Page 1

GP50 GRADIENT PUMP

OPERATOR'S MANUAL

© 2001 Dionex Corporation

Document No. 031377

Revision 03

July 2001

Page 2

©2001 by Dionex Corporation

All rights reserved worldwide.

Printed in the United States of Amer ica.

This publication is protected by federal copyright law. No part of this publication

may be copied or distributed, transm itted, tr anscri bed , stored in a retrieval system, or

transmitted into any human or computer language, in any form or by any means,

electronic, mechanical, magnetic, manual, or otherwise, or disclosed to third parties

without the express written permission of Dionex Corporation, 1228 Titan Way,

Sunnyvale, California 94088-3603 U.S.A.

DISCLAIMER OF WARRANTY AND LIMITED WARRANTY

THIS PUBLICATION IS PROVIDED “AS IS” WITHOUT WARRANT Y OF

ANY KIND. DIONEX CORPORATION DOES NOT WARRANT,

GUARANTEE, OR MAKE ANY EXPRESS OR IMPLIED

REPRESENTATI ONS RE GARD ING THE U SE, O R TH E RES ULTS OF THE

USE, OF THIS PUBLICATION IN TERMS OF CORRECTNESS, ACCURACY,

RELIABILITY, CURRENTNESS, OR OTHERWISE. FURTHER, DIONEX

CORPORATION RESERVES THE RIGHT TO REVISE THIS PUBLICATION

AND TO MAKE CHANGES FROM TIME TO TIME IN THE CONTENT

HEREINOF WITHOUT OBLIGATION OF DIONEX CORPORATION TO

NOTIFY ANY PERSON OR ORGANIZATION OF SUCH REVI SION OR

CHANGES.

TRADEMARKS

DX-LAN™ is a trademark, and PeakNet®, Self-Regenerating Suppressor®, and

SRS® are registered trademarks of Dionex Corporation

Tefzel® is a registered trademark of E.I. duPont de Nemours & Co.

PRINTING HISTORY

Revision 01, May 1998

Revision 02, October 2000

Revision 03, July 2001

Page 3

Contents

1 • Introduction

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2.1 Safety Messages and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.2.2 Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

2 • Description

2.1 Front Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.1.1 Control Panel Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.1.2 Display Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2.2 Electronics Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2.3 Mechanical Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

2.4 Mechanical Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

2.5 Vacuum Degas Pump Assembly (Optional) . . . . . . . . . . . . . . . . . . . .2-16

2.6 Piston Seal Wash (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

2.7 Eluent Reservoirs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

Doc. 031377-03 7/01

2.4.1 Pump Eluent Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

2.4.2 Pump Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

2.4.3 Pump Mixers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

2.4.4 Pump Priming Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

2.4.5 Pressure Transducer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

i

Page 4

GP50 Gradient Pump

2.8 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

2.9 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

2.9.1 Operating and Control Modes . . . . . . . . . . . . . . . . . . . . . . . . 2-18

2.9.2 Local and Remote Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2.9.3 Method Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

2.9.4 Eluent Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

3 • Operation and Maintenance

3.1 Getting Ready to Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.1 Degas Eluents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.2 Filter Eluents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.3 Pressurize Eluent Reservoirs . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.4 Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.1.5 Selecting the Pressure Limits . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.1.6 Selecting the Operating and Control Modes . . . . . . . . . . . . . . 3-5

3.2 Running Under Direct Control (Local Mode) . . . . . . . . . . . . . . . . . . . 3-6

3.3 Running Under Method Control (Local Mode) . . . . . . . . . . . . . . . . . . 3-7

3.3.1 Creating a New Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.3.2 Running a Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

3.3.3 Editing a Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.3.4 Deleting a Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.3.5 Changing the Running Method . . . . . . . . . . . . . . . . . . . . . . . 3 -12

3.3.6 Controlling the Method Clock . . . . . . . . . . . . . . . . . . . . . . . .3-12

ii

Doc. 031377 -03 7/01

Page 5

3.4 Example Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

3.4.1 Isocratic Method Example . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

3.4.2 Linear Gradient Method Example . . . . . . . . . . . . . . . . . . . . .3-14

3.4.3 Curved Gradient Method Example . . . . . . . . . . . . . . . . . . . . .3-19

3.4.4 Editing a Running Method Example . . . . . . . . . . . . . . . . . . .3-23

3.5 Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

3.5.1 Daily Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

3.5.2 Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

3.6 Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

4 • Troubleshooting

4.1 Left-Right Pump Head Pressure Fluctuations . . . . . . . . . . . . . . . . . . . .4-1

Contents

4.2 Pump Will Not Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.3 Pump Stops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.4 Liquid Leaks/Leak Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

4.5 Noisy Pump Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

4.6 Vacuum Degas Pump Does Not Run . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

4.7 Vacuum Degas Pump Calibration Fails . . . . . . . . . . . . . . . . . . . . . . .4-10

4.8 Vacuum Degas Pump Low Vacuum . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

4.9 Relays or TTLs Inoperative . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

4.10 Poor Chromatographic Reproducibility . . . . . . . . . . . . . . . . . . . . . . .4-12

Doc. 031377-03 7/01

iii

Page 6

GP50 Gradient Pump

5•Service

5.1 Cleaning and Replacing the Check Valves . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Piston Seal Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.3 Pump Piston Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.4 Pressure Transducer Waste Valve O-Ring Replacement . . . . . . . . . . 5-10

5.5 Proportioning Valve Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

5.6 Changing Main Power Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

A • Specifications

A.1 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

A.2 Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

A.3 Physical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

A.4 Display and Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

A.5 Hydraulics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

A.6 Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

A.7 Vacuum Degas Pump Assembly (Optional) . . . . . . . . . . . . . . . . . . . . .A-3

B • Installation

B.1 Facility Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

B.2 Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

B.2.1 Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

B.2.2 Electronics Chassis Connections . . . . . . . . . . . . . . . . . . . . . . .B-4

B.2.3 DX-L AN Interface: 10B ASE-T Connections (Optional). . . . .B-6

iv

Doc. 031377 -03 7/01

Page 7

B.2.4 DX-LAN Interface: BNC Connections (Optional) . . . . . . . . . B-9

B.2.5 Waste Lines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-13

B.2.6 Eluent Inlet Line Connections. . . . . . . . . . . . . . . . . . . . . . . . B-14

B.2.7 Eluent Outlet Line Connections . . . . . . . . . . . . . . . . . . . . . . B-14

B.2.8 Piston Seal Wash Connections (Optional) . . . . . . . . . . . . . . B-15

B.2.9 Priming the Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-17

B.3 Automatic SRS Power Control (Optional) . . . . . . . . . . . . . . . . . . . . B-20

C • Display Screens

C.1 Operational Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

C.1.1 Menu of Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

C.1.2 Main Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Contents

C.2 Diagnostic Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-14

Doc. 031377-03 7/01

C.1.3 Detail Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

C.1.4 Method Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

C.1.5 Method Extension Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-8

C.1.6 Degas Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-9

C.1.7 Module Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-11

C.1.8 Pump Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-12

C.1.9 Time Function In. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-13

C.2.1 Diagnostic Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-14

C.2.2 Power-Up Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-15

C.2.3 Elapsed Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-16

C.2.4 DSP Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-17

v

Page 8

GP50 Gradient Pump

C.2.5 DX-LAN Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-18

C.2.6 Keyboard Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-20

C.2.7 Diagnostic Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-21

C.2.8 Pressure Statistics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-23

C.2.9 DSP Code Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-24

C.3 Calibration Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-25

C.3.1 Calibration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-25

C.3.2 Calibration Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-26

C.3.3 Leak Sensor Calibration and Status . . . . . . . . . . . . . . . . . . . .C-27

C.3.4 Degas Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-28

C.3.5 Flow Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-29

C.3.6 Pressure Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-30

C.3.7 Degas Pump Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-34

D • TTL and Relay Control

D.1 TTL and Relay Output Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-2

D.2 TTL Input Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-3

D.2.1 TTL Input Signal Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-3

D.3 TTL and Relay Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-5

D.3.1 Example Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-6

vi

Doc. 031377 -03 7/01

Page 9

1.1 Overview

The GP50 Gradient Pump is an integral part of a Dione x chr omat ogr aphy system.

It is a microprocess or -based, dua l-pisto n, v ariable -speed, gr adient de li ver y system

designed to blend and pump mixtures of up to four different eluents at precisely

controlled flow rates. The pump can deliver the selected eluent composition

isocratically, or as a multistep linear or curved gradient. A Digital Signal

Processor (DSP) provides high speed control of pump flow and pressure.

The pump can operate as a stand-alone product or with other Dionex modules as

part of a complete chromatography system. It can also be used with non-Dionex

modules that meet interface requirements for software, TTL, or relay control.

The GP50 can be controlled locally, using the front panel keypad and display, or

from a remote host computer with a Dionex DX-LAN™ interface installed and

®

PeakNet

ava ilabl e from an y de vi ce capabl e of pro v iding compati ble TTL signa ls to contr ol

the pump.

The pump's two basic mode s of control, Dire ct control and Method control, e nable

it to operat e with or without reference to time-based events.

software installed on t he hos t comput er. Limited remote control is also

1 • Introduction

The GP50 is available in four versions. An optional vacuum degas pump is

available for all versions:

GP50 Gradient Pump V e r sio n With Degas Pump Without Degas Pump

Standard bore with PEEK

components

Standard bore with stainless steel

components

Microbore with PEEK components P/N 054045 P/N 054429

Microbore with stainless steel

components

Doc. 031377-03 7/01

P/N 054426 P/N 054427

P/N 054419 P/N 054420

P/N 054425 P/N 054424

1-1

Page 10

GP50 Gradient Pump

1.2 About This Manual

Chapter 1

Introduction

Chapter 2

Description

Chapter 3

Operation and

Maintenance

Chapter 4

Troubleshooting

Chapter 5

Service

Appendix A

Specifications

Appendix B

Installation

Appendix C

Display Screens

Appendix D

TTL and Relay

Control

Gives an overview of the GP50 Gradient Pump, and

explains conventions used in this manual, including

safety-related information.

Describes the GP50 front panel controls, electronic and

mechanical components, and operating modes.

Provides an overview of GP50 opera tion, including how to

create, edit, and run methods from the GP50 front panel.

Lists routine preventive maintenance procedures.

Lists problems and presents step-by-step procedures for

how to isolate and eliminat e them.

Provides step-by-step instructions for routine service and

parts replacement procedures.

Lists the GP50 specifications and installation site

requirements.

Describes how to install the GP50.

Illustrates and describes all of the screens that can be

displayed on the GP50 front panel.

Describes relay and TTL input and output functions and

provides installation instructions

.

1-2

Doc. 031377 -03 7/01

Page 11

1.2.1 Saf et y Me ss a ges and Note s

This manual contains warnings and precautionary statements that, when

properly followed, can prevent personal injury and/or damage to the

GP50. Safety messages appear in bold type and are accompanied by

icons, as shown below.

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

1 • Introduction

Doc. 031377-03 7/01

Indicates that the function or process of the instrument may be

impaired. Operation does not constitute a hazard.

Informational messages also appear throughout this manual. These are

labeled NOTE and are in bold type:

NOTE NOTES call attention to certain information. They alert

you to an unexpected result of an action, suggest how to

optimize instrument performance, etc.

1-3

Page 12

GP50 Gradient Pump

1.2.2 Saf et y Label s

The TUV GS, C, US Mark safety label and the CE Mark label on the

GP50 indicate that the GP50 is in compliance with the following

standards: EN 61010-1:1993 (safety), CAN/CSA-C22.2 No. 1010.1-92

(safety), UL 3101-1/10.93 (safety), EN 50082-1:1992 (susceptibility),

and EN 55011:1991 (emissions).

The symbols below appear on the GP50, or on GP50 labels.

