Page 1

A

f

Product Line o

Diodes Incorporated

ZLDO1117

1A LOW DROPOUT POSITIVE REGULATOR

1.2V, 1.5V, 1.8V, 2.5V, 3.3V, 5.0V AND ADJUSTABLE OUTPUTS

Description

ZLDO1117 is a low dropout positive adjustable or fixed-mode

regulator with 1A output current capability.

The ZLDO1117 has a 2% tolerance across the industrial temperature

range and is guaranteed to have lower than 1.2V dropout at full load

current making it ideal to provide well-regulated outputs of 1.2V to

5.0V with input supply voltages up to 18V.

The ZLDO1117 is ideally suited to provide well-regulated supplies for

low voltage IC applications such as high-speed bus termination and

low current 3.3V logic supply across the whole industrial temperature

range.

Features

• 1.2V Maximum Dropout at Full Load Current

• 2% Tolerance Over Temperature, Line and Load Variations

• Fast Transient Response

• Output Current Limiting

• Built-in Thermal Shutdown

• Good Noise Rejection

• Suitable for use with MLCC Capacitors

• Qualified to AEC-Q100 Grade 2 (see ‘Ordering Information’)

• PPAP capable (Note 4)

• -40 to +125°C Junction Temperature Range

• Available in TO252 and SOT223 with “Green” Molding Compound

(No Br, Sb)

Lead-Free Finish; RoHS Compliant (Notes 1 & 2)

Halogen and Antimony Free. “Green” Device (Note 3)

Notes: 1. EU Directive 2002/95/EC (RoHS) & 2011/65/EU (RoHS 2) compliant. All applicable RoHS exemptions applied.

2. See http://www.diodes.com for more information about Diodes Incorporated’s definitions of Halogen- and Antimony-free, "Green" and Lead-free.

3. Halogen- and Antimony-free "Green” products are defined as those which contain <900ppm bromine, <900ppm chlorine (<1500ppm total Br + Cl)

and <1000ppm antimony compounds.

4. Automotive products are AEC-Q100 qualified and are PPAP capable. Automotive, AEC-Q100 and standard products are electrically and thermally

the same, except where specified.

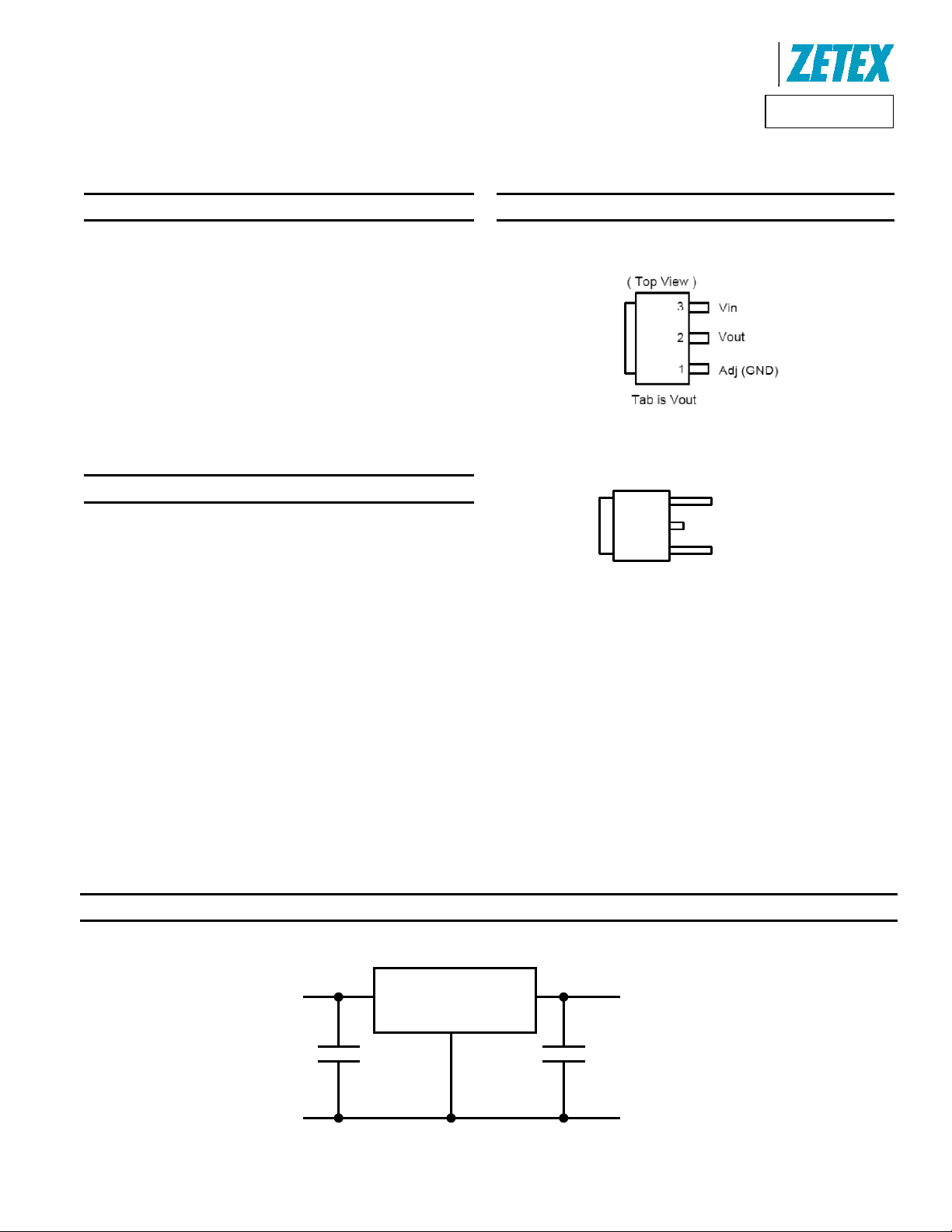

Pin Assignments

(Top View)

3

2

1

Tab is Vout

SOT223

TO252

Vin

Vout

Adj (GND)

Typical Applications Circuit

1A I/O – 1.8V Core Regulator

3.3V

ZLDO1117-18

1.8V

4.7µF

MLCC

4.7µF

MLCC

ZLDO1117

Document number: DS32018 Rev. 6 - 2

1 of 14

www.diodes.com

July 2012

© Diodes Incorporated

Page 2

A

f

Product Line o

Diodes Incorporated

ZLDO1117

Pin Descriptions

Pin

Name

Adj (GND) I 1

V

O 2

OUT

VIN I 3

I/O

Pin

Number

Function

A resistor divider from this pin to the V

Fixed-Mode).

