Features

• Guard Ring Die Construction for Transient Protection

• Low Power Loss, High Efficiency

• Patented Interlocking Clip Design for High Surge Current

Capacity

• Lead Free Finish, RoHS Compliant (Note 1)

• "Green" Molding Compound (No Br, Sb)

• Qualified to AEC-Q101 Standards for High Reliability

DFLS1150

1.0A HIGH VOLTAGE SCHOTTKY BARRIER RECTIFIER

POWERDI

Mechanical Data

• Case: POWERDI®123

• Case Material: Molded Plastic, "Green" Molding Compound. UL

Flammability Classification Rating 94V-0

• Moisture Sensitivity: Level 1 per J-STD-020

• Terminal Connections: Cathode Band

• Terminals: Finish – Matte Tin annealed over Copper Leadframe.

Solderable per MIL-STD-202, Method 208

• Weight: 0.01 grams (approximate)

Top View

®

123

Ordering Information (Note 2)

Part Number Case Packaging

DFLS1150-7

Notes: 1. EU Directive 2002/95/EC (RoHS). All applicable RoHS exemptions applied, see EU Directive 2002/95/EC Annex Notes.

2. For packaging details, go to our website at http://www.diodes.com.

POWERDI

®

123

3000/Tape & Reel

Marking Information

Date Code Key

Year 2004 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014 2015

Code R S T U V W X Y Z A B C

Month Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec

Code 1 2 3 4 5 6 7 8 9 O N D

POWERDI is a registered trademark of Diodes Incorporated.

F07

YM

DFLS1150

Document number: DS30593 Rev. 7 - 2

F07 = Product Type Marking Code

YM = Date Code Marking

Y = Year (ex: R = 2004)

M = Month (ex: 9 = September)

1 of 4

www.diodes.com

April 2011

© Diodes Incorporated

)

)

θ

θ

(BR)

TANT

O

U

F

O

RWARD CUR

RENT

Maximum Ratings @T

= 25°C unless otherwise specified

A

Single phase, half wave, 60Hz, resistive or inductive load.

For capacitance load, derate current by 20%.

Characteristic Symbol Value Unit

Peak Repetitive Reverse Voltage

Working Peak Reverse Voltage

DC Blocking Voltage

RMS Reverse Voltage

Average Forward Current

Non-Repetitive Peak Forward Surge Current 8.3ms

Single Half Sine-Wave Superimposed on Rated Load

Thermal Characteristics

Characteristic Symbol Typ Max Unit

Thermal Resistance Junction to Soldering Point (Note 3)

