Page 1

ZXLD1615

ADJUSTABLE DC-DC BOOST CONVERTER WITH INTERNAL SWITCH IN

TSOT23-5

DESCRIPTION

The ZXLD1615 is a PFM inductive boost converter

designed to provide output voltages of up to 28V

from a 2.5V to 5.5V input supply.

The ZXLD1615 includes the output switch and peak

current sense resistor, and can provide up to 10mA

output current at maximum output voltage. Higher

current is available at lower output voltages.

Quiescent current is typically 60A and a shutdown

function is provided to reduce this current to less

than 100nA in the 'off' state.

ADVANCED FEATURES

Internal 30V NDMOS switch

•

True analog output voltage control via PWM

•

with internal filter

FEATURES

Low profile TSOT23-5 pin package

•

•

Internal PWM filter for adjustable output

•

High efficiency (85% typ)

•

Wide input voltage range: 2.5V to 5.5V

•

Up to 250mA output current at 5V

Nominal output voltage can be set up to a maximum

of 28V by two external resistors and can be adjusted

to lower values by a PWM control signal applied to

the 'Enable' pin. Depending upon the control

frequency, the PWM signal will provide either

continuous (low ripple) or gated control. The PWM

filter components are contained within the chip.

Minimum output voltage is determined by the input

supply.

The device is assembled in a low profile TSOT23-5

pin package.

APPLICATIONS

LCD and OLED bias

•

Cellular / mobile phones

•

Digital cameras

•

• PDAs

•

LCD modules

•

Varactor and PIN diode bias

•

Palmtop computers

•

Low quiescent current: (60A typ)

