Diodes SBR3U20SA User Manual

)

(BR)

Please click here to visit our online spice models database.

Features

• Ultra Low Forward Voltage Drop

• Patented Super Barrier Rectifier Technology

• Soft, Fast Switching Capability

• 150ºC Operating Junction Temperature

• Lead Free Finish, RoHS Compliant (Note 1)

• Green Molding Compound (No Halogen and Antimony)

(Note 6)

NEW PRODUCT

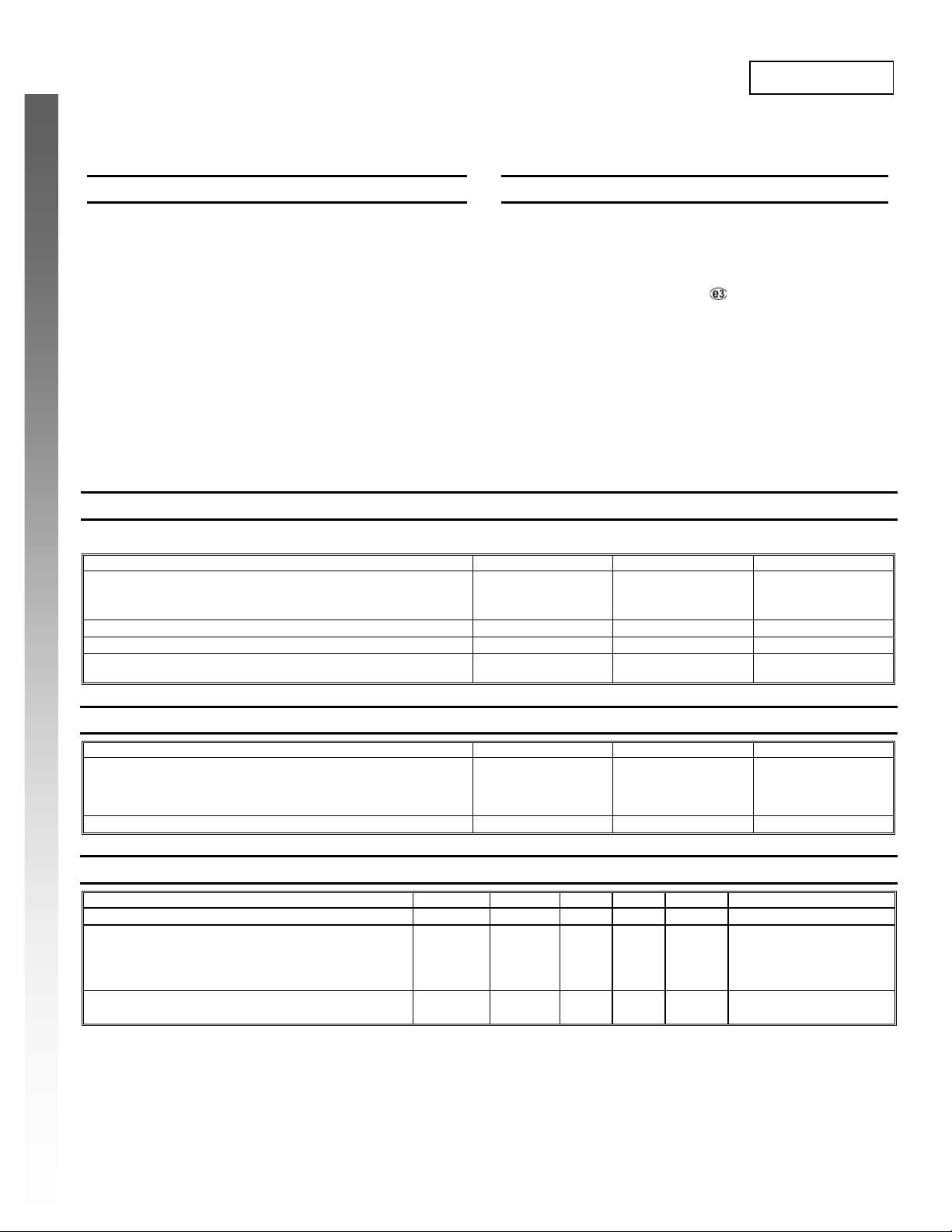

Maximum Ratings @T

Single phase, half wave, 60Hz, resistive or inductive load.

For capacitance load, derate current by 20%.

