Page 1

GP40 GRADIENT PUMP

OPERATOR’S MANUAL

© Dionex Corporation 1995

Document No. 034856

Revision 03

May 1995

Page 2

©1995 by Dionex Corporation

All rights reserved worldwide.

Printed i n the Uni ted State s of Ameri ca.

This publication is protected by federal copyright law. No part of this publication

may be copied or distributed, transmitted, transcribed, stored in a retrieval system,

or transmitted into any human or computer language, in any form or by any means,

electron ic, mecha nical, m agnetic, m anual, or othe rwise, or discl osed t o third

parties without the express written permi ssion of Dionex Corporation, 1228 Ti tan

Way, Sunnyvale, California 94088-3603 U.S.A.

DISCLAIM ER OF WARRANTY AND LIMITE D WARRANTY

THIS PUBLICATION IS PROVIDED “AS IS” WITHOUT WARRANTY OF

ANY KIND. DIONEX CORPORATION DOES NOT WARRANT,

GUARANTE E, OR MAKE ANY EXPRESS OR IMPLIED

REPRESENTATIONS REGARDI NG THE USE, OR THE RESULTS OF THE

USE, OF THIS PUBLICATION IN TERMS OF CORRECTNESS,

ACCURACY, RE LIABILITY, CURRENTNESS, OR OTHERWISE.

FURTHER, DIONEX CORPORATION RESERVES TH E RIGHT TO REVISE

THIS PUBLICATION AND TO MAKE CHANGES FROM TIME TO TIME

IN THE CONTENT HEREINOF WITHOUT OBLIGATION OF DIONEX

CORPORATION TO NOTIFY ANY PE RSON OR ORGANIZATION OF

SUCH REVISION OR CHANGES.

TRADEMARKS

DX LAN and SRS a re trademarks of Dionex Corporation.

Tefzel® is a regist ered tr ademar k of E.I . du Po nt de Ne mours & Co.

PRINTING HISTORY

Revisi on 01 , Au gust 1993

Revision 02, September 1993

Revisi on 0 3, M ay 19 95

Page 3

1 • Introduction

1.1 Ov erview . . . . . . . . . . . . . . . . . . . . . . 1-3

1.2 Ab out This Manual . . . . . . . . . . . . . . . . 1-4

1.2. 1 Typefaces . . . . . . . . . . . . . . . . . 1-5

1.2. 2 Safety Messages and Notes . . . . . . . 1-5

1.2.3 Symbols . . . . . . . . . . . . . . . . . . 1-6

1.3 Related Manual s . . . . . . . . . . . . . . . . . . 1-7

2 • Description

2.1 Front Control Panel . . . . . . . . . . . . . . . . 2-4

2.1.1 Control Panel Keypad . . . . . . . . . . 2-5

Contents

Doc. 034856 -0 3 5/95

2.1. 2 Displ a y Screens . . . . . . . . . . . . . 2-1 0

2.2 Electronics Ch assis . . . . . . . . . . . . . . . . 2-11

2.3 Mecha nica l Chas sis . . . . . . . . . . . . . . . . 2-1 4

2.4 Inter ior Components . . . . . . . . . . . . . . . . 2-14

2.4.1 Pump Eluent Manifold . . . . . . . . . . 2-15

2.4. 2 Pump Heads . . . . . . . . . . . . . . . 2-16

2.4. 3 Pump Mixer s . . . . . . . . . . . . . . . 2-17

2.4.4 Pump Pr iming Block . . . . . . . . . . . 2-17

2.4. 5 Pres sure Transducer . . . . . . . . . . . 2-17

2.5 Vacuum Degas Pump Assembly (Optional) . . . 2-18

2.6 E luent Reservoirs . . . . . . . . . . . . . . . . . 2-19

iii

Page 4

Contents

3 • Operation a nd Maintenance

2.7 Rear Panel . . . . . . . . . . . . . . . . . . . . . 2-20

2.8 Functional Descri pti on . . . . . . . . . . . . . . 2 -21

2.8. 1 Oper a t i n g M o d es . . . . . . . . . . . . . 2-23

2.8. 2 Method Control . . . . . . . . . . . . . 2-2 4

2.8.3 Eluent Delivery . . . . . . . . . . . . . . 2- 25

3.1 Getting Ready to Run . . . . . . . . . . . . . . . 3-3

3.1.1 De gas El uents . . . . . . . . . . . . . . 3-3

3.1.2 Filter E luents . . . . . . . . . . . . . . . 3-4

3.1.3 Pressurize Eluent Reservoirs . . . . . . 3-4

3.1.4 Start -Up . . . . . . . . . . . . . . . . . . 3-5

3.1.5 Selecting the Pressure Limits . . . . . . 3-5

3.2 Running Under Direct Control . . . . . . . . . . 3-6

3.3 Running Under Method Control . . . . . . . . . 3-9

3.3. 1 Creat ing a New Metho d . . . . . . . . . 3-10

3.3.2 Running a Me thod . . . . . . . . . . . . 3- 12

3.3.3 Editing a Method . . . . . . . . . . . . . 3-12

3.3.4 Delet ing a Metho d . . . . . . . . . . . . 3-14

3.3.5 Changing the Runn ing Method . . . . . 3-14

3.3.6 Controlling the Method C lock . . . . . 3-14

3.4 E x ample Method s . . . . . . . . . . . . . . . . . 3 -14

3.4.1 Isocratic M ethod Example . . . . . . . . 3-15

3.4.2 Linear Gradient Method Example . . . 3-16

3.4.3 Curved Grad ient Method Example . . . 3-22

iv

Doc. 034856 -0 3 5/95

Page 5

3.4.4 Editing a Running Method E xample . . 3-26

3.5 Routine Maint en ance . . . . . . . . . . . . . . . 3-29

3.5.1 Da ily Maint enance . . . . . . . . . . . . 3-29

3.5.2 Pe riodic Maint enance . . . . . . . . . . 3-31

3.6 Sh utd o wn . . . . . . . . . . . . . . . . . . . . . . 3-31

4 • Troubleshoot ing

4.1 Left-Right Pump Head Pressure Fluctua tions . . 4-3

4.2 Pump Will Not Start . . . . . . . . . . . . . . . . 4-6

4.3 Pu mp Stops . . . . . . . . . . . . . . . . . . . . 4-6

4.4 L iquid L e aks/Leak Alarm . . . . . . . . . . . . . 4- 9

4.5 No isy Pump Mo tor . . . . . . . . . . . . . . . . 4-11

Contents

4.6 Vacuum Degas Pump Does Not Run . . . . . . . 4-12

4.7 Vacuum Degas Pump Calibration Fails . . . . . 4-13

4.8 Inoperative Relay Control Function . . . . . . . 4-14

4.9 Poor Chromatographic Reproducibility . . . . . 4-14

5 • Service

5.1 Cleaning the Check Valve s . . . . . . . . . . . . 5 -3

5.2 P i ston S eal Replacemen t . . . . . . . . . . . . . 5-6

5.3 Pu mp Piston Repl acement . . . . . . . . . . . . 5-10

5.4 Pressu re Transducer Pad and O- Ring

Replacement . . . . . . . . . . . . . . . . . . . . 5-11

5.5 Pressure Transducer Waste Valve O-Ring

Replacement . . . . . . . . . . . . . . . . . . . . 5-13

Doc. 034856 -0 3 5/95

v

Page 6

Contents

5.6 Proportioning Valve Replacement . . . . . . . . . 5-14

5.7 Active Mixer Filter Replacement . . . . . . . . . 5-16

5.8 Changing Main Power Fuses . . . . . . . . . . . . 5-19

vi

Doc. 034856 -0 3 5/95

Page 7

A • Specifications

A.1 Electrica l . . . . . . . . . . . . . . . . . . . . . . A- 3

A.2 E nvir o n mental . . . . . . . . . . . . . . . . . . . A-3

A.3 Ph ysical . . . . . . . . . . . . . . . . . . . . . . A-3

A.4 Di splay and Keypad . . . . . . . . . . . . . . . . A- 3

A.5 Hy draulics . . . . . . . . . . . . . . . . . . . . . A-4

A.6 Gr adient Contr ol . . . . . . . . . . . . . . . . . . A-5

A.7 Vacuum Degas Pump As sembly . . . . . . . . . A-5

B • Installation

B.1 Facility Requirements . . . . . . . . . . . . . . . B-3

B. 2 Install atio n Ins tructions . . . . . . . . . . . . . . B- 4

Contents

Doc. 034856 -0 3 5/95

B. 2.1 P o wer Co nnection . . . . . . . . . . . . B-4

B.2.2 Electronic Chassis Connections . . . . . B-5

B.2.3 DX LAN Network Connec tion (Optional) B-7

B. 2.4 Waste Lines . . . . . . . . . . . . . . . . B- 9

B.2.5 Eluent Outlet Line Connection . . . . . B-10

B.2.6 E luent Inlet Line Con nectio ns . . . . . B-10

B. 2.7 P riming the Pump . . . . . . . . . . . . B- 11

B. 3 Automat ic SRS Power Co ntrol . . . . . . . . . . B- 15

B.4 Stacki n g Modules . . . . . . . . . . . . . . . . . B-17

B.5 Securing Modules (Opti o nal) . . . . . . . . . . . B-18

B.5.1 I n stalling a Shoe . . . . . . . . . . . . . B-1 8

B. 5.2 I nstalling a Tie . . . . . . . . . . . . . . B-19

vii

Page 8

Contents

C • User Interface

C.1 Operational Screens . . . . . . . . . . . . . . . . . C-5

C.1.1 Main Screen . . . . . . . . . . . . . . . . C-5

C.1.2 Detail Screen . . . . . . . . . . . . . . . . C-7

C.1.3 Method Screen . . . . . . . . . . . . . . . C-8

C.1.4 Method Extension Screen . . . . . . . . . C-10

C.1.5 Module Setup . . . . . . . . . . . . . . . . C-11

C.1.6 Pump Options . . . . . . . . . . . . . . . C-12

C.1.7 Time Function In . . . . . . . . . . . . . . C-13

C.2 Diagnostic Screens . . . . . . . . . . . . . . . . . C-14

C.2.1 Hexadecimal Entry Fields . . . . . . . . . C-14

C.2.2 Diagnostic Menu . . . . . . . . . . . . . . C-14

C.2.3 Power-Up Screen . . . . . . . . . . . . . . C-15

C.2.4 Elapsed T ime . . . . . . . . . . . . . . . . C-16

C.2.5 DSP Status . . . . . . . . . . . . . . . . . C-17

C.2.6 DX LAN Status . . . . . . . . . . . . . . C-18

C.2.7 Keyboard Test . . . . . . . . . . . . . . . C-20

C.2.8 Diagnostic Test . . . . . . . . . . . . . . . C-21

C.2.9 Pressure Statistics . . . . . . . . . . . . . C-23

C.2.10 DSP Code Version . . . . . . . . . . . . . C-24

C.3 Calibration Screens . . . . . . . . . . . . . . . . . C-25

C.3.1 Calibration Menu . . . . . . . . . . . . . C-25

C.3.2 Calibration Status . . . . . . . . . . . . . C-26

C.3.3 Leak Sensor Calibration and Status . . . C-27

C.3.4 Degas Status . . . . . . . . . . . . . . . . C-28

C.3.5 Flow Calibration . . . . . . . . . . . . . . C-29

viii

Doc. 034856 -0 3 5/95

Page 9

1 • Introduction

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.2 About This Manual . . . . . . . . . . . . . . . . . 1-4

1.2.1 Typefaces . . . . . . . . . . . . . . . . . . 1-5

1.2.2 Safety Messages and Notes . . . . . . . . 1-5

1.2.3 Symbols . . . . . . . . . . . . . . . . . . . 1-6

1.3 Related Manuals . . . . . . . . . . . . . . . . . . . 1-7

Doc. 034856 -0 3 5/95

1-1

Page 10

GP40 Gr adi ent Pu mp

1-2

Doc. 034856 -0 3 5/95

Page 11

1 • Introduction

1.1 Overview

The GP40 Gradient Pump is an integral part of a DX 500

chromatography syste m. It is a microp rocessor-based, dual-pis ton,

variable-speed, gradient de livery system designed to blend and pump

mixtures of up to four different mobile phas es at precisely controlled

flow rates. The pump can deliver the selected mobile phase

composition isocratically, or as a multistep linear or curved gradient.

