyclic Voltammetry Detection . . . . . . . . . . . . . . . . . . . . . . . . . 63

2.16.6 Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

2.16.7 Storing and Reprocessing Amperometry Data . . . . . . . . . . . . . 68

2.17 Automation Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

2.17.1 High-Pressure Switching Valves . . . . . . . . . . . . . . . . . . . . . . . 74

2.17.2 Low-Pressure Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

2.17.3 High- and Low-Pressure Valve Control . . . . . . . . . . . . . . . . . . 76

2.17.4 RCH-1 Reaction Coil Heater . . . . . . . . . . . . . . . . . . . . . . . . . . 78

2.18 I/O Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

2.18.1 I/O Option Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

2.18.2 Analog Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

2.18.3 Power, Relay, and TTL Outputs . . . . . . . . . . . . . . . . . . . . . . . . 84

2.18.4 TTL Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

TC Description

2.19 TC Front Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

2.20 TC Interior Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

2.21 TC Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

2.22 Injection Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

2.22.1 Injection Valve Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

2.22.2 Injection Valve Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

2.23 Column Identification (ID) System . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Doc. 065031-04 1/08 iii

Page 6

ICS-3000 Ion Chromatography System

2.24 Gas and Humidity Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

2.25 Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

2.25.1 Predictive Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

3 • Configurations

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

4•Startup

4.1 Operating Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

4.1.1 EG Operating Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

4.1.2 ED Amperometry Cell Operating Precautions . . . . . . . . . . . .115

4.2 System Startup Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

4.3 Preparing Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

4.3.1 Collecting and Storing Samples . . . . . . . . . . . . . . . . . . . . . . .119

4.3.2 Pretreating Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

4.3.3 Diluting Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

4.3.4 Fill the Autosampler Vials and Load the Sample Tray . . . . . .120

DP/SP Startup

4.4 Set Up the Eluent Reservoirs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

4.5 Set Up the Piston Seal Wash System . . . . . . . . . . . . . . . . . . . . . . . . . .124

4.6 Start the Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

EG Startup

4.7 Setting the Eluent Concentration . . . . . . . . . . . . . . . . . . . . . . . . . . . . .131

iv Doc. 065031-04 1/08

Page 7

DC Startup

4.8 Start the DC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

4.9 Equilibrate the System and Verify Operational Readiness . . . . . . . . . 136

TC Startup

4.10 Start the TC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

4.11 Equilibrate the System and Verify Operational Readiness . . . . . . . . . 138

5 • Operation

5.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

5.2 Loading Samples with an Autosampler . . . . . . . . . . . . . . . . . . . . . . . . 140

5.3 Loading Samples with a Syringe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

5.3.1 Loading Samples with a Syringe (Push Method) . . . . . . . . . . 141

Contents

5.3.2 Loading Samples with a Vacuum Syringe (Pull Method) . . . 143

5.4 Example Commands for Loading and Injecting Samples . . . . . . . . . . 144

5.4.1 Commands for an AS Autosampler . . . . . . . . . . . . . . . . . . . . 144

5.4.2 Commands for an AS40 Autosampler . . . . . . . . . . . . . . . . . . 144

5.4.3 Commands for a Remote Inject Device . . . . . . . . . . . . . . . . . 145

5.5 Manual Sample Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

5.5.1 Saving Manual Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

5.6 Automatic (Batch) Sample Processing . . . . . . . . . . . . . . . . . . . . . . . . 147

5.6.1 Creating a New Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

5.6.2 Starting Batch Sample Processing . . . . . . . . . . . . . . . . . . . . . 149

Doc. 065031-04 1/08 v

Page 8

ICS-3000 Ion Chromatography System

6 • Shutdown

DP/SP Shutdown

EG Shutdown

6.1 Short-term Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .153

6.2 Long-term Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .153

DC Shutdown

6.3 Consumables Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .155

6.4 Amperometry Cell Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .155

6.4.1 Short-term Storage of the Amperometry Cell . . . . . . . . . . . . .155

6.4.2 Long-term Storage of the Amperometry Cell . . . . . . . . . . . . .155

TC Shutdown

6.5 Consumables Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .157

6.6 Short-term Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .157

6.7 Long-term Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .157

7 • Maintenance

7.1 System Maintenance Checklists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .159

7.1.1 Daily Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .159

7.1.2 Weekly Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .159

7.1.3 Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .160

7.1.4 Annual Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .160

DP/SP Routine Maintenance

7.2 DP/SP Daily Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .161

vi Doc. 065031-04 1/08

Page 9

Contents

7.3 DP/SP Weekly Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

7.4 DP/SP Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

7.5 DP/SP Annual Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

EG Routine Maintenance

7.6 EG Daily Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

7.7 EG Weekly Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

7.8 EG Annual Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

DC Routine Maintenance

7.9 DC Daily Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

7.10 DC Weekly Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

7.11 DC Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

7.12 DC Annual Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

TC Routine Maintenance

7.13 TC Daily Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

7.14 TC Weekly Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

7.15 TC Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

7.16 TC Annual Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

8 • Troubleshooting

8.1 Audit Trail Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

8.1.1 DP/SP Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

8.1.2 EG Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

8.1.3 DC Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Doc. 065031-04 1/08 vii

Page 10

ICS-3000 Ion Chromatography System

8.1.4 TC Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .173

8.2 Noisy Baseline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .178

8.3 Poor Retention Time Reproducibility . . . . . . . . . . . . . . . . . . . . . . . . . .181

8.4 Peak Retention Times Are Too Early . . . . . . . . . . . . . . . . . . . . . . . . . .183

8.5 Peak Retention Times Are Too Late . . . . . . . . . . . . . . . . . . . . . . . . . .183

8.6 No Peaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .183

8.7 Tailing Peaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .185

8.8 Low System Backpressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .185

8.9 High System Backpressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .186

8.10 Low Detector Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .186

8.11 High Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .187

DP/SP Troubleshooting

8.12 Troubleshooting DP/SP Error Messages . . . . . . . . . . . . . . . . . . . . . . .189

8.13 DP/SP Does Not Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .197

8.14 DP/SP Stops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .198

8.15 DP/SP Liquid Leaks/Leak Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . .199

8.16 Vacuum Degassing Module Low Vacuum . . . . . . . . . . . . . . . . . . . . . .201

8.17 Vacuum Degassing Module Does Not Run . . . . . . . . . . . . . . . . . . . . .201

8.18 DP/SP Digital I/O Port Inoperative . . . . . . . . . . . . . . . . . . . . . . . . . . .201

EG Troubleshooting

8.19 Troubleshooting EG Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . .203

8.20 EG ALARM LED Is Lighted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .207

8.21 EG POWER LED Fails to Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .208

8.22 Liquid Leaks in the EG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .208

viii Doc. 065031-04 1/08

Page 11

Contents

8.23 No Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

8.24 EG Stops Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

DC Troubleshooting

8.25 Troubleshooting DC Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . 213

8.26 Liquid Leaks from DC Components . . . . . . . . . . . . . . . . . . . . . . . . . . 221

8.27 VALVE Button Not Working . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

8.28 Amperometry Cell Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 223