Peak Repetitive Reverse Voltage

Working Peak Reverse Voltage

DC Blocking Voltage

RMS Reverse Voltage

Average Rectified Output Current (See Figure 1)

Non-Repetitive Peak Forward Surge Current 8.3ms

Single Half Sine-Wave Superimposed on Rated Load

= 25°C unless otherwise specified

A

Characteristic Symbol Value Unit

Green

SURFACE MOUNT SUPER BARRIER RECTIFIER

Mechanical Data

• Case: SMA

• Case Material: Molded Plastic, UL Flammability Classification

Rating 94V-0

• Moisture Sensitivity: Level 1 per J-STD-020D

• Terminals: Lead Free Plating (Matte Tin Finish.) Solderable

per MIL-STD-202, Method 208

• Polarity Indicator: Cathode Band

• Marking Information: See Page 3

• Ordering Information: See Page 3

• Weight: 0.064 grams (approximate)

Top View Bottom View

V

RRM

V

RWM

V

RM

V

R(RMS

I

O

I

FSM

SBR3U20SA

3.0A SBR

®

SMA

20 V

14 V

3.0 A

66 A

Thermal Characteristics

Maximum Thermal Resistance

Thermal Resistance Junction to Soldering (Note 2)

Thermal Resistance Junction to Ambient (Note 3)

Thermal Resistance Junction to Ambient (Note 4)

Operating and Storage Temperature Range

Electrical Characteristics @T

Reverse Breakdown Voltage (Note 5)

Forward Voltage Drop

Leakage Current (Note 5)

Notes: 1. EU Directive 2002/95/EC (RoHS). All applicable RoHS exemptions applied. Please visit our website at http://www.diodes.com/quality/lead_free.html.

2. Theoretical R

3. FR-4 PCB, 2 oz. Copper, minimum recommended pad layout per http://www.diodes.com/datasheets/ap02001.pdf. T

4. Polymide PCB, 2 oz. Copper, minimum recommended pad layout per http://www.diodes.com/datasheets/ap02001.pdf

5. Short duration pulse test used to minimize self-heating effect.

6. Product manufactured with Data Code 0924 (week 24, 2009) and newer are built with Green Molding Compound.

SBR is a registered trademark of Diodes Incorporated.

SBR3U20SA

Document number: DS31209 Rev. 8 - 2

Characteristic Symbol Value Unit

A

Characteristic Symbol Min Typ Max Unit Test Condition

calculated from the top center of the die straight down to the PCB cathode tab solder junction.

θJS

T

J

= 25°C unless otherwise specified

V

R

20 - - V

-

V

F

-

-

-

I

R

-

-

1 of 4

www.diodes.com

R

R

R

, T

JS

θ

JA

θ

JA

θ

STG

44

127

ºC/W

97

-65 to +150 ºC

IR = 0.75mA

I

= 0.5A, TJ = 25ºC

V

µA

F

I

= 1.0A, TJ = 25ºC

F

= 3.0A, TJ = 25ºC

I

F

I

= 3.0A, TJ = 125ºC

F

V

= 20V, TJ = 25ºC

R

= 20V, TJ = 125ºC

V

R

= 25ºC

A

0.26

0.29

0.35

0.28

-

-

0.30

0.33

0.39

0.32

500

100

mA

July 2009

© Diodes Incorporated

P, P

O

R

PATIO

N

NEW PRODUCT

SBR3U20SA

1.2

1.0

(W)

10

1

T = 150°C

A

T = 125°C

A

0.8

0.1

0.6

DISSI

WE

0.4

D

0.2

0

0 0.4 0.8 1.2 1.6 2 2.4 2.8 3.2 3.6 4

I , AVERAGE FORWARD CURRENT (A)

F(AV)