Alternating current

Protective conductor terminal

Power supply is on

Power supply is off

1-4

Doc. 031377 -03 7/01

Page 13

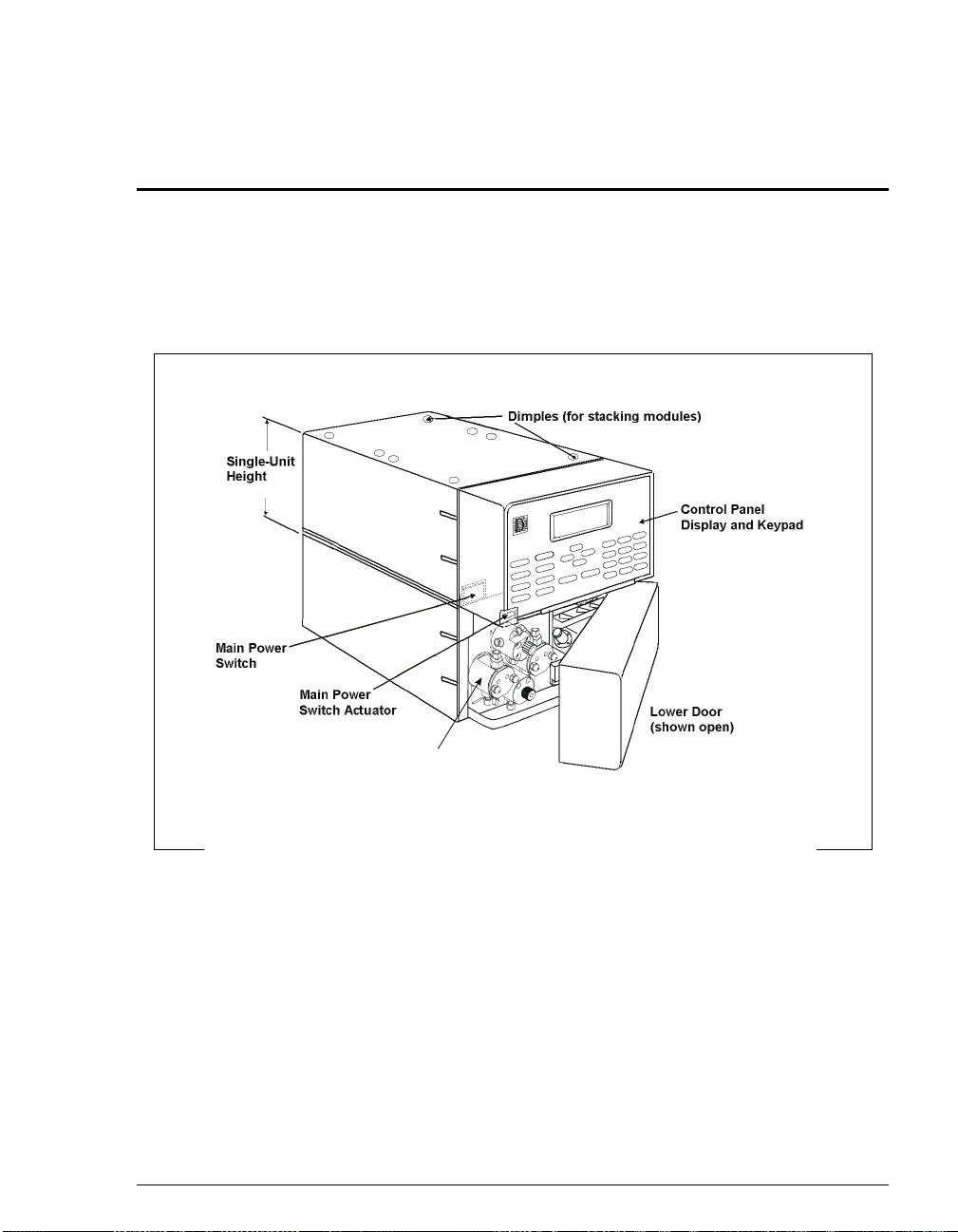

2 • Description

The GP50 Gradient Pump consists of two units (see Figure 2-1). The upper unit

houses the electronics components and the lower unit houses the pump heads and

other mechanical pump assemblies.

Doc. 031377-03 7/01

Pump

Heads

Figure 2-1. GP50 Enclosure

2-1

Page 14

GP50 Gradient Pump

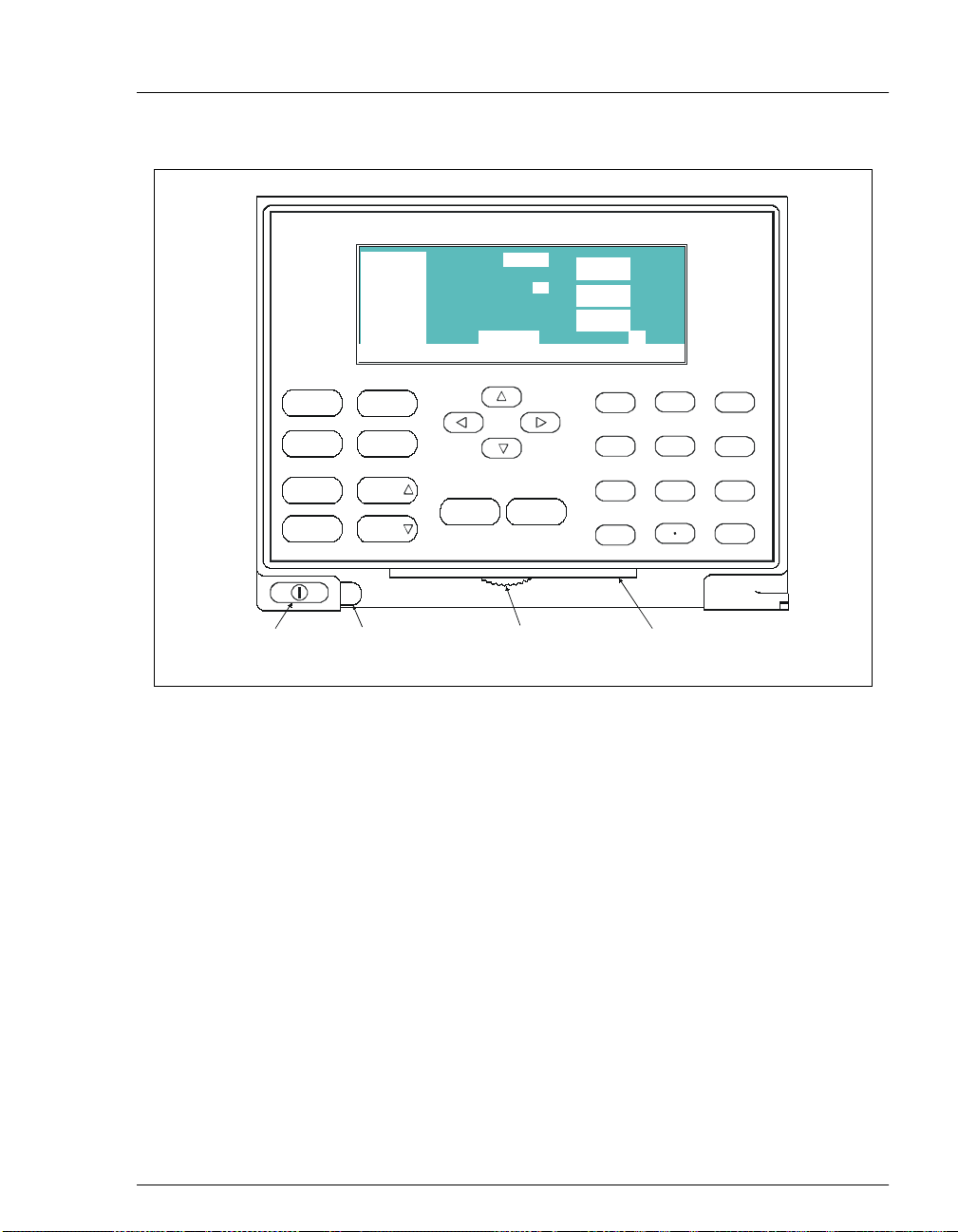

2.1 Front Control Panel

The control panel on the upper door of the pump enclosure contains a liquid

crystal display (LCD), a membrane keypad, and the actuator for the main power

switch (see Figure 2-2). The door opens to provide access to the electronics

chassis (see Section 2.2).

NOTE If no keypad buttons are pressed within a two-hour

period, the front panel backlight will automatically turn

off. To restore the backlight, press any button.

Screen Contrast

Information is displayed on the LCD, also called the

contrast, use the knurled knob in the recess below the keypad (see Figure 2-2).

Tilt Panel

To maximize visibility, the front control panel can be tilted to four different

positions. To tilt the panel, support the door at the left side (to prevent it from

opening) and lift firmly on the tab in the middle of the recess below the keypad

(see Figure 2 -2). Push on the tab t o return the panel to its vertical position.

. To adjust the screen

screen

2-2

Power Switches

The main powe r swit ch is on the bulkhead behind the uppe r door (see Figur e 2-1).

An actuator for the main power switch is on the outside of the front door, at the

lower left corner (see Figure 2-2).

The actuator functio ns only when the door is fully clos ed. Whe n the door is open,

press the main power switch on the bulkhead to turn the module off and on.

To prevent damage to the pump circuitry and components,

always wait at least 15 seconds after powering down before

turning on the power again.

Doc. 031377 -03 7/01

Page 15

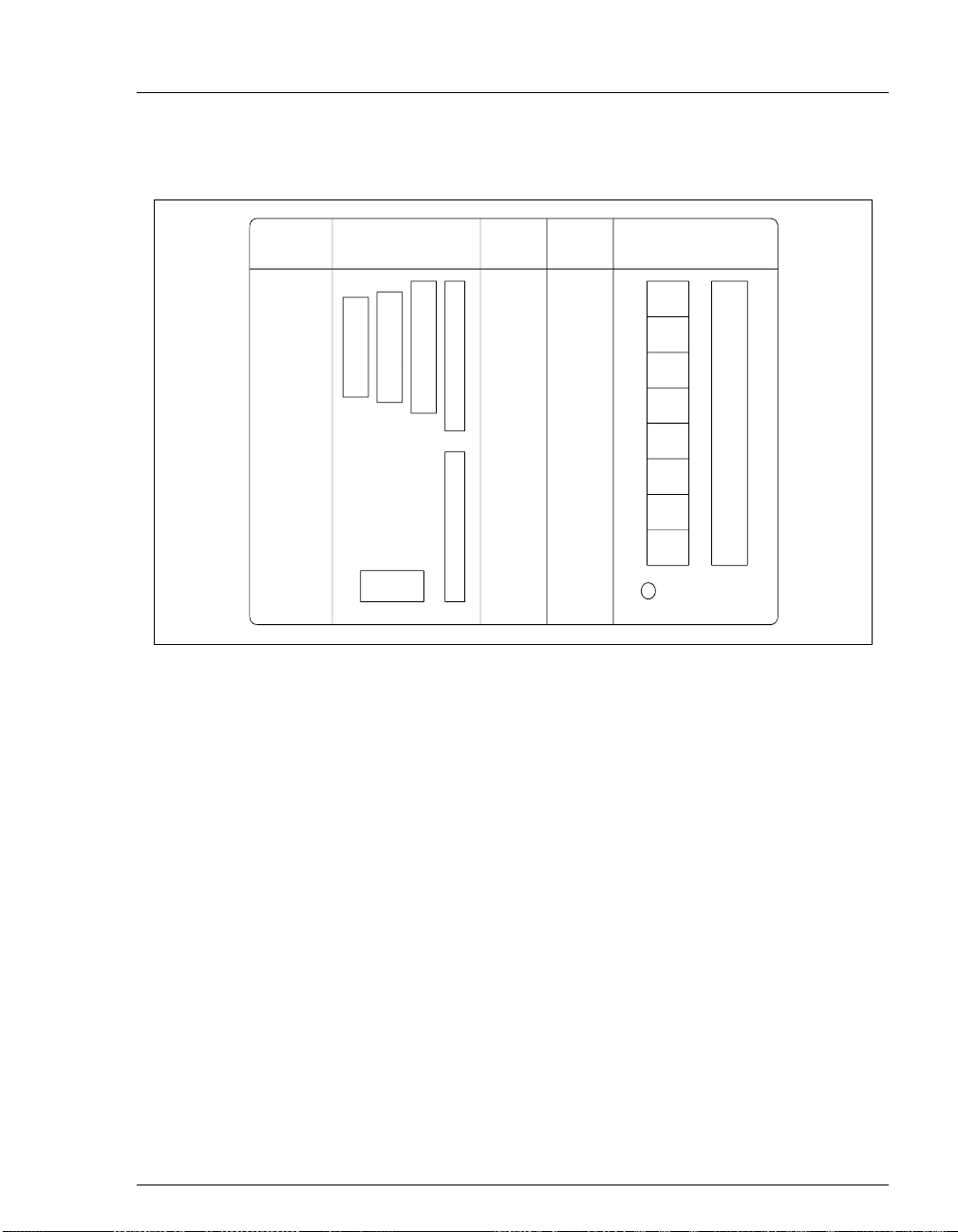

GP50 G radient Pump

100.0 %A

0.0 %B

0.0 %C

0.0 %D

Help Message

LOAD

COLUMN A

2000

2.00

LOCAL 2

10.27

METHOD

2•Description

PSI

m L /MIN

MIN

Off/O n

Prime Reset

Insert

Delete

Ma in P o wer

Sw itc h A c tu a to r

Hold/Run

Select

Select

Tab

(for opening

the door)