8.28.1 Amperometry Cell pH Readout Always 7.0 . . . . . . . . . . . . . 223

8.28.2 Cannot Set Amperometry Cell pH Readout to 7.0 . . . . . . . . . 224

8.28.3 Shift in Amperometry Cell pH Readout . . . . . . . . . . . . . . . . . 224

8.28.4 No Amperometry Cell pH Readout or Intermittent Readout . 225

8.28.5 Leak in pH Reference Electrode Compartment . . . . . . . . . . . 225

8.28.6 Shift in Ag/AgCl Reference Potential . . . . . . . . . . . . . . . . . . 226

TC Troubleshooting

8.29 Troubleshooting TC Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . 227

8.30 TC ALARM LED Is Lighted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

8.31 Liquid Leaks from TC Components . . . . . . . . . . . . . . . . . . . . . . . . . . 253

8.32 TC Temperature Does Not Increase . . . . . . . . . . . . . . . . . . . . . . . . . . 254

8.33 TC Temperature Stabilizer Not Operating Properly . . . . . . . . . . . . . . 255

9•Service

DP/SP Service

9.1 Replacing Tubing and Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

9.2 Cleaning Eluent Reservoirs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Doc. 065031-04 1/08 ix

Page 12

ICS-3000 Ion Chromatography System

9.3 Priming the DP/SP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .259

9.3.1 Priming with the

PUMP PRIME Button . . . . . . . . . . . . . . . . .259

9.3.2 Priming from the Control Panel . . . . . . . . . . . . . . . . . . . . . . .261

9.4 Replacing the Check Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .262

9.5 Replacing a Piston Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .265

9.5.1 Removing the Pump Head and Piston . . . . . . . . . . . . . . . . . . .265

9.5.2 Cleaning the Piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .268

9.5.3 Removing the Main Piston Seal . . . . . . . . . . . . . . . . . . . . . . .268

9.5.4 Removing the Piston Seal Wash Seal . . . . . . . . . . . . . . . . . . .269

9.5.5 Installing the Piston Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . .269

9.5.6 Reinstalling the Piston and Pump Head . . . . . . . . . . . . . . . . .270

9.6 Replacing the Piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .271

9.6.1 Removing the Pump Head and Piston . . . . . . . . . . . . . . . . . . .271

9.6.2 Installing the New Piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . .273

9.6.3 Reinstalling the Pump Head . . . . . . . . . . . . . . . . . . . . . . . . . .273

9.7 Replacing the Piston Seal Wash Tubing . . . . . . . . . . . . . . . . . . . . . . . .274

9.8 Replacing the DP/SP Priming Valve Knob Seal . . . . . . . . . . . . . . . . .276

9.9 Changing the DP/SP Main Power Fuses . . . . . . . . . . . . . . . . . . . . . . .278

EG Service

9.10 Replacing Tubing and Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .281

9.11 Isolating a Restriction in the Liquid Lines . . . . . . . . . . . . . . . . . . . . . .282

9.12 Replacing the EluGen Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .282

9.12.1 EG Flow Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .283

9.12.2 Removing the Old EluGen Cartridge . . . . . . . . . . . . . . . . . . .284

x Doc. 065031-04 1/08

Page 13

Contents

9.12.3 Disposing of the Old EluGen Cartridge . . . . . . . . . . . . . . . . . 286

9.12.4 Installing the New EluGen Cartridge . . . . . . . . . . . . . . . . . . . 286

9.12.5 Conditioning the New EluGen Cartridge . . . . . . . . . . . . . . . . 288

9.12.6 Completing the EluGen Cartridge Installation . . . . . . . . . . . . 289

9.13 Replacing the CR-TC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

9.13.1 Removing the Old CR-TC . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

9.13.2 Installing and Hydrating the New CR-TC . . . . . . . . . . . . . . . 291

9.13.3 Completing the New CR-TC Plumbing . . . . . . . . . . . . . . . . . 292

9.14 Replacing the RFIC Eluent Degasser . . . . . . . . . . . . . . . . . . . . . . . . . 294

9.15 Installing a Backpressure Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

9.16 Changing the EG Main Power Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . 296

DC Service

9.17 Replacing Tubing and Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

9.18 Replacing the Leak Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

9.19 Rebuilding a High-Pressure (Injection) Valve . . . . . . . . . . . . . . . . . . 300

9.20 Replacing a High-Pressure (Injection) Valve Pod . . . . . . . . . . . . . . . . 302

9.21 Installing or Replacing an I/O Option Board . . . . . . . . . . . . . . . . . . . 305

9.22 Changing the DC Main Power Fuses . . . . . . . . . . . . . . . . . . . . . . . . . 307

9.23 CD Service Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

9.23.1 Calibrating the CD Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

9.23.2 Replacing a Suppressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

9.23.3 Replacing a CD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

9.23.4 Removing Trapped Air from the Conductivity Cell . . . . . . . 312

9.24 ED Service Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

Doc. 065031-04 1/08 xi

Page 14

ICS-3000 Ion Chromatography System

9.24.1 Disconnecting the Amperometry Cell . . . . . . . . . . . . . . . . . . .313

9.24.2 Replacing an Amperometry Cell Gasket . . . . . . . . . . . . . . . . .314

9.24.3 Polishing an Amperometry Cell Working Electrode . . . . . . . .317

9.24.4 Replacing an Amperometry Cell Reference Electrode . . . . . .320

9.24.5 Calibrating the Reference Electrode . . . . . . . . . . . . . . . . . . . .322

9.24.6 Replacing the Reference Electrode O-Ring . . . . . . . . . . . . . .324

9.24.7 Replacing an ED Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . .326

TC Service

9.25 Replacing Tubing and Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .327

9.26 Setting Up the Column ID System . . . . . . . . . . . . . . . . . . . . . . . . . . . .328

9.27 Rebuilding an Injection Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .330

9.28 Replacing an Injection Valve Pod . . . . . . . . . . . . . . . . . . . . . . . . . . . .331

9.29 Changing the Main Power Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . .334

A • Specifications

DP/SP Specifications

A.1 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .335

A.2 Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .335

A.3 Physical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .335

A.4 Hydraulics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .336

A.5 Computer Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .337

A.6 I/O Interfaces and Inputs/Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . .337

EG Specifications

A.7 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .339

xii Doc. 065031-04 1/08

Page 15

Contents

A.8 Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

A.9 Physical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

A.10 EluGen Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 340

DC Specifications

A.11 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

A.12 Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

A.13 Physical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

A.14 Lower Compartment Components . . . . . . . . . . . . . . . . . . . . . . . . . . . 342

A.15 Temperature Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 342

A.15.1 Upper Compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 342

A.15.2 Lower Compartment (Optional) . . . . . . . . . . . . . . . . . . . . . . . 343

A.16 ICS-3000 Automation Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

A.16.1 RCH-1 Reaction Coil Heater. . . . . . . . . . . . . . . . . . . . . . . . . . 343

A.16.2 Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

A.17 ICS-3000 Conductivity Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344

A.18 ICS-3000 Electrochemical Detector . . . . . . . . . . . . . . . . . . . . . . . . . . 345

TC Specifications

A.19 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

A.20 Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

A.21 Physical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

A.22 Thermal Compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 348

B • Reordering Information

DP/SP Reordering Information

Doc. 065031-04 1/08 xiii

Page 16

ICS-3000 Ion Chromatography System

EG Reordering Information

DC Reordering Information

TC Reordering Information

xiv Doc. 065031-04 1/08

Page 17

1.1 ICS-3000 System Overview

1 • Introduction

Chromeleon®/Chromeleon

Xpress Monitor

ICS-3000 Eluent

Organizer

AS Autosampler

ICS-3000 Dual

ICS-3000

Detector/Chromatography

Module

Pump

ICS-3000 Eluent

Generator

Figure 1-1. ICS-3000 System for Dual-Analysis RFIC

The Dionex ICS-3000 Ion Chromatography System offers a full range of Reagent-

™ IC (RFIC™) components. RFIC combines automated eluent generation

Free

and self-regenerating suppression to make IC easier and more powerful than ever

Doc. 065031-04 1/08 1

Page 18

ICS-3000 Ion Chromatography System

before. It is no longer necessary to spend time preparing eluents and regenerants.

All you need is deionized water—the IC system automatically generates eluent in

the exact amount and concentration needed for your application, ensuring superior

analytical results.

The dual-analysis capabilities (both simultaneous and sequential) of the ICS-3000

system let you maximize efficiency and throughput and minimize downtime. The

modular system design lets you quickly configure and customize hardware.