A Digital Signal Proce ssor (DSP) provides high speed control of

pump flow and press ure.

The GP40 can op erate as a stand -alone produc t or with other Dionex

modules as part of a complete chromatography syste m. It can also

be used with non-Dionex mod ules that meet interface requirements

for so ftwar e, TT L, or r elay contr ol.

The GP40 can be controlled locally, using the front panel keypad

and display, or from a remote host computer with a Dionex

DX LAN interface installed and PeakNet software installed on the

host computer. Limited remote control is also available from any

device capable of providing compatible TTL signals to control the

pump.

The pump’s two basic modes o f control, Direct co ntrol and Metho d

control, enable it to operate with or without reference to time-based

even ts.

The GP40 is available in four versions. An optional vacuum degas

pump is available for all versions :

GP40 Gradient Pump Version With Degas Pump Without Degas

Standar d bore wi th PEEK co mponent s P/N 0441 17 P/N 04416 5

Standar d bore wi th stai nless st eel compo nents P/N 044081 P/N 044 085

Microb ore with PEEK comp onents P/N 0440 86 P/N 044 082

Microb ore with stainles s steel com ponent s P/N 0440 83 P/N 04408 7

Doc. 034856 -0 3 5/95

1-3

Page 12

GP40 Gr adi ent Pu mp

1.2 About This Manual

This manual describes the installation, operation, and maintenance

of the GP40 Gradient Pump.

Chapter 1, Introduction, introduces the product and conventions

used in the manual, and provides safety information.

Chapter 2, Descri ption, is a descri ption of the phys ical aspec ts of the

pump, followed by a des cription of the operating featur es.

Chapter 3, Operation and Maintenance, discusses th e operating

features and meth ods, and pres ents several examples of how to run

methods. Routine preventive maintenance requirements are included

in this chapter.

Chapter 4, Troubleshooting, lists p ossible causes of prob lems and

provides step-by-step procedures to isolate an d eliminate their sources.

Chapter 5, Service, presents step-by-step instructions for service and

parts replacem ent routines.

1-4

Appendix A, Specifications , contai ns the GP40 s pecifications and

installation site specifications.

Appendix B, Installation, des cribes the installation steps necessary

to place the GP40 Gradient Pu mp into operation.

Appendix C, User Inte rface, illustrates and describes a ll front panel

menus and screens .

Appendix D, Pump Head Replacement, explains how to ch ange the

pump heads from 100 µL standard bor e to 25 µL microbore, or vice

vers a.

Appendix E, Relay and TTL Control, describes the relay and T TL

input and outpu t functions and provides setup examples.

Doc. 034856 -0 3 5/95

Page 13

1.2 .1 Typefaces

Typefaces are used in this manual as follows:

•

Capitalized bold type indicates a front pan el button:

1 • Introduction

Press

•

Upper-case bold type indic ates the name of a screen, the

to begin running the metho d.

Enter

name of a m enu, or an on- screen entry:

Go to the

Move the cursor to the

METHOD

screen.

EDIT

1.2. 2 Safety Messages and Notes

This instrument is designed to comply with the requirements

for safety set forth in I EC 1010, Safety Requirements for

Electrical Equipmen t for Measurement, Control, and

Laboratory Use.

This manual contains warnings and precautionary statem ents

that can prevent personal injury and/or damage to th e

instrument when properly followed. Safety mess ages appear

in bold typ e and are acco mpanied by icons.

Indicates a potential ha zard which could result in serious

injury or loss of life. Any hazard of this type will be located

behind a barrier and will be accessible only by use of a

tool. Access may be required during installation,

maintenance, or service.

field .

Doc. 034856 -0 3 5/95

Indicates a pot ent ial haza rd to th e oper ator, or damage to

the instrument or other property.

Indicates that the function or process of the instrument

may be impaired. Oper ation does not constitute a hazard.

1-5

Page 14

GP40 Gr adi ent Pu mp

Informational messages also appear throughout this manual.

These are labeled NOTE and are in bold ty pe:

NOTES call attention to certain information. They alert

you to an unexpected result of an action, suggest how to

optimize t he performan ce of the instrum ent, e tc.

1.2.3 Symbols

The symbols below appear on the pump, or on pump lab els.

NOTE

~

Alternating current

Protective conductor terminal

Power supply is on

Power supply is off

1-6

Doc. 034856 -0 3 5/95

Page 15

1.3 Related Manuals

During installation and operation of the GP40, you may need to

refer to one or mo re of the following manuals ( depending on your

system) for information about other modules and components

included in a DX 500 sys tem.

The following m anuals are included wit h their resp ective modules or

components:

1 • Introduction

• AS3500 Autosampler Editor Manual

• AS40 Automated Sampler Operator’s Manual

(Document No. 03 4913)

(Document

No. 034970)

• CD20 Conductivity Detect or Operator’s Manual

(Document

No. 034854)

• ED40 Electrochemical Detector Operator’s Manual

(Document

No. 034855)

• E01 Eluent Organizer Installation Instructions

(Document

No. 034582)

• Pressurizable Reservoir Installation Instructions

(Document

No. 034851)

• LC10 Chromatography Organizer Operator’s Manual

No. 034858)

• LC20 Chromatography Enclosure Operator’s Manual

No. 034859)

•

LC30 Chromatography Oven Operator’s Manual

(Document

No. 034860 )

(Document

(Document

The following manual is included in the GP40 Ship Kit:

• Installation of Dionex Fe rrule Fittings

Doc. 034856 -0 3 5/95

(Document No. 034213)

