Diodes DFLS230L User Manual

Features

• Guard Ring Die Construction for Transient Protection

• Low Power Loss, High Efficiency

• Patented Interlocking Clip Design for High Surge Current

Capacity

• High Current Capability and Low Forward Voltage Drop

• Lead Free Finish, RoHS Compliant (Note 1)

• "Green" Molding Compound (No Br, Sb)

• Qualified to AEC-Q101 Standards for High Reliability

DFLS230L

2.0A SURFACE MOUNT SCHOTTKY BARRIER RECTIFIER

PowerDI

®

123

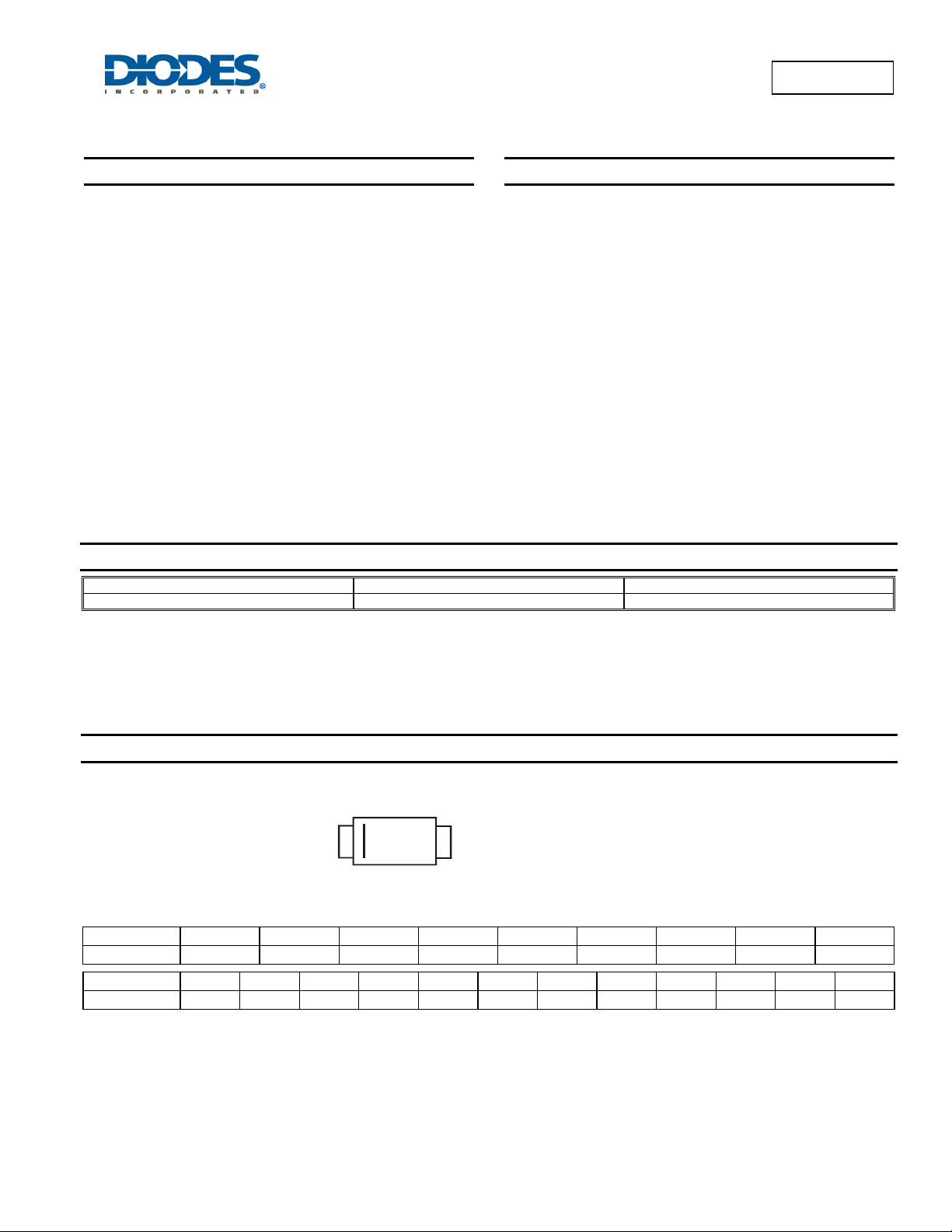

Mechanical Data

• Case: PowerDI®123

• Case Material: Molded Plastic, "Green" Molding Compound. UL

Flammability Classification Rating 94V-0

• Moisture Sensitivity: Level 1 per J-STD-02

• Terminal Connections: Cathode Band

• Terminals: Finish – Matte Tin Annealed Over Copper

Leadframe. Solderable per MIL-STD-202, Method 208

• Weight: 0.01 grams (approximate)

Top View

Ordering Information (Note 2)

Part Number Case Packaging

DFLS230L-7 PowerDI®123 3000/Tape & Reel

Notes: 1. EU Directive 2002/95/EC (RoHS). All applicable RoHS exemptions applied, see EU Directive 2002/95/EC Anne x Notes.

2. For packaging details, go to our website at http://www.diodes.com.

Marking Information

Date Code Key

Year 2004 2005 2006 2007 2008 2009 2010 2011 2012

Code R S T U V W X Y Z

Month Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec

Code 1 2 3 4 5 6 7 8 9 O N D

PowerDI is a registered trademark of Diodes Incorporated.

F03A

YM

DFLS230L

Document number: DS30515 Rev. 5 - 2

F03A = Product Type Marking Code

YM = Date Code Marking

Y = Year (ex: T = 2006)

M = Month (ex: 9 = September)

1 of 4

www.diodes.com

October 2010

© Diodes Incorporated

)

)

θ

θ

θ

(BR)

