Diodes ZXBM5210 User Manual

ZXBM5210

REVERSIBLE DC MOTOR DRIVE WITH SPEED CONTROL

Description

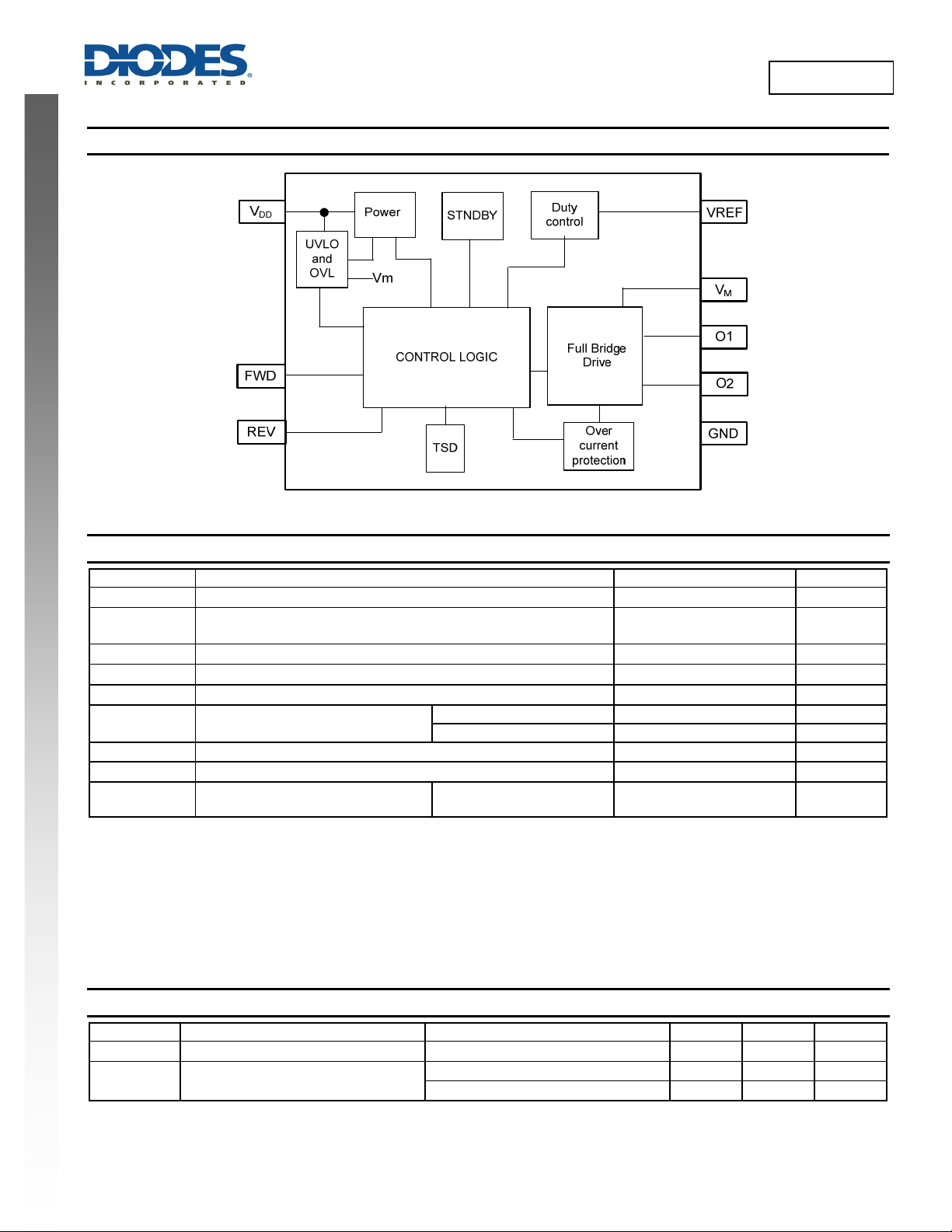

The ZXBM5210 is a single chip solution for driving a single-coil

reversible direct current (DC) fans and motors. The integrated full-

bridge driver output stage is designed to minimize audible switching

noise and electromagnetic interference (EMI) providing a low noise

solution

For system flexibility, the device has four modes of operation:

Forward, Reverse, Brake and Standby selected via FWD and REV

pins. The Forward and Reverse modes provide the motor rotation

direction control, the Brake mode allows quick stop and the Standby

mode helps system efficiency by powering down most of the internal

circuits to consume less than 32uA typical. The motor speed can be

adjusted by changing the duty ratio of the PWM signal on the FWD or

REV pins in the PWM mode or alternatively by adjusting DC voltage

NEW PRODUCT

input signal to the V

To help protect the IC and the motor coil the ZXBM5210 includes

under voltage, over voltage, over current and over temperature

protections. Once the safe operating range has been exceeded the

device shuts down the output drive to help prevent over stress on the

IC or the coil. The device internal current protection threshold is 1.5A

typical.

