Page 1

Single-cell Li-Ion Charger IC with System Power Management AUR9807

Data Sheet

General Description

The AUR9807 is a single-cell Li-ion charger IC with

system power management feature. It charges the

battery and power the system simultaneously. The

maximum charging current (up to 1.5A) is set by

external resistor for fast charging. The output

voltage for the system is regulated to a nominal

value (three different versions available: 4.4V, 5V or

6V); the actual value of the output voltage depends

on the input voltage from the adapter, the charging

current and the system loading. With the decrease of

the input voltage or the increase of the system

loading current, the output voltage drops. When the

output voltage drops to a predetermined value

(V

is activated and tries to maintain the output voltage

at V

loading with first priority and reduce the charging

current temporarily, i.e. under heavy load condition,

the AUR9807 charges the battery with the remaining

available current to keep the output voltage at V

In this manner, the charge and discharge cycle of the

battery can be reduced.

It is possible that the AUR9807 fails to maintain the

output voltage at V

system loading current exceeds the capability of the

current-limiting AC adapter. In this scenario, the

output voltage drops to the battery voltage, and the

system is allowed to draw current from the battery.

The AUR9807 is available in QFN-4.5×3.5-20

package.

), the Active Power Management function

APM-REG

; the AUR9807 will suffice the system

APM-REG

; for example, when the

APM-REG

APM

Features

• QFN Package

• Active Power Management (APM) for

Simultaneously Powering the System and

Charging the Battery

• Total Current Supported Up to 2 Amperes

(System Loading Having Higher Priority on the

Budget)

• Automatic Power Source Selection (AC Adapter

or Battery)

• 40m Power Path for the Battery to Supply the

System Power Efficiently

• Junction Temperature Detection and Thermal

Regulation During Charging Process

• External LED Indicating Charger and Power

Good Status as Well as Fault Condition

• Thermal, Short-Circuit, and Reverse Current

Protection

• Short-Circuit Protection in the Low Power

Consumption Sleep Mode

• SYSOFF Function to Cut Off the Path Between

.