1-7

Page 16

GP40 Gr adi ent Pu mp

1-8

Doc. 034856 -0 3 5/95

Page 17

2 • Description

2.1 Front Control Panel . . . . . . . . . . . . . . . . . 2-4

2.1.1 Control Panel Keypad . . . . . . . . . . . 2-5

2.1.2 Display Screens . . . . . . . . . . . . . . 2-10

2.2 Electronics Chassis . . . . . . . . . . . . . . . . . 2-11

LC Leak . . . . . . . . . . . . . . . . . 2-12

LC30 Communication . . . . . . . . . 2-12

LC Air Valves . . . . . . . . . . . . . . 2-13

TTL/Relay . . . . . . . . . . . . . . . . 2-13

CPU . . . . . . . . . . . . . . . . . . . 2-13

2.3 Mechanical Chassis . . . . . . . . . . . . . . . . . 2-14

2.4 Interior Components . . . . . . . . . . . . . . . . 2-14

2.4.1 Pump Eluent Manifold . . . . . . . . . . 2-15

2.4.2 Pump Heads . . . . . . . . . . . . . . . . 2-16

2.4.3 Pump Mixers . . . . . . . . . . . . . . . . 2-17

2.5 Vacuum Degas Pump Assembly (Optional) . . . . 2-18

2.6 Eluent Reservoirs . . . . . . . . . . . . . . . . . . 2-19

2.7 Rear Panel . . . . . . . . . . . . . . . . . . . . . . 2-20

2.8 Functional Description . . . . . . . . . . . . . . . 2-21

Doc. 034856 -0 4 10/95

2.4.4 Pump Priming Block . . . . . . . . . . . 2-17

2.4.5 Pressure Transducer . . . . . . . . . . . . 2-17

2.8.1 Operating Modes . . . . . . . . . . . . . . 2-23

Local Mode . . . . . . . . . . . . . . . 2-23

Remote Mode . . . . . . . . . . . . . . 2-23

2.8.2 Method Control . . . . . . . . . . . . . . 2-24

2.8.3 Eluent Delivery . . . . . . . . . . . . . . 2-25

Isocratic Eluent Run . . . . . . . . . . 2-25

Gradient Eluent Run . . . . . . . . . . 2-25

2-1

Page 18

GP40 Gr adi ent Pu mp

2-2

Doc. 034 856-04 10/95

Page 19

2 • Description

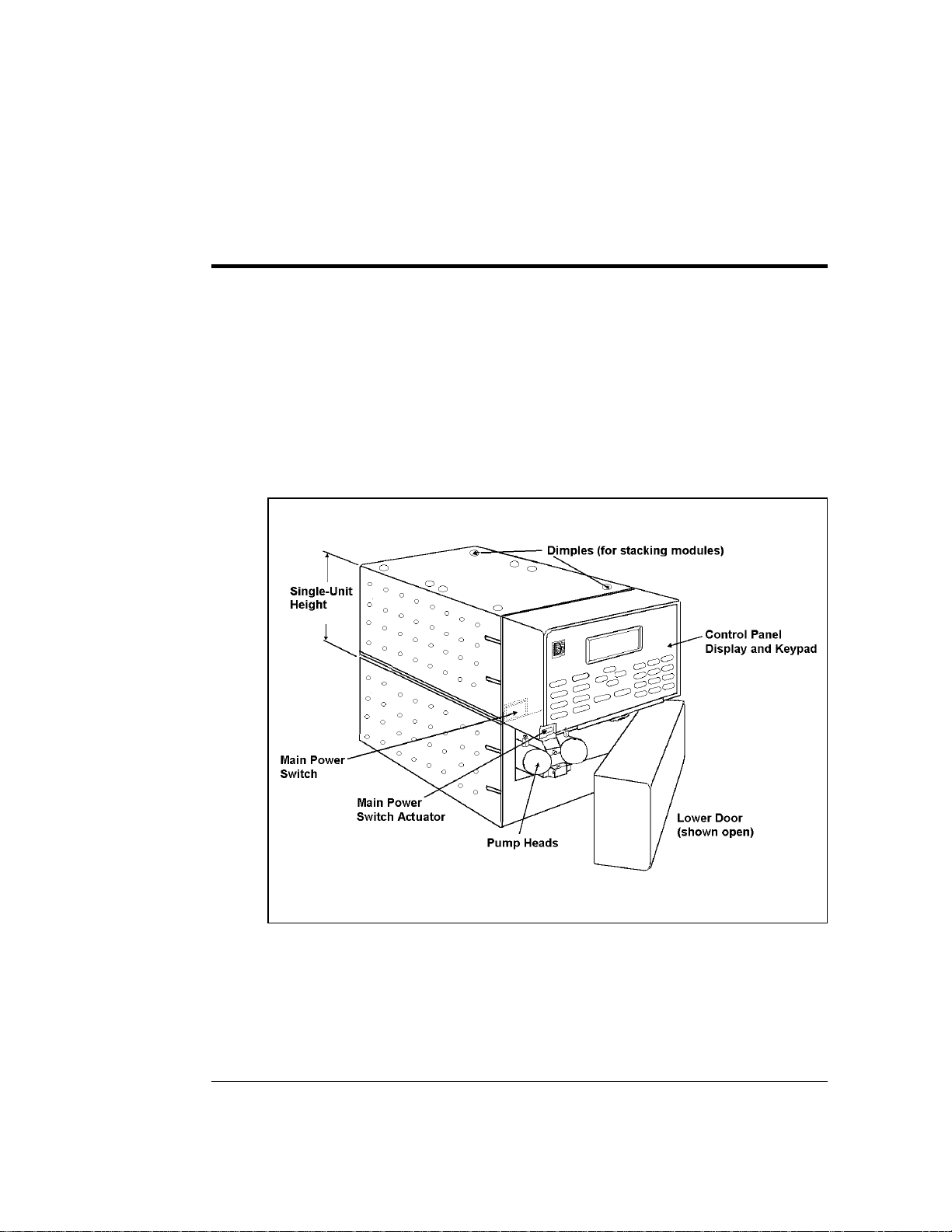

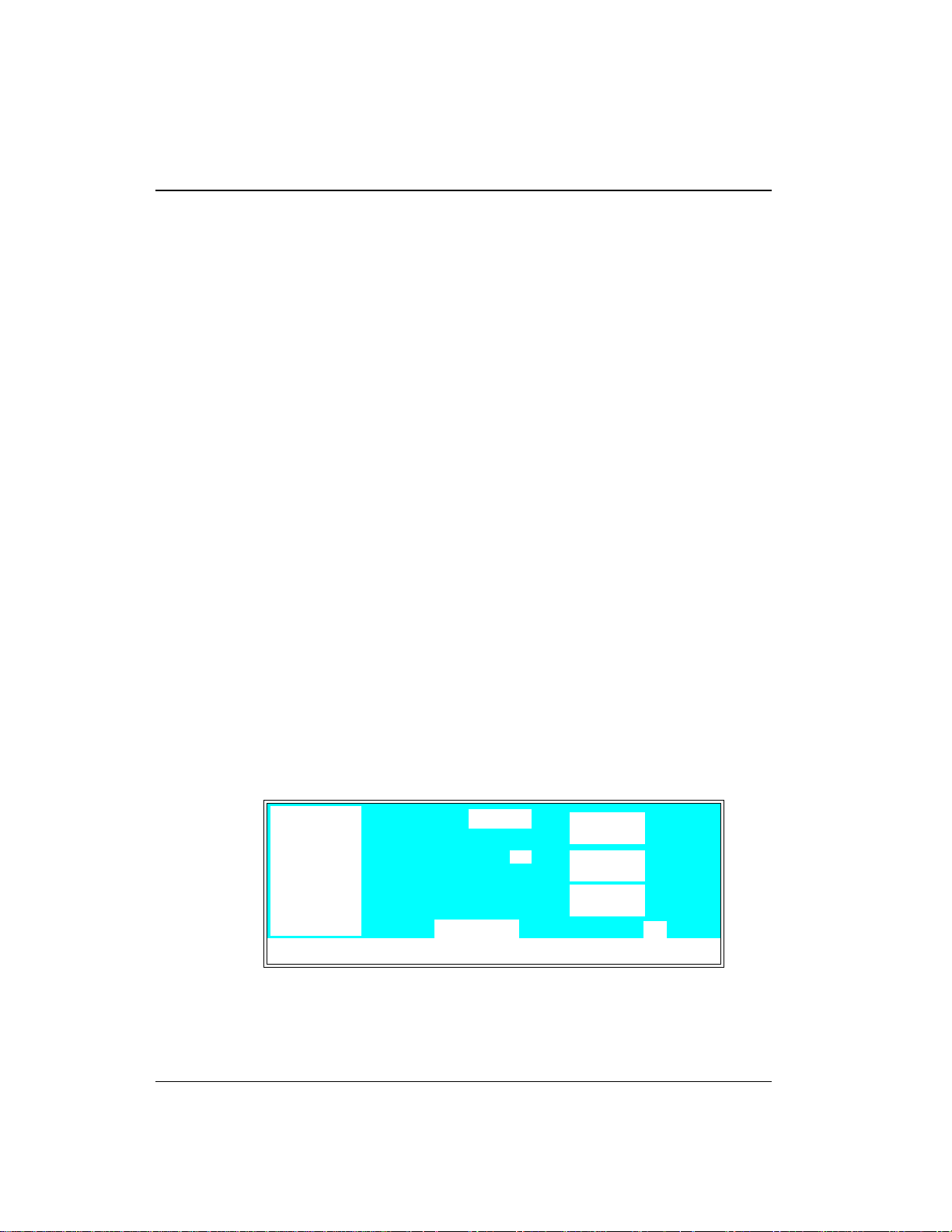

The GP40 Gradient Pump co nsists of two single-unit DX 500

encl o su re s (s ee Figure 2-1). The up per unit hous es the electronic

components, an d the lower unit ho uses the pump heads and other

mechanical pump as semblies.

The GP40 is de signed to have other single- or dual-unit modules

stacked on top of it, to a max imum of four units. See Section B.4

for the recommended s tacking configuration for DX 500 systems .

Doc. 034856 -0 4 10/95

Figure 2-1. GP40 Enclosure

2-3

Page 20

GP40 Gr adi ent Pu mp

2.1 Front Control Panel

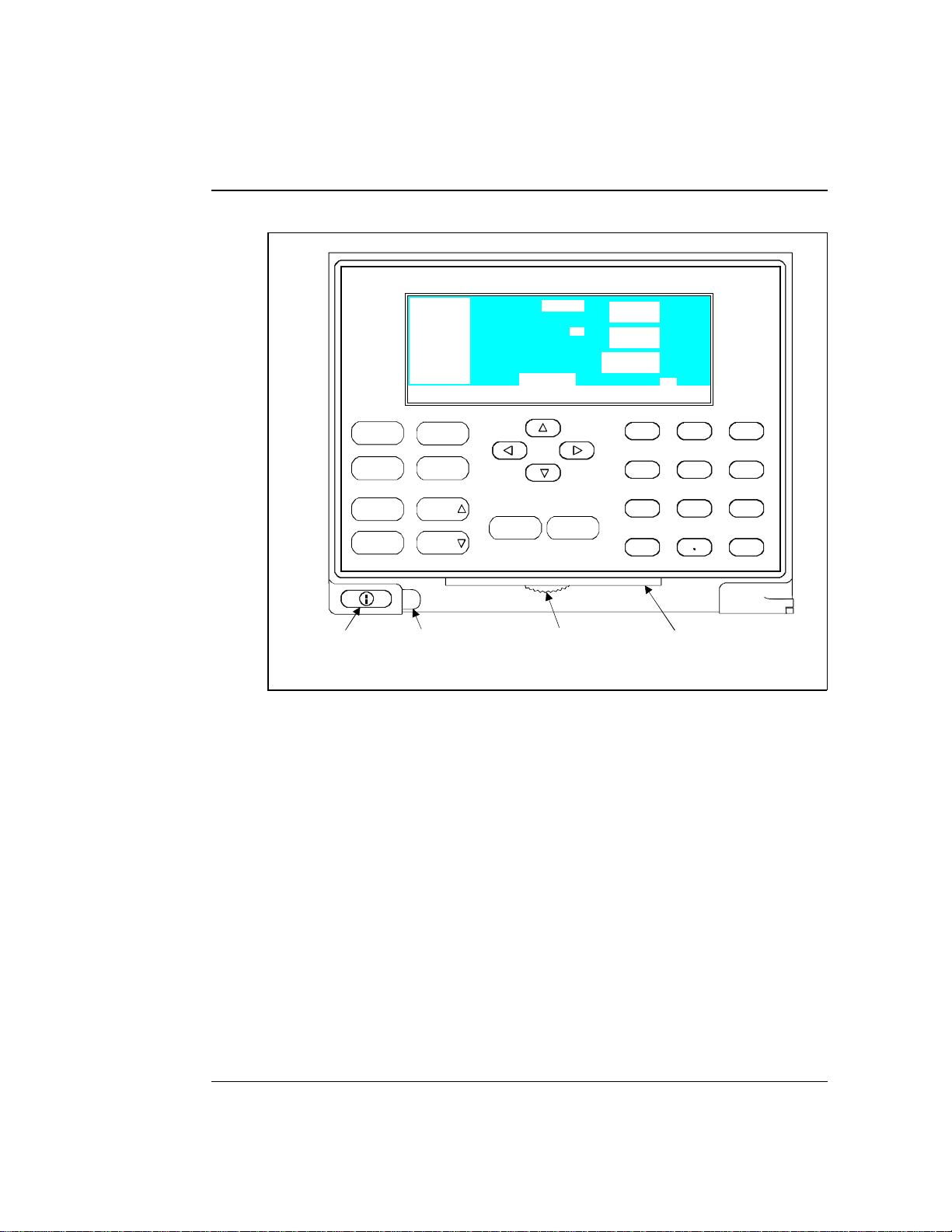

The control pa nel on the upper door of the GP40 enclosure cont ains

the liquid crystal display (LCD), the membrane keypad, and the

actuator for the main power switch (see Figu re 2-2). The doo r opens

to provide acce ss to the el ectronics cha ssis, describe d in Section 2.2.

Screen Contras t

Information is displayed on the LCD, also called the

screen

. To

adjust the screen contrast, u se the knurled kno b in the recess below

the keypad (see Figure 2- 2).

Tilt Panel

To maximize visibility, the front control panel can be tilted to four

different positions. To tilt the panel, support the door at the left side

(to prevent it from opening) and lift firmly on the tab in the middle

of the recess below the keypad (see Figure 2- 2). Push on th e tab to

return the panel to its vertical position.

Power Switc hes

The main power switch is on the bulkhead beh ind the upper door

(see Figure 2-1). An actuator for the main power switch is on the

outside of the front door, at the lower left cor ner (see Figure 2-2) .

The actuator f unctions on ly when the d oor is fully closed.

When the door is open, press th e main power switch o n the

bulkhead, instead of the actuator, to turn the module off and on.

To prevent damage to the pump circuitry and components,

always wait at least 15 seconds after powering down before

turning on the power again.

2-4

Doc. 034 856-04 10/95

Page 21

GP40 Gradient Pump

100.0 %A

0.0 %B

0.0 %C

0.0 %D

Help Message

INJECT

COLUMN A

LOCAL

2.00

PSI

mL/MIN

MIN

1000

10.25

METHOD 05

2 • Description

Off/On

Prime

Insert Select

Delete

Main Power

Switch Actuator

Hold/Run

Reset

Help Menu

Select

Tab

(for opening

the door)

Figure 2-2. GP40 Display and Keypad Layout

2. 1 . 1 Control Panel Keyp ad

The keypad is used to directly control pump operation, as

well as to create and modify programme d series of timed

events, called

•

Press

methods

Menu

to display a list of available screens.

. In summary:

Knob

(for adjusting

the contrast)

7

45

1

0

8

23

Tab

(for tilting

the panel)

9

6

Enter

•

•

Doc. 034856 -0 4 10/95

In the screens, only the fields shown in r everse video can

be edited. Oth er fields display informatio n only.

To edit a field, use the four dire ctional arrow buttons to

position the cu rsor in the reverse vid eo fields. Use the

numerical buttons to enter variable values. Use the

Select

∆

and

Select

buttons to choose between

∇

2-5

Page 22

GP40 Gr adi ent Pu mp

predetermi ned options . Pressin g a

Select

button increas es

(or decreas es) a numerica l value by one, w hile holding

down a

Select

button increa ses (or decreases) a numerical

value continuously.

•

To execute the selected value, press

Enter

, or press an

arrow button to move the cursor to the next field and

automatically enter the value.

A high-pitched be ep sounds whe n you press a button. When

an error occurs, this beep is lower in frequency. The beeps

can be disabled from the

MODULE SET-UP

screen ( see

Section C.1.6).