The ZXBM5210 is available in the standard SO8 and thermally

enhanced SO8-EP packages.

pin in the VREF speed control mode.

REF

Features

• Supports single-coil reversible DC motor applications

• Operating voltage: 3V to 18V

• Four modes of operations: Forward, Reverse, Brake and

Standby

• Low quiescent current of 0.85mA typical in normal operation

and 32µA in standby mode

• Internal over current protection

• Under voltage lockout and over voltage protection

• Over temperature protection

• -40°C to +85°C /105°C operating temperature

• 6kV ESD withstand capability

• Standard SO-8 and thermally enhanced SO-8EP

• Totally Lead-Free & Fully RoHS Compliant (Notes 1 & 2)

• Halogen and Antimony Free. “Green” Device (Note 3)

Notes: 1. No purposely added lead. Fully EU Directive 2002/95/EC (RoHS) & 2011/65/EU (RoHS 2) compliant.

2. See http://www.diodes.com/quality/lead_free.html for more information about Diodes Incorporated’s definitions of Halogen- and Antimony-free, "Green"

and Lead-free.

3. Halogen- and Antimony-free "Green” products are defined as those which contain <900ppm bromine, <900ppm chlorine (<1500ppm total Br + Cl) and

<1000ppm antimony compounds.

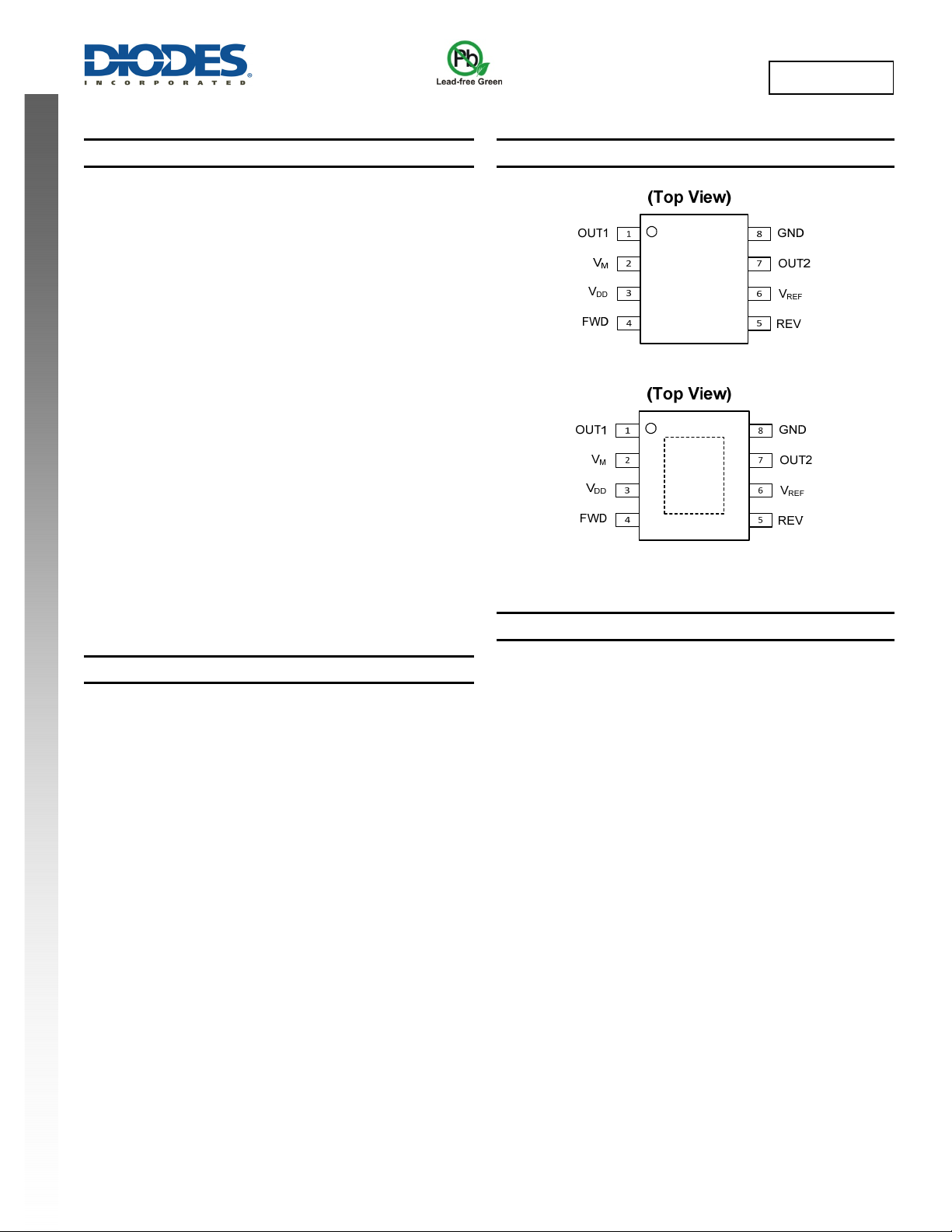

Pin Assignments

SO-8

SO-8EP

Applications

• 5V / 9V/ 12V / 15V DC reversible motors and actuators

• Home appliances

• Handheld power tools

• Valve open and close

• Remote control motorized toys

• Medium Voltage/ Low Power DC Motors

ZXBM5210

Document number: DS36765 Rev. 1 - 2

1 of 17

www.diodes.com

December 2013

© Diodes Incorporated

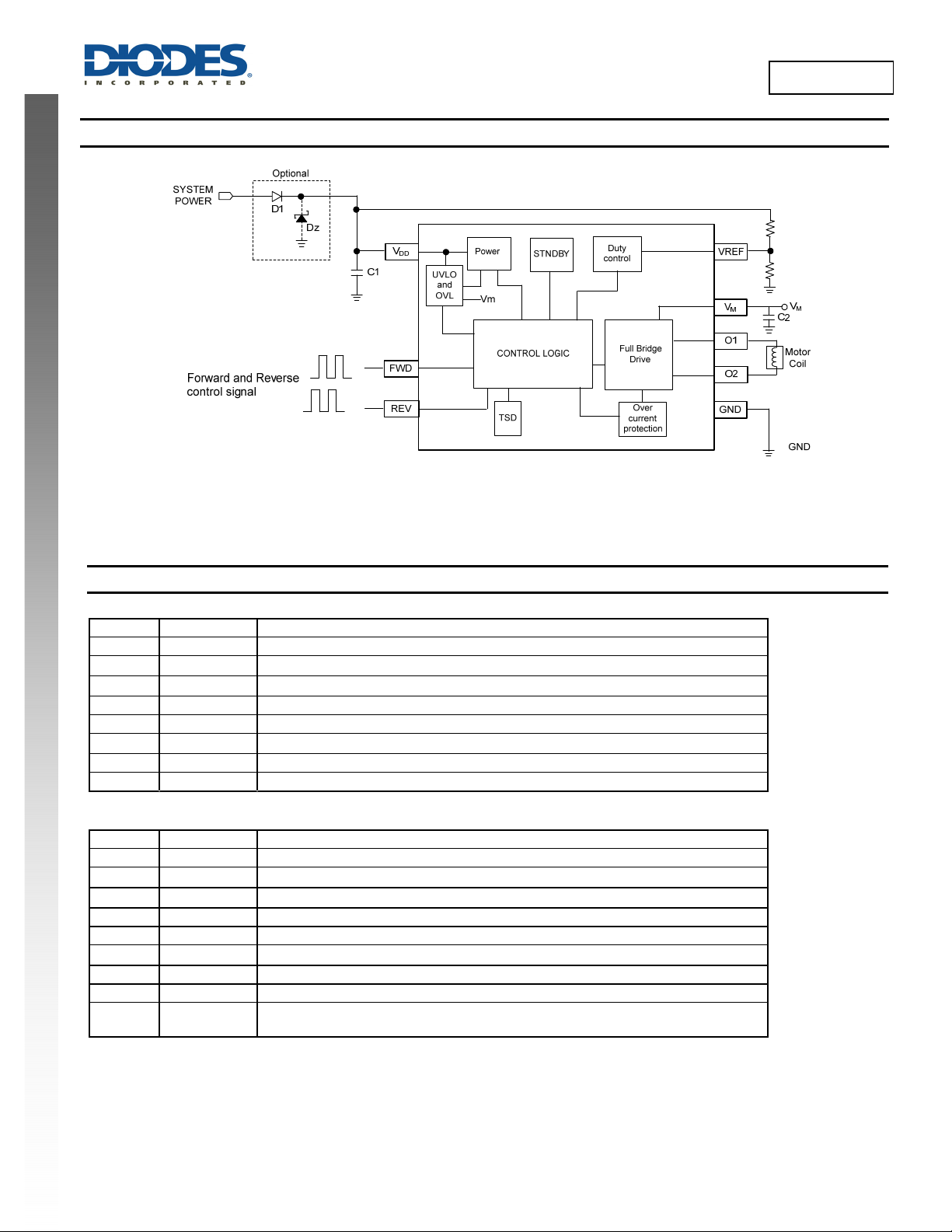

Typical Applications Circuit

ZXBM5210

NEW PRODUCT

Note: 4. C1 is for power stabilization and to strengthen the noise immunity, the recommended capacitance is 100nF to 1µF or more.