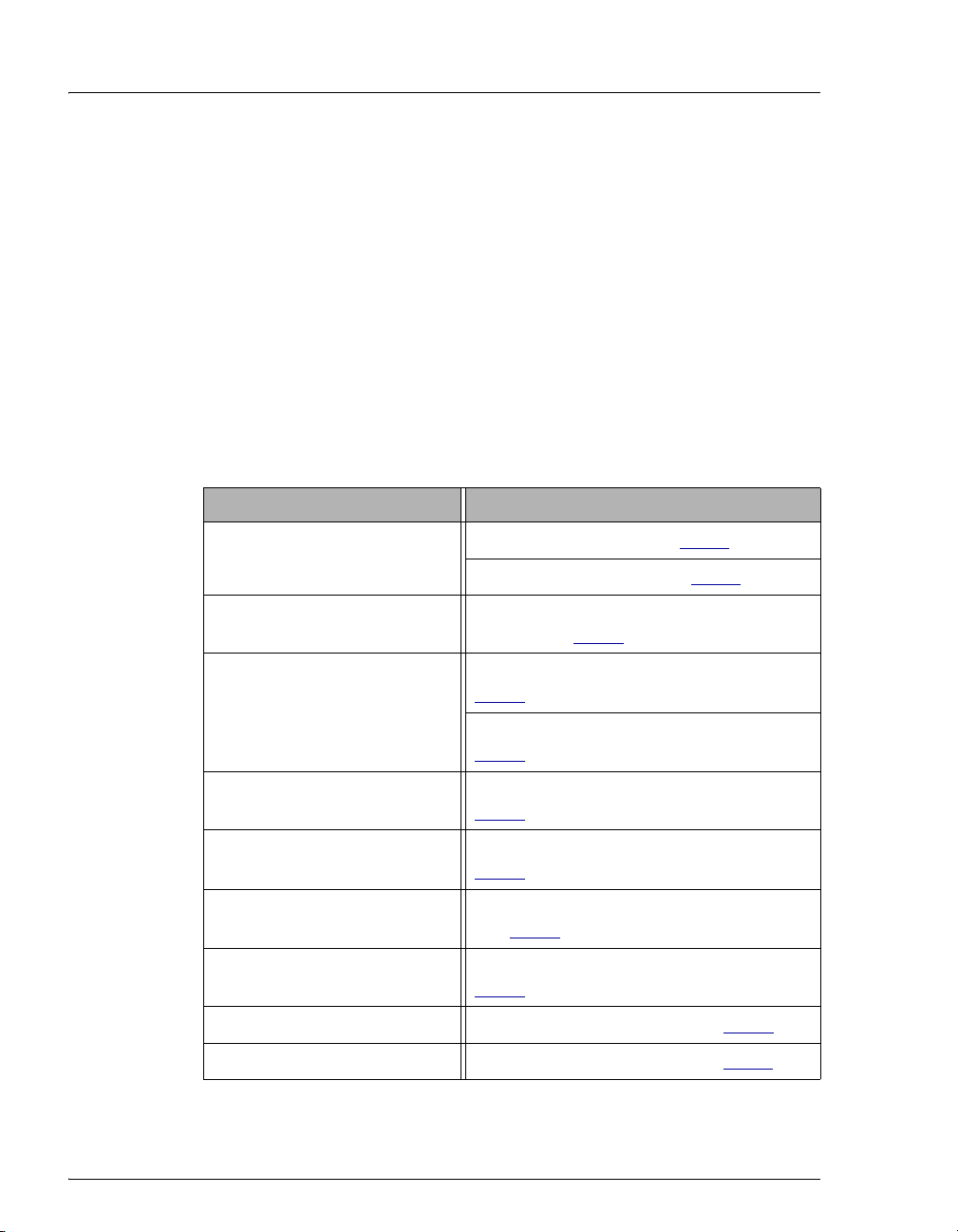

1.1.1 ICS-3000 System Components

The table below identifies modules in the ICS-3000 product line, as well

as additional products that can be added to an ICS-3000 system. Refer to

the page number indicated here for a brief product overview.

Product Type Product Name

Pump

Detector/Chromatography

Compartment

Detector (inside DC)

Accessory (inside DC)

Detector (outside DC)

Thermal Compartment

Eluent Generator

Eluent Organizer

ICS-3000 Dual Pump (see page 3)

ICS-3000 Single Pump (see page 3

ICS-3000 Detector/Chromatography

Module (see page 3

ICS-3000 Conductivity Detector (see

page 4

)

ICS-3000 Electrochemical Detector (see

page 4

)

ICS-3000 Automation Manager (see

page 4

)

ICS-Series Photodiode Array Detector (see

page 7

)

ICS-Series Variable Wavelength Detector

(see page 7

ICS-3000 Thermal Compartment (see

page 4

ICS-3000 Eluent Generator (see page 5)

ICS-3000 Eluent Organizer (see page 5)

)

)

)

)

2 Doc. 065031-04 1/08

Page 19

1 • Introduction

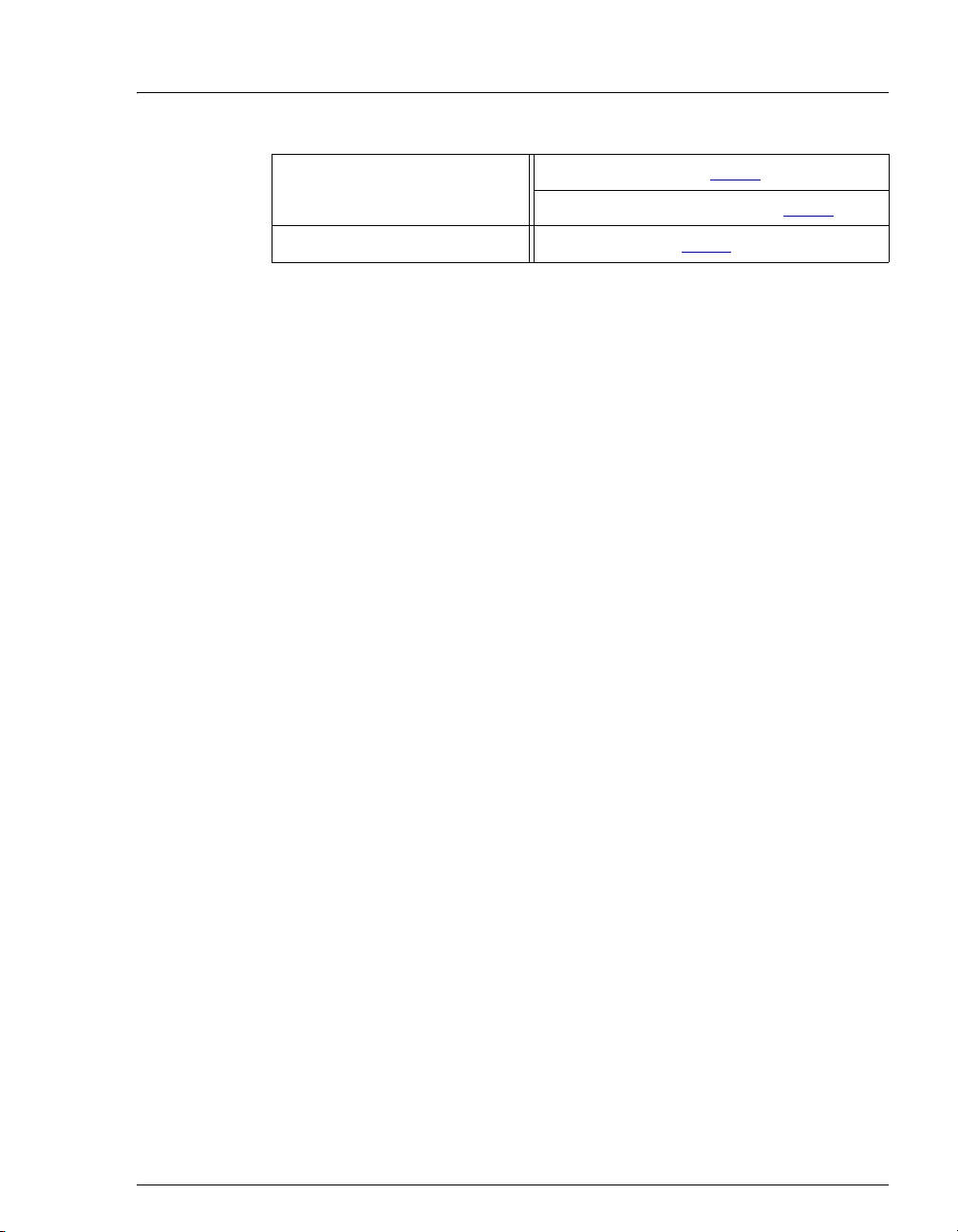

Autosampler

Mass Spectrometer

ICS-3000 Dual Pump (DP) and ICS-3000 Single Pump (SP)

AS Autosampler (see page 6)

AS40 Automated Sampler (see page 7

MSQ Plus™ (see page 8)

)

With flow rates ranging from 0.001 to 10.0 mL/min and operating

pressures up to 35 MPa (5000 psi), the DP/SP is designed for both

standard bore and microbore applications. The pump’s patented isokinetic

pre-compression phase allows a precise, almost pulse-free flow.

The SP contains one isocratic pump or one gradient pump. The DP

contains two gradient pumps, two isocratic pumps, or one isocratic pump

and one gradient pump.

The isocratic pump delivers one eluent, while the gradient pump can

deliver gradient mixtures of up to four eluent components. The selected

eluent composition can be delivered as isocratic, isocratic proportioned,

linear ramp, step, curved, or any combination of these.

With a DP, the second pump can be operated as a second-channel

chromatography pump, an auxiliary dependent pump, or an auxiliary

independent pump.

ICS-3000 Detector/Chromatography Module (DC)

The DC provides a temperature-controlled environment for ICS-3000

chromatography components. The DC can accommodate components for

two channels, plumbed either serially or in parallel.

The following components may be installed in the DC:

• Conductivity detector

• Electrochemical detector

• Injection valves

• Switching valves

• Guard and separator columns

• Suppressors

• ICS-3000 Automation Manager

Doc. 065031-04 1/08 3

Page 20

ICS-3000 Ion Chromatography System

ICS-3000 Conductivity Detector (CD)

The CD is a modular detector with integrated cell providing dual

detection capabilities (series or parallel). The CD has a signal range up to

15,000

The CD is installed in the upper compartment of the DC.

ICS-3000 Electrochemical Detector (ED)

The ED is a modular detector and cell with dual-detection capabilities

(series or parallel). The ED supports multiple waveforms, multiple

integration times, and post-analysis data manipulation. The ED is also

capable of providing 3D amperometry data. The ED cell can be

configured with gold, silver, platinum, or glassy carbon working

electrodes. The ED is installed in the upper compartment of the DC.

ICS-3000 Automation Manager (AM)

The AM consists of a component mounting panel on a base tray. The AM

provides mounting sites for sample preparation and post-column

application components: high-pressure (switching) valves, low-pressure

(solenoid) valves, reaction coils, etc. The AM is installed in the upper

compartment of the DC, above the detector.

μS and supports high background, nonsuppressed applications.

ICS-3000 Thermal Compartment (TC)

The TC provides a temperature-controlled environment for ICS-3000

chromatography components. The TC is intended for applications that do

not require conductivity or electrochemical detection.