Help Menu

Figure 2-2. GP50 Display and Keypad Layout

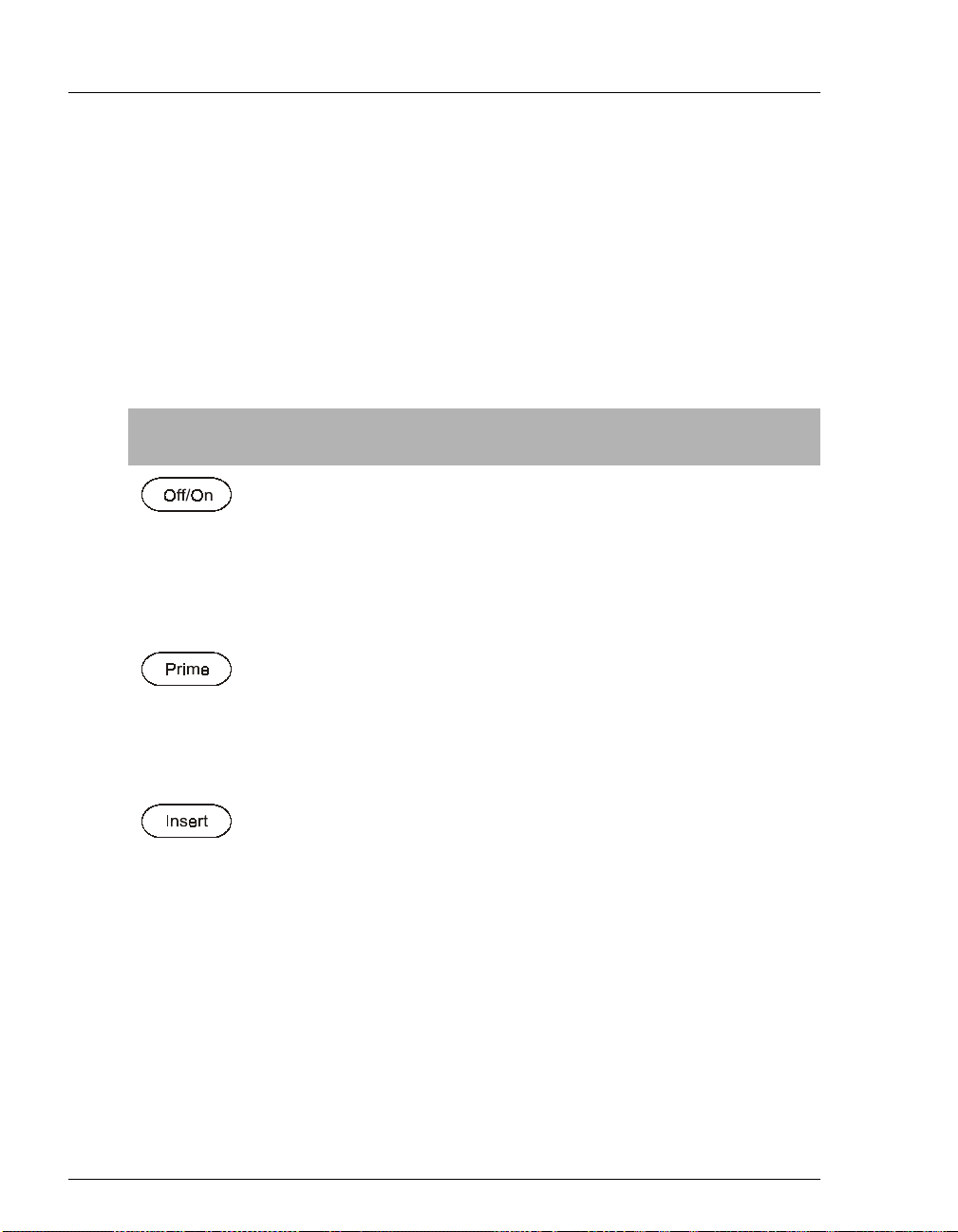

2.1.1 Control Panel Keypad

Use the keypad to directly control pump operation, as well as to create

and modify programmed series of timed events, called

summary:

Press

_

_

To go from a menu to a screen, press the numeric button that

corresponds to the screen’s number on the menu, or move the cursor

to the desired screen name and press

to display a list of available screens.

Menu

Knob

(for adjusting

the contrast)

7

4

1

0

Enter

8

5

23

Tab

(for tilting

the panel)

9

6

Enter

methods

.

. In

Doc. 031377-03 7/01

Only fields shown in reverse video on a screen can be edited. Other

_

fields display information only.

To edit a value in a reverse video field, use the four directional arrow

_

buttons to move the cursor to the field. Use the numeric buttons to

2-3

Page 16

GP50 Gradient Pump

enter variable values, or use the

choose from among predetermined options.

Select

∆

and

Select

buttons to

∇

Keypad

Buttons

To confirm the selected value, press

_

some screens or screen fields, pressing

NOTE A high-pitched beep sounds when you press a

button. When an error occurs, this beep is lower in

frequency. The beeps can be disabled from the

MODULE SET-UP

Function

Turns the pump motor off and on.

In Direct control (see Section 2.9), turnin g on the m otor cause s it to

pump isocratically using the displayed eluent percentages and flow rate.

In Method control (see Section 2.9.3), turning on the moto r causes it to

pump at the eluent percentages and flow rate for the elapsed time of the

selected method, or at the initial conditions (when the method clock is at

).

INIT

This button is used when priming the pump heads.

pump to run at maximum vo lume (2.5 mL/min, microb ore; 10.0 mL/min,

standard bore). If the pump motor is off when

pump automatically turns on. To exit priming and return to the normal

flow rate, press

See Section B.2.8 for detailed priming in str uctions.

Prime

screen (see Section C.1.7).

again or press

or an arrow button. In

Enter

is required.

Enter

Prime

is pressed, the

Prime

Off/On

to turn off the pump motor.

causes the

2-4

Inserts a new step into a method. This button functions only when the

cursor is in a

1. Move the cursor to the

added below the cursor position. Parameter values in the new step

are blank.

2. Fill in the time value and press

Note:

time value, the inserted step is not saved because it is incomplete.

3. Insert steps in any order. When you press

automatically reorganized in the correct chronological order.

TIME

field on the

If you move the cur sor out of the

Table 2-1. GP50 Front Panel Buttons

METHOD

field and press

TIME

METHOD

or

or a cursor arrow button.

Enter

TIME

Enter

extension screen.

. The new step is

Insert

field before entering a

, they will be

Doc. 031377 -03 7/01

Page 17

2•Description

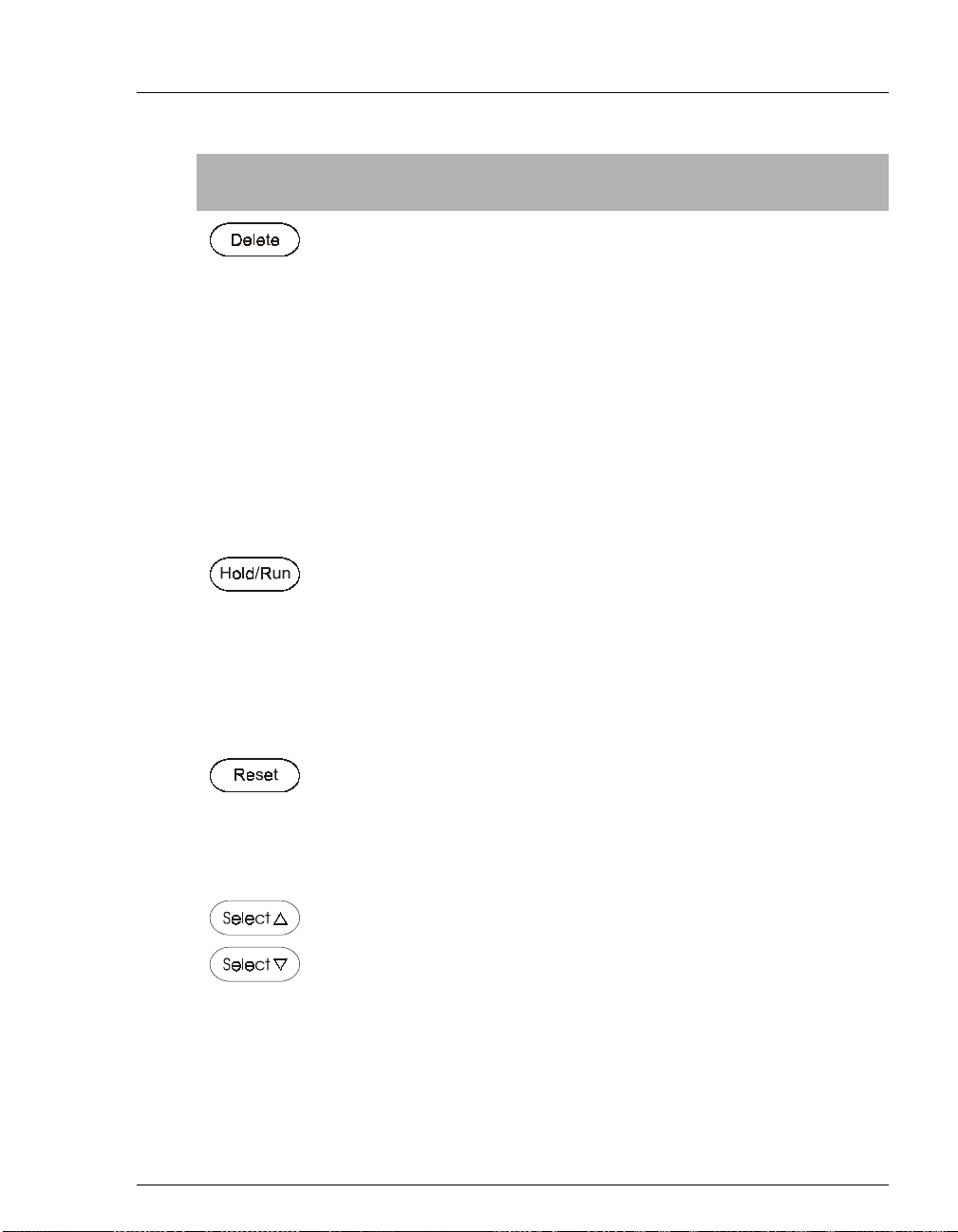

Keypad

Buttons

Function

Removes the value from the current entry field. To restore the previous

value, move the cursor from the field before entering a new value.

