Page 1

AS Autosampler

Operator's Manual

Document No. 065051

Revision 03

January 2008

Page 2

©2008 by Dionex Corporation

All rights reserved worldwide.

Printed in the United States of America.

This publication is protected by federal copyright law. No part of this publication

may be copied or distributed, transmitted, transcribed, stored in a retrieval system, or

transmitted into any human or computer language, in any form or by any means,

electronic, mechanical, magnetic, manual, or otherwise, or disclosed to third parties

without the express written permission of Dionex Corporation, 1228 Titan Way,

Sunnyvale, California 94088-3603 U.S.A.

DISCLAIMER OF WARRANTY AND LIMITED WARRANTY

THIS PUBLICATION IS PROVIDED “AS IS” WITHOUT WARRANTY OF

ANY KIND. DIONEX CORPORATION DOES NOT WARRANT,

GUARANTEE, OR MAKE ANY EXPRESS OR IMPLIED

REPRESENTATIONS REGARDING THE USE, OR THE RESULTS OF THE

USE, OF THIS PUBLICATION IN TERMS OF CORRECTNESS, ACCURACY,

RELIABILITY, CURRENTNESS, OR OTHERWISE. FURTHER, DIONEX

CORPORATION RESERVES THE RIGHT TO REVISE THIS PUBLICATION

AND TO MAKE CHANGES FROM TIME TO TIME IN THE CONTENT

HEREINOF WITHOUT OBLIGATION OF DIONEX CORPORATION TO

NOTIFY ANY PERSON OR ORGANIZATION OF SUCH REVISION OR

CHANGES.

TRADEMARKS

Chromeleon is a registered trademark and PolyVial is a trademark of Dionex

Corporation.

PEEK is a trademark of Victrex plc.

Teflon and Tefzel are registered trademarks of E.I. duPont de Nemours & Co.

Microsoft, Windows XP, and Windows 2000 are registered trademarks of Microsoft

Corporation.

PRINTING HISTORY

Revision 01, May 2005

Revision 02, August 2006

Revision 03, January 2008

Page 3

1 • Introduction

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2.1 Safety Messages and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Safety and Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3.1 Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2•Description

2.1 Overview of Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Front Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.1 Keypad Button Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Contents

2.2.2 Display Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3 Autosampler Compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.3.1 Syringe and Reservoir Organizer . . . . . . . . . . . . . . . . . . . . . . . 15

2.3.2 Sampling Needle Arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.3.3 Sampling Needle Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.3.4 Flush, Waste, and Inject Ports . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.3.5 Sample Vials and Well Plates . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.3.6 Injection Valve Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.3.7 Sample Temperature Control Option . . . . . . . . . . . . . . . . . . . . 22

2.3.8 Simultaneous Injection Option . . . . . . . . . . . . . . . . . . . . . . . . . 23

Doc. 065051-03 1/08 i

Page 4

AS Autosampler Operator’s Manual

2.3.9 Sequential Injection Option . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

2.3.10 Concentrator Injection Option . . . . . . . . . . . . . . . . . . . . . . . . . .24

2.4 Rear Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

2.4.1 USB Receptacle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

2.4.2 TTL/Relay Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

2.4.3 Fuse Holder and Power Receptacle . . . . . . . . . . . . . . . . . . . . . .26

2.5 Autosampler Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

2.5.1 Local Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

2.5.2 Computer Control (Locked Remote Mode) . . . . . . . . . . . . . . .30

2.6 System Wellness and Predictive Performance . . . . . . . . . . . . . . . . . . . .31

2.7 Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

2.7.1 Understanding the Wait Operation . . . . . . . . . . . . . . . . . . . . . .33

2.7.2 Overlapping Sample Preparation . . . . . . . . . . . . . . . . . . . . . . . .34

2.7.3 Running Samples Without Overlap . . . . . . . . . . . . . . . . . . . . . .35

2.7.4 Operating the AS as the System Master (Disabling the

Wait Operation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

2.7.5 Understanding the Cycle Time . . . . . . . . . . . . . . . . . . . . . . . . .36

2.7.6 Operating Events During a Schedule . . . . . . . . . . . . . . . . . . . .37

2.7.7 Understanding the Status Display During a Run . . . . . . . . . . . .40

2.7.8 Operating Events During Flushing and Priming . . . . . . . . . . . .41

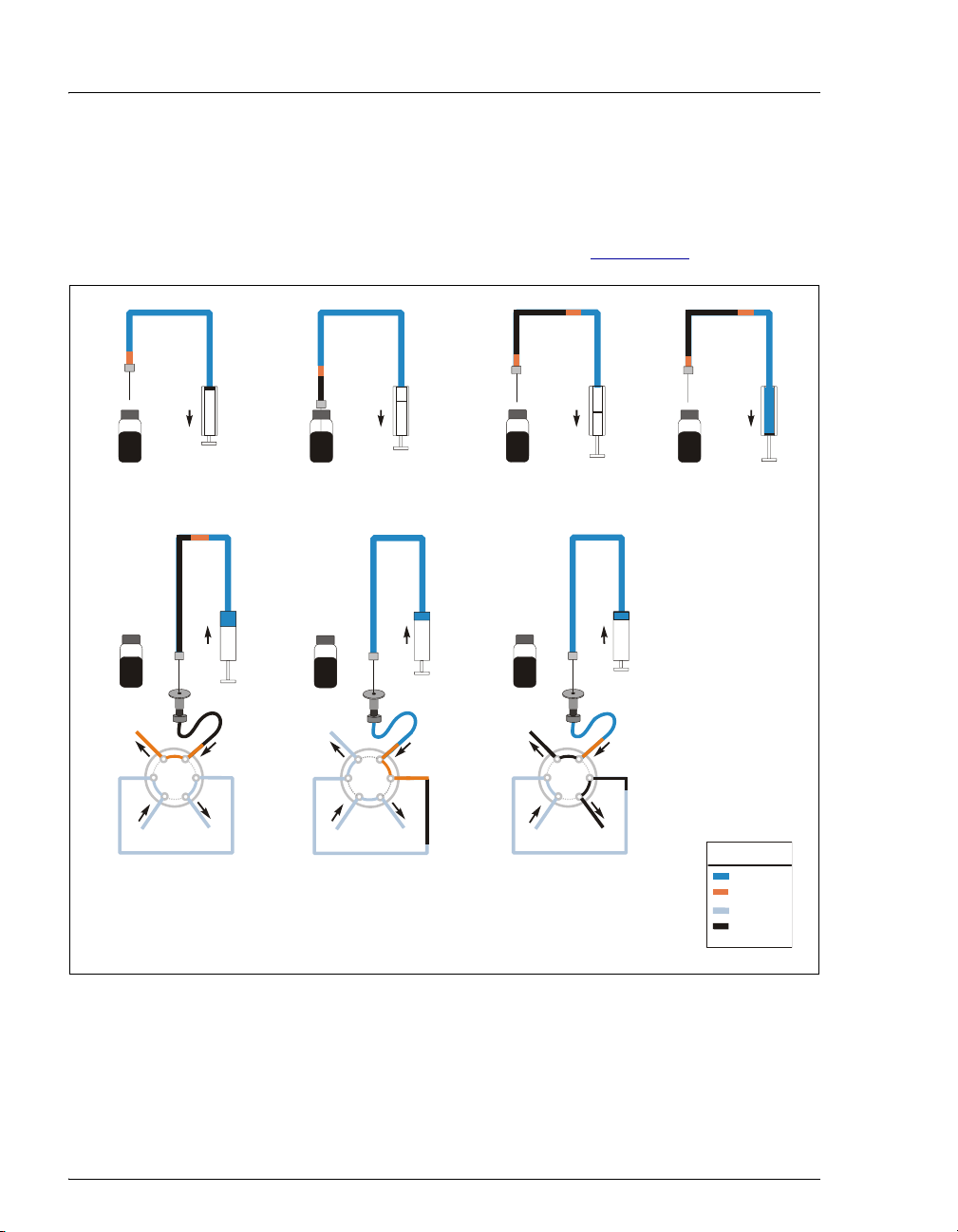

2.7.9 Sample and Prep Syringe Fluid Schematics . . . . . . . . . . . . . . .42

3 • Operation and Maintenance

3.1 Getting Ready to Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

3.1.1 Turn On the Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

ii Doc. 065051-03 1/08

Page 5

Contents

3.1.2 Fill the Vials or Wells and Load the Sample Tray . . . . . . . . . . 46

3.2 Selecting Computer or Front Panel (Local) Control . . . . . . . . . . . . . . . 51

3.2.1 Connecting to Chromeleon or Chromeleon Xpress . . . . . . . . . 52

3.2.2 Running a Sequence of Injections in Chromeleon or

Chromeleon Xpress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3.3 Default Operating Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

3.4 Specifying Sample Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

3.4.1 Vial Tray Sample Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

3.4.2 Well Plate Tray Sample Positions . . . . . . . . . . . . . . . . . . . . . . 57

3.5 Specifying Injection Volumes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

3.6 Sample Injection Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

3.6.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

3.6.2 Determining the Injection Type . . . . . . . . . . . . . . . . . . . . . . . . 62

3.6.3 Determining the Sample Loop Injection Type . . . . . . . . . . . . . 63

3.6.4 Guidelines for Sample Volumes Used, Loop Sizes, and

Injection Volumes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

3.6.5 Normal, Full-Loop Injections . . . . . . . . . . . . . . . . . . . . . . . . . . 70

3.6.6 Normal, Large-Loop Injections . . . . . . . . . . . . . . . . . . . . . . . . 72

3.6.7 Normal, Partial-Loop Injections . . . . . . . . . . . . . . . . . . . . . . . . 73

3.6.8 Normal, Partial-Loop, Limited-Sample Injections . . . . . . . . . . 76

3.6.9 Simultaneous Injections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

3.6.10 Concentrate Injections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

3.6.11 Sequential Injections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

3.6.12 Sequential Concentrate Injections . . . . . . . . . . . . . . . . . . . . . . 90

3.7 Selecting Syringe Speed Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Doc. 065051-03 1/08 iii

Page 6

AS Autosampler Operator’s Manual

3.7.1 Selecting Syringe Speeds on the Control Panel . . . . . . . . . . . .93

3.7.2 Entering Syringe Speeds in the Program . . . . . . . . . . . . . . . . . .94

3.8 Syringe Speed and Tubing Size Guidelines . . . . . . . . . . . . . . . . . . . . . .97

3.9 Opening the Autosampler Door During Operation . . . . . . . . . . . . . . .100

3.10 Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

3.10.1 Daily . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

3.10.2 Periodically . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

3.10.3 Annually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

3.10.4 Manually Flushing the Inject Port . . . . . . . . . . . . . . . . . . . . . .103

3.11 System Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

4 • Troubleshooting

4.1 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

4.2 Liquid Leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

4.2.1 Leaking Syringe or Syringe Valve Port . . . . . . . . . . . . . . . . . .124

4.2.2 Leaking Drain Line Connection . . . . . . . . . . . . . . . . . . . . . . .125

4.2.3 Leaking Inject Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

4.2.4 Leaking Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

4.2.5 Broken Liquid Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

4.3 Condensation on Well Plate Covers . . . . . . . . . . . . . . . . . . . . . . . . . . .126

5•Service

5.1 Replacement Tubing and Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

5.1.1 Syringe and Reservoir Connections . . . . . . . . . . . . . . . . . . . .127

iv Doc. 065051-03 1/08

Page 7

Contents

5.1.2 Assemblies, Tubing, and Fittings . . . . . . . . . . . . . . . . . . . . . . 128

5.2 Resetting the Usage Counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

5.2.1 Resetting a Usage Counter on the AS Wellness Panel . . . . . . 130

5.2.2 Resetting a Usage Counter on the Usage Log Screen . . . . . . 131

5.3 Replacing the Sample or Prep Syringe . . . . . . . . . . . . . . . . . . . . . . . . 132

5.3.1 Removing the Existing Syringe . . . . . . . . . . . . . . . . . . . . . . . 133

5.3.2 Filling the New Syringe and Removing Bubbles . . . . . . . . . . 134

5.3.3 Connecting the New Syringe and Flushing . . . . . . . . . . . . . . 134

5.3.4 Initializing the Syringe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

5.3.5 Resetting the Syringe Usage Counter . . . . . . . . . . . . . . . . . . . 136

5.4 Replacing the Sampling Needle Assembly . . . . . . . . . . . . . . . . . . . . . 136

5.4.1 Removing the Old Sampling Needle Assembly . . . . . . . . . . . 138

5.4.2 Installing the New Sampling Needle Assembly . . . . . . . . . . . 142

5.4.3 Resetting the Sampling Needle Assembly Usage Counter . . 145

5.5 Removing the Drip Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

5.6 Installing the Drip Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

5.7 Replacing the Needle Seal Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 148

5.8 Aligning the Sampling Needle in the Inject Port . . . . . . . . . . . . . . . . . 151

5.9 Calibrating the Inject Port Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

5.10 Replacing the Leak Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

5.11 Calibrating the Leak Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

5.12 Removing the Sample or Prep Syringe Valve . . . . . . . . . . . . . . . . . . . 164

5.13 Replacing the Sample Syringe Valve . . . . . . . . . . . . . . . . . . . . . . . . . 165

5.14 Replacing the Prep Syringe Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

5.15 Replacing a Sample or Prep Syringe Pump Assembly . . . . . . . . . . . . 169

Doc. 065051-03 1/08 v

Page 8

AS Autosampler Operator’s Manual

5.16 Rebuilding the Injection or Diverter Valve . . . . . . . . . . . . . . . . . . . . .170

5.17 Replacing the Well Plate Tray Thermal Pads . . . . . . . . . . . . . . . . . . . .172

5.18 Changing the Main Power Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . .173

A • Specifications

A.1 Autosampler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

A.1.1 Electrical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

A.1.2 Environmental/Physical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

