Page 1

DX-120 ION CHROMATOGRAPH

OPERATOR’S MANUAL

© 1998 Dionex Corporatio n

Document No . 031183

Revision 03

September 1998

Page 2

©1998 by Dionex Corpor ation

All rights reserved worldwide.

Printed in the United States of America.

This publication is protected by federal copyright law. No part of this publication

may be copied or distributed, transmitted, transcribed, stored in a retrieval system,

or transmitted into any human or computer language, in any form or by any means,

electronic, mechanical, magnetic, manual, or otherwise, or disclosed to third parties

without the express written permission of Dionex Corporation, 1228 Titan Way,

Sunnyvale, California 94088-36 03 U.S.A.

DISCLAIMER OF WARRANTY AND LIMITED WARRANTY

THIS PUBLICATION IS PROVIDED “AS IS” WITHOUT WARRANTY OF

ANY KIND. DIONEX CORPORATION DOES NOT WARRANT,

GUARANTEE, OR MAKE ANY EXPRESS OR IMPLIED

REPRESENTATIONS REGARDING THE USE, OR THE RESULTS OF THE

USE, OF THIS PUBLICATION IN TERMS OF CORRECTNESS,

ACCURACY, RELIABILITY, CURRENTNESS, OR OTHERWISE.

FURTHER, DIONEX CORPORATION RESERVES THE RIGHT TO REVISE

THIS PUBLICATION AND TO MAKE CHANGES FROM TIME TO TIME

IN THE CONTENT HEREINOF WITHOUT OBLIGATION OF DIONEX

CORPORATION TO NOTIFY ANY PERSON OR ORGANIZATION OF

SUCH REVISION OR CHANGES.

EMISSIONS COMPLIANCE

This equipment meets ITE standard EN 55022 part A for radiated emissions and is

suitable for use in a laboratory environment. Operation of this equipment in a

residential area, however, may cause interference to radio and television reception.

TRADEMARKS

Teflon® an d Tefzel® are registered t rademarks of E.I. du Pont de Ne mours & Co.

AutoSuppression, DX-LAN, IonSep®, MPIC®, OmniPac®, OnGuard,

Self-Regenerating Suppressor, and SRS are trademarks of Dionex Corp.

PRINTING HISTORY

Revision 01, May 1996

Revision 02, March 1997

Revision 03, September 1998

Page 3

Contents

1 • Introduction

1.1 About This Manual . . . . . . . . . . . . . . . . . 1-2

1.1.1 Typefaces and Conventions . . . . . . . . 1-3

1.1.2 Safety Messages and Notes . . . . . . . . 1-4

1.1.3 Symbols . . . . . . . . . . . . . . . . . . . 1-5

1.2 Related Manuals . . . . . . . . . . . . . . . . . . . 1-5

2 • Description

2.1 Operating Features . . . . . . . . . . . . . . . . . 2-1

2.1.1 Front Control Panel . . . . . . . . . . . . 2-3

2.1.2 Pump . . . . . . . . . . . . . . . . . . . . 2-6

2.1.3 Configuration DIP Switches . . . . . . . 2-6

2.1.4 Eluent Reservoirs . . . . . . . . . . . . . 2-7

Doc. 031138-03 9/98

2.1.5 Component Panel . . . . . . . . . . . . . 2-8

2.1.6 Rheodyne Injection Valve . . . . . . . . . 2-11

2.1.7 Detector Cells . . . . . . . . . . . . . . . 2-12

2.1.8 DS4 Detection Stabilizer . . . . . . . . . 2-13

2.2 Dual-Column Configuration Features . . . . . . . 2-15

2.2.1 Column Select Mode . . . . . . . . . . . 2-16

2.2.2 Eluent Select Mode . . . . . . . . . . . . 2-18

2.3 Fluid Schematics . . . . . . . . . . . . . . . . . . 2-19

2.4 Control Modes . . . . . . . . . . . . . . . . . . . . 2-22

2.4.1 Local Mode . . . . . . . . . . . . . . . . . 2-22

2.4.2 Remote Mode . . . . . . . . . . . . . . . 2-22

i

Page 4

DX-120 Operator’s Manual

2.5 TTL Control . . . . . . . . . . . . . . . . . . . . . 2-23

2.5.1 Injection Valve/Remote Start Control . . 2-23

2.5.2 Recorder Range Control . . . . . . . . . . 2-23

3 • Operation and Maintenance

3.1 Preparing Eluents . . . . . . . . . . . . . . . . . . 3-1

3.1.1 Degassing Eluents . . . . . . . . . . . . . 3-1

3.1.2 Filtering Eluents . . . . . . . . . . . . . . 3-2

3.1.3 Pressurizing Eluent Reservoirs . . . . . . 3-2

3.2 Preparing Samples . . . . . . . . . . . . . . . . . 3-3

3.2.1 Collecting and Storing . . . . . . . . . . . 3-3

3.2.2 Pretreating . . . . . . . . . . . . . . . . . 3-3

3.2.3 Diluting . . . . . . . . . . . . . . . . . . . 3-4

3.3 Operating . . . . . . . . . . . . . . . . . . . . . . 3-5

3.3.1 Starting Up . . . . . . . . . . . . . . . . . 3-5

3.3.2 Injecting the Sample . . . . . . . . . . . . 3-7

3.4 Using an Integrator . . . . . . . . . . . . . . . . . 3-9

3.5 Running under PeakNet Control . . . . . . . . . . 3-9

3.6 Optimizing Temperature Compensation . . . . . . 3-10

3.6.1 With a DS4 . . . . . . . . . . . . . . . . . 3-10

3.6.2 With a CDM-3 Cell . . . . . . . . . . . . 3-10

3.7 Maintenance . . . . . . . . . . . . . . . . . . . . . 3-11

4 • Troubleshooting

4.1 Alarms . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Error Codes . . . . . . . . . . . . . . . . . . . . . 4-3

4.3 Liquid Leaks . . . . . . . . . . . . . . . . . . . . . 4-4

4.4 Pump Difficult to Prime . . . . . . . . . . . . . . 4-8

ii

Doc. 031138-0 3 9/98

Page 5

4.5 Pump Loses Prime . . . . . . . . . . . . . . . . . 4-8

4.6 Pump Does Not Start . . . . . . . . . . . . . . . . 4-9

4.7 No Flow . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.8 Excessive System Backpressure . . . . . . . . . . 4-9

4.9 Peak “Ghosting” . . . . . . . . . . . . . . . . . . . 4-10

4.10 Nonreproducible Peak Height or Retention

Time . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4.11 Abnormal Retention Time or Selectivity . . . . . 4-11

4.12 DS4 Temperature Inaccurate . . . . . . . . . . . . 4-12

4.13 No Detector Response . . . . . . . . . . . . . . . 4-13

4.14 Low Detector Output . . . . . . . . . . . . . . . . 4-14

4.15 High Detector Output . . . . . . . . . . . . . . . . 4-14

4.16 Noisy or Drifting Baseline . . . . . . . . . . . . . 4-15

5 • Service

Contents

Doc. 031138-03 9/98

5.1 Replacing Tubing and Fittings . . . . . . . . . . . 5-2

5.2 Changing the Sample Loop . . . . . . . . . . . . 5-2

5.3 Isolating a Restriction in the Liquid Plumbing . . 5-3

5.4 Replacing the DS4 Cell . . . . . . . . . . . . . . . 5-3

5.5 Cleaning Cell Electrodes . . . . . . . . . . . . . . 5-5

5.6 Calibrating the Cell Constant . . . . . . . . . . . 5-6

5.7 Calibrating the Pump Flow Rate . . . . . . . . . . 5-8

5.8 Cleaning and Replacing Pump Check Valves . . . 5-8

5.9 Replacing a Pump Piston Seal . . . . . . . . . . . 5-9

5.10 Replacing a Pump Piston . . . . . . . . . . . . . . 5-12

5.11 Replacing the Pressure Transducer Waste

Valve O-Ring . . . . . . . . . . . . . . . . . . . . 5-14

5.12 Changing the Main Power Fuses . . . . . . . . . . 5-15

iii

Page 6

DX-120 Operator’s Manual

A • Specifications

A.1 Electrical . . . . . . . . . . . . . . . . . . . . . . . A-1

A.2 Environmental/Physical . . . . . . . . . . . . . . . A-1

A.3 Control Panel . . . . . . . . . . . . . . . . . . . . A-2

A.4 Pump . . . . . . . . . . . . . . . . . . . . . . . . . A-2

A.5 Pulse Damper . . . . . . . . . . . . . . . . . . . . A-2

A.6 Detector . . . . . . . . . . . . . . . . . . . . . . . A-2

A.7 Conductivity Cell . . . . . . . . . . . . . . . . . . A-3

A.8 DS4 Detection Stabilizer (Optional) . . . . . . . . A-3

A.9 Valves . . . . . . . . . . . . . . . . . . . . . . . . A-3

A.10 Delay Volume . . . . . . . . . . . . . . . . . . . . A-4

B • Installation

B.1 Facility Requirements . . . . . . . . . . . . . . . . B-1

iv

B.2 Installation Overview . . . . . . . . . . . . . . . B-1

B.3 Rear Panel Connections . . . . . . . . . . . . . . B-2

B.3.1 Power Connection . . . . . . . . . . . . . B-2

B.3.2 Switched AC Outlet Connection

(Optional) . . . . . . . . . . . . . . . . . . B-4

B.3.3 Waste Lines . . . . . . . . . . . . . . . . . B-5

B.3.4 Gas Connection . . . . . . . . . . . . . . B-5

B.3.5 DX-LAN Cable Connection (Optional) . B-6

B.4 Eluent Reservoir Connections . . . . . . . . . . . B-8

B.5 Pump Setup . . . . . . . . . . . . . . . . . . . . . B-8

B.5.1 Priming the Pump . . . . . . . . . . . . . B-8

B.5.2 Checking the Pump Flow Rate

Calibration . . . . . . . . . . . . . . . . . B-9

Doc. 031138-0 3 9/98

Page 7

Contents

B.6 Connections to Chromatography Components . . B-10

B.6.1 Backpressure Requirements . . . . . . . . B-12

B.6.2 Self-Regenerating Suppressor (SRS)

Installation . . . . . . . . . . . . . . . . . B-13

B.6.3 Column Installation . . . . . . . . . . . . B-17

B.7 TTL Control Connections (Overview) . . . . . . . B-19

B.7.1 TTL Inputs . . . . . . . . . . . . . . . . . B-19

B.7.2 TTL Outputs . . . . . . . . . . . . . . . . B-20

B.7.3 F errite Core Installation on TTL Output

Cables . . . . . . . . . . . . . . . . . . . . B-21

B.8 Autosampler Connections (Optional) . . . . . . . B-22

B.8.1 Autosampler Outlet Line Connection . . B-22

B.8.2 AS40 Automated Sampler Connections . B-22

B.8.3 AS3 500 Automated Sampler

Connections . . . . . . . . . . . . . . . . B-24

B.9 Recorder and Integrator Connectio ns

(Optional) . . . . . . . . . . . . . . . . . . . . . . B-27

C • Integrator Programming

Doc. 031138-03 9/98

B.9.1 Chart Recorder Connections . . . . . . . B-27

B.9.2 4400 or 4600 Integrator Connections . . B-27

B.10 Configuration DIP Switch Settings . . . . . . . . B-29

B.11 DS4 Detection Stabilizer Installation . . . . . . . B-33

B.12 CDM-3 Cell Installation . . . . . . . . . . . . . . B-35

B.13 Injection Valve Connections . . . . . . . . . . . . B-36

B.14 Column Switching Valve Connections . . . . . . . B-37

B.15 DX-LAN Card Installation (Optional) . . . . . . . B-38

C.1 Integrator Power-up Configuration . . . . . . . . C-1

C.2 Setting Offsets . . . . . . . . . . . . . . . . . . . . C-2

C.3 Area Percent Mode . . . . . . . . . . . . . . . . . C-2

v

Page 8

DX-120 Operator’s Manual

C.4 Using DIALOG to Create a Method . . . . . . . . C-3

C.4.1 Time Functions . . . . . . . . . . . . . . . C-3

C.4.2 Creating a Method . . . . . . . . . . . . . C-4

C.5 BASIC Programming . . . . . . . . . . . . . . . . C-7

D • Conductivity Detection

D.1 How Conductivity Is Measured . . . . . . . . . . D-1

D.2 Conductivity of Solutions . . . . . . . . . . . . . D-2

D.2.1 Effect of Hydration Sphere and

D.2.2 Effect of Temperature on Condu ctivity . D-4

D.2.3 Species Detected by Conductivity . . . . D-5

D.2.4 Chemical Suppression . . . . . . . . . . . D-6

D.2.5 Eluents for Conductivity Detection . . . D-9

Solvent on Conductivity . . . . . . . . . . D-4

vi

E • Glossary

Doc. 031138-0 3 9/98

Page 9

1 • Introduction

The Dionex DX-120 Ion Chro matograph performs isocratic ion

analysis applications using conductivity detection. The DX-120 is an

integrated system, which includes a pump, detector, and injection

valve. The chromatography components, including the column(s),

Self-Regenerating Suppressor (SRS), and conductivity cell are

ordered separately. These components are moun ted on the inside of

the DX-120 door.

