Page 1

Features

Glass Passivated Die Construction

·

High Case Dielectric Strength of 1500VRMS

·

Low Reverse Leakage Current

·

Surge Overload Rating to 150A Peak

·

Ideal for Printed Circuit Board Applications

·

UL Listed Under Recognized Component

·

Index, File Number E94661

Lead Free Finish, RoHS Compliant (Note 4)

·

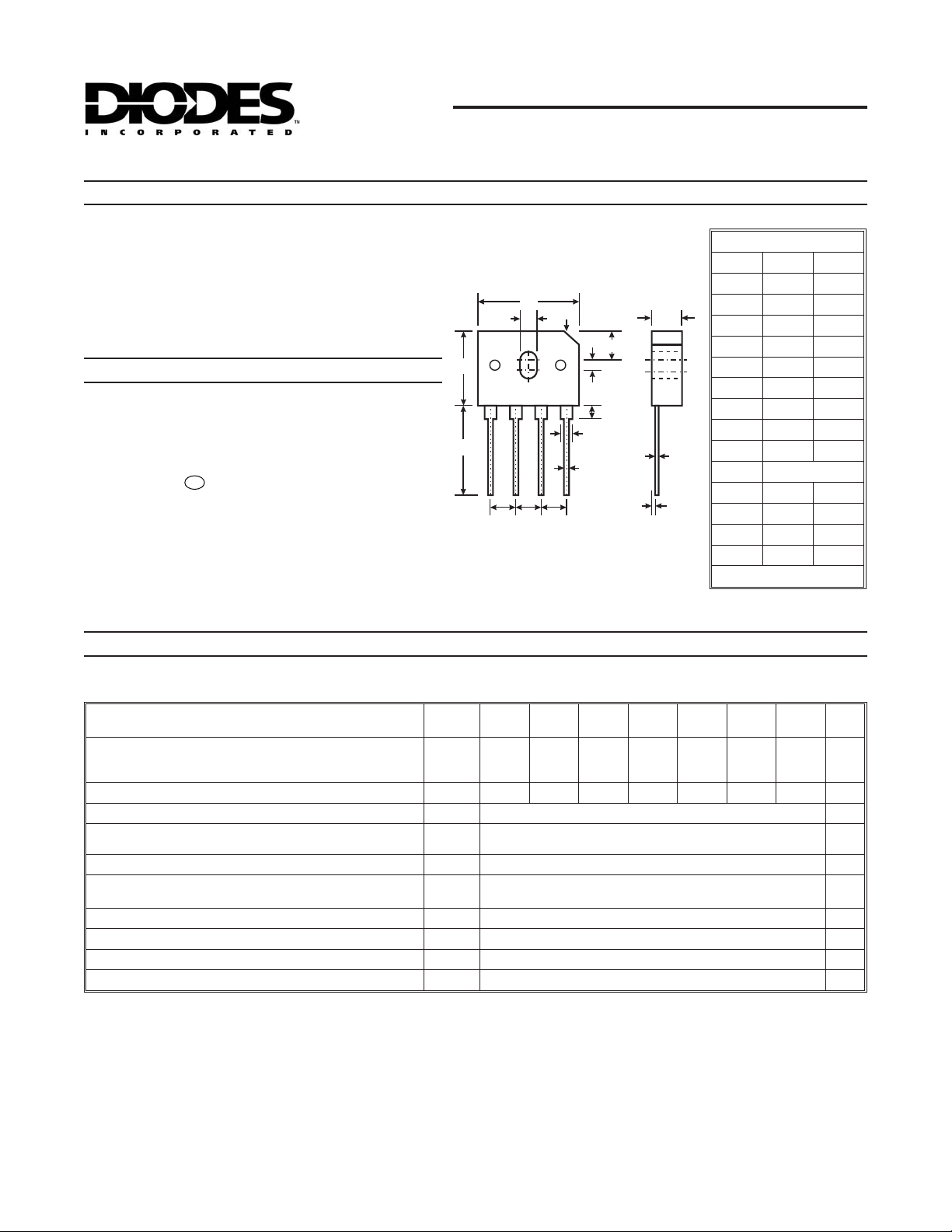

Mechanical Data

Case: GBU

·

Case Material: Molded Plastic. UL Flammability

·

Classification Rating 94V-0

Moisture Sensitivity: Level 1 per J-STD-020C

·

Terminals: Plated Leads. Solderable per MIL-STD-202,

·

Method 208

Lead Free Plating (Tin Finish)