A.1.3 Valves (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .176

A.1.4 Injection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .176

A.2 Sample Temperature Control (Optional) . . . . . . . . . . . . . . . . . . . . . . .177

B • Installation

B.1 Facility Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .179

B.2 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .180

B.3 Autosampler Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .186

B.3.1 Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .186

B.3.2 Installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .186

B.3.3 Connecting the Syringes and Drain Line . . . . . . . . . . . . . . . . .187

B.3.4 Connecting a Single Injection Valve . . . . . . . . . . . . . . . . . . . .191

B.3.5 Connecting Two Injection Valves (for Simultaneous

Injections) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .193

B.3.6 Connecting a Diverter Valve (for Sequential Injections) . . . . .197

B.3.7 Connecting a Second AS to a Dual ICS-3000 System . . . . . . .200

vi Doc. 065051-03 1/08

Page 9

Contents

B.3.8 Connecting the AS to Chromeleon or Chromeleon

Xpress (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

B.3.9 Connecting the Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . 206

B.3.10 Turning On the Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

B.3.11 Selecting Module Setup Options . . . . . . . . . . . . . . . . . . . . . . 208

B.3.12 Configuring the AS in Chromeleon or Chromeleon Xpress . . 212

B.3.13 Priming the Liquid Lines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

B.3.14 Removing Bubbles from the Syringe . . . . . . . . . . . . . . . . . . . 218

B.4 Injection Valve Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

B.5 Setting Up Chromeleon or Chromeleon Xpress for Simultaneous

Injections 220

B.5.1 Assigning Unique Names to Devices . . . . . . . . . . . . . . . . . . . 220

B.5.2 Creating Sequences, Programs, and Quantification Methods . 224

C • Display Screens

C.1 Menu of Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

C.2 Main Status Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

C.3 Detail Status Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

C.4 Method Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

C.4.1 Sample Prep Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

C.4.2 Method Setup Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

C.4.3 Timed Events Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

C.5 Schedule Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

C.6 Module Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

C.6.1 Installed Options Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Doc. 065051-03 1/08 vii

Page 10

AS Autosampler Operator’s Manual

C.6.2 Front Panel Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .248

C.6.3 Plumbing Configuration Screen . . . . . . . . . . . . . . . . . . . . . . . .249

C.6.4 Time/Date Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .251

C.6.5 System Parameters Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . .252

C.6.6 Inject Port Alignment Screen . . . . . . . . . . . . . . . . . . . . . . . . . .255

C.6.7 Door Interlock Bypass Screen . . . . . . . . . . . . . . . . . . . . . . . . .256

C.7 Flush/Prime Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .257

C.8 Time Function In Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .259

C.9 Diagnostic Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .260

C.9.1 Power-Up Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .260

C.9.2 Diagnostic Tests Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .261

C.9.3 XYZ Test Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .262

C.9.4 Temperature Statistics Screen . . . . . . . . . . . . . . . . . . . . . . . . .263

C.9.5 Liquid Control Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .264

C.9.6 Logs Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .267

C.9.7 Leak Sensor Calibration and Status Screen . . . . . . . . . . . . . . .270

C.9.8 Keyboard Test Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .271

C.9.9 Code Versions Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .272

C.10 Time Function Out Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .272

D • Front Panel Control

D.1 Accessing AS Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .273

D.2 Entering or Changing Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .273

D.3 Running a Schedule of Injections from the Front Panel . . . . . . . . . . . .274

viii Doc. 065051-03 1/08

Page 11

Contents

D.3.1 Selecting and Starting the Schedule . . . . . . . . . . . . . . . . . . . . 275

D.3.2 Placing a Running Schedule on Hold . . . . . . . . . . . . . . . . . . . 276

D.3.3 Stopping a Running Schedule . . . . . . . . . . . . . . . . . . . . . . . . . 276

D.4 Running Under Direct Control from the Front Panel . . . . . . . . . . . . . 277

D.5 Creating Methods from the AS Front Panel . . . . . . . . . . . . . . . . . . . . 279

D.5.1 Creating a Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

D.5.2 Saving a Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

D.5.3 Defining Sample Prep Steps . . . . . . . . . . . . . . . . . . . . . . . . . . 281

D.5.4 Selecting Method Setup Parameters . . . . . . . . . . . . . . . . . . . . 291

D.5.5 Defining Timed Events Steps . . . . . . . . . . . . . . . . . . . . . . . . . 294

D.5.6 Editing a Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

D.5.7 Deleting a Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

D.5.8 Copying a Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

D.5.9 Example Method for Dilution . . . . . . . . . . . . . . . . . . . . . . . . . 298

D.6 Creating Schedules from the AS Front Panel . . . . . . . . . . . . . . . . . . . 298

D.6.1 Creating a New Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

D.6.2 Saving a Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

D.6.3 Selecting an Action if a Scheduled Vial Is Missing . . . . . . . . 300

D.6.4 Defining Schedule Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

D.6.5 Editing a Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

D.6.6 Deleting a Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

D.6.7 Copying a Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

D.7 Selecting Syringe Speeds for Front Panel Operation . . . . . . . . . . . . . 304

D.8 Aligning the Sampling Needle from the AS Front Panel . . . . . . . . . . 306

D.9 Calibrating the Inject Port Volume from the AS Front Panel . . . . . . . 311

Doc. 065051-03 1/08 ix

Page 12

AS Autosampler Operator’s Manual

E • TTL and Relay Control

E.1 TTL and Relay Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .317

E.1.1 Connecting a TTL or Relay . . . . . . . . . . . . . . . . . . . . . . . . . . .318

E.1.2 Selecting TTL Input Control Types . . . . . . . . . . . . . . . . . . . . .319

E.2 Controlling TTL and Relay Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . .321

E.2.1 Example TTL/Relay Connections . . . . . . . . . . . . . . . . . . . . . .322

F • Reordering Information

x Doc. 065051-03 1/08

Page 13

1.1 Overview

The Dionex AS Autosampler precisely delivers from 1 to 8,000 μL of sample to

an injection valve. The injection volume range delivered by a particular AS

depends on the size of the sample syringe and the sampling mode.

Modes

Several sampling modes are available:

• In normal mode, sample is delivered to a single system and a sample loop is

installed on the injection valve.

• In concentrate mode, the AS delivers sample to a Dionex ultra-low pressure

concentrator column.

• In simultaneous mode, the AS can deliver sample to two independent ion

chromatography (IC) systems. Sample is delivered equally to the two IC

systems (50% of the volume to each). This mode requires the simultaneous

injection option.

1 • Introduction

• In sequential mode, a diverter valve allows sample to be delivered to two

independent channels or IC systems through sequential injections. This mode

requires the sequential injection option.

• In sequential concentrate mode, a diverter valve allows sample to be delivered

to two independent channels or IC systems on which Dionex ultra-low

pressure concentrator columns are installed.

Sample Temperature Control

The sample temperature control option provides uniform heating and cooling of

the vial tray.

Sample Preparation

The sample preparation option is used for automated dilutions and pipet functions.

Doc. 065051-03 1/08 1

Page 14

AS Autosampler Operator’s Manual

Injection Valve Options

The AS can be configured either without an injection valve, or with one or two

injection valves installed in the autosampler compartment.

Vials, Well Plates, and Sample Trays

The AS can sample from either vials or well plates. Several types of sample trays

are available to accommodate the various vial and well plate sizes. Insulated trays

are available for use with the sample temperature control option.

During sampling, the tray remains stationary and a sampling needle arm moves

from position to position. Up to 99 injections can be taken from each vial or well.

Control

The AS can be controlled locally, from the front panel keypad and display, or

remotely, with a personal computer running Windows

Chromeleon

or later), or Chromeleon Xpress (Release 1.0 or later). Limited remote control is

also available, using TTL and relay signals.

For communication between the AS and the software, the AS is connected to a

USB (Universal Serial Bus) port on the computer, USB hub, or other Dionex

module equipped with a USB hub.

® Chromatography Data Management System software (Release 6.7

® 2000 or Windows XP and

2 Doc. 065051-03 1/08

Page 15

1.2 About This Manual

1 • Introduction

Chapter 1

Introduction

Chapter 2

Description

Chapter 3

Operation and

Maintenance

Chapter 4

Troubleshooting

Chapter 5

Service

Appendix A

Specifications

Appendix B

Installation

Appendix C

Display Screens

Appendix D

Front Panel Control

Introduces the AS; explains the conventions used in

this manual, including safety-related information.

Describes the AS operating features and system

components; provides the theory of operation.

Provides operating instructions for the AS and

describes routine preventive maintenance

procedures.

Lists problems and presents step-by-step

procedures for how to isolate and eliminate the

cause of each problem.

Provides step-by-step instructions for routine

service and parts replacement procedures that the

user can perform.

Lists the AS specifications and installation site

requirements.

Describes how to install the AS.

Describes the front panel operational and diagnostic

display screens.

Provides step-by-step instructions for operating the

AS from the front panel.

Appendix E

TTL and Relay Control

Appendix F

Reordering Information

NOTE For details about using Chromeleon or Chromeleon

Xpress to operate the AS, refer to the Chromeleon or

Chromeleon Xpress Help. If you are using Chromeleon

Xpress, also refer to the Chromeleon Xpress Quick

Reference Guide (P/N 065070), provided on the Dionex

Reference Library CD-ROM (P/N 053891).

Doc. 065051-03 1/08 3

Describes the AS TTL and relay control features.

Lists spare parts for the AS.

Page 16

AS Autosampler Operator’s Manual

1.2.1 Safety Messages and Notes

This manual contains warnings and precautionary statements that can

prevent personal injury and/or damage to the AS when properly followed.

Safety messages appear in bold type and are accompanied by icons, as

shown below.

Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury. Also used to identify a situation or

practice that may seriously damage the instrument, but will not cause

injury.

Indicates that the function or process of the instrument may be

impaired. Operation does not constitute a hazard.

Messages d'avertissement en français

Signale une situation de danger immédiat qui, si elle n'est pas évitée,

entraînera des blessures graves à mortelles.

Signale une situation de danger potentiel qui, si elle n'est pas évitée,

pourrait entraîner des blessures graves à mortelles.

Signale une situation de danger potentiel qui, si elle n'est pas évitée,

pourrait entraîner des blessures mineures à modérées. Également

utilisé pour signaler une situation ou une pratique qui pourrait

gravement endommager l'instrument mais qui n'entraînera pas de

blessures.

4 Doc. 065051-03 1/08

Page 17

1 • Introduction

Warnhinweise in Deutsch

Bedeutet unmittelbare Gefahr. Mißachtung kann zum Tod oder

schwerwiegenden Verletzungen führen.

Bedeutet eine mögliche Gefährdung. Mißachtung kann zum Tod oder

schwerwiegenden Verletzungen führen.

Bedeutet eine mögliche Gefährdung. Mißachtung kann zu kleineren

oder mittelschweren Verletzungen führen. Wird auch verwendet, wenn

eine Situation zu schweren Schäden am Gerät führen kann, jedoch

keine Verletzungsgefahr besteht.

Notes

Informational messages also appear throughout this manual. These are

labeled NOTE and are in bold type:

NOTE NOTES call attention to certain information. They alert

you to an unexpected result of an action, suggest how to

optimize instrument performance, etc.

Doc. 065051-03 1/08 5

Page 18

AS Autosampler Operator’s Manual

1.3 Safety and Regulatory Information

The AS is designed for IC (ion chromatography) and HPLC (high-performance

liquid chromatography) applications and should not be used for any other

purpose. Operation of an AS in a manner not specified by Dionex may result in

personal injury.

1.3.1 Safety Labels

The TUV GS and cTUVus Mark safety labels and the CE Mark label on

the AS indicate that the AS is in compliance with the following standards:

EN 61010-1:2001 (safety), CAN/CSA-C22.2 No. 1010.1-92 + A2:97

(safety), UL 61010C-1:2002 R8.02 (safety), and EN 61326:1997,

including A1:1998 and A2:2001 (EMC susceptibility and immunity).

The symbols below appear on the AS or on AS labels.

Alternating current

Protective conductor terminal (earth ground)

Power supply is on

Power supply is off

Indicates a potential hazard. Refer to the operator’s manual for

an explanation of the hazard and how to proceed.