•

100nA maximum shutdown current

•

Up to 1MHz switching frequency

•

Low external component count

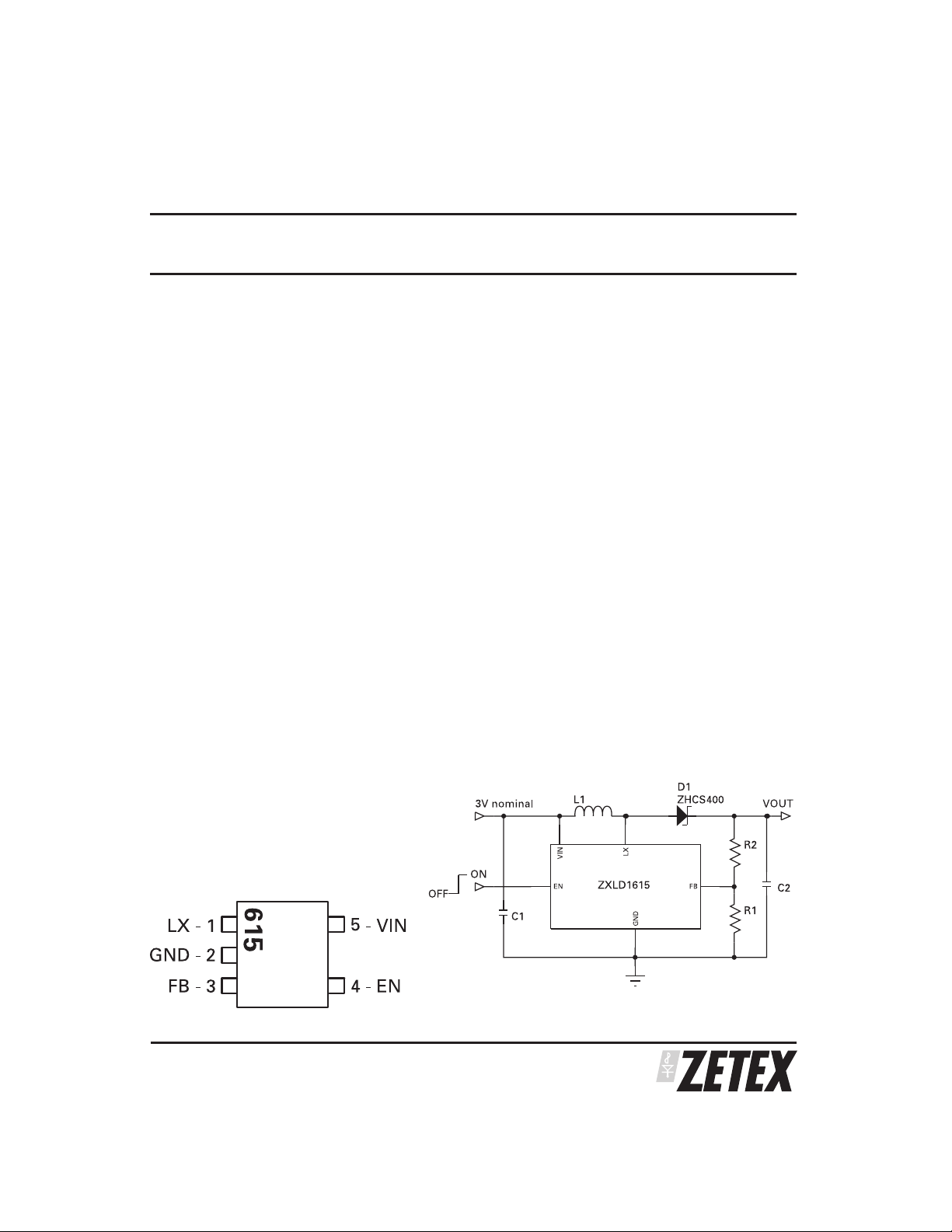

PINOUT

TOP VIEW

ISSUE 3 - AUGUST 2004

TYPICAL APPLICATION CIRCUIT

1

SEMICONDUCTORS

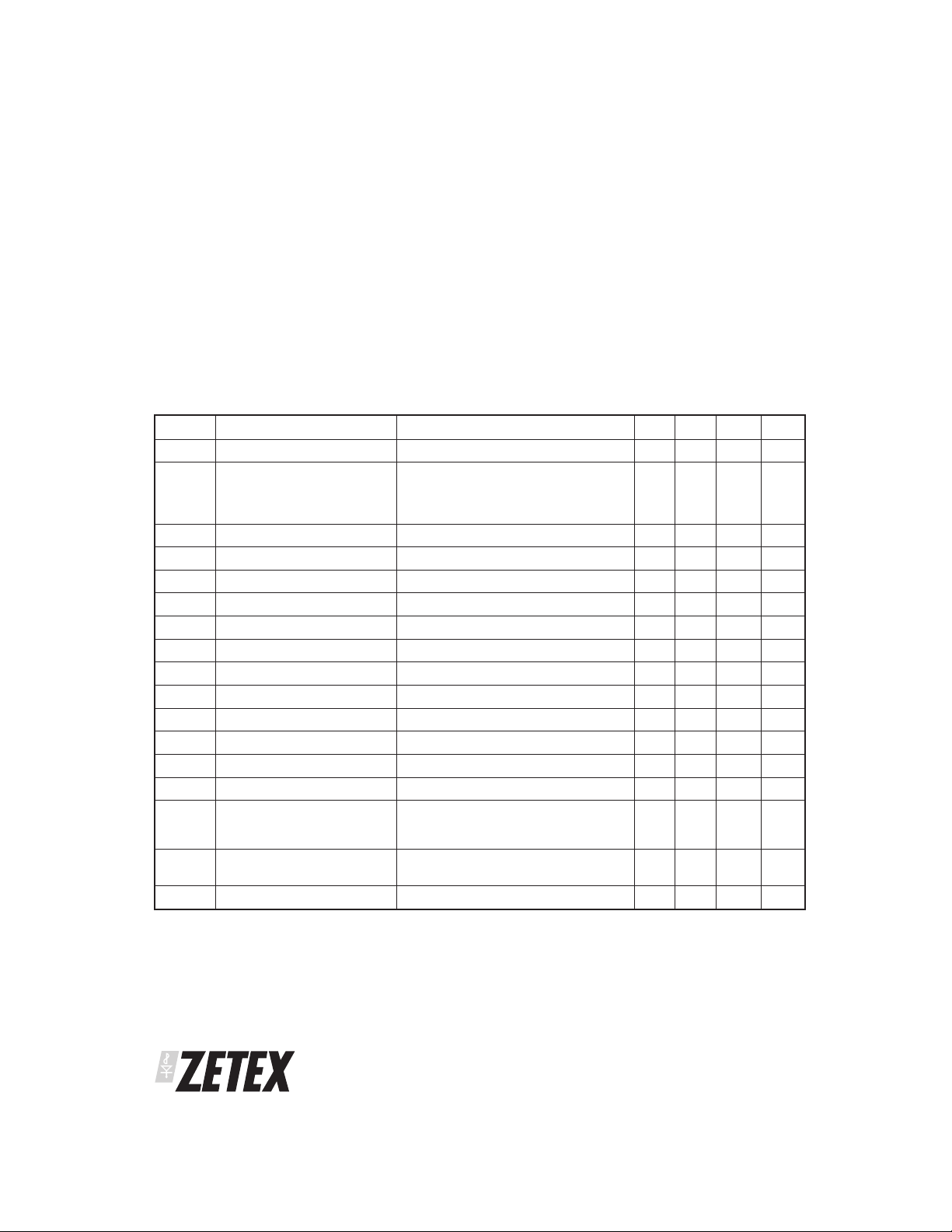

Page 2

ZXLD1615

ABSOLUTE MAXIMUM RATINGS

(Voltages to GND unless otherwise stated)

Input voltage (V

LX output voltage (V

Switch output current (I

Power dissipation (PD) 300mW

Operating temperature (T

Storage temperature (T

Junction temperature (Tj

ELECTRICAL CHARACTERISTICS: (Test conditions: V

Symbol Parameter Conditions Min Typ Max Units

V

IN

I

IN

V

FB

f

LX

T

OFF

(2)

T

ON

I

LXpk

R

LX

I

LX(leak)

V

ENH

V

ENL

I

ENL

I

ENH

(3)

T

EN(hold)

⌬T/T PWM duty cycle range at

f

LPF

A

LPF

)7V

IN

) 30V

LX

) 500mA

LX

) -40 to 85°C

OP

) -55 to 150°C

ST

) 125°C

MAX

IN=VEN

=3V, T

=25°C unless otherwise stated

AMB

(1)

Input voltage 2.5 5.5 V

Supply current

60

<10

100

100µAnA

Quiescent

Shutdown

V

EN=VIN,ILX

=0V

V

EN

= 0,Output not switching

FB pin control voltage 0.98 1.07 V

Operating frequency L=10H, V

=28V, 5mA load 600 kHz

OUT

LX output ‘OFF’ time 350 500 ns

LX output ‘ON’ time 5µs

Switch peak current limit L=10H, V