The DX-120 can be controlled locally, using the front panel keypad

and display, or remotely, from a PeakNet workstation. The PeakNet

workstation consists of a computer with a Dionex DX-LAN

interface card and PeakNet software (Release 4.30 or higher)

installed. Limited remote control is also available using TTL signals.

The DX-120 can be ordered as a single-column system or a

dual-column system. The dual-column system a llows switching

between two sets of columns (column select mode) or b etween two

eluents (eluent select mode). In the eluent select mode, the DX-120

can perform step gradients.

The following models are available:

Configuration Voltage/Line Frequency* Without

Single-column 115 VAC/60 Hz P/N 050100 P/N 050200

Dual-column 115 VAC/60 Hz P/N 050102 P/N 0502 02

*Must match the voltage and line frequency of the installation site’s

power source.

Doc. 031183-03 9/98

With

DX-LAN

100 VAC/50 Hz P/N 050103 P/N 0502 03

230 VAC/50 Hz P/N 050106 P/N 0502 06

100 VAC/50 Hz P/N 050105 P/N 0502 05

230 VAC/50 Hz P/N 050108 P/N 0502 08

DX-LAN

1-1

Page 10

DX-120 Operator’s Manual

1.1 About This Manual

Chapter 1

Introduction

Chapter 2

Description

Chapter 3

Operation and

Maintenance

Chapter 4

Troubleshooting

Chapter 5

Service

Appendix A

Specifications

Appendix B

Installation

Appendix C

Integrator

Programming

Introduces the DX-120 and explains the

conventions used in the manual, including

safety-related information.

Describes the DX-120 operating features, the

chromatographic fluid path, and the control

modes.

Provides operating and routine preventive

maintenance procedures.

Lists problems, with step-by-step procedures to

isolate and eliminate their sources.

Provides step-by-step instructions for routine

service and parts replacement procedures.

Lists the DX-120 specifications and installation

site requirements.

Describes how to install the DX-120.

Describes how to program a Dionex 4400 or

4600 integrator for automated control of the

DX-120.

1-2

Appendix D

Conductivity

Appendix E

Detection

Glossary

Describes conductivity detection and its

applications.

Defines terms commonly used in ion

chromatography.

Doc. 031183-0 3 9/98

Page 11

1.1 .1 Typefaces and Conventions

•

Capitalized bold type indicates a front panel button. For

example:

1 • Introduction

Press

•

Upper-case bold type indicates information displayed on

Pump

to turn on the pump.

the front panel screen. For example:

LEAK ALARM

•

Upper-case italic type indicates a grouping of front panel

displays when a leak occurs.

buttons. For example:

Use the buttons in the DISPLAY group to select the type

of information shown on-screen.

•

When a function can be controlled by a DIP switch

setting, the switch and position numbers are in

parentheses. For example:

(SW1-3) indicates DIP switch 1, position 3.

(SW2-5, 6, 7, 8) indicates DIP switch 2, positions 5, 6, 7,

and 8.

Doc. 031183-03 9/98

1-3

Page 12

DX-120 Operator’s Manual

1.1 . 2 Safety Mess ages and Notes

The DX-120 meets European, EMC, and safety requirements

per Council Directives 73/23/EEC and 89/336/EEC, EN

61010-1:1993 (safety), EN 5008 2-1:1992 (susceptibility), and

EN 55011:1991 (emissions). The TUV/CE and GS safety

label on the DX-120 attests to compliance with these

standards.

The DX-120 is designed for ion chromatography applications

and should not be used fo r any other purpose. If there is a

question regarding appropria te usage, contact Dionex before

proceeding.

This manual con tains warnings and precau tionary statements

that, when properly followed, can prevent personal injury

and/or damage to the instrument. Safety messages appear in

bold type and are accompanied by icons, as follows:

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

1-4

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

Indicates that the function or process of the instrument

may be impaired. Operation does not constitute a hazard.

Doc. 031183-0 3 9/98

Page 13

Informational messages also appear throughout this manu al.

These are label ed NOTE and are in bold type:

NOTES call attention to certain information. They alert

you to an unexpected result of an action, suggest how to

optimize instrument performance, etc.

1.1.3 Symbols

The symbols below appear on the DX-120, or on DX-120

labels.

1 • Introduction

NOTE

~

Alternating current

Protective conductor terminal

Power supply is on

Power supply is off

1.2 Related Manuals

During installation and operation of the DX-120, you may need to

refer to one or more of the following manuals for information about

other components or instru ments in the system.

4440 Integrator User’s Guide (Document No. 034200) or 4600

•

Integrator User’s Guide (Document No. 034408)

AS40 Automated Samp ler Operator’s Manual (Document

•

No. 034970)

Installation of Dionex Ferrule Fittings (Document No. 034213)

•

Doc. 031183-03 9/98

1-5

Page 14

DX-120 Operator’s Manual

PeakNet Software User’s Guide (Document No. 0349 14)

•

Installing the PeakNet System (Document No. 034941)

•

1-6

Doc. 031183-0 3 9/98

Page 15

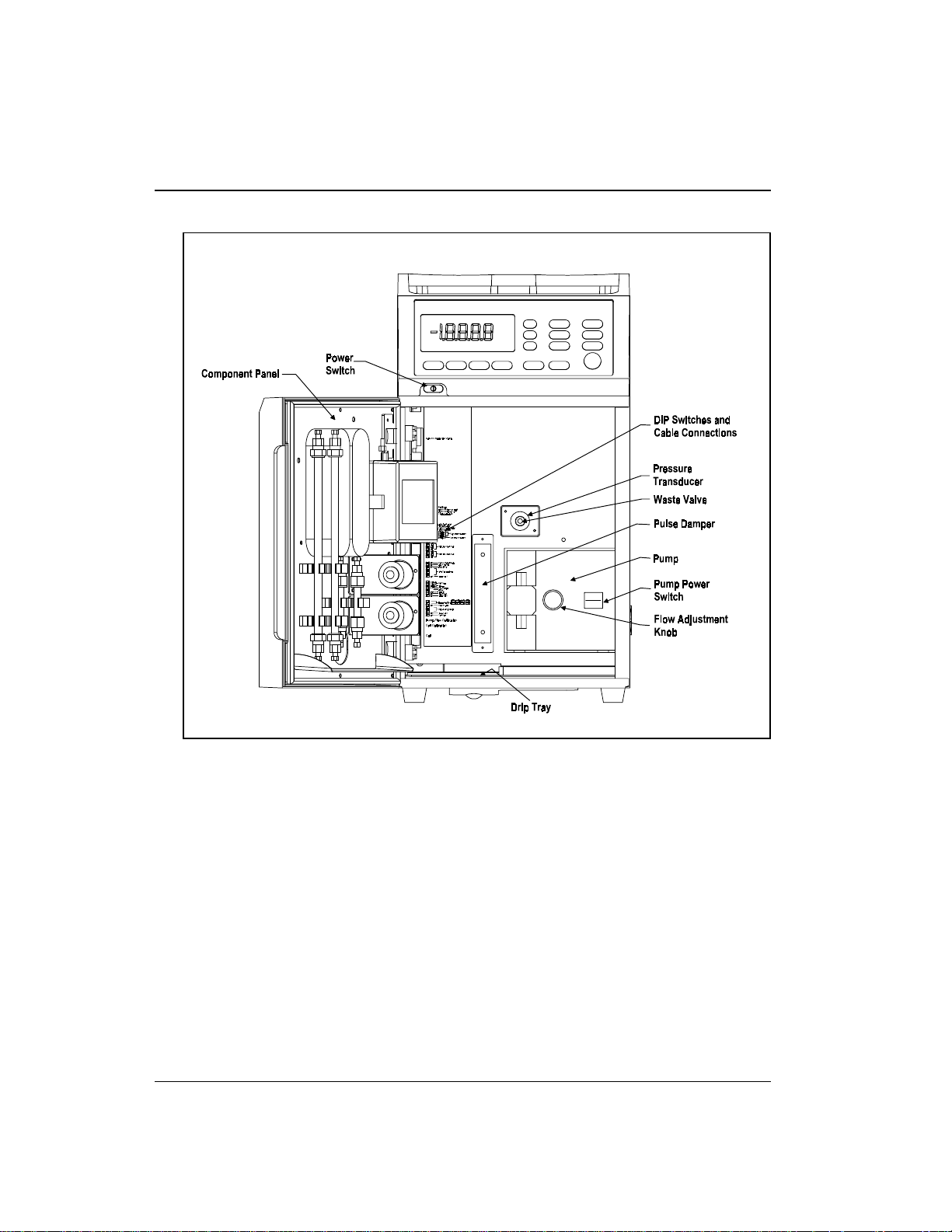

2 • Description

2.1 Operating Features

Figures 2-1 and 2-2 illustrate the main operating features of the

DX-120.