The output of the regulator. A minimum of 4.7µF capacitor (0.05Ω ≤ ESR ≤ 0.5Ω) must be connected

from this pin to ground to insure stability. For improved ac load response a larger output capacitor is

recommended.

The input pin of regulator. Typically a large storage capacitor (0.05Ω ≤ ESR ≤ 0.5Ω) is connected from

this pin to ground to ensure that the input voltage does not sag below the minimum dropout voltage

during the load transient response. This pin must always be 1.3V higher than V

device to regulate properly.

pin and ground sets the output voltage (Ground only for

OUT

in order for the

OUT

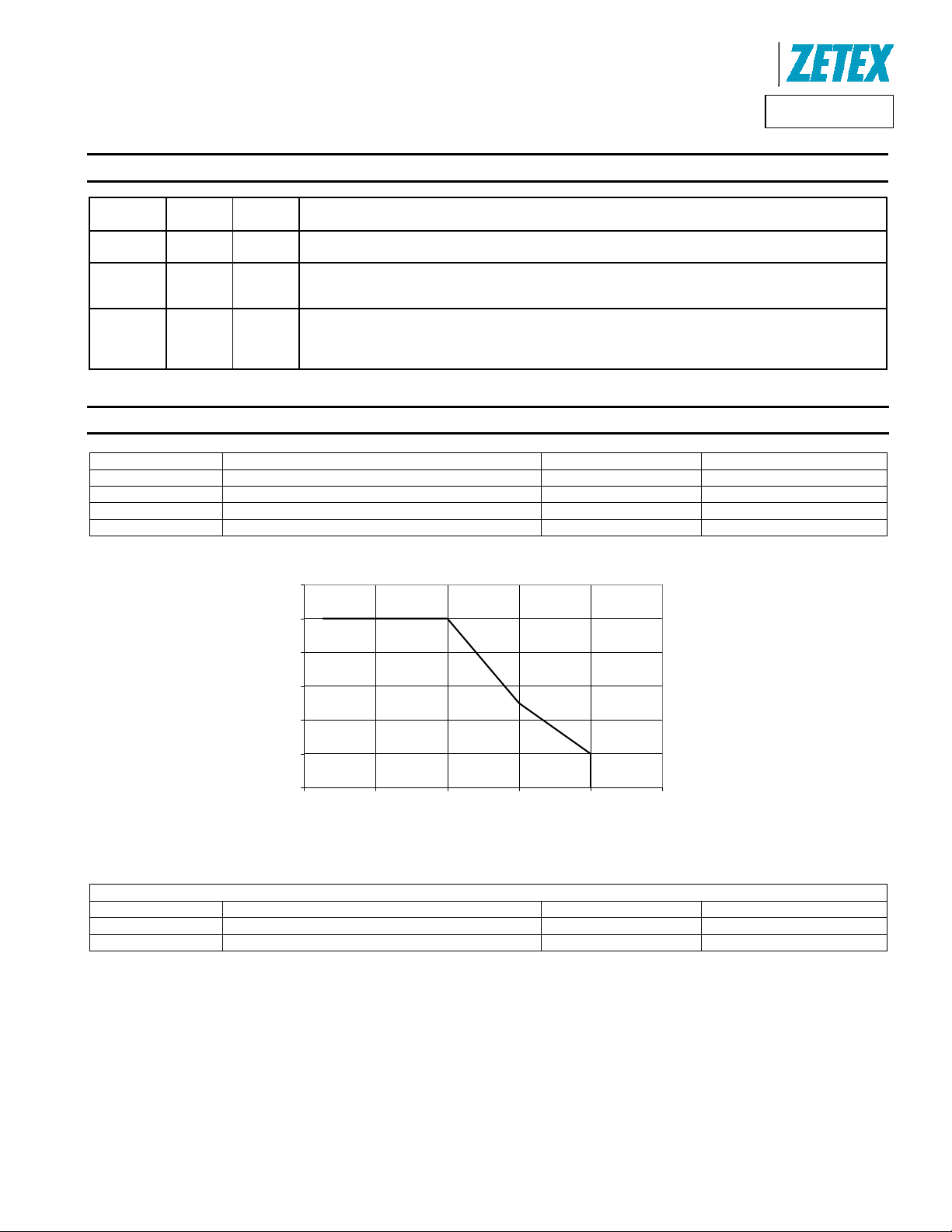

Absolute Maximum Ratings (@T

= +25°C, unless otherwise specified.)

A

Symbol Parameter Rating Unit

VIN Input Supply Voltage (Relative to Ground) -0.03 to +18 V

TJ Junction Temperature +150 °C

Power Dissipation See SOA Curve

TST Storage Temperature -65 to +150 °C

Unless otherwise stated voltages specified are relative to the ANODE pin.

1.2

1

0.8

(A)

0.6

LOAD

I

0.4

SOA

ESD Susceptibility

Symbol Parameter Rating Unit

HBM Human Body Model 4 kV

MM Machine Model 400 V

Stresses greater than the 'Absolute Maximum Ratings' specified above, may cause permanent damage to the device. These are stress ratings only; functional

operation of the device at these or any other conditions exceeding those indicated in this specification is not implied. Device reliability may be affected by exposure to

absolute maximum rating conditions for extended periods of time.

