Page 1

Issue 2 – July 2010 www.diodes.com

© Diodes Incorporated, 2010

ZXLD1370EV2 BUCK/BOOST LED DRIVER

USER GUIDE

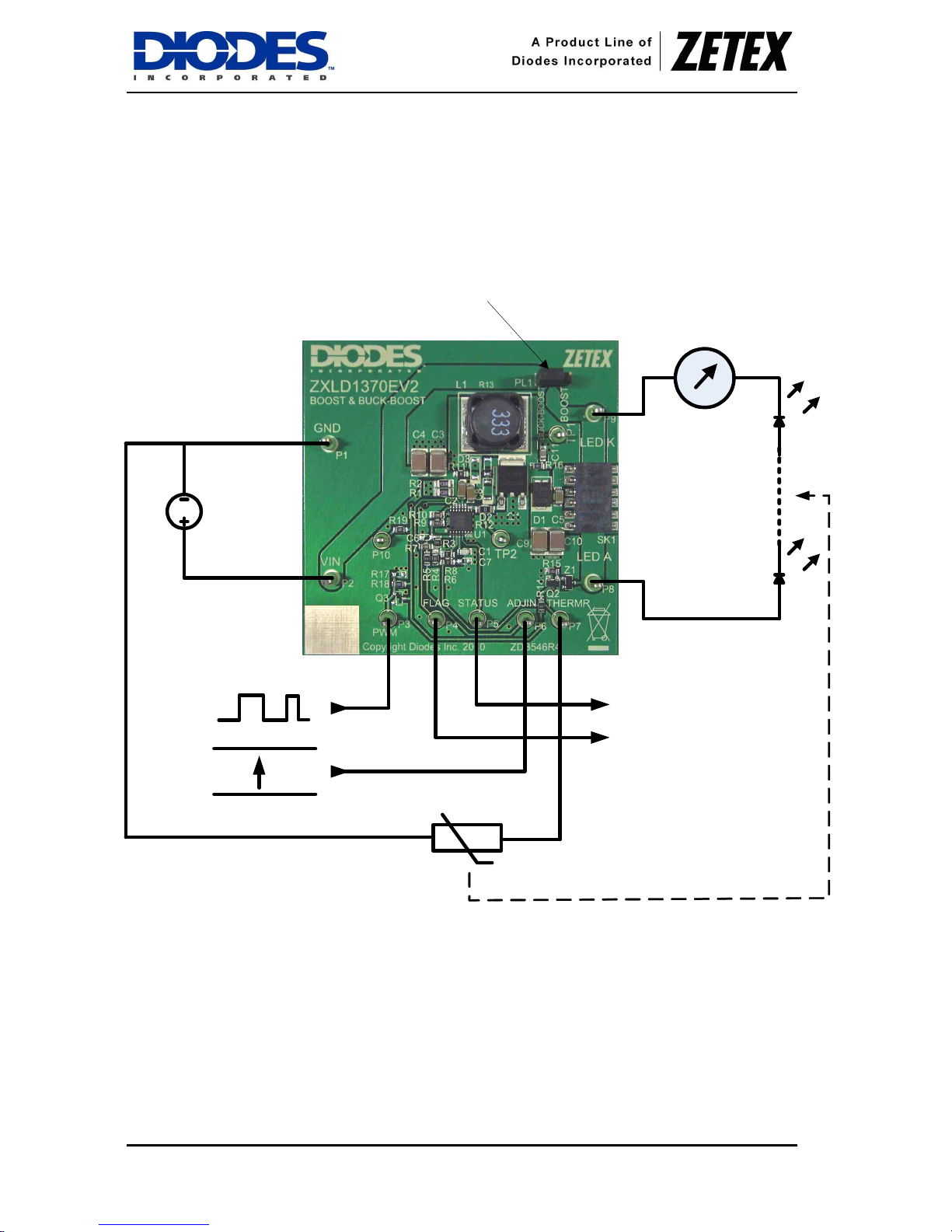

Fig.1 ZXLD1370EV2 Evaluation board connection diagram

8-48V 2A

DC PSU

0-1.5A DC

DVM

BUCK/BOOST

1 - 15 LEDs

1.5A

0V

4.5V

Open Drain output

125mV = 10%

2.5V = 200%

-t°

GND

0 – 4.5V Status steps

Thermal connection

Page 2

ZXLD1370EV2

Issue 2 – July 2010 www.diodes.com