Doc. 031183-03 9/98

Figure 2-1. DX-120 Operating Features (Exterior)

2-1

Page 16

DX-120 Operator’s Manual

2-2

Figure 2-2. DX-120 Operating Features (Interior)

Doc. 031183-0 3 9/98

Page 17

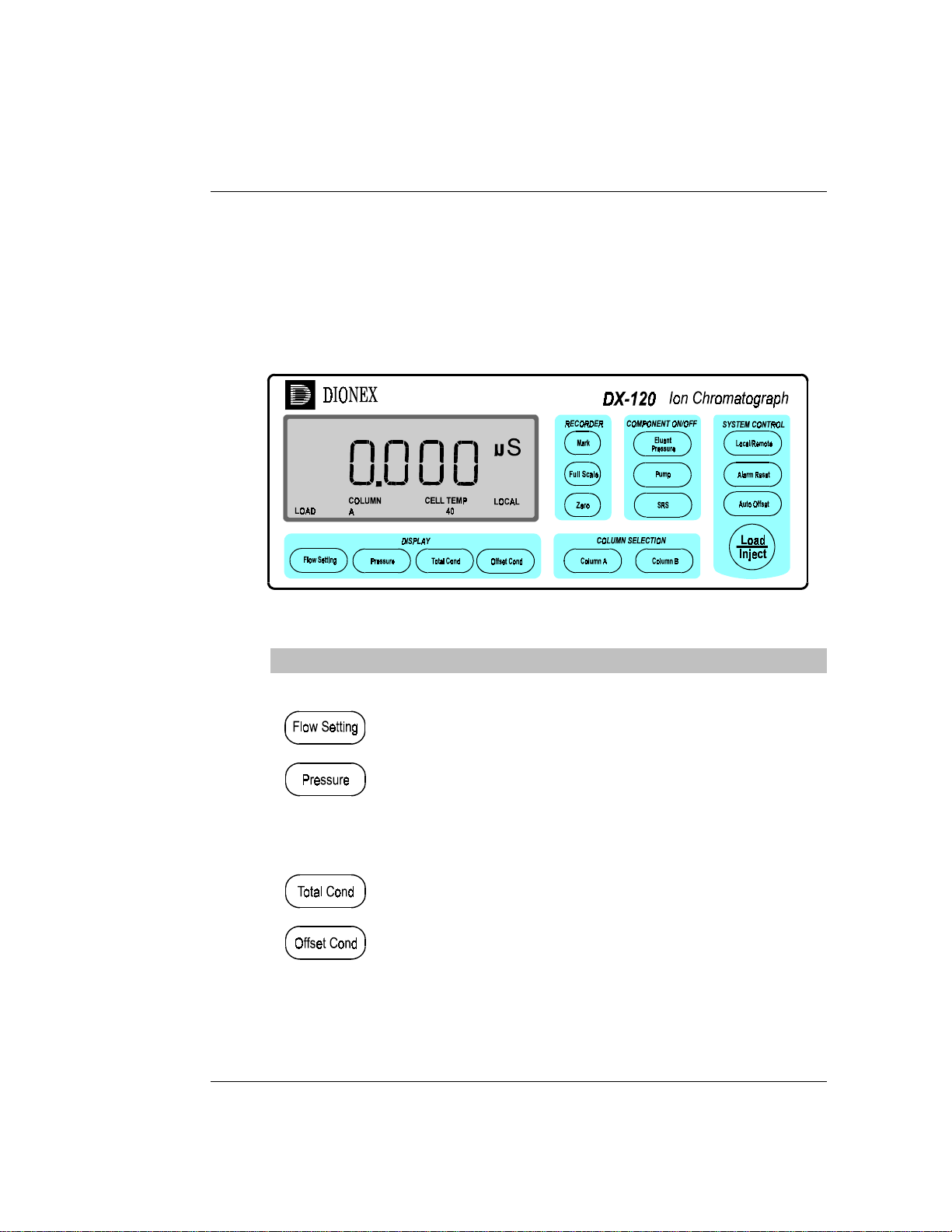

2.1 .1 Front Control Panel

The control panel liquid crystal d isplay (LCD) shows status

information and alarm conditions. Press a button in the group

labeled DISPLAY to determine the type of status information

shown. The remaining buttons control DX-120 operation.

Figure 2-3. DX-120 Control Panel

2 • Description

Button Function

DISPLAY

Doc. 031183-03 9/98

Displays the pump flow rate setting (0.5 to 4.5 mL/min).

Displays the pump pressure transducer reading (0 to

27.6 MPa or 0 to 4000 psi)

NOTE

MPa is the default pressure unit. For psi, set DIP

SW1-4 on. See Section B.10 for details.

Displays the total conductivity reading (0 to 999.9 µS).

Displays the offset conductivity reading (-999.9 to

999.9 µS). Offset conductivity is the total conductivity

minus the offset for the current run (see the description of

the Auto Offset button).

Table 2-1. Control Panel Button Functions

2-3

Page 18

DX-120 Operator’s Manual

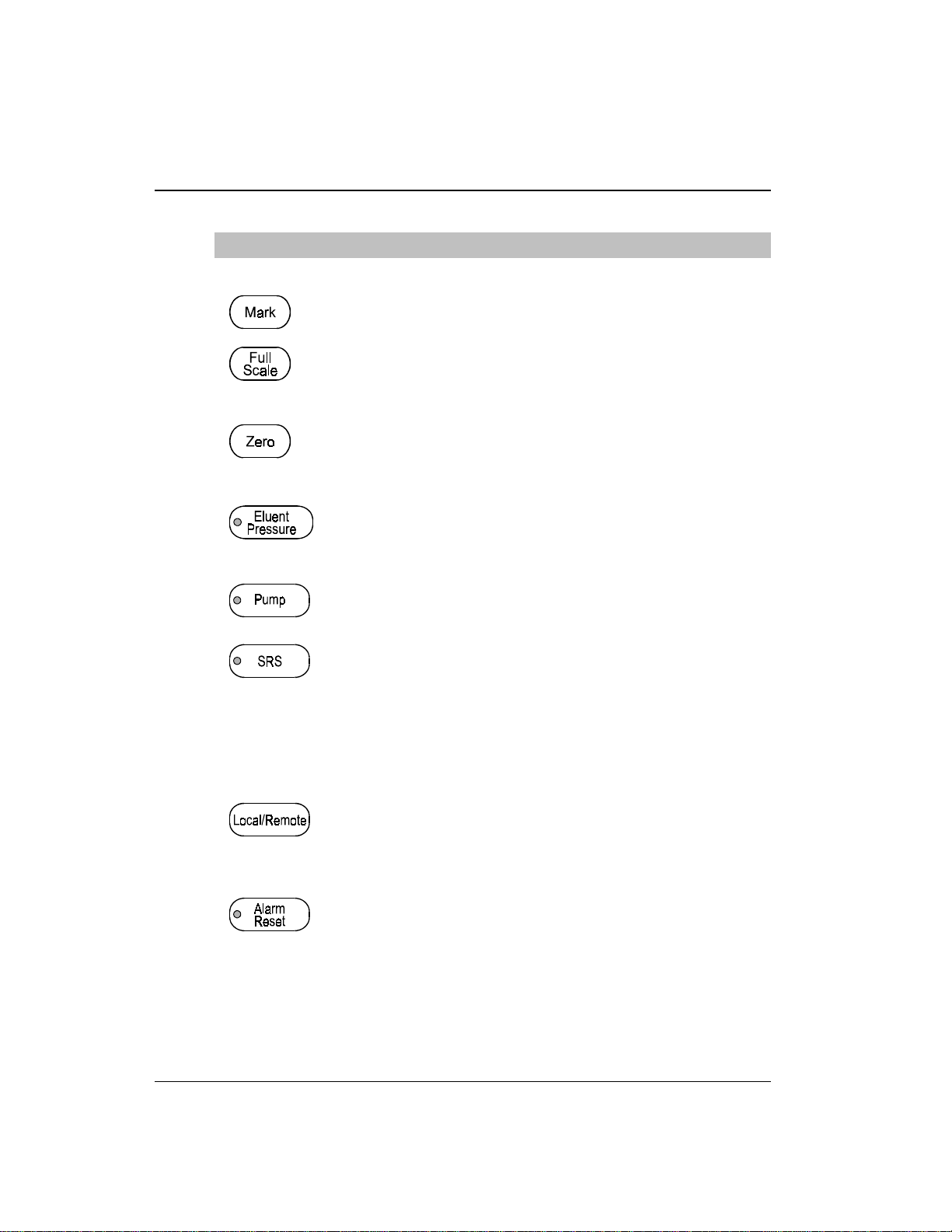

Button Function

RECORDER

Delivers a chart mark signal to the analog output. The mark

is 10% of the full-scale voltage.

Delivers a 100% signal to the analog output. Pressing the

button continuously keeps the output signal at full scale. The

default full-scale voltage is 1 V, but can be changed to 10 V

(SW4-4).

Reduces th e analog output si gnal to zero. Pres sing the

button continuously keeps the output signal at zero.

COMPONENT ON/OFF

Turns the gas pressure to the eluent reservoirs on and off.

When on, the LED on the button is illuminated. This button

is

disabled

Local/Remote below).

Turns the pump flow on and o ff. When on, the LED on the

button is illuminated. This button functions in Local or

Remote mode.

Turns the SRS power on and off, as well as the DS4

Detection Stabilizer, if installed. When on, the LED on the

button is illuminated. In the dual-column configuration, this

button controls the power to the SRS and DS4 of the

selected column set (see Section 2.2.1). This button is

disabled

Local/Remote below).

when the DX-120 is in Remote mode (see

when the DX-120 is in Remote mode (see

2-4

SYSTEM CONTROL

Toggles between Local and Remote control modes. Local is

control from the DX-120 control panel and Remote is

control from a PeakNet workstation via the DX-LAN. The

selected mode is shown in the lower right-hand corner of the

display.

A red LED on the left side of the button indicates an alarm

condition. The top line of the display in dicates the source of

the alarm: cabinet or cell leak, high or low pressure, or SRS.

Pressing the button clears the alarm. If the alarm condition

is still present, the alarm reappears after 15 seconds.

Table 2-1. Control Panel Button Functions (continued)

Doc. 031183-0 3 9/98

Page 19

Button Function

Offsets the background conductivity. After start-up, allow

the system to equilibrate. The display shows the background

conductivity (the eluent conductivity before sam ple

injection). Press Auto Offset to offset this background

reading and zero the chromatogram baseline.

Switches the injection valve between the Load and Inject

positions. The current position is shown in the lower

left-hand co rner of the dis play.

When switched from Load to Injec t, the DX-120 also:

- sends a chart mark signal to the analog output (SW4-7)

- performs an auto offset (SW3 -3)

- sends a TTL signal indicating that an injection has

occurred

After 1 minute, the valve automatically returns to the Load

position (SW1-1).

This button is

mode.

COLUMN SELECTION

The COLUMN SELECTION buttons are active in the

dual-column configuration only.

In column select mode, this button initiates the column

switching sequence from column set B to column set A (see

Section 2.2.1). In eluent select mode, this button switches to

eluent delivery from line A (see Section 2.2. 2).

In column select mode, this button initiates the column

switching sequence from column set A to column set B (see

Section 2.2.1). In eluent select mode, this button switches to

eluent delivery from line B (see Section 2.2.2).

disabled

2 • Description

when the DX-120 is in Remote

Doc. 031183-03 9/98

These buttons are

mode.

disabled

when the DX-120 is in Remote

Table 2-1. Control Panel Button Functions (continued)

2-5

Page 20

DX-120 Operator’s Manual

2.1.2 Pump

The pump is located on the rig ht side of the main

compartment (see Figure 2-2). The knob o n the front of the

pump adjusts the flow rate from 0.5 to 4.5 mL/min.

Eluent Save Mode

If the DX-120 is idle (i.e., no control panel buttons have been

pressed and no PeakNet commands have been received) for

90 minutes, the pump flow automatically decreases to 1/20 th

of its cur rent flow rate and the SRS cycles on and off. When

this occurs, the LEDs on the

Press any button to return to the last selected flow rate.

To turn off this feature, reset the Pump Time-out DIP switch

(SW1-2).

2.1 .3 Configuration DIP Switches

Pump

and

SRS

buttons flash.

The DIP switches on the left side of the main compartment

control system parameters. The factory-set defaults can be

changed to meet specific system and application requirements

(see Section B.10).

NOTE

In this manual, when a function is controlled by a DIP

switch setting, the switch and position numbers are shown

in parentheses. For example: (SW1-3, 4) indicates DIP

switch 1, positions 3 and 4.

2-6

Doc. 031183-0 3 9/98

Page 21

2.1.4 Eluent Reservoirs

Dionex strongly recommends degassing all elue nts and

storing them in reservoirs pressurized with helium. This helps

prevent bubbles (resulting from eluent outgassing) from

forming in the pump head and the detector cell. Degassed

eluents and pressu rized reservoirs are especially impo rtant

when combining aqueo us and non-aqueous components (e. g.,

water and methanol). With non-aqueous components, glass

reservoirs are recommended.

The single-column DX-120 in cludes one 2-liter plastic

reservoir (P/N 0441 29). The dual-colu mn DX-120 includes

two 2-liter plastic reservoirs.

The following additional reservoirs are available from Dionex:

•

1-liter plastic reservoir (P/N 044128)

•

1-liter glass reservoir with shatterproof plastic coating

(P/N 044126)

2 • Description

Doc. 031183-03 9/98

•

2-liter glass reservoir with shatterproof plastic coating

(P/N 044127)

The 2-liter plastic reservoir is not designed for vacuum

degassing. Do not use it for this purpose.

