Page 1

A

Product Line o

f

Diodes Incorporated

ZXLD381

SINGLE OR MULTI CELL LED DRIVER SOLUTION

Summary

The ZXLD381 is a single cell LED driver designed for a pplications where step-up voltage conversion from a very low input

voltage is required. These applications mainly operate from 1.5V or 1.2V c ells. The IC generates constant current pulses that

are ideal for driving single or multiple LEDs over a wide range of operating voltages.

The ZXLD381 uses a PFM control technique to drive an internal switching transistor which a low saturation resistance. This

ensures high efficiency, even for input voltages as low as 1V.

The IC can start up under full load and operates down to an input voltage of only 0.9V.

The ZXLD381 is offered in the space saving SOT23 packag e or in die form, offering an excellent cost vs performance s olution

for single cell LED driving applications.

Features

• 85% Efficiency

• User adjustable output current

• Single cell operation (0.9V minimum)

• Low saturation voltage switching transistor

• SOT23-3 package

• Available also in Die form

• Simple Application circuit

Application

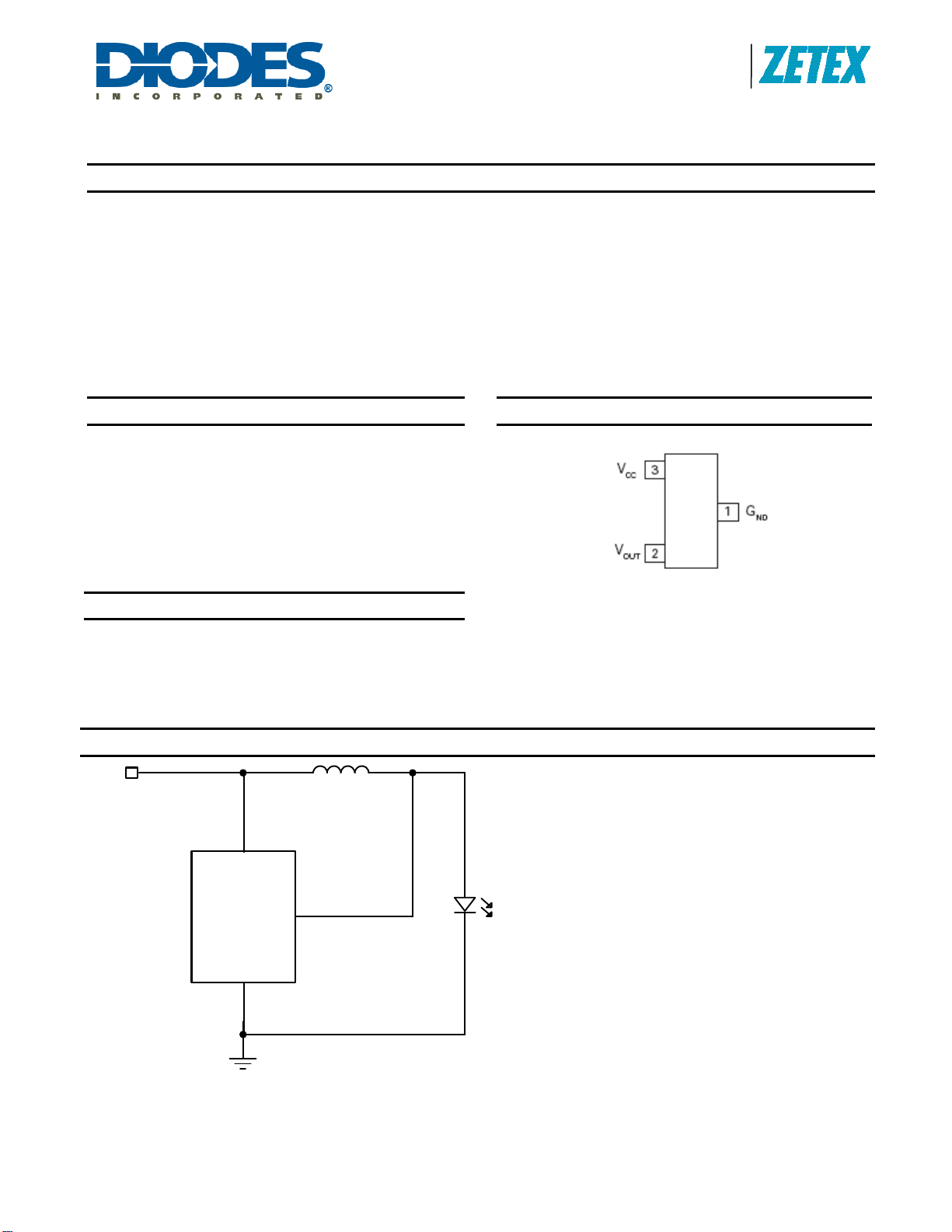

Pin Assignments

SOT23-3

(Top View)