=28V, 5mA load 320 mA

OUT

Switch 'On' resistance 1.75 ⍀

Switch leakage current VLX=20V 1 µA

EN pin high level Input voltage Device active 1.5 V

IN

EN pin low level Input voltage Device in shutdown 0.4 V

EN pin low level input current VEN=0V -100 nA

EN pin high level input current VEN=V

IN

1 A

EN pin turn off delay VENswitched from high to low 120 µs

‘EN’ input for dc output

10kHz<f<100kHz, V

ENH=VIN

20 100 %

voltage control

Internal PWM low pass filter

4 kHz

cut-off frequency

Filter attenuation f=30kHz 52.5 dB

)

V

NOTES:

1 Production testing of the device is performed at 25°C. Functional operation of the device over a –40°C to +85°C temperature range is

guaranteed by design, characterization and process control.

2 Nominal ‘on’ time (TONnom ) is defined by the input voltage (V

T

= {I

ONnom

3 This is the time for which the device remains active after the EN pin has been asserted low. This delay is necessary to allow the output to be

maintained during dc PWM mode operation.

4 The maximum PWM signal frequency during this mode of operation should be kept as low as possible to minimize errors due to the turn-off

delay

LX(pkdc)

x L/VIN} +200ns

), coil inductance (L) and peak current (I

IN

) according to the expression:

LXpkdc

ISSUE 3 - AUGUST 2004

SEMICONDUCTORS

2

Page 3

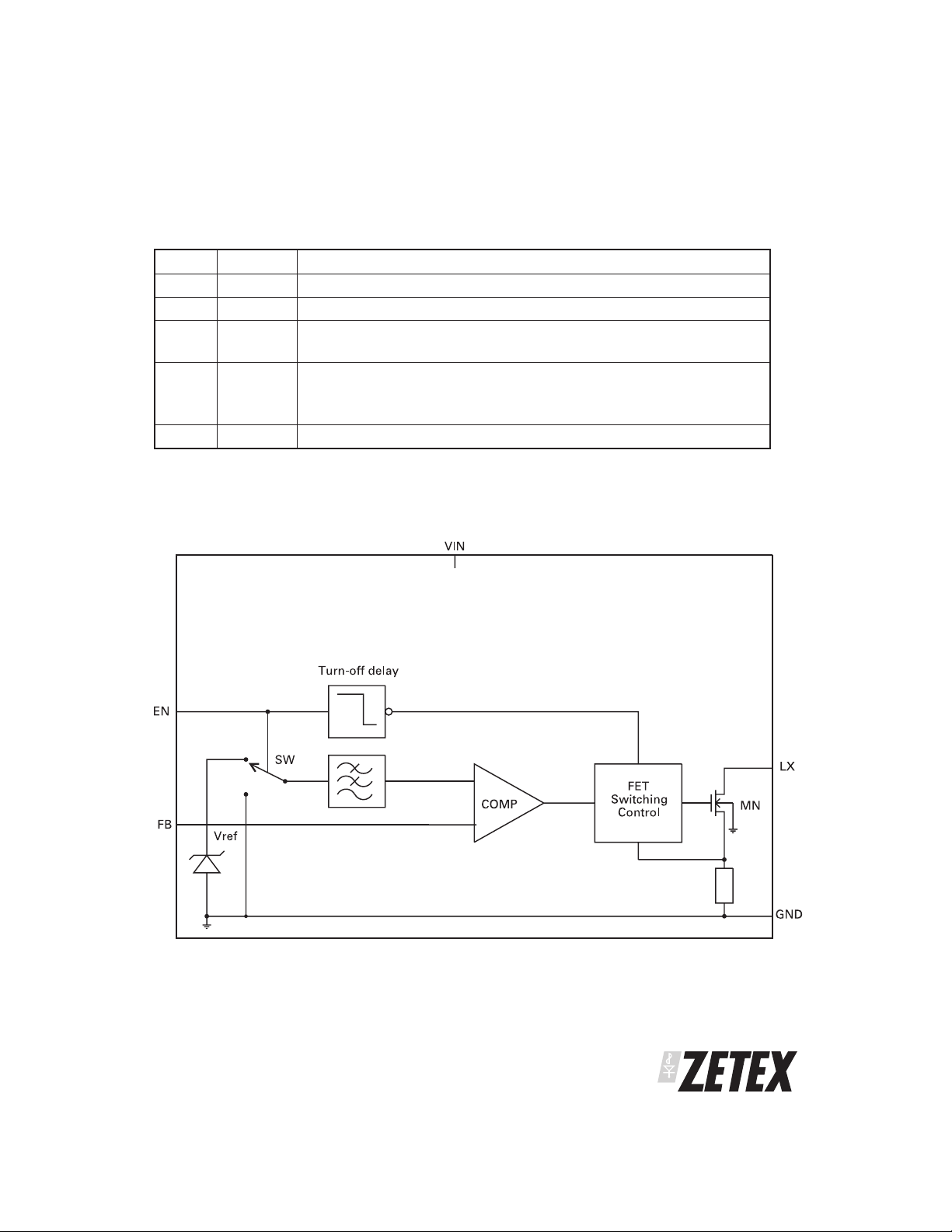

PIN DESCRIPTION

Pin No. Name Description

LX Output of NDMOS switch

1

GND Ground (0V)

2

FB Feedback pin for voltage control loop

3

Nominal voltage 1.025V

EN Enable input (active high to turn on device)

4

Also used to adjust output current by PWM signal.

Connect to V

V

5

IN

Input voltage (2.5V to 5.5V). Decouple with capacitor close to device.

BLOCK DIAGRAM

for permanent operation.

in

ZXLD1615

ISSUE 3 - AUGUST 2004

3

SEMICONDUCTORS

Page 4

ZXLD1615

Device Description

The device is a PFM flyback dc-dc boost converter,

working in discontinuous mode.