Semiconductor devices are ESD sensitive and may be damaged by exposure to ESD events. Suitable ESD precautions should be taken when handling and

transporting these devices

ZLDO1117

Document number: DS32018 Rev. 6 - 2

0.2

0

0 5 10 15 20 25

Safe Operation Area (SOA) Curve

- V

(V)

V

IN

OUT

2 of 14

www.diodes.com

July 2012

© Diodes Incorporated

Page 3

A

f

Product Line o

Diodes Incorporated

ZLDO1117

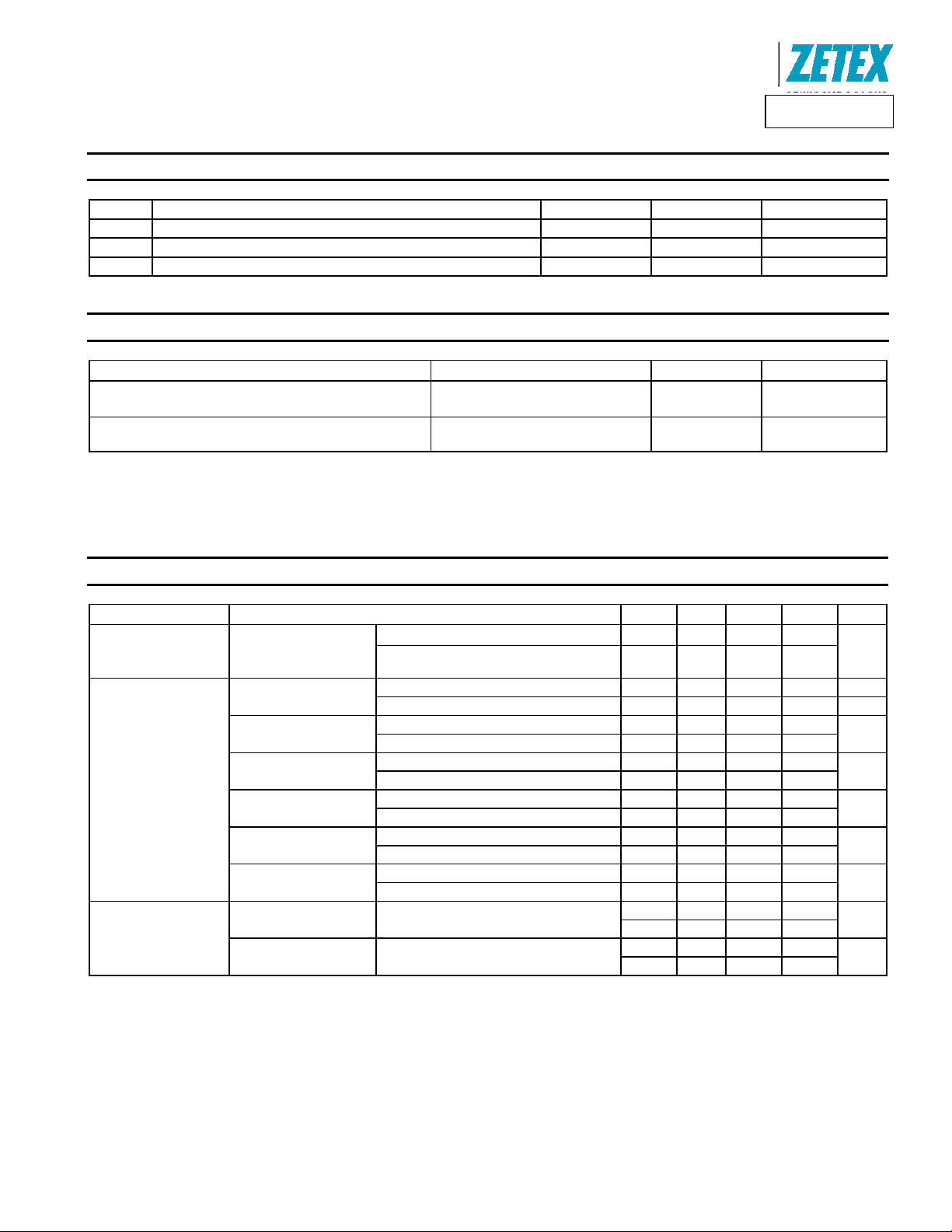

Recommended Operating Conditions (@T

= +25°C, unless otherwise specified.)

A

Symbol Parameter Min Max Unit

VIN Input voltage 2.7 (Note 8) 18 V

IO Output current 0.01 1 A

TJ Operating Junction Temperature Range (Note 5) -40 +125 °C

Package Thermal Data

Thermal Resistance Package Rating Unit

Junction-to-Ambient, θJA

Junction-to-Case, θJC

Notes: 5. ZLDO1117 contains an internal thermal limiting circuit that is designed to protect the regulator in the event that the maximum junction temperature

exceeded. When activated, typically at 150°C, the regulator Output switches off and then back on as the die cools.

6. Test condition for SOT223: T

7. Test condition for TO252: T

8. Ensures correct operation without entering dropout. Device will continue to operate below this minimum input voltage under dropout conditions.

= +27°C, no air flow, device mounted on 2”X2” polyimide PCB, 2 oz copper, 5.6mmX5.6mm pad.

A

= +27°C, no air flow, device mounted on 2”X2” polyimide PCB, 1 oz copper, 2cmX2cm pad.

A

SOT223 (Note 6)

TO252 (Note 7)

SOT223 (Note 6)

TO252 (Note 7)

Electrical Characteristics (@T

= +25°C, unless otherwise specified.)