·

Polarity: Marked on Body

·

Mounting: Through Hole for #6 Screw

·

Mounting Torque: 5.0 Inch-pounds Maximum

·

Ordering Information: See Last Page

·

Marking: Date Code and Type Number

·

·

Weight: 6.6 grams (approximate)

e

3

GBU4005 - GBU410

4.0A GLASS PASSIVATED BRIDGE RECTIFIER

GBU

Dim Min Max

21.8 22.3

A

A

K

B

C

L

D

+

~

~

-

J

H

E

F

G

M

N

P

All Dimensions in mm

B

C

D

E

F

G

H

J

K

L

M

N

P

3.5 4.1

7.4 7.9

1.65 2.16

2.25 2.75

1.95 2.35

1.02 1.27

4.83 5.33

17.5 18.0

3.2 X 45°

18.3 18.8

3.30 3.56

0.46 0.56

0.76 1.0

Maximum Ratings and Electrical Characteristics

Single phase, 60Hz, resistive or inductive load.

For capacitive load, derate current by 20%.

Characteristic Symbol

Peak Repetitive Reverse Voltage

Working Peak Reverse Voltage

DC Blocking Voltage

RMS Reverse Voltage

Average Forward Rectified Current (Note 1) @ TC= 100°C

Non-Repetitive Peak Forward Surge Current 8.3ms

single half sine-wave superimposed on rated load

Forward Voltage (per element) @ IF= 2.0A

Peak Reverse Current @ TC= 25°C

at Rated DC Blocking Voltage @ T

I2t Rating for Fusing (Note 2)

Typical Total Capacitance per Element (Note 3)

Typical Thermal Resistance Junction to Case (Note 1)

Operating and Storage Temperature Range

Notes: 1. Unit mounted on 50mm x 50mm x 1.6mm copper plate heatsink.

2. Non-repetitive, for t > 1.0ms and < 8.3ms.

3. Measured at 1.0MHz and applied reverse voltage of 4.0V DC.

4. RoHS revision 13.2.2003. Glass and High Temperature Solder Exemptions Applied, see

= 125°C

C

V

V

V

R(RMS)

I

I

V

R

T

j,TSTG

GBU

4005

RRM

RWM

V

R

(AV)

FSM

FM

I

R

2

I

t93A

C

T

qJC

@ TA= 25°C unless otherwise specified

GBU

50 100 200 400 600 800 1000 V

35 70 140 280 420 560 700 V

GBU

401

EU Directive Annex Notes 5 and 7.

GBU

402

404

4.0 A

150 A

1.0 V

5.0

50

80 pF

2.2 °C/W

-55 to +150 °C

GBU

406

GBU

408

GBU

410

Unit

mA

2

s

DS21225 Rev. 7 - 2 1 of 3 GBU4005 - GBU410

www.diodes.com

ã Diodes Incorporated

Page 2

100

g

180

g

6

)