C2 is a re-circulating capacitor for back rush voltage and recommended capacitance is 100nF for low current applications to 10µF or more for large

current applications. See application note section

Pin Descriptions

Package: SO-8

Pin # Pin Name Function

1 OUT1 Driver output

2

3

4 FWD Forward Control Input (logic level, 5.5V max)

5 REV Reverse Control Input (logic level, 5.5V max)

6

7 OUT2 Driver Output

8 GND Ground

Package: SO8-EP

Pin # Pin Name Function

1 OUT1 Driver output

2

3

4 FWD Forward Control Input (logic level, 5.5V max)

5 REV Reverse Control Input (logic level, 5.5V max)

6

7 OUT2 Driver Output

8 GND Ground

Pad Pad

V

M

V

DD

V

REF

V

M

V

DD

V

REF

Power Supply Voltage

Power Supply Voltage

Input reference voltage to set the internal PWM oscillator duty ratio

Power Supply Voltage

Power Supply Voltage

Input reference voltage to set the internal PWM oscillator duty ratio

The exposed pad is for thermal dissipation and it is internally connected to the ground.

On the PCB layout, it can be connected to GND or left open circuit.

ZXBM5210

Document number: DS36765 Rev. 1 - 2

2 of 17

www.diodes.com

December 2013

© Diodes Incorporated

Functional Block Diagram

NEW PRODUCT

ZXBM5210

Absolute Maximum Ratings (Note 5) @T

Symbol Characteristic Values Unit

VM and V

V

OUT1, VOUT2

V

REF

V

and V

FWD

V

REVERSE

I

OUTPUT

PD

Ts Storage temperature range -65 to +150

TJ

ESD HBM

Notes: 5. Stresses greater than the 'Absolute Maximum Ratings' specified above, may cause permanent damage to the device. These are stress ratings

only; functional operation of the device at these or any other conditions exceeding those indicated in this specification is not implied. Device

reliability may be affected by exposure to absolute maximum rating conditions for extended periods of time

6. The absolute maximum supply voltage of 24V is a transient stress rating and is not meant as a functional operating condition. It is not recommended

7. SO-8 soldered to minimum recommended landing pads (see Package Outline Dimension section) on a 1”x1” two-layer 2oz.copper FR4 PCB

8. SO-8EP exposed pad soldered to minimum recommended landing pads (see Package Outline Dimension section) on a 2”x2” two-layer 2oz.copper

Supply voltage (Note 6) 24 V

DD,

All other pins except FWD and REV pins 24 V

FWD and REV pin voltage 7 V

REV

Reverse supply Voltage on all pins -0.3 V

Output current (source and sink)- Peak 1500 mA

Package power dissipation

Maximum junction temperature 150

Human Body Model ESD withstand

capability

to operate the device at the absolute maximum rated conditions for any period of time.

(1.6mm thickness) without any via or copper flood on the bottom layer. See thermal de-rating curves in the thermal performance section.

FR4 PCB (1.6mm thickness) with four thermal vias in the exposed PAD to the copper flood on the bottom layer. See thermal de-rating curves in the

thermal performance section.

= +25°C, unless otherwise specified.)