6 Doc. 065051-03 1/08

Page 19

2.1 Overview of Features

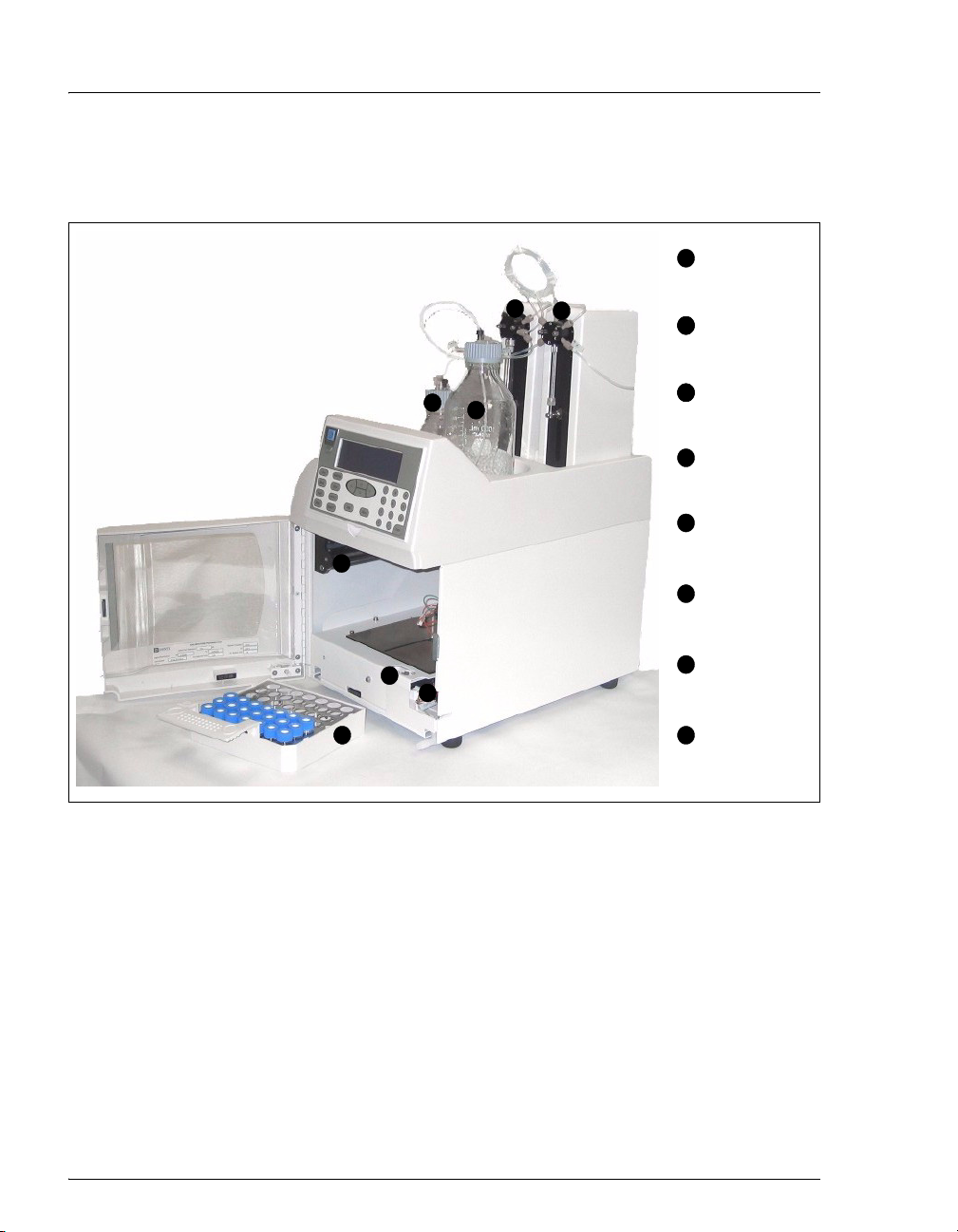

Figure 2-1 illustrates the main features of the AS Autosampler.

Flush

Reservoir

2 • Description

Sample and

Prep Syringes

Front

Panel

Autosampler

Compartment

Power

Switch

Figure 2-1. AS Operating Features

Doc. 065051-03 1/08 7

Page 20

AS Autosampler Operator’s Manual

Front Panel

The front panel contains a liquid crystal display (LCD) and membrane keypad

(see Section 2.2

Power Switch

The power switch is in the lower left corner of the AS. The switch functions only

when the door is fully closed.

Autosampler Compartment

The autosampler compartment contains a stationary sample tray and an XYZ

sampling needle arm that moves from vial to vial during operation (see

Section 2.3

port. Valves for sample injection or for diverting sample flow to different systems

can optionally be included.

Syringe and Reservoir Organizer

The organizer on top of the autosampler holds the sample syringe, the flush liquid

reservoir, and the optional prep syringe and reagent reservoirs. See Section 2.3.1

for details.

). The front panel permits manual control of AS functions.

). The compartment also contains an inject port, flush port, and waste

Options

• Sample Preparation: When this option is installed, the AS can perform

sample preparation functions such as diluting standards or dispensing

reagents. See Section 2.3.1

for details.

• Sample Temperature Control (not pictured): When this option is installed,

the AS provides uniform heating and cooling of the sample tray. See

Section 2.3.7

for details.

• Simultaneous Injection (not pictured): When this option is installed, the AS

can deliver sample to two independent ion chromatography (IC) systems

simultaneously. See Section 3.6.9

for details.

• Sequential Injection (not pictured): When this option is installed, the AS can

deliver sample to two independent ion chromatography (IC) systems

alternately.

• Concentrator Injection (not pictured): When this option is installed, the AS

can load sample to a Dionex ultra-low pressure concentrator column. See

Section 2.3.10 for details.

8 Doc. 065051-03 1/08

Page 21

Valve Options

One or two injection valves can be installed in the AS autosampler compartment.

Or, the AS can be configured without an injection valve and instead be connected

to one or two valves installed in other chromatography system modules. Two

injection valves are required for simultaneous injections.

For the sequential injection option, a diverter valve is installed in the AS.

2.2 Front Panel Features

2 • Description

Adjust screen contrast

Figure 2-2. AS Front Panel

Information is displayed on the LCD, or screen. To adjust the screen contrast, use

the knurled knob in the recess below the keypad (see Figure 2-2

).

From the keypad, you can:

• Directly control AS operation

• Create and modify programmed series of operating steps, called methods

• Create and modify programmed series of injections, called schedules

Refer to Section 2.2.2

Doc. 065051-03 1/08 9

for a summary of how to select screens and edit parameters.

Page 22

AS Autosampler Operator’s Manual

(

)

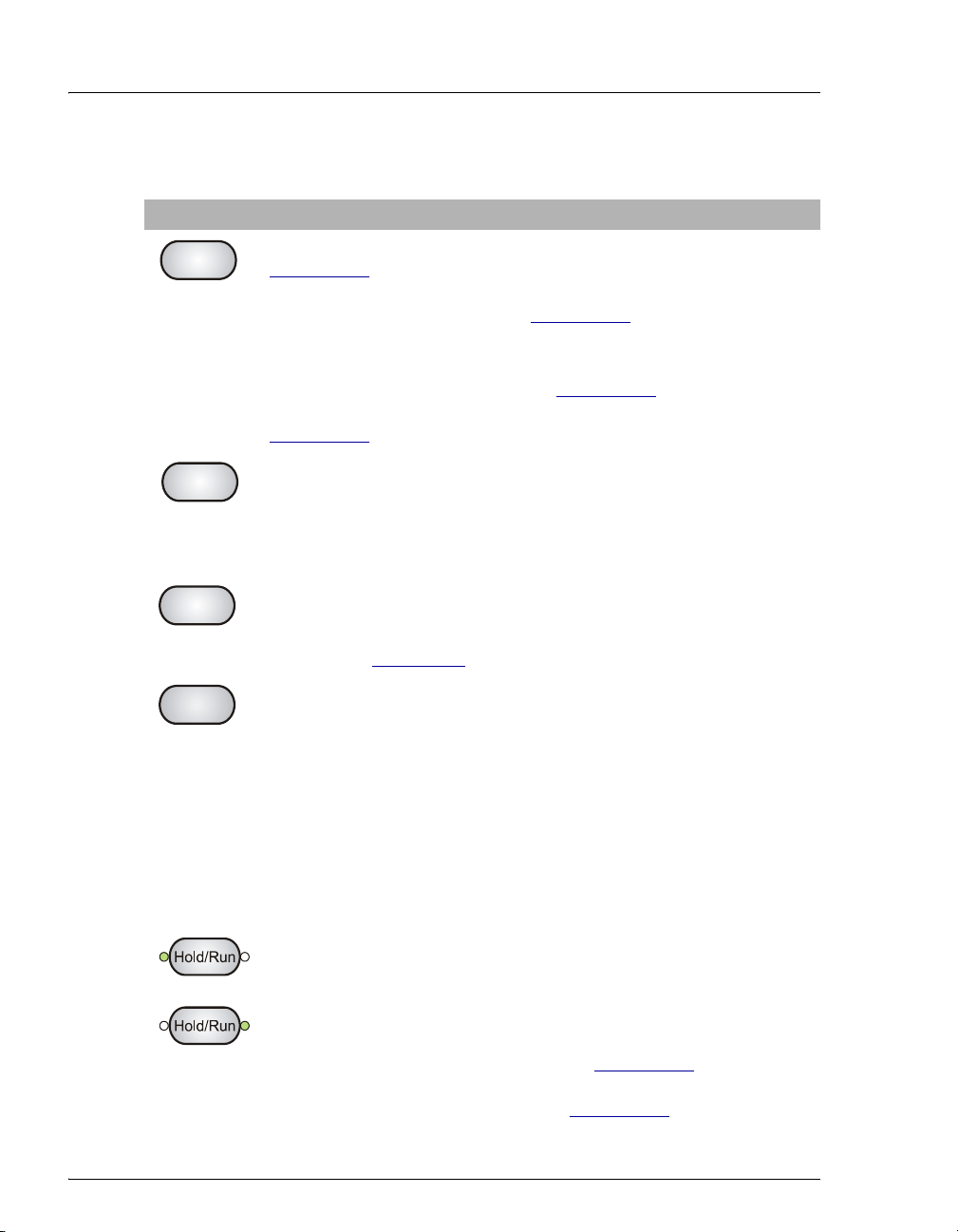

2.2.1 Keypad Button Functions

Button Function

Stop

Stops a schedule if the AS is in Local mode, Schedule control (see

Section 2.5.1

). A confirmation message appears; press Stop again to

abort the schedule or Hold/Run to resume.

If the AS is in Direct Control (see Section 2.5.1

the current syringe and/or sampling arm movement.

Note: Pressing Stop while the AS is in Direct Control, Locked

Remote mode (software control) (see Section 2.5.2

recommended. Use the controls on the software Control panel (see

Section 2.5.2

) to stop a sequence.

), pressing Stop stops

) is not

Home

Insert

Delete

(Hold)

Run

Sends the needle arm to its home position. This button functions only

when the AS is in Local mode. If a schedule is in progress, it must be

on hold. If you press Home when a schedule is on hold, and then

resume the schedule, the needle arm returns to the location it was in

when you pressed Home.

Inserts a new step into a method or schedule. Move the cursor to the

leftmost field on the

SAMPLE PREP, TIMED EVENTS, or SCHEDULE

screen and press Insert. The new step is added above the cursor

position. See Appendix D

for details about front panel operation.

Delete performs several functions:

• Cancels an entry that is in progress and restores the previous value.

• Returns a field to its default value (if an entry is not in progress).

• Deletes a line in a method or schedule. To do this, position the

cursor in the leftmost field of the line that you want to delete and

press Delete twice.

• Deletes an entire method or schedule. To do this, position the

cursor in the method or schedule edit field, or in the time field of

the

INIT step, and press Delete twice.

At power-up, the AS is on hold (the left LED is illuminated). After you

select a schedule to run, pressing Hold/Run starts the schedule (the

right LED is illuminated). When the schedule is complete, the AS

returns to hold. When running, press Hold/Run to pause the schedule.

This button functions only when the AS is in Local mode.

Note: If the wait operation is enabled (see Section 2.7.1

pauses when it reaches the wait step in the method. Press Hold/Run to

continue. You can disable the wait (see Section 2.7.4

), the AS

).

