Page 1

g

A

Features

Schottky Barrier Chip

Guard Ring Die Construction for Transient Protection

Low Power Loss, High Efficiency

High Surge Capability

High Current Capability and Low Forward Voltage Drop

For Use in Low Voltage, High Frequency Inverters, Free

Wheeling, and Polarity Protection Applications

Lead-Free Finish; RoHS Compliant (Notes 1 & 2)

Pb

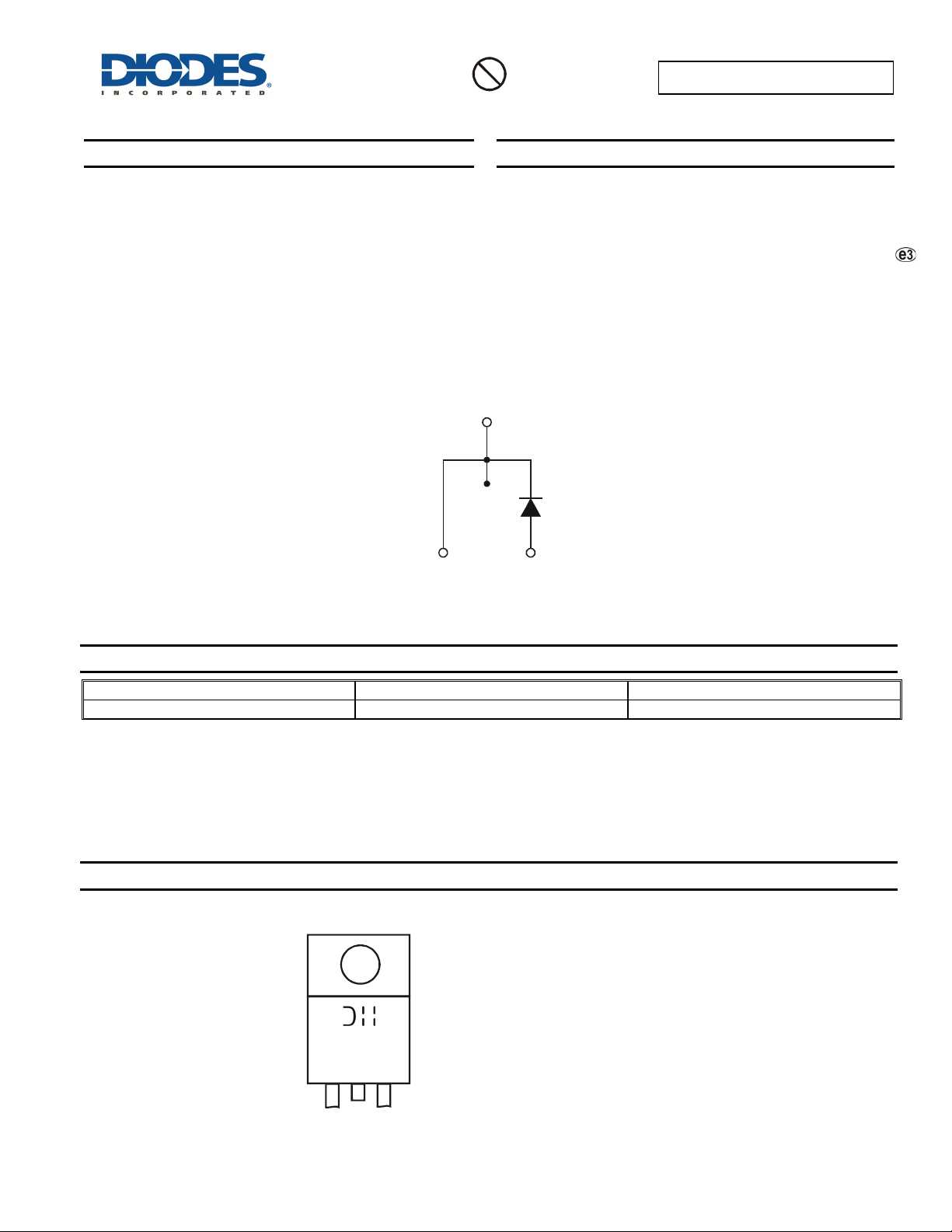

Mechanical Data

Case: TO220AC

Case Material: Molded Plastic. UL Flammability Classification

Rating 94V-0

Moisture Sensitivity: Level 1 per J-STD-020C

Terminals: Finish – Tin. Solderable per MIL-STD-202, Method 208

Polarity: See Diagram

Marking: Type Number

Weight: 2.24 grams (approximate)

Base

Cathode

1

13

Cathode

Package Pin Out

Confi

Anode

uration

MBR1635/ MBR1640

16A SCHOTTKY BARRIER RECTIFIER

Ordering Information (Note 3)

Part Number Case Packaging

MBR16xx* TO220AC 50/Tube

* xx = Device type, e.g. MBR1640

Notes: 1. EU Directive 2002/95/EC (RoHS) & 2011/65/EU (RoHS 2) compliant. All applicable RoHS exemptions applied.