the System and the Battery

• Built-in Over Voltage Protection up to 18V

Applications

• Battery-Powered Devices or Equipment

• Mobile Phones, Digital Cameras and MP3

Players

• Radios, Other Hand-Held Games and Instruments

• Solar Power System

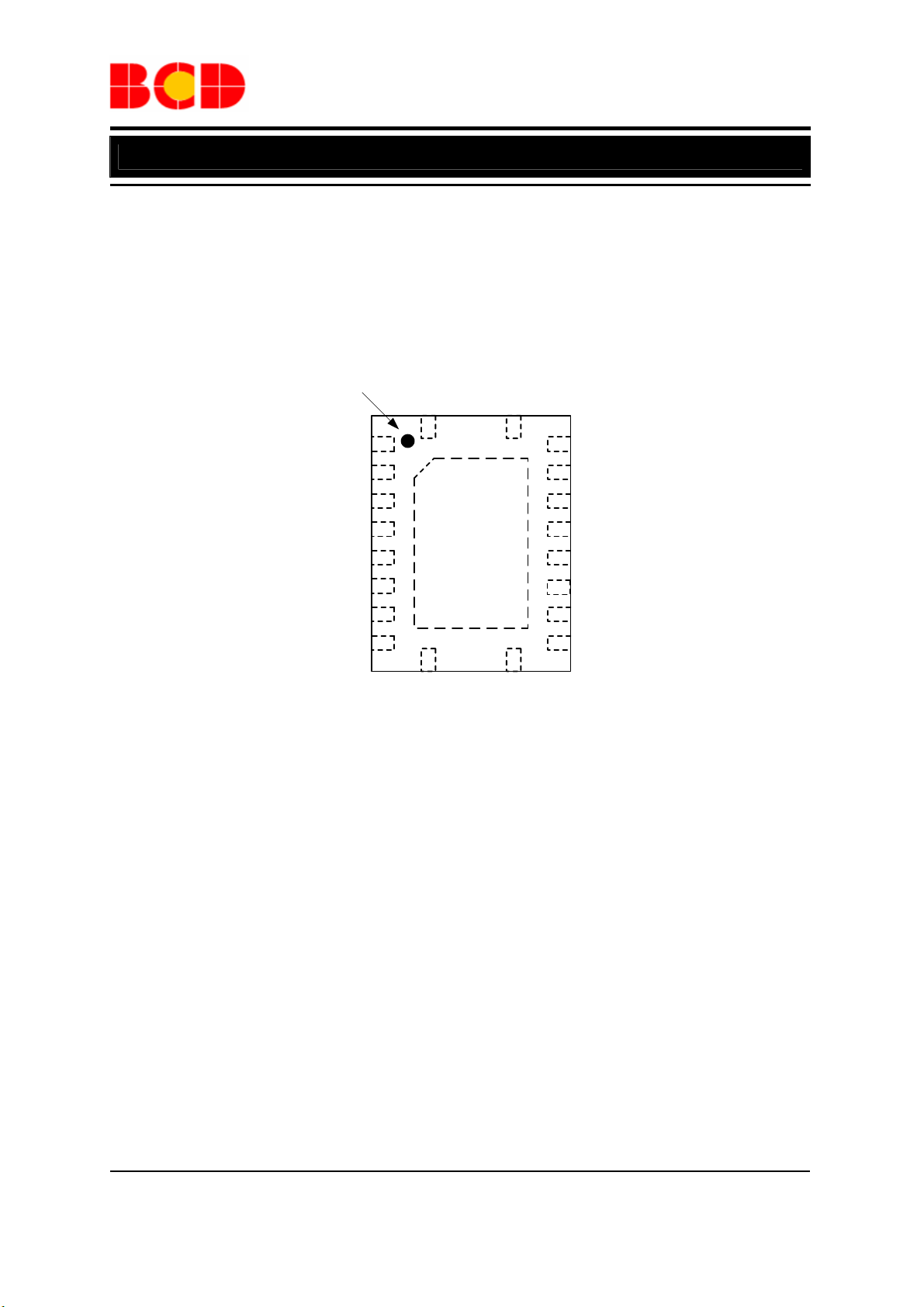

Figure 1. Package Type of AUR9807

QFN-4.5×3.5-20

Nov. 2011 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

1

Page 2

Data Sheet

Single-cell Li-Ion Charger IC with System Power Management AUR9807

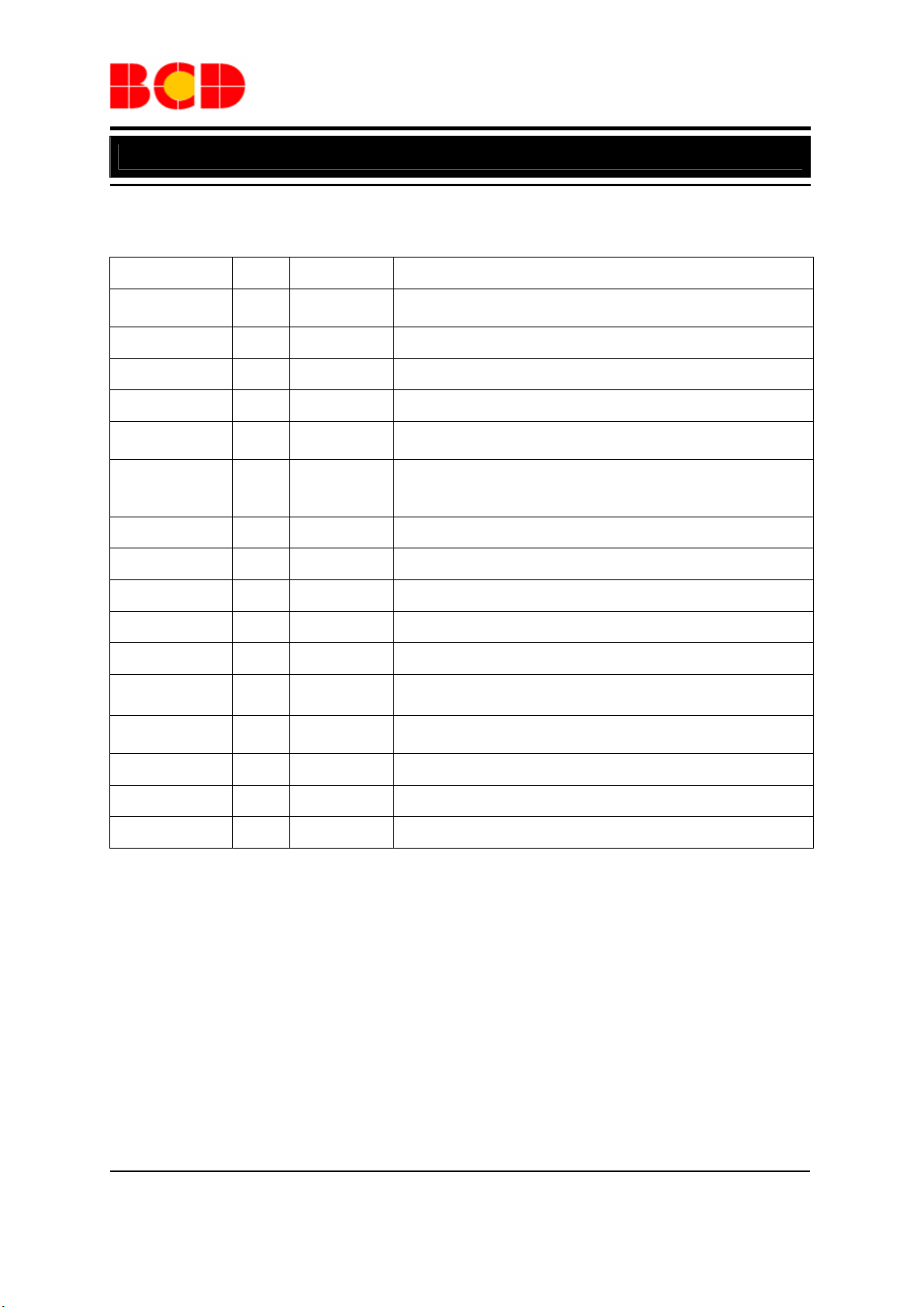

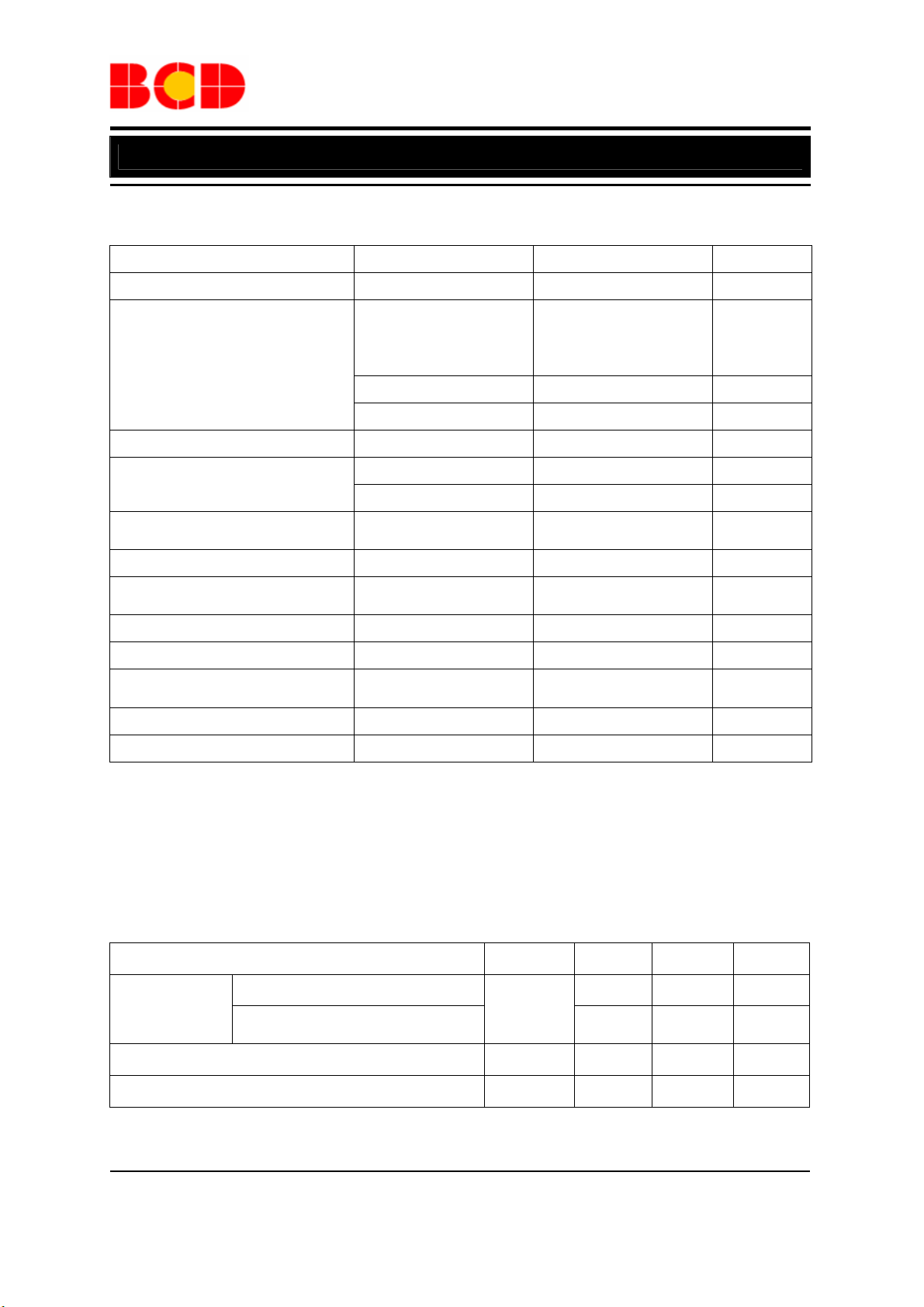

Pin Configuration

D Package

(

Pin 1 Mark

STAT1

2

QFN-4.5×3.5-20

VREF

1

20

)

GND

19

GND

STAT2

BAT

BAT

ISET2

MODE

CE

IN

3