10 Doc. 065051-03 1/08

Page 23

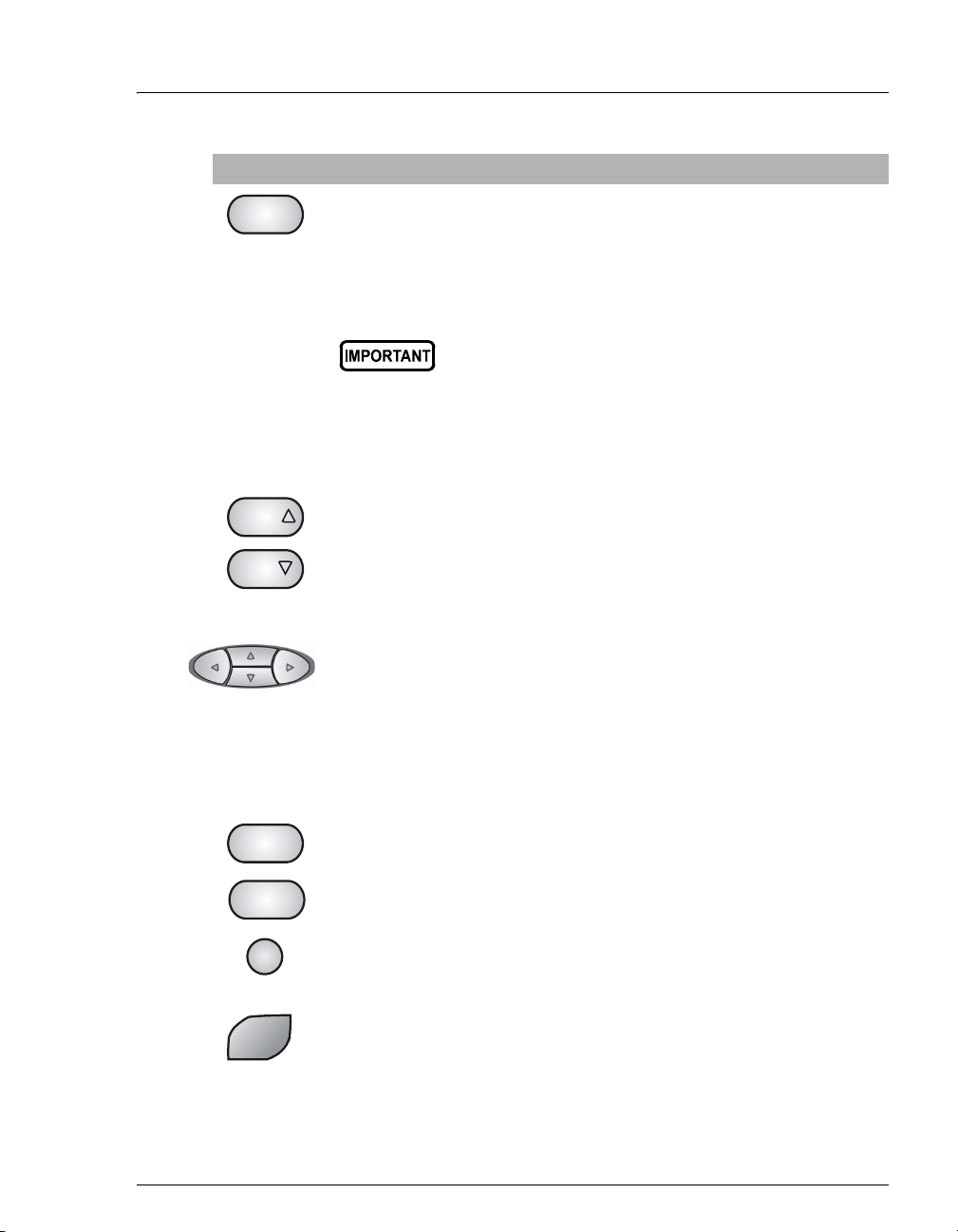

Button Function

If you press the Door button when a sequence (or front panel

Door

schedule) is running, a message screen indicates whether it is currently

safe to open the door. If it is, the screen displays for how much longer it

is safe to open the door. Opening the door without first pressing this

button, or when the message indicates it is not safe, ends the currently

running sequence (or schedule).

Select

The Select buttons scroll through predetermined options in entry

fields. To confirm the selected value, press Enter or move out of the

field by pressing a cursor arrow button. In fields that have

Select

predetermined numeric choices, Select Δ increases the value by one

unit and Select ∇ decreases the value by one. Holding down a Select

button increases (or decreases) the value continuously.

The arrow buttons move the cursor in the direction of the arrow to the

next entry field (if one exists). At the end of a line, the left arrow wraps

the cursor around to the next entry field on the line above; the right

arrow wraps the cursor to the next entry field on the line below. The up

and down arrows do not wrap around.

2 • Description

The autosampler door must remain closed during

operation. If the door is opened during operation,

the sampling arm stops immediately. If a sequence

(or schedule) is running, it is ended. If you want to

open the door during a sequence (or schedule),

first press the Door button, and then follow the onscreen instructions.

After entering a new value in an entry field, pressing an arrow button

saves and/or executes the change.

Displays a help screen specific to the current entry field.

Help

Displays a list of the available screens.

Menu

1

The numeric buttons enter the selected number into the current entry

field. On a menu, pressing a numeric button opens the corresponding

screen.

Enter

Doc. 065051-03 1/08 11

Saves and/or executes changes made in entry fields. If a menu screen is

displayed, pressing Enter opens the highlighted screen.

Page 24

AS Autosampler Operator’s Manual

g

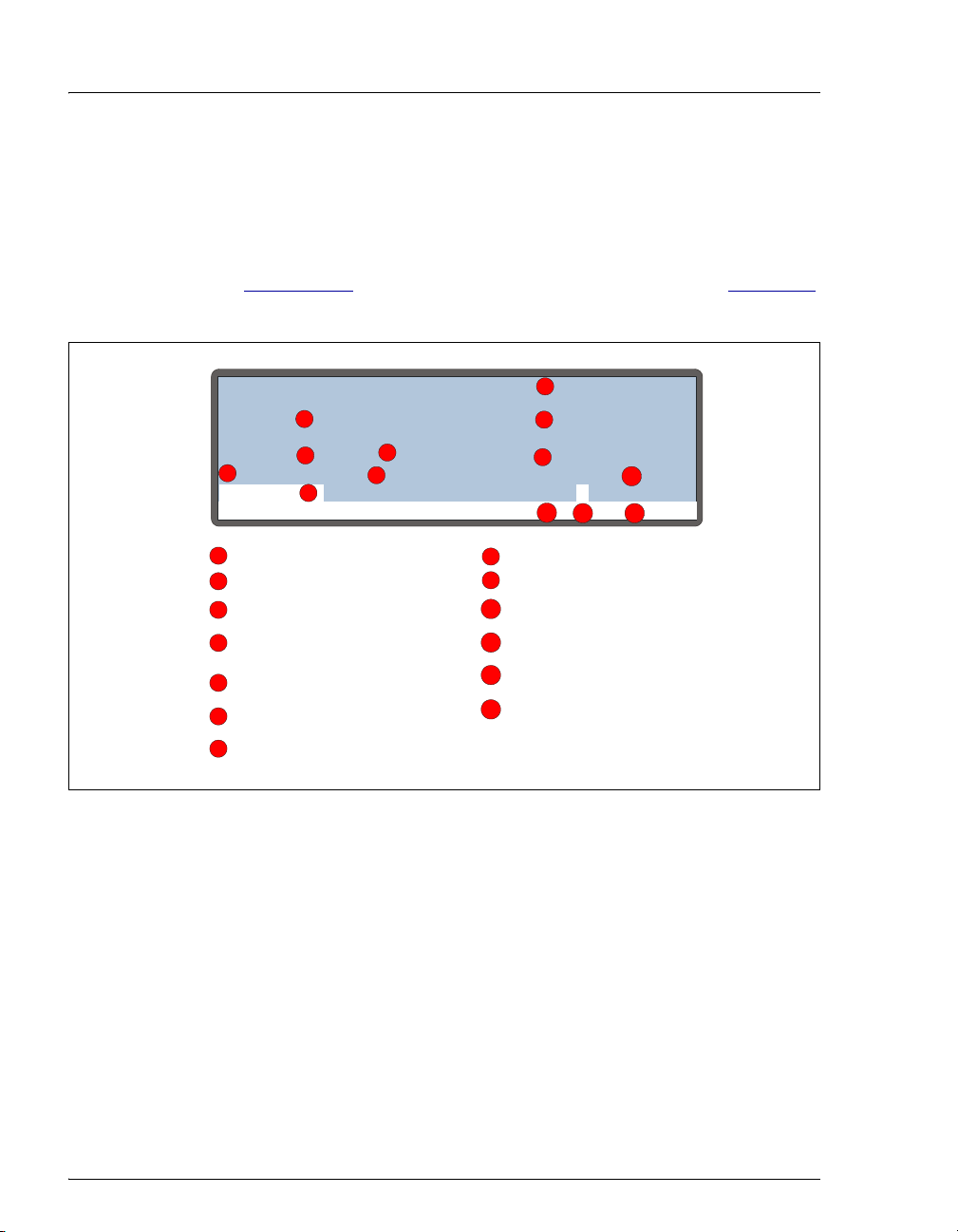

2.2.2 Display Screens

The LCD displays status information and allows access to all AS

operations.

When the power is turned on, the AS performs an initialization sequence

(see Section 3.1.1

is an example of the

) and then displays the MAIN STATUS screen. Figure 2-3

MAIN STATUS screen during AS operation.

1

8

9

VOL

8

9

20.013

METHOD: 01

SCH LINE

11

Time since last injection

Volume to be injected

Current method

Control mode

Current s chedule

Schedule line currently in

progress

10

1

121113

min

uL

8

INJ#

2

10 10.6

3

/

6

°C

↑

20

7

status

m ode

VIAL#

5

TRAY:

LOCAL

Help Prompt

Operating status

1

Current vial or well

2

3

Current injection

Total injections s cheduled

4

for this vial

Current tray temperature

5

Tray temperature

6

(increasing)

Operatin

7

LOADING LOOP

TIME

4

10

12

13

Figure 2-3. Main Status Screen

NOTE TRAY temperature is displayed only when the

sample temperature control option is installed.

12 Doc. 065051-03 1/08

Page 25

2 • Description

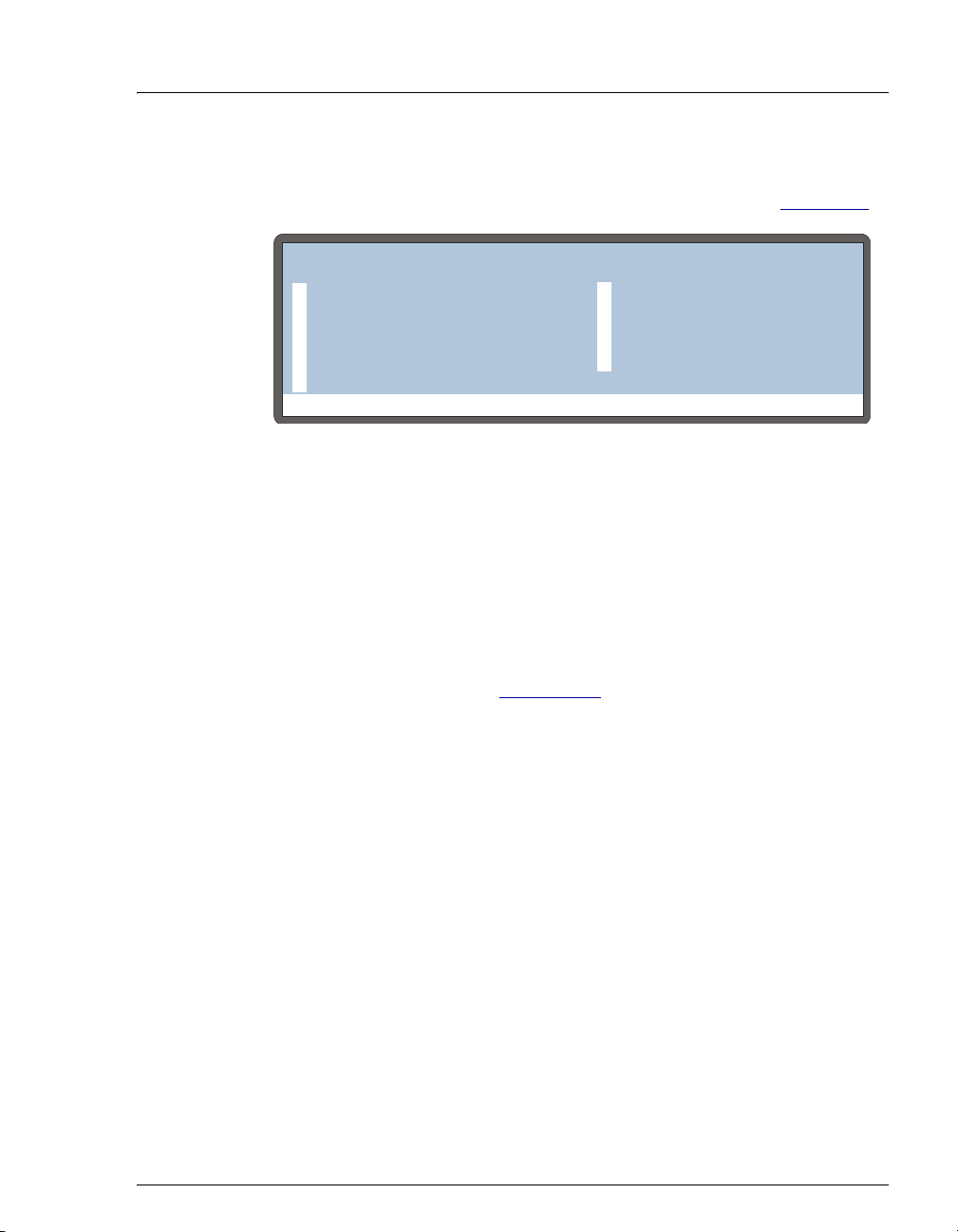

To access other AS screens:

Press the Menu button. The MENU of SCREENS appears (see Figure 2-4).

MENU of SCREENS

FLUSH/PRIME

MAIN STATUS

1

DETAIL STATUS

2

METHOD MENU

3

SCHEDULE

4

MODULE SETUP MENU

5

Help Prompt

Figure 2-4. Menu of Screens

To select a screen on the menu, use one of the following methods:

6

TIME FUNCTION IN

7

DIAGNOSTIC MENU

8

9

TIME FUNCTION OUT

• Press the keypad numeric button corresponding to the screen’s

number on the menu.

• Move the cursor to highlight the screen number and press Enter.

To display a brief description of each screen:

Press the Help button. See Appendix C for details about each screen.

To edit a field on the screen:

1. Press a cursor arrow button to position the cursor in the field to be

edited. Fields that are in reverse video (blue letters on white

background) can be edited. Other fields display information only.

2. If the field accepts numeric values, press the desired numeric buttons

to enter the value.