2-7

Page 22

DX-120 Operator’s Manual

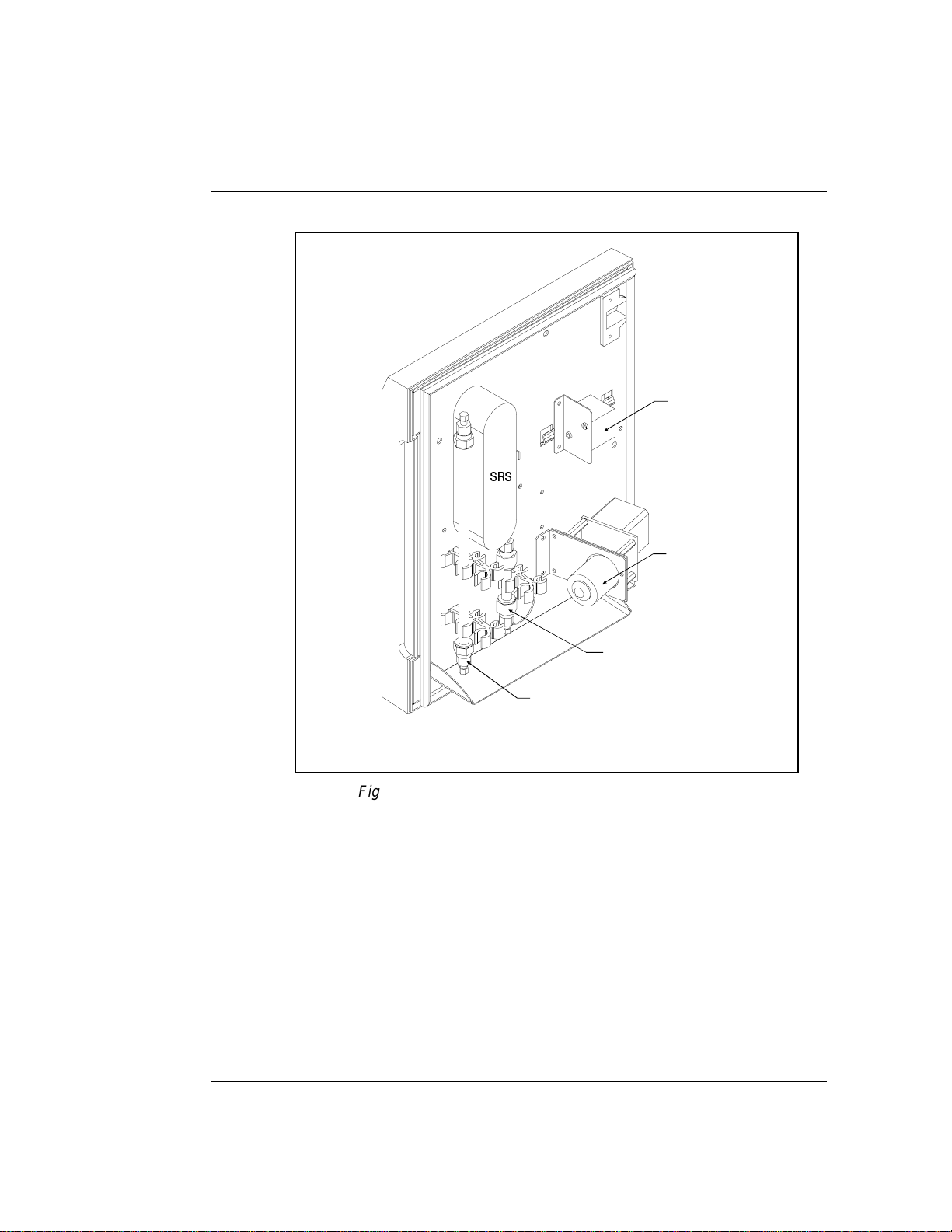

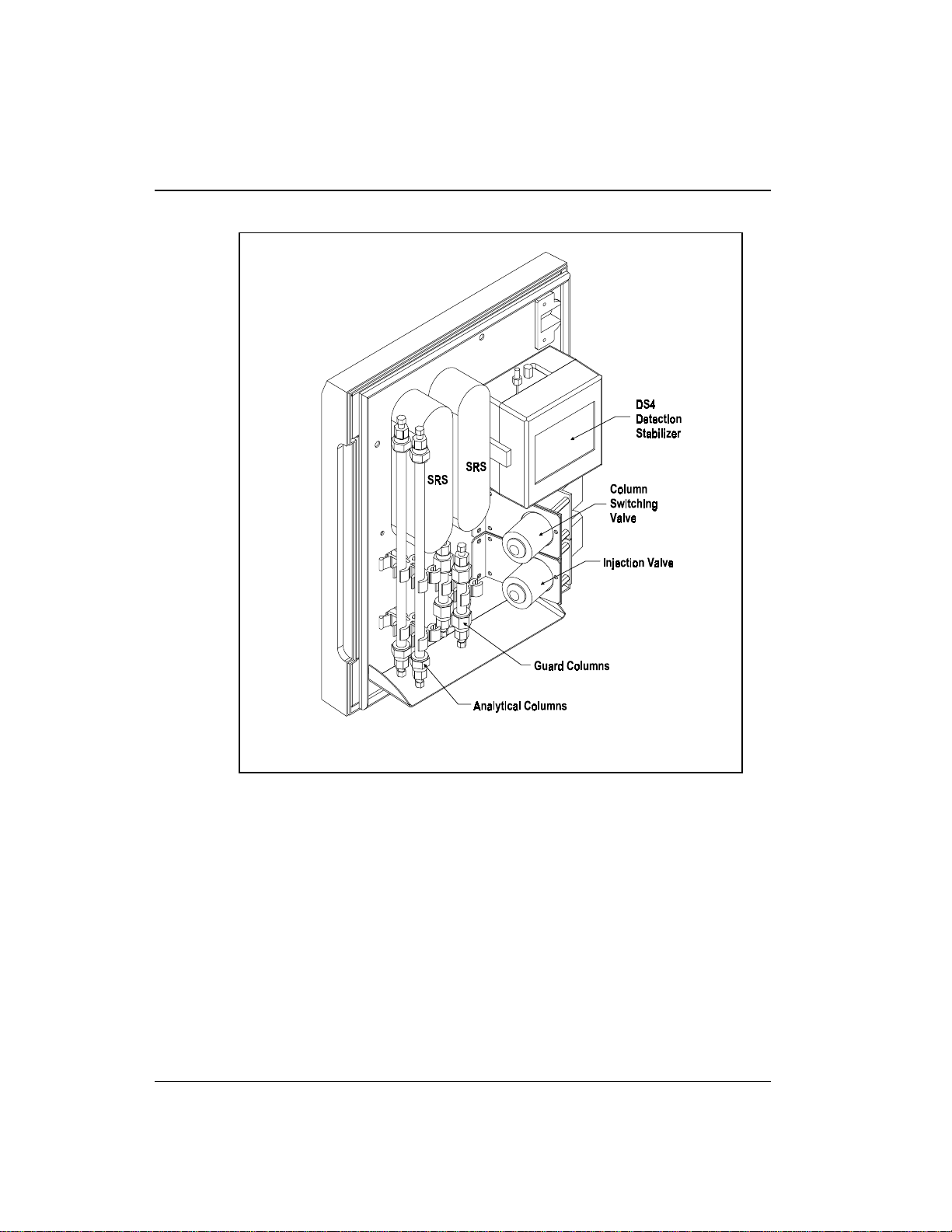

2.1 .5 Component Panel

Chromatography components are mounted on the inside fron t

door. Figure 2-4 shows the single-column component panel

layout. Figure 2-5 shows the dual-column layout.

The DX-120 is equipped with a Rheodyne injection valve

(see Section 2.1.6). The following additional components

must be ordered separately:

•

Self-Regenerating Suppressor(s) (SRS): The SRS

neutralizes the eluent and enha nces analyte conductivity.

For a dual-column system, order two suppressors.

•

Column(s): One or two analytical columns and one or two

guard columns can be installed on colu mn clips. The clips

have larger clasps on one side for supporting 4 mm

columns and smaller clasps on the other side for 2 mm

columns.

•

Column switching valve: The column switching valve is

installed only in a dual-column system. Th e valve controls

liquid flow to the selected column (in column select

mode) or from the selected eluent (in eluent sele ct mode).

See Section 2.2 for details abou t dual-column systems.

2-8

•

Detector cell: Only one flow-through cell is required in

either the single- or the dual-column system. Two cell

models are available: a DX-120 standard cell (the

CDM-3) and a DX-120 high-performance cell with heater

(the DS4 Detection Stabilizer). The DS4 is recommended

for applications requiring enhanced thermal stability. See

sections 2.1.7 and 2.1.8 for details about the cells and the

DS4.

Doc. 031183-0 3 9/98

Page 23

SRS

2 • Description

CDM-3 Cell

Injec tion Va lv e

Doc. 031183-03 9/98

Guard Column

Analytical Colum n

Figure 2-4. Single-Column Component Panel Layout

NOTE

A DS4 Detection Stabilizer can be installed instead of the CDM-3

cell.

2-9

Page 24

DX-120 Operator’s Manual

2-10

Figure 2-5. Dual-Column Component Panel Layout

NOTE

A CDM-3 cell can be installed instead of the DS4 Detection

Stabilizer.

Doc. 031183-0 3 9/98

Page 25

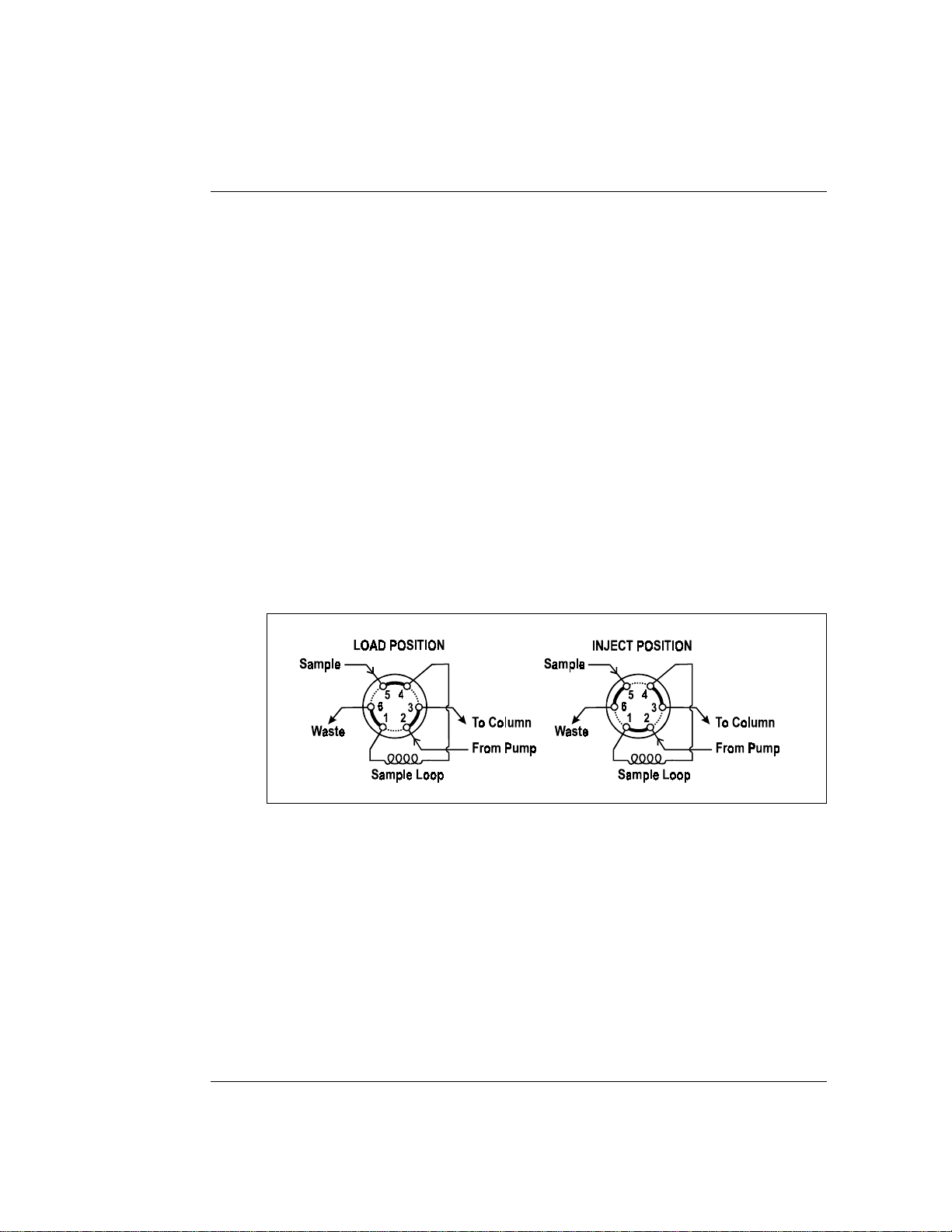

2.1 .6 Rheodyne Injection Va lve

The Rheodyne injection valve has two operating positions:

Load and Inject. In the Load position, sample is loaded into

the sample loop, where it is held until injection. In the Inject

position, sample is swept to the column for analysis. Eluent

flows through one of two paths, depending on the valve

position:

•

In the Load position, eluent flows from the pump, through

the valve, and to the column, bypassing the sample loo p.