• LED flashlights and torches

• LED backlights

• White LED driver

Typical Application Circuit

V

IN

V

CC

V

OUT

GND

ZXLD381

ZXLD381

Document number: DS32188 Rev. 3 - 2

L1

LED

1 of 9

www.diodes.com

May 2010

© Diodes Incorporated

Page 2

A

f

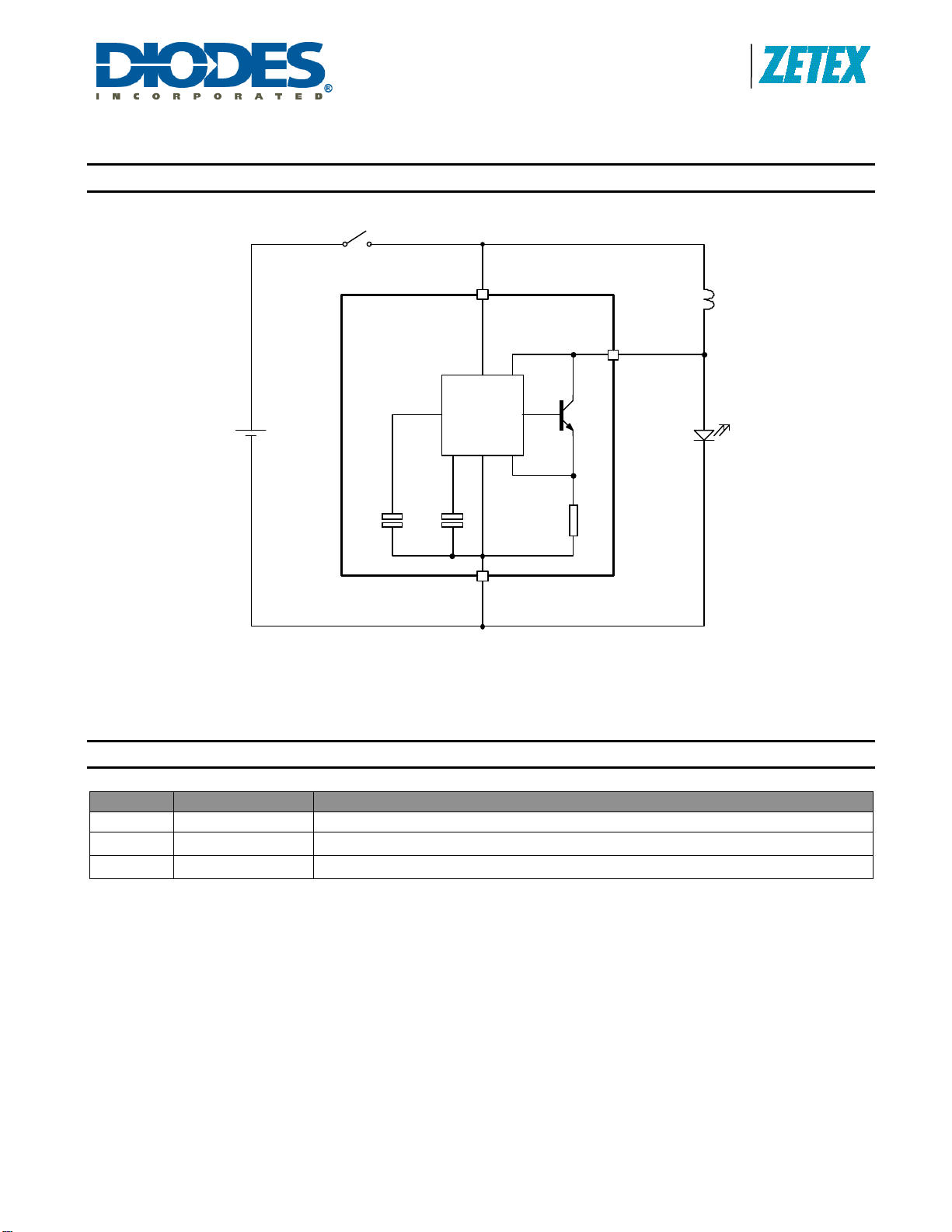

Block Diagram

1.5V

VCC

ZXLD381

Pulse

Control

Cof fCon

Rsense

GND

Fig 1. ZXLD381 Block Diagram

Product Line o

Diodes Incorporated

