Dionex 063000, 062998, DNAPAC PA200 Product Manual

DNAPac PA200 Document No. 065036 Page 1 of 25

PRODUCT MANUAL

DNAPAC PA200 ANALYTICAL COLUMN

(4 x 250mm, P/N 063000)

DNAPAC PA200 GUARD COLUMN

(4 x 50mm, P/N 062998)

©DIONEX Corporation

Document No. 065036

Revision 01

20 August 2004

DNAPac PA200 Document No. 065036 Page 2 of 25

TABLE OF CONTENTS

SECTION 1 - INTRODUCTION ...................................................................................................................4

1.1 DNAP

1.2 BIOLC S

1.3 G

1.4 DNAPAC PA200 A

1.5 DNAP

AC

PA200 ................................................................................................................................ 4

YSTEM (WITHOUT COLUMNS

UARD COLUMN USE

NION EXCHANGE COLUMNS

AC COLUMN FAMILY

) .............................................................................................. 4

........................................................................................................................ 5

............................................................................... 5

............................................................................................................... 5

SECTION 2 - OPERATION AND SYSTEM REQUIREMENTS ..............................................................6

2.1 S

2.2 S

2.3 DNAPAC PA200 C

YSTEM REQUIREMENTS

YSTEM OPERATION REQUIREMENTS

.................................................................................................................... 6

OLUMN OPERATIONAL PARAMETERS

................................................................................................ 6

................................................................. 7

SECTION 3 - PURITY REQUIREMENTS FOR CHEMICALS............................................................... 8

3.1 D

3.2 I

3.3 S

EIONIZED WATER

NORGANIC CHEMICALS

OLVENTS

.......................................................................................................................................... 8

............................................................................................................................ 8

..................................................................................................................... 8

SECTION 4 - QUALITY ASSURANCE.......................................................................................................9

4.1 C

4.2 P

ERTIFICATE OF PERFORMANCE – RESIN BATCH TESTING

RODUCTION TEST CHROMATOGRAMS

........................................................................................... 10

............................................................... 9

SECTION 5 - METHODS DEVELOPMENT............................................................................................. 11

5.1 S

5.2 E

5.3

AMPLE CLEANUP

LUTION ORDER

E

FFECT OF SALT TYPE ON OLIGONUCLEOTIDE ELUTION

............................................................................................................................ 11

............................................................................................................................... 11

................................................................ 11

5.3.1 Eluent Strength ...................................................................................................................... 11

5.3.2 Loading Capacity................................................................................................................... 11

5.4

G

5.5 E

RADIENT SLOPE

FFECT OF PH AND SOLVENT ON OLIGONUCLEOTIDE CHROMATOGRAPHY

.............................................................................................................................. 12

.................................... 12

5.5.1 Effect of pH on Hydrogen Bond Interactions ........................................................................ 12

5.5.2 Effect of pH on Retention...................................................................................................... 13

5.5.2 Effect of pH on Retention...................................................................................................... 13

5.5.3 Effect of Solvent on Retention............................................................................................... 13

5.5.4 Effect of pH on Selectivity .................................................................................................... 14

5.6 E

5.7

FFECT OF TEMPERATURE ON OLIGONUCLEOTIDE RETENTION

E

FFECT OF TERMINAL BASE ON SELECTIVITY

................................................................................. 16

...................................................... 15

5.7.1 Selectivity in Sodium Chloride (NaCl) Gradients. ................................................................ 16

5.7.2 Selectivity in Sodium Perchlorate (NaClO4) Gradients......................................................... 17

5.8 A

PPLICATION-SPECIFIC MOBILE PHASE RECOMMENDATIONS

........................................................ 18

5.8.1 For synthetic ODNs where the goal is to evaluate purity. ..................................................... 18

5.8.2 When multiple possible ODNs of similar length in the same solution must be resolved...... 18

SECTION 6 - APPLICATIONS................................................................................................................... 19