4

5

6

Exposed

Pad

7

8

9

10

11

18

17

16

15

14

13

12

/PG

OUT

OUT

OUT

TMR

APM

TS

ISET1

SYSOFF

Figure 2. Pin Configuration of AUR9807 (Top View)

Nov. 2011 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

2

Page 3

Data Sheet

Single-cell Li-Ion Charger IC with System Power Management AUR9807

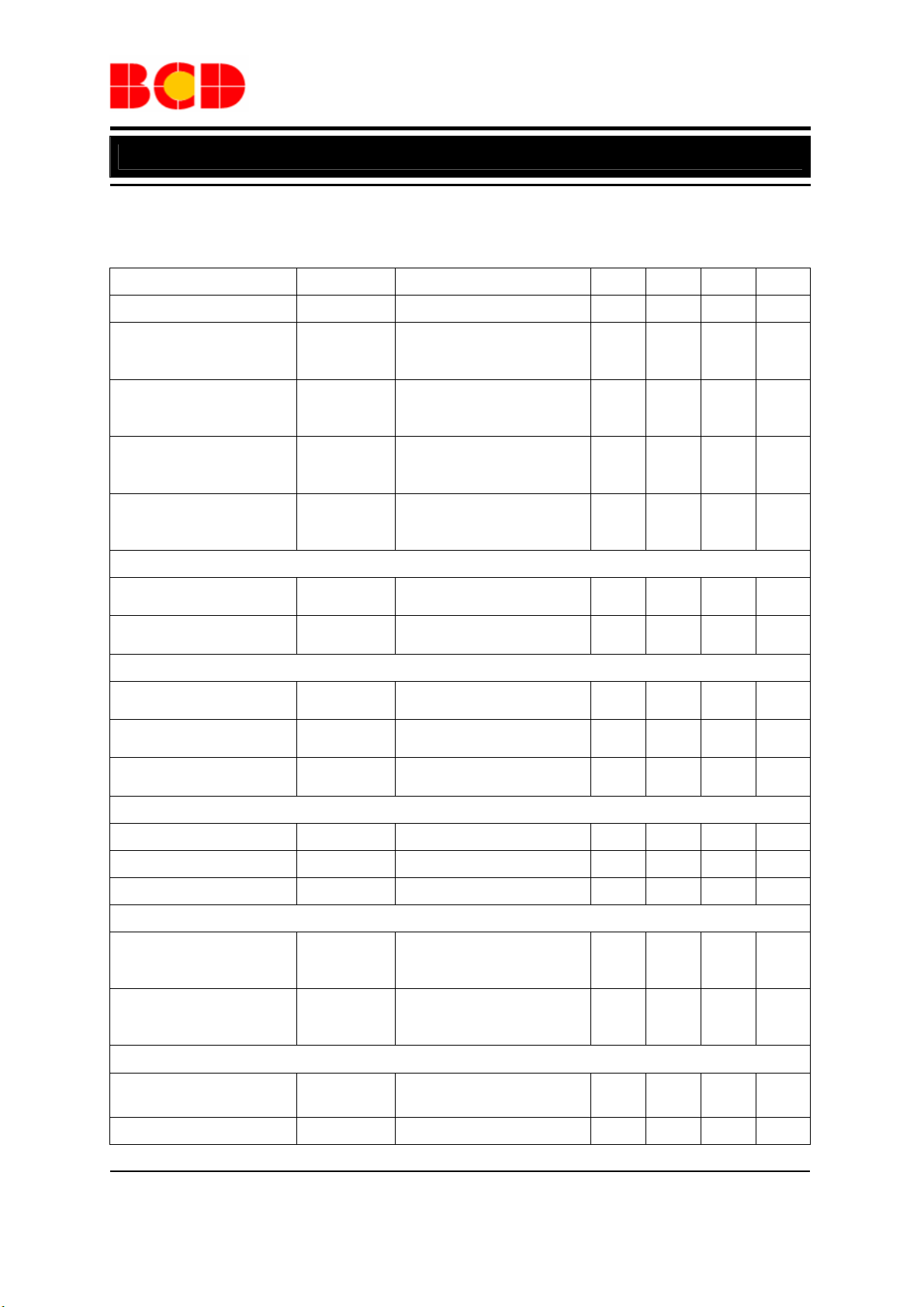

Pin Description

Pin Number I/O Pin Name Function

1 O VREF

2 O STAT1 Charge status flag 1 (open-drain)

3 O STAT2 Charge status flag 2 (open-drain)

4 I IN Chip input voltage

5 , 6 I/O BAT

7 I ISET2

8 I MODE Set AUR9807 in AC(High) or USB(Low) mode

Internal reference; VREF output capacitor not required, but

one with a value of 0.1µF is recommended.