Pressing

screen “blanks” the step parameter value. Moving the cursor to another

field does not restore the previo us v alue; ins tead, the step remains blank,

indicating no change from the previous step.

To delete an entire method step:

1. Position the cursor in the method’s time field and press

2. Press

Turns the method clock off (

only when the pump is under Method control (see Section 2.9.3).

When the method clock is in Hold, pressing

at either the initial step of a new method or, if resuming an interrupted

method, at the time at which the clock was put in Hold.

When the method clock is in Run, pressing

this “holds” the method and freezes the current conditions.

Delete

time is removed and the help line prompts you to press

again to delete the step.

parameters, press any button except

when the cursor is in a step entry field o n the

Delete

again. Or, to restore the original time and step

.

Delete

) and on

Hold

(Run)

Hold/Run

Hold/Run

METHOD

. The

Delete

Delete

. This button functions

starts the clock

stops the clock;

Doc. 031377-03 7/01

Changes the method clock time to

specified by the method to occur. This button functions only when the

GP50 is under Method control (see Section 2.9.3).

If the method is running, it continues running. If the method is in Hold,

the method clock executes the initial conditions and holds.

When the cursor is positioned at a field with predetermined parameters,

these buttons cycle through the options. In fields with predetermined

numeric values, pressing

pressing

Select

Enter

button increases (or decreases) the value continuously. Press

or a cursor arrow button to confirm the selected value.

Table 2-1. GP50 Front Panel Buttons (Continued)

∇ decreases the value by one unit. Holding down a

Select

Select

, causing the initial conditions

INIT

∆

increases the value by one unit;

2-5

Page 18

GP50 Gradient Pump

Keypad

Buttons

Function

The four cursor buttons move the cursor, in the direction of the arrow, to

the next entry field. If there is no changeable field in that direction, the

cursor moves diagonally or remains in its current location.

In most cases, after entering a new value in an entry field, pressing an

arrow button saves and/or executes the change. The exceptions are the

field, the

METHOD SAVE TO

command, the

Displays a help screen with information pertaining to the current entry

field.

Displays one of three menus, depending on the current screen:

_

From an operational screen, pressing

SCREENS

_

From a diagnostic screen, pressing

DIAGNOSTIC MENU

From a calibration screen, pressing

_

CALIBRATION MENU

Enters numeric values into the current entry field. The numeric buttons

are 0 through 9 and the decimal.

DIAGNOSTIC TESTS

.

METHOD RUN

.

.

screen, and all menu screens.

Menu

Menu

Menu

any calibration

field,

displays the

displays the

displays the

MENU of

2-6

From a menu screen, press ing a nu meri c b utt on open s t he co rres pon ding

screen.

Saves and/or executes changes made in entry fields. If a menu screen is

displayed, pressing

Table 2-1. GP50 Front Panel Buttons (Continued)

opens the highlighed screen.

Enter

Doc. 031377 -03 7/01

Page 19

2.1.2 Display Screens

When the pump has successfully powered-up and passed all diagnostic

tests, the

the

power-up, the

screen. See Section C.2.7 if this occurs.

POWER-UP

screen (see Figure 2-4). If one of the diagnostic tests fails at

MAIN

DIAGNOSTIC TEST

2•Description

screen (see Figure 2-3) displays briefly, followed by

screen displays instead of the

MAIN

NOTE

Help Message

The

selecting the screen from the

(see Section C.2.1).

GP50 GRADIENT PUMP

Figure 2-3. Power-Up Screen

100.0 %A

0.0 %B

0.0 %C

0.0 %D

Help Message

POWER-UP

screen can be viewed at any time by

PUM P H EA D VO LUM E 100 uL

MODULEWARE REV n.nn

B IO S R E V n.n n

LOAD

2000

COLUMN A

2.00

10.27

LOCAL 2

METHOD

DIAGNOSTIC MENU

PSI

mL /MIN

MIN

Doc. 031377-03 7/01

Figure 2-4. Main Screen

The

allow viewing from a d istance. Use the

parameters, such as the flow rate and the percentages of eluents to run.

T o access oth er GP50 screens, pre ss the

of SCREENS

screen displays status information in enlarged char acters to

MAIN

screen to select operating

MAIN

button to displ ay th e

Menu

(see Figure 2-5).

MENU

2-7

Page 20

GP50 Gradient Pump

There are two ways to select a screen from a menu:

Press the numeric button on the front panel keypad that corresponds

_

to the screen number on the menu. For example, p re ss 3 to di splay th e

METHOD

Move the cursor to the field containing the screen number and press

_

Enter

See Appendix C for a description of each screen.

screen.

.

MENU of SCREENS

1

M AIN S CR E EN

2

DETAIL SCREEN

3

METHOD

4

DEGAS OPTIONS

Help Message

Figure 2-5. Menu of Screens

2.2 Electronics Chassis

The electronics chassis is located behind the upper door of the pump enclosure.

The chassis includes se v eral ele ctronics car ds (printed ci rcuit boards) that are used

to control the pump. Connectors on the cards also allow communication between

the pump and other Dionex chromatography modules. Figure 2-6 shows the

electronics components with the upper door open. To open the door, pull on the

tab located to the right of the main power actuator (see Figure 2-2).

Do not remove any of the electronics cards from the pump.

There are no user-serviceable components on the cards. If

servicing is required, it must be performed by qualified

personnel and appropriate electrostatic discharge (ESD)

handling procedures must be followed.

5

MOD ULE SET-UP

PUMP OPTIONS

6

7

TIME FUNCTION IN

8

DIAGNOSTIC MENU

2-8

Ne retirez aucune des cartes électroniques de la pompe. Auc un

des composants sur les cartes ne peut être réparé par

l'utilisateur. Toute réparation doit être effectuée par un

personnel qualifié utilisant des procédures correctes de

décharge électrostatique.

Doc. 031377 -03 7/01

Page 21

2•Description

PWR SPY

L

C

L

E

A

K

GP50/IP25-DSP130W

DIST

MOTOR

SLOT 2SLOT 1

BLANK

D

L

C

C

O

M

M

P6

I

L

S

C

T

A

1

I

3

R

P

I

N

P7

D

I

S

T

1

2

P

I

N

P8

SLOT 3

BLANK

SLOT 4

LAN-000K

RLY-1

OUT

RLY-2

OUT

+

TTL-1

-

OUT

+

TTL-2

-

OUT

+

TTL-1

-

IN

+

TTL-2

-

IN

+

TTL-3

-

IN

+

TTL-4

-

IN

POWER SUPPLY

GREEN - OK

RED - FAULT

SLOT 5

CPU/RLY

F

R

O

N

T

P

A

N

E

L

Figure 2-6. GP50 Electronics Chassis

(Located behind pump door)

LC LEAK

The leak control cable from the LC10 Chromatography Organizer or

LC20 Chromatography Enclosure, connects t o the

LC LEAK

connector in

slot 1. When a leak occurs i n the LC10 or LC2 0 it is re ported to t he GP50.

Doc. 031377-03 7/01

NOTE The LC25 Chromatography Oven and LC30

Chromatography Oven do not connect to the GP50

LEAK

connector. These ovens contain internal leak

LC

control electronics.

LC COMM

The LC30 Chromatography Oven's RJ-11 serial cable connects to the

connector in slot 1. When connected, the LC30 can be remotely

COMM

controlled by the PeakNet workstation.

LC

2-9

Page 22

GP50 Gradient Pump

LC AIR

The cable from the ai r soleno id v alv es in t he LC10, LC20, L C25, or LC3 0

chromatography module conne cts to the

connected, the GP50 can electrically actuate the solenoid valves that

control the position of the injection valve and the optional column

switching valve in the chromatography module.

LC AIR

connector in slot 1. When

To select the valve positions, go to either the

Section C.1.2) or the

TTL/RELAY

METHOD

screen (see Section C.1.4).

MAIN

screen (see

A strip of eight relay and TTL connectors is located in slot 4. These

connectors interface with Dionex and non-Dionex modules for relay and

TTL control of the pump. Appendix D describes the relay and TTL

functions and the connections between the GP50 and other modules.

CPU

Control Moduleware for the pump resides on the CPU/Relay cards.

The CPU logic and Relay I/O cards occupy slot 5. The Relay I/O card

rides piggybac k o n t he CPU card and exten ds over the f ro nt of slot 4. The

card is short enough to allow the optional DX-LAN pump interface card

(P/N 044195) to mount behi nd it in slot 4. A 60- pin ri bbon cab le lin ks the

CPU logic to the display and keypad. The logic monitors the internal

power supply outputs, and reports the status on the multicolored LED at

the bottom of slot 4.

Green indicates normal operation.

_

Red indicates a power fault. The GP50 will enter its diagnostic state

_

and inhibit all other cont rols unti l the f ault is corr ected . If this occurs,

turn off the power for a few seconds and then turn it back on.

2-10

Doc. 031377 -03 7/01

Page 23

2.3 Mechanical Chassis

The mechanical chassis is housed in a pull-out drawer located behind the lower

door of the pump enclosure. The front of the chassis contains the components

described in Section2.4. Other mechanical assemblies are located inside the

chassis drawer. The drawer should be pulled out only for service procedures. For

routine operation, push in the drawer and tighten the lock located on the lower

right corner of the chassis.

Observe the warning label on the inside of the lower door. The

arrows on the label indicate moving mechanical parts that

present pinch hazards when the pump is on and the

mechanical drawer is open. Do not operate the pump with the

mechanical chassis drawer pulled out.

Respectez l'étiquette d'avertissement apposée à l'intérieur de

la porte inférieure. Les flèches sur l'étiquette indiquent des

pièces mécaniques mobiles qui posent un danger de

pincement lorsque le GP50 est sous tension et le tiroir

mécanique est ouvert. N'ut ilisez jamais le GP50 avec le tiroir

du châssis mécanique ouvert.