6.1 D

6.2 E

6.3 P

ENATURING CONDITIONS FOR CONTROL OF SECONDARY STRUCTURE

FFECT OF HIGH TEMPERATURE AND HIGH PH ON COLUMN LIFETIME

HOSPHODIESTER ANALYSIS

........................................................................................................... 20

........................................ 19

.......................................... 19

6.3.1 Sodium Perchlorate Eluent Systems ...................................................................................... 20

6.3.2 Sodium Chloride Eluent Systems .......................................................................................... 21

SECTION 7 - DNAPac™ PA200 RESOURCES.........................................................................................22

DNAPac PA200 Document No. 065036 Page 3 of 25

Section 8 - TROUBLESHOOTING GUIDE ...............................................................................................23

8.1 F

8.2 B

8.3 D

8.4

8.5

8.6

8.7

8.8 C

8.9 P

8.10 S

INDING THE SOURCE OF HIGH SYSTEM BACK PRESSURE

ACKPRESSURE ON COLUMN HAS INCREASED

ECREASING PEAK RETENTION TIMES

D

ECREASING PEAK EFFICIENCY AND RESOLUTION

P

OOR PEAK EFFICIENCY AND RESOLUTION

U

NIDENTIFIED PEAKS APPEAR

D

ECREASED DETECTION SENSITIVITY

OLUMN PROBLEMS

EAK EFFICIENCY AND RESOLUTION ARE DECREASING

YSTEM PROBLEMS

........................................................................................................................ 24

.......................................................................................................................... 24

......................................................................................................... 24

............................................................................................ 23

..................................................................................... 24

............................................................................................. 24

.............................................................. 23

................................................................................ 23

......................................................................... 23

................................................................. 24

8.10.1 High Detection Background Caused by the System .............................................................. 24

8.10.2 No Peaks, Poor Peak Area Reproducibility or Unexpectedly Small Peak Area.................... 25

8.10.3 Incorrect or Variable Retention Times .................................................................................. 25

8.11 C

OLUMN CLEANUP

........................................................................................................................... 25

8.11.1 High Salt Wash to Remove Ionic Components ..................................................................... 25

8.11.2 Organic Solvent Wash to Remove Non-Ionic Components .................................................. 25

DNAPac PA200 Document No. 065036 Page 4 of 25

SECTION 1 - INTRODUCTION

1.1 DNAPac PA200

The DNAPac PA200 is a pellicular anion exchange column designed specifically to provide high-resolution

separations of single stranded nucleic acids. The DNAPac PA200 provides n, n-1 resolution over a wide range of

oligomer lengths and can perform separations under a variety of denaturing conditions:

• High temperature, pH 8 or below

• High pH (12.4) at 30° or below

Because of the unique pH stability of the packing material, elevated pH conditions can be used to optimize

selectivity for specific oligonucleotides.

The packing material inside the DNAPac PA200 is composed of 130 nm quaternary amine functionalized

MicroBeads™ bound to an 8 µm solvent compatible, non-porous substrate. The non-porous substrate design

provides rapid mass transport resulting in narrow high efficiency peaks. The low column capacity, typical of nonporous packings, is avoided by agglomerating functionalized MicroBeads to the surface of the substrate particle,

resulting in higher loading capacity than is possible with conventional non-porous materials, and good durability.

This produces a column with oligonucleotide resolution superior to columns using 2 to 3 µm resins.

Resin Characteristics:

Particle Size: 8 µm

Pore Size: non porous

Cross-linking: 55%

Ion exchange capacity: ~40 µeq/column

Latex Characteristics:

Functional Group: quaternary ammonium ion

Latex Diameter: ~130 nm

Latex Cross-link: 5 %

Typical Operating Parameters:

pH range: 4-10 unrestricted eluents

2.5-4 and 10-12.5, (Operation at these pH values require co-ion concentration to be

at least equimolar with hydroxide at high pH or H

Temperature: ≤85°C

Pressure: 3,000 psi

Organic Solvent Limit: 100% acetonitrile or methanol for cleaning

Typical eluents: High purity water (18.2 megohm-cm), sodium chloride, sodium perchlorate, buffers,

sodium acetate and sodium hydroxide

1.2 BioLC System (without Columns)

+

at low pH)