Battery connection; charging or discharging all through this

pin

USB mode total current selection (High=450mA, Low=

90mA) and AC mode charge current selection (High=Full

current, Low=half current)

9 I CE Chip enable (active high)

10 I/O ISET1 Set the maximum charging current

11 I SYSOFF Cut off the power path between the battery and the output pin

12 I/O TS Battery Temperature sensing

13 I APM

14 I/O TMR

15 , 16 , 17 O OUT System output

18 O /PG Power-good status flag (open-drain)

19 , 20 I GND Chip Ground

Active Power Management set point ※ no need for

capacitors

Timer program by external resistor connected to this pin.

Tying TMR and VREF together to disable the safety timer

Nov. 2011 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

3

Page 4

Data Sheet

Single-cell Li-Ion Charger IC with System Power Management AUR9807

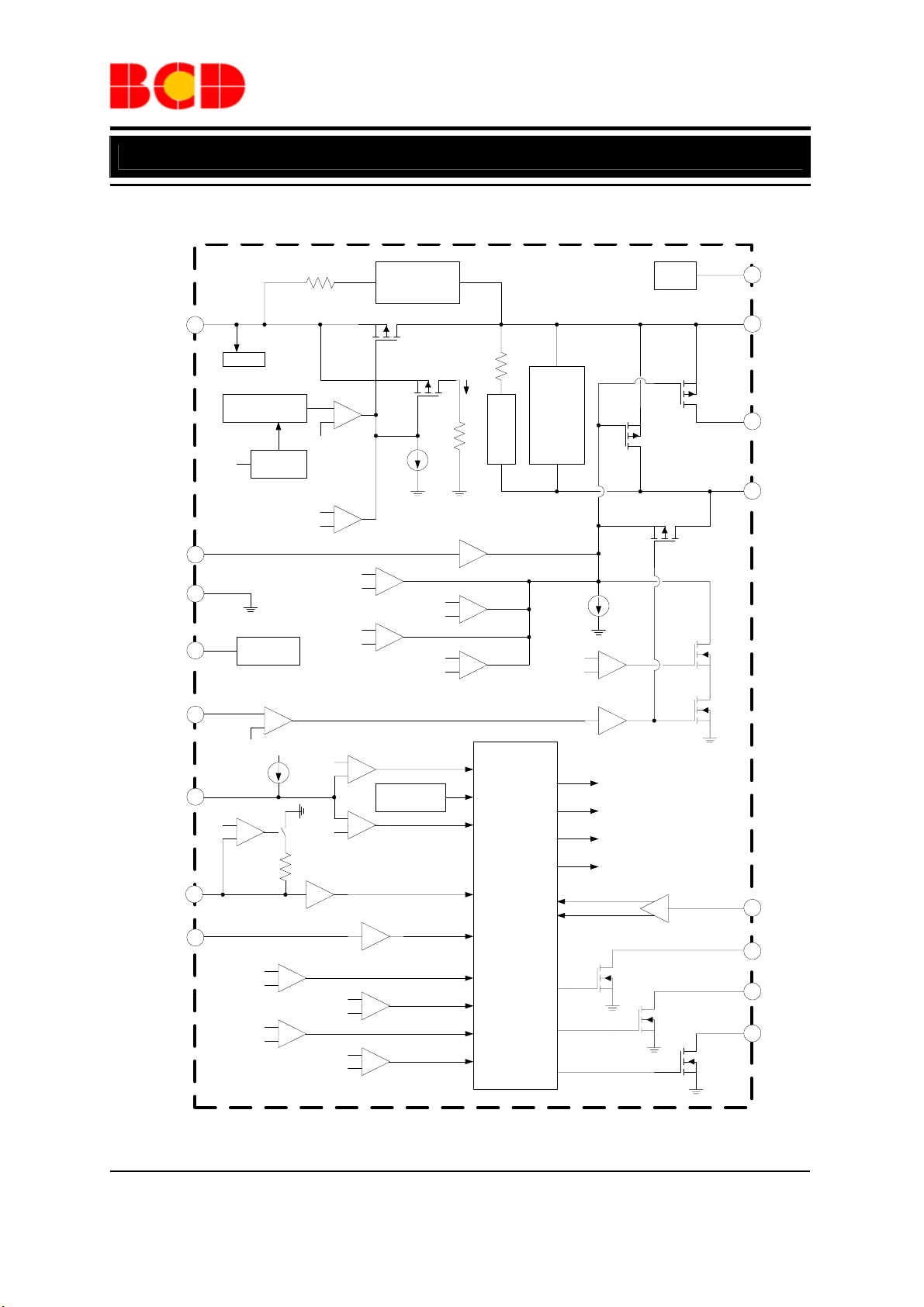

Functional Block Diagram

4

IN

UVLO

Power Source

V

SET

SYSOFF

GND

TMR Oscillator

APM

11

19, 20

14

13

Selection

100mA

500mA

V

V

OUT

OUT(REG)

I

AMP

V

ISENSE

V

V

BAT

BAT(REG)

V

SET

V

APM

Short-Circuit

Recovery

Q1

V

I(ISET1)

V

SET

T

J(REG)

15, 16, 17

V

OUT

10

V

I(ISET1)

5, 6

V

1

BAT

VREF

OUT

ISET1

BAT

3.3V

I

SENSE

BAT

Fault

Recovery

T

J

Recovery

Short-Circuit

V

BAT

V

OUT

Q2

1V

V

HTF

Thermal

Shutdown

V

LTF

AC Charge Enable

BAT Charge Enable

500mA/100mA

TS

1V

12

I

TS

Fast Precharge

MODE

CE

8

9

V

BAT

V

RCH

V

I(ISET1)