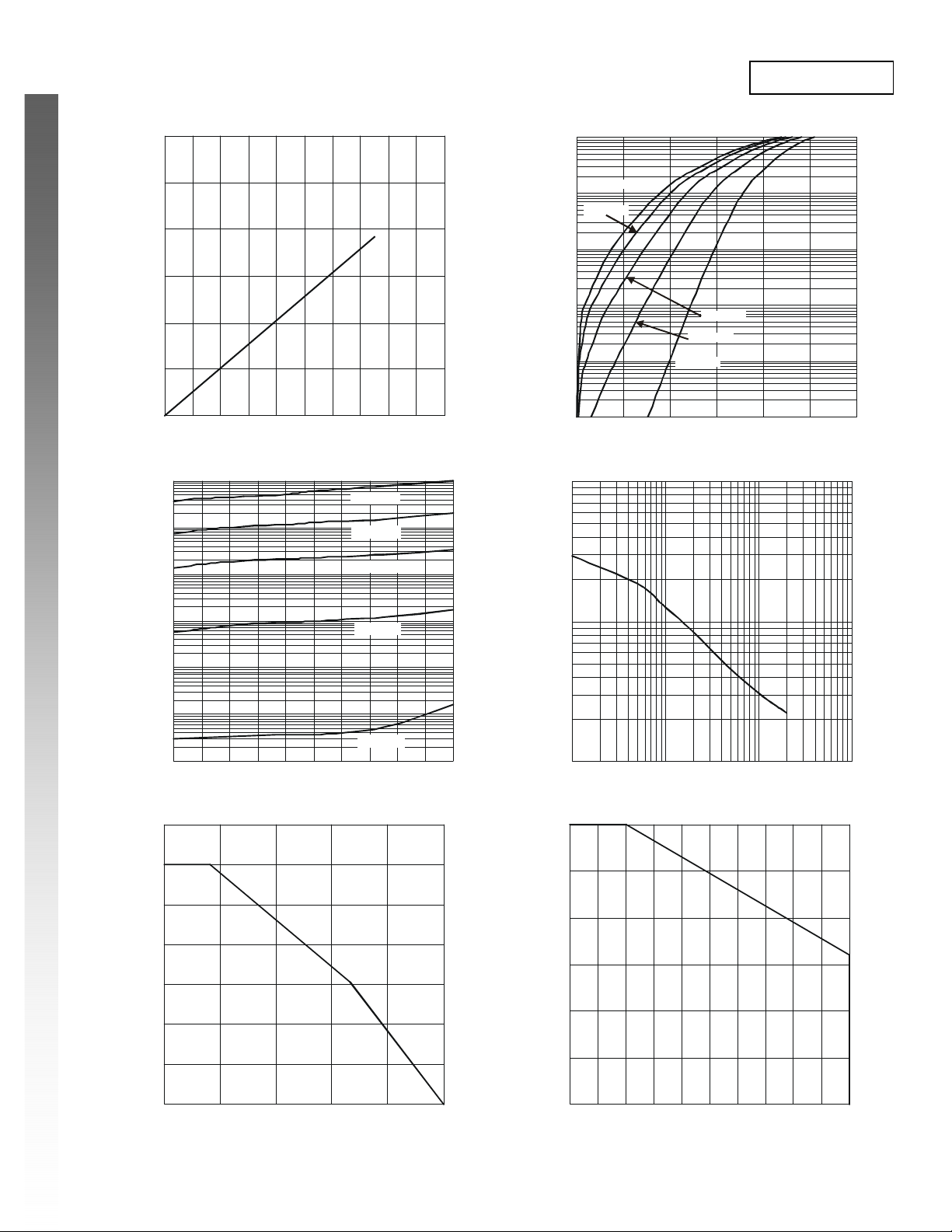

Fig. 1 Forward Power Dissipation

100,000

T = 150°C

0.01

0.001

F

I , INSTANT ANEOUS FORWARD CURRENT (A)

0.0001

0 100 200 300 400 500 600

V , INSTANTANEOUS FORWARD VOLTAGE (mV)

F

Fig. 2 Typical Forward Characteristics

10,000

A

T = 85°C

A

T = 25°C

A

T = -55°C

A

10,000

R

I , INSTANT ANEOUS REVERSE CURRENT (uA)

T = 125°C

A

T = 85°C

1,000

100

A

T = 25°C

A

10

1

T = -55°C

0.1

0 2 4 6 8101214161820

V , INSTANT ANEOUS REVERSE VOLTAGE (V)

R

Fig. 3 Typical Reverse Characteristics

A

3.5

3

2.5

2

1.5

1,000

T

C , TOTAL CAPACITANCE (pF)

100

0.1 1 10 100

V , DC REVERSE VOLT AGE (V)

R

Fig. 4 T otal Capacitance vs. Reverse Voltage

150

°

125

100

75

1

50

0.5

F(AV)

I , AVERAGE FORWARD CURRENT (A)

0

0306090120150

T , AMBIENT TEMPERATURE (°C)

A

Fig. 5 Forward Current Derating Curve

SBR is a registered trademark of Diodes Incorporated.

SBR3U20SA

Document number: DS31209 Rev. 8 - 2

2 of 4

www.diodes.com

25

A

T , DERATED AMBIENT TEMPERATURE ( C)

0

0246 8101214161820

V , DC REVERSE VOLTAGE (V)

R

Fig. 6 Operating Temperature Derating

July 2009

© Diodes Incorporated

Loading...

Loading...