Off/On

Turns the pump motor off and on.

In Direct control (see Section 2.8), turnin g on the motor

causes it to pump isocratic ally using the displayed e luent

percentages a nd flow rate.

In Method control (see Section 2 .8.2), turning on the motor

causes it to pu mp at the eluent per centages and flow ra te for

the elapsed time of th e selected method, o r at the initial

conditions (when the method clock is a t

INIT

).

2-6

Prime

This button is used when priming the pump heads.

Prime

causes the pump to run at maximum volume (2.5 mL/min,

microbore; 10.0 mL/min standard bore). If the pump motor is

off when you press

Prime

, the pump automatically turns on.

To exit priming and return to the normal flow rate, press

Prime

again or press

Off/On

to turn the pump moto r off. See

Section B.2.7 for detailed priming instructions.

Doc. 034 856-04 10/95

Page 23

2 • Description

Insert

Inserts a new timed step into a method. This button functions

only when the cursor is in a

METHOD

extension s creen.

TIME

field in the

METHOD

or

1. Move th e cursor to the

TIME

field and press

Insert

. The

new step is added after the cursor positio n. Parameter

values in the new s tep are blank.

2. Fill in the time value and press

Enter

or a cursor arrow

button. If you move the cu rsor to a di fferent field before

entering the time value, the inserted step will be

incomplete and will disappear. You can insert timed steps

in any order. After you press

Enter

, they will be

automatically organized in correct chron ological order.

Delete

Removes the value from the current entry field, allowing

entry of a new value. To restore the previous value, move the

cursor from the field before entering the new value.

In th e

METHOD

screen, pressing

Delete

when the cursor is in a

step ent ry field “blank s” the step p arameter value. When the

cursor is moved from the field, the field remains blank (the

previous value is not restor ed as in other s creens). Blank step

fields indicate there is no change from the previous step.

To us e

1. Position the cursor in the method’s time field and press

2. Press

Doc. 034856 -0 4 10/95

Delete

Delete

to delete the step, press any button exce pt

to delete an entire method step:

. The time is removed and the help line dis plays:

TO DELETE THIS STEP, PRESS DELETE AGAIN

Delete

again to delete the step. If you do not want

Delete

or the

decimal point and the origin al time and step parameters

are then resto red.

2-7

Page 24

GP40 Gr adi ent Pu mp

Hold/Run

Turns the method clock off (

Hold

) and on (

Run

). This button

functions only when the pump is under Method control (see

Section 2.8.2).

When the method clock is in Hold, pressing

Hold/Run

, starts

the clock. The clock s tarts either at the initial step of a new

method, or if resuming an interrupted method, at the time at

which the clock was put in Hold.

When the m ethod clock is in Run, pr essing

Hold/Run

, stops

the clock, thereby “holding” the method and freezing the

current conditions.

Reset

Changes the method clock time to

INIT

and causes the initial

conditions specified by the method to occur. This button

functions only when the pump is in Method control.

If the method is running, it continues running. If the method

is on hold, the metho d clock executes the initial conditions

and holds.

2-8

Select

and

∆

Select

∇

When the cursor is positioned a t a field that has

predetermined parameters, these buttons cycle through the

choices. In fields which have predeter mined numeric values,

Select

∆ increases the value by one unit and

decreases the value by one un it. Holding down the

Select

∇

Select

button increa ses (or decreases) the value cont inuously. Press

Enter

or a cursor ar row button to execute the new value.

,

, and

→

←, ↑

↓

The four cursor directional buttons move the cursor, in the

direction of the arrow, to the next entry field. If there is no

Doc. 034 856-04 10/95

Page 25

2 • Description

changeable field in that directio n, the curs or moves

diagonally or remains where it is.

After entering or selecting a new value in an entry field,

pressing an arrow button to move to another field als o saves

and/or executes the change. This performs the same function

as pressing

Enter

followed by an arrow.

In a few fields the cur sor arrow does not perform the enter

function. You must pres s

Enter

after entering or selecting

values in the following fields:

•

DIA GNOSTIC TEST

•

SA VE T O

•

Calibration screen fields

•

Menu fields

Help

and

screen fields

RUN

fields on the

METHOD

screen

Displays a help screen specific to the current entr y field.

Displays one o f three menus, dep ending on the current screen:

•

•

•

Doc. 034856 -0 4 10/95

Menu

From any operational s creen, pressing

MENU of SCREENS

.

From any diagnostic screen, pressing

DIAGNOSTIC MENU.

MENU of SCREENS

Pressing

.

Menu

again returns you to the

From any calibration scre en, pressing

CALIBRATION MENU

DIAGNOSTIC MENU

the

. Pressing

and then to the

Menu

Menu

displays the

Menu

displays the

Menu

displays the

again returns yo u to

MENU of SCREENS.

See Figure C-1 for the GP40 scree ns and menu s tructure.

2-9

Page 26

GP40 Gr adi ent Pu mp

Numeric Buttons

Enters numeric values into the current entry field. The

numeric buttons are 0 through 9 and th e decimal.

Enter

Saves and/or executes changes made in entry fields. After

pressing

the same field. It does not automa tically move to the next

entry field. In menu screens, press ing

highlighted screen.

Enter

, the cursor moves back to the left margin of

Enter

opens the

In th e

METHOD

screen, pressing

copy only. To save the editing change s to a permanent

method, move the cursor to the

method number, and press

2.1.2 Display Screens

When the pump has successfully powered-up and passe d all

diagnostic tests, the

Figure 2-3 ) and after a few se conds, th e

(see Figure 2-5) . If one of the d iagnostic tests fails at

power-up, the

MAIN

screen. See Section C.2.8 if this occurs.

Help Message

DIAGNOSTIC TEST

GP40 GRADIENT PUMP

Enter

saves entries to an edit

Enter

POWER-UP

SAVE T O

.

screen displays briefly (see

field, enter the

MAIN

screen displays

screen displays instead of the

PUMP HEAD VOLUME 100 uL

MODULEWARE REV n.nn

BIOS REV n.nn

2-10

Figure 2-3. Power- Up Screen

Doc. 034 856-04 10/95

Page 27

2 • Description

100.0 %A

0.0 %B

LOAD

COLUMN A

2000

2.00

PSI

mL/MIN

0.0 %C

10.27

0.0 %D

Help Message

POWER-UP

The

DIAGNOSTIC MENU

later time.

MAIN

The

screen displays status information in enlarged

characters to make viewing easier from a distance. From the

MAIN

screen you can set p ump operating parameters such as

the percentage of eluents to run, th e flow rate, or the method

number to run.

To access the remaining GP4 0 screens, press the

to display the

menu, you can sele ct individual operational scr eens, or the

DIAGNOSTIC MENU

number and press

screen name and press

description of ea ch GP40 screen.

screen can also be op ened from the

MENU of SCREENS

LOCAL 2

Figure 2-5. Main Screen

METHOD

, if you wish to view the information at a

(see Figure 2-4). From the

screen. To open a screen, en ter the screen

Enter

, or move the cursor to the desired

Enter

. See Appendix C for a

MIN

Menu

button

Doc. 034856 -0 4 10/95

MAIN SCREEN

1

DETAIL SCREEN

2

METHOD

3

DEGAS OPTIONS

4

Help Message

Figure 2-4. Menu of Screens

MENU of SCREENS

MODULE SET-UP

5

PUMP OPTIONS

6

TIME FUNCTION IN

7

DIAGNOSTIC MENU

8

2-11

Page 28

GP40 Gr adi ent Pu mp

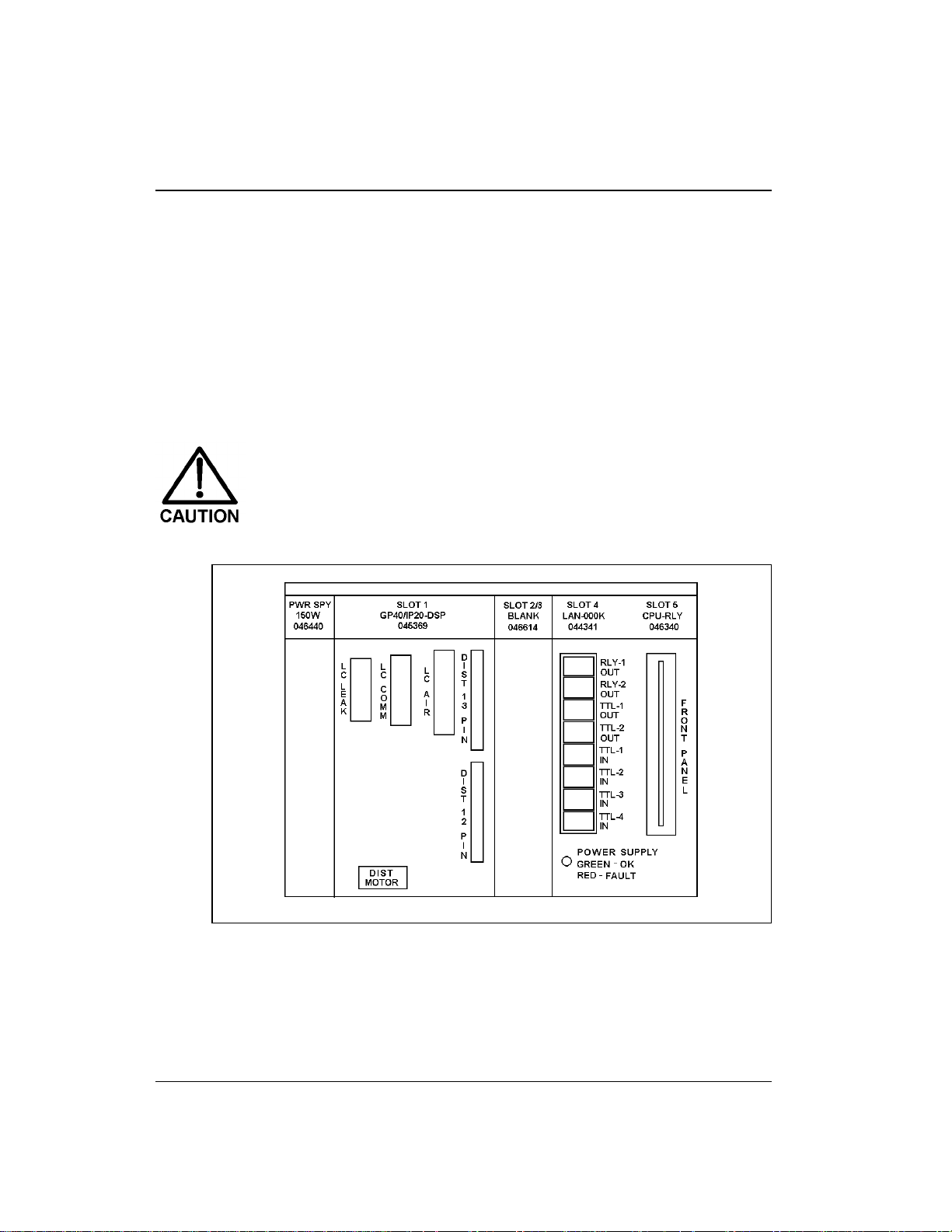

2.2 Electronics Chassis

The electronics c hassis is locate d behind the upper door of the GP4 0

enclosure . The chas sis include s several electro nic cards (pr inted

circuit boards) that are used to contr ol the GP40. Connec tors on the

cards also allow communic ation between the GP4 0 and other

DX 500 modules. Figure 2-6 shows the e lectronics components with

the upper door op en. To open the door, pull on the tab loca ted to the

right of the main power actuator (see Figure 2-2) .

