Page 1

Product Summary

• Schottky Bridge and Freewheel diode for use in MR16 LED

Drive

• Internal Ambient Temperature = 90°C MAX within MR16 circuit

enclosure

• V

R

• I

= 0.4A

F

• I

R

= 13.2V

= 10μA

AVG

RMS

Description and Applications

This low leakage Schottky bridge and freewheel diode have been

specifically designed for the MR16 LED driver solution alongside

ZXLD1350E5 as described in Design Note DN86.

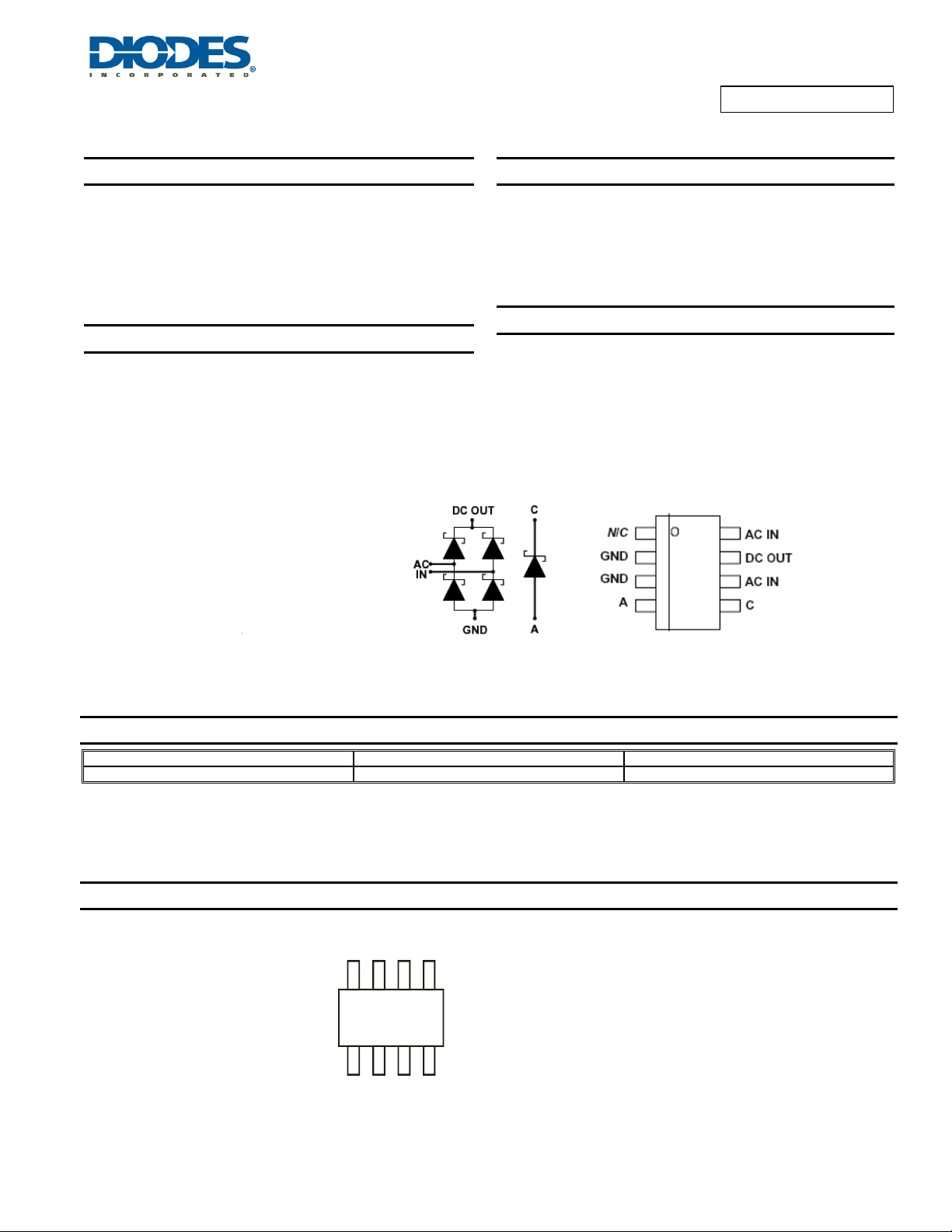

SM-8

Top View

Device Circuit

ZXSBMR16PT8

SCHOTTKY BRIDGE RECTIFIER PLUS FREEWHEEL DIODE

Features and Benefits

• Compact surface mount solution and reduced component count in

MR16 LED drive circuit

• Optimized bridge and freewheel diode for use in MR16 LED diode

circuitry

• Low V

• Qualified to AEC-Q101 Standards for High Reliability

and low reverse leakage current

F

Mechanical Data

• Case: SM-8

• Case Material: TBD

• Moisture Sensitivity: TBD

• Terminals: TBD

• Weight: TBD grams (approximate)

Top View

Pin-Out

Ordering Information (Note 1)

Device Packaging Shipping

ZXSBMR16PT8TA SM-8 1000/Tape & Reel

Notes: 1. For Packaging Details, go to our website at http://www.diodes.com.