2•Description

Doc. 031377-03 7/01

2-11

Page 24

GP50 Gradient Pump

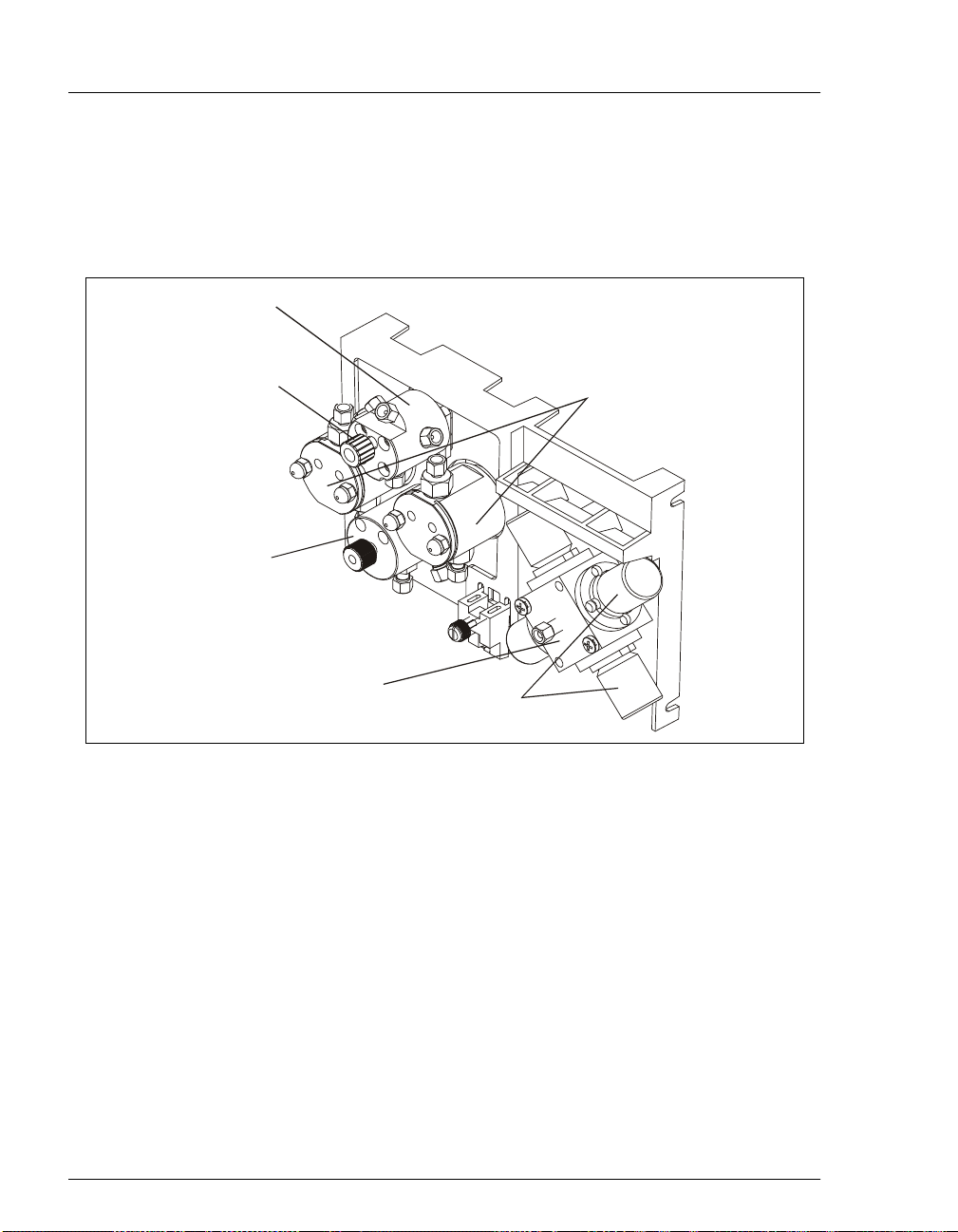

2.4 Mechanical Components

Figure 2-7 shows the mechanical componen ts located behi nd the lo wer door of the

enclosure.

Pressure

Transducer

Pressure

Transducer

Waste Valve

Pr im ing

Block

Pump

Heads

2-12

Eluent

Manifold

Proportioning

Figure 2-7. GP50 Mechanical Components

Doc. 031377 -03 7/01

Page 25

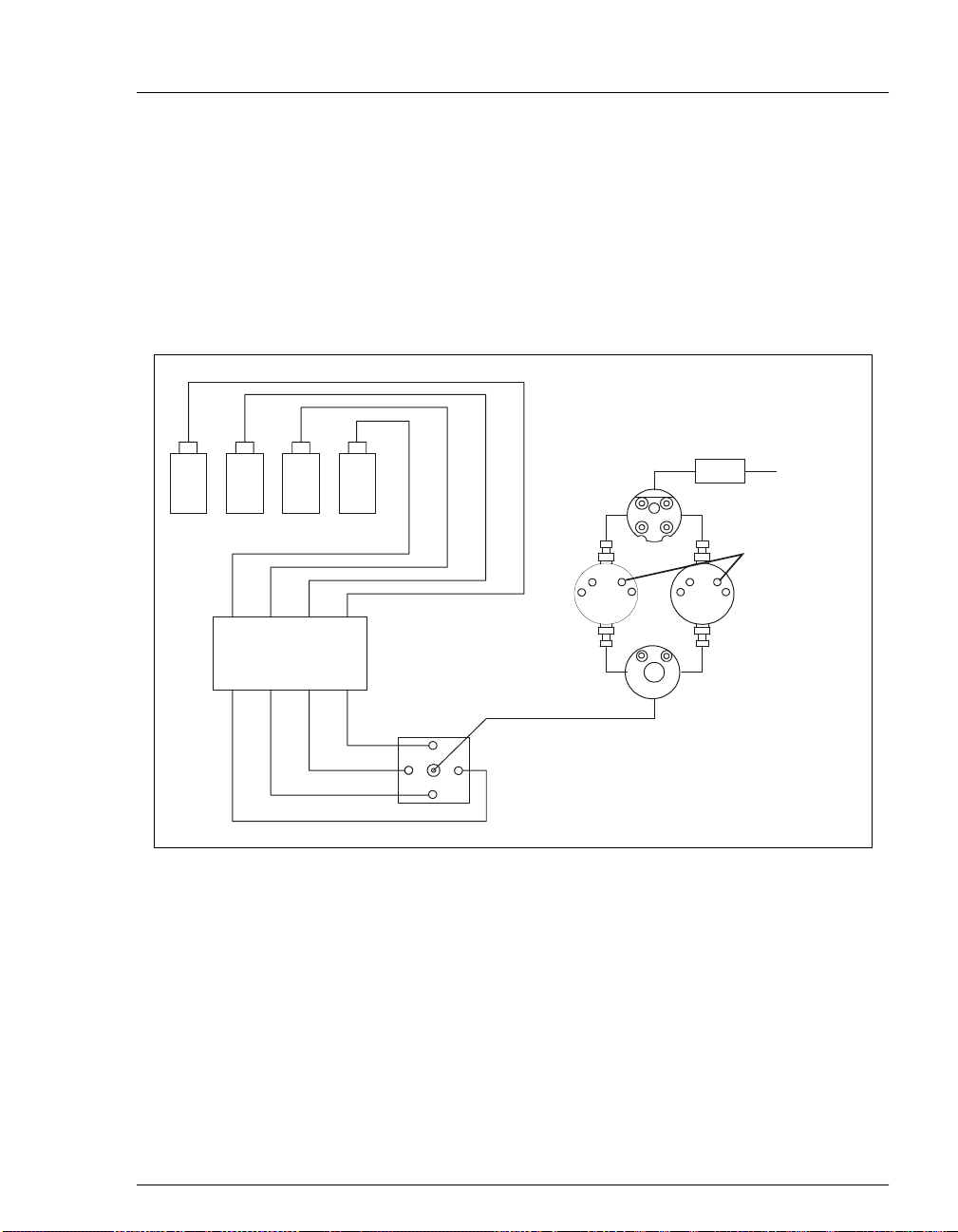

2.4.1 Pump Eluent Manifold

Eluent lines A through D are routed through the rear of the GP50 to the

vacuum de g as pump ( if ins ta ll ed) (see Sec ti on 2.5) and then to the rear of

the proportioning valve. If the vacuum degas pump is not installed, the

eluent lines are connected directly to the proportioning valve. The proper

proportion of eluent exits the front of the valve and is directed to the

priming block. Figure 2-8 shows the eluent flow path through the system.

2•Description

Eluent Reservoirs

VAC Chamber IN

VAC Chamber OUT

ABCD

Pump H eads

OUT

D

Proportioning Valve/

A

C

Manifold Assembly

B

Pressure

Transducer

Figure 2-8. Eluent Flow Schematic

Mixer To Column

Rinse Ports

Priming Block

Doc. 031377-03 7/01

2-13

Page 26

GP50 Gradient Pump

2.4.2 Pump Heads

There are two types of pump heads: standard bore and microbore. The

table below summarizes the features and operating conditions for each

type.

Pump Head

Type

Standard

Bore

Microbore 25µL Isocratic and

*Flow rates are adjustable in increments of 0.01 mL/min.

NOTE Although there is some overlap in flow rates

Piston

Volume

100µL Isocratic 0.04–10.0 35 MPa

between the two pump configurations, continuous

operation of the microbore pump at flow rates

above 2.0 mL/min will decrease seal and pump life.

For the best extended operation at 2.0 mL/min or

above, use a standard bore pump. To achieve

optimum performance at flow rates below

0.4 mL/min, use a microbore pump.

Pump

Operation

Gradient 0.4–10.0 35 MPa

Gradient

Flow Rate

(mL/min)*

0.0–2.50 35 MPa

Maximum

Operating

Pressure

(5000 psi)

(5000 psi)

(5000 psi)

2.4.3 Pump Mixers

A pump mixer ensures complet e mixi ng of the proportioned eluents prior

to injection. The mixer is installed between the pump outlet and the

injection valve. Three types of mixers are available:

_

_

_

2-14

In standard bore PEEK pumps, a GM-5 Mixer (P/N 054044) is used.

In microbore PEEK pumps, a GM-4 Mixer (P/N 049136) is used.

In stainless ste el pumps , a Sta inles s Ste el Mi x er (P /N 0 54043) is use d.

Doc. 031377 -03 7/01

Page 27

2.4.4 Pump Priming Block

The priming block “tee” directs the flow of eluent fr om the manifo ld i nto

the pump heads. The priming block is also used for rapid removal of air

from the system.

Refer to Section B. 2.8 for instructions on priming the pump heads.

2.4.5 Pressure Transducer

From the priming block, the liquid stream is directed to the inlet check

valves on the pump heads, through the pump heads, and finally through

the outlet check valves to the pressure transducer.

Flow from the outlet check valves on the pump heads is combined in the

pressure transducer. The pressure transducer measures the system

pressure at this point. The interactive constant-flow/constant-p ressure

control program on the DSP precisely controls the pump motor speed to

assure flow rate accuracy.

A waste line exits the bottom of the pressure transducer. Opening the

valve on the pressure transducer diverts flow to the waste line and relieves

system pressure, forcing air out of the system.

2•Description

Doc. 031377-03 7/01

Flow output from the pressure transducer is directed out of the pump

module, through the gradient mixer, and on to the rest of the

chromato graphy system (inj ection valve, column, detector).

See Section B.2.6 for eluent outlet line connections.

2-15

Page 28

GP50 Gradient Pump

2.5 Vacuum Degas Pump Assembly (Optional)

The Dionex vacuum degas pump provides continuous on-line vacuum degassing

of up to four eluents. The assembly, which must be installed at the factory,

consists of :

A 4-channel degas chamber (with degas membranes) with 17 mL internal

_

capacity p er channel

A dual-stage diaphragm vacuum pump

_

A solenoid valve

_

An on-board vacuum sensor

_

The electronics required to operate the vacuum pump

_

Fittings, tubing, and other accessories

_

By default, the de gas pump tur ns on f or 2 minu tes when th e GP50 power is turned

on. Thereafter, the pump turns on for 30 seconds at 10-minute intervals. The

DEGAS OPTIONS

Section C.1.6). You can check the vacuum chamber pressure from the

STATUS

screen (see Section C.3.4).

screen allows you to change the cycle time and duration (see

DEGAS

NOTE All components of the vacuum degas assembly are made

of inert materials or corrosion-resistant materials.

However, Dionex recommends thoroughly flushing any

chemicals out of the tubing with deionized water after

each use to avoid crystallization in the membrane pores.

2.6 Piston Seal Wash (Optional)

When using highly concentrated buffer solutions, Dionex recommends

continuously rinsing the piston seal with a piston seal wash. Rinsing removes salt

crystals that may abrade the piston, thereby causing the seal to wear out

prematurely and allow leaks.

Dionex offers a continuous seal wash kit (P/N 059187) for the GP50. For

installation instructions, see Section B.2.8 or the instructions included with the

kit.

2-16

Doc. 031377 -03 7/01

Page 29

2.7 Eluent Reservoirs

NOTE Dionex strongly recommends degassing all eluents and

storing them in reservoirs pressurized with helium. This

helps prevent bubbles (resulting from eluent outgassing)

from forming in the el uent proportionin g valves, pump

heads, and the detector cell.

Degassed eluents and pressurized reservoirs are

especially important when combining aqueous and nonaqueous components (e.g., water and methanol).

Pressurizable reservoirs allow eluents to be stored under

a specific atmosphere.

The following pressurizable reservoirs are available from Dionex:

1-liter glass reservoirs with shatterproof plastic coating (P/N 044126)

_

2-liter glass reservoirs with shatterproof plastic coating (P/N 044127)

_

1-liter plastic reservoirs (P/N 044128)

_

2•Description

2-liter plastic reservoirs (P/N 044129)

_

Do not use the 2-liter plastic reser voir (P/N 044129) for off-line

vacuum degassing of eluents. The reservoir was not designed

for this purpose.