Do not remove any of the electronics cards fro m the pump.

There are no user-serviceable components on t he cards.

If serv icing i s requir ed, it must be p erformed by qual ified

personnel and appropriate electrostatic discharge (ESD)

handling proc edures must be followed .

2-12

Figure 2-6. Electronics Chassis

(Located behind pump upper door)

Doc. 034 856-04 10/95

Page 29

2 • Description

LC Leak

The leak control cable from the LC20 C hromatography

Enclosure or the LC10 Chromato graphy Organizer connects

to the

LC LEAK

connector in slot 1.

When a leak occurs in the LC10 o r LC20, it is reported to the

GP40. The LC30 Chromatography Oven does not connect to

the GP40

LC LEAK

connector; it has its own internal leak

control electron ics.

LC30 Communication

The LC30 Chr omatography Oven’s RJ-11 serial cable

connects to the

LC COMM

connector in sl ot 1. When

connected, the L C30 can be remotely co ntrolled by the

PeakNet workstation.

LC Air Val ves

The cable from th e air solenoid valves on the LC1 0, LC20, or

LC30 connects to the

LC AIR

connector in s lot 1. When

connected, the GP40 can e lectrically act uate the s olenoid

valves which control the position of the injection valve and

the optional column switch ing valve in the LC10, LC20, and

LC30. Use the

MAIN

or

METHOD

screen to select the valve

positions. See Appen dix C for a description of the screens.

TTL/Relay

A strip of eight rela y and TTL conn ectors is located in slot 4 .

These connec tors interface with Dion ex and non-Dionex

modules for relay and TTL control of the pump. Appendix E

describes the r elay and TTL func tions and the connec tions

between the GP40 an d other modules .

CPU

Control Moduleware for the GP40 resides on the CPU/Relay

cards.

Doc. 034856 -0 4 10/95

2-13

Page 30

GP40 Gr adi ent Pu mp

The CPU log ic and Relay I/O cards occupy slo t 5 in the car d

cage. The R elay I/O card rid es piggyback on th e CPU card

and extends over the front o f slot 4. The card is short enough

to allow the optional DX LAN p ump interface card

(P/N 044195) to mou nt behind it in slot 4. A 60-p in ribbon

cable links the CPU log ic to the display and keypad. The

logic monitors the inter nal power supply outpu ts, and reports

the status on the multic olored LED at the bottom of s lot 4.

•

Green indicates normal operation.

•

Red indicates a power fault. The module will enter its

diagnostic state a nd inhibit all other controls u ntil the

fault is corrected. If this occurs, turn the power off for a

few seconds and then turn it back on. If the problem

persists, call Dionex.

2-14

Doc. 034 856-04 10/95

Page 31

2.3 Mechanical Chassis

The mechanic al chassis is housed in a pull-out drawer located

behind the lower door of the GP40 en closure. The front of the

chassis cont ains the interior compon ents described in Section 2.4.

Other mechan ical assemb lies are lo cated insi de the chas sis drawer.

For routine op eration, the drawer must be pu shed in and the drawer

lock, located on the lower right corner of the chassis, tight ened. The

drawer is pulled out only for service procedures.

Observe the warning label on the inside of the lower doo r.

The arrows on the label indicate moving mechanical par ts

that present pinch hazards when the pump i s on and the

mechanical drawer is open. Do not o perate the p ump wi th

the mechanical chassis drawer pulled out.

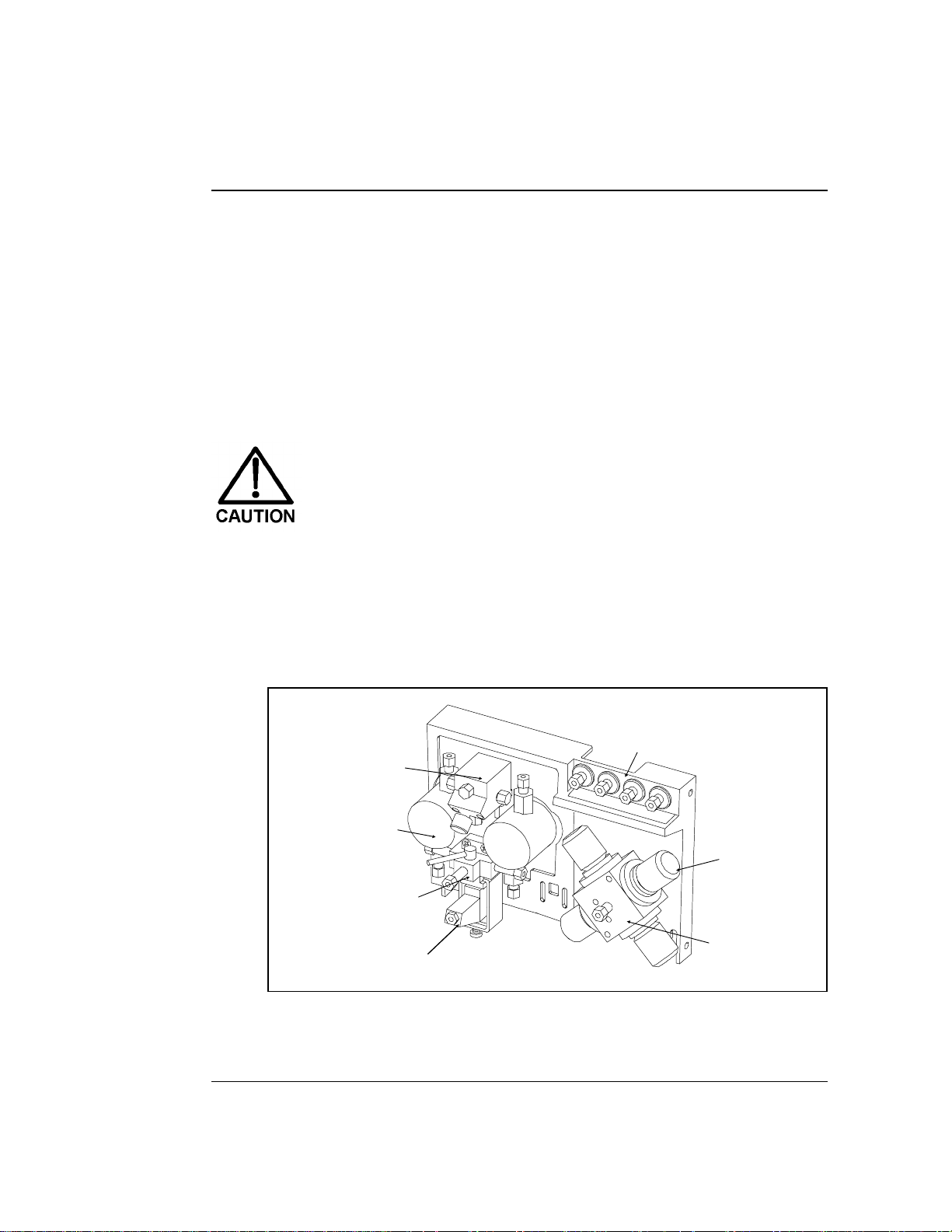

2.4 Interior Components

2 • Description

Figure 2-7 shows the interior compon ents located behind the lower

door.

Bulkhead

Pressure

Transducer

Pump Heads

Priming Block

Active Mixer

(standard bore

pumps only)

Figure 2-7. Interior Components

Fittings

Proportioning

Valves

Eluent Manifold

Doc. 034856 -0 4 10/95

2-15

Page 32

p

p

(

y)

(

y)

GP40 Gr adi ent Pu mp

To Column

Mixer

microbore onl

Pressure

Transducer

Pum

Heads

Priming Block

Mixer

standard bore onl

Figure 2-8. Eluent Flow Sc hematic

2. 4. 1 Pump Elue nt Manifol d

Front panel bulkhead fittings A through D are connected to

the chemically-inert proportioning soleno id valves that

control eluent selection. The proportioning valves gener ate

the gradient mixture by cycling ope n and closed to deliver the

desired percent age of each selected eluent t o the manifol d.

The output from the four proportionin g valves is combined in

the manifold. Figure 2-8 shows the eluent flow path through

the components.

Eluent

A In

A

Eluent

Eluent

B In

C In

B C D

D

C

A

B

Eluent

D In

Bulkhead

Fittings

Manifold and

Pro

ortioning

Valves

2-16

Doc. 034 856-04 10/95

Page 33

2.4.2 Pump Heads

There are two GP40 pump head co nfigurations: standard bore

and microbore. T he table below summarizes the features of

each type and the operating co nditions for each configuration.

2 • Description

Pump

Head Ty pe

Standard

Bore

Microbore

*Flow rates are a djusta ble in increm ents of 0 .01 mL /min.

Piston

Volume

100 µL

25 µL

Although t here is some over lap in flow rat es between the

two pum p ve rsions, continuous ope r ation of the micr ob ore

pump heads at flow rates above 2.0 mL/min will decrease

seal and pump life. For the best extended operation at

2.0 mL/min or above, repl ace the mic robore pump heads

with standard bore pump heads. Similarly, whe n running

gradients, the standard bore pump heads should not be

used below 0.4 mL/min.

Pump

Operation

Isocratic 0.04 – 10.0 4-mm and

Grad ient 0.4 – 10. 0 4-mm and

Isocratic and

Gradient

NOTE

Flow R ate

(mL/min)*

0.01 – 2.5 0 1-mm –

Instructions for replacing the pump h ead assembly are

shipped wit h the replaceme nt head and in cluded in

Appendix D of th is manual. Contact y our Dionex office to

order the conversion pump head kits. Refer to Appendix D

for kit part numbers.

Column

Sizes

9-mm I D

9-mm I D

4-mm I D

Maximum

Operating

Pressure

35 MPa

(5000 psi)

35 MPa

(5000 psi)

35 MPa

(5000 psi)

See Figures 5-1 and 5-2 for an illus tration of the pump heads

and interconnecting lines.

Doc. 034856 -0 4 10/95

2-17

Page 34

GP40 Gr adi ent Pu mp

2.4.3 Pump Mixers

A pump mixer ensures complete mixing of the proportioned

eluents prior to injection. Two types of mixers are available:

•

In standard bore GP40 pumps (10 0 µL piston volume), a

Dionex active mixer (P/N 04898 8) is installed betw een the

eluent manifold and the priming block. The active mixer

contains an electromagnetic stir bar to mix the

proportioned elu ents.

•

In microbore GP40 pumps (25 µL piston volume), a

GM-4 gradien t mixer (P/N 049135) is in stalled between

the pump outlet an d the injection valve.

2. 4. 4 Pump Pr iming Block

The priming block “tee” directs the flow of eluent from the

manifold into the pump he ads. The priming block is also used

for ra pid r emoval o f air f rom th e syst em.

2-18

Refer to Section B.2.7 for instructions on priming the pump

heads.

2.4 .5 Pressure Transducer

From the priming block, the liqu id stream is directed to the

inlet check valves on the pump heads, through the pump

heads, and finally through th e outlet check valves to the

pressure transducer.

Flow from the outlet check valves on the pump heads is

combined in the pres sure trans ducer. The press ure transd ucer

measures the system press ure at this point . The interactive

constant-flow/constant-press ure control program on the DSP

precisely controls the pump moto r speed to assure flow rate

accuracy. A Kel-F disk an d PTFE O-ring isolate the eluent from

the metal pressure transducer.

The press ure transd ucer include s a press ure waste valve for

use during priming of the pump . Open this valve for a few

Doc. 034 856-04 10/95

Page 35

2 • Description

seconds to relieve the pres sure and force air out of the

system, then cl ose it to resume analysis (see Figur e B-5).