Sample flows from the syringe or autosampler line,

through the valve, and into the sample loop; excess

sample flows out to waste.

•

In the Inject position, eluent flows from the pump,

through the sample loop, and on to the column, carrying

the contents of the sample loop with it.

2 • Description

Doc. 031183-03 9/98

Figure 2-6. Rheodyne Injection Valve Flow Schematics

2-11

Page 26

DX-120 Operator’s Manual

2.1.7 Detector Cells

The DX-120 accommodates two detector cell models. The

DX-120 standard cell (CDM-3; P/N 050776) is used for

applications that do not require th e enhanced baseline

stability gained through thermal stabilization. For increased

thermal stabilization in high-sensitivity applications, use a

DX-120 high-performance cell with heater (DS4 Detection

Stabilizer; P/N 050218).

If you change the cell model, the Cell Type DIP switches

(SW4-1, 2) must be reset to sel ect the new cell type.

Detector Cell Features

•

Both cells are flow-through conductivity cells with

polymeric bodies. Two 316 stainless steel electrodes are

permanently sealed into the cell bodies.

NOTE

•

A sensor (thermistor) located slightly downstream from

the electrodes senses the temperature of the liquid as it

exits the cell. The measured value is used for temperature

compensation.

•

The active volume is nominally 1.25 µL for the CDM-3

cell and 1.0 µL for the DX -120 high-perfo rmance cell.

•

The detector cell constant for both cells has a nominal

value of 160 cm

-1

.

The advanced geometry of the cells provide several benefits:

•

Excellent accuracy and linearity over a broad working

range

•

Efficient sweepout and low volume for low dispersion

•

Reduced sensitivity to electrode surface conditions

•

Low electrode mass

•

Effective temperature comp ensation

2-12

Doc. 031183-0 3 9/98

Page 27

2 • Description

Temperature Control and Compensation

Temperature directly affects the conductivity of a solution.

For example, laboratory heating and air conditioning systems

can cause a regular slow cycling in the baseline. This, in turn ,

can affect the reproducibility of an analysis. The higher the

conductivity, the more pronounced the effect.

In ion chromatography, suppressing eluent conductivity

minimizes the effect of temperature variation. Temperature

compensation further improves baseline stability. When the

conductivity cell is housed in a DS4 Detection Stabilizer, the

heater enhances the ability of these techniques to reduce

temperature effects on conductivity.

Temperature compensation also ensures that there is no major

change in the baseline or peak heights, should it be necessary

to change the DS4 operating set point. Readings will be

normalized to 25 °C.

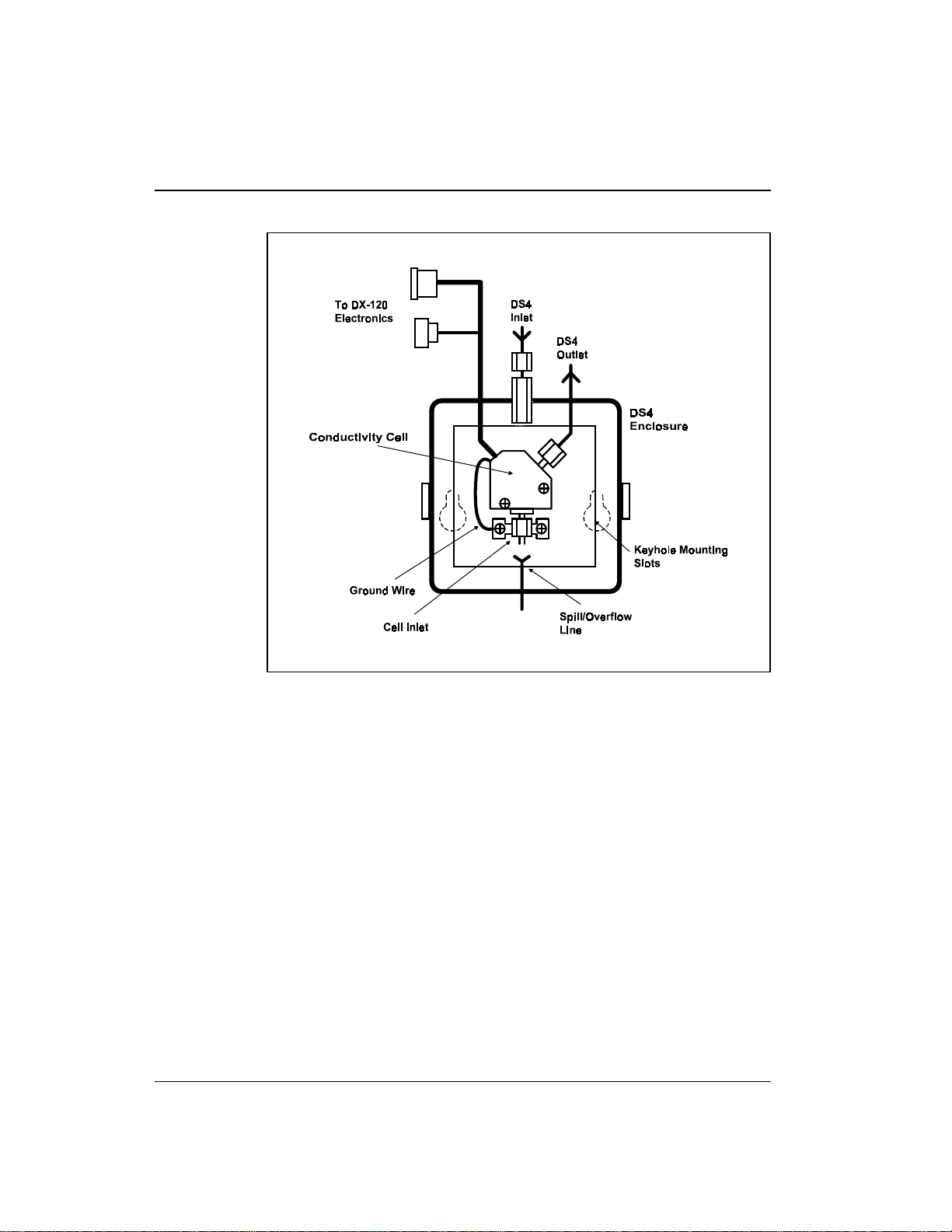

2.1.8 DS4 Detection Stabilizer

Doc. 031183-03 9/98

The DS4 is a temperature-controlled chamber consisting of a

cast aluminum base and cover enclosed in insulating foam.

The chamber houses both the cond uctivity cell and the eluent

heat exchanger. Figure 2-7 identifies the major components of

the DS4.

The DS4 provides the following benefits:

•

Conductivity measurements nearly impervious to

laboratory temperature variation

•

Very low disp ersion in the eluent heat exchan ger

•

Excellent peak height reproducibility

•

User-selected temperature set point

2-13

Page 28

DX-120 Operator’s Manual

2-14

Figure 2-7. DS4 Detection Stabilizer Features

Power input to a pair of transistors on opposite sid es of the

DS4 heats it to a user-selected temperature from 30 °C to

45 °C (SW3-4, 5, 6, 7). A sensor near the heat exchang er

outlet senses the eluent temperature. The DX-120 circuitry

compares this temperature with the selected temperature and

adjusts the heat input in real time to hold the temperature

within a few millidegrees.

The DS4 is sealed with an O-ring to trap eluent that may leak

from the cell. If 5 mL of liquid accumulates, a thermistor

sensor signals a leak to the CPU. Any additional leakage will

be discharged via the spill/overflow line. A second thermistor,

above the discharge level, acts as a temperature reference for

the leak sensor.

Doc. 031183-0 3 9/98

Page 29

2.2 Dual-Column Configuration Features

The dual-column configuration has two operating modes:

Column select mode allows switching of flow from one column

•

set to the other.

Eluent select mode allows switching of flow from one eluent to

•

the other (the column set is not switched).

The Column Select DIP switch (SW3-1) selects the mode:

on=column; off=eluent.

The dual-column system option adds the f ollowing features:

2 • Description

Column A

The

•

and

Column B

buttons on the front contro l panel

are enabled .

An eluent selection valve selects which eluent reservoir is used.

•

A column switching valve directs flow to the selected column set

•

(column select mode only).

Doc. 031183-03 9/98

2-15

Page 30

DX-120 Operator’s Manual

2.2 .1 Column Select Mode

In column select mode, you can switc h the flow path from

one column set to the other by pressing

B

or by sending a command from PeakNet.

Figure 2-8 illustrates the sequence of events when you switch

from column set A to column set B.

Column A

or

Column

2-16

Figure 2-8. Column Selection Sequence

Doc. 031183-0 3 9/98

Page 31

2 • Description

1. In Step 1, eluent A is flowing to column set A.

2. In Step 2, the following occurs:

A command is received to switch to column B.

•

The eluent selection valve switches and eluent B

•

begins flowing to the injection valve.

The display flashes

•

The injection valve switches to the Inject position and

•

RINSE

.

the previous eluent is cleared from the sample loop.

A short delay occurs before th e column switching

•

valve switches to the new position. This allows eluent

A to continue through to column set A. The duration of

the delay depends on the current flow rate. Lower flow

rates require a longer rinse time.

3. In Step 3, the following occurs:

When eluent A has been cleared from the lines, the

•

column switching valve switches and flow proceeds to

the selected column set.

The injection valve returns to the Load position.

•

RINSE

•

The

indicator stops flash ing and the display

shows the new column selection. The system is now

ready for use.

NOTE

There is a small amount of eluent carryover when switching

column sets. For this reason, ignore the first injection run after

switching columns.

Doc. 031183-03 9/98

2-17

Page 32

DX-120 Operator’s Manual

2.2.2 Eluent Select Mode

In eluent select mo de, pressing

Column A

Column B

or

, or

sending an eluent switching command from PeakNet,

switches the eluent selection valve to the new position.

In this mode, the column sw itching valve is disabled. The

selected column set remains at what it was when the DX-120

was switched to eluent select mode. The LED on the button

for the selected column set is always illuminated and the

display indicates the selected eluent (see the example in

Figure 2-9).

2-18

Figure 2-9. Display During Eluent Select Mode

Doc. 031183-0 3 9/98

Page 33

2.3 Fluid Schematics

0.03 - 0.07 MPa

(5 - 10 psi)

Figure 2-10 shows the flow path through a single-column DX-1 20

Ion Chromatograph.