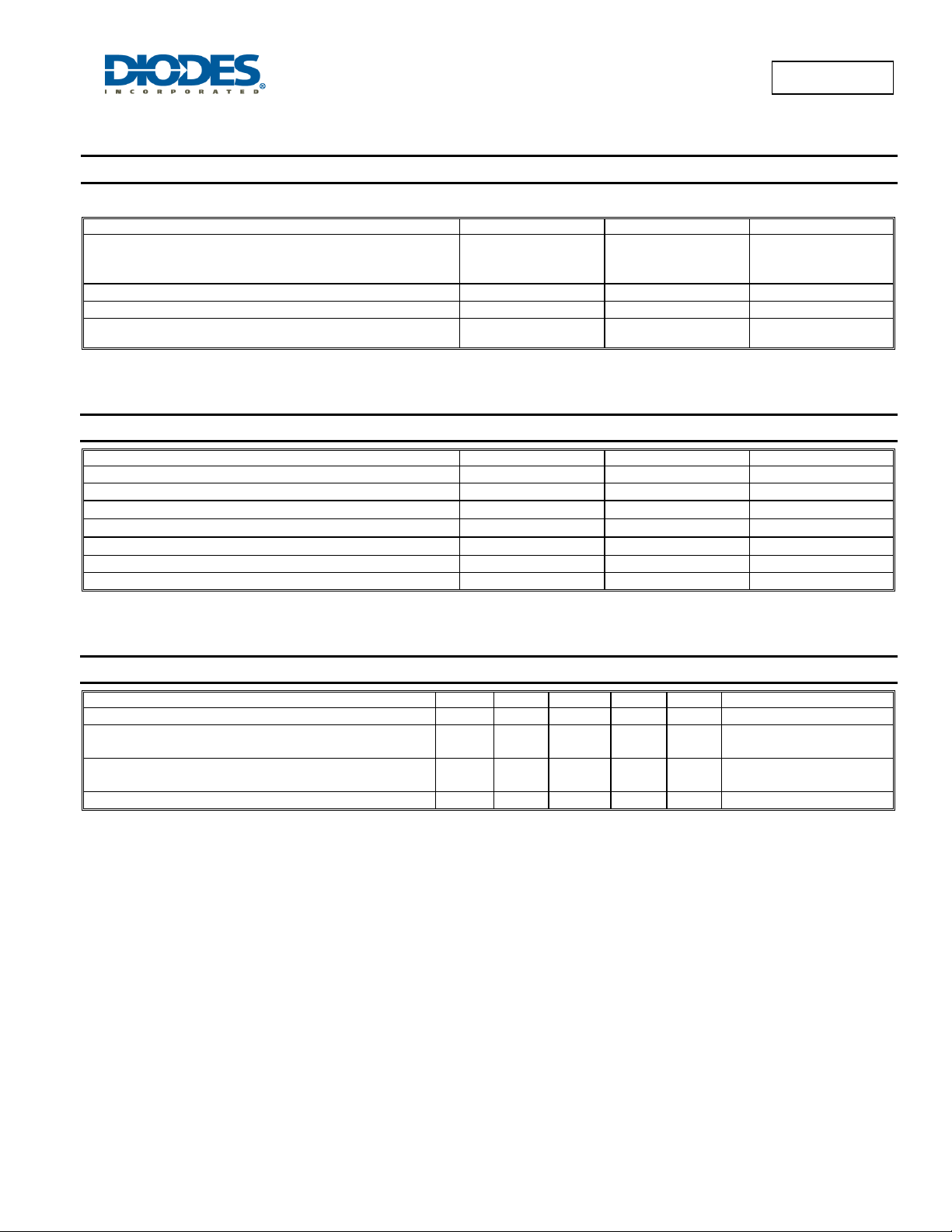

Maximum Ratings @T

= 25°C unless otherwise specified

A

Single phase, half wave, 60Hz, resistive or inductive load.

For capacitance load, derate current by 20%.

Characteristic Symbol Value Unit

Peak Repetitive Reverse Voltage

Working Peak Reverse Voltage

DC Blocking Voltage

RMS Reverse Voltage

Average Forward Current @ TT = 121°C I

Non-Repetitive Peak Forward Surge Current 8.3ms

Single Half Sine-Wave Superimposed on Rated Load

Thermal Characteristics

Characteristic Symbol Value Unit

Power Dissipation (Note 3)

Power Dissipation (Note 4)

Thermal Resistance Junction to Ambient (Note 3)

Thermal Resistance Junction to Ambient (Note 4)

Thermal Resistance Junction to Soldering (Note 5)

Operating Temperature Range

Storage Temperature Range

V

V

V

R(RMS

I

R

R

R

T

RRM

RWM

V

F(AV

FSM

P

P

T

STG

DFLS230L

R

D

D

JA

JA

JS

J

30 V

21 V

2.0 A

33 A

1.67 W

556 mW

60

180

10

-40 to +125

-40 to +150

°C/W

°C/W

°C/W

°C

°C