V

TERM

Power Source Selection

Recharge

V

V

BAT

LOWV

V

BAT

V

IN

Precharge

Termation

Sleep

Charge

Control Timer

and Display

Logic

1C - 500mA

C/S - 100mA

18

7

ISET2

/PG

2

STAT1

3

STAT2

Figure 3. Functional Block Diagram of AUR9807

Nov. 2011 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

4

Page 5

Data Sheet

Single-cell Li-Ion Charger IC with System Power Management AUR9807

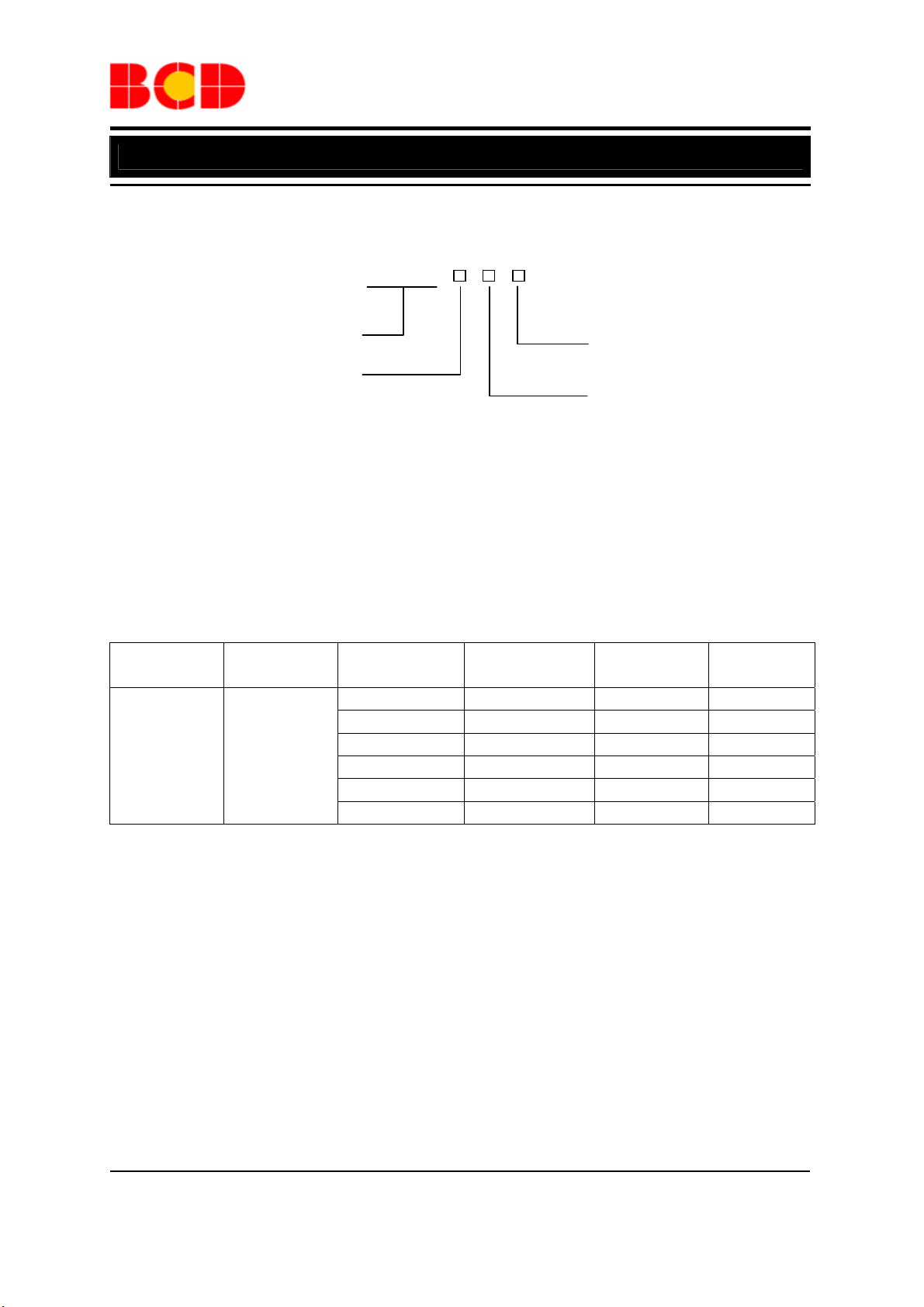

Ordering Information

AUR9807

Circuit Type

Package

QFN-4.5x3.5-20

Temperature

Output Voltage

VF: 4.4V, CV Mode

DF: 4.4V, Done

VI: 5V, CV Mode

DI: 5V, Done

VS: 6V, CV Mode

DS: 6V, Done

CV mode: After charge done, charger will stay in constant

voltage mode until time out.

Done: After charge done, charger will shut down until the

battery voltage drops below the battery recharge threshold.

Range

-40 to 85°C

Output Voltage Part Number Marking ID

4.4V, CV Mode AUR9807VFGD A9807VFG Tape & Reel

4.4V, Done AUR9807DFGD A9807DFG Tape & Reel

5V, CV Mode AUR9807VIGD A9807VIG Tape & Reel

5V, Done AUR9807DIGD A9807DIG Tape & Reel

6V, CV Mode AUR9807VSGD A9807VSG Tape & Reel

6V, Done AUR9807DSGD A9807DSG Tape & Reel

D: QFN-4.5x3.5-20

G: Green

Packing

Type

BCD Semiconductor's Pb-free products, as designated with "G" in the part number, are RoHS compliant and

green.