N'utilisez pas le réservoir en plastique de 2 litres (N /P 044129)

pour le dégazage à vide hors ligne d'éluants. Le réservoir n'a

pas été conçu à cette fin.

Refer to the

Pressurizable Reservoir Installation Instructions

(Document No.

034581) for installation details.

EO1 Eluent Organizer (Optional)

The Dionex EO1 Eluent Organizer (P/ N 044 125) holds eluent reservoirs in a liner

that contains spills and leaks. The EO1 can also be used to pressurize reservoirs.

Up to two optional E01 Eluent Organizers can be places on top of the system

Doc. 031377-03 7/01

2-17

Page 30

GP50 Gradient Pump

enclosure. Each organizer can accommodate one or two reservoirs, depending on

the type of reservoir used (see the table below).

No. of

Reservoirs

2 1-Liter glass or plastic 2 L

2 2-Liter plastic 4 L

1 2-Liter glass 2 L

Description Total Volume

2.8 Rear Panel

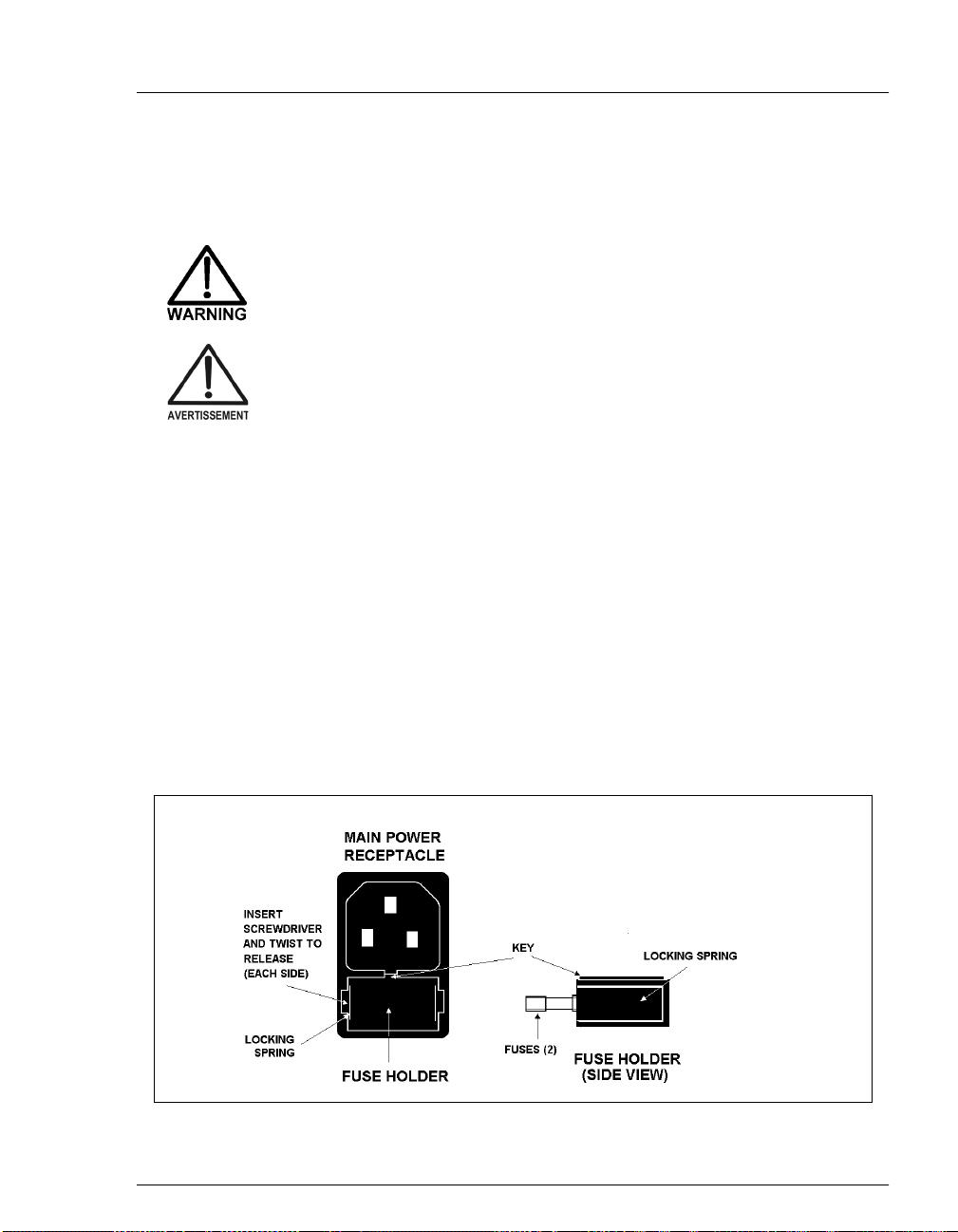

The rear panel contains the main power receptacle and fuses. It also includes a

DX-LAN connector for interfacing the GP50 with the PeakNet workstation. The

rear panel is illustrated in Figure B-1.

2.9 Functional Description

2.9.1 Operating and Control Modes

The operating mode determines

commands:

_

In Local mode, the GP50 receives commands from the front control

panel buttons and screens.

in Liters

how

the GP50 receives operating

2-18

In Remote mode, PeakNet 5 software sends commands from the host

_

computer via the DX-LAN int erfac e. Limited o perating changes fr om

the front panel are allowed.

_

In Locked Remote mode, PeakNet 5 or PeakNet 6 software sends

commands from the host computer via the DX-LAN interface. All

operating changes from the f ront pane l are disab led. When PeakNet 6

software is controlling the GP50, the pump is always in Locked

Remote mode.

The control mode determines

_

In Direct control, the GP50 exe cutes commands immediately.

when

operating commands are executed.

Because there is no time-ba sed program, th e method clock i s not used

and the

Hold/Run

and

buttons do not operate.

Reset

Doc. 031377 -03 7/01

Page 31

2•Description

_

In Method control, the GP50 executes commands according to the

timed steps in a method. The method is programmed from the GP50

front panel or from PeakNet 5 software. See Section 2.9.3 for details

about Method control from the front panel.

using PeakNet 5 to program and run methods, refer to the onli ne Help

or user’s guide.

The table below summarizes the various operating and control mode

configurations. Select the modes from the

Section C.1.2),

DETAIL

screen (see Section C.1.3), or chromatography

software.

Operating/Control Mode Pump Operat ion

Local/Direct Control Commands are entered from the GP50 front control

panel and executed immediately after being entered.

Local/Method Commands are entered from the GP50 front control

panel and executed by running a method programmed

from the front panel.

Remote/Direct Control Commands are sent from PeakNet 5 and executed

immediately when received.

For information about

screen (see

MAIN

Locked Remote/Direct

Control

Remote/Method Commands are sent from PeakNet 5 and executed by

2.9.2 Local and Remote Modes

Local Mode

When the GP50 power is turned on, the pump is in Local mode. In Local

mode the pump accepts operating commands from two sources:

_

Direct input from the front panel keypad and screens. With direct

input, all GP50 operating functions are available.

_

TTL inputs from a remote controller (for example, a Dionex detector

module or autosampler). TTL signals can be used to turn the pump

motor on and off, turn the method clock on and off, and increment or

decrement the method number.

Doc. 031377-03 7/01

Commands are sent from PeakNet 5 or PeakNet 6 and

executed immediately when received.

running a method programmed in PeakNet 5.

2-19

Page 32

GP50 Gradient Pump

Remote Mode

In Remote mode, PeakNet 5 software sends operatin g commands fr om the

host computer via the DX-LAN interface. In Remote mode, operating

parameters can be changed from the front panel, provided they do not

interfere with a running method.

Locked Remote Mode

In Locked Remote mode, PeakNet 5 or PeakNet 6 software sends

operating commands from the host computer via the DX-LAN interface.

In Locked Remote mode, all operating changes from the front panel are

disabled.

When the GP50 is controlled by PeakNet 5, select the Locked Remote

Start option from the PeakNet 5 Run program to operate in the Locked

Remote mode. To return the GP50 to Local mode, clear the Start opt ion or

turn the GP50 power off and then on.

When the GP50 is controlled by PeakNet 6, connecting to the PeakNet 6

timebase automatically selects the Locked Remote mode. To return the

GP50 to Local mode, either clea r the Connect check box on the PeakNet 6

control panel or turn the GP50 power off and then on.

2.9.3 Method Control

In Method control, commands are executed according to the time-based

steps programmed in a method. Each step specifies the eluent

composition and flow rate to be delivered by the pump at a given time.

The selected eluent mixture is delivered either isocratically, or as a

multistep linear or curved gradi ent. As the method runs, the GP50

calculates the changes i n eluent compositio n require d to deli v er a gradient

from one method step to the next or to match the selected curve.

2-20

Doc. 031377 -03 7/01

Page 33

2•Description

Methods are programmed, saved, and edited from the

METHOD

(see Figure 2-9). See Section 3.3 for programming instructions.

M E TH OD E DIT

SAVE TO RUN 100605

LIMITs 0 - 5000

TIME % A

IN IT

0.00

123.45

345.67

25.0

100.0

10.0

17.2

25.0

0.0

22.2

19.6

25.0

0.0

32.3

33.2

25.0

0.0

35.5

30.0

V

C%B %C %D

L1.00

0

I

L

5

FLOW

2.00

Help Message

Figure 2-9. Method Screen

NOTE For information about using PeakN et 5 to program and

run methods, refer to the online Help or user’s guide.

Here is a summary of basic information about using methods.

Each method can contain up to 50 time-based steps. Step 1 always

_

starts at

The GP50 can store up to 100 separate methods (0 through 99) in

_

(initial condition). Step 2 always starts at

INIT

memory. Methods are retained in memory even after the pump is

powered down.

PSI

>

>

>

>

TIME = 0.0

screen

.

Doc. 031377-03 7/01

The total number of methods that can be stored in memory

depends on the length of each method and the amount of

available memory; thus, the actual total may be less than 100.

The pump can run under method control while you are entering or

_

editing any method.

When you save changes to the currently running method or switch to

_

a different method, the method clock continues running unaffected.

Only those parameter changes which affect the method

after

the

current time will be implemented in the current run.

2-21

Page 34

GP50 Gradient Pump

2.9.4 Eluent Delivery

Isocratic Eluent Run

The simplest use of the GP50 is for the delivery of an isocratic

(unchanging) mixture of one or more eluents. If more than one eluent is

selected, the pump d elivers a proport ional mixt ure of the el uents based on

the percentage of each eluent selected. The combined percentages of all

eluents selected must total 100% or the pump will not run.