A

Parameter Conditions TA Min Typ Max Unit

(VIN-V

Reference Voltage ZLDO1117-ADJ

ZLDO1117-1.2

ZLDO1117-1.5

ZLDO1117-1.8

Output Voltage

ZLDO1117-2.5

ZLDO1117-3.3

ZLDO1117-5.0

ZLDO1117-ADJ

Line Regulation

Notes: 9. See thermal regulation specifications for changes in output voltage due to heating effects. Line and load regulation are measured at a constant

junction temperature by low duty cycle pulse testing. Load regulation is measured at the output lead = 1/18” from the package.

10. Line and load regulation are guaranteed up to the maximum power dissipation of 15W. Power dissipation is determined by the difference between input

and output differential and the output current. Guaranteed maximum power dissipation will not be available over the full input/output range.

ZLDO1117-1.2

ZLDO1117-xx

V

10mA < IO< 1A

IO = 10mA, VIN = 3.2V 25 1.188 1.200 1.212 V

10mA< IO< 1A, 2.7V <VIN< 12V FT 1.176 1.224

IO = 10mA, VIN = 3.5V 25 1.485 1.500 1.515

0 < IO< 1A, 2.9V <VIN< 12V FT 1.470 1.530

IO = 10mA, VIN = 3.8V 25 1.782 1.800 1.818

0 < IO< 1A, 3.2V <VIN< 12V FT 1.764 1.836

IO = 10mA, VIN = 4.5V 25 2.475 2.500 2.525

0 < IO< 1A, 3.9V <VIN< 12V FT 2.450 2.550

IO = 10mA, VIN = 5.3V 25 3.267 3.300 3.333

0 < IO< 1A, 4.7V <V

IO = 10mA, VIN = 7V 25 4.95 5.000 5.05

0 < IO< 1A, 6.4V <V

IO = 10mA,

V

IO = 0mA,

V

) = 2V, IO = 10mA 25 1.238 1.250 1.263

OUT

+1.4V < VIN< 10V,

OUT

+1.5V<VIN<12V

OUT

+1.5V<VIN<12V

OUT

< 12V FT 3.235 3.365

IN

< 12V FT 4.900 5.100

IN

FT 1.225 1.275

25 0.1

FT 0.2

25 0.1

FT 0.2

ZLDO1117

Document number: DS32018 Rev. 6 - 2

3 of 14

www.diodes.com

107

73

16

12

°C/W

°C/W

V

V

V

V

V

V

%

%

July 2012

© Diodes Incorporated

Page 4

A

f

Product Line o

Diodes Incorporated

ZLDO1117

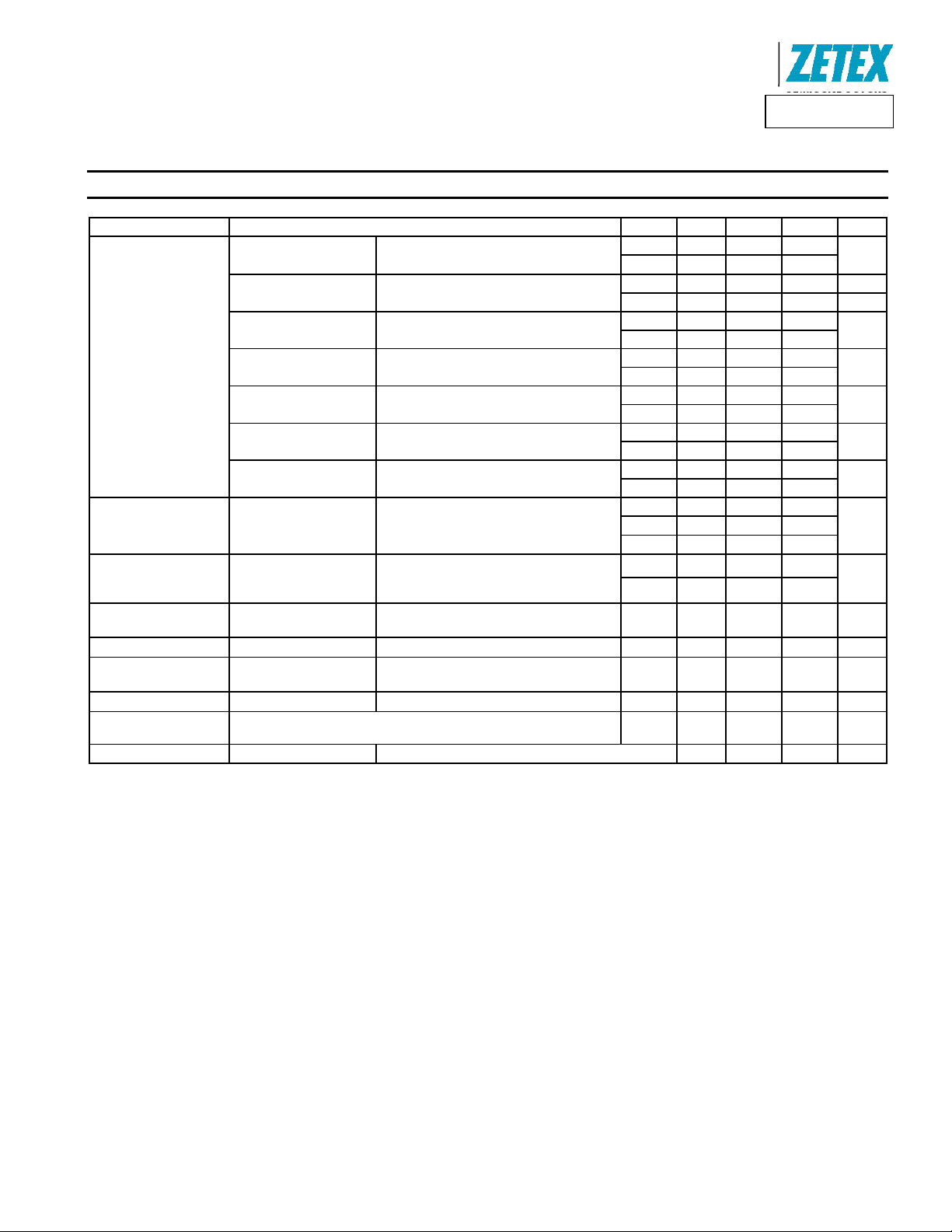

Electrical Characteristics (cont.) (@T

Parameter Conditions TA Min Typ Max Unit

ZLDO1117-ADJ

ZLDO1117-1.2

ZLDO1117-1.5

Load Regulation

Dropout Voltage

(VIN-V

Current Limit

Minimum Load Current

(Note 8)