g

g

5

4

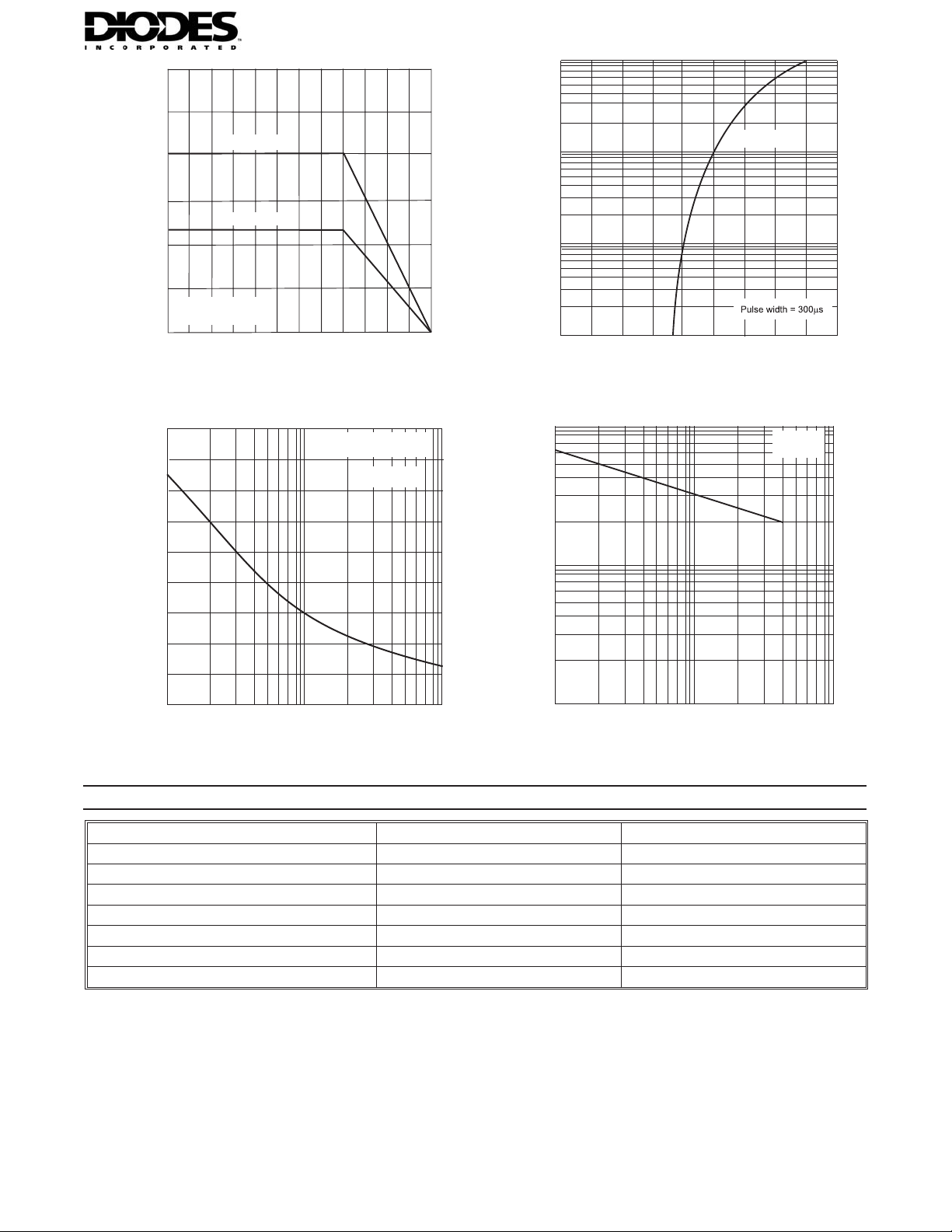

With heatsink

10

T=25Cj°

3

Without heatsink

FSM

I , PEAK FORWARD SURGE CURRENT (A)

2

1.0

1

Resistive or

Inductive load

0

(AV)

I , AVERAGE FORWARD RECTIFIED CURRENT (A

0

25 50 75 100 125 150

T , CASE TEMPERATURE ( C)

C

. 1 Forward Current DeratingCurve

Fi

°

Single half-sine-wave

160

T=25Cj°

F

I , INSTANTANEOUS FORWARD CURRENT (A)

0.1

0.2

0.0

V , INSTANTANEOUS FORWARD VOLTAGE (V)

F

.2 Typical Forward Characteristics, per element

Fi

0.6 1.0

100

1.4

T=25C

j

f = 1.0MHz

1.8

°

120

10

80

40

0

1

10

100

NUMBER OF CYCLES AT 60 Hz

Fi

. 3 Maximum Non-Repetitive Surge Current

T

C , TOTAL CAPACITANCE (pF)

1

1 10 100

V , REVERSE VOLTAGE (V)

R

.4 Typical Total Capacitance, per element

Fi

Ordering Information

Device

GBU4005

GBU401

GBU402

(Note 5)

Packaging Shipping

GBU 20/Tube

GBU 20/Tube

GBU 20/Tube

GBU404 GBU 20/Tube

GBU406

GBU408

GBU410

Notes: 5. For packaging details, visit our website at http://www.diodes.com/datasheets/ap02008.pdf

GBU 20/Tube

GBU 20/Tube

GBU 20/Tube

DS21225 Rev. 7 - 2 2 of 3 GBU4005 - GBU410

www.diodes.com

Page 3

IMPORTANT NOTICE

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes without further

notice to any product herein. Diodes Incorporated does not assume any liability arising out of the application or use of any product described herein; neither

does it convey any license under its patent rights, nor the rights of others. The user of products in such applications shall assume all risks of such use and will

agree to hold Diodes Incorporated andall the companies whose products arerepresented on our website, harmless againstall damages.

LIFE SUPPORT

Diodes Incorporated products are not authorized for use as critical components in life support devices or systems without the expressed written approval of the

President of Diodes Incorporated.

DS21225 Rev. 7 - 2 3 of 3 GBU4005 - GBU410

www.diodes.com

Loading...

Loading...