Page 1

CD25 CONDUCTIVITY DETECTOR

OPERATOR'S MANUAL

© 2000 Dionex Corporation

Document No. 031687

Revision 01

April 2000

Page 2

©2000 by Dionex Corporation

All rights reserved worldwide.

Printed in the United States of Amer ica.

This publication is protected by federal copyright law. No part of this publication

may be copied or distributed, transmitted, transcribed, stored in a retrieval system, or

transmitted into any human or computer language, in any form or by any means,

electronic, mechanical, magnetic, manual, or otherwise, or disclosed to third parties

without the express written permission of Dionex Corporation, 1228 Titan Way,

Sunnyvale, California 94088-3603 U.S.A.

DISCLAIMER OF WARRANTY AND LIMITED WARRANTY

THIS PUBLICATION IS PROVIDED “AS IS” WITHOUT WARRANTY OF

ANY KIND. DIONEX CORPORATION DOES NOT WARRANT,

GUARANTEE, OR MAKE ANY EXPRESS OR IMPLIED

REPRESENTATIONS REGARDING THE USE, OR THE RESULTS OF THE

USE, OF THIS PUBLICATION IN TERMS OF CORRECTNESS, ACCURACY ,

RELIABILITY, CURRENTNESS, OR OTHERWISE. FURTHER, DIONEX

CORPORATION RESERVES THE RIGHT TO REVISE THIS PUBLICATION

AND TO MAKE CHANGES FROM TIME TO TIME IN THE CONTENT

HEREINOF WITHOUT OBLIGATION OF DIONEX CORPORATION TO

NOTIFY ANY PERSON OR ORGANIZATION OF SUCH REVISION OR

CHANGES.

TRADEMARKS

Teflon® and Tefzel® are registered trademarks of E.I. duPont de Nemours & Co.

AutoSuppression™, DX-LAN™, IonSep®, MPIC™, OmniPac®, OnGuard™,

SRS®, and Self-Regenerating Suppressor® are trademarks of Dionex Corp.

PRINTING HISTORY

Revision 01, April 2000

Page 3

Contents

1 • Introduction

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2.1 Typefaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.2.2 Safety Messages and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.3 Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

2 • Description

2.1 Front Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.1.1 Control Panel Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.1.2 Control Panel Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.2 Electronics Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2.3 Conductivity Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

2.4 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

2.5 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

Doc. 031687-01 4/2000

2.1.3 Initial Display Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2.2.1 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

2.2.2 Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

2.3.1 DS3 Detection Stabilizer . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

2.3.2 Shielded Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

2.5.1 Operating and Control Modes . . . . . . . . . . . . . . . . . . . . . . . .2-16

i

Page 4

CD25 Conductivity Detector

2.5.2 Local and Remote Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2.5.3 Method Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

3 • Operation and Maintenance

3.1 Getting Ready to Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Running Under Direct Control (Local Mode) . . . . . . . . . . . . . . . . . . . 3-2

3.3 Running Under Method Control (Local Mode) . . . . . . . . . . . . . . . . . . 3-3

3.3.1 Running a Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3.2 Changing the Running Method . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3.3 Creating a New Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.3.4 Editing an Existing Method . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.4 Optimizing Temperature Compensation . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.4.1 With a DS3 and Conductivity Cell . . . . . . . . . . . . . . . . . . . . . 3-7

3.4.2 With a Shielded Conductivity Cell . . . . . . . . . . . . . . . . . . . . . 3-8

3.5 Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

4 • Troubleshooting

4.1 No Detector Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Low Detector Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.3 High Detector Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.4 Noisy or Drifting Baseline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.5 Liquid Leaks from the DS3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.6 DS3 Temperature Inaccurate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.7 Conductivity Inaccurate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

ii

Doc. 031687-01 4/2000

Page 5

4.8 Faulty DX-LAN Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

4.9 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

5•Service

5.1 Eliminating Liquid Leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5.2 Removing Trapped Air from the Cell . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5.3 Replacing the DS3 Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5.4 Calibrating the Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.5 Replacing the Main Power Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

A • Specifications

Contents

5.6 Physical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

A.1 Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

A.2 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

A.3 Display and Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

A.4 Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

A.5 Conductivity Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

A.6 SRS Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

A.7 DS3 Detection Stabilizer (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

B • Installation

B.1 Facility Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

B.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Doc. 031687-01 4/2000

iii

Page 6

CD25 Conductivity Detector

B.2.1 Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

B.2.2 DX-L AN Interfa ce: 10BASE-T Connection s (Optional ). . . . .B-3

B.2.3 DX-LAN Interface: BNC Connections (Optional). . . . . . . . . .B-6

B.2.4 DS3 Detection Stabilizer Installation. . . . . . . . . . . . . . . . . . . .B-9

B.2.5 Shielded Conductivity Cell Installation . . . . . . . . . . . . . . . . . .B-9

B.2.6 DS3 or Shielded Cell Plumbing. . . . . . . . . . . . . . . . . . . . . . . .B-9

B.2.7 Recorder/Diagnostic Connection . . . . . . . . . . . . . . . . . . . . . .B-17

B.3 Automatic SRS Power Control (Optional) . . . . . . . . . . . . . . . . . . . . .B-18

C • User Interface

C.1 Operational Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-2

C.1.1 Menu of Screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-2

iv

C.1.2 Main Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-3

C.1.3 Detail Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4

C.1.4 Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-5

C.1.5 Module Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-7

C.1.6 Analog Out Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-8

C.1.7 Time Function In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-9

C.2 Diagnostic Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-10

C.2.1 Diagnostic Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-10

C.2.2 Power-Up Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-11

C.2.3 Elapsed Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-12

C.2.4 Analog Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-13

C.2.5 DX-LAN Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-14

Doc. 031687-01 4/2000

Page 7

C.2.6 Keyboard Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-16

C.2.7 Diagnostic Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-17

C.2.8 Leak Sensor Calibration and Status. . . . . . . . . . . . . . . . . . . . C-19

C.2.9 Signal Statistics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-20

C.2.10 Calibrate Conductivity Cell. . . . . . . . . . . . . . . . . . . . . . . . . . C-21

D • TTL and Relay Control

D.1 TTL and Relay Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

D.2 TTL and Relay Output Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

D.3 TTL Input Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-4

D.3.1 TTL Input Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-4

D.3.2 TTL Input Signal Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-5

Contents

E • Signal Processor Functions

F • Connector Pinouts

F.1 Recorder/Diagnostic Signal Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

F.1.1 Signal Electrical Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . F-2

F.2 TTL/Relay Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-4

F.3 DS3 Connector Pinouts—SCR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-5

F.4 SRS Connector Pinouts—SCR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-6

F.5 Conductivity Cell Connector Pinouts—SP . . . . . . . . . . . . . . . . . . . . . F-6

G • Reordering Information

Doc. 031687-01 4/2000

v

Page 8

CD25 Conductivity Detector

vi

Doc. 031687-01 4/2000

Page 9

1.1 Overview

The CD25 Conductivity Det ect or is a sensitive, accurate , and versatile ins tr ument

for detecting and quant ifying ionic analytes in liq uid and ion chromatog raphy. It is

especially useful for analytes that lack UV chromophores and cannot be

determined with adequate sensitivity by UV absorbance. Conductivity detection,

especially when combined with chemical eluent suppression, provides excellent

sensitivity and selectivity for numerous ionic species, both organic and inorganic.

The major organic analytes are carboxylic, sulfonic, and phosphonic acids; and

primary, secondary, tertiary, and quaternary amines. Inorganic analytes include

strong acid anions such as the halid es, sulfate , nitrat e, and phos phate; alkali metal

and alkaline earth cations.

The CD25 ca n be controll ed locally, from the front panel, or remotely (via th e

Dionex DX-LAN™ interface) from a host computer running PeakNet 6, Release

6.1 (or later) software.

1 • Introduction

Doc. 031687-01 04/2000

1-1

Page 10

CD25 Conductivity Detector

1.2 About This Manual

Chapter 1

Introduction

Chapter 2

Description

Chapter 3

Operation and

Maintenance

Chapter 4

Troubleshooting

Chapter 5

Service

Appendix A

Specifications

Appendix B

Installation

Appendix C

Display Screens

Provides a brief overview of the CD25 Conductivity

Detector. Explains the meaning of safety messages and

icons in the manual and safety labels on the detector.

Describes physical aspects of the CD25, including the

front panel controls, electronics, and flow cell. Explains

the detecto r operating m odes.

Describes operating features and how to create, edit, and

run methods from the CD25 front panel. Lists routine

preventive maintenance requirements.

Lists possible causes of problems and step-by-step

procedures to isolate and elimina te th em.

Contains step-by-step instructions for routine service and

parts replacement procedures.

Lists the CD 25 specifica tions and installation site

requirements.

Describes how to install the CD25.

Illustrates and describes all operating and diagnostic

screens that can be displayed on the front panel.

1-2

Appendix D

TTL and Relay

Control

Appendix E

Signal Processor

Functions

Appendix F

Connector

Pinouts

Appendix G

Reordering

Information

Describes TTL and relay control functions. Provides

connection instructions.

Lists the functions of the Signal Processor (SP) card.

Describes the pinouts for all CD25 connectors.

Lists spare parts for the detector.

Doc. 031687-01 04/2000

Page 11

1.2.1 Typefaces

Capitalized bold type indicates a front panel button:

Enter

Press

Uppercase bold type indicates the name of a menu or a screen, or an

on-screen entry:

1 • Introduction

to begin running the method.

Go to the

METHOD

Move the cursor to the

screen.

EDIT

field.

1.2.2 Safety Messages and Notes

This manual contains warnings and precautionary statements that can

prevent personal injury and/or damage to the CD25 when properly

followed. Safety messages appear in bold type and are accompanied by

icons, as shown below.

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

Indicates that the function or process of the instrument may be

impaired. Operation does not constitute a hazard.

Doc. 031687-01 04/2000

1-3

Page 12

CD25 Conductivity Detector

Informational messages also appear throughout this manual. These are labeled

NOTE and are in bold type:

NOTE NOTES call attention to certain information. They alert

you to an unexpected result of an action, suggest how to

optimize instrument performance, etc.

1.3 Safety Labels

The CE and GS safety label on the CD25 attests to compliance with the following

European, EMC, and safety requirements: Council Directives 73/23/EEC and 89/

336/EEC, EN 61010-1:1993 (safety), EN 50082-1:1992 (susceptibility), and EN

55011:1991 (emissions).

The symbols below appear on the CD25 or on CD25 labels.

Alternating current

˜

Protective conductor terminal (earth ground)

Power supply is on

Power supply is off

1-4

Doc. 031687-01 04/2000

Page 13

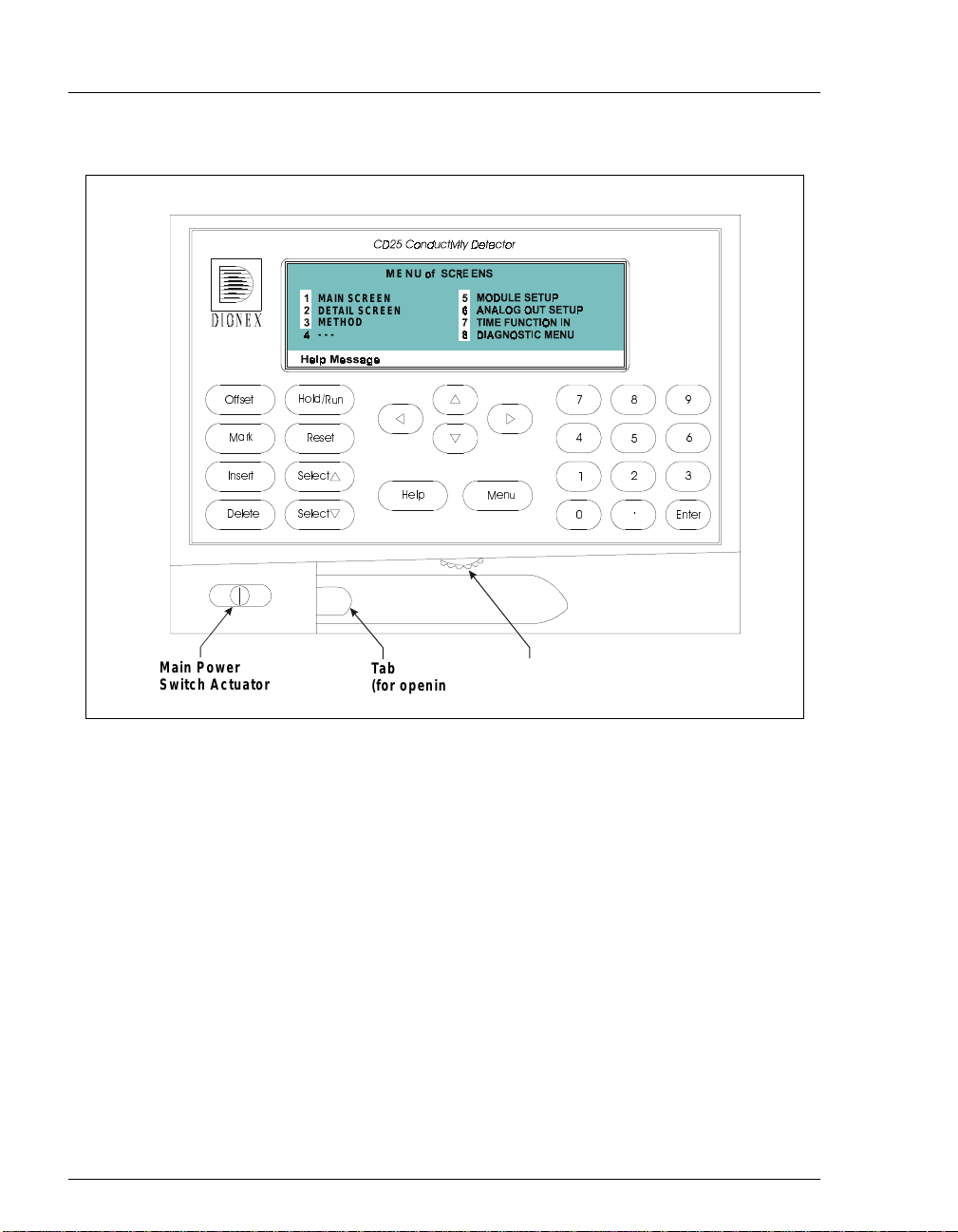

2.1 Front Control Panel

The control panel on the f ront door of t he CD25 contains the liquid crystal di splay

(LCD), the membrane keypad, and the actuator for the main power switch. The

electronics chassis, described in Section 2.1.3, is located behind the front door.

Power Switches

The main power switch is on a bulkhead inside the electronics chassis (in the

front, left-hand corner). The actuator for the power switch is on the front door,

below the control panel (see Figure 2.1.2). The actuator functions only when the

front door is fully closed. When the door is open, press the main power switch to

turn the CD25 on and off.

2.1.1 Control Panel Display

2 • Description

and

screen

, displays CD25 status and operating

Menu

buttons (see Figure 2-1).

option on the

MODULE SETUP

screen

The LCD, also called the

information. Fields on the sc ree n tha t ar e in reverse video (blue lette rs on

a white background) can be edited, while normal video fields are simply

informational displays.

To adjust the screen contrast, rotate the knurled knob in the recess

below the

To adjust the brightness of the screen backlight, select a different

DISPLAY PANEL BACKLIGHT

(see Section C.1.5).

Help

Doc. 031687-01 04/2000

2-1

Page 14

CD25 Conductivity Detector

MAIN SCREEN

DETAIL SCREEN

METHOD

---

E

!

"

Main Power

Switch Actuator

Ta b

(for opening

the door)

Figure 2-1. CD25 Front Panel

2.1.2 Control Panel Keypad

The buttons on the front panel keypad are used to affect screen functions,

to directly control CD25 operat ion, and to create and modif y programmed

series of timed events, called methods. For example, pressing

turns the method clock off

displays a list of availa ble screens. In summary:

To go from a menu to a screen, press the number button that

corresponds to the screen’s number on the menu, or move the cursor

to the desired screen name and press

Hold

(

Knob

(for a d ju s tin g

the contrast)

) and on

Run

, while pressing

(

)

Enter

.

#

Hold/Run

Menu

2-2

To edit a reverse video entry field on a screen, move the cursor to the

field using the four directional arrow buttons. Then, use the numeric

Doc. 031687-01 04/2000

Page 15

2•Description

Keypad

Buttons

Offset

Mark

buttons to enter variable values or the

Select

∆

and

Select

∇

to choose predetermined values.

In most cases, confirm the selected value, by pressing either a cursor

arrow button or

must press

METHOD SAVE TO

the

command, the

NOTE A beep sounds each time you press a keypad button,

and a lower frequency beep sounds whenever an

error occurs. You can disable the beeps from the

MODULE SETUP

Function

Returns the analog (recorder) output to a predetermined baseline and

zeros the display. The resultant value of the offset required is displayed

on the

Sends a 10% positive event mark to the analog (recorder) output. A

mark is typically used to indicate a sample injection. This fun ction can

be programmed in a method.

Enter

. In certain fields and/or screens, however, you

Enter

to confirm the selected value. These exception s are

field, the

DIAGNOSTIC TESTS

DETAIL

screen. This function can be programmed in a method.

METHOD RUN

field, any calibration

screen, and all menu screens.

screen (see Section C.1.5).

buttons

Insert

Doc. 031687-01 04/2000

Inserts a new step into a method.

T o add a new s tep, mov e the cur sor to the

A new blank step appears below the cursor position. After entering a

time value, press

order and they will be automatically reorganized in the correct

chronological order.

Enter

or a cursor arrow button. Insert steps in any

TIME

field and pr

ess

Insert

.

2-3

Page 16

CD25 Conductivity Detector

Keypad

Buttons

Delete

Hold/Run

Function

Removes the value from the curren t entry field. To restore the previous

value, move the cursor from the field before entering a new value.

Pressing

METHOD

Delete

when the cursor is in a step entry field on the

screen “blanks” the step parameter value. Moving the cu rsor

to another field does not restore the previous value; instead, the step

remains blank, indicating no change from the previous step .

To delete an entire method step:

1. Position the cursor in the method’s time field and press

Delete

.

The time is removed and the help line prompts you to press

Delete

again to delete the step.

2. Press

Turns the method clock off (

Delete

again. Or, to restore the original time and step

parameters, press any button except

Hold

) and on

Delete

(Run)

.

. This button

functions only when the detector is under Method control (see

Section 2.5.3).

When the method clock is in Hold, pressi ng

Hold/Run

starts the clock

at either the initial step of a new method or, if resuming an interrupted

method, at the time at which the clock was put in Hold.

2-4

Rese

Select

and

Select

When the method clock is in Run, pressing

Hold/Run

stops the

method clock, thereby “holding” the method and freezing the current

conditions.

t

Changes the method clock time to

INIT

, causing the initial conditions

specified by the method to occur. This button functions only when the

detector is under Method control (see Section 2.5.3).

If the method is running, it continues running. If the method is in Hold,

the method clock executes the initial conditions and holds.

∆

When the cursor is positioned at a field with predetermined

parameters, these buttons cycle through the options. In fields with

∇

predetermined numerical values, pressing

Select

Enter

Select

button increases (or decreases) the value

by one unit; pressing

Holding down a

continuously. Press

∇ decreases the value by one unit.

or a cursor arrow button to confirm the

Select

increases the value

∆

selected value.

Doc. 031687-01 04/2000

Page 17

2•Description

Keypad

Buttons

Help

Menu

Numeric

Buttons

Function

The four cursor buttons move the cursor, in the direction of the arrow,

to the next entry field. If there is no changeable field in that direction,

the cursor moves diagonally or remains in its current location.

In most cases, after entering a new value in an entry field, pressing an

arrow button saves and/or executes the change. The exceptions are the

METHOD SAVE T O

command, the

DIAGNOSTIC TESTS

field, the

METHOD RUN

screen, and all menu screens.

field,

any calibration

Displays a help screen with information pertaining to the current entry

field.

Displays one of two menus, depending on the current screen:

From an operational screen, pressing

SCREENS

From a diagnostic screen, pressing

DIAGNOSTIC MENU

MENU of SCREENS

.

; pressing

.

Menu

displays the

Menu

once returns you to the

Menu

again returns you to the

MENU of

Enters numeric values into the current e ntry field. The numer ic buttons

are 0 through 9 and the decimal.

From a menu screen, pressing a numeric button opens the

corresponding screen.

Enter

Doc. 031687-01 04/2000

Saves and/or executes changes made in entry fields. I f a menu screen is

displayed, pressing

Enter

opens the highlighed screen.

2-5

Page 18

CD25 Conductivity Detector

2.1.3 Initial Display Screens

When the CD25 has successfully powered-up and passed all diagnostic

tests, the

the

power-up, the

screen. See Section C.2.7 if this occurs.

POWER-UP

MAIN

screen (see Figure 2-3). If one of the diagnostic tests fails at

DIAGNOSTIC TEST

screen (see Figure 2-2) displays briefly, followed by

screen disp lays instead of the

MAIN

NOTE The information on the

reviewed at any time by selecting the screen from

DIAGNOSTIC MENU

the

CD25 CONDUCTIVITY DETECTOR

MODULEWARE REV

Help M essag e

Figure 2-2. Power-Up Screen

+2. 34

uS

POWER-UP

.

TOTA L 138.71 uS

RANGE

screen can be

BIO S REV n.nn

SRS

n.nn

nnnnnnDX L-AN ID#

50

1000 uS

2-6

LOCAL

H e lp Mess a g e

MAIN

The

facilitate viewing from a d istance. Operating parameters (flow rate,

method number to run, etc.) are selected here.

screen dis plays status information in enlarged characters to

METHOD 05

Figure 2-3. Main Screen

Doc. 031687-01 04/2000

Page 19

2•Description

To access other screens, press the

display the

MENU of SCREENS

Menu

(see Figure 2-4). T o select an opti on, move

the cursor to a screen name and press

on the keypad and press

Enter

. See Appendix C for a description of each

screen.

MENU of SCREENS

MAIN SCREEN

1

DETAIL SCREEN

2

METHOD

3

- - -

4

5

6

7

8

Help Message

Figure 2-4. Menu of Screens

button on the front panel to

Enter

, or enter the screen number

MODULE SETUP

ANALOG OUT SETUP

TIME FUNCTION IN

DIAGNO STIC MENU

Doc. 031687-01 04/2000

2-7

Page 20

CD25 Conductivity Detector

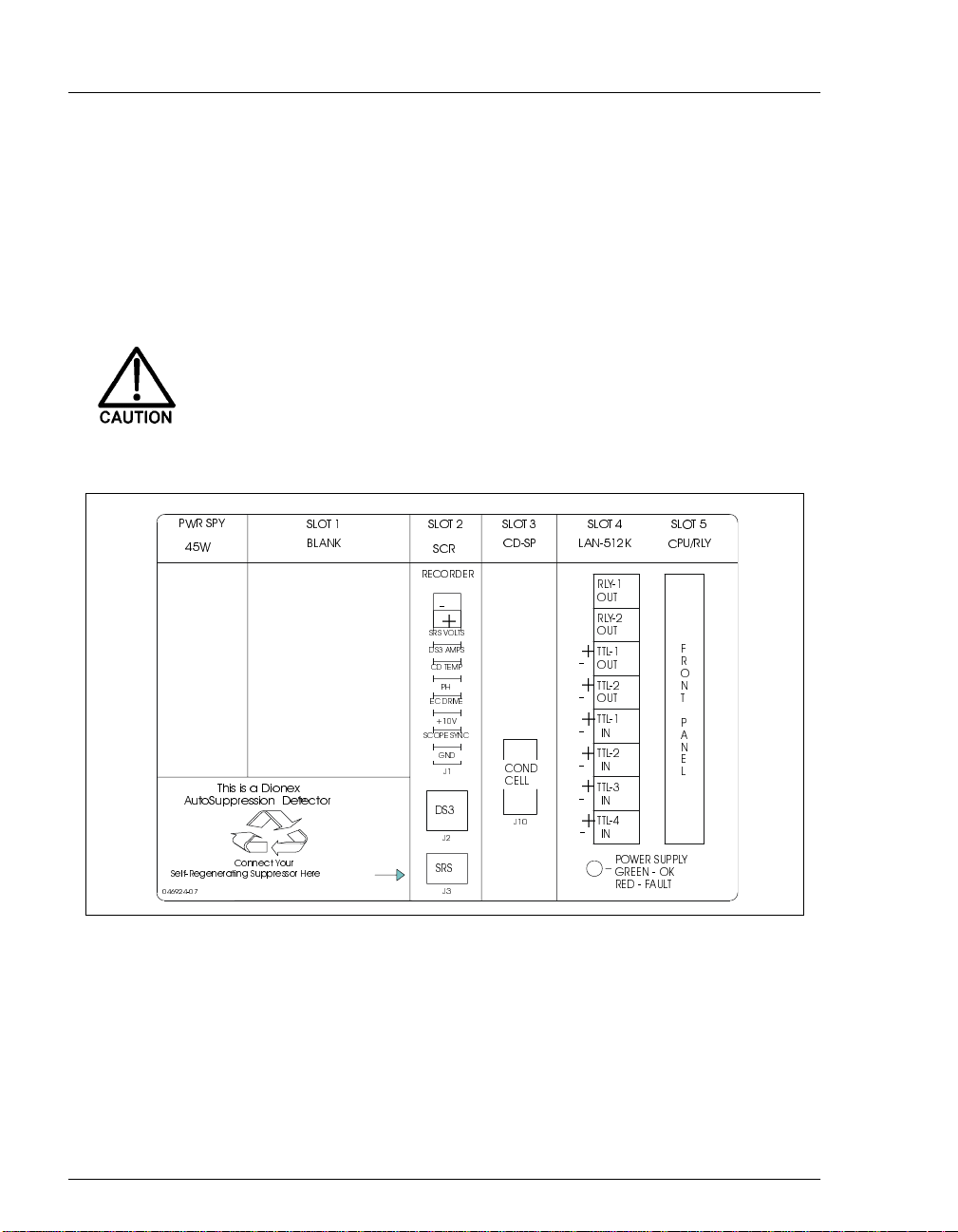

2.2 Electronics Chassis

The electronics chassis is located immediately behind the front door of the CD25 .

The chassis contai ns several el ectronics ca rds (printe d circuit boa rds) that ar e used

to control the CD25. Various connectors on the cards allow communication

between the CD25 and other system modules and accessories. Figure 2-5

identifies the cards and their connectors.

Do not remove any of the electronics card s from the detector.

There are no user-serviceable components on the cards. If

servicing is required, it must be performed by qualified

personnel using appropriate electrostatic discharge (ESD)

handling procedures.

Figure 2-5. CD25 Electronics Chassis Components

#"

!

$

!"

2-8

Doc. 031687-01 04/2000

Page 21

2.2.1 Connectors

Recorder (Slot 2)

This connector is typi cally used for a recorder/integrator or diagnostic

instruments. For a description of the connector pinouts, see Table F-1 in

Appendix F. For connection instructions, see Section B.2.7.

DS3 (Slot 2)

The control cable from the DS3 Detection Stabilizer connects here.

SRS® (Slot 2)

The control cable from the Self-Regener at ing Suppressor® conne ct s her e.

Conductivity Cell (Slot 3)

The conductivity cell cable connects here.

TTL/Relay (Slot 4)

This strip of eight connectors provides an interface with Dionex and nonDionex modules for TTL and relay control of the detector. See

Appendix D for a description of relay and TTL functions and the

connections between the CD25 and other modules.

2 • Description

60-pin Ribbon Connector (Slot 5)

The 60-pin ribbon cable to the CD25 front panel (display and keypad)

connects here.

2.2.2 Cards

Power Supply Card

Provides 45 watts of power for the detector electronics.

Blank Card

Slot 1 contains a blank card that must be present to complete the

electromag netic interference (EMI) shielding.

Doc. 031687-01 04/2000

2-9

Page 22

CD25 Conductivity Detector

SCR (Supply Control/Relay) Card

Interfaces to the CPU; th e card contains three functions:

16-bit Recorder Output Digital-to-Analog Converter

electronic switch for selection of full-scale outputs of 0.01, 0.1, and

1.0 V.

SRS Power Supply

50, 100, 300, or 500 mA to the suppressor. An over-voltage detector

shuts off the power i f the vol tage ex cee ds 8.5 V. An over- temp eratur e

detector shuts off the power if the SRS temperature excee ds 40

either of these events o ccurs, the S CR card sends an “SRS Alarm”

error message to the CPU.

DS3 Power Supply

Stabilizer . While warmi ng or coolin g to a lowe r set poin t, a “BELOW

TEMP” or “ABOVE TEMP” message is displayed. Once a set point

in the range of 25 to 45

maintains a constant temperature .

SP (Signal Processor) Card

—Includes an

—Supplies a regulated current (set by the user) of

°

C. If

—Supplies heating power to the DS3 Detection

°

C is reached, proportional heat control

2-10

Contains all the analog circuitry needed by the CD25, as well as the

digital circuitry required to interface to the CPU. See Appendix E for a

list of SP ca rd functions.

Relay/DX-LAN and CPU Cards

The CD25 control Moduleware and BIOS reside on the CPU card.

The CPU card provides control and monitoring of other modules. A

60-pin ribbon cable assembly links the logic to the CD25 front panel

display a nd keypad .

The Relay I/O card provides two isolated low voltage relay outputs,

two TTL outputs, and four TTL inputs.

The cards are installed in slot 5 of the card cage. The Relay card is a halfcard which rides piggyback on the CPU card and sits behind slot 4.

The Relay I/O card is short enough to allow th e optional detector interface

card (P/N 044196) to be mount ed behi nd it in slot 4. The interface card is

required for communica tion bet ween the CD25 an d PeakNet so ft ware via

the DX-LAN.

Doc. 031687-01 04/2000

Page 23

2 • Description

Power Supply LED

The multicolored LED below the TTL/Relay connections indicates the

power supply status:

A green LED indicates normal operation.

A red LED indicates a fault conditi on. When a fault occurs, th e CD25

enters its diagnostic state and no other control is permitted until the

problem is corrected. Turning off the power for a few seconds may

clear the fault; however, if the red LED is lighted when you turn on

the power again, notify Dionex.

Doc. 031687-01 04/2000

2-11

Page 24

CD25 Conductivity Detector

2.3 Conductivity Cell

The flow-through conductivity cell has an active volume of about 1.0 µL. T wo

316 stainless stee l elect rodes are permanentl y sealed into the PEEK cell bo dy. The

cell constant has a nominal value of 160 cm

sensor located slightly downstream from the electrodes senses the temperature of

liquid passing thro ugh the cell. The me asured value is used to provid e temperature

compensation.

The advanced geometry of the cell provides several benefits:

Excellent accuracy and linearity over the working range

Efficient sweepout and low volume for low dispersion

Reduced sensitivity to electrode surface conditions

Low electrode mass

Effective temperature compensation

You can order the conductivity cell installed in a DS3 Detection Stabilizer

(P/N 044130) for temperature control, or installed in an electrical shield

(P/N 044132) which provides no temperature control. Bec ause th e DS3 maintai ns

a constant temperature, thus reducing the effects of variations in laboratory

temperature, the DS3 is recommended for conductivity detection.

-1

and is calibrated electronically. A

2-12

Temperature Control and Compensation

Temperature directly affects the conductivity of a solution. As conductivity

increases, the effect of temperature changes becomes more pronounced. For

example, building temperature control systems can cause a regular oscillation in

the baseline. This, in turn, can affect the reproducibility of an analysis.

In ion chromatography, suppressing eluent conductivity minimizes the effect of

temperature variation. Temperature compensation further improves baseline

stability. When the conductivity cell is housed in a DS3 Detection Stabilizer, the

DS3 enhances the ability of these techniques to reduce temperature effects below

the detection limit.

Temperature compensation also ensures that th ere will be no major chang e in the

baseline or peak heights, should it be necessary to change the DS3 operating set

°

point. Readings will be normalized to 25

C.

Doc. 031687-01 04/2000

Page 25

2.3.1 DS3 Detection Stabilizer

The DS3 is a temperature-controll ed chamber c onsisting of a cast

aluminum base and cover enclosed in insulating foam. The chamber

houses both the conductivity cell and the eluent heat exchanger.

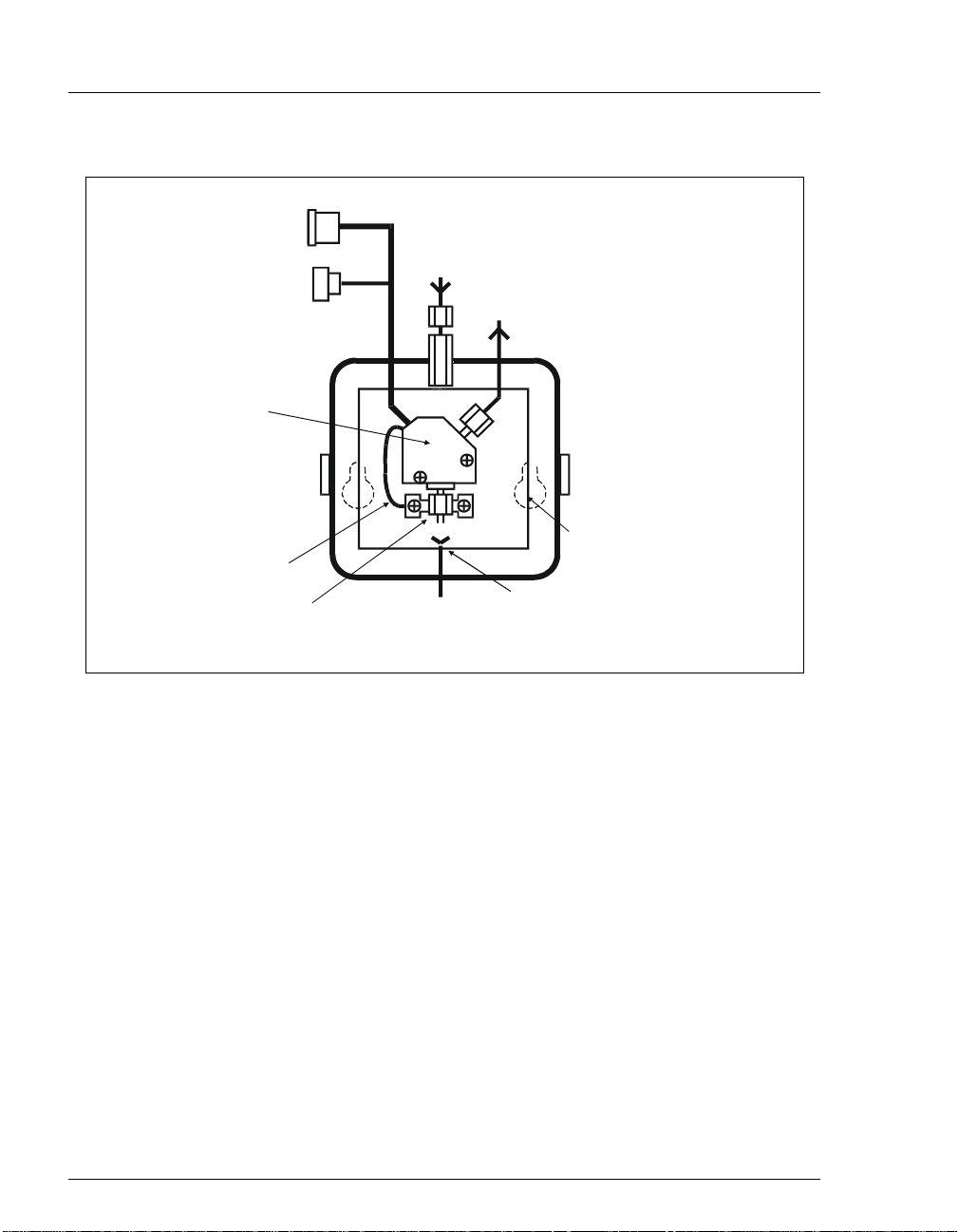

Figure 2-6 identifies the major components of the DS3.

The DS3 provides the following benefits:

Conductivity measurements that are nearly impervious to laboratory

temperature variation

Very low dispersion in the eluent heat exchanger

Excellent peak height reproducibility

Remote mo unting after either the column or suppressor

User-settable temperature

Power input to a pair of trans istors on op posite sid es of the DS3 heat s it to

°

a set temperature from 25

outlet senses the eluent temperature. The CD25 circuitry compares this

temperature with the user-selected temperature and adjusts the heat input

in real time to hold the temperature within a few millidegrees.

C to 45 °C. A sensor near the heat exchanger

2 • Description

The DS3 is sealed with an O-ring to trap eluent that may leak from the

cell. If 5 mL of liquid acc umulates, a thermistor s ensor becomes

immersed and signals a leak to the CPU. Any additional leakage will be

discharged via the spill/overflow line. A second thermistor, above the

discharge level, acts as a temperature re ference for the leak sensor.

Doc. 031687-01 04/2000

2-13

Page 26

CD25 Conductivity Detector

To Detector

Electronic s

Conductivity Cell

Ground Wire

Ce ll Inlet

Figure 2-6. DS3 Detection Stabilizer

2.3.2 Shielded Cell

A conductivity cell installed in an electrical shield (P/N 044132) is

available. The shield is a stainless steel housing that protects the cell from

electromagnetic interference (EMI), but does not provide temperature

control.

DS3

Inle t

DS3

Outlet

Sp ill/Overflo w

Line

DS3

Enclosure

Keyhole Mounting

Slots

2-14

Doc. 031687-01 04/2000

Page 27

2.4 Rear Panel

The CD25 rear panel (see Figure B-1) contains fuses, connectors for line power,

and a connection for the optional DX-LAN interface.

DX-LAN Connection (Optional)

When you order the DX-LAN network, a DX-LAN connector is factory-installed

in the upper left corner of the CD25 r ear panel (see Figure B-1). See Appendix B

for DX-LAN interface connection instructions.

External Connection Access

Connections to the front of the electronics chassis, such as TTL and relay cables,

are usually rout ed to t he back of the d etector through t he cab le chase in the bo ttom

of the electroni cs chass is. The y may also be pass ed throug h slots at the front o f the

detector. Cables exit the CD25 through an opening in the rear panel (see

Figure B-1).

2 • Description

Doc. 031687-01 04/2000

2-15

Page 28

CD25 Conductivity Detector

2.5 Functional Description

2.5.1 Operating and Control Modes

The operating mode determines

how

the CD25 receives operating

commands:

In Local mode, the CD25 receives commands from the front control

panel buttons and screens.

In Locked Remote mode, PeakNet 6 software sends commands from

the host computer via the DX-LAN interface.

The control mode determines

In Direct control, the CD25 executes commands immediately.

In Method control, the CD25 executes commands according to the

when

operating commands are executed.

timed steps in a method. The method is programmed from the CD25

front panel.

The table below summarizes the various operating and control mode

MAIN

configurations. Select the modes from the

Section C.1.2),

DETAIL

screen (see Section C.1.3), or chromatography

screen (see

software.

Operating/Control Mode Detector Operation

Local/Direct Control Commands are entered from the CD25 front control

panel and executed immediately after being entered.

2-16

Local/Method Commands are entered from the CD25 front control

panel and executed by running a method programmed

from the front panel.

Locked Remote/Direct

Control

Commands are sent from PeakNet 6 and executed

immediately when received.

Doc. 031687-01 04/2000

Page 29

2.5.2 Local and Remote Modes

Local Mode

When the CD25 is powered up, it is a lways in Loc al mode. In Loc al mode

the detector accepts operating commands from two sources:

Direct input from the front panel keypad and screens. All operating

functions are available with direct input.

TTL inputs from a remote controller (for example, a Dionex gradient

pump module or an integrator). TTL signals can be used to offset the

recorder, run a method, turn the SRS off and on, send a mark to the

recorder, and increase the recorder range.

Locked Remote Mode

In Locked Remote mode, the CD25 accepts operating commands from a

Dionex data station via the DX-LAN.

In Locked Remote mode, all operating changes from the front panel are

disabled. Selecting the Connect command from PeakNet 6 immediately

selects the Locked Remote mode. To return the CD25 to Local mode,

select the Disconnect command, or turn off the CD25 power.

2 • Description

2.5.3 Method Control

In Method control, commands are executed according to the time-based

steps specified in a metho d. Methods are crea ted, edite d, and saved on the

METHOD

instructions.

METHOD EDIT SAVE TO

TEMP COMP

TIME

INIT

0.00

2.00

Help M essag e

Doc. 031687-01 04/2000

screen (see Figure 2-7). See Section 3.3 for programming

RUN

RANGE

200 uS

v

1.6

OFFSET MARK

**

Figure 2-7. Method Screen

3333

SRS 100DS3 TEMP 40

TTL RLY

1

0

1

25

212

000

1

2-17

Page 30

CD25 Conductivity Detector

The following summarizes basic information about using methods:

The CD25 can run under method control while you are entering or

editing any method (including the one that is currently running).

When saving changes to the currently running method, or switching

to a different method, the method cloc k continue s running unaf fected.

Only those p arameter changes which affect the method after the

current time will be implemented in the current run.

The CD25 can store up to 100 separate methods (0 through 99) in

memory. The actual number, which depends on the size of each

method and the amount of available memory, is typically less than

this.

Methods are retained in memory even after the CD25 is powered

down.

Each method can have a maximum of 32 time-based steps. Step 1

always starts at

0.0.

INIT

(initial conditions). Step 2 always starts at

TIME

=

2-18

Doc. 031687-01 04/2000

Page 31

3 • Operation and Maintenance

3.1 Getting Ready to Run

NOTE The CD25 is designed for use with IC (ion

chromatography) and HPLC (high-performance liquid

chromatography) applications and should not be used

for any other purpose. If there is a question regarding

appropriate usage, contact Dionex before proceeding.

After installing the CD25 Conductivity Detector, or after the power has been off

for some time, use the following check list to ready the detector for operation.

Verify that all cables are correctly connected to the CD25.

Verify that the CD25 power cord is plugged into the main power.

Press the power switch actuator on the CD25 front panel (see Figure 2-1) to

turn on the power. The

diagnostic tests begin running. If the tests are successfully completed, the

MAIN

screen appears after a few seconds. If one or more tests fails, the

DIAGNOSTIC TEST

POWER-UP

screen appears, inst ead.

screen displays briefly and then some

If the conductivity cell is in a DS3 Detec t ion Stabiliz er, set the DS3

temperature from the

guidelines:

If the DS3 is installed in a non-temperature controlled module, for

example, an LC10 Chromatography Organizer or LC20 Chromatography

Enclosure, select a temperature at least 5 °C above the highest expected

ambient temperature surrounding the DS3.

If the DS3 is installed in an LC30 Chromatography Oven, select a

temperature at least 5 °C above th e oven te mperatu re. Do not set t he oven

temperature above 40 °C (104 °F).

Turn on the DS3 power. The DS3 will begin warming up at about

1 °C/minute. Baseline conducti vit y should stabilize once the DS3 reaches the

selected temperature.

Doc. 031687-01 04/2000

DETAIL

screen (see Section C.1.3), according to these

3-1

Page 32

CD25 Conductivity Detector

As soon as the proper current is determined and eluent is flowing through the

Self-Regenerating Suppressor (SRS) at the correct rate, turn on the SRS. (The

SRS power is always off when the CD25 is powered up.) After start-up, the

usual direction of drift is downward as SRS efficiency improves.

While waiting for acceptable drift, you may want to select a lower sensitivity.

Set the offset to 50%.

When you are ready to start a run, select the desired sensitivity and offset (if

you have not already do ne so). Pr ess

Offset

before injection and du ri ng a run,

also, if nec essary.

3.2 Running Under Direct Control (Local Mode)

In the Direct cont rol operat ing mod e, commands a re ca rrie d out immediat ely a fter

they are entered. All detector pa ramete rs remai n in ef fect unti l new comma nds are

entered. Because ther e ar e no ti me- base d st eps, the method clock is not used. The

Hold/Run

and

Reset

buttons are not operable in Direct control.

Select Direct control from the

DIRECT CNTRL

If

is displayed, this mode is already selected and no action is

necessary.

METHOD

If

Select

or

is displayed, move the cursor to

∇

button to toggle to

button to activate the selection.

MAIN

or

DIRECT CNTRL

DETAIL

screen, as follows:

METHOD

. Press

and press the

Enter

or a cursor arrow

Select

∆

3-2

Doc. 031687-01 04/2000

Page 33

3 • Operation and Maintenance

3.3 Running Under Method Contr ol (Local Mode)

In the Method control operating mode, the CD25 is controlled by a series of

programmed timed events, known as a

even after the detector power is turned off.

3.3.1 Running a Method

method

. Methods are retained in memory

1. Go to the

CNTRL

to

2. In the

METHOD

Enter

or a cursor arrow button.

NOTE The method can also be selected from the

MAIN

METHOD

DETAIL

or

screen. If necessary, toggle from

.

field, enter the desired method number and press

METHOD

the

screen. Enter the method number in

RUN

field and press Enter.

DIRECT

3. If the method clock is already running, the method will start as soon

as you enter the method number. If the clock is in Hold, press

Hold/Run

to start the method.

4. The elapsed time on the method clock when the method begins

determines at which step the method begi ns runni ng:

If the method clock is at

running using the

INIT

INIT

or time zero, the method begins

condition parameters, f ollowed by the t ime

zero step. The remaining steps are executed according to their

programmed times.

If the method clock is greater than zero, the method begins

running using the paramete rs speci fi ed in the step for the elapsed

time. To start the method at the

Reset

.

INIT

conditions instead, press

3.3.2 Changing the Running Method

To switch from the method currently running to a different method, enter

the new method number in the

Enter

. The new method will begin running, using the parameters

specified in the step for the current elapsed time. If you prefer to start the

method at the

Doc. 031687-01 04/2000

INIT

conditions, press

RUN

field on the

Reset.

METHOD

screen and press

3-3

Page 34

CD25 Conductivity Detector

3.3.3 Creating a New Method

1. Go to the

METHOD

screen. In the

number from 0 through 99 and press

EDIT

field, enter an

Enter

unused

method

or a cursor arrow button.

This displays a blank method on the screen.

The first step of every meth od is an in itia l condi tions step wi th

TIME

the

TIME

field. The second step is always a time step with 0.00 in the

field. You cannot delete these steps, although you can change

their parameters.

2. Enter the parameters for the initial conditions and time 0.00 steps.

NOTE The

METHOD EDIT SAVE TO

TEMP COMP

TIME

field is the only field in each method step

that must have an entered value. Leaving any other

field blank indicates that the value selected for that

parameter in the preceding step is still in effect.

RUN

3333

1.6

25

SRS 100DS 3 TE M P 40

TTL RLY

TIME

INIT

0.00

2.00

RANGE

200 uS

v

OFFSE T M ARK

**

1

212

0

000

1

1

Help M essage

INIT

in

3-4

Figure 3-1. Method Screen

3. To create a new method step, move the cursor to a blank

TIME

field,

enter the time (in minutes) for the action to be performed, and press

Enter

or a cursor arrow button. Enter a value for each step parameter,

or leave a field blank if you want the value selected in the preceding

step to remain in effect.

4. Repeat Step 3 for each additional step. Up to 30 steps can be added

after the time 0.00 step.

Sometimes a method contains more steps than can be seen on the

v

screen at one time. If there is a small

bottom of the screen, move the cursor

next to the time entry at the

down

to view additional steps.

If there is a caret (^) next to the top tim e entry, move the cursor up to

view additional steps.

Doc. 031687-01 04/2000

Page 35

3 • Operation and Maintenance

5. To save the new method, move the cursor to the

the number that appears in the

3.3.4 Editi n g an Ex is ting Method

NOTE Once you sav e chan ges to a m eth od, t here i s no way

to recall the original method. To make experimental

changes while retainin g th e orig inal me thod , be s u r e

to save the new method, or a copy of the original

method, under a different method number.

Y ou can modify an existi ng method by changing, ad ding, or deletin g steps

and/or parameters. If the method you are editing is currently running, the

changes are stored in memory and implemented when you save the

method.

To edit an existing method, go to the

number in the

Follow the editing instructions in the appropriate section below. When

you finish, save t he cha nges t o the curr ent me thod nu mber or s elect a ne w

number.

Changing Method Parameters

EDIT

field, and press

EDIT

field, and press

METHOD

Enter

screen, enter the method

or a cursor arrow button.

SAVE TO

Enter

field, enter

.

Move the cursor to the desired field and enter a new value, using the

CD25 front panel buttons. Press

editing change.

Adding a Method Step

There are two ways to add a step to an existing method:

Doc. 031687-01 04/2000

Enter

or a cursor arrow button after each

Move the cursor on the

METHOD

screen to any

time and pa rameters for the new step, and press

TIME

field. Enter the

Enter

or a cursor

arrow button. If neces sary , the step will automatical ly be moved to th e

correct chronological point in the method.

Move the cursor on the

preceding the intended location of the new step. Press

METHOD

screen to the line immediately

Insert

to insert

a blank line below the cursor location . Enter the time and parameters

for the new step, and the n press

Enter

or a cursor arrow button.

3-5

Page 36

CD25 Conductivity Detector

Deleting a Method Step

Delete

METHOD

twice.

METHOD

screen to t he time of the step to be

screen to the

EDIT

Move the cursor on the

deleted and press

Deleting an Entire Method

Move the cursor o n the

twice.

Saving a Modified Method

replace

To

of the original method in the

retain

To

the original me th od wi t h a m odi fi ed version, ente r the number

SAVE TO

field and press

the original method an d sa ve t he modi fi ed version elsewhere in

memory, enter an unused method number in the

Enter

.

field and press

Enter

.

SAVE TO

field and press

Delete

3-6

Doc. 031687-01 04/2000

Page 37

3 • Operation and Maintenance

3.4 Optimizing Temperature Compensation

The CD25 built-in temperature compensation stabilizes conductivity readings by

correcting for changes in ambient temperature that occur during a run. For more

information about temperature control and compensation, see Section 2.3.

3.4.1 With a DS3 and Conductivity Cell

If the ambient temperature exceeds 45 °C, the DS3 may be

permanently damaged. If the DS3 is installed in an LC30

Chromatography Oven, do not se t the ov en temp erat ure abo v e

40 °C (104 °F).

Housing the cell in a DS3 Detection S tabilizer ensures that there is no

more than a minor temperature varia tion in liquid re aching th e cell. Thus ,

TEMP COMP

the

setting on the

Many users are able to keep their systems at a single operating

temperature. For optimal accuracy, calibrate the cell at this temperature,

using the proper temperature coefficient setting. If you later reset the

temperature, the CD25 temperature compensation will normalize

conductivity measurements to 25 °C (77 °F) to prevent a major upset in

system calibration. If you change the DS3 set point, recalibrate the cell.

DETAIL

screen can remain at 1.7% per ºC.

If temperature-induced baseline cycling occurs, it is probably caused by

another component of the chromatography system. If the variation

increases as the eluent reservoir empties, move the reservoir to a more

temperature-stable environment and/or wrap the reservoir in thermal

insulation.

Doc. 031687-01 04/2000

3-7

Page 38

CD25 Conductivity Detector

3.4.2 With a Shielded Conductivity Cell

When the conductivity cell is not inside a DS3 Detection Stabilizer, actual

conductivity drifts up and down with fluctuations in laboratory

temperature. This is especially noticeable when the thermostat cycles on

and off in laboratories with very high air turnover rates and controlled

temperature. Selecting the proper temperature compensation factor will

minimize the effect of temperature fluctuations.

Start by setting

TEMP COMP

baseline variation of the same period as the laboratory cooling or heating

occurs, increase or decrease the temperature compensation setting.

Continue adjusting it until you find the optimal setting. This is typically

between 1.5% to 2% per ºC, suppressed or non-suppressed.

If you notice a slowly increasing or decreasing baseline drift in a

laboratory with out a te mperature control system, l ook for a cor responding

temperature drift. If there is a correlation, adjust the temperature

compensation setting until you find the optimal setting.

3.5 Routine Maintenance

This section describes routine maintenance procedures that can be performed by

the user. Any other maintenance procedures must be performed by qualified

Dionex personnel.

NOTE The CD25 electronic components are not customer-

serviceable. Repair of electronic components must be

performed by Dionex.

Periodically check liquid line conne ctions to the cell (inside the

chromatography module) for leaks, and clean up any spills.

on the

DETAIL

screen to 1.7%. If a sinusoidal

3-8

Doc. 031687-01 04/2000

Page 39

This chapter is a guide to troubleshooting problems that may occur while

operating the CD25 Conduc ti vi ty De te ctor. Turn to the section that b est des cr ibe s

the operating problem. There, the possible causes of the problem are listed in

order of probability, along with the recommended courses of action. For

additional help, refer to Appendix C for instructions on running the CD25

diagnostics program.

If you are unable to eliminate a problem, contact Dionex. In the U.S., call 1-800346-6390 and select the Technical Support option. Outside the U.S., call the

nearest Dionex office.

4.1 No Detector Response

Cell is off

4 • Troubleshooting

Turn on the cell (from the

Analog output range set too high; although the display indicates a

response, no recorder response observed

Select a more sensitive analog output range.

Wrong full-scale output (or no full-scal e output) selected

Select 0.01, 0.10, or 1 volt full-scale.

No flow from pump

Check the pressure reading on the pump to verify that the pump is on.

Detector o f fset out of range

Offset

Press

on the CD25 front panel.

MAIN

or

DETAIL

screen).

Doc. 031687-01 04/2000

4-1

Page 40

CD25 Conductivity Detector

4.2 Low Detector Output

Analog output range set too high; although the display indicates a

response, no recorder response observed

Select a more sensitive analog output range.

Insufficient sample injected

Increase the injection size or concentration.

Cell out of ca libration

Recalibrate the cell (see Section 5.4).

4.3 High Detector Output

Auto offset not activated recently

Offset

Press

Background not suppressed by SRS

Check the SRS regenerant out line for bubbles; if there are no bubbles, the

suppressor may be contaminated. Refer to the SRS manual for

troubleshooting guidanc e.

on the CD25 front panel before making an injection.

4.4 Noisy or Drifting Baseline

Flow system leak ahead of cell; erratic baseline

Check all fittings and liquid lines for leaks. Tighten or, if necessary, replace

all liquid line connections. If the connections are made with ferrule fittings,

Installation of Dionex Ferrule Fittings

4-2

first refer to

requirements.

Pump not properly primed

Prime the pump as instructed in the pump manual.

Rapid changes in ambient temperature

Redirect heating and air conditioning vents away from the cell.

Purchase a cell in a DS3 Detection Stabilizer (P/N 044130).

When using a shielded cell, install the cell in a chromatography oven.

for tightening

Doc. 031687-01 04/2000

Page 41

4 • Troubleshooting

Insufficient system equilibration following any changes to operating

parameters; especially apparent when operating at high sensitivities

Allow longer system equilibration before beginning operation.

Air trapped in cell; excessive regular pulses in baseline

Remove the trapped air (see Section 5.2). To prevent air fro m becoming

trapped in the cell in the future, increase backpressure on the cell by reducing

the inner diameter of the tubing installed after the cell and before the SRS.

Inappropriate SRS operating conditions

Refer to the SRS manual for the correct operating conditions.

Temperature compensation setting not optimized

Optimize the selected setting (see Section 3.4).

DS3 above or below set point

See Section 4.6.

Doc. 031687-01 04/2000

4-3

Page 42

CD25 Conductivity Detector

4.5 Liquid Leaks from the DS3

When a leak is detected, the DS3 leak sensor signals the CPU. If more than 5 mL

of liquid accumu lat es i n t h e DS3, the excess will be dr ained via the spill overflow

line (see Figure 2-6).

Loose or defective fittings, or overpressurization caused by a restriction

Check the waste line for blockage; a trapped particle can plug the line,

causing a restri ction and/or lea k. If necessar y , c lear the waste line by rever sing

the direction of flow.

Make sure the plumbing downst r eam f rom t he DS3 is clear; a blockage in the

plumbing may overpressurize the DS3, causing it to leak.

Make sure the downstream backpressure coils are appropriate for the

operating flow rate (see Section B.2.4).

Follow the steps below to disassemble the DS3 and inspect it for the source of

the leak. Test and dry the DS3 before reassembly.

1. Turn of f the CD25 power.

2. Disconnect the DS3 cables.

3. Disconnect the DS3 inlet and outlet lines. Do not misplace the ferrule

fittings at the end of the tubing (see Figure 4-1).

4. Remove the DS3 by lifting it upward and then pulling it away from its

mounting location. Place the DS3 on the workbench.

5. Open both latches on the DS3 and carefully lift off the top half of the

cover, along with its insulating foam insert, exposing an aluminum box

(see Figure 4-1).

6. Remove the box from the bottom half of the cover.

7. Remove the four Phillips screws securing the top of the box to its bottom

plate. Carefully separ at e t he t wo par ts , expos in g the cel l ( see Figure 4-2).

Lay the top aside, being careful not to pull or stress the group of wires that

connect the two parts.

8. Check the inlet and outlet cell fittings for leaks. Tighten or replace if

necessary.

9. Dry the DS3, test for leaks, and reassemble. Make sure the foam insert is

adjusted evenly aroun d the vari ous DS3 component s, with no pin ching or

4-4

Doc. 031687-01 04/2000

Page 43

Bo tto m

Cover

4 • Troubleshooting

folding. Check that the top and bottom inserts meet on all sides before

latching the cover.

Ins u la t in g

Cables

Foam

Ins e rt

Aluminum

Box

Inle t

Outlet

Ph illips

Screws (4)

Sp ill Ov e rf lo w

Line

Figure 4-1. DS3 Exploded View

Inle t

Grounding Strap

Outlet

Cell

Outlet

Fitting

Inle t

Fitting

Figure 4-2. DS3 Interior Components

Top

Cover

Ph illi p s

Screws

Doc. 031687-01 04/2000

4-5

Page 44

CD25 Conductivity Detector

Liquid seeping from around cell cables

The cell is inoperable; return it to Dionex for repair or exchange.

4.6 DS3 Temperature Inaccurate

“DS3 SET POINT XX C READY” message displays continuously

The control sensor may be faulty. Remove the DS3 cover and measure the

temperature of the housing, using any surface thermometer. The cell sensor

can be read on the detecto r and should be wi thin 1 or 2 de gre es of the DS3 set

point tempe r ature.

“DS3 SET POINT XX C UNDER TMP” or “DS3 SET POINT XX C

OVER TMP” message displays continuously

Verify that the set temperature is at least 5 °C above the external DS3

temperature. Allow 30 to 60 minutes for the DS3 to heat or cool.

At high flow rates and temperature settings far above ambient, the DS3

requires more time to heat. In extreme cases, such as a very cold room and a

high DS3 set point, the DS3 may not be able to reach the set point

temperature.

4-6

DS3 does not heat

Remove the cover and inspect the DS3 for broken or shorted wires or for

moisture bridging the control thermistor. If a wire is broken or shorted,

replace the wire or call Dionex for assistance. If a leak has caused a short, fix

the leak and dry the control sensor.

“DS3 SET POINT XX C READY” message displays intermittently

Make sure that the heater transistors are snug and the control sensor has not

been pulled out of the heat exchanger plate.

Doc. 031687-01 04/2000

Page 45

4.7 Conductivity Inaccurate

4 • Troubleshooting

Cell constant reported on

calibration is not 130 to 190 µS

The DS3 has not reached its set point temperature. Set the intended operating

temperature and wait until 5 minutes after the “NOT READY” message is

displayed, or until the reading is stable.

Make sure the selected temperature compensation setting is 1.7%/°C. Except

at 25 °C, an incorrect temperature co mpensation set ting can caus e an incorrec t

reading.

The 1 mM KCl calibration solution is spoiled, or there was a mixing error.

Remake the solution.

The electrodes are fouled by grease, precipitate, etc. Flush with a suitable

solvent, such as acid, and then flush with 1 mM KCl until the reading is

stable.

The cause is internal leaks, broken or shorted cell or sensor wires. Check the

sensor by comparing the cell temperature readout with the actual DS3

temperature. If necessary, return the cell to Dionex for repair.

disassemble the cell; this will break the seal and v oid your warranty.

Cell temperature readout deviates by more than 2°C from DS3 set

temperature

This indicates a serious cell or DS3 sensor problem. Call Dionex for

assistance.

CONDUCTIVITY CALIBRATION

screen after cell

Do not

4.8 Faulty DX-LAN Communication

DX-LAN interface incorrectly install ed

See Section B.2.2 for 10BASE-T connection inst ructions or Section B.2.3 for

BNC connection instructions.

Doc. 031687-01 04/2000

4-7

Page 46

CD25 Conductivity Detector

4.9 Diagnostics

NOTE The CD25 electronic components are not customer-

serviceable. Before running a diagnostic test, use the

troubleshooting information in earlier sections of

Chapter 4 to isolate problems that are unrelated to the

CD25 electronics.

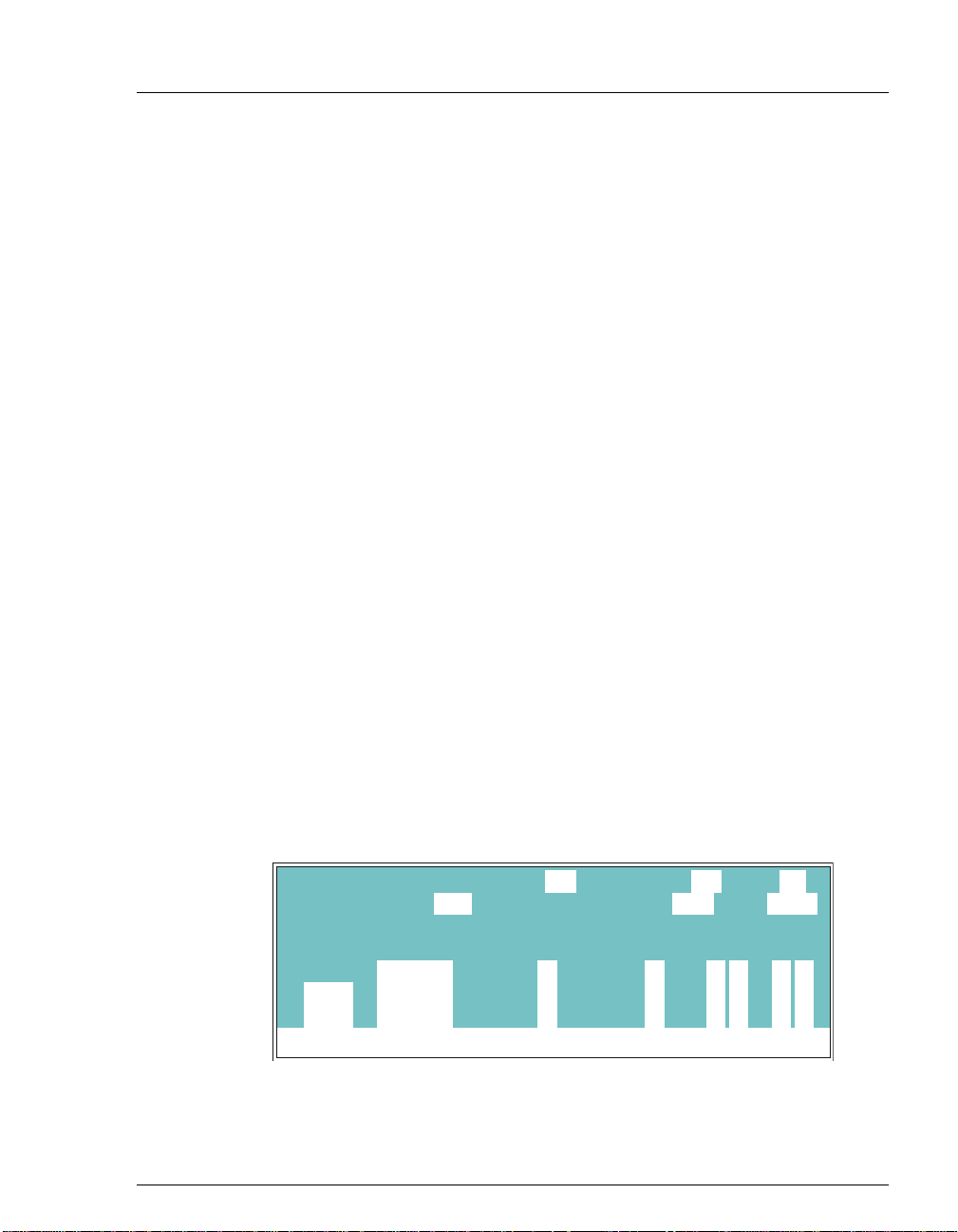

The CD25 Moduleware includes several diagnostic tests of the electronics. To

access these, select the

diagnostic screens are illustrated and described in Appendix C.

DIAGNOSTIC MENU

from the

DIAG NOSTIC MENU

MENU of SCREENS

. The

POWER-UP SCREEN

1

ELAPSED TIME

2

ANALOG STATUS

3

-

4

DX LAN STATUS

5

KEYBOARD TEST

Help M essag e

Figure 4-3. Diagnostic Menu Screen

6

DIAG NOSTIC TESTS

LEAK CAL & STATUS

7

8

SIGNAL STATISTICS

9

CALIBRATE CD CELL

10

4-8

Doc. 031687-01 04/2000

Page 47

5 • Service

This chapter describes routine service procedures that the user can perform. All

other procedures must be performed by Dionex personnel.

NOTE The CD25 electronics components are not customer-

serviceable. Repair of electronics components must be

performed by Dionex.

The CPU card contains a lithium battery. If the CPU card is

replaced, dispose of the used battery according to the

manufacturer's instructions.

Before replacing any parts, refer to th e troubleshooting information in Ch apter 4

to isolate the cause of the problem. To contact Dionex in the U.S., call 1-800-3466390 and select the Technical Support option. Outside the U.S., call the nearest

Dionex office.

Substituting non-Dionex parts may impair CD25 performance, thereby voiding

the product warranty. Refer to the warranty statement in the Dionex Terms and

Conditions for more information.

Doc. 031687-01 04/2000

5-1

Page 48

CD25 Conductivity Detector

5.1 Eliminating Liquid Leaks

The PEEK version of the CD25 is plumbed with 1.60-mm (1/16-in) OD PEEK

tubing, Dionex ferrule fittings (P/N 043276), and 10-32 fitting bolts (P/N

043275). For tightening requirements, refer to

Fittings

.

Installation of Dionex Ferrule

5.2 Removing Trapped Air from the Cell

Air bubbles in the cell can cause regular pulsations of the baseline, random

noise, and low r eadings. Ai r may have bee n intr oduced in the columns d uring

installation, or ma y result from outgassing of the mobi le phase. Connecting a

backpressure line to the cell applies enough backpressure to shrink bubbles,

thereby allow ing them to pass more easily through the cell.

1. Connect a piece of 0.25-mm (0.010-in) ID tubing (P/N 042690), with fittings

on both ends, to the cell outlet. Make the line 1 m long for a flow rate of

1.0 mL/min, 2 m for 0.5 mL/min, etc.

2. Use tubing with an inn er diameter of at least 1mm (0.04 in) t he rest of the way

to the waste containe r. Use a union (P/N 042627) to connect the backpres sur e

line to the w aste line.

Make sure the a dded backpres sure does not exceed 0.20 MPa

(30 psi). Avoid large increases in flow rate tha t would result in

more than 1.4 MPa (200 psi) being applied to the cell.

5.3 Replacing the DS3 Cell

Follow the steps below to disassemble the DS3 and replace the cell. After

replacing the cell you must recalibrate it (see Section 5.4).

1. Turn of f the CD25 power.

2. Disconnect the DS3 cables.

3. Disconnect the DS3 inlet and outlet lines. Do not misplace the ferrule fittings

at the end of the tubing (see Figure 5-1).

4. Remove the DS3 by lifting it upward and then pulling it away from its

mounting location. Place the DS3 on the workbench.

5-2

Doc. 031687-01 04/2000

Page 49

5 • Service

5. Open both latches on the DS3 and carefully lift off the top half of the cover,

along with its insulating foam insert, exposing an aluminum box (see

Figure 4-1).

6. Remove the box from the bottom half of the cover.

7. Remove the four Phil lips screws securing the top of the box to its bottom

plate. Carefully sep arate the two par ts, exp osing t he cel l (see Figure 5-1). Lay

the top aside, bein g careful not to pull or stres s the grou p of wires t hat connec t

the two parts .

8. Disconnect the grounding strap. Remove the two cell mounting screws.

9. Rotate the cell inlet tube fitting counterclockwise. Let the cell body back

away from the fitting until the fitting threads are fully disengaged.

the ferrule

.

10. Check that the end of the inner Tefzel tubing is flush with the end of the

plastic sleeve. If nec essary, trim the sleeve slightly to prevent dis persion. Push

the tubing into the new cell until it bottoms out in the hole; then, hold the

tubing in place while tightening the nut.

11. After testing for liquid leaks, dry the DS3 and reassemble. Make sure the

foam insert is adjusted evenly around the various components, with no

pinching or folding. Before latching the cover, make sure the top and bottom

inserts meet on all sides.

Do not lose

12. Reconnect the DS3 cables and turn on the CD25 power. Calibrate the cell

constant (s ee Section 5.4).

Doc. 031687-01 04/2000

Inle t

Grounding Strap

Figure 5-1. DS3 Interior Components

Outlet

Cell

Outlet

Fitting

Inle t

Fitting

Ph illi p s

Screws

5-3

Page 50

CD25 Conductivity Detector

5.4 Calibrating the Cell

Every conductivity cell is calibr ated be fore it is shi pped from the fa ctory. The cell

calibration constant is recorded on a tag attached to the cell cable, and is also

stored in permanent detector memory for use when calculating the measured

conductivity.

The calibration const ant normal ly rema ins uncha nged, unl ess the cell i s damaged.

To check the value entered in memory, select

DIAGNOSTIC MENU

cell calibration constant shown on the screen does not match the value recorded

on the tag, do

Enter a new value, regardless of the composition of the solution in the cell.

Calibrate the cell at 147.00 µS/cm. This automatically enters a new value for

the cell calibration constant into CD25 memory.

To calibrate the cell, follow the steps below.

1. Disconnect the pump output line from the injection valve.

2. Connect the pump output directly to the inlet of the DS3 or the shielded cell.

to display the

one

of the following:

CALIBRATE CD CELL

CALIBRATE CONDUCTIVITY CELL

from the

screen. If the

3. Pump 0.001 M KCl calibration solution through the cell. Conductivity is

slightly flow-rate sensitive , so select t he flow rate used in the majority of your

applications.

4. Set

TEMP COMP

on the

5. If using a DS3, set

DETAIL

DS3 SETPOINT

screen to 1.7%.

on the

DETAIL

screen to the intended

operating point. Wait until the “DS3 READY” message appears.

6. Wait until the conductivity reading st abili zes ( within 0 .1 µS), and then, on the

CALIBRATE CONDUCTIVITY CELL

screen, select

CAL

and press

Enter

to

calibrate the cell.

7. After calibration, t he conducti vity rea ding should b e exactly 14 7.00 µS/cm. A

new value for the cell constant will be shown on the

CONDUCTIVITY CELL

screen; thi s value will al so be entered in memory.

CALIBRATE

8. Flush the KCl solution from the system by pumping deionized water through

the DS3 or cell lines. When the conductivity reading drops to near zero, stop

the pump.

9. Disconnect the pump from the DS3 or shielded cell.

5-4

Doc. 031687-01 04/2000

Page 51

5 • Service

10. Reconnect the pump to the chromatography module.

11. Reconnect the liquid line from the suppressor outlet to the cell inlet.

12. Reset

TEMP COMP

to the optima l value for the eluent.

13. S et the pump to a flow rate that is safe for the system in use.

Doc. 031687-01 04/2000

5-5

Page 52

CD25 Conductivity Detector

5.5 Replacing the Main Power Fuses

The fuse holder is in the main power receptacle on the CD25 rear panel.

1. Turn of f the main power.

HIGH VOLTAGE—Disconnect the main power cord from its

source and also from the rear panel of the CD25.

2. A recessed lock is located on each side of the fuse holder (see Figure 5-2).

Using a small screwdriver, push each lock toward the center to rel eas e it . The

fuse holder pops out approximately slightly when the locks release. When

both locks are released, pull the fuse holder straight out of its compartment.

3. The holder contains two fuses. Replace both with new 3.15 amp fast-blow

IEC127 fuses (P/N 954745). Dionex recommends replacing both fuses even

though only one is open.

4. Reinsert the fuse holder into its compartment. The fuse holder is keyed to fit

only in its proper orientation. Apply sufficient pressure evenly against the

holder to engage the two locks. The holder is flush against the panel when

both locks are engaged.

5-6

5. Reconnect the main power cord and turn on the power.

Locking Spring

Fuse Holder

Insert screwdriver

and twist to release

(each side)

M a in Po we r

Receptacle

Figure 5-2. Main Power Fuse Holder

Fuses (2)

Key

Fuse Holder

(side vie w )

Doc. 031687-01 04/2000

Page 53

5.6 Physical

A • Specifications

Dimensions

Weight

Decibel Level

A.1 Environmental

Operating

Temperature

Operating

Humidity

A.2 Electrical

Main Power

Fuses

22.5 cm W x 17.0 cm H x 42.0 cm D

(8.8 in W x 6.6 in H x 16.4 in D)

6 cm (2.4 in) clearance required behind the detector

8.2 kg (18 lb)

50 db (“A WEIGHING” setting)

4 ºC to 40 ºC (40 ºF to 104 ºF)

5 to 95% relative humidity, non-condensing

85 to 270 Vac, 47/63 Hz; 40 W Max, 25 W typical. The CD25

power supply is auto-sensing and requires no voltage

adjustment.

Two 3.15 amp fast-blow IEC127 fuses (P/N 954745)

Analog Ou tput

Doc. 031687-01 04/2000

User-selectable full-scale output of 10, 100, or 1000 mV

A-1

Page 54

CD25 Conductivity Detector

A.3 Display and Keypad

Display

Keypad

Liquid crystal display with adjustable backlighting

26-button keypad for entering commands and numerical values

for screen parameters

A.4 Detector

Range

Temperature

Compensation

Cell Drive

Local Operation

Remote

Operation

DX-LAN

Operation

(Optional)

0.01 µS to 3000 µS, full-scale

0.0 to 3.0% per ºC

Variable 8 kHz square wave

Front panel controls and display status of all functions

Control of four functions via TTL or Relay contacts

All functions can be controlled by PeakNet software on a PC

connected to the CD25 via the DX-LAN interface

A.5 Conductivity Cell

A-2

Cell Body

Active Volume

Maximum

Pressure

Electrodes

PEEK

1.0 µL

2.0 MPa (300 psi)

316 stainless steel

Doc. 031687-01 04/2000

Page 55

A.6 SRS Power Supply

A • Specifications

Supply Current

Over-Voltage

Alarm

Over-

Temperature

Alarm

50, 100, 300, 500 mA at 1.5 to 7.5 V

8.5 V

40 ºC (104 ºF)

A.7 DS3 Detection Stabilizer (Optional)

Operating

Temperature

Warm-up Time

Temperature

Alarms

25 ºC to 40 ºC (50 ºF to 104 ºF)

10 minutes (typical)

Not Ready

temperature

message displayed when under or over the set

Doc. 031687-01 04/2000

A-3

Page 56

CD25 Conductivity Detector

A-4

Doc. 031687-01 04/2000

Page 57

B.1 Facility Requirements

Make sure the CD25 installation site meets the el ectrical and environmental

specifications listed in Appendix A.

Install the CD25 on a sturdy table or workbench, at a height that ensures

convenient viewing of the front panel display.

Allow at least 6 cm (2.4 in) clear ance behind the CD25 for power con nections

and ventilation.

B.2 Installation