2. See http://www.diodes.com/quality/lead_free.html for more information about Diodes Incorporated’s definitions of Halogen- and Antimony-free, "Green"

and Lead-free.

3. For packaging details, go to our website at http://www.diodes.com/products/packages.html.

Marking Information

MBR16xx

YYWW AB

MBR1635/ MBR1640

Document number: DS23011 Rev. 9 - 2

MBR16xx = Product Type Marking Code

B = Foundry and Assembly Code

YYWW = Date Code Marking

YY = Last two digits of year (ex: 10 = 2010)

WW = Week (01 - 53)

1 of 4

www.diodes.com

May 2013

© Diodes Incorporated

Page 2

R

GE F

O

R

R

C

URR

T

T

T

O

U

FORWARD CUR

R

T

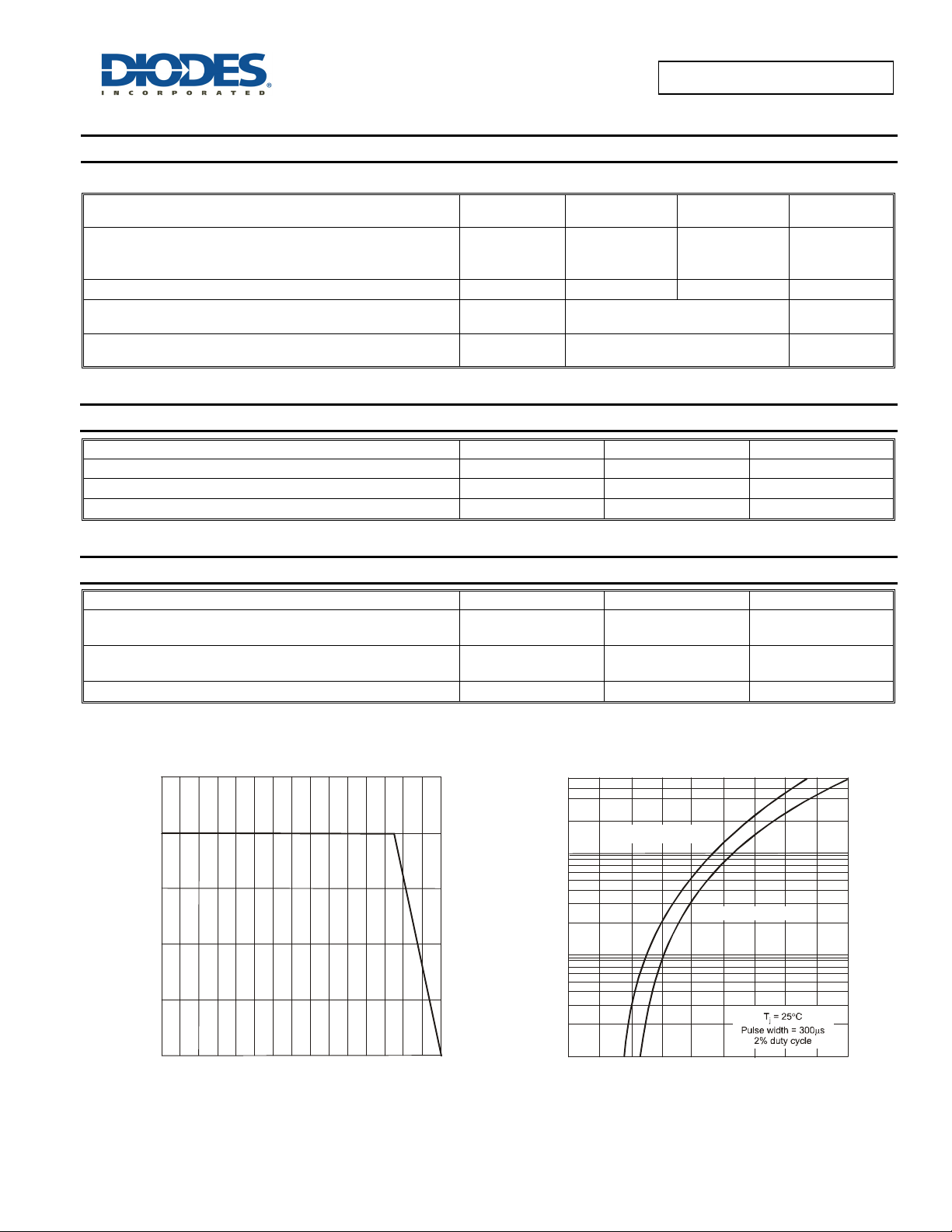

Maximum Ratings (@T

Single phase, half wave, 60 Hz, resistive or inductive load.

For capacitive load, derate current by 20%.

= +25°C, unless otherwise specified.)