The TC is available in four configurations:

• With one 2-position, 6-port high-pressure injection valve

• With two 2-position, 6-port high-pressure injection valves

• With one 2-position, 6-port high-pressure injection valve and one 2-

position, 10-port high-pressure injection valve

• With no injection valves

An optional temperature stabilizer (standard bore, P/N 064548;

microbore, P/N 064650) can be installed inside the TC, if necessary. The

temperature stabilizer brings the eluent to the column temperature before

it enters the column.

4 Doc. 065031-04 1/08

Page 21

1 • Introduction

ICS-3000 Eluent Generator (EG)

The EG generates high purity acid or base eluents online from deionized

water. The EG can be configured for single- or dual-channel operation.

Each channel includes:

• A high precision programmable current source (power supply)

• A high pressure gas removal device that removes electrolysis gases

created during eluent generation

The following options must be ordered separately for installation inside

the EG:

• A disposable EluGen® cartridge to generate eluent. Each cartridge

contains 900 mL of the appropriate electrolyte concentrate solution.

• A Continuously Regenerated Trap Column (CR-TC) to remove any

extraneous contaminants from the deionized water source. The CRTC is electrolytically-regenerated, which allows it to operate for

extended periods without chemical regeneration.

ICS-3000 Eluent Organizer (EO)

The EO holds eluent reservoirs in a liner that contains spills and leaks. Up

to two EOs can be installed on top of the DC. Each EO accommodates up

to four 1-liter or 2-liter reservoirs or up to two 4-liter reservoirs. The EO

is typically ordered configured with four 2-liter reservoirs (P/N 062629).

All eluent reservoirs available for use with the DP/SP can be pressurized.

If you plan to pressurize the eluent reservoirs, the optional EO Regulator

Accessory and Stand (P/N 063493) is required.

The Regulator Accessory includes a pressure regulator and gauge

assembly with four outputs (for connections to four eluent reservoirs), as

well as the tubing and connection fitting required. If more reservoirs are

required, order a second regulator (P/N 064387).

Doc. 065031-04 1/08 5

Page 22

ICS-3000 Ion Chromatography System

AS Autosampler (AS)

The AS is a powerful, full-featured autosampler that precisely delivers

from 1.0 to 99.9 µL (in 0.1 µL increments) or 100 to 1000 µL (in 1 µL

increments) of sample to an injection valve. The autosampler can operate

in several modes:

• Concentrate—Sample is delivered to a single analytical system for

trace analysis and matrix elimination; a concentrator column is

installed on the injection valve in place of a loop.

• Simultaneous—Sample is delivered to two analytical systems

simultaneously; a sample loop is installed on each injection valve.

Sample is delivered equally to the two systems (50% of the volume to

each), allowing two complete, separate analyses to be performed with

just one sample.

• Sequential—Sample is delivered to two analytical systems in

sequence. This allows on-demand injection of two independent

samples to two applications, using one autosampler. While the first

system is being analyzed, the second system is being prepped and

loaded for sample analysis.

• Sequential Concentrate—Sample is delivered to two analytical

systems in sequence; a concentrator column is installed on the

injection valve in place of a loop.

• Reagent Prime (available in Concentrate mode only)—Primes the

lines with reagent. For example, implementing the Reagent Prime

mode during the matrix elimination step ensures that the appropriate

reagent is in line for matrix elimination and prevents crosscontamination between reagents.

• Reagent Flush (available in Concentrate mode only)—Flushes the

concentrator column with reagent (for example, a known source of

clean deionized water) to remove unwanted sample matrix.

6 Doc. 065031-04 1/08

Page 23

1 • Introduction

AS40 Automated Sampler (AS40)

The AS40 is a low-cost, metal-free, sample loading device designed for

ion chromatography applications. The AS40 is capable of delivering

between 0.2 and 5.0 mL of sample in set increments. The AS40 holds

between 66 and 88 vials, depending upon the vial size in use: 0.5 mL,

5.0 mL, or a combination of both sizes. Up to three injections can be

taken from each vial.

The AS40 holds up to 11 cassettes of six 5-mL vials or eight 0.5-mL vials.

Each sample is filtered during loading through a 20-µm filter in the vial

cap, so there is no need to prefilter samples. Samples can be loaded

against backpressures up to 690 kPa (100 psi) without an external

sampling pump, thus facilitating preconcentration work.

ICS-Series Photodiode Array Detector (PDA)

The PDA optical detector is capable of measuring the absorbance

spectrum from 190 to 800 nm. A deuterium lamp optimizes the UV range

(190 to 380 nm) and a tungsten lamp optimizes the visible range (380 to

800 nm).

The PDA enables you to collect up to five single wavelengths (2D

chromatograms) without being required to collect 3D data. Collecting

individual wavelengths instead of the spectra offers two advantages: it

eliminates the need to perform extractions for analyses that do not require

spectral data and it conserves disk space.

ICS-Series Variable Wavelength Detector (VWD)

The VWD is a dual-beam, variable wavelength photometer with one

measurement and one internal reference beam. Spectral capability from

190 to 900 nm is provided by two light sources: a deuterium lamp for

ultraviolet detection and a tungsten lamp for visible wavelength

operation. The four-channel detector measures at up to four wavelengths

simultaneously. The VWD contains a built-in holmium oxide filter for

wavelength verification. To suppress higher-order radiation, two optical

filters can be inserted (automatically) into the light path.

Doc. 065031-04 1/08 7

Page 24

ICS-3000 Ion Chromatography System

MSQ Plus Mass Spectrometer

The MSQ Plus is an advanced analytical instrument that includes an MS

detector, vacuum pumps, and data system. When integrated with an IC

system, the MSQ Plus provides the separation capability of an IC and the

detection capability of a single-quadrupole MS detector. This provides a

strong starting point for sample analysis by offering a quick and clear

mass identification for chromatographic peaks.

The MS detector contains an atmospheric pressure ionization (API)

source, advanced high efficiency transmission ion optics of a square

quadrupole RF lens and dual RF generators, a mass analyzer, and an ion

detection system. An optional cone wash pump is available for improved

performance when dealing with dirty matrices.

The MS detector is equipped with FastLock™ probes for two

complementary ionization techniques: atmospheric pressure chemical

ionization (APCI) and electrospray ionization (ESI). Both ionization

techniques can be run in either the positive or negative ion polarity mode.

The design of the interchangeable probes enables rapid switching of

ionization modes.

During a scan, ions of selected mass-to-charge ratios are sequentially

transmitted through a quadrupole mass filter analyzer. The MS detector

has fully automatic mass scale calibration (15 to 2000 m/z) and tuning

that makes optimization simple and direct. The MS detector can perform

both full-range scans and selected ion monitoring (SIM) scans. When

operating in conjunction with Chromeleon, the MSQ Plus can be set up to

vary the scan type, the ionization technique, and the ion polarity mode.