© Diodes Incorporated 2010

2

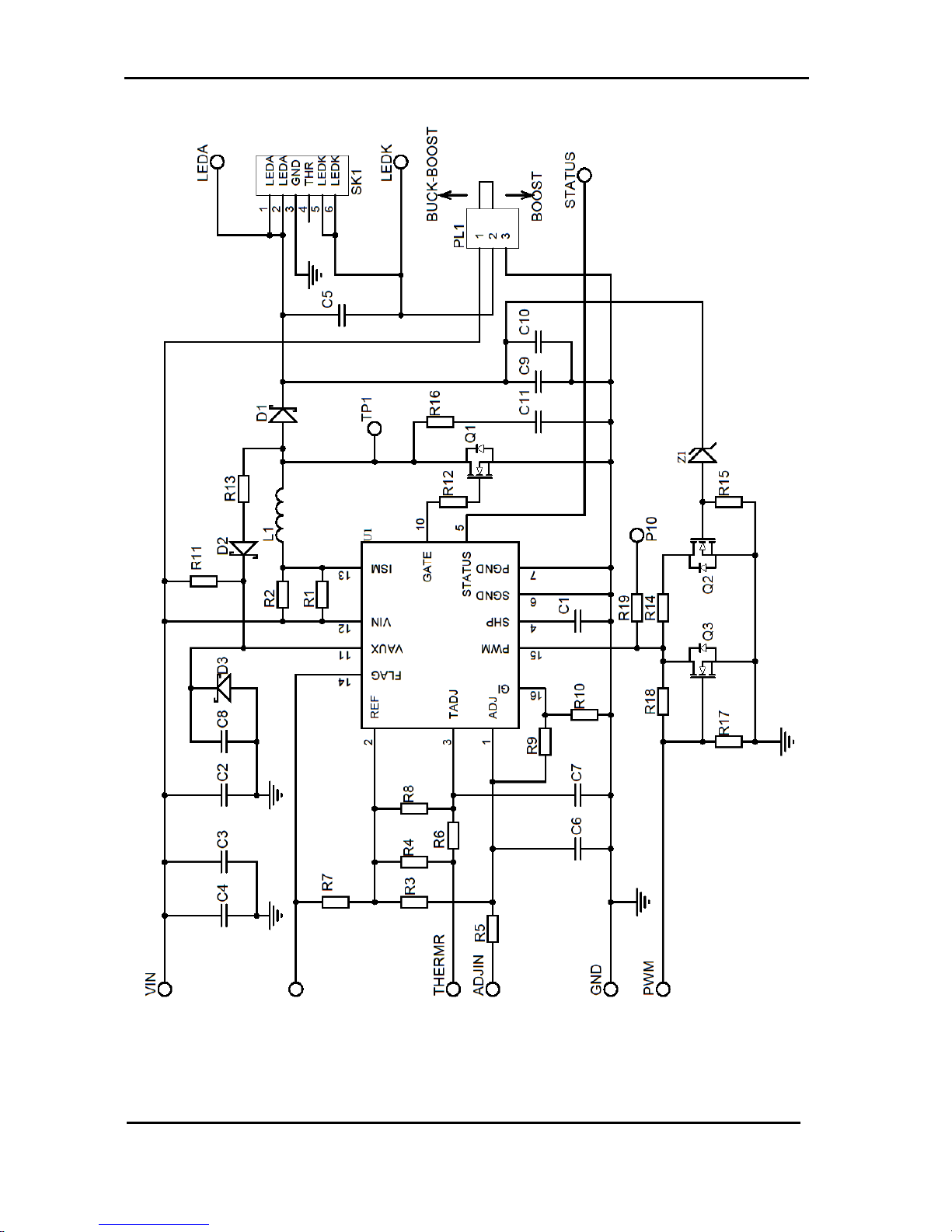

Fig2. Schematic diagram

FLAG

Page 3

ZXLD1370EV2

Issue 2 – July 2010 www.diodes.com

© Diodes Incorporated 2010

3

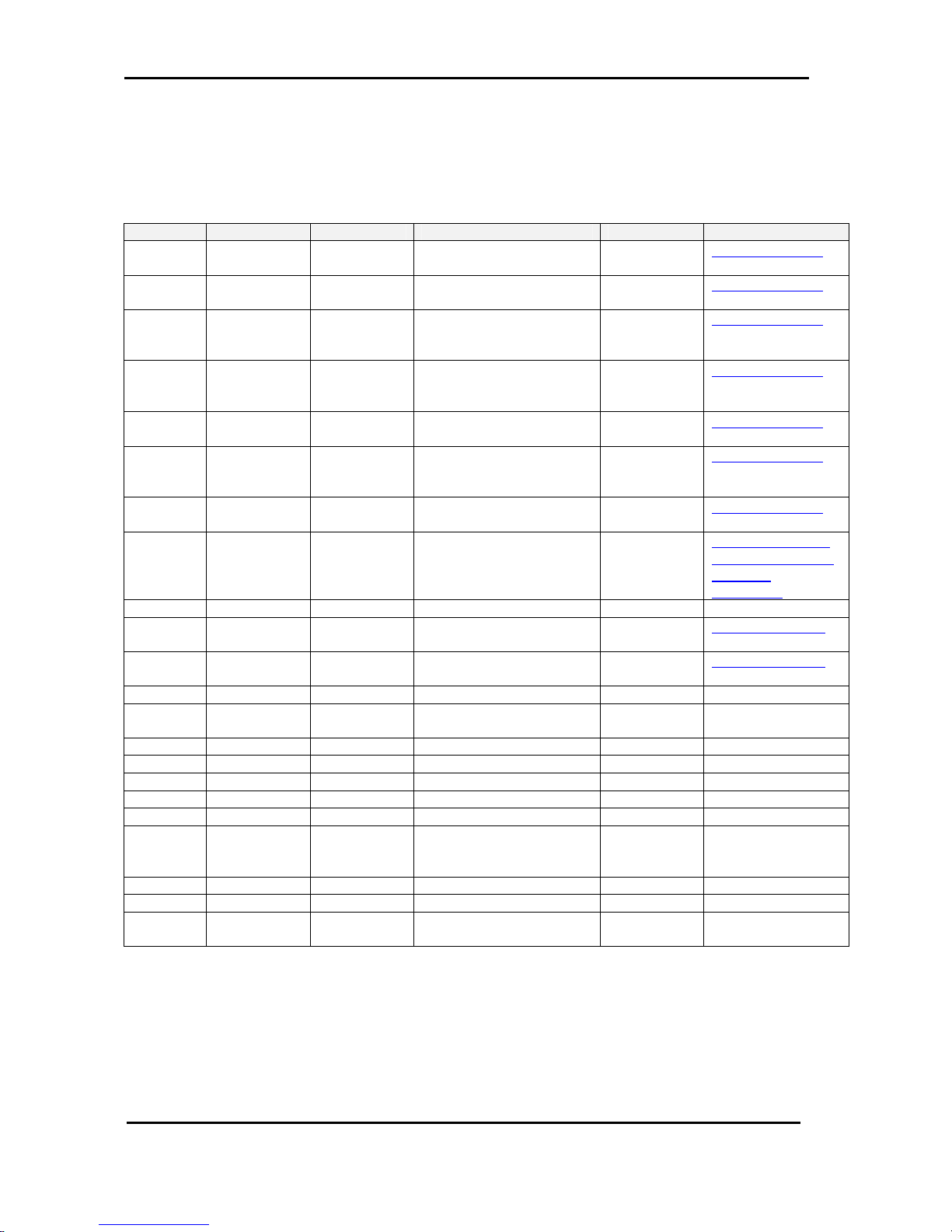

PARTS LIST

Ref Value Package Part Number Manufacturer Contact Details

U1 LED Driver

Controller

TSSOP16L ZXLD1370 Diodes Zetex www.diodes.com

Q1 60V N-ch

MOSFET

DPAK DMN6068LK3 Diodes Zetex www.diodes.com

Q2 Q3 60V General

Purpose

Mosfet

SOT23 2N7002 Diodes www.diodes.com

D1 Freewheeling

diode 3A

100V

PowerDI5 PDS3100 Diodes www.diodes.com

D2 51V 200mW

Zener Diodes

SOD323 BZT52C51 Diodes www.diodes.com

D3 Freewheeling

diode 3A

100V

PowerDI5 PDS3100 Diodes www.diodes.com

Z1 47V 300mW

Zener Diode

SOT23 BZX84C47 Diodes www.diodes.com

L1 33uH 2.3A MS1246-333MLB

NPIS24H330MTRF

744-7715330

Coilcraft

NIC Comps.