Nov. 2011 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

5

Page 6

Data Sheet

Single-cell Li-Ion Charger IC with System Power Management AUR9807

Absolute Maximum Ratings (Note 1)

Parameter Symbol Value Unit

Supply Input Voltage VIN -0.3 to 18 V

V

, VCE, V

BAT

, V

V

MODE

, V

V

ISET2

STAT1

Input Voltage

V

V

Input Current IIN 3.5 A

I

Output Current

I

Output Source Current

(In Regulation at 3.3V V

REF

)

Output Sink Current I

/PG

, I

I

STAT1

Thermal Resistance

(Junction to Ambient)

Storage Temperature T

Junction Temperature TJ -40 to 150 °C

Lead Temperature

(Soldering, 10 Seconds)

ESD (Human Body Model) V

ESD (Machine Model) VMM 200 V

, V

APM

, V

OUT

, V

V

TS

-0.3 to V

REF

-0.3 to V

TMR

4 A

OUT

-4 to 1.5 A

BAT

30 mA

REF

, I

θ

JA

-65 to 150 °C

STG

,

/PG

,

ISET1

,

STAT2

15 mA

STAT2

-0.3 to 7 V

+0.3 V

OUT

+0.3 V

OUT

52 °C/W

300 °C

2000 V

HBM

Note 1: Stresses greater than those listed under “Absolute Maximum Ratings” may cause permanent damage to

the device. These are stress ratings only, and functional operation of the device at these or any other conditions

beyond those indicated under “Recommended Operating Conditions” is not implied. Exposure to “Absolute

Maximum Ratings” for extended periods may affect device reliability.

Recommended Operating Conditions

Parameter Symbol Min Max Unit

AUR9807DSGD, AUR9807VSGD 4.35 6.3 V

Supply Voltage

AUR9807DFGD,AUR9807VFGD,

AUR9807DIGD, AUR9807VIGD

V

IN

4.35 5.5 V

Input Current IIN 2 A

Operating Junction Temperature Range TOP -40 125 °C

Nov. 2011 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

6

Page 7

Data Sheet

Single-cell Li-Ion Charger IC with System Power Management AUR9807

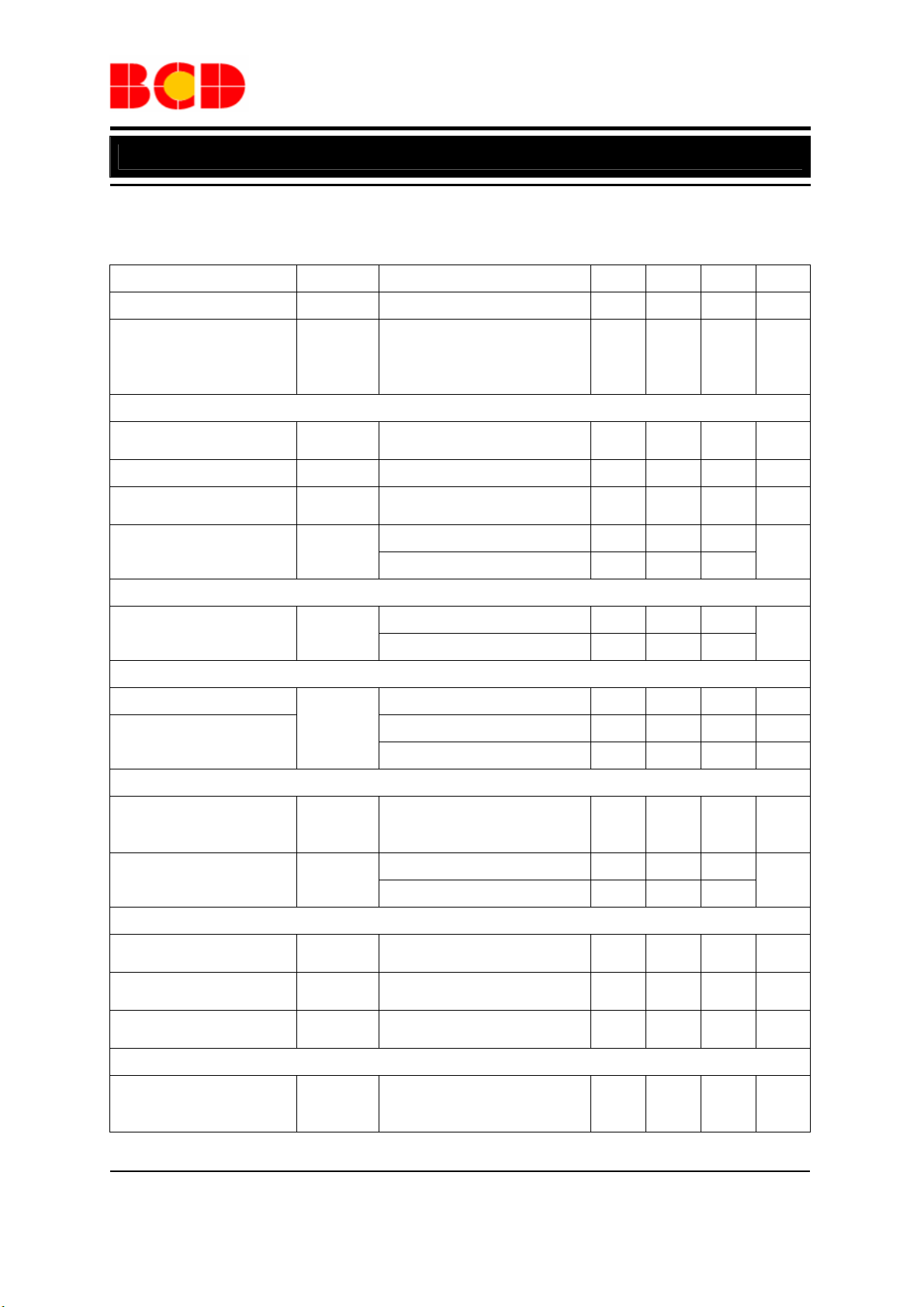

Electrical Characteristics

TA=25oC, VIN is within the recommended range, unless otherwise specified.