ZXLD381

L1

VOUT

LED

Pin Description

Pin No. Name Description

1 GND Ground

2

3

V

V

OUT

CC

ZXLD381

Document number: DS32188 Rev. 3 - 2

Switch output external inductor/LED

Supply voltage, generally Alkaline, NiMH or NiCd single cell

2 of 9

www.diodes.com

May 2010

© Diodes Incorporated

Page 3

A

f

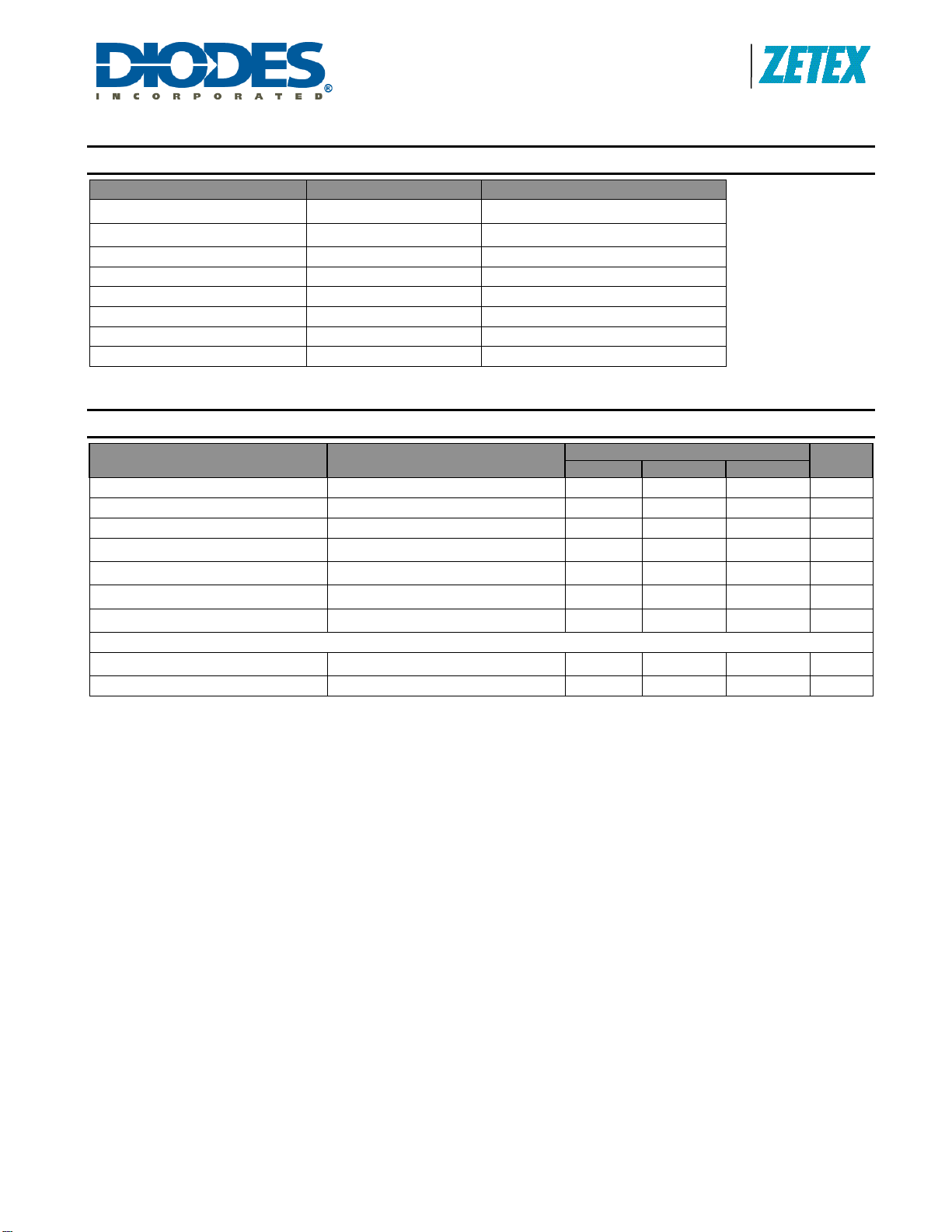

Absolute Maximum Ratings

Parameter Rating Unit

Supply Voltage (VCC)