Marking Information

ZXSBMR16PT8

Document number: DS33612 Rev. 2 - 2

ZXMB

MR16P

www.diodes.com

ZXSBMR16P = Product Type Marking Code

1 of 6

February 2011

© Diodes Incorporated

Page 2

)

ZXSBMR16PT8

Maximum Ratings @T

= 25°C unless otherwise specified

A

Characteristic Symbol Value Units

Maximum Repetitive Reverse Voltage

Maximum RMS Bridge Input Voltage

Average Rectified Forward Current (Notes 2 & 3)

Peak Repetitive Forward Current

Non Repetitive Forward Current

≤ 100μs

t

t ≤ 10ms

V

V

I

F(AV

I

I

RRM

RMS

FPK

FSM

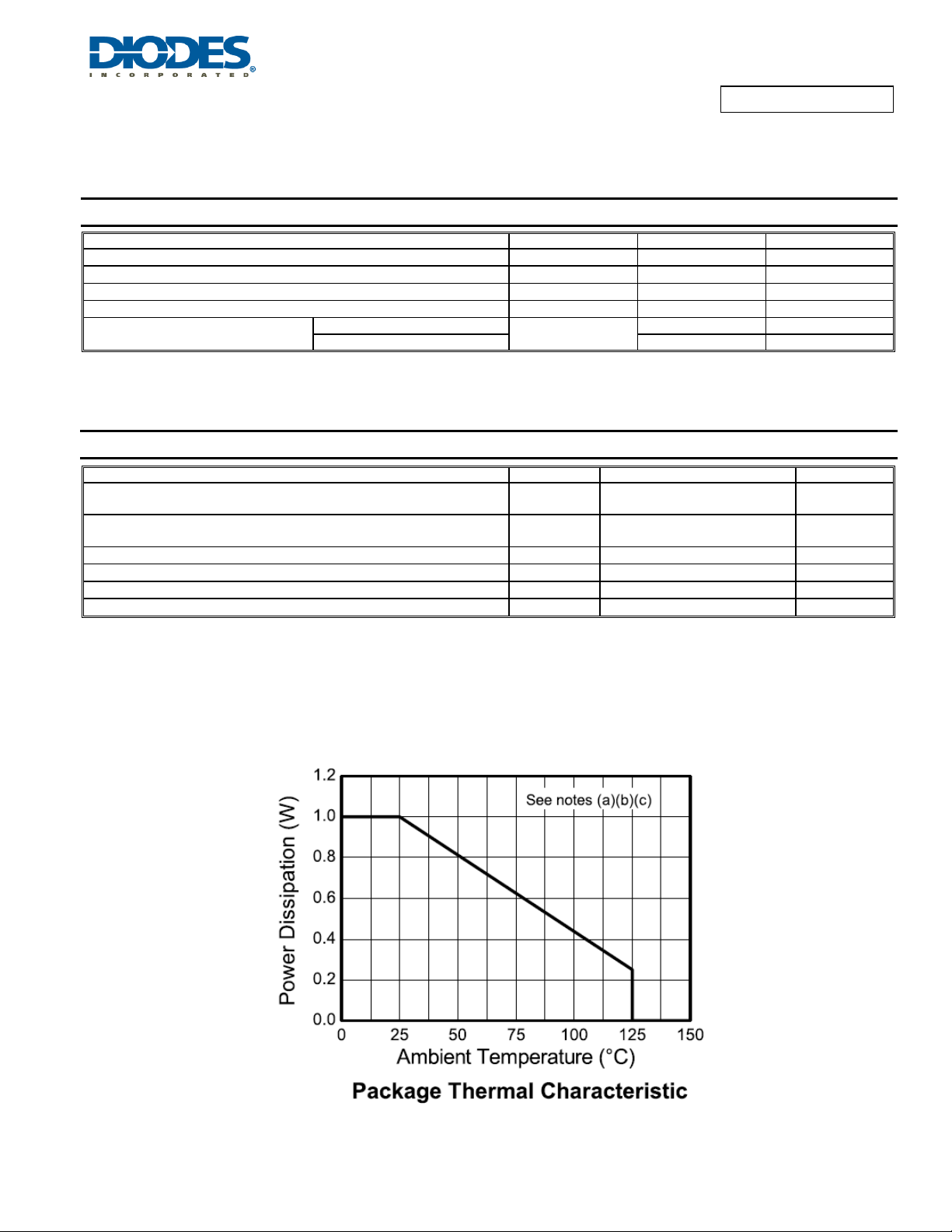

Thermal Characteristics

Characteristic Symbol Value Unit

Power Dissipation, TA = 25°C (Note 2) PD

Thermal Resistance, Junction to Ambient (Note 2)

Junction Temperature, Forward Dissipation Only

Junction Temperature, Reverse Dissipation (Notes 2, 3, & 4)

Storage Temperature Range

MR16 LED Internal Ambient Temperature (Note 4)

Notes: 2. For a bridge mounted on1.6mm FR4 PCB with minimum copper pads and track dimensions in still air.