2 • Description

Doc. 031183-03 9/98

Figure 2-10. DX-120 Flow Schematic: Single-Column

2-19

Page 34

0.03 - 0.07 MPa

(5 - 10 psi)

DX-120 Operator’s Manual

Figure 2-11 shows the flow path through a dual-column DX-1 20 Ion

Chromatograph in column select mode.

2-20

Figure 2-11. DX-120 Flow Schematic: Dual-Column System

Column Select Mode

Doc. 031183-0 3 9/98

Page 35

0.03 - 0.07 MPa

(5 - 10 psi)

2 • Description

Figure 2-11 shows the flow path through a dual-column DX-1 20 Ion

Chromatograph in eluent select mode.

Doc. 031183-03 9/98

Figure 2-12. DX-120 Flow Schematic: Dual-Column System

Eluent Select Mode (Column Set A Active)

2-21

Page 36

DX-120 Operator’s Manual

2.4 Control Modes

The DX-120 has two control modes: Local and Remote. Select Local

for control from the DX-120 front control panel and select Remote

for control from a PeakNet workstation.

To change the mode, press

Local/Remote

. The selected mode is

shown in the lower right-hand corner of the display.

2.4 .1 Local Mode

When the DX-120 is powered up, it defaults to L ocal mode.

Local mode allows two types of operating commands:

•

Direct input from the DX-120 front control panel buttons

•

TTL inputs from a remote controller, such as an integrator

or recorder

2.4 .2 Remote Mode

In Remote mode, the DX-120 accepts operating commands

from PeakNet software via the DX-LAN interface. Sending

an operating command from PeakNet automatically selects

Remote mode, if it was not already selected.

Several DX-120 control panel buttons are disabled in Remote

mode, as indicated in the following table.

Disabled Buttons in Remote Mode Active Buttons in Remote Mode

2-22

Load/Inject

Eluent Pressure

(on/off)

SRS

Column A

and

(on/off)

Column B

DISPLAY

RECORDER

Pump

Local/Remot e

Alarm Reset

Auto Offset

group (all)

(on/off)

group (all)

Doc. 031183-0 3 9/98

Page 37

2.5 TTL Control

The TTL input connectors on the DX-120 rear panel allow limited

remote control of the DX-120. With TTL input, a controlling d evice

(such as an integrator or automated sampler) sends TTL signals to

the DX-120. TTL input signals can be use d to:

Toggle the position of the injection valve and start a PeakNet run

•

(these two functions are controlled simu ltaneously)

Offset the background conductivity

•

Change th e recorder ran ge by 10x

•

Turn the pump flow on and off

•

TTL control is available when the DX-120 is in either Local or

Remote mode.

Refer to Section B.7 for TTL connection instru ctions.

2 • Description

2.5 .1 Injection Valve/Remote Start Control

A TTL output signal from another device, such as an

automated sampler, can switch the injection valve to the

Inject position. The same TTL input signal is also used to

start a PeakNet run when the DX-120 is connected to a

PeakNet workstation.

NOTE

If required for an application, disable the TTL injection

valve control and use only the remote start function. See

Section B.8. 3 for instructions.

2.5 .2 Recorder Range Control

The default full- scale recorder output signal range is

1000 µS. This is set by the Range DIP switch (SW4-3).

Sending a 10X Range TTL input signal when the recorder

output is at 100 µS changes the fu ll-scale recorder range to

1000 µS. The range will remain at 1000 µS as long as the

input signal is being sent from the controlling device.

Doc. 031183-03 9/98

2-23

Page 38

DX-120 Operator’s Manual

If the Range DIP switch is set to 1000 µS, sending the 10X

Range TTL input sign al will have no effect.

The table below summarizes the relationship between the 10X

Range TTL input and th e Range DIP switch.

Range DIP Switch

(SW4-3) Setting

1000 µS*

1000 µS

100 µS

100 µS

*Default settings

The Range DIP switch setting and the 10X Range TTL

input are only for recorder output control; they do not

affect either the conductivity readings shown on the

control panel display or the PeakNet data.

10X Range TT L Input

Status

1X*

10X

1X

10X

NOTE

Signal Output

1000 µS*

1000 µS

100 µS

1000 µS

2-24

Doc. 031183-0 3 9/98

Page 39

3 • Operation and Maintenance

3.1 Preparing Eluents

3.1 .1 Degassing Eluents

Dionex strongly recommends degassing all eluents an d

storing them in reservoirs pressurized with filtered inert gas

(see Section 3.1.3). This helps prevent bubbles (resulting

from eluent outgassing) from forming in th e pump and the

detector cell. Degassed eluents and pressu rized reservoirs are

especially important when combining aqueous and

nonaqueous components (for example, water and methanol).

Several degassing procedures can be used, includ ing vacuum

degassing, sparging with helium, or sonication without

vacuum. Follow the steps below for vacuum degassing:

1. Prepare the eluent required for the application. Pour it

into a clean vacuum flask and attach the flask to a

vacuum pump or water aspirator.

Doc. 031183-03 9/98

2. Vacuum degas the eluent for 5 min utes while agitating the

solution by shaking or sonication.

When using nonaqueous components, do not degas eluents

for longer than 5 minutes; volatile compounds may be lost.

3. Remove the flask from the vacuum. Do not allow water

to flow from the a spirator back into the flask.

4. Pour the degassed eluent into a pressurizable reservoir. Be

careful not to shake the eluent.

5. Install end-line filters and pressurize the reservoirs (see

Sections 3.1.2 and 3.1.3).

3-1

Page 40

DX-120 Operator’s Manual

3.1 .2 Filtering Eluents

Always filter eluents before operation to remove small

particulates that may contaminate the pump check valves and

cause erratic flow rates or loss of prime. End-line filters

(P/N 045987) are sup plied in the pressurizable reservoir ship

kits for this purpose.

Install an end-line filter on the end of the eluent line inside

the reservoir. To pr event air from being drawn through th e

lines, make sure that the end of the filter reaches the bottom

of the eluent reservoir.

3.1 .3 Pressurizing Eluent Reservoirs

Pressurize eluent reservoirs with filtered inert gas (preferably

helium). Refer to the Pressurizable Reservoir Installation

Instructions for details.

1. Verify that the gas supply is connected to the HELIUM

INPUT connector on the rear panel and is regulated to

between 0.14 and 0.69 MPa (20 and 100 psi).

3-2

2. Press

Eluent Pressure

to turn on the gas pressure to the

eluent reservoir(s). A regulator inside the DX-120

regulates the pressure to between 0.03 and 0 .07 MPa (5 to

10 psi).

Never pressurize the reservoirs above 0.07 MPa (10 psi). If

using glass reservoirs, inspect them periodically for

scratches or cracks.

Doc. 031183-0 3 9/98

Page 41

3.2 Preparing Samples

3.2 .1 Collecting and Storing

Collect samples in high density polyethylene con tainers that

have been thoroughly cleaned with deionized water. Do not

clean containers with strong acids or detergents because they

will leave traces of ions on the container walls. These ions

may interfere with analysis.

If samples will not be analyzed on the day they are collected,

filter them through clean 0.45 µm filters immediately after

collection; otherwise, bacteria in the samples may cause the

ionic concentrations to change over time. Refrigerating the

samples at 4 °C will minimize, but not eliminate, bacterial

grow th .

Analyze samples containing nitrite or sulfite as soon as

possible. Nitrite oxidizes to nitrate, and sulfite to sulfate, thus

increasing the measured concentrations of these ions in the

sample. In general, samples that do not contain nitrite or

sulfite can be refrigerated for at least one week with no

significant changes in anion concentrations.

3 • Operation and Maintenance

3.2.2 Pretreating

Doc. 031183-03 9/98

Analyze rain water, drinking water, and air particulate leach

solutions directly with no sample preparation (other than

possibly filtering and diluting).

Filter groundwater and wastewater samples through 0.45 µm

filters before injection, unless samples were filtered after

collection.

Before injection, pretreat samples that may contain high

concentrations of interfering substances by putting them

through Dionex OnG uard cartridges. Refer to the

Installation and Troubleshooting Guide for O nGuard

Cartridges (Document No. 0329 43) for instructions.

3-3

Page 42

DX-120 Operator’s Manual

3.2.3 Diluting

Because the concentrations of ionic species in d ifferent

samples can vary widely from sample to sample, no single

dilution factor can be recommended for all samples of one

type. In some cases (for example, many water samples)

concentrations are so low that dilution is not necessary.

Use deionized water or eluent to dilute the sample. When

using carbonate/b icarbonate eluents, d iluting with eluent

minimizes the effect of the water dip at the beginning of the

chromatogram. If you dilute the sample with eluent, also use

eluent to prepare the calibration blank and standard s. This is

most important for fluoride and chloride, which elute near the

water dip.

To improve the accuracy of early eluting peak determinations,

such as fluoride, at concentrations below 50 ppb, dilute

standards in eluent or spike the samples with concentrated

eluent to minimize the water dip. For example, spike a 100

mL sample with 1.0 mL of a 1 00 X eluent concentrate.

3-4

Doc. 031183-0 3 9/98

Page 43

3.3 Operating

3.3.1 Starting Up

1. Press the power switch below the DX-120 front control

panel (see Figure 2-2) to turn on the system power.

Microprocessor code revision levels are displayed briefly

on the screen, and then the offset conductivity reading is

displayed.

These are the conditions at power-up:

•

•

•

•

3 • Operation and Maintenance

The DX-120 is in Local mode.

The eluent pressure, pump, and SRS are off.

The DS4 Detection Stabilizer (if installed) is on.

The injection and column selection valves are in their

last selected positions.

The offset value is reset to zero.

•

2. Press the power switch on the front o f the pump (see

Figure 2-2) to turn on the pump p ower.

3. Press

4. Press

5. Press

Eluent Pressure

Pump

to turn on the pump flow.

SRS

to turn on the SRS power. The screen briefly

to pressurize the eluent rese rvoirs.

displays the SRS current setting in mA.

6. Press

Flow Rate

and verify that the pump flow rate is

correct. If necessary, pull out the kn ob on the front of the

pump and turn it right or left to increase or decrease the

flow rate. When the correct rate is displayed, push in the

knob.

7. Press

Offset Cond

to display the offset conductivity

reading.

Doc. 031183-03 9/98

3-5

Page 44

DX-120 Operator’s Manual

8. Allow the system to equilibrate for 15 to 20 minutes. The

screen displays the background conductivity (the

conductivity of the eluent before injecting sample). Press

Auto Offset

If a DS4 is installed, system equilibration must also

include the time required for the DS4 to reach operating

temperature. The DS4 warms up at about 1 °C/minute

above ambient. Baseline conductivity should stabilize

once the DS4 reaches the selected temperature. The DS4

temperature status appears at the bottom of the display:

to offset the backgro und and zero the read ing.

LO CELL TEMP

•

appears and the temperature set point

flashes when the DS4 is below temperature.

CELL TEMP

•

appears and the set point stops flashin g

when the DS4 has reached operating temperature.

CELL TEMP HI

•

appears and the temperature set point

flashes when the DS 4 is above operating temperatu re.

Figure 3-1 shows the display after all start-up steps are

complete and the DX-120 is ready for a sample injection.

Figure 3-1. Display after Start-Up Completed

3-6

NOTE

If the DX-120 receives no input for 90 minutes, the

pump flow is reduced to 1/20th of its current rate and

the SRS cycles on and off (SW1-2). The LEDs on the

Pump

and SRS buttons flash when this occurs. Press

any button to return to the previous flow rate.

Doc. 031183-0 3 9/98

Page 45

3.3 .2 Injecting the Sample

This section describes how to inject sample when the DX-120

is in Local control. PeakNet software can also be used to

switch the injection valve position.

Using a Syri nge

3 • Operation and Maintenance

1. Verify that

the display. If necessary, press

LOCAL

is shown at the lower-right corner of

Local/Remote

to toggle to

Local mode.