A

SO8 (Note 7) 1043 mW

SO8-EP (Note 8) 2980 mW

, VM, V

V

DD

GND and OUT1 OUT2 pins

, FWD, REV,

REF

6 kV

°C

°C

Recommended Operating Conditions

Symbol Characteristic Conditions Min Max Unit

VDD

TA

Supply Voltage Operating 3

Operating Temperature Range

ZXBM5210

Document number: DS36765 Rev. 1 - 2

Operating, SO8 package -40

Operating, SO8-EP package -40

3 of 17

www.diodes.com

18

+85

+105

December 2013

© Diodes Incorporated

V

°C

°C

ZXBM5210

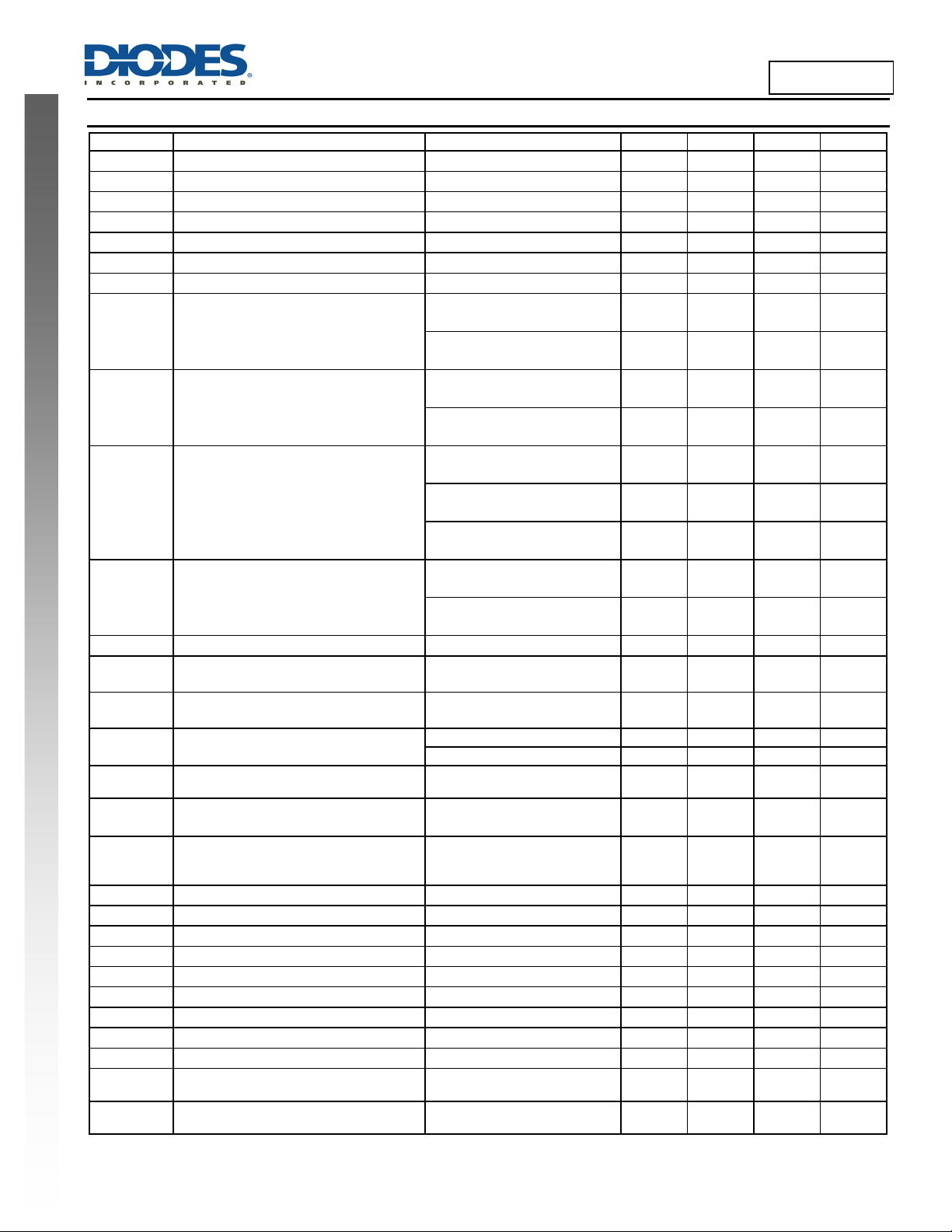

Electrical Characteristics (Note 9)(@T

= +25°C, VDD = 12V, unless otherwise specified.)

A

Symbol Characteristics Conditions Min Typ Max Unit

IDD

I

DD_STNDBY

V

UV_TH

V

UVLO_R

V

UV_HYS

V

OV_TH

V

OV_RLTH

VOH

VOL

NEW PRODUCT

VOH+ VOL

R

ON_Total

I

LIM_TH

V

REF

I

VREF

F

OUT

F

FWD_REV

T

DEAD

t

SDN_DELAY

V

FWDH

V

FWDL

I

FWDH

I

FWDL

V

REVH

V

REVL

I

REVH

I

REVL

D

PWM_MIN

Tj_

SDN_TH

Tj_

SDN_HYST

Note: 9. Typical data is at TA = +25°C, VDD = 12V. The maximum and minimum parameters values over the operating temperature range are not tested in

production, they are guaranteed by design, characterization and process control.

ZXBM5210

Document number: DS36765 Rev. 1 - 2

Supply Current No Load — 0.85 2.5 mA

Standby Supply Current FWD=REV=LOW (GND)

Under Voltage lock Out Threshold Voltage Decreasing

Under Voltage Lock Out Release Threshold Voltage Increasing

Under Voltage Hysteresis Voltage Increasing

Overvoltage Threshold Voltage Increasing

Overvoltage Release Threshold Voltage Decreasing 17.0 19 — V

= 300mA,

I

OUT

= -40°C to +105°C

T

Output Voltage High

Output Voltage Low

Output voltage of N- and PMOS and bond

wire voltage drop combined

Combined N- and PMOS R

bond wire resistance

Over current protection threshold 1.2 1.5 A

V

voltage range

REF

( DC voltage speed control mode)

V

bias current

REF

( DC voltage speed control mode)

Output PWM switching frequency

(Internal PWM oscillator)

Input PWM frequency of speed control

signal

Dead time between current reversal

DSON

including

Shutdown delay – Internal circuits active

after FWD = REV = L

(except from brake mode)