Table 1: System Components Recommended for DNA Analysis

Basic Gradient System Standard Gradient System

BioLC gradient pump, with degas BioLC gradient pump (degas recommended)

Chromatography oven with injection valve

and regulator assembly

Column Oven

Absorbance detector (D2 lamp for UV) Absorbance detector (D2 lamp for UV)

EO1 eluent organizers EO1 Eluent organizers

Autosampler

DNAPac PA200 Document No. 065036 Page 5 of 25

1.3 Guard Column Use

A guard column is usually placed before the analytical column to prevent contaminants in the sample from eluting

onto the analytical column. The addition of the guard column increases the net column capacity, which translates

into an increase of about 20% in the retention times for isocratic runs. If a guard is added to a system running a

gradient method that was initially developed for an analytical column alone, the analytes will elute slightly later and

usually with slightly better resolution.

1.4 DNAPAC PA200 Anion Exchange Columns

Part Number Product Description

063000 DNAPac PA200, Analytical (4 x 250mm)

062998 DNAPac PA200, Guard (4 x 50mm)

1.5 DNAPac Column Family

There are two varieties of columns in the DNAPac column family. Both columns are non-porous anion exchangers

that provide high-resolution oligonucleotide separations. The choice of column depends upon the goal of the

separation. The DNAPac PA100 consists of a 13 µm substrate particle with 100 nm functionalized MicroBeads.

This column is available in a variety of formats and should be used when higher capacity is required and if scale-up

to semi-preparative scale separations is anticipated.

The DNAPac PA200 consists of an 8 µm substrate particle with 130 nm functionalized MicroBeads. This column

provides higher resolution than the DNAPac PA100. The DNAPac PA200 is operated at a lower flow rate than the

DNAPac PA100, thus less eluent is consumed during a run. In addition, the DNAPac PA200 has been

manufactured to provide greater stability to high pH at elevated temperature, although this combination is not

recommended.

Assistance is available for any problem that may be encountered during the shipment or operation of

DIONEX instrumentation and columns through the DIONEX North America Technical Call Center at 1800-DIONEX-0 (1-800-346-6390) or through any of the DIONEX offices listed in “DIONEX Worldwide

Offices.”

DNAPac PA200 Document No. 065036 Page 6 of 25

SECTION 2 - OPERATION AND SYSTEM REQUIREMENTS

2.1 System Requirements

Oligonucleotide separations with the DNAPac PA200 columns are optimized for use with NON-METALLIC

systems, such as the Dionex BioLC. The key issue is that the eluent flow path from reservoir to detector is metalfree, because the salts used for oligonucleotide elution attack the metallic components of metallic pumps and

tubing. The released metals will irreversibly foul the column.

Each of the possible configurations offers multiple sampling options; however, consistently reproducible

quantification and an absence of disturbing artifacts are achieved best using an autosampler and “full loop”

injection mode. Reproducibility of retention time results can be enhanced by regulating the temperature of the

column using a column oven or thermal compartment.