8 Doc. 065031-04 1/08

Page 25

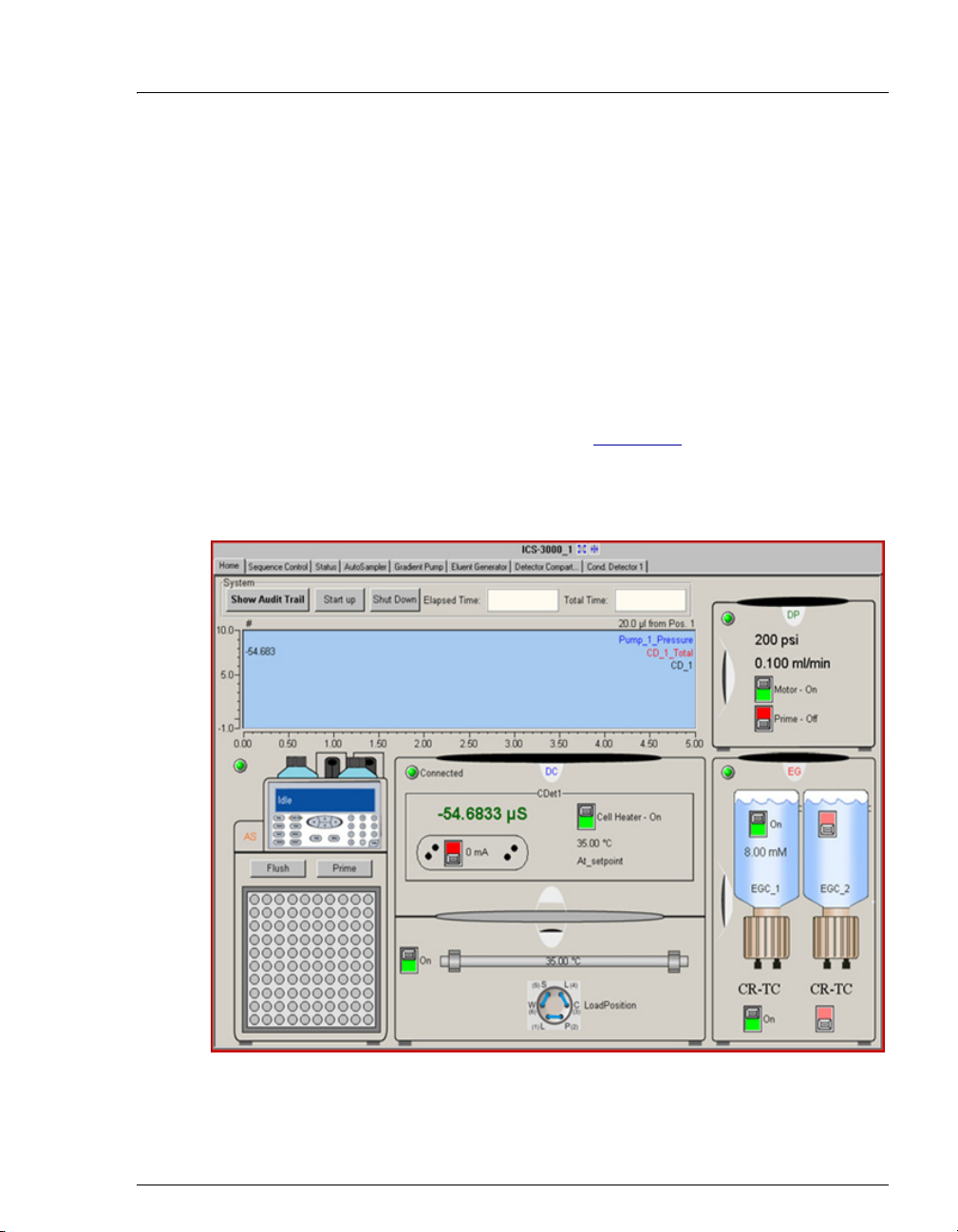

1.1.2 ICS-3000 System Control

The ICS-3000 system is controlled by a PC configured with Chromeleon

Chromatography Management System (version 6.7 or later) or

Chromeleon Xpress. The Chromeleon

System provides complete instrument control, data acquisition, and data

management. Chromeleon Xpress

monitoring of Dionex chromatography instruments, but does not

include data management capabilities.

Chromeleon and Chromeleon Xpress provide a panel tabset that replaces

and combines the module front panels into one centralized system control

panel. A convenient Home panel (see Figure 1-2

system status. Individual tabs provide quick access to module functions,

as well as detailed status and diagnostics.

1 • Introduction

Chromatography Management

provides real-time control and

) shows the overall

Figure 1-2. ICS-3000 Panel Tabset (Home Panel Shown)

Doc. 065031-04 1/08 9

Page 26

ICS-3000 Ion Chromatography System

1.2 ICS-3000 System Documentation

Every effort has been made to provide complete and accurate user documentation

for the ICS-3000 system. The table below lists the primary sources of product

information and the formats in which information is available.

Source Part

Number

ICS-3000 Ion Chromatography System

Operator’s Manual

Installing the ICS-3000 Ion Chromatography

System

AS Autosampler Operator’s Manual 065051 Yes No

ICS-Series Photodiode Array Detector

Operator’s Manual

ICS-Series Variable Wavelength Detector

Operator’s Manual

Chromeleon Xpress Quick Reference Guide 065070 Yes No

Chromeleon Xpress online Help N/A N/A N/A

Chromeleon Software User’s Guide

Installing the Chromeleon Chromatography

Management System with a Dionex Ion

Chromatograph (IC)

Chromeleon online Help N/A N/A N/A

065031 Yes No

065032 Yes Yes

065147 Yes No

065141 Yes No

4829.5060

031883 Yes Yes

PDF

File

Ye s N o

Printed

Manual

All Adobe

® PDF files listed above are shipped on the Dionex Reference Library

CD-ROM (P/N 053891), which is included in the ship kit of each ICS-3000

system module. In addition, the software manuals are provided as PDF files on the

Chromeleon or Chromeleon Xpress CD-ROM.

A printed copy of the software installation instructions is provided in the software

ship kit.

Consumables documentation: For complete information about Dionex columns,

suppressors, EluGen cartridges, etc., refer to the appropriate product manual.

These manuals are provided on the Reference Library CD-ROM.

10 Doc. 065031-04 1/08

Page 27

1.3 The ICS-3000 System Operator’s Manual

1.3.1 Overview

The electronic version (i.e., PDF file) of the ICS-3000 system operator’s

manual contains numerous hypertext links that can take you to other

locations within the file. These links include:

• Table of contents entries

• Index entries

• Cross-references (underlined in blue) to sections, figures, tables, etc.

If you are not familiar with how to navigate PDF files, refer to the Help

system for Adob

e® Acrobat® or Adobe Reader® for assistance.

1 • Introduction

Chapter 1

Introduction

Chapter 2

Description

Chapter 3

System

Configurations

Chapter 4

Getting Started

Chapter 5

Operation

Chapter 6

Shutdown

Chapter 7

Maintenance

An overview of the ICS-3000 system; includes a

brief description of the ICS-3000 modules, the

software required for ICS-3000 operation, and the

ICS-3000 user manuals.

Detailed descriptions of ICS-3000 system

components and important operating features;

includes an introduction to Chromeleon and

Chromeleon Xpress software.

Detailed illustrations of component plumbing for

several different ICS-3000 system configurations.

Tasks to be performed before beginning operation

of the ICS-3000 system.

Instructions for routine operation of the ICS-3000

system with Chromeleon or Chromeleon Xpress

software.

Short-term and long-term shutdown procedures

for the ICS-3000 system.

Routine preventive maintenance procedures for

the ICS-3000 system.

Doc. 065031-04 1/08 11

Page 28

ICS-3000 Ion Chromatography System

Chapter 8

Troubleshooting

Minor problems that may occur during operation

of the ICS-3000 system, with step-by-step

procedures for how to isolate and eliminate the

cause of each problem. Includes a list of

Chromeleon and Chromeleon Xpress Audit Trail

error messages, with an explanation of the

possible cause of each message and the corrective

action to take.

Chapter 9

Service

Step-by-step instructions for routine service and

parts replacement procedures the user can

perform for the ICS-3000 system.

Appendix A

Specifications

Appendix B

Reordering

Information

Specifications and installation site requirements

for the ICS-3000 modules.

Spare parts for the ICS-3000 modules.

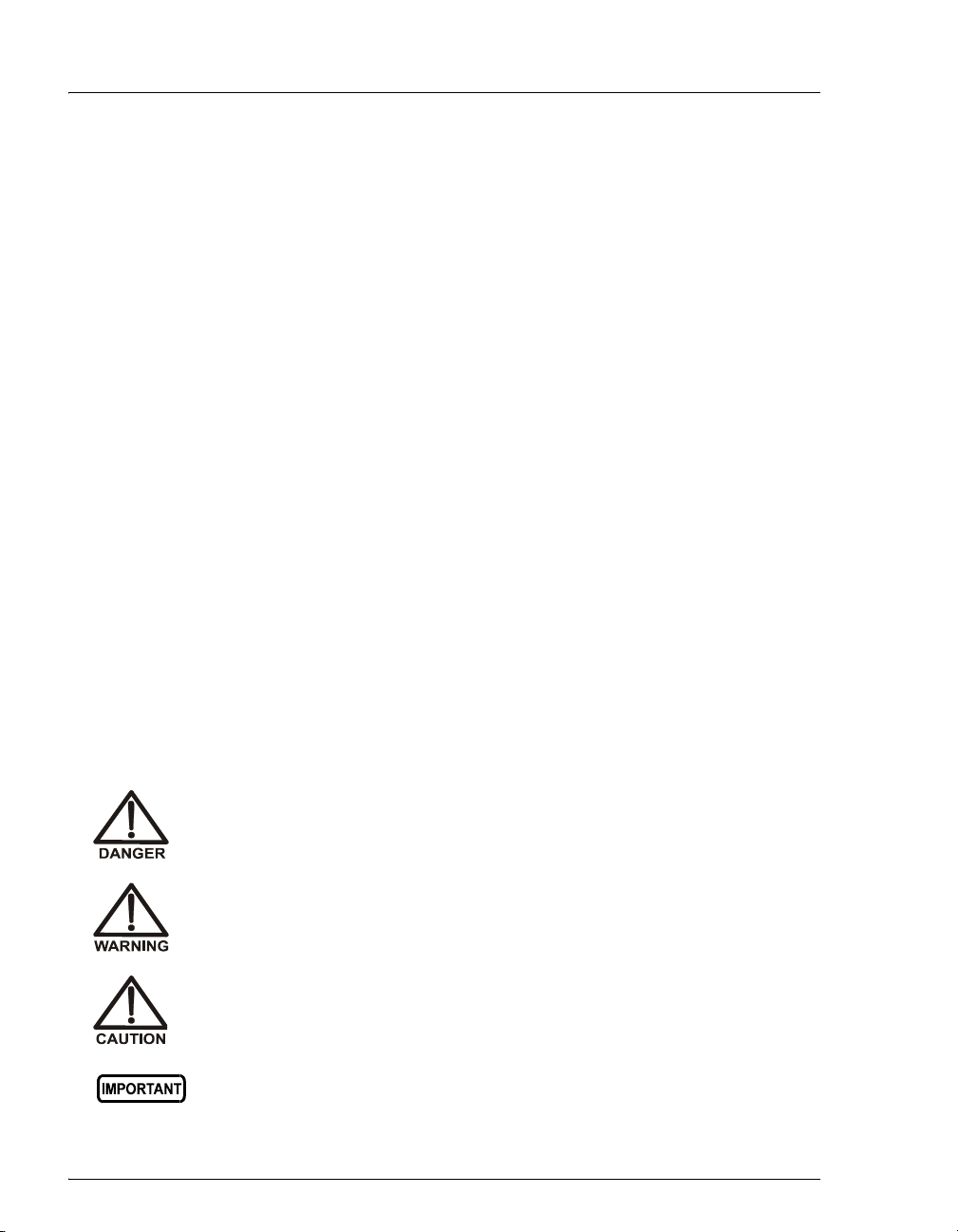

1.3.2 Safety Messages and Notes

This manual contains warnings and precautionary statements that can

prevent personal injury and/or damage to the ICS-3000 system when

properly followed. Safety messages appear in bold type and are

accompanied by icons, as shown below.

Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury. Also used to identify a situation or

practice that may seriously damage the instrument, but will not cause

injury.

Indicates that the function or process of the instrument may be

impaired. Operation does not constitute a hazard.

12 Doc. 065031-04 1/08

Page 29

1 • Introduction

Messages d'avertissement en français

Signale une situation de danger immédiat qui, si elle n'est pas évitée,

entraînera des blessures graves à mortelles.

Signale une situation de danger potentiel qui, si elle n'est pas évitée,

pourrait entraîner des blessures graves à mortelles.

Signale une situation de danger potentiel qui, si elle n'est pas évitée,

pourrait entraîner des blessures mineures à modérées. Également

utilisé pour signaler une situation ou une pratique qui pourrait

gravement endommager l'instrument mais qui n'entraînera pas de

blessures.

Warnhinweise in Deutsch

Bedeutet unmittelbare Gefahr. Mißachtung kann zum Tod oder

schwerwiegenden Verletzungen führen.

Bedeutet eine mögliche Gefährdung. Mißachtung kann zum Tod oder

schwerwiegenden Verletzungen führen.

Bedeutet eine mögliche Gefährdung. Mißachtung kann zu kleineren

oder mittelschweren Verletzungen führen. Wird auch verwendet, wenn

eine Situation zu schweren Schäden am Gerät führen kann, jedoch

keine Verletzungsgefahr besteht.

Doc. 065031-04 1/08 13

Page 30

ICS-3000 Ion Chromatography System

Notes

Informational messages also appear throughout this manual. These are

labeled NOTE and are in bold type:

NOTE NOTES call attention to certain information. They

alert you to an unexpected result of an action,

suggest how to optimize instrument performance,

etc.

1.4 Safety and Regulatory Information

The ICS-3000 system is designed for IC (ion chromatography) and HPLC (highperformance liquid chromatography) applications and should not be used for any

other purpose. Operation of an ICS-3000 module in a manner not specified by

Dionex may result in personal injury.

1.4.1 Safety Labels

The TUV GS, C, US Mark safety label and the CE Mark label on the ICS3000 modules indicate that they are in compliance with the following

standards:

EMC Susceptibility and Immunity

• (DC, EG, DP, SP) EN 61326 1997 including A1:1998 and A2:2001

• (TC) EN 61326 1997 including A1:1998, A2:2001, and A3:2003

Safety

• (DC, EG, DP, SP) EN 61010-1:2001, UL 61010-1:2004, CAN/CSA-

C22.2 61010-1:2004

• (TC) EN 61010-1:2001, UL 61010A:2002, CAN/CSA-C22.2 61010-

1:2004

NOTE The TC does not carry the TUV GS Mark safety

label.

14 Doc. 065031-04 1/08

Page 31

1 • Introduction

These symbols appear on the ICS-3000 modules or on labels affixed to

the modules:

Alternating current

˜

Protective conductor terminal

Power supply is on

Power supply is off

Indicates a potential hazard. Refer to this operator’s manual

for an explanation of the hazard and how to proceed.

Doc. 065031-04 1/08 15

Page 32

ICS-3000 Ion Chromatography System

16 Doc. 065031-04 1/08

Page 33

DP/SP Description

2.1 DP/SP Front Features

A status bar on the front of the ICS-3000 Dual Pump (DP) and ICS-3000 Single

Pump (SP) includes buttons for controlling certain pump functions, as well as

LEDs (light emitting diodes) that indicate the status of several pump functions

(see Figure 2-1

and Figure 2-2).

2 • Description

CONNECTED

CONNECTED

ALARM

ALARM

FLOW PRIME

PUMP 1 PUMP 2

FLOW PRIME

Figure 2-1. DP Status Bar

PRIME

FLOW

PUMP 1

Figure 2-2. SP Status Bar

Doc. 065031-04 1/08 17

Page 34

ICS-3000 Ion Chromatography System

Button/LED Label If the LED Is On If the LED Is Flashing

CONNECTED

The DP/SP is connected to a

Chromeleon or Chromeleon

Xpress timebase.

Does not flash.

ALARM

A DP/SP-related problem has

Does not flash.

occurred (for example, a

pressure limit was activated).

Check the Chromeleon or

Chromeleon Xpress Audit

Trail for the cause.

PUMP 1 FLOW*

PUMP 2 FLOW**

PUMP 1 PRIME*

PUMP 2 PRIME**

The DP/SP is on and is

delivering flow.

Use the

PRIME button to

prime the pump.

Does not flash.

The pump is being primed.

The LED indicates whether

the pump is being primed.

POWER

Use this POWER button for

Does not flash.

routine on/off control of the

DP/SP. When the power is on,

this LED is lighted. To turn off

the DP/SP, press and hold this

POWER button for 2 seconds.

Note: The main power switch

is on the rear panel.

* Pump 1 is always installed in the lower half of the DP/SP enclosure.

** SP only: This button is not present.

18 Doc. 065031-04 1/08

Page 35

2.2 DP/SP Interior Components

The pump’s mechanical components are located directly behind the front door of

the module. Figure 2-3

both a gradient pump (pump 1) and an isocratic pump (pump 2).

For servicing components, the component mounting panel slides out about 5 cm

(2 in) for easy access to components. To pull the panel out, use the handles on the

top and bottom of the panel.

1

3

2

4

10

5

shows the mechanical components of a DP that contains

7

6

8

9

12

11

2 • DP/SP Description

Status Bar

1

Secondary Pump Head

2

Priming Valve

3

Pressure Transducer

4

Primary Pump Head

5

Peristaltic Pump (for

6

seal wash system)

Vacuum Degas Chamber

7

(one channel)

Eluent Supply On/Off Valve

8

Tubing Chase (Pump 2)

9

Handle

10

Piston Seal Wash Reservoir

11

Vacuum Degas Chambers

12

(four channels)

Static Mixer

13

Proportioning Valve Fittings

14

Tubing Chase (Pump 1)

15

Leak Sensor

16

10

13

16

14

15

Figure 2-3. DP/SP Interior Components (DP Shown)

Doc. 065031-04 1/08 19

Page 36

ICS-3000 Ion Chromatography System

2.2.1 Pump Heads

The DP/SP is a zero-pulsation, serial dual-piston pump with electronic

compressibility compensation. Two pump heads—a primary head and a

secondary head—are connected in series. Eluent passes through both

pump heads in succession.

The primary pump head delivers eluent at the selected flow rate, while

simultaneously filling the secondary pump head. The latter serves as a

reservoir and delivers eluent while the primary head carries out the refill

stroke.

The characteristic feature of the patented isokinetic pre-compression

phase is the programmed overlapping of the delivery strokes of the two

pump heads. When delivering compressible liquids without controlled

pre-compression, the pulsation increases as the operating pressure

increases, since part of the delivery stroke is required to compress eluent

in the pump head.

During the pre-compression phase, pulsation is minimized by velocity

modulation of the drive. A patented secondary control system (automatic

compressibility compensation) ensures highly constant eluent delivery.

The flow rate remains constant in relation to the pressure.

2.2.2 Pressure Transducer

The secondary pump head contains a built-in pressure transducer to

measure the system pressure. The DP/SP Moduleware (the instrument

control firmware installed in the pump) precisely controls the pump motor

speed to ensure flow rate accuracy and to maintain constant flow and

constant pressure.

Flow output from the secondary pump head passes through a static mixer

(described in Section 2.2.6

chromatography system (the injection valve, columns, and detector).

) before being directed to the remainder of the

2.2.3 Proportioning Valves (Gradient pump only)

In the gradient pump, eluent flows from the eluent reservoirs, through the

vacuum degas chambers, and into a four-way proportioning valve

assembly (see Figure 2-3

proportioned by the four valves.

20 Doc. 065031-04 1/08

). Programmed percentages of each eluent are

Page 37

2.2.4 Vacuum Degassing Module

The DP/SP vacuum degassing module provides continuous, online eluent

degassing. Eluent quality significantly affects DP/SP performance, and

vacuum degassing eluents is one way to ensure high eluent quality.