With reference to the chip block diagram and typical

application circuit, the operation of the device is as

follows:

Control loop

When 'EN' is high, the control circuits become active

and the low side of the coil (L1) is switched to ground

via NDMOS transistor (MN). The current in L1 is

allowed to build up to an internally defined level

(nominally 320mA) before MN is turned off. The

energy stored in L1 is then transferred to the output

capacitor (C2) via schottky diode (D1). The output

voltage is sensed at pin 'FB' by external resistors R1

and R2 and compared to a reference voltage V

(1.025V nominal). A comparator senses when the

output voltage is above that set by the reference and

its output is used to control the 'off' time of the

output switch. The control loop is self-oscillating,

producing pulses of up to 5s maximum duration

(switch 'on'), at a frequency that varies in proportion

to the output current. The feedback loop maintains a

voltage of V

maximum output voltage equal to V

The minimum 'off' time of the output switch is fixed

at 0.5s nominal, to allow time for the coil's energy

to be dissipated before the switch is turned on again.

This maintains stable and efficient operation in

discontinuous mode.

at the FB pin and therefore defines a

REF

REF

REF

*(R1+R2)/R1.

Filtered PWM operation

The input of an internal low pass filter is switched to

V

when the EN pin is high and switched to ground

REF

when the EN pin is low. The output of this filter

drives the comparator within the control loop. A

continuous high state on EN therefore provides a

filtered voltage of value Vref to the comparator.

However, by varying the duty cycle of the EN signal

at a suitably high frequency (f>10kHz), the control

loop will see a voltage, that has an average value

equal to the duty cycle multiplied by V

provides a means of adjusting the output voltage to a

lower value. It also allows the device to be both

turned on and adjusted with a single signal at the

‘EN’ pin. The output during this mode of operation

will be a dc voltage equal to V

cycle.

*(R1+R2)/R1 x duty

REF

REF

. This

Gated PWM operation

The internal circuitry of the ZXLD1615 is turned off

when no signal is present on the 'EN' pin for more

than 120s (nominal). A low frequency signal applied

to the EN pin will therefore gate the device 'on' and

'off' at the gating frequency and the duty cycle of this

signal can be varied to provide an average output

equal to V

accuracy, the gating frequency should be made as

low as possible (e.g. below 1kHz), such that the turn

off delay of the chip is only a small proportion of the

gating period

Further details of setting output current are given in

the application notes.

*(R1+R2)/R1 x duty cycle. For best

REF

SEMICONDUCTORS

ISSUE 3 - AUGUST 2004

4

Page 5

TYPICAL CHARACTERISTICS

ZXLD1615

ISSUE 3 - AUGUST 2004

5

SEMICONDUCTORS

Page 6

ZXLD1615

TYPICAL PERFORMANCE GRAPHS

(For typical applications circuit at 22H Murata LQH32CN series, TA=25 °C unless otherwise stated)

SEMICONDUCTORS

ISSUE 3 - AUGUST 2004

6

Page 7

APPLICATIONS

Setting output voltage

The ZXLD1615 has an adjustable output voltage

allowing the end user maximum flexibility. To set the

output voltage a potential divider network is needed

(see R1 and R2 in typical applications circuit).

The output voltage is determined by the equation:

R

2

⎛

⎞

⎜

VV

=+

OUT FB

where VFB = 1.025V.

The following table gives suggested values for

various output voltages.

Required

output voltage

5V 270K⍀ 1M⍀

12V 91K⍀ 1M⍀

18V 60K⍀ 1M⍀

21V 51K⍀ 1M⍀

25V 43K⍀ 1M⍀

28V 39K⍀ 1M⍀

Output voltage can be adjusted from V

maximum output voltage rating of the internal

switch, 30V.

Once the nominal output voltage has been set, it can

be adjusted to a lower value by applying a pulse

width modulated (PWM) control signal to the EN pin.

PWM adjustment permits the device to be turned on

and the output voltage set by a single logic signal

applied to the EN pin. No external resistors are

required and the amplitude of the control signal is

not critical, providing it conforms to the limits

defined in the electrical characteristics.

⎟

1

⎝

⎠

R

1

R1 R2

+ VFto the

IN

ZXLD1615

1) PWM output voltage adjustment (analogue mode)

During this mode of operation the device operation is

continuous, providing a low ripple output voltage

(V

) directly proportional to the duty cycle (D) of

OUT

the logic signal applied to the EN pin according to the

relationship:

V

= D x V

OUT

Square wave signals applied to the EN pin, for

example, will turn the device on and produce a

nominal regulated output of 13.5V.