Electrical Characteristics @T

= 25°C unless otherwise specified

A

Characteristic Symbol Min Typ Max Unit Test Condition

Reverse Breakdown Voltage (Note 6)

Forward Voltage

Leakage Current (Note 6)

Total Capacitance

Notes: 3. Part mounted on 2"x2" GETEK board with 1"x1" copper pad, 25% anode, 75% cathode. TA = 25°C.

4. Part mounted on FR-4 board with recommended pad layout, which can be found on our website at http://www.diodes.com.

5. Theoretical R

6. Short duration pulse test used to minimize self-heating effect.

calculated from the top center of the die straight down to the PCB/cathode tab solder junction.

θJS

V

V

F

I

R

C

T

30

R

⎯

⎯

⎯

⎯

⎯

⎯ ⎯

0.310

0.375

0.260

⎯

76

⎯

0.420

⎯

1.0

⎯

V

IR = 1.0mA

= 1.0A

I

F

V

= 2.0A

I

F

= 5V, TA = 25°C

V

mA

R

V

= 30V, TA = 25°C

R

pF

VR = 10V, f = 1.0MHz

PowerDI is a registered trademark of Diodes Incorporated.

DFLS230L

Document number: DS30515 Rev. 5 - 2

2 of 4

www.diodes.com

October 2010

© Diodes Incorporated

Loading...

Loading...