FWD Input H Level 2 — 5.5 V

FWD Input L Level 0 — 0.8 V

FWD pin current – H Level

FWD pin current – L Level

REV Input H Level 2 — 5.5 V

REV Input L Level 0 — 0.8 V

REV pin current – H Level

REV pin current – L Level

Output minimum duty ratio 0% 100 %

IC junction temperature thermal shutdown

threshold

IC junction temperature thermal shutdown

hysteresis

A

I

=500mA

OUT

= -40°C to +105°C

T

A

= 300mA,

I

OUT

= -40°C to +105°C

T

A

I

= 500mA,

OUT

T

= -40°C to +105°C

A

I

= 300mA,

OUT

= -40°C to +105°C

T

A

I

= 500mA,

OUT

= -40°C to +105°C

T

A

I

= 300mA, VDD = 3V

OUT

= -40°C to +105°C

T

A

I

= 500mA,

OUT

= -40°C to +105°C

T

A

I

= 300mA, VDD = 3V

OUT

= -40°C to +105°C

T

A

3 —

= VDD

V

REF

VREF control mode 20 26.5 35 kHz

PWM speed control mode 20 — 100 kHz

PWM control mode 20 — 100 kHz

V

= 3V to 18V

DD

= -40°C to +105°C

T

A

FWD = GND

REV = GND

FWD pin: V

FWD pin: V

REV pin: V

REV pin: V

FWD

FWD

RVS

RVS

= 5V

= 0V

= 5V

= 0V

— 165 —

— 25 —

—

—

—

—

—

V

- 0.25 VDD - 0.15

DD

V

- 0.43 VDD - 0.25

DD

32 45 uA

2.6 — V

2.8 3.0 V

200 — mV

20.7 24 V

— 0.15 0.25 V

— 0.25 0.43 V

— 0.3 0.5 V

— 0.5 0.86 V

— 0.39 0.66 V

— 1 1.72

— 1.3 2.2

(18V max)

-15 0 15 μA

2.1 3 3.9 μs

125 180 — μs

— 50 — μA

— 50 — μA

— 50 — μA

— 50 — μA

4 of 17

www.diodes.com

— V

— V

Ω

Ω

V

DD

© Diodes Incorporated

V

o

C

o

C

December 2013

ZXBM5210

Application Note

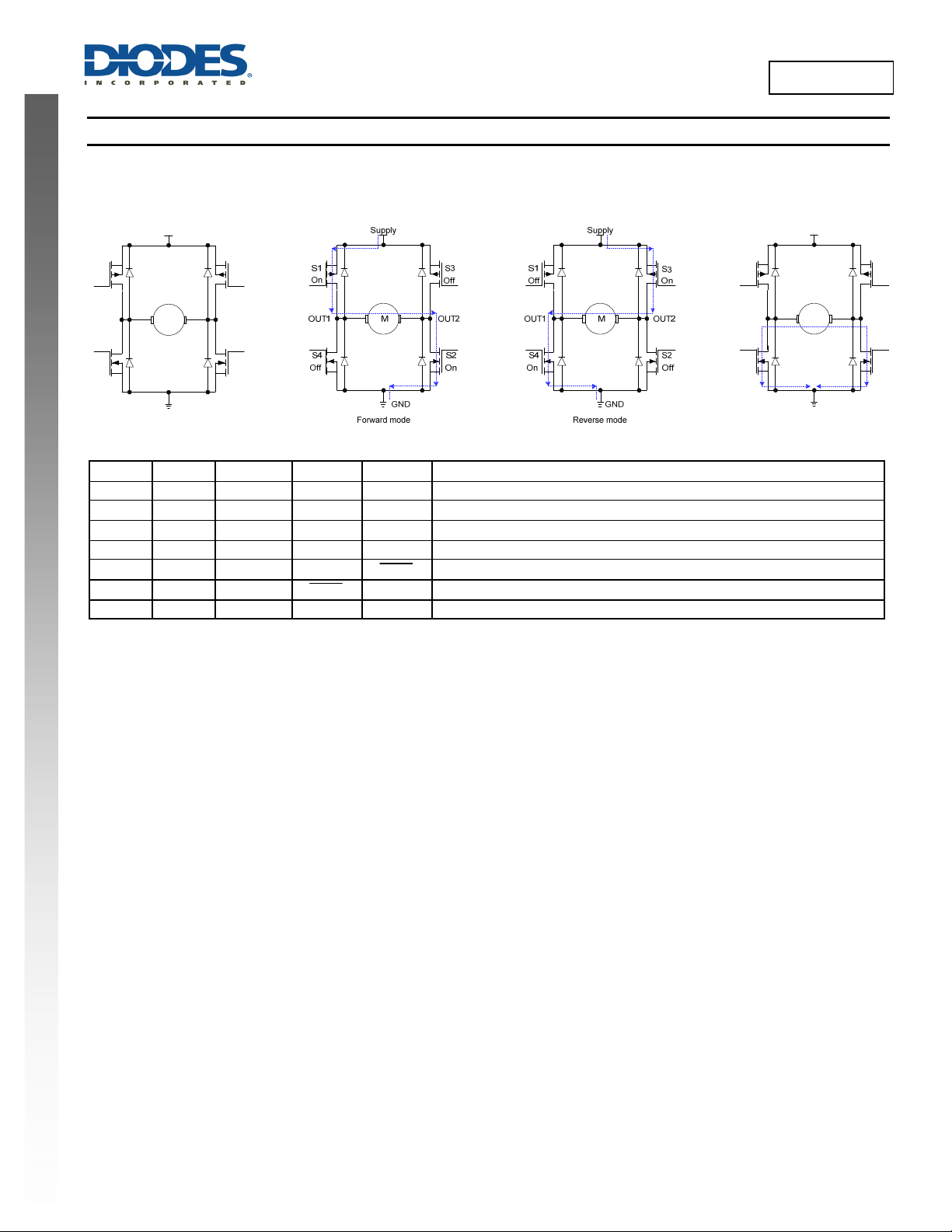

Rotation Control and Standby Modes

The device has FWD and REV pins for controlling the motor rotation directions. The device has four motor operation modes: 1) Standby mode,

2) Forward mode, 3) Reverse mode and 4) Brake mode. The four modes are controlled by the FWD and REV logic pins.