Thermal Resistance Junction to Ambient (Note 4) TA = 25°C R

Operating and Storage Temperature Range

T

DFLS1150

V

RRM

V

RWM

V

R

V

R(RMS

I

F(AV

I

FSM

R

JS

JA

, T

J

STG

⎯

125

150 V

106 V

1.0 A

50 A

7

⎯

-55 to +175

°C/W

°C/W

°C

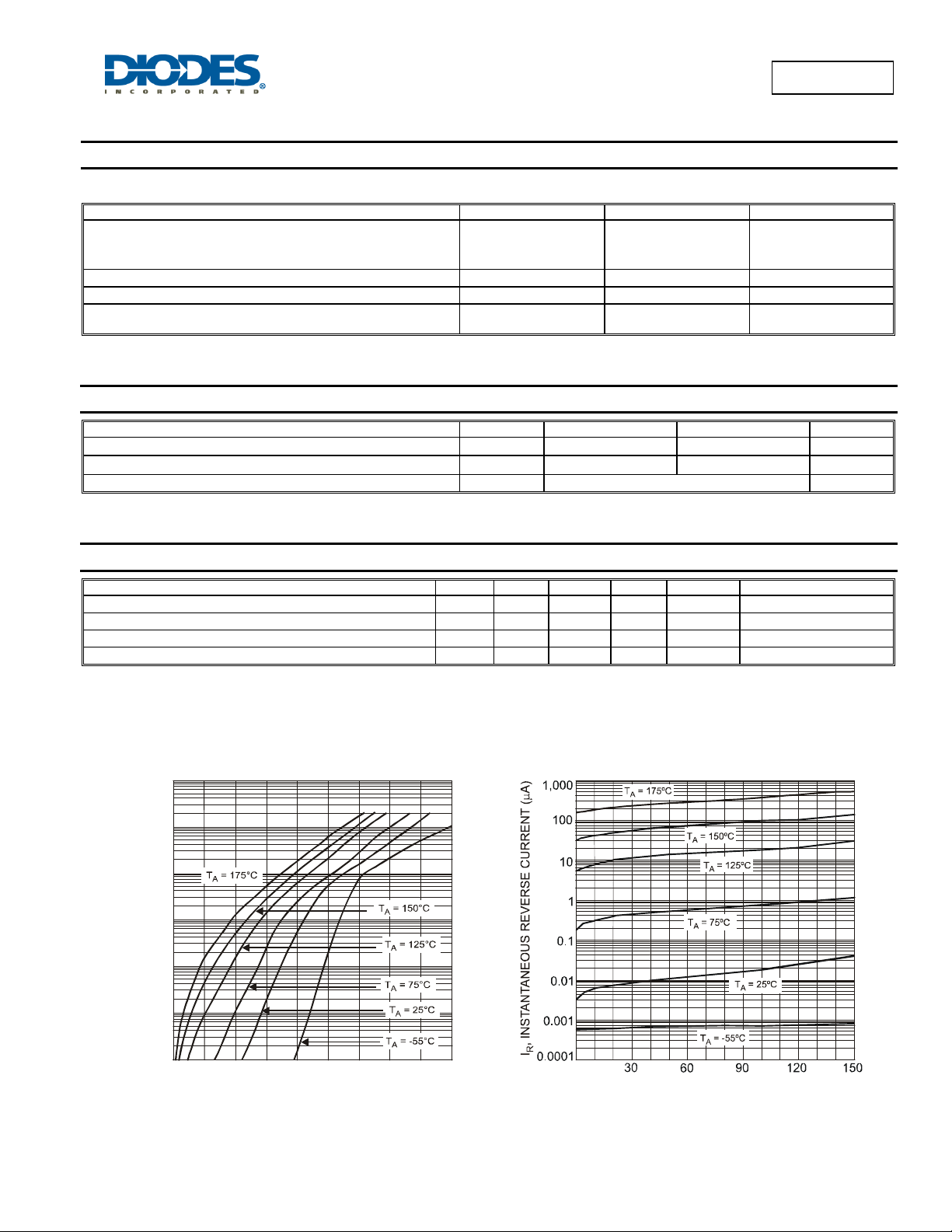

Electrical Characteristics @T

Characteristic Symbol Min Typ Max Unit Test Condition

Reverse Breakdown Voltage (Note 5)

Forward Voltage

Leakage Current (Note 5)

Total Capacitance

Notes: 3. Theoretical R

4. Part mounted on FR-4 board with 2 oz., minimum recommended copper pad layout, which can be found on our website at http://www.diodes.com.

5. Short duration pulse test used to minimize self-heating effect.

10

(A)

1

0.1

0.01

S

0.001

ANE

calculated from the top center of the die straight down to the PCB/cathode tab solder junction.

θJS

= 25°C unless otherwise specified

A

V

R

V

⎯ ⎯

F

I

⎯ ⎯

R

C

⎯

T

150

⎯ ⎯

0.82 V

2

28

⎯

V

μA

pF

IR = 2μA

IF = 1.0A

= 150V, TA = 25°C

V

R

VR = 5VDC, f = 1MHz

0.0001

F

I , INS

0.00001

00.40.5

V , INSTANTA NEOUS FORW ARD VOLTAGE (V)

0.20.1

0.3

F

Fig. 1 Typical Forward Characte r is ti cs

0.6 0.7 0.8 0.9

0

V , INSTANTANEOUS REVERSE VOLT AGE (V)

R

Fig. 2 Typical Reverse Characteristics

POWERDI is a registered trademark of Diodes Incorporated.

DFLS1150

Document number: DS30593 Rev. 7 - 2

2 of 4

www.diodes.com

April 2011

© Diodes Incorporated

Loading...

Loading...