If the field has predetermined options, press the

Select Δ or Select ∇

button to choose the desired option.

3. To confirm the selected value, press

Enter or move the cursor out of

the field by pressing an arrow button.

Doc. 065051-03 1/08 13

Page 26

AS Autosampler Operator’s Manual

2.3 Autosampler Compartment

3

5

Prep Syringe

1

(Optional)

1

2

4

Sample

2

2

Syringe

Reagent

3

3

Reservoir

(Optional)

Flush

4

Reservoir

XYZ Sampling

5

Needle Arm

Flush, Waste,

6

and Inject Ports

6

7

8

Figure 2-5. Autosampler Compartment Features

Injection and/or

Diverter Valves

7

(Optional)

Sample Tray

8

(for Vials or

Well Plates)

14 Doc. 065051-03 1/08

Page 27

2.3.1 Syringe and Reservoir Organizer

The organizer on top of the autosampler holds the sample syringe, 1 L

flush reservoir, and the optional prep syringe and reagent reservoirs (see

Figure 2-5

Sample Syringe Functions

).

The sample syringe performs these operations:

• Pipettes liquid from one vial to another or to waste.

• Mixes a vial by repeatedly drawing and expelling the vial contents. If

AS is equipped with the sample preparation option, mixing is done

the

with the sample prep syringe instead of the sample syringe.

• Delivers sample to the injection valve.

The following sample syringe volumes are available:

2 • Description

Sample Syringe

Vol ume

100 μL 055064

250 μL (standard) 053916

500 μL 055065

1,000 μL 055066

5 mL* 053915

10 mL* 055068

*A 5 or 10 mL syringe is required for simultaneous

injections and optional for all other sampling modes. If a

5 or 10 mL syringe is installed, an 8.5 mL sampling

needle assembly (P/N 061267) is required.

Part Number

Doc. 065051-03 1/08 15

Page 28

AS Autosampler Operator’s Manual

Sample Preparation Option Functions

The AS can be equipped with a sample preparation option that includes a

sample prep syringe, a sample prep valve, and one 250 mL reagent

reservoir. Up to three additional reagent reservoirs can be configured.

The sample prep syringe performs these operations:

• Dispenses reagents from external reservoirs to any vial

• Mixes a vial by repeatedly drawing and expelling the vial contents

• Performs dilutions, allowing preparation of multilevel calibration

standards

• Performs liquid-liquid extractions by adjusting the height of the

needle in the vial

The following sample prep syringe volumes are available:

Prep Syringe Volume Part Number

250 μL 053916

500 μL 055065

1,000 μL 055066

2.5 mL 055067

5 mL (standard) 053915

10 mL 055068

The reagent reservoir connects to port A on the sample prep valve.

Additional reservoirs can be connected to ports B, C, and D. Commands

from the AS front panel screens or from Chromeleon or Chromeleon

Xpress let you select the reservoirs.

NOTE The 5 mL and 10 mL syringes are intended for most

sample prep functions. Use the smaller syringes only

for applications that require low flow rates.

NOTE The 2.5 mL syringe (P/N 055067) can only be used

with the sample preparation option. It cannot be

used as a sample syringe.

16 Doc. 065051-03 1/08

Page 29

2.3.2 Sampling Needle Arm

The autosampler door must remain closed during operation. If you

open the door during operation, the sampling arm stops immediately.

If a schedule is running, it is ended. To safely open the door during a

schedule, press the Door button. See Section 3.9 for details.

During operation, the sampling needle arm moves the sample needle

along X-, Y-, and Z-axes. The sample tray remains stationary throughout

the sampling process.

To sample from a vial or well plate, the arm moves to the specified

position in the tray and lowers the needle into the vial or well. The

sampling needle pierces the vial cap or well plate cover to allow fluid to

be drawn or delivered. When sampling is complete, the arm raises the

needle out of the vial or well. When running a schedule of injections, vials

or wells can be sampled in any order.

The needle height (the distance from the tip of the needle to the bottom of

the vial or well) can be adjusted, allowing operations such as liquid-liquid

extraction.You can set the needle height in a Chromeleon or Chromeleon

Xpress program (see Section 3.2.2

page 292

).

2 • Description

) or in a front panel program (see

NOTE Changing the needle height is not recommended

when sampling from a micro-well well plate,

because the well depth is shallow. You can adjust the

needle height in a deep-well well plate as required,

provided the needle remains submerged in sample.

This ensures accurate sample aspiration.

During a flush operation, the sampling needle arm delivers flush fluid to

the flush port (see Figure 2-7

Doc. 065051-03 1/08 17

).

Page 30

AS Autosampler Operator’s Manual

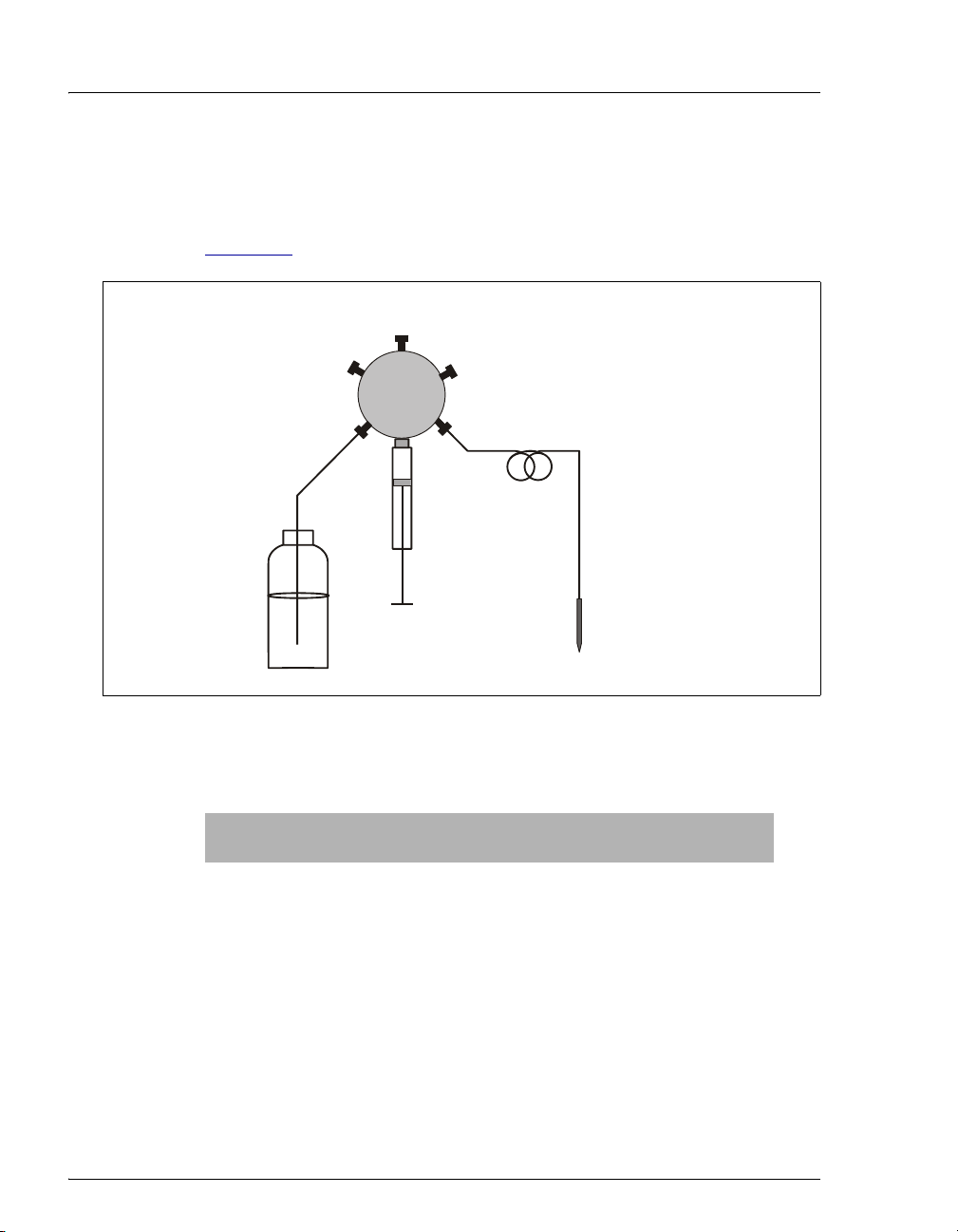

S

eedle

A

y

2.3.3 Sampling Needle Assembly

The sampling needle assembly consists of a PEEK™ sampling needle and

a line, which connects the sample syringe and the sampling needle (see

Figure 2-6

).

ample Syringe

Valve

A

F

E

D

Sample

Syringe

B

C

Sampling

Needle

ssembl

Flush Reservoir

Sampling

N

Figure 2-6. Sample Syringe with Sampling Needle Assembly

Two assemblies are available (see the table below).

Sampling Needle

Assembly

PEEK Needle with

1.2 mL line

PEEK Needle with

8.5 mL line

a

a. The 8.5 mL sampling needle assembly is standard when the AS is

configured with the simultaneous injection option.

18 Doc. 065051-03 1/08

Used With Part Number

Sample syringe volumes

054271

1mL or less

Sample syringe volumes

061267

greater than 1 mL

Page 31

2.3.4 Flush, Waste, and Inject Ports

The flush port flushes the outside of the sampling needle with fluid from

the flush reservoir. Excess fluid flows to the waste port. The waste port

accepts waste fluid from the sampling needle and the flush port, and

directs it out the drain line. The inject port (see Figure 2-7

sample from the sampling needle and delivers it to the injection valve.

Waste Port

Flush Port

Figure 2-7. Flush, Waste, and Inject Ports

2.3.5 Sample Vials and Well Plates

2 • Description

) accepts the

Inject Port

Vial Trays and Vials

The following vial trays are available. See the following section for well

plate information.

Tray Material Vial Size Held Tray Capacity Part Number

Plastic 10 mL 49 062374

Aluminum 0.3 mL, 1.5 mL 100 062481

a

Insulated Aluminum

a. Required for the sample temperature control option. Includes tray

covers for empty tray rows.

0.3 mL, 1.5 mL 100 062377

The following vials are available:

Vial Size and Material Quantity Part Number

0.3 mL polymer Package of 100 055428

1.5 mL glass Package of 100 055427

10 mL PolyVial™ Package of 100 055058

1.5 mL plastic Package of 100 061696

Doc. 065051-03 1/08 19

Page 32

AS Autosampler Operator’s Manual

Dionex does not recommend using the 10 mL plastic tray with the

sample temperature control option because the plastic tray is

inefficient at heating and cooling the vials. In addition, the tray is not

designed for temperatures above 40 °C (104 °F) and may deform at

temperatures above 40

Well Plates and Trays

°C.

Dionex recommends using well plates in the AS if you have limited

amounts of sample or if you require more than 100 sample positions.

Follow these guidelines when using well plates:

• 2 mL deep-well plates are suitable for ion chromatography (IC)

applications, where concentration of ions is above 1 ppm.

• 0.5 mL and 0.45 mL micro-well plates are not recommended for IC

applications.

• Where concentration of ions is below 1 ppm, Dionex recommends

using 10 mL PolyVials (P/N 055058, package of 100).

The following well plate tray packages are available:

Well Plate Tray Type Includes Part Number

Micro-well plate tray One micro-well plate tray, two micro-well

plates with 0.5 mL round (U-shaped) wells, and

two covers (not suitable for IC applications)

Deep-well plate tray One deep-well plate tray, two deep-well plates

with 2 mL wells, and two covers (suitable for

IC applications, where concentration of ions is

above 1 ppm)

066324

066325

Additional well plates and covers can be ordered separately. See

Appendix F

Well Plate Tray Notes

for reordering information.

• All well plate trays can be used with the sample temperature control

option.

• Each well plate tray also holds ten, 1.5 mL vials.

• The micro-well plate tray can hold either type of micro-well plate (V-

shaped wells or U-shaped wells).

20 Doc. 065051-03 1/08

Page 33

• The AS automatically detects the type of tray installed.

n

2.3.6 Injection Valve Options

The AS can optionally have one or two injection valves installed inside

the autosampler compartment. The injection valves are six-port,

electrically-activated Rheodyne valves. The valves have two operating

positions: Load and Inject (see Figure 2-8

2 • Description

).

Concentrator

Column

(optional—

replaces loop)

Sample In

Sample

Loop

To Wa st e

LOAD POSITION

(5)

S

(6)

W

(1)

L

L

(4)

C

(3)

P

(2)

From Pump

Sample In

To Co l u m n

Sample

Loop

(6)

To Wa st e

INJECT POSITION

(5)

W

(1)

S

L

L

From Pump

(4)

C

P

(2)

To C o l u m

(3)

Figure 2-8. Injection Valve Flow Schematics

Eluent flows through either the Load or Inject path, depending on the valve

position:

• In the Load position, sample flows from the AS inject port line, through the

valve, and into the sample loop, where it is held until injection. Eluent flows

from the pump, through the valve, and to the column, bypassing the sample

loop. Excess sample flows out to waste.

• In the Inject position, sample is swept to the column for analysis. Eluent flows

from the pump, through the sample loop, and on to the column, carrying the

contents of the sample loop with it.