2. Verify that

display. If necessary, press

LOAD

is shown at the lower-left corner of the

Inject/Load

to switch the

injection valve to the Load position.

3. Fill the syringe with a calibration standard or sample.

4. Insert the syringe into the p ort on the front of the DX-120

(see Figure 2-2).

5. Overfill the sample loop with several sample loop

volumes. Excess sample will exit through the waste line.

6. Leave the syringe in the port.

7. Press

Using an Autosampler

Inject/Load

to switch the injection valve to Inject.

The autosampler output line connects to port 5 on the

injection valve. See Section B.8 for installation instructions.

Doc. 031183-03 9/98

1. Verify that

the display. If necessary, press

LOCAL

is shown at the lower-right corner of

Local/Remote

to toggle to

Local mode.

2. Verify that

display. If necessary, press

LOAD

is shown at the lower-left corner of the

Inject/Load

to switch the

injection valve to the Load position.

3. Follow the instructions included with the autosampler to

load the injection valve loop.

3-7

Page 46

DX-120 Operator’s Manual

4. Press

Injection Events

Inject/Load

to switch the injection valve to Inject.

By default, the following events occur after injection:

•

An auto offset occurs (SW 3-3), which include s two steps:

- The analog output signal is set to zero.

- The background conductivity is offset from the total,

thereby zeroing the baseline conductivity value. This is

the same function as pressing

Auto Offset

on the front

panel.

•

An inject mark is sent out on the analog output (SW4-7).

•

The Inject TTL output sends o ut a pulse indicating that

injection occurred.

•

After 1 minute, the injection valve returns to the Load

position (SW1-1).

Injection Duration

To ensure complete injection of the sample, at least 10

sample volumes must be pumped through the loop before the

valve is switched back to the Load position. For most

applications, automatically returning to Load after 1 minute is

sufficient. Here are the maximum loop sizes for a one-minute

injection at 1 mL/min and 2 mL/min:

3-8

•

At 1 mL/min, use a loop of 100 µL or less.

(1000 µL/min)(1 sample vol/100 µL)=10 sample vol/min

•

At 2 mL/min, use a loop of 200 µL or less.

(2000 µL/min)(1 sample vol/200 µL)=10 sample vol/min

If your flow rate/loop combination requires more time,

disable the automatic return (SW1-1) (see Section B. 10).

Doc. 031183-0 3 9/98

Page 47

3 • Operation and Maintenance

3.4 Using an Integrator

You can connect an integrator, such as the Dionex 4400 or 4600

Integrator, to the DX-120 and use a DIALOG or BASIC program to

automate analyses. If you also connect an autosampler, sample

loading can also be controlled. See Appendix C for integrator

programming examples.

3.5 Running under PeakNet Control

When the DX-120 is connected to a PeakNet workstation via the

DX-LAN interface, PeakNet software (Release 4.30 or higher) can

monitor DX-120 status and control the following functions:

Select the position of the injection and colu mn switching valves

•

Turn the pump flow, SRS power, and eluent pressure on and off

•

Perform an auto offset

•

Select the pressure units displayed on the screen (MPa or psi)

•

Control TTL1 and TTL2 output signals

•

Control the auxiliary AC outlet (PeakNet control only)

•

For more information, refe r to the PeakNet So ftware User’s G uide.

Doc. 031183-03 9/98

3-9

Page 48

DX-120 Operator’s Manual

3.6 Optimizing Temperature Compensation

The DX-120 built-in temperature compensation stabilizes

conductivity readings by correcting for changes in ambient

temperature that occur during a run. For more information about

temperature control and compensation, see Section 2.1.7.

3.6.1 With a DS4

Housing the cell in a DS4 Detection Stabilizer ensures that

there is no more than a minor temperature variation in liquid

reaching the cell. Thus, the temperature compensation DIP

switch setting can remain at the default of 1.7% per ºC.

Many users are able to keep th eir systems at a single

operating temperature. For optimal accuracy, calibrate the cell

at this temperature. If you later reset the temperature, th e

DX-120 temperature compensation will normalize

conductivity measurements to 25 °C (77 °F) to p revent a

major upset in system calibration. If you change the DS4 set

point, recalibrate the cell.

3-10

If temperature-induced baseline cycling occurs, it is probably

caused by another component of the chromatography system.

If the variation increases as the eluent reservoir empties,

move the reservoir to a more temperature-stable environment

and/or wrap the reservoir in thermal insulation.

3.6.2 With a CDM-3 Cell

When the CDM-3 cell is installed, conductivity drifts up and

down with fluctuations in laboratory temperature. This is

especially noticeable in laboratories with very high air

turnover rates or no air conditioning. Selecting the proper

temperature compensation factor will minimize the effect of

temperature fluctuations.

The temperature compensation setting is selected with a DIP

switch (SW5-3, 4, 5). Three settings are available: 1.5%,

1.7%, and 1.9%. Start with the default setting of 1.7%. If a

Doc. 031183-0 3 9/98

Page 49

3 • Operation and Maintenance

sinusoidal baseline variation of the same period as the

laboratory cooling or heating occurs, increase or decrease the

temperature compensation setting. If the baseline variation

still occurs, try the other setting.

3.7 Maintenance

This section describes routine maintenance procedures that users can

perform. All other maintenance procedures must be performed by

Dionex personnel.

Daily

Check the interior of the main compartment for leaks or spills.

•

Wipe up spills. Isolate and repair leaks (see Section 4.3). Rinse

off any dried eluent or reagent with deionized water.

Check the waste container daily and empty when needed.

•

Weekly

Once a week, chec k air lines for crimping or discoloration.

•

Relocate any pinched lines. Replace damaged lines.

Check the junction between the p ump head and the metal pump

•

casting for evidence of liquid leaks. Normal friction and wear

may gradually result in small liquid leaks aroun d the piston seal.

If unchecked, these leaks can gradually contaminate the piston

housing, causing the pump to operate poorly. If leaks occur,

replace the piston sea ls (see Section 5.9).

Doc. 031183-03 9/98

3-11

Page 50

DX-120 Operator’s Manual

3-12

Doc. 031183-0 3 9/98

Page 51

4 • Troubleshooting

This chapter is a guide to troubleshooting problems that may occur

while operating the DX-120. If an alarm sounds, check Section 4.1

for possible cause s. If an error code is display ed, check Section 4.2

for possible causes. To resolve other problems, turn to the section

that best describes the operating problem.

If you are unable to eliminate a problem, contact Dionex for help. In

the U.S., call Dionex Technical Support at 1-800-346-6390. Outside

the U.S., call the nearest Dionex office.

4.1 Alarms

Three events signal an alarm condition: a tone sounds, the LED on

Alarm Reset

the

and the ala rm’s source. To clear the alarm, pre ss

alarm condition still exists, the alarm will reappear after 15 seconds.

The alarm tone can be disabled with a DIP switch (SW3-2).

LEAK ALARM

•

button blinks, and the display indicates ALARM

Alarm Reset

. If the

There is liquid in the drip tray. Wipe up spills in the tray and

check for leaks (see Section 4.3).

CELL LEAK ALARM

•

There is a leak in the DS4 (see “Leaking DS4” in Section 4.3).

LOW PRESSURE ALARM

•

The system pressure is less than or equal to the low pressure

limit of 1.7 MPa (250 psi). T his condition automatically turns off

the pump and SRS. Th is alarm can be turned off with a DIP

switch (SW1-8 ).

1. Make sure the eluent reservoirs are full.

2. Check for liquid leaks (see Section 4.3).

Doc. 031183-03 9/98

4-1

Page 52

DX-120 Operator’s Manual

3. Make sure the pressu re transducer waste valve is closed. To

close the valve, turn the knob clockwise, just until tight. Do

not overtighten! Overtightening may damage the valve

and the pressure transducer housing.

4. Restart the pump.

5. Prime the pump (see Section B.5.1).

HIGH PRESSURE ALARM

•

The system pressure is greater than or equal to th e high pressure

limit selected (SW1-5, 6, 7). This condition auto matically turns

off the pump and SRS.

1. Make sure the selected flow rate is not too high.

2. Check for blockages in the liquid line from the pump

pressure transduc er to the waste cont ainer.

3. Make sure the columns are not the so urce of the high

pressure.

4-2

4. Set the high pressure limit to 3.4 MPa (500 psi) above the

normal system operating pressure.

5. Restart the pump.

SRS ALARM

•

The SRS has exceed ed the accepted curr ent/voltage range.

1. The SRS may be dry. Make sure the eluent reservoir is filled

and sufficiently pressurized. Check all liquid lines and valves

for leaks, crimping, or blockage.

2. Make sure the cable connecting the SRS to the DX-120

electronics card is connected (see Figure B-10).

3. Refer to the SRS manual for more trou bleshooting

information.

Doc. 031183-0 3 9/98

Page 53

4.2 Error Codes

When an error occurs, an error code number displays in the middle

of the screen. The error code remains for several seconds, and th en

the display returns to normal.

E000

•

Cause: No Moduleware is installed. Moduleware is the DX-120

instrument control microprocessor code.

Action: Download a new copy of the Moduleware, if the system

includes Pe akNet software, o r contact Dionex f or assistance.

E001

•

4 • Troubleshooting

Cause: The

Column B

button was pressed, although the system is

configured for a single column.

Action: If it is a dual-column system, verify that the Column

Configuration DIP switch (SW1-3) is set to dual-column.

E002

•

Cause: Two or more conflicting DIP switch settings.

Action: Reset the DIP switches (see Section B.10).

E003

•

Cause: More than one high-pressure alarm setting is selected.

The pump and SRS will turn off when this error occurs.

Action: Check the high-pressure alarm setting (SW1-5 , 6, 7).

One switch position must be on and the other two off.

E004

•

Cause: During the rinse portion of the column switching

sequence, a command to switch columns was received from the

Column A

Column B

or

button, or from PeakNet.

Action: The DX-1 20 cannot begin another colu mn switching

sequence during the rinse cycle. Wait until the column switching

sequence is completed.

Doc. 031183-03 9/98

4-3

Page 54

DX-120 Operator’s Manual

E005

•

Cause: A command to switch columns was received from either

Column A

the

Column B

or

pump was off or the flow rate was very low. The rinse cycle step

of the column switching sequence requires an adequate flow rate

to flush the previous eluent from the system before switching.

Action: Turn on the pump or increase the flow rate.

E006

•

Cause: The SRS will not turn o n. Either the pump is not on or

the suppressor is disconnected.

Action: Turn on the pump. Make sure the cable connecting the

SRS to the DX-120 electronics card is connected (see

Figure B-10).

4.3 Liquid Leaks

button, or from PeakNet, while the

Leaking fitting

•

Locate the source of the leak. Tighten or, if necessary, replace

the liquid line connection (see Section 5.1). Refer to Installation

of Dionex Ferrule Fittings for tightening requirements.

Broken liquid line

•

Replace the line and fittings (see Section 5.1).

Blocked or improperly installed waste line

•

Make sure the waste lines are not crimped or otherwise blo cked.

Also make sure waste lines are not elevated at any point after

they exit the DX-120.

Loose pump check valve housing

•

Make sure the check valves are firmly seated in the pump head.

If they are not, tighten them carefully with an open end wrench

just until the leak stops.

4-4

Doc. 031183-0 3 9/98

Page 55

4 • Troubleshooting

Damaged pump piston seal

•

1. Replace the piston seal (see Section 5.9).

2. If the prob lem persists, replace the p iston (see Section 5.10 ).

Pump head not tigh t against casting

•

Carefully tighten the pump head mounting nuts just until the leak

stops. DO NOT OVERTIGHTEN!

Leaking pressure transducer

•

Make sure the liquid line connections into the transducer are

tight. Refer to Installa tion of Dionex Ferrule Fittings for

tightening requirements. Replace any damaged fittings.

Make sure the waste valve is closed. To close the valve, turn the

knob clockwise, just until tight. DO NOT OVERTIGHTEN!