Gradient Eluent Run

The GP50 can produce step, linear, concave, or convex curves in eluent

concentration over a specified time period. The slope of the gradient is

determined by the selected gradient curve (see Figure 2-10) and the time

between the starting and end ing points of a grad ient step. It is important to

note the following points:

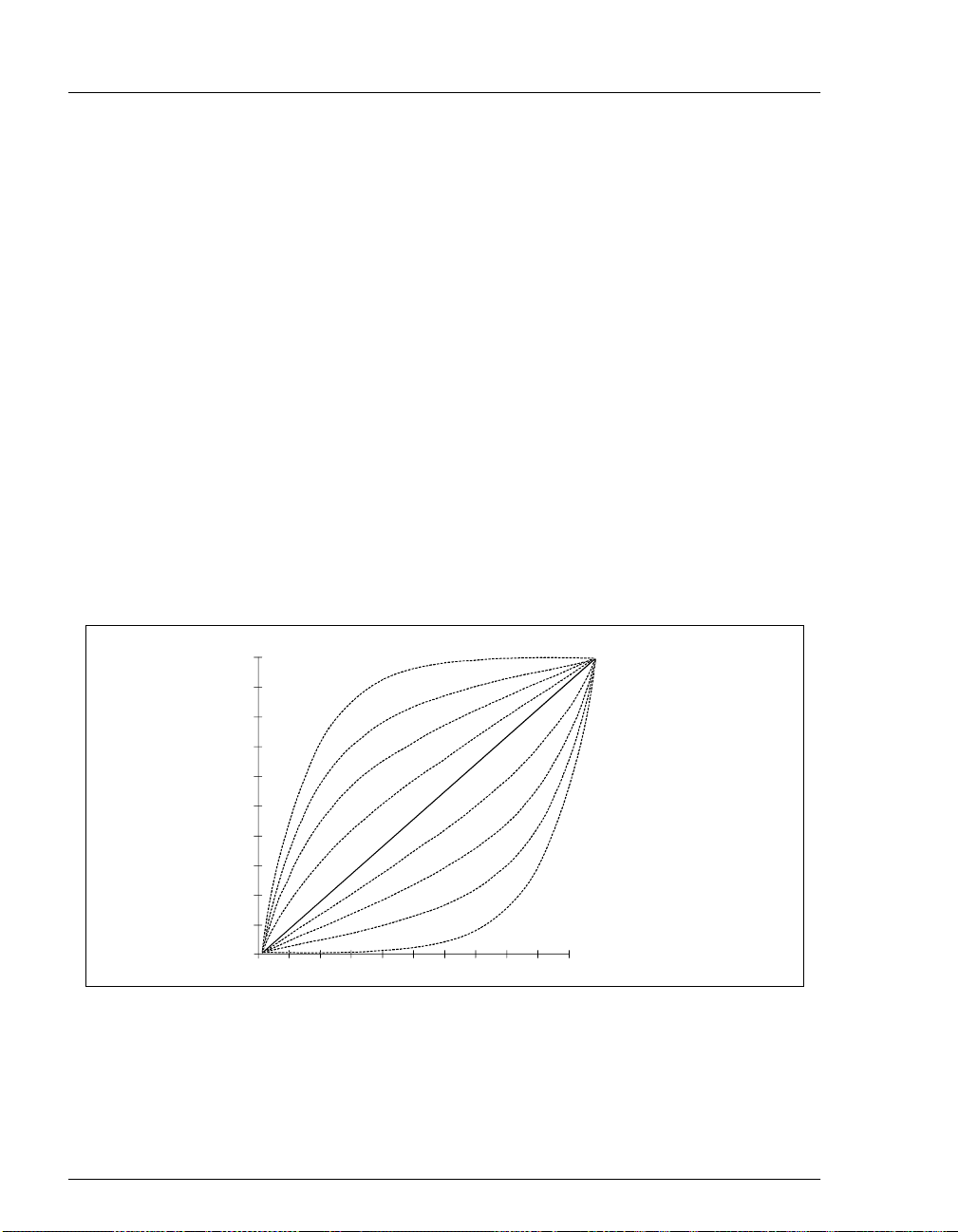

The curve number p arameter determines whethe r the pump deliver s a

_

linear or curved gradient.

2-22

1.0

.9

.8

.7

.6

.5

.4

.3

.2

.1

0

1

0

1

2

3

4

5

6

7

8

9

2

45678

3

910

Figure 2-10. Eluent Composition Profile for Curves 1 - 9

Doc. 031377 -03 7/01

Page 35

2•Description

Curve numbers are defined as follows:

Curve Number Gradient Type

1, 2, 3, 4 Convex

5 Linear (power-up default)

6, 7, 8, 9 Concave

NOTE A curve number in a step instructs the pump to use

the selected curve number when moving from the

previous step to that step. Because there are no

previous steps for

cannot be entered for these steps.

The gradient slope does not change during a step if curve 5 (the

_

INIT

default setting) is selected, because curve 5 represents a linear

gradient.

Convex curves cause rapid changes in eluent composition at the

_

beginning of the curve and slower changes at the end. Concave curves

cause slower changes at the beginning and rapid changes at the end.

TIME=0.0

or

, curve numbers

Slope changes o ver time become mor e ex treme as c urves go from 6 t o

_

9 (more concave) and from 4 to 1 (more convex). Figure 2-10 shows

the eluent composition profiles corresponding to curves 1 through 9,

normalized for 0–100% for 10 minutes.

Any consecutive method steps specifying identical eluent

_

compositions will generate an isocratic segment, regardless of the

curve number selecte d.

A step change is a steep linear gradient in which the eluent

_

composition changes from one eluent to another within 6 seconds.

Doc. 031377-03 7/01

2-23

Page 36

GP50 Gradient Pump

2-24

Doc. 031377 -03 7/01

Page 37

3 • Operation and Maintenance

3.1 Getting Ready to Run

NOTE The GP50 Gradient Pump is designed to perform ion

chromatography and BioLC applications only and

should not be used for any other purpose. If there is a

question regarding appropriate usage, contact Dionex.

3.1.1 Degas Eluents

Dionex strongly recommends degassing all eluents and storing them in

reservoirs pressurized with filtered inert gas (see Sect ion 3.1. 3). This

helps prevent bubbles caused by eluent outgassing from forming in the

eluent proportioning valves, pump heads, and the detector cell. Degassed

eluents and pressurized reservoirs are especially important when

combining aqueous and nonaqueous components (e.g., water and

acetonitrile).

The GP50 with the optional vacuum degas pump assembly provides

continuous on-line vacuum degassing of up to four eluents.

Doc. 031377-03 7/01

If the GP50 is not equipped with the vacuum degas assembly, manually

vacuum-degas eluents daily, as described below, and store them in

pressurized reservoirs.

Degassing Eluents Manually

1. Prepare the eluent required for your applicat ion. Pour it into a v acuu m

flask and attach the flask to a vacuum pump or water aspirator.

2. Vacuum degas the eluent for 5-10 minutes by shaking or sonication.

3. Remove the flask from the vacuum.

the aspirator back into the flask.

4. Pour the degassed eluent into a press uriza ble res ervoir . Be car eful not

to shake the e luent.

5. Install end-line filters and press urize the re servoi rs (see Sectio ns 3.1.2

and 3.1.3).

Do not allow water to flo w fr om

3-1

Page 38

GP50 Gradient Pump

3.1.2 Filter Eluents

Always f il t er e lue nt s bef or e beginning operation. Fil ter in g re moves small

particulates that may contaminate the eluent proportioning valves or the

pump check valves and cause erratic flow rates or loss of prime. The

pressurizable reservoir Ship Kits supply end-line filters (P/N 045987) for

this purpose.

Install an end-li ne f il ter on the end of each elu ent li ne insi de the re se rv oir.

To prevent air from being drawn through the lines, mak e sure that the end

of each filter r eaches the bot tom of the el uent reser voi r and that eac h fi lter

is submerged in eluent.

3.1.3 Pressurize Eluent Reservoirs

The GP50 Gradient Pump is capable of operation with or without head

pressure on the eluent. Pressurization of the eluent reservoirs, if used,

should be with filtered inert gas (preferably helium). Refer to the

Pressurizable Reservoir Installation Instructions

1. V erify that a re gu lator (P/ N 046594) is install ed on the g as supp ly line

to the reservoirs.

for details.

3-2

2. Turn on the gas supply and adjust the pressure to 55 KPa (8 psi).

Never pressurize the reservoirs above 69 KPa (10 psi).

Ne mettez jamais les réservoirs d'éluants sous une pression

supérieure à 69 kPa (10 lb/po²) .

Doc. 031377 -03 7/01

Page 39

3.1.4 Start-Up

1. Turn on the main pump switch.

3 • Operation and Maintenance

The

POWER-UP

screen displays (see Figure 2-4). A series of diagnostics tests is

MAIN

run at power -up. If one of the test s fail s, the

screen displays briefly (see Figure 2-3) and then the

DIAGNOSTIC TEST

displays instead. See Section C .2.7 if this occurs.

When the GP50 powe r is turned on, the injection v alv e is initia lized to

the Load position.

2. Press

Off/On

3. Check the pressure reading on the

to start the pump flow.

screen. The GP50 display

MAIN

updates the pressure readout once pe r piston str oke. The rea ding from

one stroke to the next should be within 3%.

A variation of more than 3% indicate s that the pump is out of prime.

Refer to Section B.2.8 for priming instructions, or see Section 4.1 for

other conditions which can cause the pump to lose prime.

NOTE After starting the pump or changing the flow

rate, wait at least 5 minutes (up to 20 minutes

for low flow rates in a standard bore pump)

before beginning an analysis. This allows the

pump's real-time electronic pulse damping

circuitry to stabilize the flow rate.

screen

Doc. 031377-03 7/01

3-3

Page 40

GP50 Gradient Pump

3.1.5 Selecting the Pressure Limits

The high and low pres sur e li mit s aut omat ic all y st op the pump if a sy stem

malfunction occurs, such as overpressurization caused by a blockage or

low pressure caused by a leak downstream from the pump.

When PeakNet is controlling the pump, select the pressure limits

_

from the software.

When the pump is running under Local mode, Direct control, enter

_

the pressur e limits on the

When the pump is running under Local mode, Method control, enter

_

the pressure limits on the

are set in the

When a limit trip stops t he pump, the method c lock immediate ly stops

and goes to Hold. The current status of the program that was running

at the time is displayed on the front panel.

To select the pressure limits from the front panel:

step and remain unch anged t hro ughout the ana lysis .

INIT

DETAIL

METHOD

screen (see Figure 3-1).

screen (see Figure 3-5). The limits

1. Go to the

DETAIL

or

METHOD

screen and move the cursor to the

field.

2. Enter a low pressure limit between 1.4 and 2.8 MPa (200-400 psi).

DETAIL SCREEN

100.0 %A

0.0 %B

0.0 %C

0.0 %D

LOCAL

Help Message

Figure 3-1. Detail Screen: Setting Pressure Limits

2125

2.00

IN J E C T

COLUMN

LIMIT

DIRECT CNTRL

PSI

m L/M IN

SAMPLE

A

300-2500 PSI

TTL1

TTL2

RLY1

RLY200

1

1

The setting may vary, depending on the system operating pressure.

The low pressure limit is activated after 13 pump piston strokes (i.e.,

after 1.3 mL (standard bore) or 0.325 mL (microbore) of fluid is

pumped through).

3. Enter a high pressure limit that is 2.8 to 3.4 MPa (400-50 0 psi ) above

the normal system operating pressure. The pump is equipped with a

pressure limit that prevents operation above 35 MPa (5076 psi).

LIMIT

3-4

Doc. 031377 -03 7/01

Page 41

3 • Operation and Maintenance

3.1.6 Selecting the Operating and Control Modes

1. Go to either the

displays

displays

2. To select the operating m ode:

_

_

3. To select the control mode, move the cursor to the field, press

Select

a cursor arrow button.

LOCAL, REMOTE

DIRECT CNTRL

GP50 is controlled by PeakNet 6

If the

PeakNet 6 timebase a utomatica lly select s

the GP50 to

PeakNet 6 control panel or turn the GP50 power off and then on.

GP50 is controlled by PeakNet 5

If the

on the

Select

Enter

To select

Remote Start option from t he Run program. To return the GP50 to

LOCAL

on

MAIN

or

∆

or a cursor arrow button.

LOCKED RMT

, clear the Start op tion o r turn the GP50 po wer of f and then

.

or

Select

∆

or

MAIN

LOCAL

or

Select

DETAIL

or

, either clear the Connect check box on the

DETAIL

to toggle to the desired mode, and press

∇

to toggle to the desired mode, and press

∇

screen. The operating mode field

, or

LOCKED RMT

METHOD

screen. Move the cursor to the field, press

with PeakNet 5, select the Locked

. See the example in Figure 3-2.