3. Supply 12V RMS with capacitive bridge load.

4. Maximum bridge operating junction temperature must be reduced with increased reverse bias voltage to maintain unconditional thermal stability.

5. Refer to Design Note DN86

R

T

θJA

T

T

STG

T

J

J

A

40 V

13.2 V

0.4 A

3.5 A

13 A

3.5 A

1 W

125 °C/W

150 °C

125 °C

-55 to +150 °C

90 °C

ZXSBMR16PT8

Document number: DS33612 Rev. 2 - 2

2 of 6

www.diodes.com

February 2011

© Diodes Incorporated

Page 3

(BR)

ZXSBMR16PT8

Electrical Characteristics @T

= 25°C unless otherwise specified

A

Characteristic Symbol Min Typ Max Unit Test Condition

Reverse Breakdown Voltage

Forward Voltage (Note 4)

Reverse Current

Diode Capacitance

V

V

F

I

R

C

D

Reverse Recovery Time trr - 3 - ns

40 - - V

R

- 305 360

- 355 410

- 405 470

- 485 550

- 570 660

- 640 750

- 415 -

- 6 10

- 370 -

- 16 - pF

IR = 200μA

I

F

I

F

I

F

mV

I

F

I

F

I

F

I

F

V

μA

R

V

R

f = 1MHz, VR = 30V

Switched from I

I

R

Measured @ I

Reverse Recovery Charge

Notes: 4. Measured under pulsed conditions. Pulse width = 300μS. Duty cycle ≤ 2%.

Q

rr

- 210 - pC

di/dt = 500mA/ns.

R

source

= 50mA

= 100mA

= 250mA

= 500mA

= 750mA

= 1A

= 500mA, TA = 100°C

= 30V

= 30V, TA = 85°C

= 100mA to

F

= 100mA

= 10mA

R

= 6Ω; R

load

= 10Ω

ZXSBMR16PT8

Document number: DS33612 Rev. 2 - 2

3 of 6

www.diodes.com

February 2011

© Diodes Incorporated

Page 4

ZXSBMR16PT8

ZXSBMR16PT8

Document number: DS33612 Rev. 2 - 2

4 of 6

www.diodes.com

February 2011

© Diodes Incorporated

Page 5

ZXSBMR16PT8

Package Outline Dimensions

b

D

15°

E1

E

ee1

45°

c

L

A

A1

Dim Min Max Typ

A

A1 0.02 0.1

b

c 0.24 0.32

D 6.3 6.7

e

e1

E 6.7 7.3

E1 3.3 3.7

L 0.9

SM-8

1.7

−

0.7

−

− −

− −

All Dimensions in mm

− −

−

−

−

−

−

1.53

4.59

−

−

Suggested Pad Layout

Y1

C1

X (8x) C

Y (8x)

Dimensions Value (in mm)

C 1.52

C1 4.6

X 0.95

Y 2.80

Y1 6.80

ZXSBMR16PT8

Document number: DS33612 Rev. 2 - 2

5 of 6

www.diodes.com

February 2011

© Diodes Incorporated

Page 6

IMPORTANT NOTICE

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS DOCUMENT,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

(AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes

without further notice to this document and any product described herein. Diodes Incorporated does not assume any liability arising out of the

application or use of this document or any product described herein; neither does Diodes Incorporated convey any license under its patent or

trademark rights, nor the rights of others. Any Customer or user of this document or products described herein in such applications shall assume

all risks of such use and will agree to hold Diodes Incorporated and all the companies whose products are represented on Diodes Incorporated

website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized sales channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorize d application, Customers shall indemnify and

hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees arising out of, directly or

indirectly, any claim of personal injury or death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names and markings

noted herein may also be covered by one or more United States, international or foreign trademarks.

LIFE SUPPORT

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems without the express

written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided in the

labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected to cause the

failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices or systems, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any

use of Diodes Incorporated products in such safety-critical, life support devices or systems, notwithstanding any devices- or systems-related

information or support that may be provided by Diodes Incorporated. Further, Customers must fully indemnify Diodes Incorporated and its

representatives against any damages arising out of the use of Diodes Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2011, Diodes Incorporated

www.diodes.com

ZXSBMR16PT8

ZXSBMR16PT8

Document number: DS33612 Rev. 2 - 2

6 of 6

www.diodes.com

February 2011

© Diodes Incorporated

Loading...

Loading...