Overtightening may damage the valve and the pressure

transducer housing.

Inspect the pressure transducer. If the waste valve is the source

of the leak, repla ce the waste valve O-ring (see Section 5. 11). If

the leak is from the rear of the transdu cer, contact Dionex for

assistance.

Leaking SRS

•

See the SRS manual f or troubleshooting proc edures.

Leaking injection valve or column switching valve

•

Liquid leaks from behind the valve stator may indicate a

scratched rotor seal. Contact Dionex for assistance.

Doc. 031183-03 9/98

4-5

Page 56

DX-120 Operator’s Manual

Leaking DS4

•

Check the waste lines for blockage; trapped particles can plug

the lines and cause a restriction and/or leak. If necessary, clear

the waste lines by reversing the direction of flow.

Make sure the plumbing downstream from the DS4 is clear; a

blockage may overpressurize the DS4, causing it to leak.

Make sure the downstream backpressure coils are appropriate for

the operating flow rate (see Section B.6.1).

Follow the steps below to disassemble the DS4 and inspect it for

the source of the leak.

1. Turn off the DX-120 power.

2. Disconnect the DS4 cables.

3. Disconnect the DS4 inlet and outlet lines. Do not misplace

the ferrule fittings at the end of the tubing (see Figure 4-1).

4. Remove the DS4 by lifting it upward and th en pulling it

away from its mounting location. Place the DS4 o n the

workbench.

5. Open both latches on the DS4 and carefully lift off the top

half of the cover, along with its insulating foam insert,

exposing an aluminum box (see Figure 4-1).

6. Remove the box from the bottom half of the cover.

7. Remove the four Phillips screws securing the top of the box

to its bottom plate. Carefully separate the two parts, exposing

the cell (see Figure 4-2). Lay the top aside, being careful not

to pull or stress the group of wires that con nect the two parts.

8. Check the inlet and outlet cell fittings for leaks. Tighten or

replace if necessar y.

9. Dry the DS4, test fo r leaks, and reassemble. Make sure the

foam insert is adjusted evenly around the various DS4

components, with no pinching or folding. Befo re latching the

cover, make sure the top and bottom inserts meet on all sides.

4-6

Doc. 031183-0 3 9/98

Page 57

4 • Troubleshooting

Doc. 031183-03 9/98

Figure 4-1. DS4 Exploded View

Figure 4-2. DS4 Interior Components

4-7

Page 58

DX-120 Operator’s Manual

Liquid seeping from around cell cables

•

The cell has an internal leak and must be replaced. Contact

Dionex for assistance.

4.4 Pump Difficult to Prime

Empty reservoir and/or no eluent connected

•

Connect the pump inlet line to the eluent reservoir. Fill the

reservoir.

Eluent reservoir not pressurized

•

Connect the air line to the reservoir and press

turn on the pressure to the reservoir.

Partially blocked end-line filter

•

If the end-line filter (P/N 045987) is no lo nger pure white,

replace it.

Liquid leaks at junction between pump head and pump

•

casting

Replace the piston sea l (see Section 5.9).

Dirty or defect ive check valves

•

Clean the inlet and outlet check valves (see Section 5.8).

4.5 Pump Loses Prime

Eluent reservoir empty

•

Refill the reservoir.

Liquid leaks at junction between pump heads and pump

•

casting

Eluent Pressure

to

4-8

Replace the piston sea l (see Section 5.9).

Dirty or defect ive check valves

•

Clean the inlet and outlet check valves (see Section 5.8).

Doc. 031183-0 3 9/98

Page 59

4.6 Pump Does Not Start

Power switch on pump or

•

Turn on both switches.

No power (control panel LED indicators are not lighted)

•

Check that the power cor d is plugged in.

Check the main power fuses and replace if needed (see

Section 5.12).

4.7 No Flow

Pump not primed

•

Prime the pump (see Section B.5.1).

Flow rate set to zero

•

Reset the flow rate.

4 • Troubleshooting

Pump

button on front panel is off

Broken pump piston

•

Replace the piston (P/N 036904) (see Sectio n 5.10).

4.8 Excessive System Backpressure

Restriction in the hydraulic system

•

Check all liquid lines for crimping o r blockage. Make sure the

ferrule fittings are not overtightened onto tubing. Refer to

Installation of Dionex Ferrule Fittings for details.

Plugged or damaged fitting

•

Isolate the faulty fitting by loosening fittings one-by-one until

the pressure returns to normal. Repair or replace the fitting (see

Section 5.1).

Flow rate through the co lumns too high

•

1. Verify that the co lumn flow rate matches the flow rate set for

the pump.

Doc. 031183-03 9/98

4-9

Page 60

DX-120 Operator’s Manual

2. Measure the pump flow rate, using a 10 mL graduated

cylinder and stopwatch. Calibrate the flow rate if needed (see

Section 5.7).

Clogged column bed supports

•

Replace the bed supports as instructed in the column manual.

Contaminated columns

•

Clean the columns as instructed in the column manual.

Plugged Rheodyne valve passages

•

Contact Dionex for assistance.

4.9 Peak “Ghosting”

Ghosting is the appearance of extraneous peaks in a chromatogram.

These may be late-eluting peaks from a previous injection or they

may result from a contaminated, malfunctioning, or incorrectly

installed injection valve. These peaks may co-elute with peaks of

interest, resulting in nonreproducible peak heights/areas.

4-10

Insufficient time between sample injections

•

Wait un til the previous sample has been completely eluted before

making another injection.

Insufficient flush between samples

•

Flush the sample loop with at least 10 loop volumes of deionized

water or sample between sample injections (see Section 3.3.2).

Malfunctioning injection valve

•

Contact Dionex for assistance.

Doc. 031183-0 3 9/98

Page 61

4 • Troubleshooting

4.10 Nonreproducible Peak Height or Retention Time

Column overloading

•

1. Dilute the sample.

2. Change to a sample loop with a smaller volume (see

Section 5.2).

Liquid leaks

•

Locate and eliminate the leaks (see Section 4.3).

Incomplete or imprecise filling of the sample loop

•

1. Fill the sample loop until excess sample exits the waste line.

2. Inspect the syringe (P/N 01 6387, 10 cc; 016388, 1 cc) and

replace if damaged.

4.11 Abnormal Retention Time or Selectivity

System not equilibrated following an eluent change

•

Allow the system to equilibrate with at least 20 column volumes

of eluent (for example, 30 minutes at 2.0 mL/min for 4 mm

anion separator columns).

Incorrect flow rate through system

•

1. Check that the correct flow rate is selected.

2. Calibrate the pump flow rate (see Section 5.7).

3. Locate and eliminate any liquid leaks (see Section 4.3).

Contaminated or incorrect eluent

•

Remake the eluent using reagent grade chemicals and ASTM

filtered, Type I (18-megohm) deionized water.

Contaminated or degraded sample

•

Take appropriate prec autions when prepar ing and storing samples

to prevent contamination and degradation (see Section 3.2).

Doc. 031183-03 9/98

4-11

Page 62

DX-120 Operator’s Manual

Contaminated column

•

1. Clean the column as instructed in th e column manual.

2. If cleanin g is unsuccessful , replace the c olumn.

4.12 DS4 Temperature Inaccurate

CELL TEMP HI

•

displays continuously

Verify that the set temperature is at least 5 °C above ambient

(SW4-4, 5, 6, 7). Allow 30 to 60 minutes fo r the initial warm-up

period. If you later select a higher set point, allow an additional

3 to 7 minutes for each 5-degree increment in the set point.

The DS4 can take from 1 to 2 hours to complete ly cool down.

LO CELL TEMP

•

displays continuously

At high flow rates and temperature settings far above ambient,

the DS4 requires more time to heat. In extreme cases, such as a

very cold room and a high DS4 set point, the DS4 may not be

able to reach the set point temperature.

DS4 does not heat

•

Make sure the Cell Type DIP switches (SW4-1, 2) are set to the

DS4 position (off).

Make sure that one of the DS4 temperature switch positions

(SW4-4, 5, 6, 7) is on. If all switches are off, the DS4 will not

heat.

4-12

Remove the cover and inspect the DS4 for broken or shorted

wires or for moisture b ridging the control thermistor. If a wire is

broken or shorted, replace the wire or call Dionex for assistance.

If a leak has caused a short, fix the leak (see Section 4.3,

“Leaking DS4”) and dry the contro l sensor.

Doc. 031183-0 3 9/98

Page 63

4.13 No Detector Response

Cell not connected

•

Check the cell cable connection.

Analog output range too high; although the display indicates

•

a response, no recorder response observed

Select the 100 µS range setting (SW4-3, off).

Full-scale output too low

•

Select the 10.0 V full-scale setting (SW4-4, off).

No flow from pump

•

Check that the LED on the

power switch on the front of the pump.

Make sure the flow rate is not set to zero.

Detector offset out of range

•

4 • Troubleshooting

Pump

button is lighted. Check the

Press

Cell electronics malfunctioning

•

Test the electronics as follows:

1. Disconnect the cell cable from the electronics card at the left

2. Set SW4-1, 2 to the off position.

3. Set SW5-8 to the on position.

4.

Doc. 031183-03 9/98

Auto Offset

on the front control panel.

side of the pump compartment (see Figure B-10).

The conductivity reading on the display shou ld be 25.0 µS. If

this is not the case, there may be a problem with the cell

electronics. Contact Dionex for assistance.

4-13

Page 64

DX-120 Operator’s Manual

4.14 Low Detector Output

Analog output range set too high; altho ugh the display

•

indicates a response, no recorder response observed

Select the 100 µS range setting (SW4-3, off).

Insufficient sample injected

•

Increase the injection size or concentration. See Section 5.2 for

information on changing the sample loop size.

Cell out of calibration

•

Recalibrate the cell (see Section 5.6).

4.15 High Detector Output

Auto offset not activated recently

•

Auto Offset

Press

Background not suppressed by SRS

•

Check that the SRS is on (the LED on the

on the front panel before making an injection.

SRS

button should be

illuminated).

Check the SRS regenerant out line for bubbles; if there are no

bubbles, the suppressor may be contaminated. Refer to the SRS

manual for troubleshooting guidance.

Sample concentration too high

•

Dilute the sample or install a smaller sample loop (see

Section 5.2).

Wrong eluent

•

Make sure you are using the correct eluent.

Cell out of calibration

•

Recalibrate the cell (see Section 5.6).

4-14

Doc. 031183-0 3 9/98

Page 65

4.16 Noisy or Drifting Baseline

Flow system leak ahead of cell; errati c baseline

•

Check all fittings and liquid lines for leaks. Tighten or, if

necessary, replace all liquid line connections. Refer to

Installation of Dionex Ferrule Fittings for tightening

requirements.

Pump not properly primed

•

Prime the pump (see Section B.5.1).

Rapid changes in ambient temperature

•

Redirect heating and air conditioning vents away from the

DX-120.

Replace the CDM-3 cell with a DS4 Detection Stabilizer

(P/N 050218).

Insufficient system equilibration following changes to

•

operating parameters; especially apparent when operating at

high sensitivities

4 • Troubleshooting

Allow longer system equilibration time before starting operation.

Air trapped in cell; excessive regular pulses in baseline

•

Check that the correct backpressure coils are installed after the

cell and before the SRS (see Section B.6.1 ).

Incorrect SRS operating conditions

•

Refer to the SRS manual for troubleshooting information.

Temperature compensation setting not optimized

•

Optimize the setting (see Section 3.6).

DS4 above or below set point

•

Wait fo r the DS4 to reach the selected temperature before

beginning operation. The display will in dicate

the selected temperature. If the temperature is above or below the

set point,

Doc. 031183-03 9/98

CELL TEMP HI

LO CELL TEMP

or

CELL TEMP

is displayed.

and

4-15

Page 66

DX-120 Operator’s Manual

4-16

Doc. 031183-0 3 9/98