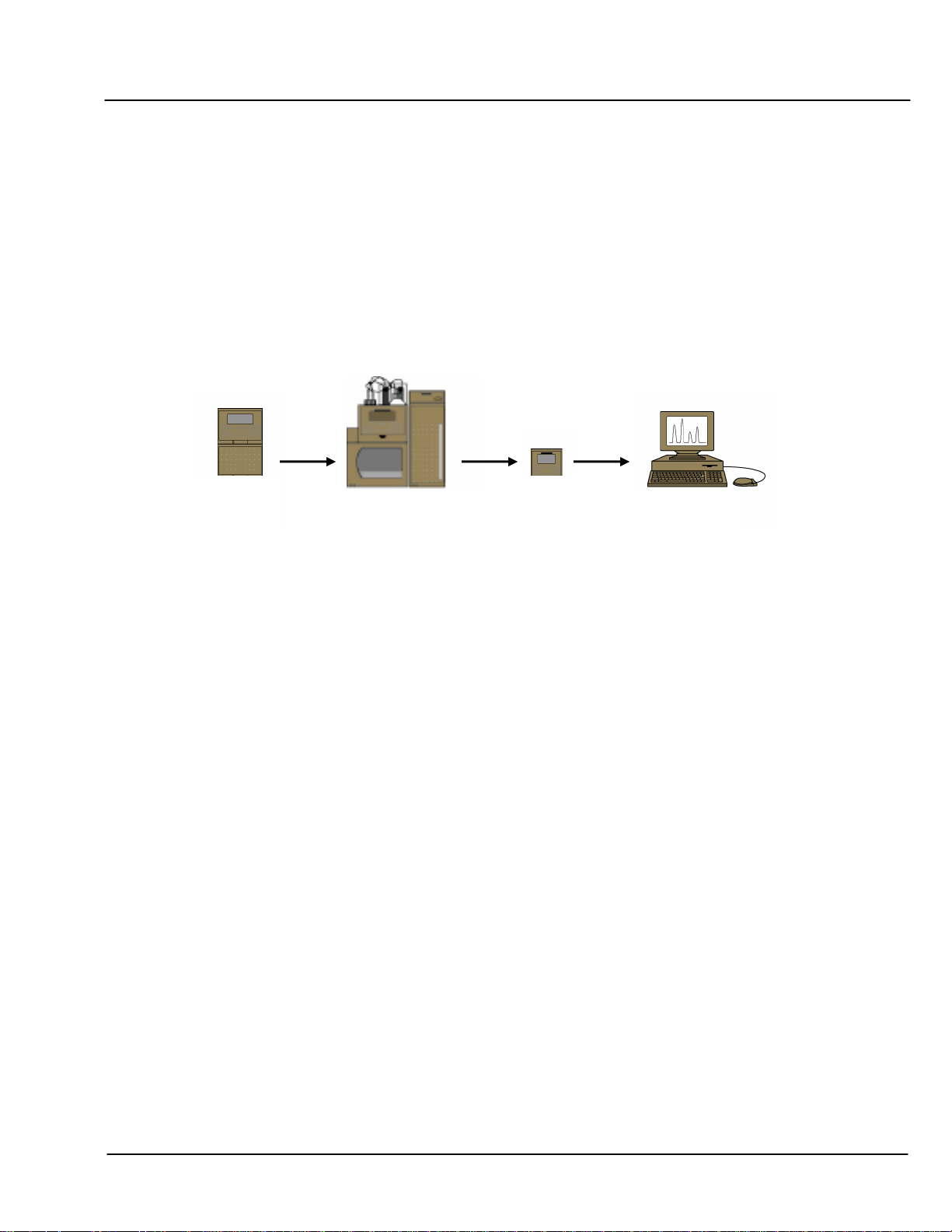

Gradient

Pump

Autosampler

Thermal

Compartment

Absorbance

Detector

Data System

Figure 1 Oligonucleotide System Configuration

2.2 System Operation Requirements

The oligonucleotide analysis systems should be configured with Dionex modules to provide the following

attributes:

a) All components of the fluid path are non-metallic, to eliminate column poisoning.

b) Mobile phase components are kept under helium or nitrogen to minimize out-gassing (bubble formation)

in the detector cell. On-line degassing of eluents may be provided with the eluent degas option on Dionex

pump modules.

c) Accurate reproducible flow and gradient generation at settings between 0.20 and 2.0 mL/min.

d) Minimal contribution to the background signal by contaminants from the system and reagents.

e) Thermostated column compartment for consistent temperature control of the guard and separation

columns.

f) Minimal system volumes (employ low volume unions and minimal tubing length).

• 4-mm operation, liquid line inside diameter (I.D.) should be between .007” and 0.01”.

• 2mm operation, liquid line inside diameter (I.D.) should be between .003” and 0.005”.

In both operations, PEEK tubing is preferred as it does not contribute to metal leaching.