Parameter Symbol Test Condition Min Typ Max Unit

Active Supply Current I

Sleep Mode Current into

BAT Pin

Input Pin Standby

Current

BAT Pin Standby Current I

Charge Done Current,

BAT

I

I

IN(STDBY)

BAT(STDBY)

I

BAT(TERM)

Q1,Q2 DROP-OUT VOLTAGE

IN to OUT Dropout

Voltage

BAT to OUT Dropout

Voltage

V

DO(IN-OUT)

V

DO(BAT-OUT)VBAT

VOLTAGE REGULATION

Regulation V

9807VF 9807DF

Regulation V

9807VI 9807DI

Regulation V

9807VS 9807DS

OUT

OUT

OUT

V

V

V

APM REGULATION

VIN>4.35V 1.1 2 mA

IN(SPLY)

BAT(SLP)

V

IN<VBAT

2.6V<V

,

BAT<VBAT(REG)

2.5 5 µA

No load at OUT pin

V

<6V, Total current flow

IN

into IN pin with CE pin

200 µA

low; no load

Total current flow into

BAT pin with input source

45 65 µA

present and CE pin low

Current flows into BAT

pin after the termination of

1 5 µA

the charging process

MODE=High , IIN=1A 300 475 mV

OUT(REG)

OUT(REG)

OUT(REG)

> 4V , I

VIN>4.4V+V

VIN>5V+V

VIN>6V+V

=1A 40 100 mV

BAT

DO(IN-OUT)

DO(IN-OUT)

DO(IN-OUT)

4.4 4.5 V

4.9 5.1 V

6 6.3 V

APM Set Point V

APM Current Source I

APM-SET

APM-SET

APM Scale Factor SF V

V

APM-SET<VOUT

2.6 3.8 V

Input present 95 100 105 µA

APM-REG=VAPM-SET

x SF 1.139 1.15 1.162

BATTERY SUPPLEMENT MODE

V

<

Run Battery Supplement

Mode

Escape Battery

Supplement Mode

V

V

BSUP1

BSUP2

V

V

BAT

BAT

>2V

>2V

OUT

V

BAT

60mV

–

V

V

>

OUT

–

V

BAT

20mV

V

CHARGING-PRECHARGE

Precharge to Fast-charge

Transition Voltage

Precharge Current Range I

Nov. 2011 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

V

Voltage on BAT 2.9 3 3.1 V

LOWV

10 150 mA

PRECHG

7

Page 8

Data Sheet

Single-cell Li-Ion Charger IC with System Power Management AUR9807

Electrical Characteristics (Continued)

TA=25oC, VIN is within the recommended range, unless otherwise specified.

Parameter Symbol Test Condition Min Typ Max Unit

Precharge Set Voltage V

De-glitch Time Between

Fast Charge and

Precharge Transition

225 250 275 mV

PRECHG

t

=100ns,

FAL L

10mV overdrive,

t

DGLF

decreasing below

V

BAT

22.5 ms

threshold

CHARGING-CURRENT REGULATION

Fast Charge Current

Range

BAT to OUT Pull-up R

Battery Charge Current

Set Voltage

(1)

Charge Current Set

Factor

V

I

V

CHG

PBAT

SET

BAT>VLOWV

V

<1V 1000

BAT

Voltage on ISET1 2.4 2.5 2.6 V

100mA<I

K

SET

10mA<I

, Mode=High 100 1000 1500 mA

<1.5A 375 425 450

CHG

<100mA 300 450 600

CHG

USB MODE INPUT CURRENT LIMIT

ISET2=High 400 500

USB Input Current Range I

USB

mA

ISET2=Low 80 90 100

CHARGING VOLTAGE REGULATION

Battery-charge-voltage 4.2 V

Battery Charge Voltage

Regulation Accuracy

V

BAT(REG)

TA=25°C -0.5 0.5 %

-1 1 %

CHARGE TERMINATION DETECTION

Charge Done Detection

Current

Charge Done Set Voltage,

Measured on ISET1

I

TERM

V

TERM

V

BAT>VRCH

I

TERM

R

SET

V

BAT>VRCH

V

BAT>VRCH

,

=(K

SET

x V

TERM

)/

10 150 mA

, Mode=High 230 250 270

, Mode=Low 95 100 130

mV

TEMPERATURE SENSE COMPARATORS

High Voltage, Low

Temperature Threshold

Low Voltage , High

Temperature Threshold

Current Source for

Temperature Sense

Temp fault at VTS>V

V

LTF

Temp fault at VTS<V

V

HTF

95 100 105 µA

I

TS

2.5 V

LTF

0.5 V

HTF

BATTERY RECHARGE THRESHOLD

Recharge Threshold

Voltage

V

RCH

(1) For half-charge rate, V

Nov. 2011 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

is 1.25V.

SET

8

V

-0.125

BAT(RE

G)

V

BAT(RE

-0.1

G)

V

BAT(RE

G)

-0.075

V

Page 9

Data Sheet

Single-cell Li-Ion Charger IC with System Power Management AUR9807

Electrical Characteristics (Continued)

TA=25oC, VIN is within the recommended range, unless otherwise specified.

Parameter Symbol Test Condition Min Typ Max Unit

STAT1, STAT2, AND /PG

I

=5mA, requiring an

Low-level Output

Saturation Voltage

Input Leakage Current I

V

OL

LKG

ISET2, CE

t

CE Pin Hold-off Time

CE-HLDOF

F

Low-level Input Voltage VIL 0 1.1

High-level Input Voltage VIH 1.5

CE Pin

Low-level Input Current

CE Pin

High-level Input Current

ISET2 Pin

Low-level Input Current

ISET2 Pin

High-level Input Current

I

IL1

I

IH1

I

IL2

I

IH2

MODE

Mode Pin

Low-level Input Voltage

Mode Pin

High-level Input Voltage

Mode Pin

Low-level Input Current

V

IL

V

IH

I

IL

TIMERS

OL

external pull-up resistor>

0.25 V

1k

1 5 µA

CE fall low only 4 6 ms

V

-1

1

µA

V

V

=0.4V -20

ISET2

ISET2=VIN

40

Falling HiLow;

280k±10% applied when

0.975 1 1.025 V

low

Input R

hysteresis

sets external

MODE

VIL+

0.01

+

V

IL

0.024

V

-1 µA

Timer Set Factor K

External Resistor Limits R

Precharge Timer t

Timer Fault Recovery

Pull-up from OUT to BAT

Time Out Extension

Factor1

Time Out Extension

Factor2

t

TMR

TMR

PRECHG

R

FAULT

CHG=KTMR

30 100 k

1 k

x R

0.313 0.36 0.414 s/

TMR

0.115

t

x

CHG

0.125

x

t

CHG

The actual charge current less

K

EXT1

than 50% of maximum fast

2

charge current

The actual charge current less

K

EXT2

than 25% of maximum fast

4

charge current

0.135

x

t

CHG

s

Nov. 2011 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

9

Page 10

Data Sheet

Single-cell Li-Ion Charger IC with System Power Management AUR9807

Electrical Characteristics (Continued)

TA=25oC, VIN is within the recommended range, unless otherwise specified.