Doc. 065051-03 1/08 21

Page 34

AS Autosampler Operator’s Manual

2.3.7 Sample Temperature Control Option

The sample temperature control option provides heating and cooling of

the sample tray. You can program the temperature set point from 4

60

°C. Samples in the tray are uniformly heated or cooled to the

programmed set point (to a minimum of 20

maximum of 40

The sample temperature control option sits on the workbench below the

autosampler compartment (see Figure 2-9

°C above ambient). The absolute range is 4 °C to 60 °C.

°C to

°C below ambient and a

).

Sample

Temperature

Control Option

Figure 2-9. AS with Sample Temperature Control Option

NOTE The temperature inside the autosampler compartment

may exceed ambient by up to 2 °C. The sample

temperature control option is recommended for samples

that are temperature sensitive.

22 Doc. 065051-03 1/08

Page 35

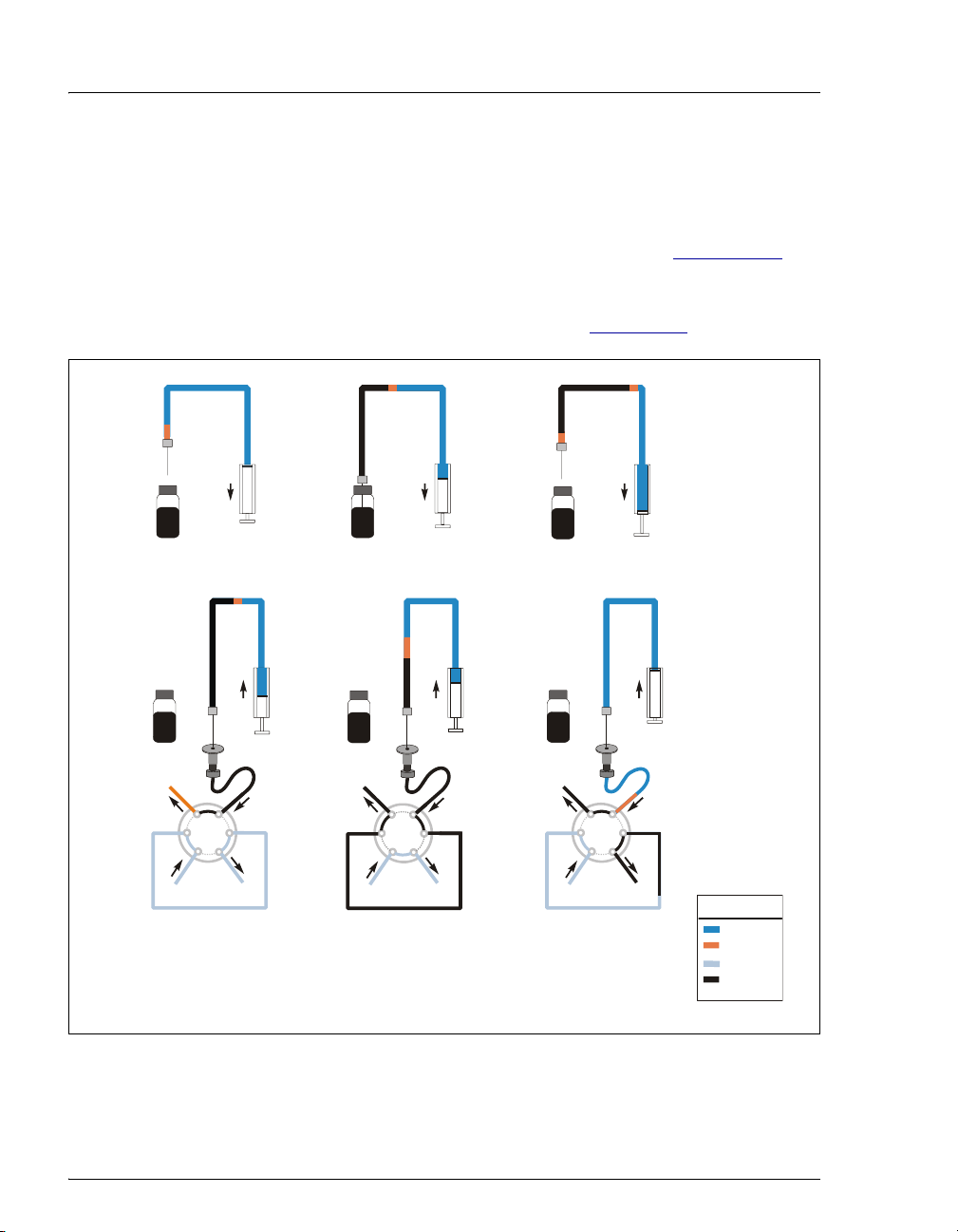

2.3.8 Simultaneous Injection Option

When the AS simultaneous injection option is installed, a single AS can

deliver sample to two independent chromatography systems. The sample

is injected simultaneously to both systems (two injection valves are

required). Dual analyses can be performed with only one sample, thus

increasing sample throughput and eliminating the need to label, fill, and

track two sample vials.

In Chromeleon or Chromeleon Xpress, the two chromatography systems

and the AS are configured into a single timebase and each system is

assigned a unique device name and channel. This lets you monitor and

control both systems from one Control panel and run all samples in one

sequence.

2 • Description

The simultaneous injection option requires a 5 or 10 mL

and an 8.5 mL sampling needle assembly (see Section 2.3.3

injections are required with this option.

See Section 3.6.9

for details about simultaneous injections.

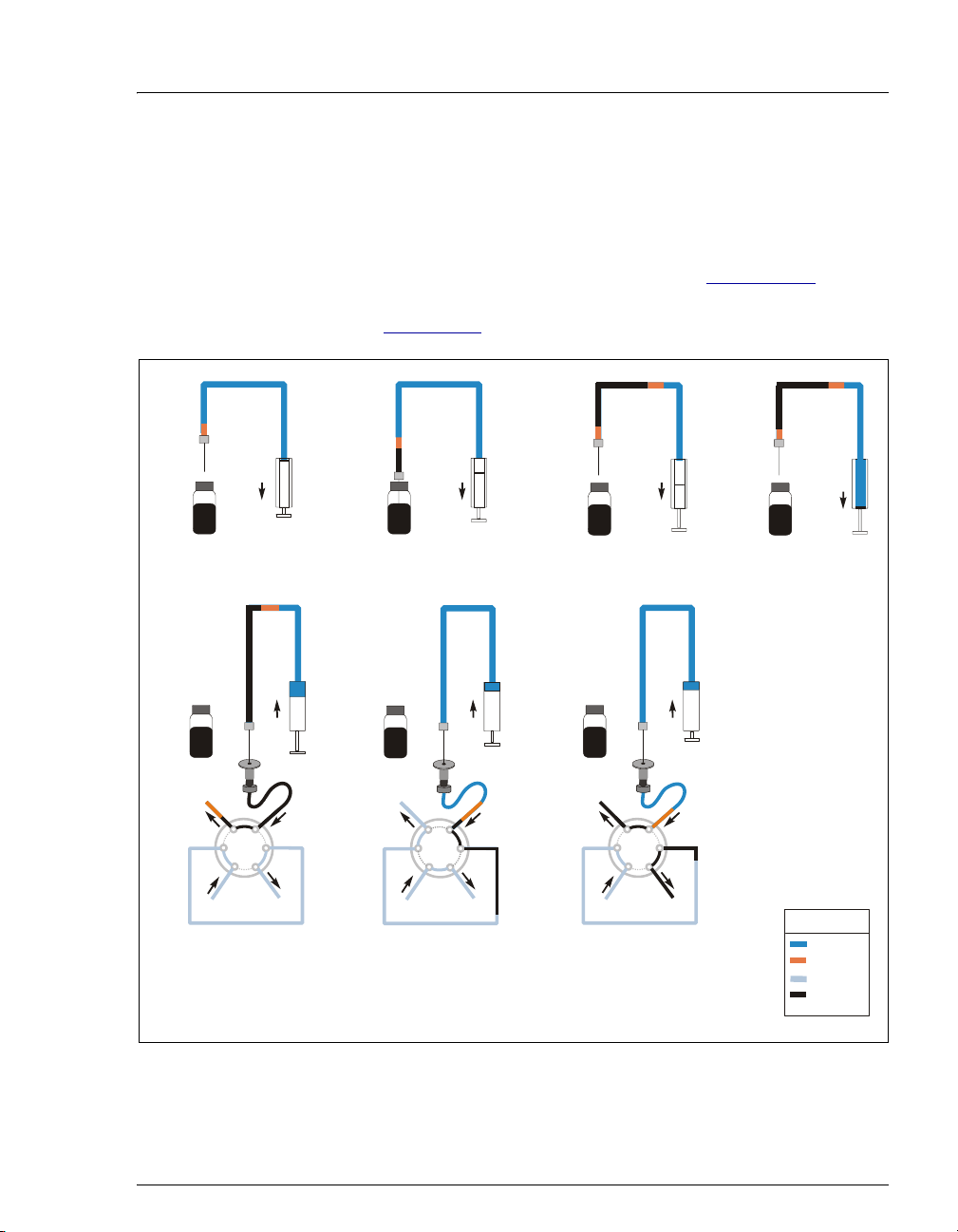

2.3.9 Sequential Injection Option

When the simultaneous option is installed, a single AS can deliver sample

to two independent chromatography systems. With the sequential option,

sample is delivered to the first system, flow is rerouted (diverted), and

sample is then delivered to the second system. Sequential injection allows

different samples to be injected into each system.

The sequential injection option requires two injection valves and a

diverter valve (for switching sample flow between the two systems). The

diverter valve is installed in the AS autosampler compartment. The

injection valves must be installed in the IC system’s chromatography

compartment.

See Section 3.6.11

NOTE The diverter valve can only be controlled by

for details about sequential injections.

Chromeleon or Chromeleon Xpress. It is not

controllable from the AS front panel.

sample syringe

). Full-loop

Doc. 065051-03 1/08 23

Page 36

AS Autosampler Operator’s Manual

2.3.10 Concentrator Injection Option

The AS concentrator injection option lets an AS deliver sample and

reagent to a Dionex ultra-low pressure concentrator column. With this

option, a concentrator column is installed on the injection valve instead of

a sample loop. A 5 or 10 mL

larger sample loading volumes. If the 5 or 10 mL

installed, an 8.5 mL sampling needle assembly must also be installed (see

Section 2.3.3

The AS is capable of delivering at a maximum pressure of 690 kPa

(100 psi). When setting up concentrator injections, make sure to select

syringe speeds that will keep the backpressure below 690 kPa (100 psi),

taking into account the pressure from the installed tubing and the

concentrator column. A syringe speed of 1 or 2 is required. See

Section 3.8

).

for details.

sample syringe can be installed to allow

sample syringe is

See Section 3.6.10

for details about concentrator injections.

24 Doc. 065051-03 1/08

Page 37

2.4 Rear Panel Features

1 2 3

2 • Description

USB

1

Receptacle

TTL/Relay

2

Connectors

Syringe

3

Connectors

Auxiliary

4

Power

Connector

4

5

Main Power

5

Receptacle and

Fuse Holder

Figure 2-10. AS Rear Panel

2.4.1 USB Receptacle

The USB receptacle provides a connection to the Chromeleon or

Chromeleon Xpress computer. To enable computer control of the

autosampler, connect a USB cable between the USB receptacle on the AS

rear panel and a USB port on the computer or USB hub. See Section B.3.8

for USB connection instructions.

Doc. 065051-03 1/08 25

Page 38

AS Autosampler Operator’s Manual

2.4.2 TTL/Relay Connectors

The eight TTL and relay connectors interface with Dionex and nonDionex modules. The input connectors allow for relay and TTL control of

the autosampler by a connected module(s). The output connectors allow

the AS to control other module(s). Appendix E

TTL functions and the connections between the AS and other modules.

2.4.3 Fuse Holder and Power Receptacle

The fuse holder contains two 3.15 amp fast-blow fuses (P/N 954745). For

instructions on how to change the fuses, see Section 5.18

The power cord plugs into the IEC 320 three-prong receptacle.

The power supply cord is used as the main disconnect device. Make

sure the socket-outlet is located near the AS and is easily accessible.

Le cordon d'alimentation principal est utilisé comme dispositif

principal de débranchement. Veillez à ce que la prise de base soit

située/installée près du module et facilement accessible.

Das Netzkabel ist das wichtigste Mittel zur Stromunterbrechung.

Stellen Sie sicher, daß sich die Steckdose nahe am Gerät befindet und

leicht zugänglich ist.

describes the relay and

.

26 Doc. 065051-03 1/08

Page 39

2.5 Autosampler Control

The AS can be controlled locally, from the front panel keypad and display (see

Section 2.5.1

Chromeleon Xpress software is installed (see Section 2.5.2

from an integrator or other remote controller can also be used to control the AS.

See Appendix E

2.5.1 Local Control

), or remotely, with a personal computer on which Chromeleon or

for details about TTL control.

In Local mode, the AS receives commands from the front panel buttons

and screens. When the AS is powered up, it is always in Local mode.

When the AS is in Local mode, two types of control are available: Direct

and Schedule.

• In Direct control, you enter control commands and parameters on the

AS screens, and the AS executes the commands immediately.

• In Schedule control, you define a list of injections (a schedule) to be

run in sequence. The schedule can be defined, saved, and then run at a

later time.

2 • Description

). TTL input signals

The table below summarizes the AS Local control configurations:

Operating/Control Mode Autosampler Operation

Local/Direct Control Commands are entered from the AS front panel

and executed immediately after being entered.