Supply

Supply

S1

OUT1

S4

On

Brake mode

NEW PRODUCT

S1

Off

OUT1 OUT2

Off

M

GND

Standby mode

S3

Off

S2S4

Off

FWD REV

V

REF

OUT1 OUT2 Operating mode

L L x Open Open Standby mode – All switches are off

H L

L H

3V to V

3V to V

DD

DD

H L

L H

Forward mode – Current flows from OUT1 to OUT2; V

Reverse mode – Current flows from OUT2 to OUT1; V

duty control

REF

duty control

REF

H H x L L Brake mode – Short circuit brake with low side switches on

PWM L

L PWM

V

DD

V

DD

H PWM

PWM H

Forward mode – Current flows from OUT1 to OUT2; PWM control mode

Reverse mode – Current flows from OUT2 to OUT1; PWM control mode

H H x L L Brake mode – Short circuit brake with low side switches on

In the brake mode, switches S2 and S4 are ON allowing the motor to stop quickly. All the internal control circuits are fully operational.

In the standby mode all the output drive switches are off and additionally, the internal circuits are also turned off to minimize power consumption.

The power consumption in the standby mode is less than in the brake mode. If running motor enters the Standby mode, due to the body diodes

the motor free wheels to idle state. Whenever the motor enters the standby mode from any mode (except the brake mode) the control logic will

remain active in previous mode for at least 125µs before shutting down the internal circuits. To prevent device entering the standby mode during

operating mode changes, the mode change signals should be completed within 125µs.

In the forward mode, with switches S1-S2 ON and S3-S4 OFF, OUT1 is high and OUT2 is low. The motor current flows from OUT1 to OUT2. In

the reverse mode, switches S1-S4 are ON while S1-S2 are OFF to allow motor current flow from OUT2 to OUT1.

In the forward or reverse mode, for V

speed control, the output drive duty ratio is generated internally based on the voltage on the V

REF

For PWM speed control, external PWM signals applied to the FWD or REV pins control the PWM switching of the low side S2 (forward mode)

or S4 (reverse mode). See application section for further details.

The ZXBM5210 has three modes of speed control: V

speed control mode, PWM speed control mode and by adjusting the supply voltage

REF

S3

OffOf f

M

GND

OUT2

S2

On

pin.

REF

ZXBM5210

Document number: DS36765 Rev. 1 - 2

5 of 17

www.diodes.com

December 2013

© Diodes Incorporated

ZXBM5210

Application Note (cont.)

Motor Speed Control with DC Voltage on V

Motor speed can be controlled by adjusting the DC voltage into the V

voltage to the supply V

voltage.

DD

In V

speed control mode, FWD and REV pins are only used for direction control and therefore high frequency PWM control signal should not

REF

be applied to the FWD and REV pins. If repetitive direction changes required, it is recommended to keep direction change frequency of below

400Hz.

The speed and direction control is given by:

FWD REV

V

REF

OUT1 OUT2

L L x Open Open Standby mode – All switches are off

NEW PRODUCT

H L

H L

L H

L H

V

DD

3V to V

V

DD

3V to V

DD

DD

H H x L L Brake mode – Short circuit brake with low side switches on

H L

H L

L H

L H

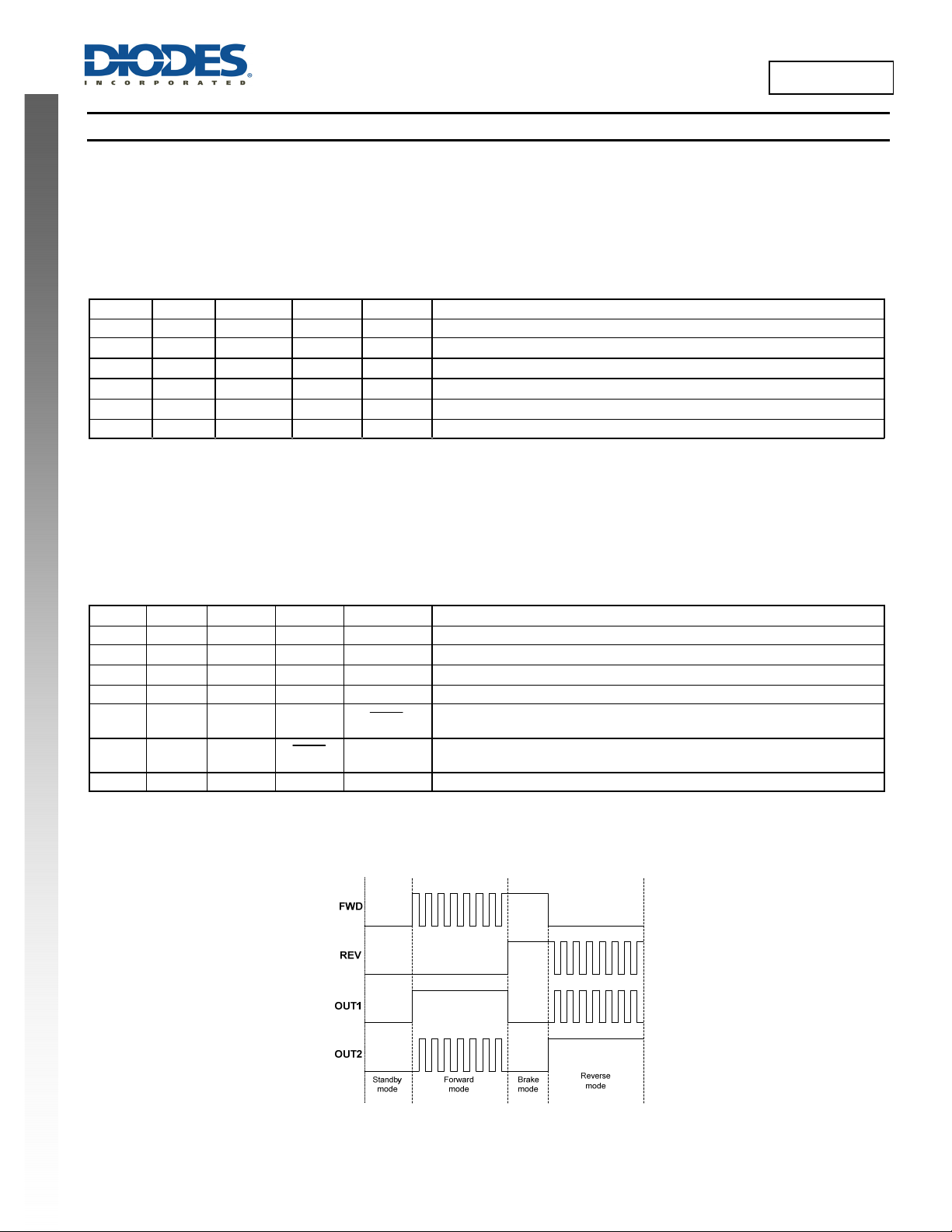

Motor Speed Control with a PWM Input Signal

Motor speed can be controlled by adjusting the duty cycle of the PWM speed control signal into the FWD or REV while keeping the VDD pin at

the nominal motor voltage. In this mode the input voltage on the V

In PWM speed control mode the high side switches S1 and S3 are kept fixed while the low side switches S2 or S4 are switched. In the forward

mode, S1 is kept switched on, S2 is switched in accordance with the PWM signal and S3 and S4 are switched off. In reverse mode, S3 is

switched on, S4 is switched in accordance with the PWM signal and S1 and S2 are switched off.

The speed and direction control is given by:

FWD REV

V

REF

L L x Open Open Standby mode – All switches are off

H L

L H

V

DD

V

DD

H H x L L Brake mode – Short circuit brake with low side switches on

PWM L

L PWM

V

DD

V

DD

H H x L L Brake mode – Short circuit brake with low side switches on

The motor speed is proportional to the input PWM signal duty. For example, for a 12V motor the V

PWM control signal duty to adjust the motor speed linearly. The timing diagram below shows the output O1 and O2 in relation to PWM speed

control signal at PWM pin.

OUT1 OUT2 Operating mode

H L

L H

H PWM

PWM H

REF

Pin

pin. The output drive PWM duty ratio is defined by the ratio of the V

REF

Operating mode

Forward mode – Current flows from OUT1 to OUT2; 100% duty

Forward mode – Current flows from OUT1 to OUT2; V

duty control

REF

Reverse mode – Current flows from OUT2 to OUT1; 100% duty

Reverse mode – Current flows from OUT2 to OUT1; V

pin must be greater than or equal to VDD.

REF

duty control

REF

Forward mode – Current flows from OUT1 to OUT2; 100% duty

Reverse mode – Current flows from OUT2 to OUT1; 100% duty

Forward mode – Current flows from OUT1 to OUT2;

PWM control mode

Reverse mode – Current flows from OUT2 to OUT1

PWM control mode

pin is maintained at 12V while varying the

DD

REF

Frequency of PWM speed control signal can be between 8kHz to 100kHz. Recommended typical PWM signal frequency is 25kHz to keep

switching frequency away from the audible band.

ZXBM5210

Document number: DS36765 Rev. 1 - 2

6 of 17

www.diodes.com

December 2013

© Diodes Incorporated

Loading...

Loading...