Output Voltage (V

Supply Current 20 mA

Output Switch Current 800 mA

Power Dissipation SOT23-3 450 mW

Power Dissipation Die 1 W

Operating Temperature Range 0 to 85 °C

Storage Temperature Range -55 to 150 °C

OUT

)

-0.6 to 10 V

-0.6 to 20 V

Product Line o

Diodes Incorporated

ZXLD381

Electrical Characteristics Measured at T

Parameter Conditions

Supply Voltage Operating Range L = 10μH 0.9 2.2 V

Minimum Supply Start-up Voltage L = 10μH 0.8 0.9 V

Switch Current At turn-off 250 320 400 mA

Switch Saturation Voltage

Switch Leakage Current

Mean LED Current

Efficiency

Operating Frequency

Discharge Pulse Width 0.7 1.5 2.5 µs

I

OUT

V

V

V

V

OUT

LED

LED

LED

= 200mA

= 25°C, L = 4.7µH and VCC = 1.5V unless otherwise specified.

AMB

Min Typ. Max

100 300 mV

= 20V

= 3.5V

= 3.5V

= 3.5V

40 70 120 µA

40 55 70 mA

85 %

350 kHz

Limits

Units

ZXLD381

Document number: DS32188 Rev. 3 - 2

3 of 9

www.diodes.com

May 2010

© Diodes Incorporated

Page 4

A

Product Line o

f

Diodes Incorporated

ZXLD381

Device Description

The ZXLD381 is a simple PFM, DC-DC controller com bined with a high performance internal switching transistor, enabling the

production of a high efficiency boost converter for use in single cell applications. A block diagr am is sho wn for the ZXLD381 in

Fig 1.

When power is applied, an oscillator within the pulse control block forces the internal switching transistor to s witch on to start

an energy charge cycle. The low saturation voltag e switch pulls the V

across the external inductor L1. This causes a current to build up, storing energ y in the inductor. During this phase, switch

current and supply voltage are monitored and use d by the pulse control circuit to determ ine the optimum drive cond itions and

on-time. At the end of the energy charge cycle, the internal switch is turne d off rapidly, in terrupting the current fl ow through L1

which causes the voltage on V

voltage, the inductor current is transferred from the internal switch to the LED, starting the energ y discharge cycle. With the

voltage across the inductor reversed, the current flowing through it (and the LED) no w falls. When the inductor current reach e s

zero, the voltage on the V

next energy charge cycle. Except for low level losses, all the energy stored in the inductor during a charge cycle will be

channeled to the load LED during the following discharge cycle.

The current fed into the load LED has a sawtooth waveform, the average (DC) value of which is kept constant by the pulse

control circuit for varying supply voltage and temperature. It is possible to change the output current given by the ZXLD38 1 by

changing the value of inductor L1. The larger the inductance of L1, the lower the output current. A table/graph showing the

relationship between inductance and output current is given later in this datasheet. Since the output current of the ZXLD3 81 is

a sawtooth waveform, its peak value is substantially larger than the DC/average value. The table also provid es this data.

The internal switching transistor has a minimum collector-emitter breakd own voltage of 20V and this sets the maximum load

voltage allowable. The minimum value is set by a f eature of the pulse control circuit that requires the load voltage to be at least

0.8V greater than V

impaired.) Higher than nominal load voltages will lower the average (DC) output current generated for a given inductor value.

OUT

. (The device will function with load voltages smaller than this but output current regulation will be

CC

to rise dramatically. When the voltage on V

OUT

pin falls back towards VCC. This action is sensed by the pulse control circuit, which initiates the

pin close to ground which forces the supply voltage

OUT

reaches the load LED's forward (on)

OUT

ZXLD381

Document number: DS32188 Rev. 3 - 2

4 of 9

www.diodes.com

May 2010

© Diodes Incorporated

Page 5

A

f

Typical Characteristics

100

90

80

70

2.2µH

3.3µH

100

90

80

70

Product Line o

Diodes Incorporated

22µH

47µH

15µH

10µH

ZXLD381

OUT

I (mA)

350

300

250

200

IN

I (mA)

150

60

50

40

30

20

10

0

0.8

11.2

I vs. V for L = 2.2µH to 47µH

OUT(AVERA GE) CC

2.2µH

3.3µH

6.8µH

4.7µH

1.4 1.6

V (V)

