Page 1

Features

• Ultra Low Forward Voltage Drop

• Superior Reverse Avalanche Capability

• Patented Interlocking Clip Design for High Surge Current

Capacity

• Patented Super Barrier Rectifier Technology

• Soft, Fast Switching Capability

• 150ºC Operating Junction Temperature

• ±16KV ESD Protection (HBM, 3B)

• ±25KV ESD Protection (IEC61000-4-2 Level 4, Air Discharge)

• Lead Free Finish, RoHS Compliant (Note 1)

• “Green” Molding Compound (No Br, Sb)

• Qualified to AEC-Q101 Standards for High Reliability

SBR3U30P1

SUPER BARRIER RECTIFIER

Mechanical Data

• Case: PowerDI®123

• Case Material: Molded Plastic, “Green” Molding Compound.

UL Flammability Classification Rating 94V-0

• Moisture Sensitivity: Level 1 per J-STD-020D

• Polarity Indicator: Cathode Band

• Terminals: Matte Tin Finish annealed over Copper leadframe.

Solderable per MIL-STD-202, Method 208

• Marking Information: See Page 4

• Ordering Information: See Page 4

• Weight: 0.018 grams (approximate)

Top View

3.0A SBR

PowerDI

®

123

®

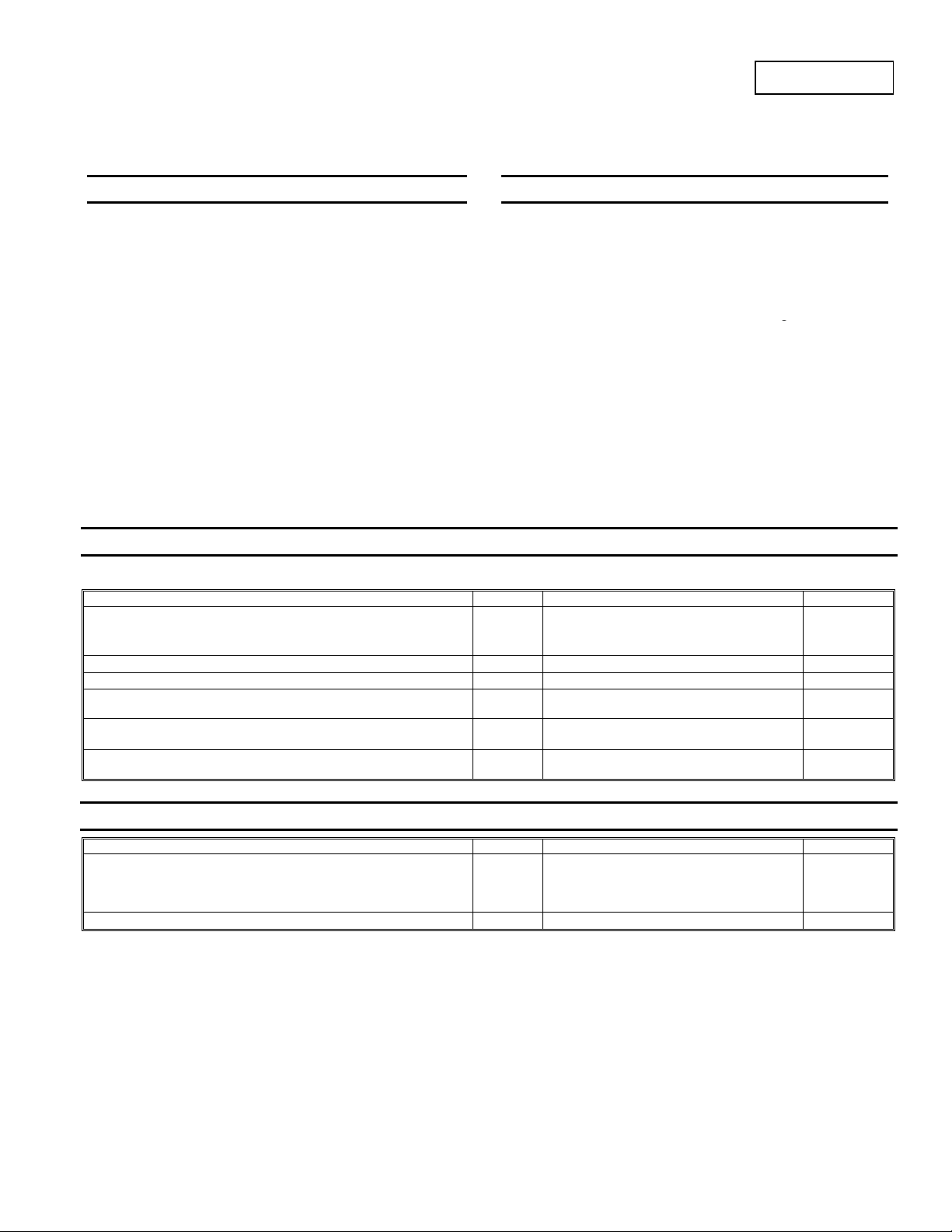

Maximum Ratings @T

= 25°C unless otherwise specified

A

Single phase, half wave, 60Hz, resistive or inductive load.

For capacitance load, derate current by 20%.

Characteristic Symbol Value Unit

V

Peak Repetitive Reverse Voltage