Local/Schedule Control Commands are entered from the AS front panel

and executed by running a schedule programmed

from the front panel.

Local/Direct Control Mode

You can directly control the following AS functions from the front panel:

• TTL and relay outputs

• Injection valve position

• Second injection valve position or diverter valve (if installed)

• Tray set point (if installed)

Doc. 065051-03 1/08 27

Page 40

AS Autosampler Operator’s Manual

Set these functions from the DETAIL STATUS screen (see Figure 2-11).

DETAIL

VIAL#:

INJ#:

METHOD:

TRAY:

LOCAL

Help Prompt

Local/Schedule Control Mode

20 °C25

Figure 2-11. Detail Status Screen Example

IDLE

TIME:

VOL:

TRAY:

LOOP:

NORMAL FULL

DIRECT CONTROL

100

min

uL

2mL

uL

TTL1

TTL2

RLY1

RLY2

INJ VLV L

The AS runs all injections according to a programmed schedule. The

schedule defines a series of vials to be sampled and the operating

parameters to run on each vial. A schedule consists of the following

parameters:

• The vials to sample

• The number of injections to draw from each vial

• The volume of each injection

• The method to run on each injection

• The action to take when a scheduled vial is missing

1

0

0

0

You program, save, and edit schedules from the

Figure 2-12

). The AS can store up to nine schedules in memory. The

SCHEDULE screen (see

stored schedules are retained in memory when the AS is turned off.

Section D.6

MISSING VIAL ACTION:

LINE ENDSTART

1

Help Prompt

28 Doc. 065051-03 1/08

describes how to create schedules.

EDIT

VIAL#

-

-

Figure 2-12. Schedule Screen

SAVE TO

STOP

INJ/ INJ

VIAL METHODVOL(uL)

1

RUNSCHEDULE

25.0 111

Page 41

2 • Description

Each injection in a schedule is assigned a method (a series of operating

instructions that tells the AS how to perform a single injection). A method

consists of the following three phases:

Method Phase Used To Examples

Sample prep Prepare the sample for injection Pipetting, mixing, diluting

Method setup Set parameters that remain

constant throughout the method

Timed events Perform functions at a specific

time in the method

When the method runs, the

AS performs the sample prep steps first,

followed by the method setup, and then the timed events steps.

Section D.5

Notes

describes how to create methods.

• See Appendix D for details about front panel operation.

• Some autosampler operations are not available from the AS front

panel and can only be accessed from Chromeleon or Chromeleon

Xpress. These include setting different aspirate and dispense syringe

speeds and sampling from well plates.

Sample needle height, sample

temperature

Loading the sample loop,

injecting

Doc. 065051-03 1/08 29

Page 42

AS Autosampler Operator’s Manual

2.5.2 Computer Control (Locked Remote Mode)

In Locked Remote mode, Chromeleon or Chromeleon Xpress software

sends commands from the host computer via the USB interface.

Connecting the AS to a Control panel (see Figure 2-13

selects the Locked Remote mode. In this mode, you cannot change any

operating parameters from the front panel keyboard. To return the AS to

Local mode, clear the Connect check box on the AS Control panel.

) immediately

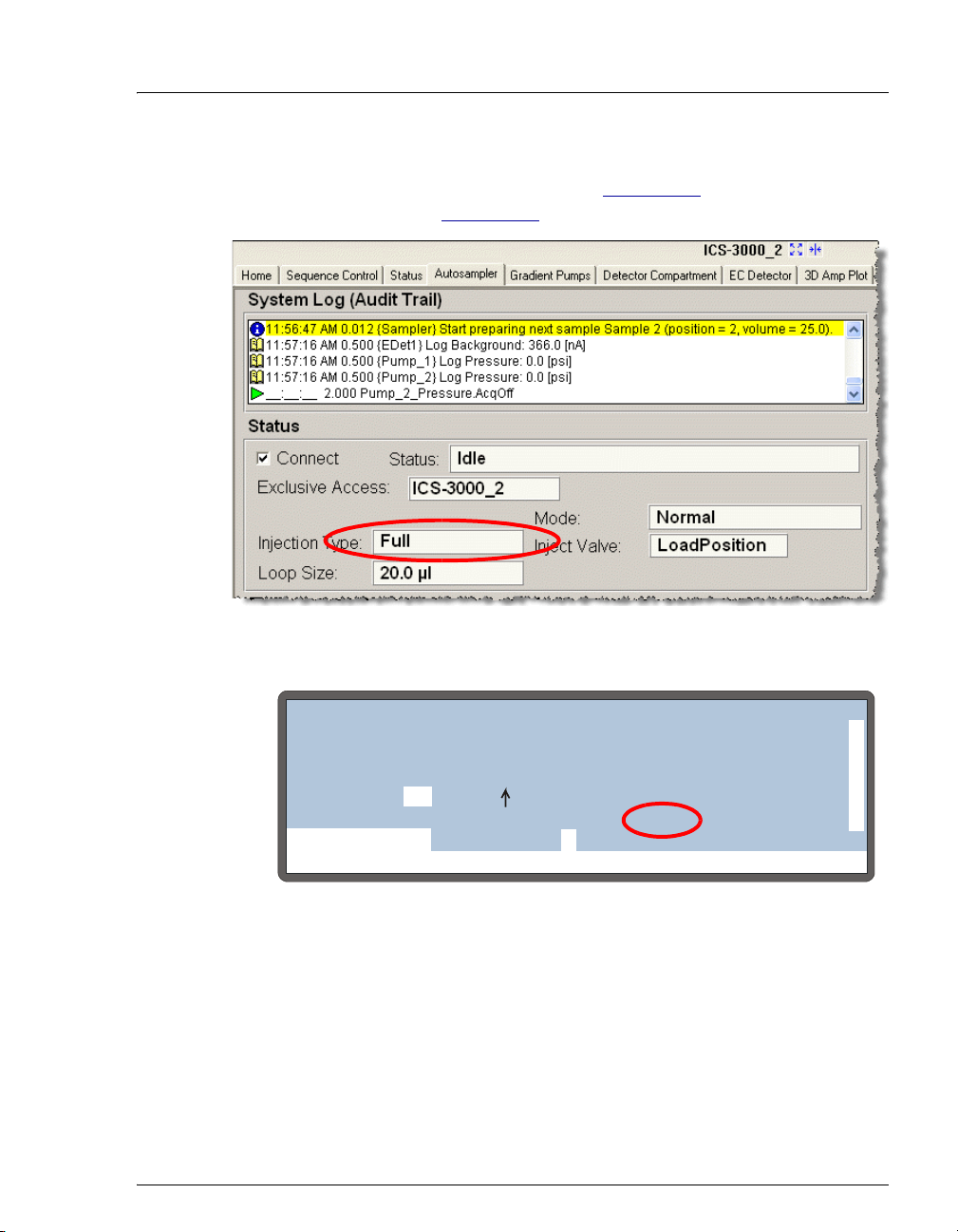

Figure 2-13. Example AS Control Panel

There are two modes for controlling the AS using Chromeleon or

Chromeleon Xpress:

• In Direct mode, you select operating parameters and commands

directly from the Control panel. The AS executes the commands

immediately.

30 Doc. 065051-03 1/08

Page 43

2 • Description

• In Automatic mode, you create a list of samples (a sequence) to be

processed automatically. The sequence defines a series of vials to be

sampled and the AS operating parameters to run on each vial. The

sequence is similar to a front panel schedule (see Section 2.5.1

For instructions on how to connect the AS to Chromeleon or Chromeleon

Xpress, see Section 3.2.1

autosampler using Chromeleon or Chromeleon Xpress, see Section 3.2.2

For detailed instructions, refer to the Chromeleon Help or Chromeleon

Xpress.

. For an overview of how to operate the

2.6 System Wellness and Predictive Performance

The Chromeleon System Wellness panels provide easy access to the

autosampler’s built-in diagnostic and calibration features. You can use the

Wellness panels to perform the following tasks:

• Calibrate the inject port tubing volume

• Align the sampling needle in the inject port

),

.

• Calibrate and test the leak sensor

• Monitor usage of replaceable parts (see the description of Predictive

Performance below)

Wellness panels for calibrating the inject port tubing, aligning the sampling

needle, and monitoring usage of parts are available on the Control panel (see

Figure 2-13

sensor (see Section 5.11

The Chromeleon Predictive Performance feature provides functions for

monitoring the lifetime of replaceable parts and for planning and recording

service procedures. You can use the Chromeleon Predictive Performance feature

to perform the following tasks:

). A separate panel is available for calibrating and testing the leak

).

NOTE You can also perform System Wellness tasks from the

front panel screens. See Appendix D

for details.

• Monitor how many times a part has been used since it was last replaced.

Chromeleon monitors usage of the following AS parts: injection valve,

diverter valve, XYZ sampling needle arm, sampling needle assembly, needle

seal assembly, sample syringe, and prep syringe.

Doc. 065051-03 1/08 31

Page 44

AS Autosampler Operator’s Manual

• Display a warning message in the Chromeleon Audit Trail when a monitored

part is approaching its usage limit and when the limit is reached.

• Set the usage limits for monitored parts to suit your needs.

• Record when a part is serviced and reset the usage counter.

All Predictive Performance commands and parameters are available in the

Chromeleon Commands dialog box (press the F8 key or select Command on the

Control menu to open the Commands dialog box).

You can view and reset the usage counters for the various replaceable parts on

either the AS Wellness panel (see Figure 2-14

Section C.9.6

above, are available only in Chromeleon.

). The remaining Predictive Performance functions, described

) or the USAGE LOG SCREEN (see

Figure 2-14. Example AS Wellness Panel

(Default Warning Values for All Parameters Shown)

32 Doc. 065051-03 1/08

Page 45

2.7 Theory of Operation

2.7.1 Understanding the Wait Operation

NOTE This section pertains to AS operation in

Local/Schedule Control mode (see Section 2.5.1

only.

The wait operation is a step in the sample prep phase of a method. After

performing all other sample prep steps, the AS waits for a continue

command before performing the method’s timed events. The continue

command can be sent via the front panel

signal.

The wait’s position in the sample prep steps determines whether samples

are overlapped or run sequentially:

• When the wait operation is the last step in the sample prep phase (the

default), samples are overlapped (see Section 2.7.2

• When the wait operation is at the beginning of the sample prep phase,

samples are run sequentially (see Section 2.7.3

2 • Description

)

Hold/Run button or a TTL input

).

).

NOTE The wait operation can be disabled (see

Section 2.7.4

Doc. 065051-03 1/08 33

).

Page 46

AS Autosampler Operator’s Manual

US

2.7.2 Overlapping Sample Preparation

When the wait operation is at the end of the sample prep phase (the

default), the

collection is occurring for one injection, the AS performs the sample prep

steps for the next injection (see Figure 2-15

the schedule run flow of operations, see Section 2.7.6

AS overlaps sample preparation. This means that while data

). For a detailed description of

.

Start First Method

SAMPLE PREPWASH /

FLUSH

NOTE:

The WAIT is ignored for

the first injection in a

Schedule.

Sample Overlap with Chromeleon or Chromeleon Xpress

If Chromeleon or Chromeleon Xpress is controlling the AS, front panel

settings for the wait operation are ignored. Instead, the Sample Overlap

option determines whether sample preparation is overlapped. Sample

overlap, which is selected in the Chromeleon Server Configuration

program, is enabled by default. For instructions on how to configure the

AS in Chromeleon, see Section B.3.12

Injection 1

SETUP TIMED EVENTSINIT

0.0

Overlap

Start Next Method

WAS H/

SAMPLE PREP SETUP TIMED EVENTSINIT

FLUSH

Wait for Continue

Command

WAI T

CONTINUE

Injection 2

0.0

Overlap

Start Next Method

WASH /

SAMPLE PREP

FL

H

Figure 2-15. Sample Prep Overlap: Wait Operation at

End of Sample Prep Phase (Default)

.

WAI T

34 Doc. 065051-03 1/08

Page 47

2.7.3 Running Samples Without Overlap

Placing the wait operation at the start of the sample prep steps allows

samples to be run sequentially. The

timed events for an injection before starting the next injection (see

Figure 2-16

).

AS completes the sample prep and

2 • Description

Start First Method Start Next Method

Run

FLUSH

SAMPLE PREPWAS H/

SETUP

TIMED EVENTS

INIT

Injection 1

Injection 2

WASH /

FLUSH

Continue Continue

WAIT

SAMPLE PREP

SETUP

TIMED EVENTS

INIT

Figure 2-16. No Sample Prep Overlap: Wait Operation at

Beginning of Sample Prep Phase

2.7.4 Operating the AS as the System Master (Disabling the Wait Operation)

When the wait operation is disabled, a single run command (for example,

pressing the

performs the schedule lines without requiring additional commands. This

allows the

sending TTL signals to start the pump and detector methods).

To disable the wait operation, press

SETUP MENU and press 5 to go to the SYSTEM PARAMETERS screen. Set

WAIT field to DISABLED (see Figure 2-17).

the

METHOD SYRINGE SPEED:

CUT SEGMENT VOLUME:

FLUSH SYRINGE SPEED:

Help Prompt

Hold/Run button) starts the schedule. Thereafter, the AS

AS to act as the system master (the AS controls the system by

Menu and 5 to go to the MODULE

SYSTEM PARAMETERS

WAIT:

DISABLED

4

SAMPLE MODE:

INJECT PORT VOLUME:

10

43

uL

NORMAL

uL

4

WASH /

FLUSH

Figure 2-17. System Parameters Screen

For details about the order of events during a schedule when the wait

operation is disabled, see Figure 2-20

Doc. 065051-03 1/08 35

.