DNAPac PA200 Document No. 065036 Page 7 of 25

2.3 DNAPAC PA200 Column Operational Parameters

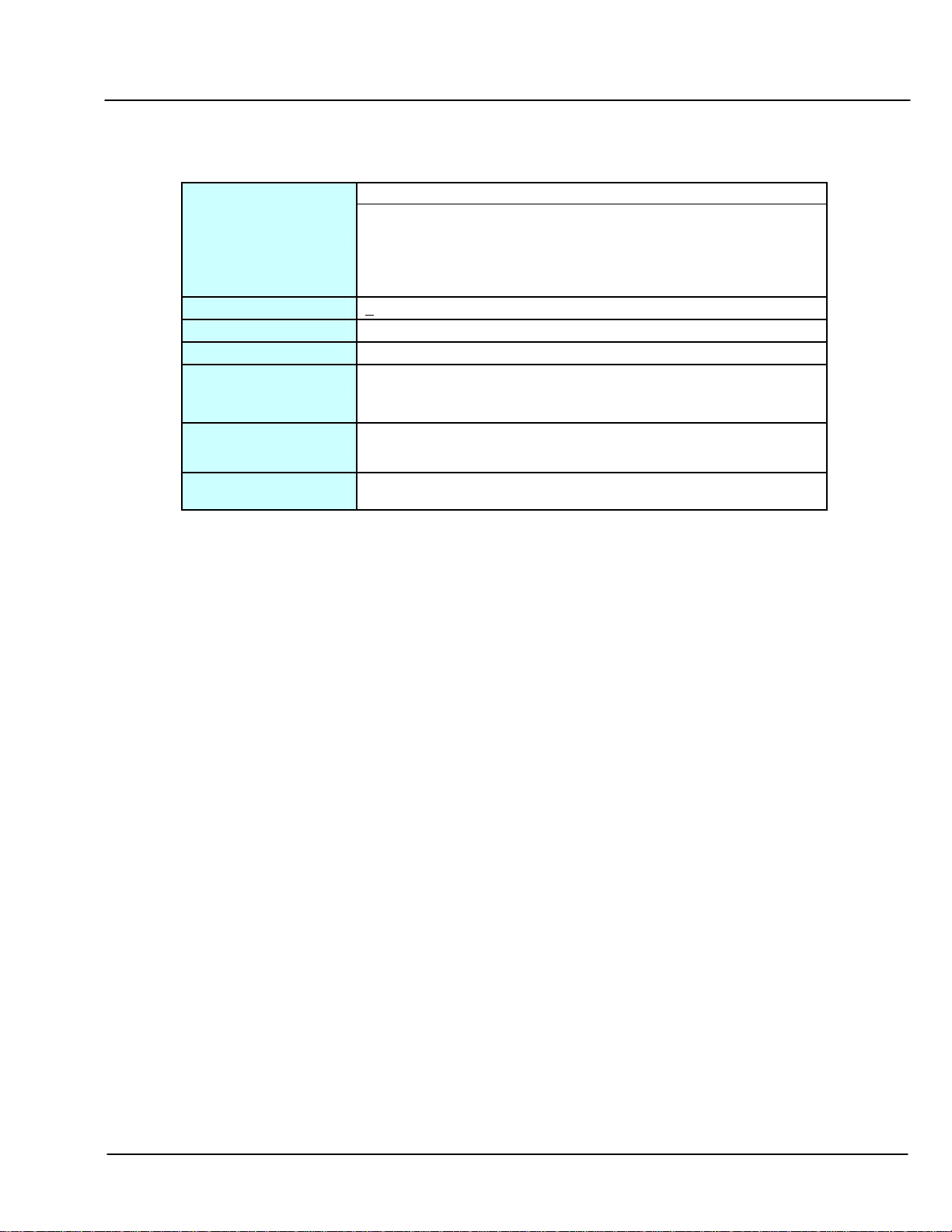

TABLE 2 Column Operational Parameters

pH

= 4-10 (unrestricted eluents)

pH

pH Range:

Temperature Limit:

Pressure Limit:

Organic Solvent Limit:

Chaotrope Limit:

Typical Eluents:

Detergent

Compatibility:

CAUTION:

Do not use anionic detergents. Anionic detergents will bind irreversibly to the column.