Degassing helps prevent bubbles (caused by eluent outgassing) from

forming in the eluent proportioning valves (gradient pump only), pump

heads, and detector cell. Degassing eluents is especially important when

combining aqueous and nonaqueous components (for example, water and

acetonitrile).

The vacuum degassing module is either single-channel (in an isocratic

pump) or quad-channel (in a gradient pump). The module consists of:

• A degas chamber (with degassing membranes) with internal capacity

of 670

μL per channel

• A dual-stage diaphragm vacuum pump

• An on-board vacuum sensor

• The electronics required to operate the vacuum pump

2 • DP/SP Description

• Tubing, fittings, and other accessories

The vacuum degassing module is automatically activated when the DP/SP

power is turned on. Allow about 10 minutes for the module to equilibrate.

NOTE Make sure the run time is long enough to ensure

that the vacuum degassing module delivers the

optimal degassing performance.

Manual Control of the Vacuum Degassing Module

The vacuum degassing module normally remains on continuously. To turn

it off (for example, to investigate a leak), follow these steps:

1. In Chromeleon or Chromeleon Xpress, select Command on the

Control menu or press the F8 key.

2. In the Commands dialog box, select the pump name.

3. Select the Degasser command.

4. Select Off and click the Execute button.

5. To turn on the degasser again, select On and click Execute.

Doc. 065031-04 1/08 21

Page 38

ICS-3000 Ion Chromatography System

2.2.5 Piston Seal Wash System

The piston seal wash system consists of a peristaltic pump, a reservoir

containing wash solution, and the connecting tubing. The wash solution is

usually ASTM Type I (18 megohm-cm) filtered and deionized water.

When seal washing is activated, the back of the main piston seal is rinsed

with wash solution; this prolongs seal lifetime by preventing eluent

crystallization on the seal surfaces.

Notes About the DP Piston Seal Wash System

The piston seal wash system is designed for use with only one of the two

pumps in a DP module. When the DP is shipped from Dionex, the seal

wash system is connected to pump 1 (the bottom pump). If necessary,

connect the seal wash system to pump 2 (the top pump), instead. For

instructions on how to replumb the system, refer to Section 4.5

NOTE Dionex offers an External Seal Wash Kit

(P/N 063518) for users who need to operate a piston

seal wash system for both pumps in the DP.

Installation instructions are provided in the kit.

.

2.2.6 Static Mixer

A GM-3 or GM-4 static mixer is installed after the secondary pump head

(see Figure 2-3

proportioned eluents are mixed thoroughly. In the isocratic pump, the

mixer is optional, but can function as a pulse damper.

The DP/SP gradient delay volume is 600

μL when a GM-4 is installed. The gradient delay volume (or dwell

380

volume) is the volume of liquid in the system between the point where the

gradient is formed and the point where it enters the column. This includes

the mixer, transfer tubing, and swept volume in the injector or

autosampler.

22 Doc. 065031-04 1/08

). In the gradient pump, the mixer helps to ensure that

μL when a GM-3 is installed and

Page 39

2.3 DP/SP Flow Schematics

ON/O

E

2.3.1 Isocratic Pump Flow Schematic

Figure 2-4 illustrates the liquid flow path through an isocratic pump.

2 • DP/SP Description

TO INJECTION VALV

ELUENT

OUTLET

CHECK VALVE

VACUUM

DEGAS

ELUENT SUPPLY

FF VALVE

PUMP

HEAD

PUMP

HEAD

INLET

CHECK VALVE

Figure 2-4. Isocratic Pump Flow Schematic

• Eluent flows from the reservoir, through the vacuum degas chamber

(if the vacuum degas module is installed), through the eluent supply

on/off valve, and into the inlet check valve on the primary pump head.

• The inlet check valve opens, drawing eluent into the primary pump

head. At the same time, the secondary piston pushes forward, pushing

eluent into the system. After completing the intake, the primary

piston pushes eluent through the outlet check valve and into the

secondary pump head.

• Flow exits the secondary pump head and is directed to the remainder

of the chromatography system (the injection valve, columns, and

detector).

Doc. 065031-04 1/08 23

Page 40

ICS-3000 Ion Chromatography System

E

2.3.2 Gradient Pump Flow Schematic

Figure 2-5 illustrates the liquid flow path through a gradient pump.

ELUENT

D

ELUENT

C

ELUENT

B

ELUENT

A

STATIC

MIXER

TO INJECTION VALV

OUTLET

CHECK VALVE

VACUUM

DEGAS

PROPORTIONING

VALV E

PUMP

HEAD

D

C

A

B

PUMP

HEAD

INLET

CHECK VALVE

Figure 2-5. Gradient Pump Flow Schematic

• Eluent flows from the reservoirs and through the vacuum degas

chambers. The selected proportions of eluent flow out of the

proportioning valve assembly and into the inlet check valve on the

primary pump head.

• The inlet check valve opens, drawing eluent into the primary pump

head. At the same time, the secondary piston pushes forward, pushing

eluent into the system. After completing the intake, the primary

piston pushes eluent through the outlet check valve and into the

secondary pump head.

• Flow exits the secondary pump head, continues through the static

mixer, and is then directed to the remainder of the chromatography

system (the injection valve, columns, and detector).

24 Doc. 065031-04 1/08

Page 41

2.4 DP/SP Rear Panel

Figure 2-6 illustrates the rear panel of the DP/SP.

1

1

2

4

7

2 • DP/SP Description

Tubing Chase (2)

1

Main Power Switch, Fuse Holder,

3

2

and Power Receptacle

Analog Pressure Output

3

5

Digital I/O Port

4

6

USB Receptacle

5

(“B” Connectors)

USB Ports (3)

6

(“A” Connectors)

Exhaust Port from Vacuum

7

Degas Module

Waste Line from

8

Drip Tray

8

Figure 2-6. DP/SP Rear Panel

Tubing Chases

The tubing chases route tubing from the front of the DP/SP, through the interior of

the module, and to the rear panel.

Main Power Switch, Fuse Holder, and Power Receptacle

The rear panel power switch is the main power switch for the DP/SP. Turn on the

main power switch before initial operation and leave it on unless instructed to turn

it off (for example, before performing a service procedure).

NOTE For routine on/off control, use the POWER button on the

front of the DP/SP (see Figure 2-1

and Figure 2-2). To

Doc. 065031-04 1/08 25

Page 42

ICS-3000 Ion Chromatography System

turn off the pump, press and hold the POWER button for

2 seconds.

The fuse cartridge contains two 2-amp IEC 60127-2 slow-blow fuses

(P/N 954773). For instructions on how to change the fuses, see Section 9.9

The power cord plugs into the IEC 320 three-prong receptacle.

The power supply cord is used as the main disconnect device. Make

sure the socket-outlet is located near the DC and is easily accessible.

Le cordon d'alimentation principal est utilisé comme dispositif

principal de débranchement. Veillez à ce que la prise de base soit

située/installée près du module et facilement accessible.

Das Netzkabel ist das wichtigste Mittel zur Stromunterbrechung.

Stellen Sie sicher, daß sich die Steckdose nahe am Gerät befindet und

leicht zugänglich ist.

Digital I/O Port

The digital I/O port provides a connection to an AS40 Automated Sampler or

other auxiliary device. The connector includes three TTL inputs and four relay

outputs. Table 2-1

indicates the functions assigned to the connector pins.

.

For instructions on connecting the pump to an AS40, refer to the ICS-3000 Ion

Chromatography System Installation Instructions (Document No. 065032). The

manual is included on the Dionex Reference Library CD-ROM (P/N 053891).

The maximum switching voltage of the relays is 24 V. The switching

current must not exceed 100 mA.

Pin Number Signal Name Signal Level Description

1 ----- ----- Not used

2 ----- ----- Not used

3 Relay 3 Out Potential-free Normally open

4 Relay 1 Out Potential-free Normally closed

5 Relay 2 Out Potential-free Normally closed

6 Relay 3 Out Potential-free Normally closed

Table 2-1. 25-Pin D-Sub I/O Port (Female)

26 Doc. 065031-04 1/08

Page 43

2 • DP/SP Description

Pin Number Signal Name Signal Level Description

7 Relay 1 Out Potential-free Common

8 Relay 2 Out Potential-free Common

9 Gnd Ground Ground

10 Gnd Ground Ground

11 Gnd Ground Ground

12 Gnd Ground Ground

13 ----- ----- Not used

14 Relay 4 Out Potential-free Normally open

15 Relay 4 Out Potential-free Common

16 Relay 4 Out Potential-free Normally closed

17 ----- ----- Not used

18 Relay 3 Out Potential-free Common

19 Relay 1 Out Potential-free Normally open

20 Relay 2 Out Potential-free Normally open

21 Vcc Out +5V +5V, 500 mA

22 TTL Input 1 TTL Hold/Run

23 TTL Input 2 TTL Stop

24 TTL Input 3 TTL Start

25 ----- ----- Not used

Table 2-1. 25-Pin D-Sub I/O Port (Female) (Continued)

Analog Pressure Output

The analog pressure output indicates the operating pressure of the pump. The

pressure output is set to 50 mV/MPa (5 mV/14.51 psi). To monitor the pressure,

connect the pressure output to a recorder or an A/D converter. These are the pin

assignments for the 2-pin Cinch connector (P/N 8005.9001A):

Signal Level Function

Inner ring: Signal (pressure)

Outer ring: Ground

Doc. 065031-04 1/08 27

Page 44

ICS-3000 Ion Chromatography System

The analog pressure output defaults to the pump 1 (bottom pump) output signal.