Flow output from th e pressure tr ansducer is directed out o f

the pump module to the rest of the chromatography system

(injection valve, column, detector). On microbore pumps,

flow passes through the GM-4 mixer be fore entering the

injection valve.

See Section B.2.5 in A ppendix B for outlet line connections .

Refer also to the manual for the module being us ed for

specific int erconnect info rmation.

2.5 Vacuum Degas Pump Assembly (Optional)

The Dionex vacuum degas pu mp (P/N 047263) provides continuous

on-line vacuum degassin g of one to four eluents (see Fig ure 2-9). If

ordered, the assembly is installed in the pump at the factory. This

assembly consists of:

•

A 4-channel degas cha mber (with degas membrane s) with 17 mL

internal capacity per chan nel

•

A dual-stage d iaphragm vacuum pump

•

A solenoid valve

•

An on-board vacuum sensor

•

The electronics required to operate the vacuum pump

•

Fittings, tubing, and other accessories

Doc. 034856 -0 4 10/95

2-19

Page 36

GP40 Gr adi ent Pu mp

Figure 2-9. Vacuum Degas Component Schematic

By default, at power-up, the degas pump turns on for 2 minutes.

Thereafter, the pump turns on for 30 sec onds at 10-minute inte rvals.

You can check the vacuum chamber pressure from the

screen (s ee Section C. 3.4). The

change the cycle time and duration (see Section C.1.5).

DEGAS OPTIONS

DEGAS STATUS

screen allows you to

All components of the vacuum degas assembly are made of inert

materials or corrosion-resistant materials. However, Dionex

recommends that you thoroughly flush any chemicals out of the

tubing with deionized water after each use to avoid crystallization in

the membrane pores.

2.6 Eluent Reservoirs

Dionex strongly reco mmends degassing all eluents and st oring them

in reservoirs pressurized with helium. This help s prevent bubbles

(resulting from eluent outgassing) from forming in the eluent

proportioning valves, pu mp heads, and the detector cell. D egassed

eluents and pressurized reservoirs a re especially imp ortant when

combining aqueo us and non-aqueo us component s (e.g., water and

methanol). Pressur izable reservoirs allow eluents to be stored under

2-20

Doc. 034 856-04 10/95

Page 37

2 • Description

a specific atmosphere. The following reservoirs are available from

Dionex:

•

1-liter glass reservoirs with shatterproof plastic coating

(P/N 044126)

•

2-liter glass reservoirs with shatterproof plastic coating

(P/N 044127)

•

1-liter plastic reservoirs (P/N 044128)

•

2-liter plastic reservoirs (P/N 044129)

Do not use the 2-liter plastic reservoir (P/N 044129) for

off-line vacuum degassing of eluents. The reservoir was

not designed for this purpose.

Refer to the

Pressurizable Reserv oir Installation Instructions

(Document No. 0345 81) for installation d etails.

Two optional E01 Eluent Organizers (P/N 044125) fit on top of the

system encl osure. Each organizer can accommodate up to two

reservoirs with the volume listed below. Contact your Dionex office

for ordering information.

No. of

Reservoirs

2

2

1

Description

1 Liter glas s or plas tic

2 Liter plastic

2 Liter glas s

Total Volume

in Liters

2 L

4 L

2 L

2.7 Rear Panel

The rear p anel contains t he main power rece ptacle with fuses, a nd a

BNC connector for interfacing the GP40 with the PeakNet

workstation through the DX LAN. The r ear panel is illustrated in

Figure B-1 in Appendix B.

Doc. 034856 -0 4 10/95

2-21

Page 38

GP40 Gr adi ent Pu mp

2.8 Functional Description

There are t hree ways to op erate the GP4 0 pump:

•

In Local mode, y ou use the fron t control panel buttons an d

screens to set operating parameters. See Section 2.8.1 f or a

description of Local mode.

•

In Remote mode, you us e PeakNet to send operating commands

from th e host compu ter via the D X LAN. See S ection 2.8 .1 for a

description of Remote mode.

•

With TTL input, a controlling device, such as an integrator or

another DX 5 00 module, sends TTL si gnals to the pump. T he

TTL input signals can be used to turn the pump motor off and

on, set the method clo ck to hold or run, or incremen t and

decrement the meth od number. All other GP40 operating

parameters must be set locally with th e control panel. See

Appendix E for a description of TTL control.

To select the ope rating mode:

1. Open either the

displays either

2. To chang e the mode, move the cursor to this field; press

Select

or

cursor arrow button. (For TTL input control, set the GP40 to

Local mode. )

∇

MAIN

LOCAL

to toggle to the d esired mode and press

100.0 %A

0.0 %B

DETAIL

or

REMOTE

or

COLUMN A

screen. The o perating m ode field

(see Figur e 2-10)

LOAD

2000

2.00

.

Enter

PSI

mL/MIN

0.0 %C

MIN

0.0 %D

Help Message

Figure 2-10. Main Screen

10.27

LOCAL 2

METHOD

Select

or a

∆

2-22

Doc. 034 856-04 10/95

Page 39

2 • Description

In addition to the operatin g modes, two pump cont rol modes are

availab le:

•

In Direct control, commands are executed immediately when

entered. Because there is no time-based program, the method

clock is not u sed and

•

In Method con trol, comman ds are executed accor ding to the

Hold/Run

and

Reset

do not operate.

timed steps in a pro grammed method. See Section 2.8.2 for

details about M ethod control.

To select the con trol mode:

1. Open either the

displays either

MAIN

DIRECT CN TRL

2. To chang e the mode, move the cursor to this field; press

Select

or

to toggle to the d esired mode and press

∇

or

DETAIL

or

screen. The c ontrol mode field

METHOD

(see Figure 2-10).

Select

Enter

or a

cursor arrow button.

NOTE

If the GP 40 is connected to a host c omp ut er, PeakNet commands

can also be used to change the operating and control modes.

Both Direct and Method control are available in either the Local

mode or the Remote mode. T he combination of available operating

modes and control modes provides flexibility in the way the pump

can be oper ated. The tab le below summarizes the different oper ating

and control mode configurations:

Operating/Control Mode Pump Oper ation

Local/Direct

Local/ Met hod

Commands entered from the control panel and

executed imme diately af ter bein g enter ed

Commands entered from the control panel and

executed by r unning a p rogram med meth od

∆

Remote/Direct

Remote/Method

Doc. 034856 -0 4 10/95

Commands sen t from PeakN et and execu ted

immediately wh en received

Commands sen t from PeakN et and execu ted by

running a programmed method

2-23

Page 40

GP40 Gr adi ent Pu mp

2.8.1 Operating Modes

Local Mode

When the pump is powered up, it is in Local mode (see

Figure 2-1 0). In Local mode, the pu mp accepts o perating

commands from two sources:

•

Direct input from th e front panel keypad

•

TTL inputs from a remote controller, such as an integrator

or another DX 500 module

Remote Mode

In Remote mode, the pump acc epts operating commands from

the host comp uter, which are se nt via the DX LAN using

PeakNet software.

Remote control can be set to either n ormal Remote or Locked

Remote:

2-24

•

In normal Remote mode, all front pane l buttons function

except

Hold/Run

. Operating parameters can be ch anged,

providing they do not interfere with a method while it is

running in remote contro l.

•

In the Locked R emote mode, al l operating chan ges from

the GP40 front panel ar e disabled. Lo cked Remote mo de

can be sel ected only fr om the host computer. It can be

cleared eit her from the co mputer or by p owering the

GP40 down. The GP40 always powers up in the L ocal

mode.

If the pump is running a method when you c hange to the

Remote mode, the computer will n ot interrupt the method

unless you s end an abort command from the compu ter.

Doc. 034 856-04 10/95

Page 41

2.8.2 Method Control

In Method con trol, comman ds are executed accor ding to the

time-based steps programmed in a method. Each step

specifies the eluent co mposition and flow rate to be delivered

by the pump at a given time. The s elected eluent mixture is

delivered either isocratically, or as a mu ltistep linear or

curved gradient. As the method runs, the GP40 calculates the

changes in eluent composition req uired to deliver a gradient

from one method step to the next or to match the selected

curve.

2 • Description

Methods are programme d, saved, and edited from the

METHOD

screen (see Figure 2-11). See Section 3.3 for programming

instructions.

METHOD EDIT

TIME %A

INIT

25.0

0.00

123.45

345.67 v

Help Message

100.0

10.0

17.2

%B %C %D V

25.0

0.0

22.2

19.6

Figure 2-11. Method Screen

SAVE TO RUN 100605

LIMITs 0 - 5000

C FLOW

25.0

0.0

32.3

33.2

25.0

0.0

35.5

30.0

0

5

L 1.00

I

L

2.00

PSI

>

>

>

>

The following summarizes basic information about using

methods.

•

The pump can run under method con trol while you are

entering or editin g any method, even the one th at is

currently running.

•

When saving changes to the currently ru nning method, or

switching to a different method, the method clock

continues runnin g unaffected. Only tho se parameter

changes which affect the method after the c urrent time

will be implemented in the current run.

Doc. 034856 -0 4 10/95

2-25

Page 42

GP40 Gr adi ent Pu mp

•

The GP40 can s tore up to 100 separate methods

(0 through 99) in memory. The actual number is

memory-dependen t, i.e, depends on the size of e ach

method and the amount of available memory. Typica lly,

less than 1 00 can be stored.

•

Methods are retaine d in memory even after the pump is

powered-down.

•

Each method can have a maximum of 50 time-based steps.

Eac h method step specifies a time, an eluent co mposition, a

gradient curve number, an injection valve position (Load or

Inject), and a flow rate . Step 1 always star ts at

condition). Step 2 always starts at

•

After PeakNet downloads a method to the GP40 , the

computer sends a command to activate the method number

and execute the

running when the compu ter activates the new method, the

old method is in terrupted and the method clock is r eset to

INIT

conditions.

TIME = 0.0

INIT

conditions step. If a method is

INIT

.

(initial

2-26

2.8 .3 Eluent Delivery

Isocrati c Eluent R un

The simplest use of the GP40 Gradient Pump is for the

delivery of an isocratic (uncha nging) mixture of one or more

eluents. If more than one eluen t is selected, the pump delivers

a proportional mixtur e of the eluents b ased on the percentage

of each eluent s elected. The combined percent ages of all

eluents selected must tota l 100% or the pump will no t run.