Wurth

www.coilcraft.com

www.niccomp.com

www.we-

online.com

C1 100pF 10V 0805 Generic

C2 C5 C8 1uF 100V

X7R

1206 GRM31CR72A105KA01L Murata www.murata.com

C3 C4 C9

C10

2.2uF 100V

X7R

1812 GRM43ER72A225KA01L Murata www.murata.com

C6 C7 Not fitted

C11 10nF 100V

X7R

0805 Generic

R1 R2 0R3 1206 Generic

R4 1K3 0805 Generic

R7 47K 0805 Generic

R9 120K 1% 0805 Generic

R10 36K 1% 0805 Generic

R3 R5 R6

R8 R11

R12 R14

0R 0805 Generic

R15 2K 0805 Generic

R13 R18 Not fitted

R16 R17

R19

1K 0805 Generic

Page 4

ZXLD1370EV2

Issue 2 – July 2010 www.diodes.com

© Diodes Incorporated 2010

4

NOTES

The PCB is supplied with R3 and R8 0R0 resistors fitted.

The ‘ADJ’ pin and the ‘TADG’ pin are disabled.

Boost-only mode is selected by changing PL1

In boost mode, the total LED output voltage is <=47V.

The supply voltage for the ZXLD1370EV2 is >=6V, <= (total LED voltage).

In buck-boost operation, the input voltage range is limited by the overvoltage threshold voltage and the

LED voltage. >=6V, <=(47V – VLED).

For other reference designs or further applications information, please refer to the ZXLD1370

datasheet.

Q2 and Z1 protect the circuit from open-circuit LEDs.

The overvoltage threshold of the evaluation board is 47V. (Set by the 47V Zener diode Z1)

The overvoltage threshold can be increased by using a Zener diode with a higher voltage (56V)

Do not use a Zener diode of higher voltage than the MosFet or ZXLD1370.

Boost and Buck-boost modes, average I

LED

= average I

INDUCTOR

x R10/(R9+R10)

OPERATION

In Boost and Buck-boost mode the LED current is sensed by the series resistor (R1 // R2). An output

from the control loop drives the input of a comparator. The comparator drives the gate of the external

NMOS switch transistor via ‘GATE’. When the NMOS switch is on, current flows from VIN, via (R1 //

R2), inductor and switch to ground and increases until a high value is reached. Then, GATE goes low,

the switch turns off and the current flows through (R1 // R2), the inductor, D1 and the LED, to ‘VIN’

(Buck-boost mode), or ‘GND’ (Boost mode). When the inductor current has gone low, ‘GATE’ goes high,

and the cycle of events repeats. The circuit oscillates. The average current in the LEDs is equal to the

average of the maximum and minimum threshold currents. The ripple current (hysteresis) is equal to the

difference between the thresholds. The average current in the LED is always less than the average

current in the inductor and the ratio between these currents is set by the values of resistors R9 and

R10. The peak current in the LED is equal to the peak current in the inductor. The control loop keeps

the average LED current at the level set by the voltage on the ‘ADJ’ pin. Loop compensation is

achieved by C1.

Bootstrap Circuit

The ZXLD1370 works normally between 8-60V. For input voltages between 6-8V and high switch

currents that require a fully enhanced MOSFET, it is recommended to use the bootstrap network D2R13 and remove R11.

Page 5

ZXLD1370EV2

Issue 2 – July 2010 www.diodes.com

© Diodes Incorporated 2010

5

Fig. 3 Waveforms for Boost and Buck-boost modes

Page 6

ZXLD1370EV2

Issue 2 – July 2010 www.diodes.com

© Diodes Incorporated 2010

6

ADJ Terminal (DC output current adjustment)

On the ZXLD1370EV2, the ‘ADJ’ pin R3 connects the internal 1.25V reference (V

REF

) give 100% LED

current.

The ADJ pin can also be driven with an external DC voltage >=125mV and <= 2.5V to adjust the LED

current to >= 10% and <=200% of the nominal value.

To do this, remove R3, fit R5 and apply an external DC voltage between ‘ADJIN’ and ‘GND’

The voltage V

ADJ

can be derived from a resistor-divider connected between ‘REF’ and ‘GND’.

‘ADJ’ has high impedance within its normal operating voltage range. An internal 2.6V clamp protects the

device against excessive input voltage and limits the maximum output current to approximately 4% above

the maximum current set by ‘V

ADJ

‘ if the maximum input voltage is exceeded.