= 2.5- 4, and 10-12.5: Operation at these pH values require co-ion

concentration (e.g., Cl

pH) to be at least equimolar with hydroxide at high pH or H

-

or ClO

-

at high pH and Na+ or NH

4

+

at low

4

+

at

low pH.

<

85°C

4,000 psi

100% Acetonitrile, or methanol, if required for cleaning.

30% formamide, 6 M Urea.

Note:

Use of these chaotropes will increase back pressure, and

reduce column lifetime.

High purity water (18 megohm-cm), sodium chloride, sodium

perchlorate, buffers, sodium acetate and sodium hydroxide.

Nonionic, cationic or zwitterionic detergents.

DNAPac PA200 Document No. 065036 Page 8 of 25

SECTION 3 - PURITY REQUIREMENTS FOR CHEMICALS

Reliable and reproducible results require eluents that are prepared consistently and are free from impurities.

3.1 Deionized Water

The de-ionized (DI) water, used to prepare eluents, should be Type I reagent grade water with a specific resistance

of 18 megohm-cm. The water should be free from ionized impurities, organics, microorganisms, and particulate

matter. Ultra Violet (UV) treatment in the water purification unit is recommended. Follow the manufacturer’s

instructions regarding the replacement of ion exchange and adsorbent cartridges. All filters used for water

purification must be free from UV absorbing components. Contaminated water in eluents causes high background

signals, gradient artifacts, and even sample degradation due to nucleases arising from microbial contamination.

3.2 Inorganic Chemicals

Inorganic chemicals of reagent grade or better should be used to prepare ionic eluents. Whenever possible,

inorganic chemicals that meet or surpass the latest American Chemical Society standard for purity should be used.

These products will include detailed lot analyses on their labels.

3.3 Solvents

Solvents can be added to the ionic eluents used in DNAPac PA200 columns to modify the ion exchange process.

The solvents used must be free from ionic impurities; however, since most manufacturers of solvents do not test for

ionic impurities, it is important that the highest grade of solvents available be used. Currently, several

manufacturers are making “ultra high” purity solvents that are compatible with HPLC and spectrophotometric

applications. These “ultra high” purity solvents will usually be of sufficient purity to ensure that your

chromatography is not affected by ionic impurities in the solvent. At Dionex, we have obtained consistent results

using High Purity Solvents manufactured by Burdick and Jackson or Optima Solvents by Fischer Scientific.

When using an ionic eluent with solvent, column generated back pressure will depend on the solvent used, the

concentration of the solvent, the ionic strength of the eluent, and the flow rate applied. The column backpressure

will also vary if the composition of the water-solvent mixture varies. The practical backpressure limit for the

DNAPac PA200 is 4,000 psi (27.6 MPa). The DNAPac PA200 can withstand common HPLC solvents in a

concentration range of 0-100%. Solvents and water should be premixed in concentrations which allow proper

mixing by the gradient pump and to minimize out-gassing. Ensure that all of the inorganic chemicals are soluble in

the highest solvent concentration to be used during the analysis.

Solvent-Water mixtures are usually specified with a volume to volume basis. If a procedure requires an eluent of

90% acetonitrile; prepare the eluent by adding 900 mL of acetonitrile to an eluent reservoir. Then add 100 mL of

deionized water, or eluent concentrate, to the acetonitrile in the reservoir. Using this procedure to mix solvents with

water will ensure that a consistent true volume/volume eluent is obtained. Premixing water with solvent will also

minimize the possibility of out gassing which causes bubble formation in the detector cell. If you choose to mix

eluents containing solvents with those that do not – the eluent degas option for the pump is highly recommended.

As a second choice, pre-degassing the eluents and covering the eluent reservoir with Helium gas to limit gas

dissolution into the eluents will help limit out-gassing.

Loading...

Loading...