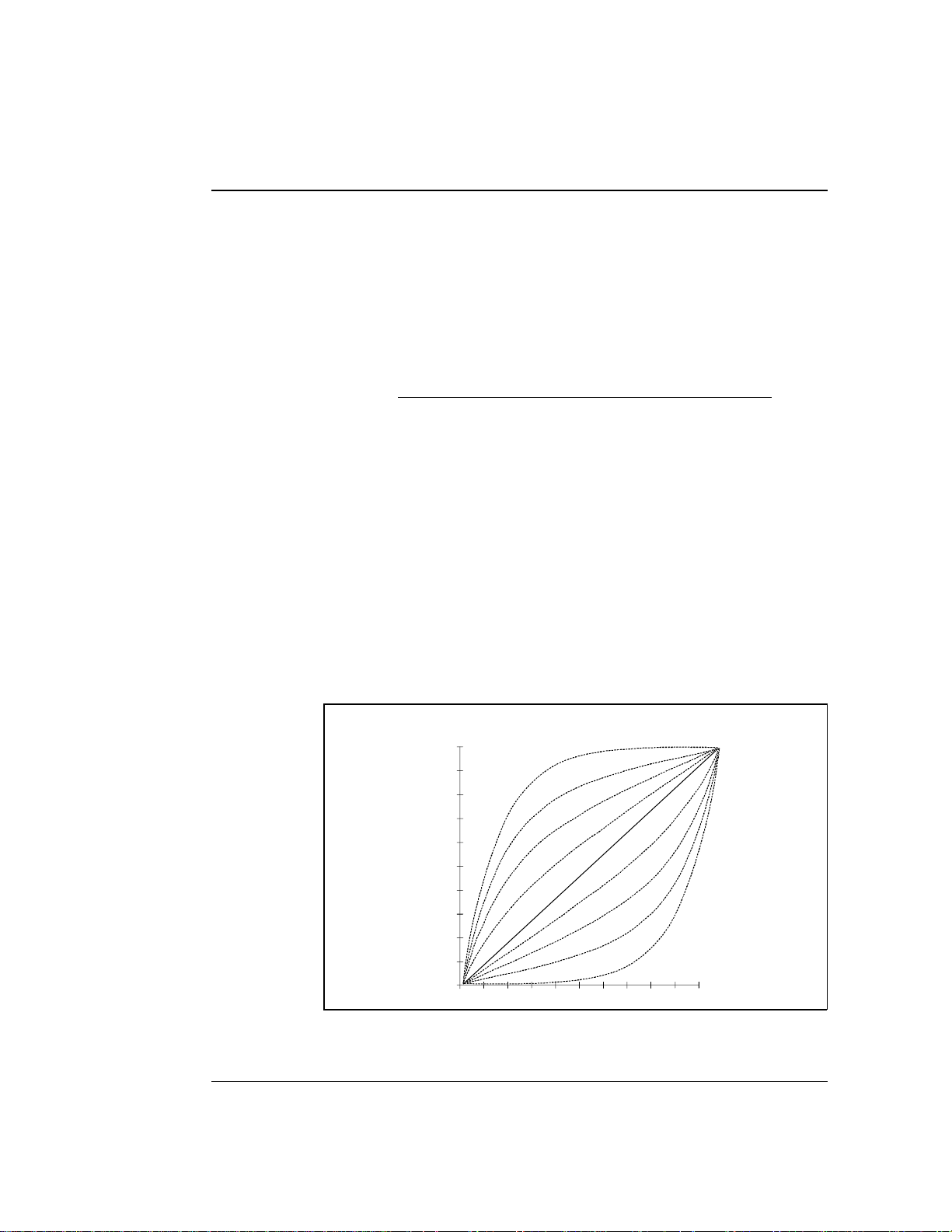

Gradient El uent Run

The pump ca n produce ste p, linear, concave, or convex curves

in eluent concentration over a specified time period. The

slope of the gradient is determine d by the selected gradient

curve (see Figure 2-12) and the time between th e starting and

Doc. 034 856-04 10/95

Page 43

2 • Description

ending points of a gradient s tep. It is important to note the

following points:

•

The curve number parameter determines whether the

pump delivers a linear or curved gr adient.

Curve numbers are defined as follows:

Curve No. Gradient Type

1, 2, 3, 4 Convex

5 Linear ( powe r-up defa ult )

6, 7, 8, 9 Concave

•

Convex curves cause rapid changes in eluent composition

at the beginni ng of the curve an d slower changes at the

end. Concave cur ves cause slower changes at the

beginning and rapid changes at th e end.

•

Slope changes over time become more extreme as curves

go from 6 to 9 (more concave) and from 4 to 1 (more

convex). Figure 2-12 shows the eluent co mposition

profiles correspond ing to curves 1 thro ugh 9, normalized

for 0-100% for 10 minutes.

Doc. 034856 -0 4 10/95

1.0

.9

.8

.7

.6

.5

.4

.3

.2

.1

0

0

1

2

3

4

5

6

7

8

9

1

2

45678910

3

Figure 2-12. Eluent Compositi on Profile for Curves 1-9

2-27

Page 44

GP40 Gr adi ent Pu mp

A curve numb er in a step inst ructs the pump to use

the selected curve number when moving from the

previous step to that step. Because there are no

previous ste ps for

camnot be e ntered for thes e steps .

•

The gradient slop e does not change during a step if curve

5 (the d efault setting) is selected, b ecause cur ve 5

represen ts a linear gr adient.

•

Any consecutive method steps specifying identic al eluent

compositions will ge nerate an isocratic segment,

regardless of the curve number selected.

•

A step gradien t change is a steep linea r change from o ne

eluent to another. A step change occurs automatically if

the following three conditions occur: the time interval

between two steps is less than 0.1 minute; at the

beginning of the step, one eluent is at 0%; and at the en d

of the step , none of the eluents is at 0%.

INIT

NOTE

or

TIME = 0 .0

, curve numbers

2-28

Doc. 034 856-04 10/95

Page 45

3 • Operation and Maintenance

3.1 Getting Ready to Run . . . . . . . . . . . . . . . . 3-3

3.1.1 Degas Eluents . . . . . . . . . . . . . . . 3-3

Degassing Eluents Manually . . . . . . 3-3

3.1.2 Filter Eluents . . . . . . . . . . . . . . . . 3-4

3.1.3 Pressurize Eluent Reservoirs . . . . . . . 3-4

3.1.4 Start-Up . . . . . . . . . . . . . . . . . . . 3-5

3.1.5 Selecting the Pressure Limits . . . . . . . 3-5

3.2 Running Under Direct Control . . . . . . . . . . . 3-6

3.3 Running Under Method Control . . . . . . . . . . 3-9

3.3.1 Creating a New Method . . . . . . . . . . 3-10

3.3.2 Running a Method . . . . . . . . . . . . . 3-12

3.3.3 Editing a Method . . . . . . . . . . . . . . 3-12

3.3.4 Deleting a Method . . . . . . . . . . . . . 3-14

3.3.5 Changing the Running Method . . . . . . 3-14

Doc. 034856 -0 3 5/95

3.3.6 Controlling the Method Clock . . . . . . 3-14

3.4 Example Methods . . . . . . . . . . . . . . . . . . 3-14

3.4.1 Isocratic Method E xample . . . . . . . . 3-15

3.4.2 Linear Gradient Method Example . . . . 3-16

3.4.3 Curved Gradient Method Example . . . . 3-22

3.4.4 Editing a Running Method Exa mple . . . 3-26

3.5 Routine Maintenance . . . . . . . . . . . . . . . . 3-29

3.5.1 Daily Maintenance . . . . . . . . . . . . . 3-29

3.5.2 Periodic Maintenance . . . . . . . . . . . 3-31

3.6 Shutdown . . . . . . . . . . . . . . . . . . . . . . . 3-31

3-1

Page 46

GP40 Gr adi ent Pu mp

3-2

Doc. 034856 -0 3 5/95

Page 47

3 • Operation and Maintenance

3.1 Getting Ready to Run

3.1.1 Degas Eluents

Dionex strongly reco mmends degassing all eluents and

storing them in reservoirs pressurized with filtered inert gas

(see Section 3.1.3) . This helps prevent bubbles (resulting

from eluent outgassing) from forming in the eluent

proportioning valves, pump he ads, and the detector cell.

Degassed elue nts and press urized rese rvoirs are espe cially

important when comb ining aqueous an d non-aqueous

components (e.g., water and methanol).

The GP40 with the option al vacuum degas pump assembly

provides continuou s on-line vacuum degassin g of eluents and

reagents (four maximum).

If the GP40 is not equ ipped with the vacuum degas assembly,

manually vacuum-degas eluents daily, as described below,

and store them in pressurized reservoirs.

Doc. 034856 -0 3 5/95

Degassing Eluents Manually

1. Prep are the eluent requ ired for your application . Pour it

into a vacuu m flask and atta ch the flask to a vacuum

pump or water aspirator.

2. Vacuum degas the eluen t for 5 minutes by shaking or

sonication.

3. R emove the flask from the vacuum. Do not allow water

to flow from the aspirator back into the flask.

4. Po ur the degassed elue nt into a pressuriza ble reservoir. Be

careful not to shake the eluent.

3-3

Page 48

GP40 Gr adi ent Pu mp

5. Install end-line filters and pressurize the reservoirs (see

Sections 3.1 .2 and 3.1.3).

3.1.2 Filter Eluents

Always filter eluents before operation to remove small

particulates that may contaminate the prop ortioning valves or

the pump c heck valves and cau se erratic fl ow rates or loss of

prime. End-line filters (P/N 045987) are su pplied in the

pressurizable rese rvoir ship kits for this pur pose.

Install an end-line filter on the end of each eluent line inside

the reservoir. To prevent air from being drawn through th e

lines, make sure that the end of th e filter reaches the bottom

of the eluent r eservoir.

3.1. 3 Pressuriz e Eluent Reservoirs

Pressurize eluent reservoirs with filtered inert gas (preferably

helium). If helium is not available, argon or nitrogen can be

used. Refer to the Pressurizable Reservoir Installation

Instructions for details.

3-4

1. Verify that a regulator (P/N 04659 4) is installed on the

gas supply line to the reservoirs.

2. Turn on the gas supply and adjus t the pressure to 55 KPa

(8 psi).

Never pressurize the reservoirs above 69 KPa (10 psi).

Doc. 034856 -0 3 5/95

Page 49

3.1.4 Start-Up

3 • Operation and Maintenance

1. Turn on the main pump power. The

displays brief ly (see Figure 2 -3) and after a f ew seconds,

MAIN

the

screen d isplays (see Fig ure 2-5). A series of

diagnostics tests is run at power-up. If one of the tests

fails, the

DIAGNOSTIC TEST

screen displays instead. See

Section C.2.8 if this o ccurs.

2. Press

Off/On

to start the pump flow.

3. C heck the pres sure readin g on the

display updates the pressure rea dout once per pisto n

stroke. The rea ding from one str oke to the next should be

within 3%.

A variation of more than 3% , indicates the pump is out of

prime. The pump can lose prime if it h as been shut down

for an extended period of time. (Overnight shutdown

generally does not cause loss of prime.) Refer to

Section B.2.7 fo r priming instructions, or see Section 4. 1

for other conditions whic h can cause the pump to lo se

prime.

3.1. 5 Selecting the Pr essure Limits

POWER-UP

MAIN

screen. The GP40

screen

Doc. 034856 -0 3 5/95

The high and low pressure limits automatically stop the pump

in the event of a system malfunction (e.g., overpressurizing

because of a bloc kage, or low pressur e caused by a lea k

downstream from the pump).

When running un der Direct control, enter the pressur e limits

from t he

DETAIL

screen (see Figu re 3-1).

When running un der Method contr ol, enter the limits from

METHOD

the

in the

scr een as a par t of e ach method. The limits are se t

INIT

step and remain unchange d throughou t the analy sis.

When a limit trip s tops the pump , the method clock immediately

stops and goe s to Hold. T he current status of the program tha t

was running at the time is displayed on the front panel.

3-5

Page 50

GP40 Gr adi ent Pu mp

To select the limits:

1. Go to the

LIMIT

field.

DETAIL

or

METHOD

screen and move the cursor t o the

2. Enter a low pressure limit that is 1.4 to 2 MPa (200-300 psi)

below the norm al system o perating pres sure, as ind icated by the

pressure display on the front panel. The low pressure limit is

activated after 13 pump pist on strokes, i.e. , after 1.3 mL

(standard) or 0 .325 mL (microbore) of fluid is pumped throu gh.