Quiescent current

GND current

Thermal Regulation

Ripple Rejection

Temperature Stability

Notes: 8. See thermal regulation specifications for changes in output voltage due to heating effects. Line and load regulation are measured at a constant

junctiontemperature by low duty cycle pulse testing. Load regulation is measured at the output lead = 1/18” from the package.

9. Line and load regulation are guaranteed up to the maximum power dissipation of 15W. Power dissipation is determined by the difference between input

and output differential and the output current. Guaranteed maximum power dissipation will not be available over the full input/output range.

OUT

)

ZLDO1117

Document number: DS32018 Rev. 6 - 2

ZLDO1117-1.8

ZLDO1117-2.5

ZLDO1117-3.3

ZLDO1117-5.0

ZLDO1117ADJ/1.2/1.5/1.8/2.5/

3.3/5.0

ZLDO1117-

ADJ/1.2/1.5/1.8/2.5/

3.3/5.0

ZLDO1117-ADJ

ZLDO1117-1.2

ZLDO1117-xx VIN< 18V, IO = 0mA

ZLDO1117-ADJ

ZLDO1117-1.2

30ms pulse

f = 120Hz, C

I

= 100mA, ZLDO1117-XXX VIN = V

OUT

IO = 10mA

= 25µF Tantalum,

OUT

= +25°C, unless otherwise specified.)

A

VIN=3.3V,V

(Notes 9, 10)

VIN=2.7V, 10mA < IO < 1A,

(Notes 9, 10)

VIN = 3V, 0 < IO< 1A,

(Notes 9, 10)

VIN = 3.3V, 0 < IO< 1A,

(Notes 9, 10)

VIN = 4V, 0 < IO< 1A,

(Notes 9, 10)

VIN = 4.8V, 0 < IO< 1A,

(Notes 9, 10)

VIN = 6.5V, 0 < IO< 1A,

(Notes 9, 10)