PWM Terminal (PWM output current control/dimming)

The LED current can be adjusted digitally, by applying a low frequency PWM logic signal to the ‘PWM’ pin

to turn the controller on and off. This will produce an average output current proportional to the duty cycle of

the control signal. During PWM operation, the device remains powered up and only the output switch is

switched by the control signal.

The device can be shut down by taking the PWM pin to < 0.4V with a short to 0V or suitable open collector

NPN, or open drain NMOS transistor, for >15ms. In the shutdown state, most of the circuitry inside the

device is off and the quiescent current will be typically 90µA.

TADJ Terminal (Thermal control of LED current)

The ‘Thermal control’ circuit monitors the voltage on the ‘TADJ’ pin and reduces the output current linearly

if the voltage on ‘TADJ’ < 625mV. An NTC thermistor and resistor can be connected to set the voltage on

the ‘TADJ’ pin = 625mV at the required threshold temperature. This will give 100% LED current below the

threshold temperature and <100% above it as shown in the graph. The temperature threshold can be

changed by adjusting the value of Rth and/or the thermistor to suit the LED used.

On the ZXLD1370EV2, Rth is 1K3 (R4). In order to use thermal control, remove R8, fit R6, and fit a 10K

NTC Negative Temperature Coefficient) type thermistor between ‘TADJ’ and ‘GND’. This will set the

threshold temperature to ~ 90ºC.

Thermal control by LED current reduction

Fig. 4 Thermal control

The Thermal Control feature can be disabled by connecting TADJ to REF through the jumper resistor R8.

Page 7

ZXLD1370EV2

Issue 2 – July 2010 www.diodes.com

© Diodes Incorporated 2010

7

BOARD LAYOUT

Page 8

ZXLD1370EV2

Issue 2 – July 2010 www.diodes.com

© Diodes Incorporated 2010

8

Sales offices

The Americas

3050 E. Hillcrest Drive

Westlake Village,

CA 91362-3154

Tel: (+1) 805 446 4800

Fax: (+1) 805 446 4850

Europe

Kustermannpark

Balanstraße 59,

D-81541 München

Germany

Tel: (+49) 894 549 490

Fax: (+49) 894 549 4949

Taiwan

7F, No. 50,

Min Chuan Road

Hsin-Tien

Taipei, Taiwan

Tel: (+886) 289 146 000

Fax: (+886) 289 146 639

Shanghai

Rm. 606, No.1158

Changning Road

Shanghai, China

Tel: (+86) 215 241 4882

Fax (+86) 215 241 4891

Shenzhen

Room A1103-04,

ANLIAN Plaza, #4018

Jintian Road

Futian CBD,

Shenzhen, China

Tel: (+86) 755 882 849 88

Fax: (+86) 755 882 849 99

Korea

6 Floor, Changhwa B/D,

1005-5 Yeongtong-dong,

Yeongtong-gu, Suwon-si,

Gyeonggi-do, Korea 443-813

Tel: (+82) 312 731 884

Fax: (+82) 312 731 885

IMPORTANT NOTICE

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARD TO THIS

DOCUMENT, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements,

corrections or other changes without further notice to this document and any product described herein. Diodes Incorporated

does not assume any liability arising out of the application or use of this document or any product described herein; neither

does Diodes Incorporated convey any license under its patent or trademark rights, nor the rights of others. Any Customer

or user of this document or products described herein in such applications shall assume all risks of such use and will agree

to hold Diodes Incorporated and all the companies whose products are represented on Diodes Incorporated website,

harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through

unauthorized sales channels. Should Customers purchase or use Diodes Incorporated products for any unintended or

unauthorized application, Customers shall indemnify and hold Diodes Incorporated and its representatives harmless

against all claims, damages, expenses, and attorney fees arising out of, directly or indirectly, any claim of personal injury or

death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product

names and markings noted herein may also be covered by one or more United States, international or foreign trademarks.

LIFE SUPPORT

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or

systems without the express written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use

provided in the labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably

be expected to cause the failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support

devices or systems, and acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related

requirements concerning their products and any use of Diodes Incorporated products in such safety-critical, life support

devices or systems, notwithstanding any devices- or systems-related information or support that may be provided by

Diodes Incorporated. Further, Customers must fully indemnify Diodes Incorporated and its representatives against any

damages arising out of the use of Diodes Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2009, Diodes Incorporated

www.diodes.com

Loading...

Loading...