Page 48

AS Autosampler Operator’s Manual

0.0

2.7.5 Understanding the Cycle Time

Cycle time is an optional feature that can be used to control the time

between injections. When a method is assigned a cycle time, the AS

delays sample injection until the specified time has elapsed since the

previous injection. Cycle time is measured from the start of the previous

method's timed events (see Figure 2-18

time zero for each method (the default), specifying a cycle time allows a

consistent time interval between injections, regardless of differences in

sample prep and timed events among methods.

). Assuming injection occurs at

WASH /

FLUSH

SAMPLE PREP

SETUP TIMED EVENTSINIT

Injection 1Start First Method

0.0

Start Next Method

WAS H/

SAMPLE PREP SETUP

FLUSH

Cycle Time

Wait fo r end

of cycle time

INIT

Injection 2

TIMED EVENTS

0.0

Start Next Method

WASH /

FLUSH

Cycle Time

SAMPLE PREP SETUP INIT

Figure 2-18. Cycle Time Example

A cycle's duration is never shorter than the specified time. However, cycle

time will be ignored, thus delaying injection, if any of the following

events occurs:

• WAIT FOR TEMP STABLE is enabled in the METHOD SETUP screen

(see Section C.6

the cycle time.

) and the temperature did not stabilize by the end of

• The sample prep wait operation is enabled and a run command did

not occur by the end of the cycle time.

• The previous method’s timed events extend beyond the cycle time.

If the cycle time expires before the injection occurs, a warning message is

displayed and the message is logged on the

Section C.9.6

36 Doc. 065051-03 1/08

).

MESSAGE LOG screen (see

Page 49

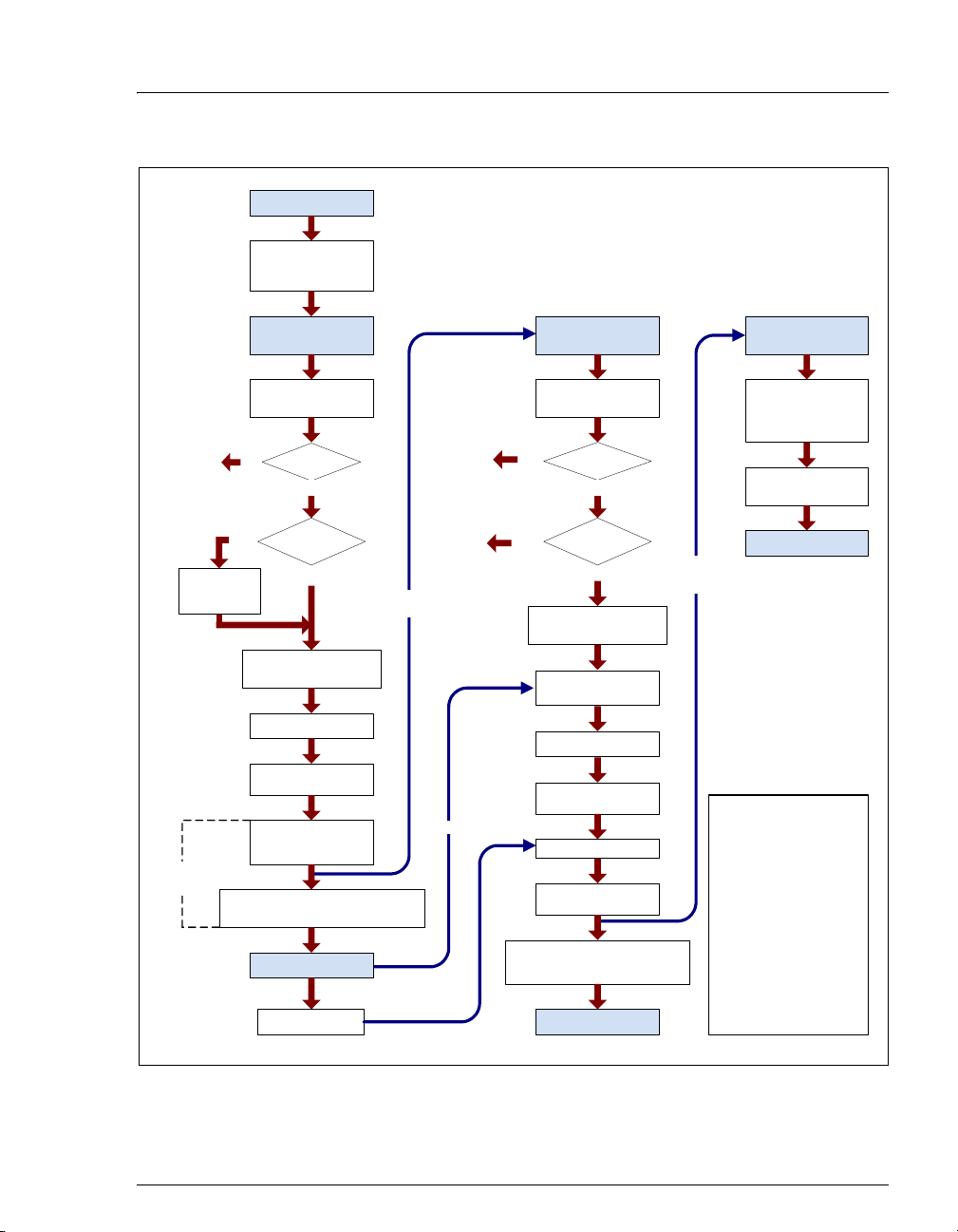

2.7.6 Operating Events During a Schedule

• Figure 2-19 shows the order of events during a schedule when the

wait operation is enabled.

• Figure 2-20 shows the order of events during a schedule when the

wait operation is disabled.

2 • Description

See Section 2.7.1

for details about the wait operation.

Doc. 065051-03 1/08 37

Page 50

AS Autosampler Operator’s Manual

Schedule Started

Preparing to Run:

Flush Inject Port and

Wash Needle

See Note #1

Wait for

Temperature

to Stabilize

See Note #2

Timed

Events

See Note #4

Method Starts for

Injection #1

Flush Inject Port and

Wash Needle

Vial Present?

No

Yes

Yes

Set

Temperature(s)

?

No

Do Sample Prep

(Pipetting, Mixing, etc.)

Method Setup

Execute INIT Step

Load Loop

Method Time 0.0

Inject

Start Cycle Timing

Method Times x.x to x.x

Set TTLs/Relays, etc.

Method Finished

See Note #3

End of Cycle Time

See Note #1

Sample Prep

Overlap

Continue

See Note #2

Method Starts for

Injection #2

Flush Inject Port and

Wash Needle

No

Vial Present?

No

Yes

Yes

Set

Temperature(s)

?

No

Do Sample Prep

(Pipetting, Mixing, etc.)

Wait for Previous

Method to Finish

Wait for Continue

Command

Method Setup

Execute INIT Step

Load Loop

Wait for Cycle Time

Method Time 0.0

Inject

Method Times x.x to x.x

Set TTLs/Relays, etc.

Method Finished

Sample Prep

Overlap

Method Starts for

Injection #3

Continue as Shown

for Method #2 Until

Last Scheduled

Injection Completed

Flush Inject Port and

Wash Needle

Schedule Ends

Notes:

1. The schedule either

stops and waits or skips to

the next vial, depending on

the action selected in the

schedule.

2. If multiple injections

from the same vial are

specified in the schedule,

the sample prep steps are

perfomed once only

(before the first injection).

3. The continue command

can be sent via the front

panel Hold/Run button or a

TTL input signal.

4. Use of cycle time is

optional.

Figure 2-19. Order of Events During a Schedule Run (Wait Enabled)

38 Doc. 065051-03 1/08

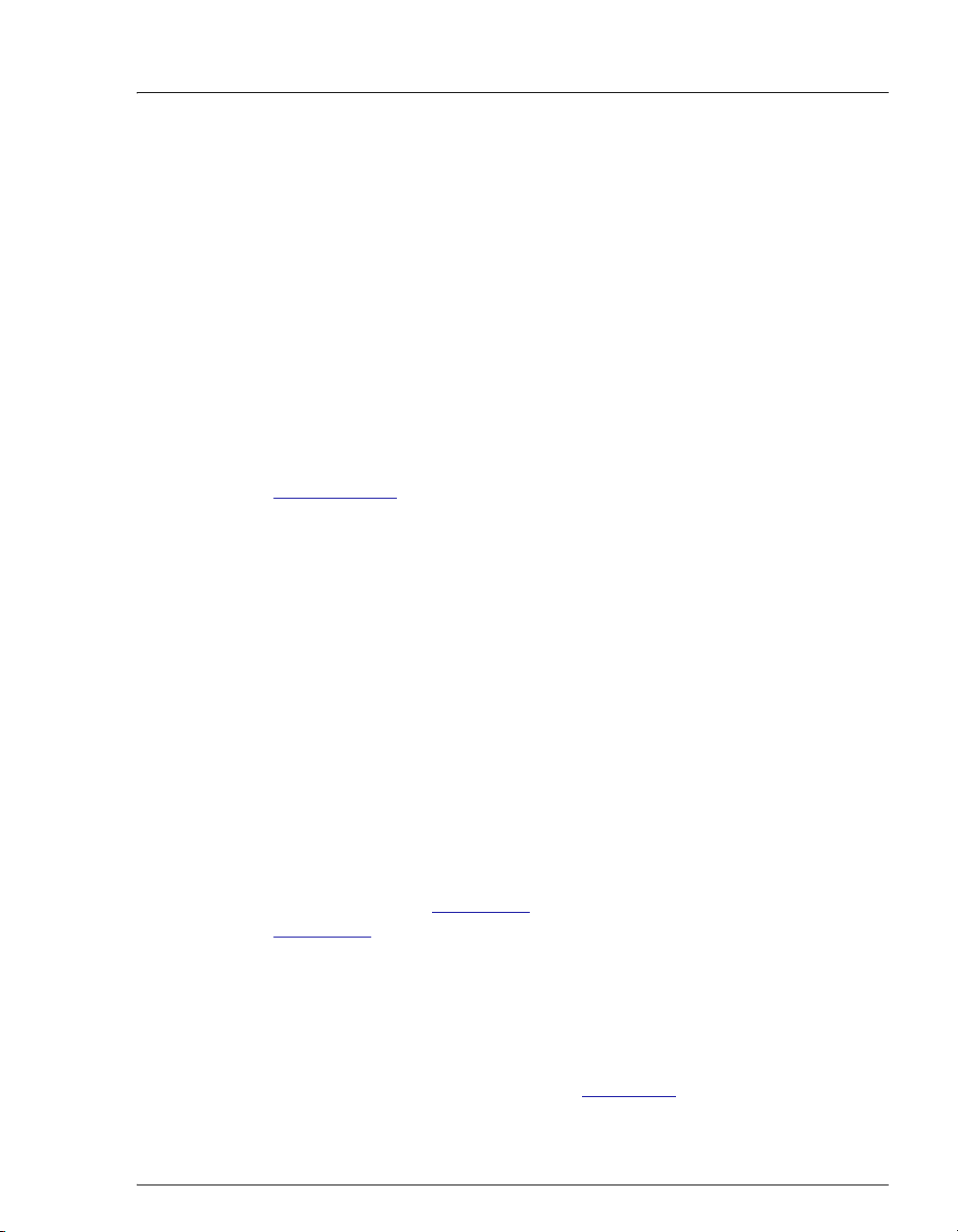

Page 51

Schedule Started

Preparing to Run:

Flush Inject Port

and Wash Needle

2 • Description

See Note #1

Wait for

Temperature

to Stabilize

See Note #2

Timed

Events

Method Starts for

Injection #1

Flush Inject Port and

Wash Needle

Vial Present?

No

Yes

Yes

Set

Temperature(s)

?

No

Do Sample Prep

(Pipetting, Mixing, etc.)

Set Up Method

Execute INIT Step

Load Loop

Method Time 0.0

Inject

Start Cycle Timing

Method Times x.x to x.x

Set TTLs/Relays, etc.

Method Finished

End of Cycle TimeSee Note #3

See Note #1

Sample Prep

Overlap

See Note #2

Yes

Method Starts for

Injection #2

Flush Inject Port and

Wash Needle

No

Vial Present?

No

Yes

Yes

Set

Temperature(s)

?

No

Do Sample Prep

(Pipetting, Mixing, etc.)

Wait for Previous

Method to Finish

Setup Method

Execute INIT Step

Load Loop

Wait for Cycle Time

Method Time 0.0

Inject

Method Times x.x to x.x

Set TTLs/Relays, etc.

Method Finished

Sample Prep

Overlap

Method Starts for

Injection #3

Continue as Shown

for Method #2 Until

Last Scheduled

Injection Completed

Flush Inject Port and

Wash Needle

Schedule Ends

Notes:

1. The schedule either

stops and waits or skips to

the next vial, depending on

the action selected in the

schedule.

2. If multiple injections

from the same vial are

specified in the schecule,

the sample prep steps are

perfomed once only

(before the first injection).

3. Use of cycle time is

optional.