To redirect the output to pump 2 (the top pump), follow these steps:

1. In Chromeleon or Chromeleon Xpress, select Command on the Control

menu or press the F8 key.

2. In the Commands dialog box, select the pump name.

3. Select the AnalogOut command.

4. Select PumpTop in the AnalogOut drop-down box and click Execute.

USB Connections

• One USB receptacle (“B” type connector) allows a connection from the PC on

which Chromeleon or Chromeleon Xpress software is installed.

• Three USB (Universal Serial Bus) ports (“A” type connectors) are provided

for connections to other ICS-3000 modules.

One 1.8-m (6-ft) USB cable (P/N 960777) is provided in the ship kit (DP Ship Kit,

P/N 062463; SP Ship Kit, P/N 063342).

Waste Lines

• One waste line is connected to the secondary pump head.

• One waste line exits the drip tray and is routed to the rear panel.

Place the free ends of the waste lines into one waste container. To maintain a

positive siphon, position the waste container below the level of the pump.

NOTE To ensure proper drainage, the waste lines must remain

above the liquid level in the waste container.

28 Doc. 065031-04 1/08

Page 45

2.5 Eluent Reservoirs

The following reservoirs are available for use with the DP/SP:

• 1-liter plastic reservoir (P/N 063291)

• 2-liter plastic reservoir (P/N 062510)

• 4-liter plastic reservoir (P/N 063292)

Do not use the 2-liter plastic reservoir (P/N 062510) for offline vacuum

degassing of eluents. The reservoir was not designed for this

purpose.

N'utilisez pas le réservoir en plastique de 2 litres (N/P 062510) pour le

dégazage à vide hors ligne d'éluants. Le réservoir n'a pas été conçu à

cette fin.

Verwenden Sie den 2-Liter Plastikbehälter (Bestell-Nr. 062510) nicht

zum Offline Vakkum-Entgasen von Eluenten. Der Behälter ist dafür

nicht ausgelegt.

2 • DP/SP Description

All eluent reservoirs listed above are pressurizable. Although the DP/SP does not

require pressurized reservoirs, Dionex recommends pressurizing reservoirs with

helium or nitrogen under the following circumstances:

• When using eluents that are sensitive to contamination.

• When combining aqueous and nonaqueous components (for example, water

and acetonitrile). Pressurizable reservoirs allow eluents to be stored under a

specific atmosphere.

Never pressurize eluent reservoirs above 0.07 MPa (10 psi).

Pressurizing reservoirs above this limit can cause the reservoir to

explode.

Ne mettez jamais les réservoirs d'éluants sous une pression

supérieure à 0,07 MPa (10 psi).

Doc. 065031-04 1/08 29

Page 46

ICS-3000 Ion Chromatography System

Setzen Sie den Eluentbehälter auf keinen Fall einem Druck über

0,07 MPa aus.

2.6 EO (Optional)

The ICS-3000 Eluent Organizer (EO) holds eluent reservoirs in a liner that

contains spills and leaks. Up to two EOs can be installed on top of the DC. Each

EO accommodates up to four 1-liter or 2-liter reservoirs or up to two 4-liter

reservoirs. The EO is typically ordered configured with four 2-liter reservoirs

(P/N 062629).

All eluent reservoirs available for use with the DP/SP can be pressurized. If you

plan to pressurize the eluent reservoirs, an optional regulator kit is required. The

kit is available in two versions:

• When the DC is installed as the topmost module in the system, the EO

Regulator Kit (P/N 063493) is required. The kit includes a pressure regulator

and gauge assembly with four outputs (for connections to four eluent

reservoirs), as well as the tubing and connection fitting required.

• When the TC, ICS-Series Variable Wavelength Detector, or ICS-Series

Photodiode Array Detector is installed as the topmost module in the system,

the TC/VWD/PDA Regulator Bracket Kit (P/N 064792) is required. The kit

includes the EO Regulator Kit described above, as well as a right-angle

regulator bracket and mounting hardware. After attaching the bracket to the

TC or detector, you will mount the gas regulator assembly on the bracket.

If more reservoirs are required, order a second regulator (P/N 062345).

30 Doc. 065031-04 1/08

Page 47

EG Description

2.7 EG Front Features

The status bar on the front of the ICS-3000 Eluent Generator (EG) includes

buttons that provide control of certain EG functions, as well as LEDs that indicate

the status of several EG functions (see Figure 2-7

).

CONNECTED

Button/LED

Label

CONNECTED

ALARM

EGC 1

EGC 2

CR-TC 1

CR-TC 2

12

CR-TC

ALARM

12

EGC

Figure 2-7. EG Status Bar

If the LED Is On Comment

The EG is connected to a Chromeleon

-----

or Chromeleon Xpress timebase.

An EG-related problem has occurred

(for example, the EluGen cartridge

was disconnected).

The EluGen cartridge is on and is

generating eluent.

Check the Chromeleon or

Chromeleon Xpress Audit

Trail for the cause.

EGC 1 is always installed in

the left section of the

component compartment.

EGC 2, if present, is installed

in the right section of the

compartment.

The CR-TC is on. CR-TC 1 is always installed in

the left section of the

component compartment.

CR-TC 2, if present, is

installed in the right section of

the compartment.

Doc. 065031-04 1/08 31

Page 48

ICS-3000 Ion Chromatography System

Button/LED

Label

POWER

If the LED Is On Comment

Use this POWER button for routine

on/off control of the EG. When the

power is on, this LED is lighted. To

turn off the EG, press and hold this

POWER button for 2 seconds.

NOTE: The EG status bar LEDs do not flash.

The main power switch is on

the EG rear panel.

32 Doc. 065031-04 1/08

Page 49

2.8 EG Interior Components

Figure 2-8 shows the EG component compartment, which is located directly

behind the front door. The component mounting panel divides the compartment

into two sections. In a single-channel EG, components are installed in the left

section only.

To access components for maintenance or service procedures, push down on the

slide release latch and pull the tray forward until it reaches the stop.

1

2

2 • EG Description

EluGen Cartridge

1

RFIC Eluent Degasser

3

2

Electrical Connectors

3

CR-TC

4

Waste Line

5

Drip Tray

6

Slide Release Latch

7

4

5

6

7

Figure 2-8. EG Interior Components

(Second (Right Side) Channel of a Dual-System EG Shown)

Doc. 065031-04 1/08 33

Page 50

ICS-3000 Ion Chromatography System

EluGen Cartridge

Several types of EluGen cartridges are available for use with the EG (see the table

below). Each cartridge contains 900 mL of the appropriate electrolyte concentrate

solution for eluent generation.

EluGen Cartridge Part Number Function

EGC II K2CO3

EluGen Cartridge

058904 Generates potassium carbonate eluent

for anion exchange separations.

Note: Produces a carbonate/bicarbonate

mixture when installed with the EPM

Electrolytic pH Modifier (P/N 063175)

EGC II KOH

EluGen Cartridge

EGC II LiOH

EluGen Cartridge

EGC II MSA

EluGen Cartridge

EGC II NaOH

EluGen Cartridge

and EGC-CO

058900 Generates potassium hydroxide eluent

for anion exchange separations.

058906 Generates lithium hydroxide eluent for

anion exchange separations.

058902 Generates methanesulfonic acid eluent

for cation exchange separations.

058908 Generates sodium hydroxide eluent for

anion exchange separations.

Mixer (P/N 061686).

3

For more information, refer to the EluGen cartridge manual. The manual is

included on the Dionex Reference Library CD-ROM (P/N 053891).

RFIC Eluent Degasser

The RFIC Eluent Degasser (P/N 062137) contains a tubing assembly that purges

the electrolysis gas from the freshly-generated eluent before it is directed to the

separator column.

Backpressure Coil (Optional)

The EluGen cartridge requires at least 14 MPa (2000 psi) of system backpressure

for removal of electrolysis gas from the eluent produced by the cartridge. A

system backpressure of 16 MPa (2300 psi) is ideal.

If necessary, increase the system backpressure by installing a backpressure coil

between the injection valve and the EluGen cartridge

refer to Section 9.15

34 Doc. 065031-04 1/08

.

OUTLET port. For details,

Page 51

2 • EG Description

Continuously Regenerated Trap Column (CR-TC)

The CR-TC is a high pressure, electrolytically-regenerated trap column. The CRTC is designed to remove anionic or cationic contaminants in the eluent or

deionized water and to reduce drift during gradient separations. Two versions of

the CR-TC can be used with the EG: