Page 1

AS-HV Autosampler

Operator's Manual

Document No. 065125

Revision 01

October 2006

Page 2

© 2006 by Dionex Corporation

All rights reserved worldwide.

Printed in the United States of America.

This publication is protected by federal copyright law. No part of this publication

may be copied or distributed, transmitte d, tr anscribed, stored in a retrieval system, or

transmitted into any human or computer language, in any form or by any means,

electronic, mechanical, magnetic, manual, or otherwise, or disclosed to third parties

without the express written permission of Dione x Corporation , 1228 Titan Way,

Sunnyvale, California 94088-3603 U.S.A.

DISCLAIMER OF WARRANTY AND LIMITED WARRANTY

THIS PUBLICATION IS PROVIDED “AS IS” WITHOUT WARRANTY OF

ANY KIND. DIONEX CORPORATION DOES NOT WARRANT,

GUARANTEE, OR MAKE ANY EXPRESS OR IMPLIED

REPRESENTATIONS REGARDING THE USE, OR THE RESULTS OF T HE

USE, OF THIS PUBLICA TION IN TERMS OF CORRECTNESS, ACCURACY,

RELIABILITY, CURRENTNESS, OR OTHERWISE. FURTHER, DIONEX

CORPORATION RESERVES THE RIGHT TO REVISE THIS PUBLICATION

AND TO MAKE CHANGES FROM TIME TO TIME IN THE CONTENT

HEREINOF WITHOUT OBLIGATION OF DIONEX CORPORATION TO

NOTIFY ANY PERSON OR ORGANIZATION OF SUCH REVISION OR

CHANGES.

TRADEMARKS

Chromeleon® is a registered trademark of Di onex Corporation. Self-Regenerating

Suppressor™ and SRS™ are trademarks of Dionex Corporation.

MASTERFLEX® C/L® is a registered trademark of Barnant Company.

Microsoft® Windows® XP and Windows® 2000 are registered trademarks of

Microsoft Corporation.

Nalgene® is a registered trademark of Nalge Nunc International.

PEEK™ is a trademark of Victrex PLC.

Plexiglas® is a registered trademark of Rohm & Haas Company.

Santoprene® is a registered trademark of Advanced Elastomer Systems, L.P.

Tefzel® is a registered trademark of E.I. duPont de Nemours & Company.

PRINTING HISTORY

Revision 01, October 2006

Page 3

1 • Introduction

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.1 Safety Messages and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2•Description

2.1 AS-HV Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 AS-HV Side Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Sample Loading Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.4 Sample Loading Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Contents

2.4.1 Syringe Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.4.2 AXP Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.4.3 External Peristaltic Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.4.4 Internal Peristaltic Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.4.5 Relay-Controlled Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.5 Chromeleon Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Doc. 065125-01 10/06 i

Page 4

AS-HV Operator’s Manual

3 • Operation and Maintenance

3.1 Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

3.2 Getting Ready to Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

3.2.1 Filling Sample Containers and Loading the Racks . . . . . . . . . .22

3.2.2 Turning On the Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

3.2.3 Selecting the Rinse Pump Speed . . . . . . . . . . . . . . . . . . . . . . . .24

3.2.4 Creating a Chromeleon Program . . . . . . . . . . . . . . . . . . . . . . . .25

3.3 Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

3.3.1 Daily Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

3.3.2 Weekly Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

3.3.3 Monthly Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

3.3.4 Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

4 • Troubleshooting

4.1 Liquid Leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

4.1.1 Leaking Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

4.1.2 Leaking Syringe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

4.1.3 Leaking Waste Line (Fixed Rinse Reservoir) . . . . . . . . . . . . . .40

4.2 Sampling Arm Jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

4.3 Initialization Sequence Fails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

4.4 Power LED Fails to Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

4.5 CPU Activity LED Fails to Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

4.6 Power Supply Fails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

4.7 Cavitation in the Syringe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

ii Doc. 065125-01 10/06

Page 5

5•Service

5.1 Cleaning the Syringe Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.2 Replacing the Sample Syringe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.2.1 Removing the Existing Syringe . . . . . . . . . . . . . . . . . . . . . . . . 48

5.2.2 Filling the New Syringe and Removing Bubbles . . . . . . . . . . . 49

5.2.3 Installing the New Syringe . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.2.4 Initializing the New Syringe . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.3 Replacing the Sampling Needle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.3.1 Removing the Existing Sampling Needle . . . . . . . . . . . . . . . . 52

5.3.2 Installing the New Sampling Needle . . . . . . . . . . . . . . . . . . . . 53

5.4 Replacing the Syringe Pump Distribution Valve . . . . . . . . . . . . . . . . . 55

5.4.1 Removing the Existing Valve . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Contents

5.4.2 Installing the New Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.5 Replacing the Main Power Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

A • Specifications

A.1 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

A.2 Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

A.3 Physical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

A.4 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Doc. 065125-01 10/06 iii

Page 6

AS-HV Operator’s Manual

B • Installation

B.1 Facility Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

B.2 Unpacking the AS-HV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

B.3 Installing the AS-HV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

B.3.1 Installing the Spill Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

B.3.2 Installing the Rack Location Mat. . . . . . . . . . . . . . . . . . . . . . . .63

B.3.3 Installing the Fixed Rinse Reservoir . . . . . . . . . . . . . . . . . . . . .64

B.3.4 Connecting the Rinse Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . .65

B.3.5 Installing the Standards Rack. . . . . . . . . . . . . . . . . . . . . . . . . . .66

B.3.6 Installing the Sample Rack. . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

B.3.7 Installing the Trace Analysis Cover (Optional) . . . . . . . . . . . . . 67

B.3.8 Installing the Sampling Needle . . . . . . . . . . . . . . . . . . . . . . . . .68

B.3.9 Connecting the Syringe Pump (Optional) . . . . . . . . . . . . . . . . .71

B.3.10 Connecting the AXP Pump (Optional). . . . . . . . . . . . . . . . . . . .73

B.3.11 Connecting the External Peristaltic Pump (Optional) . . . . . . . .75

B.3.12 Connecting the Internal Peristaltic Pump (Optional) . . . . . . . . .77

B.3.13 Connecting a Relay-Controlled Pump (Optional) . . . . . . . . . . .77

B.3.14 Connecting the AS-HV to the Chromeleon PC . . . . . . . . . . . . .78

B.3.15 Connecting the Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

B.3.16 Configuring the AS-HV in Chromeleon. . . . . . . . . . . . . . . . . . .80

B.3.17 Removing Bubbles from the Syringe. . . . . . . . . . . . . . . . . . . . .82

iv Doc. 065125-01 10/06

Page 7

C • Error Messages and Codes

C.1 Audit Trail Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

C.2 AS-HV ERROR Indicator Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

D • Reordering Information

Contents

Doc. 065125-01 10/06 v

Page 8

AS-HV Operator’s Manual

vi Doc. 065125-01 10/06

Page 9

1.1 Overview

The Dionex AS-HV Autosampler is a random access robotic device that can be

commanded to execute a series of liquid handling steps. The AS-HV can hold up

to 250 mL of sample and, through the use of a sample loading pump, deliver

sample to an ion chromatography (IC) system or other analyzer. Sample loading

pump options include a syringe pump, piston pump, or peristaltic pump (for

details, refer to Section 2.4

The AS-HV is designed to accommodate a variety of accessories, including a

sample rack, a standards rack, and a rinse reservoir. The standard configuration

for the AS-HV includes the following components:

• A 24-position sample rack that accommodates 250 mL Nunclon sample flasks

• An 11-position standards rack for loading of standards and/or samples

• A PEEK™ sampling needle for aspirating sample from sample containers

• A sampling needle guide that prevents the PEEK sampling needle from

bending or flexing as it pierces a septum

1 • Introduction

).

• A rack location mat that houses the sample rack and ensures alignment of the

sampling needle over each vial

• A built-in rinse station (consisting of a peristaltic pump and a 150 mm

reservoir that circulates rinse fluid) that can be used to clean the sampling

needle between samples

• A spill tray for secondary containment of samples

• An RS-232 cable for communication with a PC (personal computer)

The AS-HV is usually controlled remotely from a PC running Microsoft®

Windows® XP or Windows® 2000 operating system and Dionex Chromeleon

Chromatography Management System software. The AS-HV communicates with

the PC via the RS-232 interface. Limited remote control is also available, using

relay signals.

Doc. 065125-01 10/06 1

®

Page 10

AS-HV Operator’s Manual

1.2 About This Manual

Chapter 1

Introduction

Chapter 2

Description

Chapter 3

Operation and

Maintenance

Chapter 4

Troubleshooting

Chapter 5

Service

Appendix A

Specifications

An overview of the AS-HV; includes a brief description of

the standard AS-HV configuration and the software

required for operation. An explanation of the conventions

used in this manual (including safety-related information).

Descriptions of physical aspects of the AS-HV, including

mechanical components and the LEDs, controls and

connectors on the side panel; an explanation of sample

loading modes; and an introduction to Chromeleon

software.

Procedures to complete before beginning operation,

instructions for creating Chromeleon programs for AS-HV

control, and routine preventive maintenance requirements.

Minor problems that may occur during operation, with

step-by-step procedures for how to isolate and eliminate

the cause of each problem.

Step-by-step instructions for routine service and parts

replacement procedures for the AS-HV.

Specifications and installation site requirements for the

AS-HV.

Appendix B

Installation

Appendix C

Error Messages

and Codes

Appendix D

Reordering

Information

2 Doc. 065125-01 10/06

Installation instructions for the AS-HV.

Chromeleon Audit Trail error messages and AS-HV

ERROR indicator codes, along with an explanation of the

possible cause of each problem and the corrective action to

take.

Spare parts for the AS-HV.

Page 11

1.2.1 Safety Messages and Notes

This manual contains warnings and precautionary statements that can

prevent personal injury and/or damage to the AS-HV when properly

followed. Safety messages appear in bold type and are accompanied by

icons, as shown below.

Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

Indicates that the function or process of the instrument may be

impaired. Operation does not constitute a hazard.

1 • Introduction

Messages d’avertissement en français

Signale une situation de danger immédiat qui, si elle n'est pas évitée,

entraînera des blessures graves à mortelles.

Signale une situation de danger potentiel qui, si elle n'est pas évitée,

pourrait entraîner des blessures graves à mortelles.

Signale une situation de danger potentiel qui, si elle n'est pas évitée,

pourrait entraîner des blessures mineures à modérées. Également

utilisé pour signaler une situation ou une pratique qui pourrait

gravement endommager l'instrument mais qui n'entraînera pas de

blessures.

Warnhinweise in Deutsch

Bedeutet unmittelbare Gefahr. Mißachtung kann zum Tod oder

schwerwiegenden Verletzungen führen.

Doc. 065125-01 10/06 3

Page 12

AS-HV Operator’s Manual

Bedeutet eine mögliche Gefährdung. Mißachtung kann zum Tod oder

schwerwiegenden Ve rletzungen führen.

Bedeutet eine mögliche Gefährdung. Mißachtung kann zu kleineren

oder mittelschweren Verletzungen führen. Wird auch verwendet, wenn

eine Situation zu schweren Schäden am Gerät führen kann, jedoch

keine Verletzungsgefahr besteht.

Informational messages also appear throughout this manual. These are

labeled NOTE and are in bold type:

NOTE NOTES call attention to certain information. They alert

the user to an unexpected result of an action, suggest

how to optimize instrument performance, etc.

1.3 Safety Labels

The TUV GS and cTUVus Mark safety labels and the CE Mark label on the ASHV indicate that the AS-HV is in compliance with the following standards and

directives: EN 61010-1:2001 (safety), CAN/CSA-C22.2 No. 61010-1:2004

(safety), UL 61010-1:2004 (safety), EN 61326 1997 + A1:1998 + A2:2001

(EMC), Low-Voltage Equipment Directive 73/23/EEC, and EMC Directive

89/336/EEC.

These symbols appear on the AS-HV or on AS-HV labels:

Alternating current

˜

Protective conductor terminal

Power supply is on

Indicates a potential hazard. Refer to the operator’s manual for

an explanation of the hazard and how to proceed.

4 Doc. 065125-01 10/06

Page 13

2.1 AS-HV Overview

Figure 2-1 is an overview of the main features of the AS-HV Autosampler.

Power

LED

Sampling Needle

Sampling Needle

Guide

Rinse Pump

Speed Knob

Rinse Pump

2 • Description

Sampling Arm

Support

Sampling Arm

Standards Rack

Nunclon Sample

Flasks

Fixed Rinse

Reservoir

Sample Rack

Rack Location Mat

Base Support Tube

Figure 2-1. AS-HV Autosampler

Doc. 065125-01 10/06 5

Page 14

AS-HV Operator’s Manual

Power LED

The power LED lights when power to the AS-HV is turned on, and should remain

lit as long as the main power supply is operational. If the LED fails to light when

the power is turned on, refer to Section 4.4

NOTE The power switch is located on the AS-HV side panel

(see Section 2.2

Sample Rack

The sample rack houses the sample containers. The AS-HV is shipped with a 24position sample rack (P/N 064233) designed to accommodate 250 mL Nunclon

sample flasks (flasks: P/N 064053, pkg. of 50; caps and septa: P/N 064235; pkg.

of 50).

All sample container caps contain a split septum that allows the PEEK sampling

needle to pierce the cap, while also maintaining sample integrity and minimizing

sample evaporation.

Optional: A 15-position sample rack (P/N 064234) that accommodates 250 mL

narrow-mouth Nalgene® bottles (bottles: P/N 064236, pkg. of 72; caps and septa:

P/N 064232, pkg. of 72).

for troubleshooting help.

).

Rack Location Mat

The rack location mat (P/N 064250) is mounted on the spill tray. The mat houses

the sample rack and provides calibration coordinates for properly aligning the

sampling needle over a sample container.

Spill Tray

The spill tray (P/N 064251) provides secondary containment for sample

containers in the autosampler.

Standards Rack

Standards and/or samples can be loaded onto the standards rack. The AS-HV is

shipped with an 11-position standards rack (P/N 064253).

Optional: A 6-position standards rack (P/N 064252).

6 Doc. 065125-01 10/06

Page 15

2 • Description

Sampling Needle

The sampling needle is used to aspirate sample from sample containers.

The AS-HV is shipped with a PEEK Sampling Needle Kit (P/N 064511). The kit

includes the sampling needle (a piece of specially pre-bent 0.8-mm (0.030-in) ID

PEEK tubing), fittings, and mounting hardware.

The PEEK tubing is not only the sampling needle, but the point at which the

sample is introduced to the IC. This transfer mechanism minimizes contamination

that can be caused by fittings, extra tubing, and manual sample handling.

Optional: A Sampling Needle Kit–PTFE Lined and Sleeved (P/N 064056)

containing a stainless steel needle that is lined and sleeved with PTFE

(polytetrafluoroethylene).

Sampling Needle Guide

The AS-HV is shipped with a sampling needle guide (P/N 064519). The guide

serves two purposes:

• To ensure that the PEEK sampling needle does not bend or flex as it pierces

the septum in the sample container cap.

• To ensure that the sample container is not lifted out of the sample rack during

sampling.

Rinse Station

The rinse station cleans the sampling needle between samples. During the

cleaning cycle, the needle is inserted into the rinse fluid, fluid is drawn and then

dispensed through the needle, and the dispensed fluid is directed to waste. The

rinse station consists of:

• A 150 mm reservoir of rinse fluid. Dionex recommends using ASTM Type I

(or better) filtered, deionized water as the rinse fluid.

• A variable-speed peristaltic pump that provides a supply of fresh rinse fluid to

the reservoir. The potentiometer knob fitted above the pump is used to adjust

the flow rate (see Section 3.2.3

If an external rinse source is available, the reservoir can be connected directly to

this source and the peristaltic pump can be replumbed for operation as the sample

loading pump. For more information, refer to Section 2.4.4

).

.

Doc. 065125-01 10/06 7

Page 16

AS-HV Operator’s Manual

2.2 AS-HV Side Panel

This section describes (from top to bottom) the components located on the right

side panel of the AS-HV.

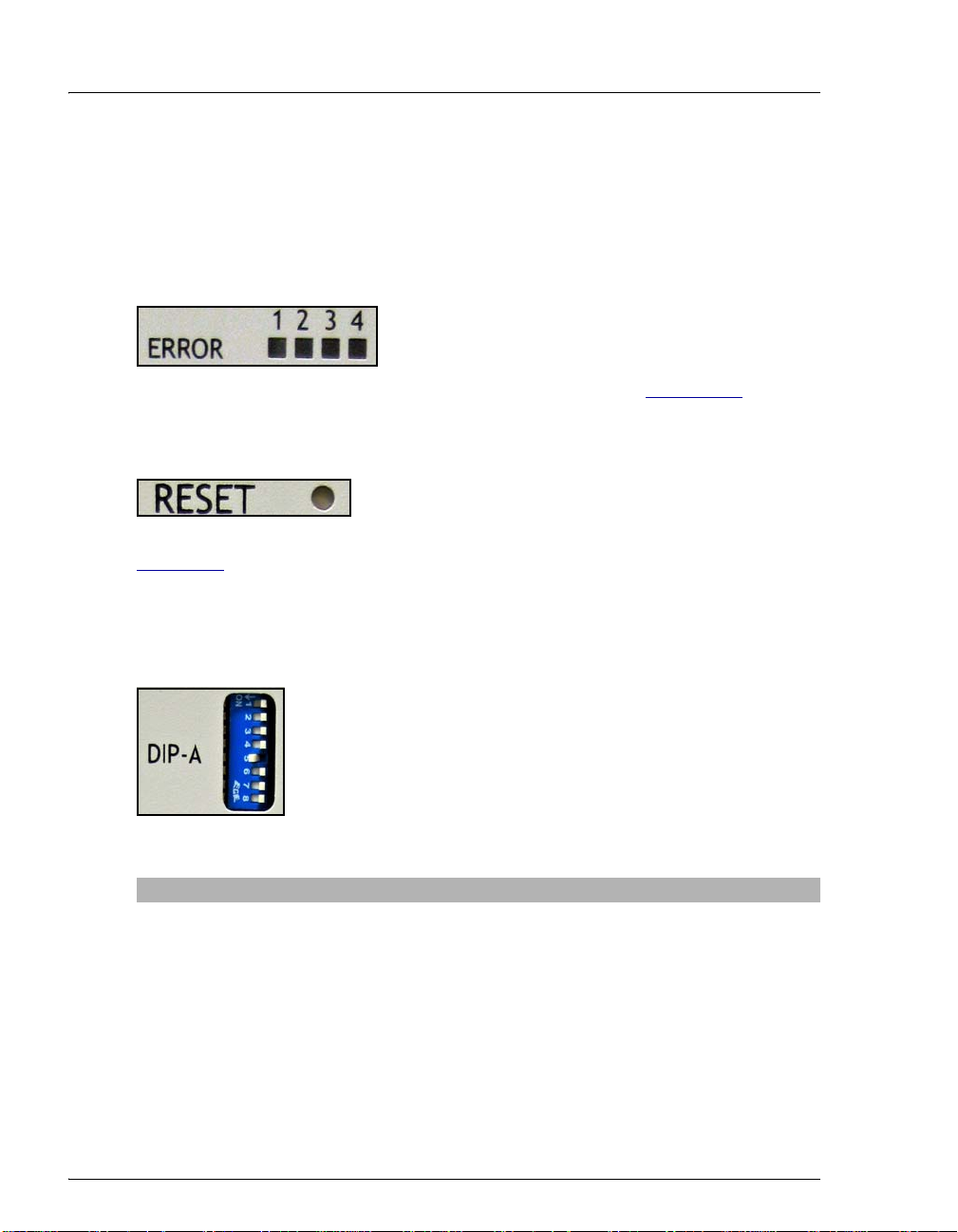

ERROR Indicators

that Error 6 (an X-axis position error) has occurred. Refer to Section C.2

explanation of all of the error codes.

RESET Switch

problems with autosampler movement in the X-, Theta-, and Z-axes (see

Figure 3-1

motors operate and the action of the carriages is correct.

A small pointed device is required to depress the recessed switch.

). Successful completion of the reset procedure confirms that the

If a fault occurs, the ERROR indicators light to

display a binary error code (in blue) that identifies

the fault. For example, the error code 0110 indicates

for an

Pressing the RESET switch returns the AS-HV to its

initial start-up sequence. The reset procedure identifies

DIP-A DIP Switches

The DIP switches are numbered 1 to 8 (from top to bottom).

SW5 sets the baud rate (the only communication parameter

that can be set on the AS-HV).

The table below lists the DIP switch functions and default

settings. The switch positions are indicated as 0 = Off

(Up/Open) or 1= On (Down/Closed).

DIP Switch Default Setting Description

SW1 Off Self-test mode

SW2 Off Reserved

SW3 Off Reserved

SW4 Off Reserved

SW5 On Baud rate

SW6 Off Mode selection

SW7 Off Mobile rinse station expiration timer

SW8 Off Wash select MRS/FWR (mobile rinse

station/fixed rinse reservoir)

8 Doc. 065125-01 10/06

Page 17

2 • Description

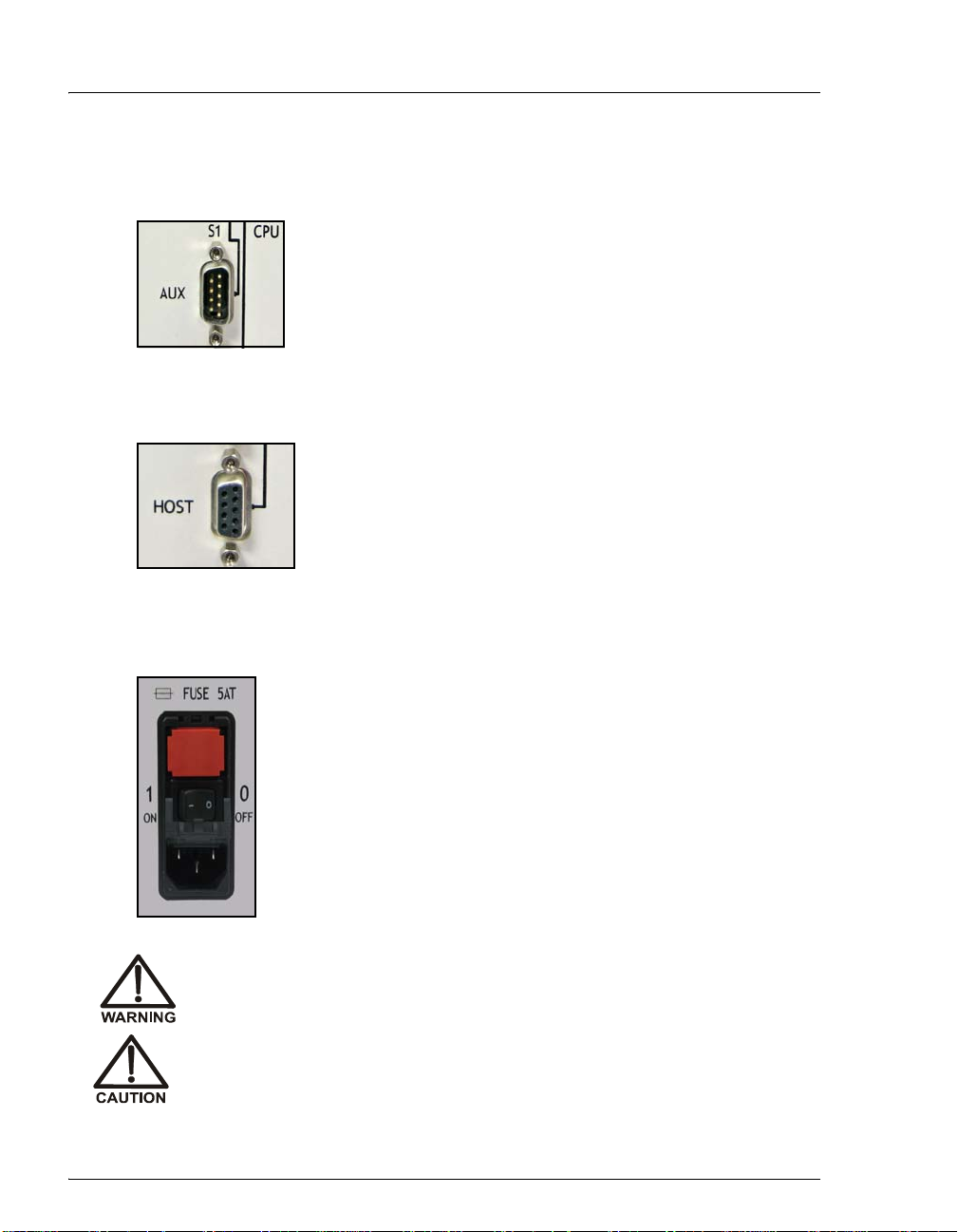

I/O Port

The I/O port provides eight contact closure inputs and four relay

outputs.

The autosampler has four internal relays (A, B, C, and D).

Normally open and normally closed contact pairs are available on

the external I/O connector.

Relay A is reserved for control of the internal peristaltic pump.

Relay B is reserved for control of an external relay-controlled

pump operating as the sample loading pump. The relays can be

controlled through commands programmed in Chromeleon.

RELAY Status Indicators

These indicators light (yellow) to indicate the

state of the internal relays (A, B, C, and D).

When a relay is energized, the corresponding

indicator is lit.

The relay outputs can be used to connect and control low power devices. These

outputs should be limited to loads of 1 amp or less. The eight digital inputs

available on the autosampler allow monitoring of electrical signals between 0 and

+24 volts.

System Status Indicators

These indicators light (yellow) to identify certain

autosampler conditions. For details, see the table below.

.

Status Indicator Description Indication

S1 Programmable behavior

LED

AUX Auxiliary instrument port

activity LED

HOST Host interface port

activity LED

CPU Central processor unit

(CPU) activity LED

Doc. 065125-01 10/06 9

ON when programmed

ON when a byte is sent or received

on Auxiliary Instrument Port, then

OFF

ON when a byte is sent or received

on Host Interface Port, then OFF

OFF for 10 seconds, then ON for

1 second

Page 18

AS-HV Operator’s Manual

AUX (Auxiliary Communications) Port

The AUX port provides a standard RS-232 interface connection

from the AS-HV to the optional syringe pump or AXP pump.

The port supports a baud rate of 9600 and operates as

connected DCE (Data Computer Equipment); the pumps

operate as DTE (Data Terminal Equipment). The RS-232 cable

required to connect the pump to the

the pump Ship Kit.

HOST (Host Communications) Port

The HOST port provides a connection from the AS-HV to a

serial port on the Chromeleon PC. The AS-HV Ship Kit

(P/N 064051) includes an RS-232 cable (P/N 060683) for this

connection.

If a serial port is not available on the PC, order the optional

RS-232-to-USB cable (P/N 064261) and use this cable to

connect the autosampler to a USB port on the PC.

AUX port is provided in

Power Entry

SHOCK HAZARD—To avoid electrical shock, use a grounded

receptacle. Do not operate the AS-HV or connect it to AC power mains

without an earthed ground connection.

The power supply cord is used as the main disconnec t device. Make

sure the socket-outlet is located near the AS-HV and is easily

accessible.

The power entry incorporates the AS-HV main power switch and

the fuse compartment.

The AS-HV operates from input voltages over a range of 100 to

240 VAC, 50 to 60 Hz power, and requires a grounded, singlephase power source. The typical input power is 75 W and the

maximum line draw is 1.8 amps at 110 VAC (when the power is

turned on). The appropriate line voltage and frequency are

selected automatically.

10 Doc. 065125-01 10/06

Page 19

2 • Description

Operation at AC input levels outside of the specified operating voltage

range may damage the AS-HV.

DANGER D'ÉLECTROCUTION—Pour éviter toute électrocution, il faut

utiliser une prise de courant avec prise de terre. Ne l'utilisez pas et ne

le branchez pas au secteur C.A. sans utiliser de branchemen t mis à la

terre.

Le cordon d'alimentation principal est utilisé comme dispositif

principal de débranchement. Veillez à ce que la prise de base soit

située/installée près du module et facilement accessible.

STROMSCHLAGGEFAHR—Zur Vermeidung von elektrischen

Schlägen ist eine geerdete Steckdose zu verwenden. Das Gerät d arf

nicht ohne Erdung betrieben bzw. an Wechselstrom angeschlossen

werden.

Das Netzkabel ist das wichtigste Mittel zur Stromunterbrechung.

Stellen Sie sicher, daß sich die Steckdose nahe am Gerät befindet und

leicht zugänglich ist.

DANGER D'ÉLECTROCUTION—Pour éviter toute électrocution, il faut

utiliser une prise de courant avec prise de terre. Ne l'utilisez pas et ne

le branchez pas au secteur C.A. sans utiliser de branchemen t mis à la

terre.

Le cordon d'alimentation principal est utilisé comme dispositif

principal de débranchement. Veillez à ce que la prise de base soit

située/installée près du module et facilement accessible.

Fuse Compartment

The fuse compartment contains two slow-blow fuses rated at 5 amps

(P/N 064248). For instructions on how to replace the fuses, refer to Section 5.5

For continued protection against risk of fire or shock, replacement

fuses must be the type and rating specified in this manual.

Doc. 065125-01 10/06 11

.

Page 20

AS-HV Operator’s Manual

Pour maintenir la protection contre les risques d'incendie ou

d'électrocution, remplacez toujours les fusibles par des fusibles du

même type et du même calibre.

Zum Schutz vor Feuer und Stromschlägen müssen beim

Sicherungswechsel immer Sicherungen des gleichen Typs und mit

gleicher Leistung verwendet werden.

2.3 Sample Loading Modes

The AS-HV supports two sample loading modes:

• In the push mode, sample enters the sample loading pump and is then pushed

into the sample loop or concentrator column.

• In the pull mode, sample is pulled into the sample loop or concentrator

column via the sample loading pump.

The sample loading mode is determined by the components that are installed and

the plumbing connections; for schematics showing typical configurations, refer to

Appendix B

.

Sample Overlap

To reduce the time between injections, some Dionex devices, including the ASHV, support overlapping sample preparation. This means that, while data

collection and analysis for the current sample are still in progress, the AS-HV can

perform sample preparation steps for the next sample. When the autosampler

finishes the overlapped functions, the Chromeleon program waits, if necessary , to

finish the currently running sample. Then, the remaining commands in the

overlapped sample's program are executed.

Sample overlap is enabled in the Chromeleon Program Wizard (see Section 3.2.4

12 Doc. 065125-01 10/06

).

Page 21

2.4 Sample Loading Pumps

This section provides a brief overview of the sample loading pump options for the

AS-HV:

• A syringe pump (see Section 2.4.1)

• A single-piston pump—the AXP Pump (see Section 2.4.2)

• An external peristaltic pump—the MASTERFLEX® C/L® Pump System

(see Section 2.4.3

• An internal peristaltic pump (see Section 2.4.4)

• A relay-controlled pump (see Section 2.4.5)

2.4.1 Syringe Pump

The syringe pump (P/N 064506) contains a stepper-motor driven syringe

and a three-way distribution valve to aspirate and dispense measured

quantities of liquid. A control cable connects the syringe pump to the

AUX and I/O ports on the AS-HV side panel (see Section 2.2).

)

2 • Description

When coupled with the syringe pump, the AS-HV is capable of both

concentrator and loop loading in the push or pull mode (see Section 2.3

This configuration provides maximum flexibility in terms of Chromeleon

control and flow precision.

T o ensure optimal performance when doing concen trator loading with the

syringe pump, follow these guidelines:

).

• All points in the system that will be aspi rated should be plumbed with

1.0-mm (0.040-in) ID PEEK tubing (P/N 054410).

• Push mode only: Dionex does not recommend using the push mode

with the syringe pump. If you do use the push mode, make sure the

backpressure does not exceed 0.41 MPa (60 psi).

• Pull mode only: If the Dionex TCC-XLP1 concentrator column is

installed, the maximum flow rate is 0.5 mL/min and the backpressure

should not exceed 0.10 MPa (15 psi).

• Pull mode only: If the Dionex UTAC-XLP1 concentrator column is

installed, the maximum flow rate is 1.0 mL/min and the backpressure

should not exceed 0.10 MPa (15 psi).

Doc. 065125-01 10/06 13

Page 22

AS-HV Operator’s Manual

2.4.2 AXP Pump

The single-piston AXP pump (P/N 064507) can deliver from 0.01 to

10.00 mL/min of a single solution or eluent. A serial cable connects the

AXP pump to the

The AXP pump is controlled via Chromeleon.

When coupled with the AXP pump, the AS-HV is capable of concentrator

and sample loop loading in the push or pull mode (see Section 2.3

users may prefer to configure the pump as a “pull” device in order to

minimize the contamination that can result when the sample comes into

contact with check valves and seals.

However, Dionex does not recommend using the pull mode for

concentrator loading. Piston pumps can cavitate and lose prime unless

there is a continuous flow of liquid through the pump. With the AXP

pump, these problems are most likely to occur when performing

concentrator loading in the pull mode.

T o ensure op timal performance when doi ng concentrator loadin g with the

AXP pump, follow these guidelines:

AUX port on the AS-HV side panel (see Section 2.2).

). Some

• Any Dionex concentrator column (or guard column used as a

concentrator column) may be installed for loading in the push mode.

Select the flow rate recommended for your concentrator column. All

points in the system that will be aspirated should be plumbed with

1.0-mm (0.040-in) ID PEEK tubing (P/N 054410).

When doing sample loop loading with the AXP pump, follow these

guidelines:

• Pull mode only: The maximum flow rate is 0.75 mL/min. The

backpressure should not exceed 0.07 MPa (10 psi).

NOTE An electronic copy of the AXP/AXP-MS Metering

Pump Operator’s Manual (Document No. 031897) is

provided on the Dionex Reference Library CDROM. Before beginning operation with the pump,

familiarize yourself with the content of the manual.

14 Doc. 065125-01 10/06

Page 23

2.4.3 External Peristaltic Pump

The external peristaltic pump (P/N 064508) is a MASTERFLEX C/L

Pump System. A relay cable connects the AS-HV to the terminal strip on

the pump’s rear panel.

When coupled with the external peristaltic pump, the AS-HV is capable

of sample loop loading in either the push or pull mode (see Section 2.3

This configuration is typically used to load sample when a large sample

loop is installed.

NOTE To minimize potential sample contamination,

Dionex recommends using the pull mode with the

external peristaltic pump.

T o ensure optimal performance when doing loop loading with the external

peristaltic pump, follow these guidelines:

• All points in the system that will be aspi rated should be plumbed with

1.0-mm (0.040-in) ID PEEK tubing (P/N 054410).

• To ensure that the proper sample volume is loaded, measure the flow

rate after replacing any component in the flow path. It is advisable to

measure the flow rate periodically, as flow rates may fluctuate over

time as the columns and peristaltic pump tubing age.

2 • Description

).

• Push mode only: The backpressure should not exceed 0.10 MPa

(15 psi).

• Pull mode only: The maximum flow rate is 1.75 mL/min. The

backpressure should not exceed 0.07 MPa (10 psi).

NOTE A printed copy of the MASTERFLEX C/L Pump

System Operator’s Manual is shipped with the pump.

Before beginning operation with the pump,

familiarize yourself with the content of the manual.

Doc. 065125-01 10/06 15

Page 24

AS-HV Operator’s Manual

2.4.4 Internal Peristaltic Pump

The AS-HV rinse station includes a built-in peristaltic pump that provides

a supply of fresh rinse fluid to the reservoir (see page 7

controlled through Relay A.

If the rinse station is connected directly to an external rinse source, the

peristaltic pump can be replumbed for use as the sample loading pump in

either the push or pull mode (see Section 2.3

instructions, refer to Section B.3.12

To ensure optimal performance when using the internal peristaltic pump

for sample loading, the delivery pressure should be less than 0.03 MPa

(5 psi).

2.4.5 Relay-Controlled Pump

An external relay-controlled pump from a third-party vendor can be used

for sample loading in either the push or pull mode (see Section 2.3

pump is controlled through Relay B.

). The pump is

). For replumbing

.

). The

A relay cable connects the pump to the

(see Section 2.2

although only through relay control.

If you have a question regarding the use of third-party pumps with th e

AS-HV, please contact Dionex. In the U.S., call 1-800-346-6390 and

select the Technical Support option. Outside the U.S., call the nearest

Dionex office.

). Note that the pump is supported by Chromeleon,

I/O port on the AS-HV side panel

16 Doc. 065125-01 10/06

Page 25

2.5 Chromeleon Software

Chromeleon software is required for control of AS-HV operation. Two modes of

software control are available: direct control and automated control.

• With direct control, the user selects operating parameters and commands from

the Chromeleon menu bar, toolbars, and AS-HV Control panels. Direct

control commands are executed as soon as they are entered.

• With automated control, the user creates a program (sometimes called a PGM

file) that contains a list of commands that will be performed at specified times

for automated operation of the AS-HV. You can create program files

automatically , using the Program Wizard, or manually, by modifying an

existing program.

In addition to general commands for device control, Chromeleon includes many

commands specifically for the AS-HV and the sample loading pumps (see

Table 2-1

You can select these commands from the default Control panel or the Commands

dialog box. To open the dialog box, press F8 or select Control > Command.

through Table 2-4).

2 • Description

Command Function

FlushAspirateSpeed* Specifies the speed at which the sampling needle is

filled with rinse fluid.

RinseVolume Specifies the volume of rinse fluid used to wash the

sampling needle.

SampleAspirateSpeed* Specifies the speed at which the syringe draws sample

from the sample container.

SyringeAspirate The syringe pump aspirates the specified volume of

liquid through the sampling needle.

SyringeDispense The syringe pump dispenses the specified volume of

liquid through the sampling needle.

SyringeReset Resets the syringe pump to the initial position.

SyringeSize Reports the volume of the syringe (read-only).

SyrPumpPosition Reports the position of the syringe pump plunger

(read-only).

SyrPumpStatus Reports whether the syringe pump is busy and whether

an error condition has been detected (read-only).

Table 2-1. Chromeleon Commands for the Syringe Pump

Doc. 065125-01 10/06 17

Page 26

AS-HV Operator’s Manual

Command Function

ValvePosition Sets the position of the distribution valve in the syringe

WashPortDispenseSpeed* Specifies the speed at which rinse fluid is dispensed

WasteDispenseSpeed* Specifies the speed at which liquid is directed to waste.

* There are six syringe speeds, and each speed has 10 levels. The flow rate varies,

depending on the command and the speed setting. For details, refer to the tables in

“

Sampler Options Screen: Syringe Pump Version” on page 27.

Table 2-1. Chromeleon Commands for the Syringe Pump (Continued)

Command Function

AxpCurrentSetup Reports the AXP pump configuration and the status of

AxpState Turns the AXP pump on and off.

Flow Sets the flow rate for the AXP pump.

Pressure.LowerLimit* Sets the lower pressure limit for the AXP pump.

Pressure.UpperLimit* Sets the upper pressure limit for the AXP pump.

Pressure.Value* Reports the current AXP pump pressure (read-only).

RinseVolume Specifies the volume of rinse fluid used to wash the

* To display this command, click the plus sign beside the Pressure command.

pump.

through the sampling needle.

several operating parameters (read-only). To view

details, click the plus sign beside this command.

sample loop, sampling needle, and sample loading

path.

Table 2-2. Chromeleon Commands for the AXP Pump

18 Doc. 065125-01 10/06

Page 27

2 • Description

Command Function

InternalPumpOff* Turns off the internal peristaltic pump.

InternalPumpOn* Turns on the internal peristaltic pump.

IntPumpDirection* Specifies the direction of operation for the internal

peristaltic pump.

Flow Sets the flow rate of the internal peristaltic pump.

RinseVolume Specifies the volume of rinse fluid used to wash the

sample loop, sampling needle, and sample loading

path.

* This command is not available unless the internal peristaltic pump is selected as the

Sample Loading Pump in the AS-HV Properties dialog box (see Section B.3.16

Table 2-3. Chromeleon Commands for the Internal Peristaltic Pump

Command Function

Flow Sets the flow rate of the relay-controlled pump.

RinseVolume Specifies the volume of rinse fluid used to wash the

sample loop, sampling needle, and sample loading

path.

).

Table 2-4. Chromeleon Commands for the Relay-Controlled Pump

Doc. 065125-01 10/06 19

Page 28

AS-HV Operator’s Manual

20 Doc. 065125-01 10/06

Page 29

3 • Operation and Maintenance

The AS-HV Autosampler is designed for use with IC (ion chromatography) and

HPLC (high-performance liquid chromatography) systems and should not be used

for any other purpose. Operation of the AS-HV in a manner not specified by

Dionex may result in personal injury.

If you have a question regarding appropriate usage, please contact Dionex before

proceeding. In the U.S., call 1-800-346-6390 and select the Technical Support

option. Outside the U.S., call the nearest Dionex office.

3.1 Safety Guidelines

SHOCK HAZARD—To avoid electrical shock, use a grounded

receptacle. Do not operate the AS-HV or connect it to AC power mains

without an earthed ground connection.

The power supply cord is used as the main disconnect device. Make

sure the socket-outlet is located near the AS-HV and is easily

accessible.

Operation at AC input levels outside of the specified operating voltage

range may damage the AS-HV.

DANGER D'ÉLECTROCUTION—Pour éviter toute électrocution, il faut

utiliser une prise de courant avec prise de terre. Ne l'utilisez pas et ne

le branchez pas au secteur C.A. sans utiliser de branchemen t mis à la

terre.

Le cordon d'alimentation principal est utilisé comme dispositif

principal de débranchement. Veillez à ce que la prise de base soit

située/installée près du module et facilement accessible.

STROMSCHLAGGEFAHR—Zur Vermeidung von elektrischen

Schlägen ist eine geerdete Steckdose zu verwenden. Das Gerät d arf

nicht ohne Erdung betrieben bzw. an Wechselstrom angeschlossen

werden.

Doc. 065125-01 10/06 21

Page 30

AS-HV Operator’s Manual

Das Netzkabel ist das wichtigste Mittel zur Stromunterbrechung.

Stellen Sie sicher, daß sich die Steckdose nahe am Gerät befindet und

leicht zugänglich ist.

• Always stay clear o f the sampling arm during operation. Al though the AS-HV

is designed to stop running as soon as the arm encounters an obstruction, the

arm can move fast and injury may occur if a user is struck. For added

protection, place the optional Plexiglas

over the autosampler (see Section B.3.7

To avoid injury, always maintain a safe distance from the sampling

arm during operation.

Afin d'éviter toute blessure, maintenez vous toujours à distance de

sécurité du bras robotique pendant son déplacement.

Um Verletzungen zu vermeiden, behalten Sie immer eine sichere

Entfernung vom Probenarm während Betriebs bei.

® trace analysis cover (P/N 064052)

).

3.2 Getting Ready to Run

3.2.1 Filling Sample Containers and Loading the Racks

1. Fill the Nunclon sample flasks (P/N 064053, pkg. of 50) or Nalgene

bottles (P/N 064236, pkg. of 72) with sample.

2. Install the caps and septa (Nunclon sample flask caps and septa:

P/N 064235, pkg. of 50; Nalgene bottle caps and septa: P/N 064232,

pkg. of 72) as follows:

a. Turn one of the sample container caps upside down. Place a

septum, white side facing down, in the cap. Push the septum fully

into the cap. (This prevents the septum from falling into the

sample container when pierced by the sampling needle.)

b. Repeat Step a

22 Doc. 065125-01 10/06

for the required number of caps.

Page 31

c. Place the caps on the sample containers. After checking that the

white side of the septum faces up, tighten each cap loosely.

Overtightening the caps may twist the septa, making them

unusable.

3. Load the sample containers into the sample rack and/or standards

rack in the order required for the application.

3.2.2 Turning On the Power

1. Turn on the AS-HV main power switch.

At power-up, the AS-HV automatically begins an initialization

sequence in which the sampling needle moves through the extent of

the autosampler’s working envelope. Upon completing the

initialization sequence, the needle returns to the home position above

the fixed rinse reservoir. During initialization (see Figure 3-1

• The needle raises to the full extremes of the Z-axis.

• The needle travels to the full extremes of the X-axis.

3 • Operation and Maintenance

):

• The needle travels to the full extremes of the Theta-axis.

If the sampling needle fails to initialize successfully, refer to

Section 4.3 for troubleshooting assistance.

Theta-Axis

Z-Axis

Figure 3-1. Mechanical Axes

X-Axis

Doc. 065125-01 10/06 23

Page 32

AS-HV Operator’s Manual

3.2.3 Selecting the Rinse Pump Speed

Use the potentiometer knob above the

rinse pump to set the flow rate for the

application (see Figure 3-2

The default speed is nominally set to

obtain a minimum speed of 40 rpm and

a maximum of 100 rpm.

When pumping viscous fluids, run at a

slow speed.

).

Pump Speed

Control Knob

Rinse Pump

Figure 3-2. Rinse Pump Speed Control Knob

NOTE When the rinse pump is not in use, release the track

occlusion arm; this will extend the life of the bridge

tubing (see Figure B-4

).

24 Doc. 065125-01 10/06

Page 33

3 • Operation and Maintenance

3.2.4 Creating a Chromeleon Program

A Chromeleon program (sometimes called a PGM file) is a list of control

commands—to be executed at specified times—created by the user for

automated operation of the AS-HV. There are two ways to create

programs:

• Automatically, using the Program Wizard

• Manually, by modifying an existing program

This section provides an overview of how to create a program with the

Program Wizard. For detailed instructions, refer to the Chromeleon Help

or user’s guide.

To create a program:

1. Start the Chromeleon Server, if it is not already running:

If the Chromeleon Server icon on the Windows taskbar is crossed out

in red , the Server is not running. Start the Server by right-

clicking the icon and selecting Start Server. When the server is

running, the icon is gray .

If the Server Monitor icon is not on the taskbar, click Start on the

taskbar and select All Programs (or Programs, depending on the

operating system) > Chromeleon > Server Monitor. Click Start to

start the server.

2. To start the Chromeleon client, click Start on the Windows taskbar

and select All Programs (or Programs) > Chromeleon >

Chromeleon.

3. Select File > New.

A dialog box appears.

4. Select Program File and click OK.

Doc. 065125-01 10/06 25

Page 34

AS-HV Operator’s Manual

The initial Program Wizard screen is displayed.

5. Select the Timebase where the program will run.

6. Click Next to continue.

If the selected timebase includes other devices, Program Wizard

screens for these devices are displayed before the AS-HV screens. On

each screen, select the required parameters and click Next until the

Sampler Options screen is displayed.

7. There are three versions of the Sampler Options screen. The version

that appears now depends on the sample loading pump selected in the

Server Configuration (see Section B.3.16

All versions of the Sampler Options screen include the Needle

Height control and the Options group box. In addition, each screen

includes a group box with special controls for the selected pump.

26 Doc. 065125-01 10/06

).

Page 35

3 • Operation and Maintenance

Sampler Options Screen: Syringe Pump Version

When the sample loading pump is the syringe pump , this screen is

displayed:

Select the Needle Height.

Select the Rinse Volume.

Select the syringe speed for the remaining parameters in the Syringe

Pump group box. There are two syringe speeds (fast and slow), and

each speed has 10 levels. The actual speed depends on multiple

factors; for details, refer to the following sections.

“Fast” Syringe Speed

The syringe operates at the “fast” speed for Aspirate Speed from

Flush Bottle and Dispense Speed to Waste Bottle (see Table 3-1)

.

In the default AS-HV configuration, liquid moves through large bore

tubing during these operations. When selecting a speed setting, be

sure to take into account the tubing bore.

Doc. 065125-01 10/06 27

Page 36

AS-HV Operator’s Manual

.

Table 3-1. “Fast” Syringe Speed Settings

Speed Setting Top Speed

(steps/sec)

Flow Rate

(mL/min)

1 800 10.0

2 1200 15.0

3 1600 20.0

4 2000 25.0

5 2400 30.0

6 2800 35.0

7 3200 40.0

8 3600 45.0

9 4000 50.0

10 4800 60.0

“Slow” Syringe Speed

The syringe operates at the “slow” speed for Dispense Speed to

Wash Port and Aspirate Speed from Sample Container. The actual

speed depends on the parameter, the speed setting, the sample loading

type, and the sample loading mode (see Table 3-4

for an overview).

In the default AS-HV configuration, liquid moves through smaller

bore tubing during these operations. When selecting a speed setting,

be sure to take into account the tubing bore.

Table 3-2. Overview of “Slow” Syringe Speed Settings

Sample Loading Type/

Sample Loading Mode

Sample loop/Push See Table 3-3 See Table 3-4

Sample loop/Pull See Table 3-3 See Table 3-4

Concentrator column/

Push

Concentrator column/

Pull

28 Doc. 065125-01 10/06

Dispense Speed to

Was h Port

Aspirate Speed from

Sample Container

See Table 3-4 See Table 3-4

See Table 3-5 See Table 3-6

Page 37

3 • Operation and Maintenance

Table 3-3. “Slow” Syringe Speed Settings: Wash Port Dispense

Speed for Sample Loop/Push or Pull Mode

Speed Setting Top Speed

(steps/sec)

Flow Rate

(mL/min)

1801.00

2 160 2.00

3 200 2.50

4 240 3.00

5 280 3.50

6 320 4.00

7 360 4.50

8 400 5.00

9 440 5.50

10 480 6.00

Table 3-4. “Slow” Syringe Speed Settings: Sample Aspirate Speed

for Sample Loop/Push or Pull Mode or Concentrator Column/Push

Mode

Speed Setting Top Speed

(steps/sec)

Flow Rate

(mL/min)

1320.40

2640.80

3961.20

4 128 1.60

5 160 2.00

6 192 2.40

7 224 2.80

8 256 3.20

9 288 3.60

10 320 4.00

Doc. 065125-01 10/06 29

Page 38

AS-HV Operator’s Manual

Table 3-5. “Slow” Syringe Speed Settings: Wash Port Dispense

Speed for Concentrator Column/Push or Pull Mode

Speed Setting Top Speed

(steps/sec)

Flow Rate

(mL/min)

1400.50

2801.00

3 100 1.25

4 120 1.50

5 140 1.75

6 160 2.00

7 180 2.25

8 200 2.50

9 220 2.75

10 240 3.00

Table 3-6. “Slow” Syringe Speed Settings: Sample Aspirate Speed

for Concentrator Column/Pull Mode

Speed Setting Top Speed

(steps/sec)

Flow Rate

(mL/min)

1 8 0.10

2160.20

3240.30

4320.40

5400.50

6480.60

7560.70

8640.80

9720.90

10 80 1.00

30 Doc. 065125-01 10/06

Page 39

3 • Operation and Maintenance

To enable control of the injection valve by another device in the

timebase, select the V alve Contr ol check box. When the check box is

selected, the following options are enabled:

• Load/Inject Valve Using: Select the injection valve or relay/TTL

device that will control sample loading and injection.

• Injection Duration: Specify for how long injection occurs. (This

setting is ignored unless you select Sample Loop as the sample

loading type in the Server Configuration (see Section B.3.16

NOTE For sample overlap programs, the Injection

Duration must be less than the Delay Before

Processing Next Sample (see below).

).

To enable sample overlap (see Section 2.3), select the Sample

Overlap check box. When the check box is selected, the following

option is enabled:

• Delay Before Processing Next Sample: Specify for how long

the Chromeleon program waits in order to finish the currently

running sample before executing the remaining commands in the

program.

Doc. 065125-01 10/06 31

Page 40

AS-HV Operator’s Manual

Sampler Options Screen: AXP Pump Version

When the sample loading pump is the AXP pump, this screen is

displayed:

Select the Needle Height.

Select the Rinse Volume.

In the AXP Pump group box:

• Select the Rinse Volume.

• Select the Flow Rate.

• Set the Low Pressure Limit. The maximum value is the current

upper pressure limit setting (in psi) minus 100; the minimum

value is 0.

• Set the High Pressure Limit. The maximum value is 3000; the

minimum value is the current lower pressure limit setting (in psi)

plus 100.

Select the desired settings in the Options group box; for details, refer

to page 31

32 Doc. 065125-01 10/06

.

Page 41

3 • Operation and Maintenance

Sampler Options Screen: Internal Peristaltic Pump or RelayControlled Pump Version

When the sample loading pump is either the internal peristaltic pump

or a relay-controlled pump, this screen is displayed:

Select the Needle Height.

Select the Rinse Volume.

In the Internal Peristaltic Pump/Relay-Controlled Pump group

box:

• Select the Rinse Volume.

• Select the Flow Rate.

Select the desired settings in the Options group box; for details, refer

to page 31

Doc. 065125-01 10/06 33

.

Page 42

AS-HV Operator’s Manual

8. When you finish selecting parameters on the Sampler Options

screen, click Next to continue.

The following screen is displayed.

NOTE If you have already selected these parameters on the

device page for a particular module, the list box on

the Relay and State Devices Options page already

contains this information. If you change any settings

here, Chromeleon will automatically copy the

changes to the appropriate device page.

9. The window on the left lists the devices in the selected timebase.

Select a device from the list, and then click the plus sign to the left of

the device name to view the device states.

34 Doc. 065125-01 10/06

Page 43

3 • Operation and Maintenance

10. Specify the State or Duration for the selected device:

• Clicking State specifies a simple switch command. Select Open

or Closed from the drop-down list box.

• Clicking a state description sets the device to the selected state

and lets you specify a Duration. Enter the duration of the

selected state in the edit box.

NOTE Relays A and B are reserved for internal use

and cannot be selected.

11. To add the following information to the list box, click Add:

• Retention Time value

• Name of the selected Device

• State or Duration value

Chromeleon will automatically organize all entries in the list box in

chronological order.

To remove an entry from the list box, select the entry and click

Delete. (All entries in the list box will automatically be reorganized.)

12. Click Next to continue.

Doc. 065125-01 10/06 35

Page 44

AS-HV Operator’s Manual

The following screen is displayed.

13. (Optional) Type a descriptive Title for the program.

14. Select one of the following options:

• To save the program without first reviewing it, select Save the

program immediately. Clicking Finish opens a dialog box in

which you can save the program.

• To review the program before saving it, select Review the

program in a new window. Clicking Finish opens the program

in the Program Editor. Use the Program Editor to review the

program and to manually edit it, if necessary. When you finish,

exit the Program Editor. This displays a prompt asking whether

the program should be saved; clicking Yes opens a dialog box in

which you can save the program.

36 Doc. 065125-01 10/06

Page 45

3.3 Routine Maintenance

This section describes routine maintenance procedures that the user can perform

for the AS-HV and the syringe pump. Any maintenance procedures for the ASHV and the syringe pump that are not described here must be performed by

Dionex personnel. For maintenance procedures for other sample loading pumps,

refer to the respective product manual.

To contact Dionex in the U.S., call 1-800-346-6390 and select the Technical

Support option. Outside the U.S., call the nearest Dionex office.

NOTE The AS-HV has no lubrication requirements. Do not

apply lubrication to the sampling arm or any other

components.

3.3.1 Daily Maintenance

• Wipe up all spills immediately, especially spills of corrosive liquids.

• Inspect the syringe pump for leaks, and correct any problems.

3 • Operation and Maintenance

• Flush the syringe pump thoroughly with distilled or deionized water

after each use and when the pump is not in use.

NOTE Do not allow the syringe pump to run dry for

more than a few cycles.

• Check for air bubbles in the syringe(s) and tubing and remove any

bubbles that appear (see Section B.3.17

).

• Replace the rinse fluid. Dionex recommends using ASTM Type I (or

better) filtered, deionized water as the rinse fluid.

• To ensure correct drainage, the end of the waste line should not be

submerged in waste liquid. Check the volume of liquid in the waste

container and empty when needed.

Neutralize acidic and caustic wastes before disposal. Dispose of all

wastes in accordance with local regulations.

Doc. 065125-01 10/06 37

Page 46

AS-HV Operator’s Manual

Neutralisez les déchets acides ou caustiques avant d e les jeter. Jetez

les déchets aux règlements locaux.

Neutralisieren Sie säurehaltige und ätzende Abfälle vor ihrer

Entsorgung. Entsorgen Sie alle Abfälle entsprechend den lokalen

Bestimmungen.

3.3.2 Weekly Maintenance

• Check the tubing connected to the internal peristaltic pump. If the

tubing is crimped or blocked, replace it (rinse line: 2.06-mm (0.08-in)

ID Santoprene® tubing, P/N 064521; sample line: 0.64-mm (0.03-in)

ID Santoprene tubing, P/N 064825). Crimped or blocked tubing can

cause unexpected changes in the flow rate.

3.3.3 Monthly Maintenance

• Clean the fluid path of the syringe pump to remove precipitates (for

example, salts) and eliminate bacterial growth. For instructions, see

Section 5.1

.

3.3.4 Periodic Maintenance

• Clean the AS-HV external covers, spill tray, rack location mat, and

accessories with a damp soft cloth and diluted mild detergent.

• When operating the syringe pump in the push mode, check the

backpressure to confirm that it is less than 0.41 MPa (60 psi). This

prevents damage to the distribution valve.

• Replace the syringe pump inlet and outlet tubing and valve as

required. The frequency of replacement will depend on the duty

cycle, fluids used, and instrument maintenance.

38 Doc. 065125-01 10/06

Page 47

This chapter is a guide to troubleshooting minor problems that may o ccur during

operation of the AS-HV Autosampler. Turn to the section of this chapter that best

describes the operating problem or symptom that you have observed. Each section

lists possible causes of the problem or symptom.

If necessary, refer to the following sections of this manual for more information:

• Section C.1 contains a description of error messages that may be reported by

Chromeleon software and details about how to troubleshoot them.

• Section C.2 contains a description of error codes that may be displayed by the

AS-HV

If you are unable to solve a problem by following the instructions here, contact

Dionex Technical Support. In the U.S., call 1-800-346-6390. Outside the U.S.,

call the nearest Dionex office.

ERROR indicators and details about how to troubleshoot them.

4.1 Liquid Leaks

4.1.1 Leaking Fitting

4 • Troubleshooting

Locate the source of the leak and tighten (or replace) the liquid line

connection. For tightening requirements, refer to Installation of Dionex

Liquid Line Fittings (Document No. 031432). The manual is on the

Dionex Reference Library CD-ROM (P/N 053891).

4.1.2 Leaking Syringe

Possible Causes:

• Cracked syringe

• Damaged seal

• Loose fitting

• Loose syringe

Doc. 065125-01 10/06 39

Page 48

AS-HV Operator’s Manual

Actions:

• Check for a crack in the syringe. If the syringe is cracked, it must be

replaced (see Section 5.2

• Check the seal for scratches, deformation, or other damage. If the seal

is damaged, the syringe must be replaced (see Section 5.2

• If the syringe is not cracked and the seal is

not damaged, check that the syringe is

tightened. To tighten, hold the syringe at

the top and bottom fittings and turn it

clockwise (as viewed from the top) (see

Figure 4-1

not overtighten.

). Tighten fingertight only; do

).

).

Figure 4-1. Tightening the Syringe

4.1.3 Leaking Waste Line (Fixed Rinse Reservoir)

• Check that the waste line is pushed tightly onto the drip tray fitting

and that it is not elevated at any point after it exits the AS-HV.

• Check that the waste line is not crimped or otherwise blocked.

• To ensure correct drainage, make sure the end of the waste line is not

submerged in waste liquid.

• Check the volume of liquid in the waste container; empty as needed.

Neutralize acidic and caustic wastes before disposal. Dispose of all

wastes in accordance with local regulations.

40 Doc. 065125-01 10/06

Page 49

Neutralisez les déchets acides ou caustiques avant d e les jeter. Jetez

les déchets aux règlements locaux.

Neutralisieren Sie säurehaltige und ätzende Abfälle vor ihrer

Entsorgung. Entsorgen Sie alle Abfälle entsprechend den lokalen

Bestimmungen.

4.2 Sampling Arm Jams

If the sampling arm becomes jammed, the following events occur:

• The AS-HV error control system locks the motor drive.

• The ERROR indicators on the AS-HV side panel display an error code (see

Table C-1)

• The error is reported to Chromeleon and recorded in the Audit Trail.

Corrective action:

.

4 • Troubleshooting

1. Initialize the AS-HV. (Turn off the power, wait 10 seconds, and turn on the

power again.)

2. If the autosampler initializes correctly but the sampling arm becomes jammed

again, check into these possible causes:

• The arm may have hit an obstacle while moving into position.

• The arm may have stopped because it failed to reach a position within

the defined limits of the intended position. (Movement errors of less

than 1 mm will cause a jam.)

• If the mechanical movement has so much excessive friction that the

arm has difficulty in moving, it will cause the drive to stop.

• The posit ion of the arm may ha ve been moved with out being actively

driven by the autosampler.

If you are unable to eliminate the cause of the jam, contact Dionex for

assistance.

Doc. 065125-01 10/06 41

Page 50

AS-HV Operator’s Manual

4.3 Initialization Sequence Fails

If the AS-HV fails to complete the initialization sequence by driving the sampling

arm (see Section 3.2.2

• The ERROR indicators on the AS-HV side panel display error code 0101 (see

Table C-1)

.

• The error is reported to Chromeleon and recorded in the Audit Trail.

Corrective action:

1. Turn off the AS-HV power.

To avoid injury, turn off the power to prevent the sampling arm from

inadvertently moving while you are manually checking each axis.

Afin d'éviter toute blessure par suite du déplacement inopiné du bras

robotique, couper l'alimentation secteur pendant le contrôle manuel

des axes.

), the following events occur:

Um Verletzungen zu vermeiden, schalten Sie das Gerät bitte immer

aus, während Sie die Achsen manuell überprüfen, damit sich der

Probenarm nicht unbeabsichtigt bewegt.

2. Check each axis (see Figure 3-1

) manually for correct travel to determine

whether there is any mechanical obstruction.

3. If you do not find any mechanical obstructions, turn on the A S-H V power. If

the autosampler again fails to initialize, contact Dionex for assistance.

42 Doc. 065125-01 10/06

Page 51

4.4 Power LED Fails to Light

To troubleshoot:

1. Initialize the AS-HV. (Turn off the power, wait 10 seconds, and turn on the

power again.)

2. If the AS-HV initializes but the power LED still fails to light, the indicator is

faulty and should be replaced. Contact Dionex for assistance.

If the AS-HV fails to initialize and the power LED still fails to light, the

power supply fuse may have blown or the internal power supply may be

faulty. Contact Dionex for assistance.

NOTE The AS-HV electronics cannot be serviced by the user.

All repairs of the electronics components must be

performed by Dionex personnel.

4.5 CPU Activity LED Fails to Light

4 • Troubleshooting

To troubleshoot:

1. Initialize the AS-HV. (Turn off the power, wait 10 seconds, and turn on the

power again.)

2. If the AS-HV initializes but the

CPU LED still fails to light, the indicator is

faulty and should be replaced. Contact Dionex for assistance.

If the AS-HV fails to initialize and the LED still fails to light, the internal

power supply or the main PC board may have malfunctioned. Co ntact Dionex

for assistance.

NOTE The AS-HV electronics cannot be serviced by the user.

All repairs of the electronics components must be

performed by Dionex personnel.