3. Enter a hi gh pressure limit that is 2 to 2.75 MPa (300-40 0 psi)

above the normal system oper ating pressu re. The pump is

equipped with a pressure limiter that prevents operation above

35 MPa (5076 psi) .

DETAIL SCREEN

100.0 %A

0.0 %B

0.0 %C

0.0 %D

LOCAL

Help Message

2125

2.00

INJECT

COLUMN

LIMIT

DIRECT CNTRL

PSI

mL/MIN

SAMPLE

A

1200-1900 PSI

TTL1

TTL2

RLY1

RLY200

1

1

Figure 3-1. Detail Screen: Setting Pressure Limits

3.2 Running Under Direct Control

Direct control is most often used for s imple runs, such as the

delivery of an isocratic (uncha nging) mixture of one or more eluents.

Direct Control Example:

Specify an isocratic mix ture of 60% eluent A, 25% eluent B , and

15% eluent C to be pumped at 2.0 mL/min. Figure 3-2 illustrates th e

isocratic profile for this example. Figure 3-3 illustrates the

screen as it will appear when the example is set up.

3-6

MAIN

Doc. 034856 -0 3 5/95

Page 51

3 • Operation and Maintenance

Figure 3-2. Isocratic Run Profile

60.0 %A

25.0 %B

LOAD

COLUMN A

2000

2.00

PSI

mL/MIN

15.0 %C

0.0 %D

Help Message

Figure 3-3. Main Screen: Running Under Direct Control

1. Go to the

MAIN

or

DETAIL

LOCAL

screen.

2. Check that the operating fields are set to

CNTRL

(see Figure 3-3). If

REMOTE

set, move the cursor to the appropriate field; press

Select

to toggle the value, and press

∇

button.

3. Move to the %A field and enter 60; move to the %B field and

enter 25; move to the %C field and press

automatically filled in to make the e luent percentages equal 100).

4. Move to the

mL/MIN

field and enter 2.

DIRECT CNTRL

LOCAL

Enter

METHOD

Enter

and/or

DIRECT

and

are currentl y

Select

or

∆

or a cursor arrow

(15 is

5. If the pump is cu rrently off, press

and begin the isocratic delivery.

Doc. 034856 -0 3 5/95

Off/On

to turn on the motor

3-7

Page 52

GP40 Gr adi ent Pu mp

Wait at least 10 minutes after starting the pump or changin g the flow

rate before beginning an analysis. This allows the pump’s real-time

electronic pulse damping circuitry to stabilize the flow rate.

3.3 Running Under Method Control

This section provides general instructions on how to create, edit, and

run methods. Sectio n 3.4 provides s tep-by-step examples for

creating linea r gradient and curved gradient methods, and f or

modifying an existing method.

Use the following guidelines when entering time-based parameters

in the

•

•

METHOD

screen :

When setting method times, allow at least 10 minutes after

starting the pump or changing the flow rate before beginning a n

analysis. This allows the pump ’s real-time electronic pulse

damping circuitry to stabilize the flow rate.

In th e %A, %B, %C, and %D columns, enter decimal percentage

values from 0.1% th rough 100% for the eluen t compositions. The

combined percentages for all eluents mu st total 100% or the

pump will not ru n.

3-8

•

In th e V column, select the position o f the injection valve (either

L

for load or I for inject).

•

In th e

FLOW

column, enter the pump flow rate. Flow rates are

adjustable in increments o f 0.01 mL/min. See Section 2.4 .2 for

the available flow rate ranges. They vary, depending on the size

of the pump head and whether the run is isocratic or grad ient.

Continuous operation of the micr obore pump heads at flow

rates above 2.0 mL/min will decrease seal and pump l ife.

For the best extended operation at 2.0 mL/min or above,

replace the microbore pump heads with standard bore

pump heads. Similarly, when running gradients, the

standard bore pump heads should not be used below

0.4 mL/min.

Doc. 034856 -0 3 5/95

Page 53

3 • Operation and Maintenance

•

For steps other than

INIT

and time zero, enter a curve number in

the C column. The curve number determines whe ther the pump

delivers a linear o r curved gradi ent (see Section 2.8.3). The

default is curve 5 (linear).

NOTE

A curve numb er in a st ep inst ructs the pump t o use the s electe d

curve number when moving f rom the p revious s tep to t hat st ep.

Because th ere are no previ ous steps for

numbers are not entered for these steps.

•

If a step field is blank, the value set in the previous step is used.

•

If a method contains more steps than ca n be displayed o n one

INIT

TIME = 0 .0

or

, curve

screen, they are scrolled off the screen. A small arrow down (∨)

next to the time entry at the b ottom of the screen indicates there

are additional steps below. A small arrow up (^) adjacent to the

top time entry indicates there a re additional steps above (see

Figure 3-16). Move the cursor to the bottom or top of the screen

and then move one more line to view the additional steps.

3.3. 1 Creating a New Method

Doc. 034856 -0 3 5/95

You can create a new method when th e method cl ock is in

either

Hold

1. Go to the

2. Check that the pump is set to

currently set, move the cursor to the field; press

Select

or

Run

or

∇

.

MAIN

or

DETAIL

screen .

LOCAL

to toggle the value, and press

. If

REMOTE

Enter

is

Select

or a cur sor

arrow button.

3. Go to the

4. In th e

METHOD

EDIT

field, enter the number of the method to be

screen.

created. You can enter the nu mber of an unused method or

the number of an existing meth od that you want to edit

and save as a new method . If you enter the number of an

unused method, the screen will lo ok similar to the

example screen in Figu re 3-4.

∆

3-9

Page 54

GP40 Gr adi ent Pu mp

5. In th e

LIMITs

field, set the low and high pressu re limits

(see Section 3. 1.5).

METHOD EDIT

TIME %A

100.0

0.00

Help Message

Figure 3-4. Method Screen: Creating a New Method

%B %C %D V

SAVE TO RU N 055

LIMITs 0 - 5000

C FLOW

_

L 1.00INIT

_

PSI

6. Each method starts out with two timed steps (see

Figure 3-4). The first step is an initial condition s step

INIT

with

in the

zero step w ith

TIME

column. The second step is a time

0.00

in the

TIME

column. The parameters in

each of t hese first two steps can be ch anged but the ste ps

cannot be d eleted. Enter the parameters for thes e two

steps as required for the method.

>

>

>

>

3-10

7. To enter a new step, use one of the following method s:

Move the cursor to the emp ty

•

TIME

field below the last

step and enter the elapsed time at whic h to start the

new step.

Move the cursor to a ny of the

•

Insert

. This adds a new step after the cursor position.

TIME

fields and press

Enter the elapsed time at whic h to start the new step.

After you pres s

Enter

or a cursor arrow button, timed

steps are automatic ally organized in chronolo gical order.

8. Enter the remainder of th e parameters for the new step.

Doc. 034856 -0 3 5/95

Page 55

9. After entering the time-based parameters, move the cursor

to the

SAVE T O

field. If you ar e editing an existing method,

enter a new number for the method and press

save the method to a new number. If not, press

save the current method.

3. 3 . 2 Runni ng a Meth od

3 • Operation and Maintenance

Enter

to

Enter

to

1. If the pump motor is off, pres s

Off/On

to turn the motor

on.

2. Go to the

from

LOCAL.

3. In th e

MAIN

DIRECT CN TRL

METHOD

You can also select the method numb er in the

screen. Move th e cursor to

DETAIL

or

screen and, if necessary, toggle

to

METHOD

and from

REMOTE

to

field, enter the des ired method number.

METHOD

RUN

and enter the desired

method number.

If the method clock is already runnin g when you enter the

method number, the method sta rts immediately.

If the clock is in Hold, press

Hold/Run

to start the method.

4. The elapsed time on the method clo ck when the method

begins determines where (at what step an d parameters)

the method begins run ning:

If the method clock is at

•

begins running using the

INIT

or time zero, the method

INIT

ial condition parameters.

3. 3 . 3 Editing a Method

Doc. 034856 -0 3 5/95

If the method clock is greater than zero, the method

•

begins running using the parameters spe cified in the

step for that elapsed time. Press

method at the

INIT

ial conditions.

Reset

to start the

After entering a method, you can modify it by changing,

adding, or de leting steps and par ameters. These ch anges can

3-11

Page 56

GP40 Gr adi ent Pu mp

be made when the me thod clock is s topped, or while it is

running. If the method y ou are editing is curren tly running,

the changes are stored in me mory and implemented when yo u

save the method.

After you save changes, there is no way to recall the original

method. Theref ore, if you plan to make experimental changes

to a method but want to retain the original meth od in its

unmodified form, save a copy of the or iginal to a different

number.

Use the following basic steps to e dit a method:

1. Go to the

METHOD

screen. In the

EDIT

field, enter the

number of the meth od to be modified.

2. M ake changes as ne eded:

To change a field’s value

•

, position the cursor in the

field and enter th e new value. The previous value is

automatically deleted.

To add a method step

•

TIME

fields and press

empty

TIME

field below the last step and enter the

, move the cursor to any of the

Insert

, or move the cursor to the

elapsed time at which to start the new step. After you

press

Enter

or a cursor arr ow button, the new step is

automatically moved to the correct chronological

position. Continue e ntering parameters for the new

step.

To de lete a meth od s tep

•

to be deleted and p ress

, move the cursor to the step

Delete

twice.

3. When c hanges are complete, move the cursor to the

SA VE TO

field . Pre ss

Enter

to save the changes to the

current method, or enter a new method number a nd press

Enter.

3-12

If you save changes to th e currently running me thod, they

are immediately incorporated in the run and executed at

the programmed time. If, however, a change is made to an

Doc. 034856 -0 3 5/95

Page 57

event that has already been executed, it will not be

incorporated a s part of th e current run. To run the

changed version of the method, press

method at the

INIT

3.3.4 Deleting a Method

3 • Operation and Maintenance

Reset

to restart the

ial conditions.

To delete an entire method, move the cursor on the

screen to the

INIT

step, then p ress

3. 3 .5 C hang ing t he Ru nni ng Met hod

To change from the metho d currently running to a different

method, enter the new method number in the

METHOD

screen, and press

Enter

. The new method begins

running using the p arameters specified in the step for the

current elapsed time. Press

INIT

ial conditions.

Reset

3. 3. 6 Control ling the Method Cl ock

Hold/Run

The

MAIN

the

•

To start a nd stop the method clock, press

•

To reset the clock to

•

To set the clock to a specific e lapsed time, enter the time

into the

button, the

DETAIL

and

MIN

field in the

Reset

button, and the

screens control the metho d clock:

INIT

, press

MAIN

or

method will star t (or continue) running using the method

parameters specified for that time.

METHOD

Delete

twice.

RUN

field on the

to start the method at the

MIN

fie ld s in

Reset

DETA IL

Hold/Run

.

screen. The

.

3.4 Example Methods

The examples in this s ection provide step-by-s tep instructions for

creating three types of methods: isocratic, line ar gradient, and

curved gradient. The last example demonstrate s how to edit a

running method.

Doc. 034856 -0 3 5/95

3-13

Page 58

GP40 Gr adi ent Pu mp

For all of the method examples, set the pump to Local mode,

Method control. To do this, go to the

necessary, toggle from

LOCAL.

3.4. 1 Isocratic Method Example

Specify an isocratic mix ture of 60% eluent A, 25% elu ent B,

and 15% eluent C to be p umped at 2.0 mL/min. Figure 3-2

illustrates the isocratic profile for this example.

DIRECT CN TRL

MAIN

to

DETA IL

or

METHOD

screen, and if

and from

REMOTE

to

Figure 3-5 illustrates the

METHOD

screen as it will a ppear

when the example i s set up.

METHOD EDIT

TIME %A

60.0

0.00

Help Message

Figure 3-5. Method Screen: Isocratic Run Example

1. Go to the

EDIT

the

METHOD