The ZXLD1615 contains a timing circuit that switches

the device on a few microseconds after the

application of a rising edge to EN and turns it back

off again nominally 120µs after the falling edge of

EN. For continuous PWM mode operation, the

frequency of the control signal must therefore be

maintained above 10kHz at all times, to prevent the

internal delay circuit from timing out and switching

the device into standby mode. The maximum

frequency applied to EN should be limited to 100kHz

to minimize errors due to internal switching delays

2) PWM output voltage adjustment (gated mode)

This method of adjustment can be used in

applications where the output ripple is less important

than the supply current. The method of adjustment is

the same as in 1) above, however, during this mode

of operation, the device is gated on and off,

providing an average output voltage (V

proportional to the duty cycle (D) of the logic signal

applied to the EN pin according to the relationship:

V

OUT(AVG)

The ripple on this voltage will be determined by the

size of the output capacitor.

The output voltage can be adjusted all the way down

to the input voltage by either method of PWM

control, but for best results, the duty cycle range

should be kept within the specified range. Lower duty

cycles will result in increased output ripple and

non-linearity in the relationship between duty cycle

and output voltage. If a greater control range is

required, the nominal output can be reduced by the

use of external resistors before the PWM signal is

applied.

OUT(nom)

= D x V

OUT(nom)

OUT

) directly

ISSUE 3 - AUGUST 2004

Minimizing output voltage ripple

For applications requiring lower output ripple it may

be necessary to add a small ceramic capacitor in

parallel with R2. A value of 4.7pF is suitable for most

output ranges.

7

SEMICONDUCTORS

Page 8

ZXLD1615

Capacitor selection

A ceramic capacitor grounded close to the GND pin

of the package is recommended at the output of the

device. Surface mount types offer the best

performance due to their lower inductance. A

minimum value of 0.22F is advised, although higher

values will lower switching frequency and improve

efficiency especially at lower load currents. A higher

value will also minimize ripple when using the device

to provide an adjustable dc output current.

A good quality, low ESR capacitor should also be

used for input decoupling, as the ESR of this

capacitor is effectively in series with the source

impedance and lowers overall efficiency. This

capacitor has to supply the relatively high peak

current to the coil and smooth the current ripple on

the input supply. A minimum value of 4.7F is

acceptable if the input source is close to the device,

but higher values will improve performance at lower

input voltages, when the source impedance is high.

The input capacitor should be mounted as close as

possible to the IC.

Inductor selection

The choice of inductor will depend on available

board space as well as required performance. Small

value inductors have the advantage of smaller

physical size and may offer lower series resistance

and higher saturation current compared to larger

values. A disadvantage of lower inductor values is

that they result in higher frequency switching, which

in turn causes reduced efficiency due to switch

losses. Higher inductor values can provide better

performance at lower supply voltages. However, if

the inductance is too high, the output power will be

limited by the internal oscillator, which will prevent

the coil current from reaching its peak value. This

condition will arise whenever the ramp time (I

x L/VIN) exceeds the nominal 5s maximum 'on' time

limit for the LX output.

LX(peak)

For maximum stability over temperature, capacitors

with X7R dielectric are recommended, as these have

a much smaller temperature coefficient than other

types.

A table of recommended manufacturers is provided

below:

Manufacturer Website

Murata www.murata.com

Taiyo Yuden www.t-yuden.com

Kemet www.kement.com

AVX www.avxcorp.com

Recommended inductor values for the ZXLD1615 are

in the range 6.8H to 22H. The inductor should be

mounted as close to the device as possible with low

resistance connections to the LX and V

Suitable coils for use with the ZXLD1615 are shown

in the table below:

IN

pins.

Part No. L

(

CMD4D11-100MC 10 0.457 0.5 Sumid a

DO1608-103 10 0.16 1.1 Coilcraft

LQH31CN100 10 1.3 0.23 Murata

LB2012Y100MR 10 0.5 0.1 Taiyo Yuden

SEMICONDUCTORS

DCR

H)

( )

I

Manufacturer

SAT

(A)

www.sumida.com

www.coilcraft.com

www.murata.com

www.t-yuden.com

8

ISSUE 3 - AUGUST 2004

Page 9

Diode selection

The rectifier diode (D1) should be a fast low

capacitance schottky diode with low reverse leakage

at the working voltage. It should also have a peak

current rating above the peak coil current and a

continuous current rating higher than the maximum

output load current.