Working Peak Reverse Voltage

DC Blocking Voltage

RMS Reverse Voltage

Average Rectified Output Current (See Figure 1)

Non-Repetitive Peak Forward Surge Current 8.3ms

Single Half Sine-Wave Superimposed on Rated Load

Non-Repetitive Avalanche Energy

= 25°C, IAS = 5A, L = 8.5 mH)

(T

J

Repetitive Peak Avalanche Energy

(1µs, 25°C)

V

V

V

R(RMS)

I

E

P

RRM

RWM

RM

I

O

FSM

AS

ARM

30 V

21 V

3.0 A

75 A

105 mJ

1100 W

Thermal Characteristics

Maximum Thermal Resistance

Thermal Resistance Junction to Soldering (Note 2)

Thermal Resistance Junction to Ambient (Note 3)

Thermal Resistance Junction to Ambient (Note 4)

Operating and Storage Temperature Range (Note 5)

Notes: 1. RoHS revision 13.2.2003. High temperature solder exemption applied, see EU Directive Annex Note 7.

2. Theoretical R

3. FR-4 PCB, 2 oz. Copper, minimum recommended pad layout per http://www.diodes.com/datasheets/ap02001.pdf.

4. Polymide PCB, 2 oz. Copper, minimum recommended pad layout per http://www.diodes.com/datasheets/ap02001.pdf

SBR and PowerDI are registered trademark of Diodes Incorporated.

SBR3U30P1

Document number: DS30974 Rev. 6 - 2

Characteristic Symbol Value Unit

R

JS

θ

R

JA

θ

R

JA

θ

T

, T

J

STG

calculated from the top center of the die straight down to the PCB cathode tab solder junction.