. The control mode field

, connecting to the

LOCKED RMT

select

,

LOCAL

. To return

or

REMOTE

or

Enter

25.0 %B

15.0 %C

0 .0 %D

Doc. 031377-03 7/01

60.0 % A

LOAD

COLUMN A

LOCA L

2000

2.00

DIRECT CNTRL

PSI

m L/MIN

Help Message

Control ModeOperating Mode

Figure 3-2. Main Screen: Operating and Control Mode Fields

3-5

Page 42

GP50 Gradient Pump

3.2 Running Under Direct Control (Local Mode)

Direct Control, Local mode is use d most often when a PeakNet workst atio n is not

configured.

Direct Control Example

Specify an isocrati c mi xture of 60% eluent A, 25% eluent B, and 15% eluent C to

be pumped at 2.0 mL/min (see Figure 3-3).

3-6

1. Go to the

control modes to

Figure 3-4 illustrates the

up.

MAIN

60.0 % A

25.0 %B

15.0 %C

0 .0 %D

Help Message

Figure 3-4. Main Screen: Running Under Direct Control

Figure 3-3. Isocratic Run Profile

or

LOCAL

DETAIL

screen and if necessary, change the operating and

and

DIRECT CNTRL

screen as it wil l appear when the e xa mple is set

MAIN

LOAD

2000

COLUMN A

LOCA L

DIRECT CNTRL

(see Section 3.1.6).

PSI

2.00

m L/MIN

Doc. 031377 -03 7/01

Page 43

3 • Operation and Maintenance

2. Move to the %A field and enter 60; move to the %B field and enter 25; move

to the

eluent percentages equa l 100).

field and press

%C

(15 is automatically filled in to ma ke the

Enter

3. Move to the

mL/MIN

4. If the pump is currently off, press

field and enter 2.

Off/On

to turn on the motor and begin the

isocratic delivery.

NOTE After starting the pump or changing the flow rate, wait

at least 5 minutes (up to 20 minutes for low flow rates in

a standard bore pump) before beginning an analysis.

This allows the flow rate to stabilize.

3.3 Running Under Method Control (Local Mode)

This section pro vi des general instructions on how to create, edit , and run methods

from the GP50 front panel. For step-by-step examples, see Section 3.4.

When entering parameters on the

After starting the pump or changing the flow rate, wait at least 5 minutes (up

_

METHOD

to 20 minutes for low flow r ates in a sta ndard bore p ump) befor e beginning an

analysis. T his allows the flow rate to stabilize.

In the %A, %B, %C, and %D columns, enter decimal percentage values from

_

0.1% through 100% for the eluent compositions. The combined percentages

for all eluents must total 100% or the pump will not run.

In the V column, select the injection valve posi tion (L for load or I for inject).

_

screen, observe these guidelines:

In the

_

increments of 0.01 mL/min. See Section 2.4.2 for the available flow rate

ranges. They vary, depending on the size of the pump head and whether the

run is isocratic or gradient.

For steps other than

_

The curve num ber determines whether the pump delivers a lin ear or curved

Doc. 031377-03 7/01

column, ent er the pump flow rate. Fl ow rates are adjustable in

FLOW

Continuous operation of the microbore pump at flow rates

above 2.0 mL/min will decrease seal and pump life. For

optimum performance above 2.0 mL/min, a standard bore

pump should be used.

INIT

and

TIME=0.0

, enter a curv e number in the C column.

3-7

Page 44

GP50 Gradient Pump

gradient when moving to the step from the one preceding it (see

Section 2.9.4). The default is curve 5 (linear).

NOTE Because there are no previous steps f or

curve numbers are not entered for them.

If a step field is “blank” (has no entry), the last selected value for the field

_

INIT

TIME=0.0

or

remains in effect.

The symbol

_

next to the bottom time ent ry indicates there are addit ional steps

∨

below. Move the cursor to the bottom time entry and press the down arrow to

see the additional step(s).

The symbol ^ next to the top time entry indicates that it is preceded by at least

_

one more step. Move the cursor to the entry and press the up arrow to see the

additional step(s).

The symbol > at the right edge of each line indicates a lateral extension to the

_

line. Move the cursor to the end of a line and press the right arrow to display

the

METHOD

extension screen (see Section C.1.5).

3.3.1 Creating a New Method

You can create a new method when the method clock is in either

.

Run

1. Go to the

MAIN

or

DETAIL

operating and control modes to

Section 3.1.6).

screen and if necessary, change the

LOCAL

and

METHOD

(see

,

Hold

or

3-8

2. Go to the

3. In the

EDIT

METHOD

field, enter the number of the method to be created. This

screen.

can be the number of an unused method or of an existi ng met hod that

you plan to edit and sa v e as a new method. If you enter the number of

an unused method, the screen will look similar to th e example screen

in Figure 3-5.

Doc. 031377 -03 7/01

Page 45

3 • Operation and Maintenance

M ETHO D E DIT

TIME %A

100.0

0.00

Help Message

Figure 3-5. Method Screen: Creating a New Method

4. In the

5

%B %C %D V

field, set the low and high pressure limi ts (see

LIMITs

SAVE TO RUN

LIMITs

5

0 - 5000

C FLOW

_

L1.00IN IT

_

0

PSI

>

>

>

>

Section 3.1.5).

5. Each method starts out with two timed steps (see Figure 3-5): an

initial conditions st ep (contai ning

zero step (containing 0.00 in the

in the

INIT

column). The parameters in

TIME

column) and a time

TIME

each of these first two steps can be changed but the steps cannot be

deleted. Enter the parameters for both steps.

6. Enter a new step using one of the following methods:

Move the cursor to the empty

_

field below the last step and

TIME

enter the elapsed time at whic h to start the new step. Press

or a cursor arrow button.

Enter

Doc. 031377-03 7/01

Move the cursor to any of the

_

fields and press

TIME

Insert

. This

adds a ne w step af ter th e curs or posit ion. Ente r the elapsed time at

which to start the new step and pres s

or a cursor arrow

Enter

button.

After entering a new step, all timed steps are automatically organized

in chronological order.

7. Continue entering parameters for the new step. When you finish,

move the cursor to the

If you are editing an exist in g metho d, ent er a new number for the

_

method and press

If you are editing an unused method, press

_

SAVE TO

Enter

field and do one of the following:

.

.

Enter

3-9

Page 46

GP50 Gradient Pump

3.3.2 Running a Method

1. If the pump motor is off, press

2. Go to the

MAIN

or

DETAIL

screen and if necessary change the

operating and control modes to

to turn on the motor.

Off/On

LOCAL

and

METHOD

(see

Section 3.1.6).

3. In the

METHOD

# field, enter the desired method number. If the

method clock is already runn ing, the method starts immediatel y . If the

clock is in Hold, press

NOTE You can also select the method number in the

METHOD

and enter the desired method number.

Hold/Run

screen. Move the cursor to the

to start the method.

RUN

fiel d

4. The elapsed time on the method clock when the method begins

determines where (at what step and parameters) the method begins

running:

If the method clock is at

_

running using the

If the method clock is greater than zero, the method begins

_

ial condition parameters.

INIT

or time zero, the method begins

INIT

running using the par ameters s pec if ie d in the s tep f or t hat e lap sed

time. To start the method at the

.

Reset

ial conditions instead, press

INIT

3-10

Doc. 031377 -03 7/01

Page 47

3.3.3 Editing a Method

Existing methods can be modified by changing, adding, or deleting steps

and parameters. Changes can be made when the method clock is stopped

or running. If the meth od you ar e editin g is curre ntly runn ing, the cha nges

are stored in memory and implemented when you save the method.

NOTE After saving changes, there is no way to recall the

original method. If you plan to make experimental

changes to a method but also want to retain the original

method, save the modified method to a new number.

To edit a method:

3 • Operation and Maintenance

1. Go to the

METHOD

screen. In the

field, enter the number of the

EDIT

method to be modified.

2. Make the required changes:

To change a parameter

_

, position the cursor in the field and enter

the new value. The previo us value is automatically deleted.

To add a method step

_

, or move the cursor to the empty

Insert

, move the cur sor to an y

TIME

field and press

TIME

field below the last

step and enter the elapsed time at which to start the new step.

When you press

or a cursor arrow button, the new step is

Enter

automatically moved to the correct chronological position.

Continue entering parameters for the new step.

To delete a method step

_

and press

Delete

3. When changes are complete, move the cursor to the

Press

to save the changes to the current method, or enter a new

Enter

method number and press

, move the cur so r to th e step to be deleted

twice.

SAVE TO

Enter.

If you save changes to the currently running method, they are

immediately incorporated in the run and execut ed at the prog rammed

time,

the method at the

method, press

the modified event has already been executed. To restart

unless

ial conditions and run all steps of the updated

INIT

.

Reset

field.

Doc. 031377-03 7/01

3-11

Page 48

GP50 Gradient Pump

3.3.4 Deleting a Method

To delete an entire me th od, move the cursor on the

step and press

INIT

Delete

twice.

3.3.5 Changing the Running Method

To change from t he method currently running t o a di fferent method, g o to

the

field, and press

MAIN

or

DETAIL

Enter

screen, enter the new method number in the

.

The new met hod will begin runnin g, u si ng the parameters speci fied in the

step for the current elapsed time. To start the method at the

conditions, press

Reset

.

3.3.6 Controlling the Method Clock

The

Hold/Run

and

DETAIL

To start and stop the method clock, press

_

To reset the clock to

_

To set the clock to a specific elapsed time, enter the time in the

_

field on the

continue) running, using the method parameters specified for that

time.

button, the

button, and the

Reset

screens control the method clock:

ial conditions, press

INIT

MAIN

or

DETAIL

screen. The method will start (or

METHOD

field s in the

MIN

Hold/Run

Reset

screen to the

INIT

.

.

METHOD

ial

MAIN

MIN

3-12

Doc. 031377 -03 7/01

Page 49

3.4 Example Methods

The examples in this section provide step-by-step instructions for creating three

types of methods: iso crati c, linea r gra dient, and cur v ed g radie nt. The l ast ex ample

demonstrates how to edit a running method.

3 • Operation and Maintenance

For all of the examples, set the pump to

LOCAL

Section 3.1.6).

3.4.1 Isocratic Method Example

Specify an isocratic mixture of 60% eluent A, 25% eluent B, and 15%

eluent C to be pumped at 2.0 mL/min. Figure 3-3 illu strates the isocratic

profile for this example. Figure 3-6 illus trates the

appears when the example is set up .

M ETHO D E DIT

TIME %A

60 .0_ 25.0 15.0

0.00

Help Message

Figure 3-6. Method Screen: Isocratic Run Example

1. Go to the

%B %C %D V

METHOD

screen and enter a method number in the

field (1, for example). The screen auto matically changes the number

in the

SAVE TO

field to the number of the method being edited.

SAVE TO

LIMITs 0 - 5000

mode,

METHOD

C FLOW

_

METHOD

RUN

L2.00IN IT

control (see

screen as it

011

PSI

>

>

>

>

EDIT

Doc. 031377-03 7/01

If Method 1 currently e xis ts and you w ant to ret ain it, e nter a ne w,

_

unused, method number in the

If Method 1 currently exists and you want to delete it, move the

_

cursor to

TIME=INIT

2. Move the cursor to the

and enter 25; move to the

and press

field and enter 60; move to the %B field

%A

field and press

%C

EDIT

Delete

field.

twice.

Enter

(15 is

automatically filled in to make the eluent percentages equal 100).

Ignore the

(Curve) an d V (Valve) fields. Mov e to the

C

FLOW

enter a flow rate of 2.00.

field and

3-13

Page 50

GP50 Gradient Pump

3. Move the cursor to

4. Move the cursor to

press

off, press

to select the programmed method. If the pump motor is

Enter

Off/On

SAVE TO

Run

to have the pump st ar t del ivering the eluen t mixt ur e.

5. If the method clock is in hold, press

and press

, enter the method number (1, in this case) and

Hold/Run

method.

3.4.2 Linear Gradient Method Example

The following summarizes the linear gradient method steps:

Create Method 2 to be gin under i socratic co nditions with 10 0% eluent

_

A at 2.0 mL/min.