The table below gives some typical characteristics for

diodes that can be used with the ZXLD1615:

ZXLD1615

Diode VF@ 100mA (mV) I

ZHCS400 300 1000 400 15 SOD323

ZHCS500 300 1000 500 15 SOT23

Layout considerations

PCB tracks should be kept as short as possible to

minimize ground bounce, and the ground pin of the

device should be soldered directly to the ground

plane. It is particularly important to mount the coil

and the input/output capacitors close to the device to

minimize parasitic resistance and inductance, which

will degrade efficiency. The FB pin is a high

impedance input, so PCB track lengths to this should

also be kept as short as possible to reduce noise

pickup. Excess capacitance from the FB pin to ground

should be avoided.

(mA) Ic (mA) IRat 30V ( A) Package

FSM

ISSUE 3 - AUGUST 2004

9

SEMICONDUCTORS

Page 10

ZXLD1615

REFERENCE DESIGNS

General Boost Converter

VIN=2.5V to 5.5V, V

See page 7 in datasheet for R1 and R2 values for various output voltages.

OUT

up to 28V

1 Cell Li-Ion to 3.3V Sepic Converter

SEMICONDUCTORS

ISSUE 3 - AUGUST 2004

10

Page 11

1 Cell Li-Ion to 5V Sepic Converter

Triple Output Boost Converter for LCD or OLED Bias

ZXLD1615

Note: For all manufacturers listing please refer to application section on page 7 of this datasheet.

ISSUE 3 - AUGUST 2004

11

SEMICONDUCTORS

Page 12

ZXLD1615

PACKAGE OUTLINE

PACKAGE DIMENSIONS

Millimeters Inches

DIM

MIN. MAX. MIN. MAX.

A - 1.00 - 0.0393

A1 0.01 0.10 0.0003 0.0039

A2 0.84 0.90 0.0330 0.0354

b 0.30 0.45 0.0118 0.0177

c 0.12 0.20 0.0047 0.0078

D 2.90 BSC 0.114 BSC

E 2.80 BSC 0.110 BSC

E1 1.60 BSC 0.062 BSC

e 0.95 BSC 0.037 BSC

e1 1.90 BSC 0.074 BSC

L 0.30 0.50 0.0118 0.0196

L2 0.25 BSC 0.010 BSC

Q 4° 12° 4° 12°

ORDERING INFORMATION

DEVICE DEVICE DESCRIPTION TEMPERATURE

RANGE

ZXLD1615ET5 Boost converter in SOT23-5 -40°C to +85°C 615 TA, TC

PART MARK TAPING OPTIONS

TA reels 3,000 devices, TC reels 10,000 devices

© Zetex Semiconductors plc 2004

Europe

Zetex GmbH

Streitfeldstraße 19

D-81673 München

Germany

Telefon: (49) 89 45 49 49 0

Fax: (49) 89 45 49 49 49

europe.sales@zetex.com

These offices are supported by agents and distributors in major countries world-wide.

Thispublicationisissued to provideoutlineinformationonly which(unless agreed by the Companyin writing)may not be used, appliedor reproduced

for any purpose or form part of any order or contract or be regarded as a representation relating to the products or services concerned. The Company

reserves the right to alter without notice the specification, design, price or conditions of supply of any product or service.

For the latest product information, log on to www.zetex.com

Americas

Zetex Inc

700 Veterans Memorial Hwy

Hauppauge, NY 11788

USA

Telephone: (1) 631 360 2222

Fax: (1) 631 360 8222

usa.sales@zetex.com

Asia Pacific

Zetex (Asia) Ltd

3701-04 Metroplaza Tower 1

Hing Fong Road, Kwai Fong

Hong Kong

Telephone: (852) 26100 611

Fax: (852) 24250 494

asia.sales@zetex.com

Corporate Headquarters

Zetex Semiconductors plc

Lansdowne Road, Chadderton

Oldham, OL9 9TY

United Kingdom

Telephone (44) 161 622 4444

Fax: (44) 161 622 4446

hq@zetex.com

ISSUE 3 - AUGUST 2004

SEMICONDUCTORS

12

Loading...

Loading...