CC

4.7µH

10µH

47µH

1.8

6.8µH

15µH

22µH

60

50

6.8µH

40

Efficiency (%)

4.7µH

30

20

3.3µH

10

2.2µH

0

2

0.8 1 1.2 1.4 1.6 1.8 2

V (V)

Efficiency vs. V for L = 2.2µH to 47µH

CC

CC

10µH

100

15µH

22µH

50

47µH

0

0.8 1 1.2 1.4 1.6 1.8 2

I vs. V for L = 2.2µH to 47µH

IN CC

V (V)

CC

Channel-1 (Upper): I @ 100mA/cm

Channel-2 (Low er): V @ 1V/cm

LED

OUT

Timebase: 500ns/cm

Operating Waveforms for L = 4.7µH, V = 1.5V

CC

Notes: V

= 3.5V for all graphs

LED

ZXLD381

Document number: DS32188 Rev. 3 - 2

5 of 9

www.diodes.com

May 2010

© Diodes Incorporated

Page 6

A

f

Typical Characteristics (Cont.)

450

400

350

300

250

200

OSC

f (kHz)

150

100

50

Product Line o

Diodes Incorporated

ZXLD381

0

0.8 1 1.2 1.4 1.6 1.8 2

f vs. V for L = 47µH

OSC CC

V (V)

CC

Notes: V

= 3.5V for all graphs

LED

ZXLD381

Document number: DS32188 Rev. 3 - 2

6 of 9

www.diodes.com

May 2010

© Diodes Incorporated

Page 7

A

f

Application Examples

Standard Operating Mode

Notes: V

Low Ripple LED Current Mode

Notes: V

= 3.5V

LED

= 3.5V, D1 = ZHCS1000, C1 = 1F (low ESR)

LED

Product Line o

Diodes Incorporated

ZXLD381

ZXLD381

Document number: DS32188 Rev. 3 - 2

7 of 9

www.diodes.com

May 2010

© Diodes Incorporated

Page 8

A

Product Line o

f

Diodes Incorporated

ZXLD381

Ordering Information

Part Number Package Part Mark

ZXLD381FHTA SOT23 381 8 3000

Tape Width

(mm)

Quantity

(per reel)

Package Outline Dimensions

b

3leads

L1

Dim.

A - 1.12 - 0.044 e1 1.90 NOM 0.075 NOM

A1 0.01 0.10 0.0004 0.004 E 2.10 2.64 0.083 0.104

b 0.30 0.50 0.012 0.020 E1 1.20 1.40 0.047 0.055

c 0.085 0.20 0.003 0.008 L 0.25 0.60 0.0098 0.0236

D 2.80 3.04 0.110 0.120 L1 0.45 0.62 0.018 0.024

e 0.95 NOM 0.037 NOM - - - - -

ZXLD381

Document number: DS32188 Rev. 3 - 2

E

e

e1

E1

D

A

A1

Millimeters Inches

Min. Max. Min. Max. Min. Max. Min. Max.

L

c

Millimeters Inches

Dim.

8 of 9

www.diodes.com

May 2010

© Diodes Incorporated

Page 9

A

Product Line o

f

Diodes Incorporated

ZXLD381

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS DOCUMENT,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

(AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes

without further notice to this document and any product described herein. Diodes Incorporated does not assume any liability arising out of the

application or use of this document or any product described herein; neither does Diodes Incorporated convey any license under its patent or

trademark rights, nor the rights of others. Any Customer or user of this document or products described herein in such applications shall assume

all risks of such use and will agree to hold Diodes Incorporated and all the companies whose products are represented on Diodes Incorporated

website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized sales channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorize d application, Customers shall indemnify and

hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees arising out of, directly or

indirectly, any claim of personal injury or death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names and markings

noted herein may also be covered by one or more United States, international or foreign trademarks.

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems without the express

written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided in the

labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected to cause the

failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices or systems, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any

use of Diodes Incorporated products in such safety-critical, life support devices or systems, notwithstanding any devices- or systems-related

information or support that may be provided by Diodes Incorporated. Further, Customers must fully indemnify Diodes Incorporated and its

representatives against any damages arising out of the use of Diodes Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2010, Diodes Incorporated

www.diodes.com

IMPORTANT NOTICE

LIFE SUPPORT

ZXLD381

Document number: DS32188 Rev. 3 - 2

9 of 9

www.diodes.com

May 2010

© Diodes Incorporated

Loading...

Loading...