IO = 1A, ΔV

(VIN-V

VIN = <18V FT 2 5 mA

VIN = 7V FT 35 120 µA

=0, 10mA<IO<1A,

ADJ

= 1%V

OUT

) = 5V

OUT

+3V

OUT

4 of 14

www.diodes.com

OUT

25 0.2

FT

25 0.2 %

FT 0.4

25 3

FT 6

25 4

FT 8

25 5

FT 10

25 6.6

FT 13

25 10

FT 20

25 1.11 1.2

0 ~ 125

FT

25

FT 1. 1

FT 4 10 mA

25 0.1 %/W

25 60 80 dB

0.5 %

0.4

1.3

1.35

© Diodes Incorporated

%

mV

mV

mV

mV

mV

V

A

July 2012

Page 5

A

f

A

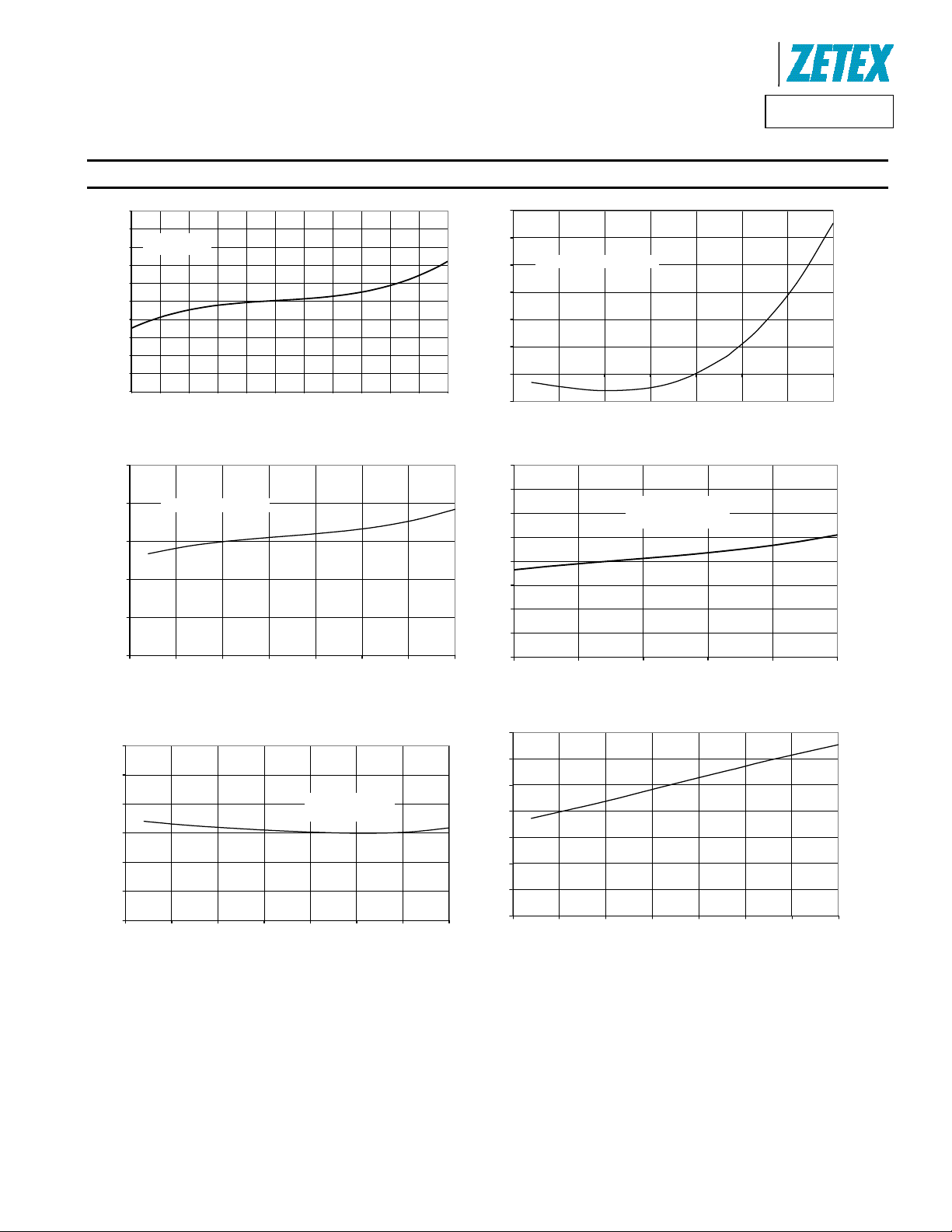

Typical Characteristics

0.5

0.4

Adjustable version

0.3

= 10mA

I

LOAD

0.2

0.1

0

∆Vout (%)

-0.1

-0.2

-0.3

-0.4

-0.5

-40 -25 -10 5 20 35 50 65 80 95 110 125

Output Voltage Variation vs. Temperature Line Regulation vs. Temperature

0.25

0.2

0.15

0.1

Load Regulation (%)

0.05

VIN=3.3V, 10mA<I

0

-50 -25 0 25 50 75 100 125

Load Regulation vs. Temperature Drop-Out Voltage vs. Current

Temperature (°C)

<1A

OUT

Temperature (°C)

Product Line o

Diodes Incorporated

ZLDO1117

0.06

0.05

V

+1.5V<VIN<12V, I

0.04

0.03

0.02

Line Regulation (%)

0.01

-0.01

1.4

1.3

1.2

1.1

0.9

Dropout voltage (V)

0.8

0.7

0.6

OUT

0

-50-250 255075100125

1

0 0.2 0.4 0.6 0.8 1

=10mA

OUT

Temperature (C)

∆V

OUT

TJ = 25ºC

= 1% of V

(A)

I

OUT

OUT

1.4

Dropout vs Temperature

70

60

1.3

I

=1A

1.2

1.1

Dropout (V)

1

0.9

0.8

-50 -25 0 25 50 75 100 125

Temperature (°C)

∆V

OUT

= 1% of V

OUT

OUT

Drop-Out Voltage vs. Temperature

50

40

(µA)

30

ADJ

I

20

10

0

-50 -25 0 25 50 75 100 125

Temperature (°C)

djust Pin Input Current

ZLDO1117

Document number: DS32018 Rev. 6 - 2

5 of 14

www.diodes.com

July 2012

© Diodes Incorporated

Page 6

A

f

r

r

A

A

V

V

A

A

Typical Characteristics

Product Line o

Diodes Incorporated

ZLDO1117

ZLDO1117-2.5V

= 1µF, C

C

IN

I

PRELOAD

= 100mA, I

= 10µFTANT

OUT

step

= 500mA

10m

0

-10m

600m

100m

Transient Load Regulation with 10µF Tantalum

Capacitor

ZLDO1117 2.5V

= 1µF, C

C

IN

I

LOAD

= 100mA

= 4.7µF MLCC

OUT

10

0

ZLDO1117-2.5V

= 1µF, C

C

IN

I

PRELOAD

= 100mA, I

= 4.7µF MLCC

OUT

= 500mA

STEP

10mV

0

-10mV

600m

100m

Transient Load Regulation with 4.7µF MLCC Capacito

5V

4V

10µs/div

Transient Line Regulation with 4.7µF MLCC Capacito

90

85

80

75

70

65

Ripple Rejection (dB)

60

55

50

10 100 1,000 10,000 100,000

I

= 100mA, VIN - V

LOAD

= 3V

OUT

Frequency (Hz)

Ripple Rejection

ZLDO1117

Document number: DS32018 Rev. 6 - 2

6 of 14

www.diodes.com

July 2012

© Diodes Incorporated

Page 7

A

f

Product Line o

Diodes Incorporated

ZLDO1117

Application Information

The ZLDO1117 family of quasi-LDO regulators is easy to use. They are protected against short circuit and thermal overloads. (see block

diagram).

Thermal protection circuitry will shut down the regulator should the junction temperature exceed +150°C at the sense point. The ZLDO1117 is

pin compatible with similar ‘1117 regulators and offers extended temperature range and improved regulation specifications.

Operation

The ZLDO1117 develops a 1.25V reference voltage between the output and the adjust terminal (see block diagram). By placing a resistor

between these two terminals, a constant current is caused to flow through R1 and down through R2. For fixed outp ut variants Resistors R1 and

R2 are internal.

Stability

The ZLDO1117 requires an output capacitor as part of the device frequency compensation. As part of its improved performance over industry

standard 1117 the ZLDO1117 is suitable for use with MLCC (Multi Layer C eramic Chip) capacitors. A minimum of 4.7µF ceramic X7R, 4.7µF

tantalum, or 47 µF of aluminum electrolytic is required. The ESR of the output capacitor should be less than 0.5Ω. Surface mount tantalum

capacitors, which have very low ESR, are available from several manufacturers. When using MLCC capacitors avoid the use of Y5V dielectrics.

Load Regulation

For improved load regulation the ZLDO1117-ADJ should have the upper feedback resistor, R1, connected as close as possible to V

lower resistor, R2, connected as close as possible to the load GND return. This helps reduce any parasitic resistance in series with the load.

and the

OUT

Thermal Considerations

ZLDO1117 series regulators have internal thermal limiting circuitry designed to protect the device during overload conditions. For continuous

normal load conditions however, the maximum junction temperature rating of +125°C must not be exceeded.

It is important to give careful consideration to all sources of thermal resistance from junction to ambient. For the SOT223-3L and TO252-3L

packages, which are designed to be surface mounted, additional heat sources mounted near the device must also be considered. Heat sinking is

accomplished using the heat spreading capability of the PCB and its copper traces. The θ

+12°C/W and +16°C/W respectively.

Thermal resistances from tab to ambient can be as low as +30°C/W. The total thermal resistance from junction to ambient can be as low as

+42 to +46°C/W. This requires a reasonable sized PCB with at least one layer of copper to spread the heat across the board and couple it into

the surrounding air. Datasheet specifications using 2 oz copper and a 5mmx5mm pad with T

+73°C/W and +107°C/W for TO252-3L and SOT223-3L respectively.

The thermal resistance for each application will be affected by thermal interactions with other components on the board. Some experimentation

will be necessary to determine the actual value.

(junction to tab)of the TO252-3L and SOT223-3L are

JC

= +27°C, no air flow yielded θJA (junction to tab) of

A

Ripple Rejection

When using the ZLDO1117 adjustable device the adjust terminal can be bypassed to improve ripple rejection. When the adjust terminal is

bypassed the required value of the output capacitor increases.

The device will require an output capacitor of 22µF tantalum or 150µF aluminum electrolytic when the adjust pin is bypassed. Normally, capacitor

values on the order of 100µF are used in the output of many regulators to ensure good load transient response with large load current changes.

Output capacitance can be increased without limit and larger values of output capacitance further improve stability and transient response.

The curves for Ripple Rejection were generated using an adjustable device with the adjust pin bypassed. These curves will hold true for all

values of output voltage. For proper bypassing, and ripple rejection approaching the values shown, the impedance of the adjust pin capacitor, at

the ripple frequency, should be < R1. R1 is normally in the range of 100Ω to 200Ω. The size of the required adjust pin capacitor is a function of

the input ripple frequency. At 120Hz, with R1 = 100Ω, the adjust pin capacitor should be >13µF. At 10kHz only 0.16µF is needed.

For fixed voltage devices, and adjustable devices without an adjust pin capacitor, the output ripple will increase as the ratio of the output voltage

to the reference voltage (V

It will increase by a factor of four. Ripple rejection will be degraded by 12dB from the value shown on the curve.

). For example, with the output voltage equal to 5V, the output ripple will be increased by the ratio of 5V/1.25V.

OUT/VREF

ZLDO1117

Document number: DS32018 Rev. 6 - 2

7 of 14

www.diodes.com

July 2012

© Diodes Incorporated

Page 8

A

f

Typical Application Circuits

Figure 1 Basic Adjustable Regulator with 5V Output

Product Line o

Diodes Incorporated

ZLDO1117

Using

⎧

2R

⎫

+•=

125.1V

⎨

OUT

then the output voltage becomes:

OUT

⎬

1R

⎭

⎩

⎧

330

125.1V

⎨

⎩

⎫

110

=

⎬

⎭

+•=

V0.5

Figure 2 Adjustable Regulator with IADJ Errors

⎧

2R

⎫

125.1V

+•=

⎨

⎬

ADJOUT

1R

⎭

⎩

Because I

A. Output capacitor selection is critical for regulator stability. Larger C

B. C

C. C

D. An external diode is recommended to protect the regulator if the input instantaneously is shorted to GND.

E. This device is designed to be stable with tantalum and MLCC capacitors with an ESR less than 0.47Ω.

ZLDO1117

Document number: DS32018 Rev. 6 - 2

typically is 55μA, its effect is negligible in most applications.

ADJ

⎧

330

125.1V

OUT

stability.

can be used to improve ripple rejection. If C

ADJ

is recommended if ZLDO1117 is not located near the power supply filter.

in

⎨

⎩

is used, a C

ADJ

110

values benefit the regulator by improving transient response and loop

out

that is larger in value than C

out

8 of 14

www.diodes.com

6

−

••++•=

2RI

•+

⎫

=

⎬

⎭

~ 0.4%

V02.53301055

must be used.

ADJ

July 2012

© Diodes Incorporated

Page 9

A

f

Other Application Circuits

Product Line o

Diodes Incorporated

ZLDO1117

Figure 3 ZLDO1117 with Extended Output Voltage

V

IN

TTL

ZLDO1117

IN OUT

C1

10

F

R3

1k

R4

1k

ADJ

T1

MMBT3904

R1

121Ω

1%

R2

365Ω

1%

V

C2

100

OUT

F

Figure 4 ZLDO1117 with Disable Function

AC

IN

C1

10 F

ZLDO1117x50

IN OUT

ADJ

C2

100

F

VOUT = -5V

Figure 5 ZLDO1117 as a Negative LDO

ZLDO1117

Document number: DS32018 Rev. 6 - 2

www.diodes.com

9 of 14

© Diodes Incorporated

July 2012

Page 10

A

f

Product Line o

Diodes Incorporated

ZLDO1117

Ordering Information

Part Number Output Voltage

ZLDO1117KTC

ZLDO1117GTA SOT223

ZLDO1117K12TC

ZLDO1117G12TA SOT223

ZLDO1117K15TC

ZLDO1117G15TA SOT223

ZLDO1117K18TC

ZLDO1117G18TA SOT223

ZLDO1117K25TC

ZLDO1117G25TA SOT223

ZLDO1117K33TC

ZLDO1117G33TA SOT223

ZLDO1117K50TC

ZLDO1117G50TA SOT223

ZLDO1117QKTC

ZLDO1117QGTA SOT223

ZLDO1117QK12TC

ZLDO1117QG12TA SOT223

ZLDO1117QK15TC

ZLDO1117QG15TA SOT223

ZLDO1117QK18TC

ZLDO1117QG18TA SOT223

ZLDO1117QK25TC

ZLDO1117QG25TA SOT223

ZLDO1117QK33TC

ZLDO1117QG33TA SOT223

ZLDO1117QK50TC

ZLDO1117QG50TA SOT223

Note: 11. Pad layout as shown on Diodes Inc. suggested pad layout document AP02001, which can be found on our website at

http://www.diodes.com/datasheets/ap02001.pdf.

Adjustable

1.2V

1.5V

1.8V

2.5V

3.3V

5.0V

Adjustable

1.2V

1.5V

1.8V

2.5V

3.3V

5.0V

Packaging

(Note 11)

TO252

TO252

TO252

TO252

TO252

TO252

TO252

TO252

TO252

TO252

TO252

TO252

TO252

TO252

Status Reel Quantity Tape width Reel size

Active

Active

Active

Active

Active

Active

Active

Active

Active

Active

Active

Active

Active

Active

Active

Active

Active

Active

Active

Active

Active

Active

Active

Active

Active

Active

Active

Active

2500

1000

2500

1000

2500

1000

2500

1000

2500

1000

2500

1000

2500

1000

2500

1000

2500

1000

2500

1000

2500

1000

2500

1000

2500

1000

2500

1000

16 mm

12 mm 7”

16 mm 13”

12 mm 7”

16 mm 13”

12 mm 7”

16 mm 13”

12 mm 7”

16 mm 13”

12 mm 7”

16 mm 13”

12 mm 7”

16 mm 13”

12 mm 7”

16 mm

12 mm 7”

16 mm 13”

12 mm 7”

16 mm 13”

12 mm 7”

16 mm 13”

12 mm 7”

16 mm 13”

12 mm 7”

16 mm 13”

12 mm 7”

16 mm 13”

12 mm 7”

13”

13”

ZLDO1117

Document number: DS32018 Rev. 6 - 2

10 of 14

www.diodes.com

July 2012

© Diodes Incorporated

Page 11

r

n

n

w

D

A

t

r

L

f

2

e

2

Marking I

TO252

SOT223

formatio

Produc

iodes Inco

Line o

porated

Z

DO1117

ZLDO1117

Document numbe

: DS32018 Rev. 6

- 2

11 of 14

ww.diodes.co

m

July 201

© Diodes Incorporat

d

Page 12

A

f

Product Line o

Diodes Incorporated

ZLDO1117

Package Outline Dimensions (All dimensions in mm.)

SOT223

Dim Min Max Typ

A

SOT223

A 1.55 1.65 1.60

A1 0.010 0.15 0.05

b1 2.90 3.10 3.00

b2 0.60 0.80 0.70

C 0.20 0.30 0.25

D 6.45 6.55 6.50

E 3.45 3.55 3.50

E1 6.90 7.10 7.00

e — — 4.60

e1 — — 2.30

L 0.85 1.05 0.95

Q 0.84 0.94 0.89

All Dimensions in mm

A1

TO252

2X b2

E

b3

L3

D

L4

e

3X b

A

c2

A2

H

A1

L

a

E1

Dim Min Max Typ

A1 0.00 0.13 0.08

A2 0.97 1.17 1.07

b2 0.76 1.14 0.95

b3 5.21 5.46 5.33

c2 0.45 0.58 0.531

D1 5.21

E1 4.32

L3 0.88 1.27 1.08

L4 0.64 1.02 0.83

All Dimensions in mm

TO252

A 2.19 2.39 2.29

b 0.64 0.88 0.783

D 6.00 6.20 6.10

− −

e

− −

E 6.45 6.70 6.58

H 9.40 10.41 9.91

L 1.40 1.78 1.59

a 0° 10°

2.286

− −

−

ZLDO1117

Document number: DS32018 Rev. 6 - 2

12 of 14

www.diodes.com

July 2012

© Diodes Incorporated

Page 13

A

f

Product Line o

Diodes Incorporated

ZLDO1117

Suggested Pad Layout

SOT223

X2

X1

C2

C1

Dimensions Value (in mm)

X1 3.3

X2 1.2

Y1 1.6

Y2 1.6

C1 6.4

C2 2.3

TO252

Y1

Y2

Y1

X1

X2

E1

Dimensions Value (in mm)

Z 11.6

X1 1.5

Z

C

X2 7.0

Y1 2.5

Y2 7.0

C 6.9

E1 2.3

13 of 14

www.diodes.com

July 2012

© Diodes Incorporated

ZLDO1117

Document number: DS32018 Rev. 6 - 2

Y2

Page 14

A

f

Product Line o

Diodes Incorporated

ZLDO1117

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS DOCUMENT,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

(AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes

without further notice to this document and any product described herein. Diodes Incorporated does not assume any liability arising out of the

application or use of this document or any product described herein; neither does Diodes Incorporated convey any license under its patent or

trademark rights, nor the rights of others. Any Customer or user of this document or products described herein in such applications shall assume

all risks of such use and will agree to hold Diodes Incorporated and all the companies whose products are represented on Diodes Incorporated

website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized sales channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorize d application, Customers shall indemnify and

hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees arising out of, directly or

indirectly, any claim of personal injury or death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names and markings

noted herein may also be covered by one or more United States, international or foreign trademarks.

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems without the express

written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided in the

labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected to cause the

failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices or systems, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any

use of Diodes Incorporated products in such safety-critical, life support devices or systems, notwithstanding any devices- or systems-related

information or support that may be provided by Diodes Incorporated. Further, Customers must fully indemnify Diodes Incorporated and its

representatives against any damages arising out of the use of Diodes Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2012, Diodes Incorporated

www.diodes.com

IMPORTANT NOTICE

LIFE SUPPORT

ZLDO1117

Document number: DS32018 Rev. 6 - 2

14 of 14

www.diodes.com

July 2012

© Diodes Incorporated

Loading...

Loading...