Doc. 065125-01 10/06 43

Page 52

AS-HV Operator’s Manual

4.6 Power Supply Fails

If the green power indicator on the front of the AS-HV and/or the system status

indicator LEDs on the AS-HV side panel fail to light when expected, it may

indicate that the AS-HV power supply is not operational.

Corrective action:

1. Check that the power cable is connected to the AS-HV power entry and that

the power switch is turned on.

2. Check the fuses. If a fuse is blown, replace both fuses with new 5 amp slowblow fuses (P/N 064248). For fuse replacement instructions, refer to

Section 5.5

For continued protection against risk of fire or shock, replacement

fuses must be the type and rating specified here.

Pour maintenir la protection contre les risques d'incendie ou

d'électrocution, remplacez toujours les fusibles par des fusibles du

même type et du même calibre.

.

Zum Schutz vor Feuer und Stromschlägen müssen beim

Sicherungswechsel immer Sicherungen des gleichen Typs und mit

gleicher Leistung verwendet werden.

3. If the autosampler still fails to power up, contact Dionex for assistance.

NOTE Access to the power supply unit and components

requires removal of the main housing. Do not attempt to

access these components. All repairs of the electronics

must be performed by Dionex personnel.

44 Doc. 065125-01 10/06

Page 53

4.7 Cavitation in the Syringe

Cavitation in the syringe may occur when the syringe pump is operating in the

pull mode.

To troubleshoot:

1. The flow rate may be too high. Reduce the flow rate.

2. The concentrator column may be plugged. Refer to the column manual for

troubleshooting assistance. Column manuals are provided on the Dionex

Reference Library CD-ROM (P/N 053891).

4 • Troubleshooting

Doc. 065125-01 10/06 45

Page 54

AS-HV Operator’s Manual

46 Doc. 065125-01 10/06

Page 55

5•Service

This chapter describes routine service procedures that the user can perform for the

AS-HV Autosampler and the syringe pump. All procedures for the AS-HV and

the syringe pump that are not described here must be performed by Dionex

personnel. (For service procedures for other sample loading pumps, refer to the

respective product manual.)

To contact Dionex in the U.S., call 1-800-346-6390 and select the Technical

Support option. Outside the U.S., call the nearest Dionex office.

NOTE All repairs of the AS-HV electronics must be performed

by Dionex personnel.

Before replacing any part, refer to the troubleshooting information in Section 4 to

isolate the cause of the problem.

Substituting non-Dionex parts may impair the performance of the ASHV, thereby voiding the product warranty. Refer to the warranty

statement in the Dionex Terms and Conditions for more information.

5.1 Cleaning the Syringe Pump

To remove precipitates (salts, etc.) and eliminate bacterial growth, clean the fluid

path of the syringe pump monthly.

1. Make a solution of 10% methanol (MeOH) by adding one part of MeOH to

nine parts of deionized water. Dionex recommends using ASTM Type I (or

better) filtered, deionized water.

2. Prime the pump with the 10% MeOH and allow the solution to remain in the

pump, with the syringe fully lowered, for 30 minutes.

3. After the 30-minute period, remove the reagent tubing from the 10% MeOH

solution and cycle all the fluid from the syringe and tubing into a waste

container.

4. Prime the pump a minimum of 10 cycles with distilled or deionized water.

Doc. 065125-01 10/06 47

Page 56

AS-HV Operator’s Manual

k

Val

5.2 Replacing the Sample Syringe

Follow the instructions here to install a new 10 mL syringe (P/N 064224) in the

syringe pump.

5.2.1 Removing the Existing Syringe

Refer to Figure 5-1 when removing the existing syringe.

1. Remove the liquid from the

syringe.

2. Remove the plunger lock

screw .

3. In Chromeleon, select

SyringeAspirate in the

Commands dialog box.

Select the maximum Volume

(i.e., the size of the installed

syringe) and click OK to

lower the plunger drive.

4. Unscrew the syringe from the

valve.

ve

Syringe

Remove the plunger loc

screw

Figure 5-1. Removing the Syringe

48 Doc. 065125-01 10/06

Page 57

5•Service

5.2.2 Filling the New Syringe and Removing Bubbles

Method A

1. Fill a container with isopropyl alcohol. Place the threaded end of the

syringe into the container and slowly pull liquid into the syringe.

2. If air bubbles are present, pull the syringe plunger up and then push

down rapidly with short movements to dislodge the bubbles. Repeat

until all bubbles are dislodged.

3. Draw a full syringe volume up by slowly pulling out the plunger.

4. Keep the syringe in the liquid and slowly push the syringe plunger

until the bubble(s) exit the syringe. Then, fill the syringe.

5. Remove the syringe from the liquid. While holding it vertically, push

a small amount of liquid out the top to make sure no air remains.

Method B

1. Fill a container with isopropyl alcohol. Place the threaded end of the

syringe into the container and slowly pull liquid into the syringe.

2. Remove the syringe from the liquid and hold it with the threaded end

up under a stream of deionized water.

3. Push the syringe plunger up and pull down until the bubbles are

removed.

Doc. 065125-01 10/06 49

Page 58

AS-HV Operator’s Manual

Val

w

5.2.3 Installing the New Syringe

Refer to Figure 5-2 when installing the new syringe.

1. Screw the new syringe into

the valve.

2. Pull the syringe plunger

down to the plunger holder

assembly.

3. Screw the syringe plunger

into place.

4. Slide the plunger lock screw

through the plunger buttons

and fasten to the carriage.

NOTE Make sure the

plunger lock screw is

securely tightened

and the plunger

button is free to move

on the plunger lock

screw.

ve

Syringe

Plunger Lock Scre

Figure 5-2. Installing the New Syringe

50 Doc. 065125-01 10/06

Page 59

5.2.4 Initializing the New Syringe

1. Turn off the AS-HV power,

wait 10 seconds, and turn on the

power again.

2. In Chromeleon, select

SyringeReset in the Commands

dialog box and click OK.

This moves the syringe plunger

down slightly, into its initial

position (see Figure 5-3

).

5•Service

Initial

Position

Figure 5-3. Initializing the New Syringe

Doc. 065125-01 10/06 51

Page 60

AS-HV Operator’s Manual

5.3 Replacing the Sampling Needle

5.3.1 Removing the Existing Sampling Needle

1. In Chromeleon, select NeedleHome in the Commands dialog box and

click OK.

2. Turn off the AS-HV power switch.

To avoid injury, always turn off the power to the AS-HV before

installing or removing the sampling needle.

Afin d'éviter toute blessure, couper impérativement l'alimentation

secteur avant d'installer ou de démonter l'aiguille de prélèvement.

Um Verletzungen zu vermeiden, schalten Sie den AS-HV bitte immer

aus, ehe Sie die Probennadel installieren oder deinstallieren.

3. Disconnect the power cord from the AS-HV power entry.

4. Remove the tubing from the tube anchors on the sampling arm (see

Figure 5-6

).

5. Cut off the tie wrap that secures the tubing through the eyelet

underneath the sampling arm housing (see Figure 5-5

).

6. Unscrew the mounting nut on the Z-axis slide and pull the sampling

needle mounting block out of the slide (see Figure 5-4

).

52 Doc. 065125-01 10/06

Page 61

5.3.2 Installing the New Sampling Needle

1. Move the Z-axis slide to the top of the carriage (see Figure 5-4).

Z-Axis Slide

Sampling Needle

Mounting Block

Mounting Nut

PEEK Sampling Needle Kit (P/N 064511);

Sampling Needle Kit–PTFE Lined and

Sleeved (P/N 064056)

Accessories Plate

Sampling Needle Guide

(P/N 064519)

5•Service

Figure 5-4. Installing the Sampling Needle

2. Slide the sampling needle mounting block into the Z-axis slide,

ensuring that the new sampling needle (PEEK Sampling Needle Kit,

P/N 064511; Sampling Needle Kit–PTFE Lined and Sleeved,

P/N 064056) passes through the accessories plate, and secure the

mounting block with the knurled mounting nut (see Figure 5-4

).

3. Screw the sampling needle guide (P/N 064519) onto the underside of

the accessories plate.

NOTE The sampling needle guide ensures that the

PEEK needle does not bend or flex as it pierces

the septum in the sample container cap.

4. Route the tubing to the right, around the sampling arm housing.

Doc. 065125-01 10/06 53

Page 62

AS-HV Operator’s Manual

e

5. Using a cable tie, attach

the tubing through the

Sampling Arm

Housing

eyelet on the underside of

the housing (see

Figure 5-5

). Leave a loop

of about 10 mm (0.39 in)

Use a cable tie to

attach the tubing

through the eyelet

in the cable tie.

Figure 5-5. Attaching the Cable Tie to the Tubing

6. Locate one tube anchor along the X-axis cover, about 18 cm (7 in)

from the column case. Locate the second tube anchor toward the

back, about 11.4 cm (4.5 in) from the column case (see Figure 5-6

X-Axis Cover

Install this tube

anchor first

Install this tub

anchor second

).

Figure 5-6. Attaching the Tubing to the Middle Tube Anchor

7. Attach the tubing to the middle tube anchor (the anchor installed

first), using the two tube markers (see Figure 5-6

).

8. Route the tubing along the side of the X-axis arm. Anchor the tubing

in position, spacing the tube anchors so as to minimize the route to the