θJS

5

178

123

-65 to +150 ºC

1 of 4

www.diodes.com

ºC/W

October 2008

© Diodes Incorporated

Page 2

P, P

OWER

PATIO

N

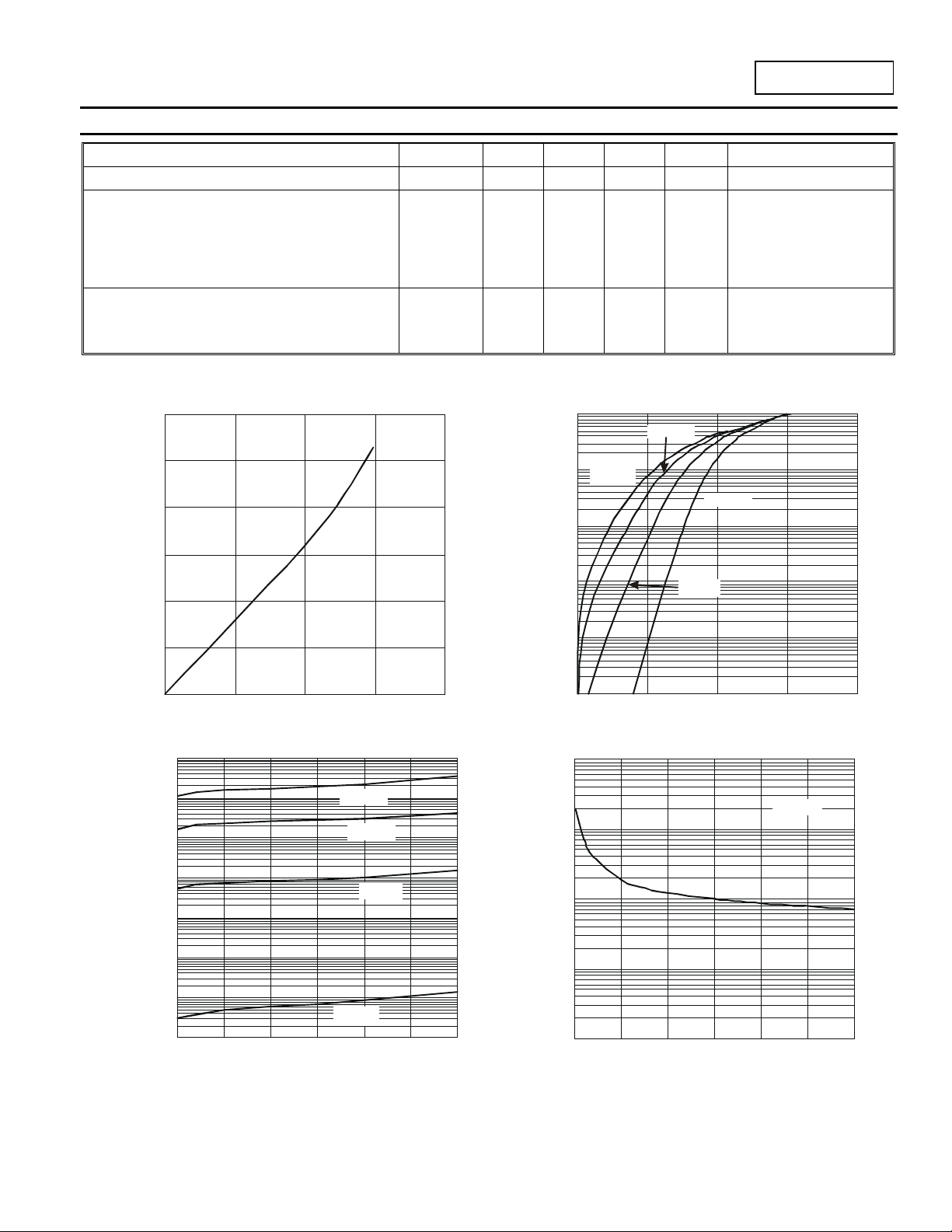

Electrical Characteristics @T

= 25°C unless otherwise specified

A

Characteristic Symbol Min Typ Max Unit Test Condition

Reverse Breakdown Voltage (Note 5)

Forward Voltage Drop

Leakage Current (Note 5)

Notes: 5. Short duration pulse test used to minimize self-heating effect.

V

(BR)R

V

F

I

R

1.2

1

(W)

0.8

SBR3U30P1

30 - - V

0.28

0.31

-

0.39

0.20

0.23

0.35

70

-

150

6

12

10,000

1,000

0.32

0.35

0.43

0.23

0.26

0.38

150

400

T=150C

°

A

15

20

T =100 C

A

°

V

µA

µA

mA

mA

IR = 400µA

I

F

I

F

I

F

I

F

I

F

I

F

V

V

V

V

T= -65C

°

A

100

= 0.5A, TJ = 25ºC

= 1.0A, TJ = 25ºC

= 3.0A, TJ = 25ºC

= 0.5A, TJ = 125ºC

= 1.0A, TJ = 125ºC

= 3.0A, TJ = 125ºC

= 5V, TJ = 25ºC

R

= 30V, TJ = 25ºC

R

= 5V, TJ = 125ºC

R

= 30V, TJ = 125ºC

R

0.6

DISSI

0.4

D

0.2

0

0123

I , AVERAGE FORWARD CURRENT (A)

F(AV)

Fig. 1 Forward Power Dissipation

1.0E+02

T =150 C

1.0E+01

1.0E+00

1.0E-01

A

T =100 C

A

T=25C

10

1

4

I , INSTANTANEOUS FORWARD CURRENT (mA)

0 0.2 0.4 0.6 0.8

V , INSTANTAN EOUS FORW ARD VOLTAG E (V)

F

Fig. 2 Typical Forward Ch ar acteristics

F

0.1

10,000

°

°

°

A

1,000

100

T=25C

°

A

f = 1.0MHz

1.0E-02

1.0E-03

1.0E-04

T= -65C

°

A

R

1.0E-05

I , INSTANTANEOUS REVERSE CURRENT (mA)

0 5 10 15 20 25 30

V , INSTANTANEOUS REVERSE VOLT AGE (V)

R

Fig. 3 Typical Reverse Characteristics

10

T

C , TOTAL CAPACITANCE (pF)

1

0 5 10 15 20 25 30

V , DC REVERSE VOLTAGE (V)

R

Fig. 4 Total Capacitance vs. Reverse Voltage

BR and PowerDI are registered trademark of Diodes Incorporated.