A

Characteristic Symbol

Peak Repetitive Reverse Voltage

Working Peak Reverse Voltage

DC Blocking Voltage

RMS Reverse Voltage

Average Rectified Output Current

(Note 4) @ TC = +125°C

Non-Repetitive Peak Forward Surge Current 8.3ms

Single Half Sine-Wave Superimposed on Rated Load

Thermal Characteristics

Characteristic Symbol Value Unit

Typical Thermal Resistance Junction to Case (Note 4)

Voltage Rate of Change (Rated VR)

Operating and Storage Temperature Range

MBR1635/ MBR1640

MBR

1635

V

V

RRM

RWM

35 40 V

VR

V

R(RMS)

I

IO

FSM

R

θJC

24.5 28 V

16 A

150 A

1.5

dV/dt 1000 V/µs

T

J, TSTG

-65 to +150

MBR

1640

Unit

C/W

C

Electrical Characteristics (@T

= +25°C, unless otherwise specified.)

A

Characteristic Symbol Value Unit

Forward Voltage Drop @ IF =16A, TC = +25°C

@ IF =16A, TC =+125°C

Peak Reverse Current @TC = +25°C

at Rated DC Blocking Voltage @ TC = +125°C

Typical Total Capacitance (Note 5)

Notes: 4. Thermal resistance junction to case mounted on heatsink.

5. Measured at 1.0MHz and applied reverse voltage of 4.0V DC.

20

VFM

IRM

CT

50

0.63

0.57

0.2

40

mA

450 pF

V

(A)

(A)

EN

16

EN

MBR1630 - MBR1645

10

D

12

WA

8

A

4

(AV)

I, AVE

0

050100150

T , CASE TEMPERATURE ( C)

C

°

Fig. 1 Forward Current Derating Curve

MBR1635/ MBR1640

Document number: DS23011 Rev. 9 - 2

2 of 4

www.diodes.com

S

1.0

ANE

AN

F

I, INS

0.1

0.2 0.4 0.6 0.8 1.0

V , INSTANTANEOUS FORWARD VOLTAGE (V)

F

Fig. 2 Typical Forward Voltage Characteristics

MBR1650 / MBR1660

May 2013

© Diodes Incorporated

Page 3

P

FORWAR

URGE CUR

RENT

C, CAPACITAN

C

TANT

O

US R

R

CUR

RENT

300

(A)

250

200

150

D S

100

EAK

50

FSM

I,

0

110100

100

(mA)

NUMBER OF CYCLES AT 60Hz

Fig. 3 Max Non-Repetitive Surge Current

4,000

E (pF)

1,000

T

100

0.1 1.0 10 100

V , REVERSE VOLTAGE (V)

Fig. 4 Typical Total Capacitance

MBR1635/ MBR1640

R

T= 25C

°

j

f = 1.0MHz

10

SE

1.0

EVE

ANE

0.1

R

0.01

I , INS

0 20 40 60 80 100 120 140

PERCENT OF RATED PEAK REVERSE VOLTAGE (%)

Fig. 5 Typical Reverse Characteristics

Package Outline Dimensions

Please see AP02002 at http://www.diodes.com/datasheets/ap02002.pdf for latest version.

Q

D

D1

b2

E

e1

P

H1

L1

L

b

MBR1635/ MBR1640

Document number: DS23011 Rev. 9 - 2

A

A1

SEATING PLANE

c

A2

3 of 4

www.diodes.com

TO220AC

Dim Min Typ Max

A 3.56 - 4.82

A1 0.51 - 1.39

A2 2.04 - 2.92

b 0.39 0.81 1.01

b2 1.15 1.24 1.77

c 0.356 - 0.61

D 14.22 - 16.51

D1 8.39 - 9.01

e1 5.08

E 9.66 - 10.66

H1 5.85 - 6.85

L 12.70 - 14.73

L1 - - 6.35

P 3.54 - 4.08

Q 2.54 - 3.42

All Dimensions in mm

May 2013

© Diodes Incorporated

Page 4

IMPORTANT NOTICE

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS DOCUMENT,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

(AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes

without further notice to this document and any product described herein. Diodes Incorporated does not assume any liability arising out of the

application or use of this document or any product described herein; neither does Diodes Incorporated convey any license under its patent or

trademark rights, nor the rights of others. Any Customer or user of this document or products described herein in such applications shall assume

all risks of such use and will agree to hold Diodes Incorporated and all the companies whose products are represented on Diodes Incorporated

website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized sales channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorized application, Customers shall indemnify and

hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees arising out of, directly or

indirectly, any claim of personal injury or death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names and markings

noted herein may also be covered by one or more United States, international or foreign trademarks.

This document is written in English but may be translated into multiple languages for reference. Only the English version of this document is the

final and determinative format released by Diodes Incorporated.

LIFE SUPPORT

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems without the express

written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided in the

labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected to cause the

failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices or systems, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any

use of Diodes Incorporated products in such safety-critical, life support devices or systems, notwithstanding any devices- or systems-related

information or support that may be provided by Diodes Incorporated. Further, Customers must fully indemnify Diodes Incorporated and its

representatives against any damages arising out of the use of Diodes Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2013, Diodes Incorporated

www.diodes.com

MBR1635/ MBR1640

MBR1635/ MBR1640

Document number: DS23011 Rev. 9 - 2

4 of 4

www.diodes.com

May 2013

© Diodes Incorporated

Loading...

Loading...