S

SBR3U30P1

Document number: DS30974 Rev. 6 - 2

2 of 4

www.diodes.com

October 2008

© Diodes Incorporated

Page 3

RAGE FORWARD CUR

RENT

T

RAT

T TEMP

R

TUR

C

P

U

NCHE P

OWER

SBR3U30P1

5.0

(A)

4.0

3.0

2.0

1.0

F(AV)

I, AVE

0

025

120

100

80

50

T , AMBIENT TEMPERATURE (°C)

Fig. 5 Forward Current Derating Curve

75 100

A

125 150

175 200

160

)

150

E (°

140

A

130

E

120

110

100

ED AM BIE N

70

, DE

A

10,000

(W)

1,000

90

80

60

0

Fig. 6 Operating Temperature Derating

10

5

V , DC REVERSE VOLTAGE (V)

R

15 25

20 30

60

40

20

DERATING IN PERCENTAGE (%)

ARM

P , AVAL ANCHE PEAK PULSE POWER

0

0 25 50 75 100 125 150 175

T , JUNCTION TEMPERATURE ( C)

J

Fig. 7 Pulse Derating Curve

100

M AVALA

10

, MAXIM

ARM

1

°

0.001 0.01 0.1 1 10 100 1,000

T , PULSE DURATION (uS)

Fig. 8 Maximum Avalanche Power Curve

P

BR and PowerDI are registered trademark of Diodes Incorporated.

S

SBR3U30P1

Document number: DS30974 Rev. 6 - 2

3 of 4

www.diodes.com

October 2008

© Diodes Incorporated

Page 4

SBR3U30P1

Ordering Information (Note 6)

Part Number Case Packaging

SBR3U30P1-7 PowerDI®123 3000/Tape & Reel

Notes: 6. For packaging details, go to our website at http://www.diodes.com/datasheets/ap02007.pdf.

Marking Information

Date Code Key

Year 2006 2007 2008 2009 2010 2011 2012 2013 2014 2015

Code T U V W X Y Z A B C

Month Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec

Code 1 2 3 4 5 6 7 8 9 O N D

3U3

YM

3U3 = Product Type Marking Code

YM = Date Code Marking

Y = Year (ex: T = 2006)

M = Month (ex: 9 = September)

Package Outline Dimensions

C

D

L

E

B

PowerDI®123

E

H

L1

L2

A

Dim Min Max Typ

A 3.50 3.90 3.70

B 2.60 3.00 2.80

C 1.63 1.93 1.78

D 0.93 1.00 0.98

E 0.85 1.25 1.00

H 0.15 0.25 0.20

L 0.55 0.75 0.65

L1 1.80 2.20 2.00

L2 0.95 1.25 1.10

All Dimensions in mm

Suggested Pad Layout

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes

without further notice to any product herein. Diodes Incorporated does not assume any liability arising out of the application or use of any product

described herein; neither does it convey any license under its patent rights, nor the rights of others. The user of products in such applications shall

assume all risks of such use and will agree to hold Diodes Incorporated and all the companies whose products are represented on our website,

harmless against all damages.

Diodes Incorporated products are not authorized for use as critical components in life support devices or systems without the expressed written

approval of the President of Diodes Incorporated.

Y2

X1

GX2

IMPORTANT NOTICE

LIFE SUPPORT

Y1

Dimensions

G 1.0

X1 2.2

X2 0.9

Y1 1.4

Y2 1.4

Value (in mm)

SBR and PowerDI are registered trademark of Diodes Incorporated.

SBR3U30P1

Document number: DS30974 Rev. 6 - 2

4 of 4

www.diodes.com

October 2008

© Diodes Incorporated

Loading...

Loading...