Parameter Symbol Test Condition Min Typ Max Unit

CHARGER SLEEP THRESHOLDS

Sleep-mode Entry

Threshold

Sleep-mode Exit

Threshold

V

V

SLPENT

SLPEXIT

DE-GLITCH TIME

De-glitch Time for

Charge Done Detection,

18.75 ms

Temperature Fault,

t

DEG

Recharge and Sleep

Mode Detection

START-UP CONTROL BOOT-UP

Boot-up Time t

BOOT-UP

On the first application

of input low

SWITCHING POWER SOURCE TIMING

Switching Power Source

from Input to Battery

t

SW-BAT

When input applied.

Measure from: [/PG: Lo

Hi to I

THERMAL SHUTDOWN REGULATION

>5 mA ]

IN

V

BAT

+0.195

120 150 180 ms

50 µs

V

BAT

+0.125

mV

Temperature Trip T

SHTDWN

Thermal Hysteresis TJ (Q1 and Q3 only) 25

Temperature Regulation

Limit

T

TJ (Q1 and Q3 only) 150

TJ (Q2) 110 130

J(REG)

°C

UVLO

Under-voltage Lockout V

Decreasing VIN 2.45 2.5 2.65 V

UVLO

Input power detected

Input Power Detection

Threshold

V

IN(DT)

when

V

IN>VBAT

=3.6V

V

BAT

: 3.5V 4V

V

IN

+ V

IN(DT)

55 80 130 mV

Hysteresis 27 mV

VREF OUTPUT

Output Regulation

Voltage

V

REF

Active only if ADP or

USB is present

3.3 V

Regulation Accuracy -5 +5 %

Output Current I

On Resistance R

Output Capacitance C

20 mA

REF

OUT to VREF 50

DS(ON)

1 µF

OUT

Nov. 2011 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

10

Page 11

Data Sheet

Single-cell Li-Ion Charger IC with System Power Management AUR9807

Electrical Characteristics (Continued)

TA=25oC, VIN is within the recommended range, unless otherwise specified.

SHORT CIRCUIT PROTECTION

Pull-up source from

Short-circuit Recovery

Between BAT to OUT

IN to OUT Short-circuit

Protection

I

R

OSH1

SHAC

Output Short-circuit

Detection Threshold,

V

OUT(SC1)

Power-on

Output Short-circuit

Detection Threshold,

Supplement mode

(V

BAT

– V

OUT

)>V

OUT(SC2)

V

OUT(SC2)

Indicates Short-circuit

Deglitch Time,

Supplement Mode Short

t

DGL(SC2)

Circuit

Maximum Short-current

for V

BAT>VOUT

I

SHORT

(2) For short current>I

, short-protection may not work due to avalanche breakdown phenomenon.

SHORT

BAT to OUT for

short-circuit recovery

V

OUT<VBAT

V

V

<1V 500

OUT

V

IN>VUVLO

V

IN>VBAT

>2.5V 160 200 240 mV

BAT

–200mV

and

+ V

IN(DT)

10 mA

0.9 1 1.1 V

512 µs

(2)

V

>2.5V 9 A

BAT

Typical Performance Characteristics

Figure 4. Output Voltage vs. Output Current Figure 5. Output Voltage vs. Charge Current

Nov. 2011 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

11

Page 12

Data Sheet

Single-cell Li-Ion Charger IC with System Power Management AUR9807

Typical Performance Characteristics (Continued)

V

OUT

2V/div

V

2V/div

I

CHG

0.5A/div

IN

Figure 6. Charge Current vs. Input Voltage Figure 7. Power On

V

2V/div

V

2V/div

I

CHG

1A/div

V

SYSOFF

2V/div

OUT

IN

V

2V/div

V

OUT

2V/div

I

CHG

0.5A/div

V

MODE

2V/div

IN

Time 1ms/div

Figure 8. SYSOFF Floating Figure 9. MODE Pin Pull Low

Time 20ms/div

Time 200µs/div

Nov. 2011 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

12

Page 13

Data Sheet

Single-cell Li-Ion Charger IC with System Power Management AUR9807

Typical Performance Characteristics (Continued)

V

IN

2V/div

V

OUT

2V/div

I

CHG

0.5A/div

V

2V/div

V

OUT

2V/div

I

CHG

0.5A/div

IN

V

V

2V/div

ISET2

ISET2

2V/div

Time 40µs/div Time 400µs/div

Figure 10. ISET2 Pin Pull High Figure 11. ISET2 Pin Pull Low

V

IN

2V/div

V

OUT

2V/div

I

CHG

0.5A/div

V

MODE

2V/div

Time 40µs/div

Figure 12. MODE Pin Pull High

Nov. 2011 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

13

Page 14

Data Sheet

Single-cell Li-Ion Charger IC with System Power Management AUR9807

Power Flow

The AUR9807 selects the power source automatically.

In the absence of the input source (AC adapter or USB),

the battery is chosen to power the system. Under this

circumstance, the AUR9807 consumes less than 5µ

Ampere; the power path resistance from the battery to

the system is only 40m

efficiency and elongate the battery discharge time. With

this stringent sleep current budget (<5µA), the

AUR9807 is still able to detect an output short

condition and cuts off the power path between the

battery and the system under short condition.

With the input power present, the MODE pin sets the

AUR9807 in adapter mode or USB mode. In adapter

mode, the AUR9807 does not limit the total current

MODE Pin

Level

Low

(3)

; all these guarantee a high

Power Source Selection and Charge Current Setting

AC Adapter

Yes USB ISET1, limitation depends on ISET2 setting

No Battery N/A

Loading Power

Source

directly, current limiting phenomenon occurs through

Adaptive Power Management in response to the output

voltage drop. The resistor connected to ISET1 pin sets

the maximum charging current. This maximum

charging current can be halved by pulling down the

ISET2 pin. In USB mode, the AUR9807 will limit the

total current within 450mA (ISET2=High) or 90mA

(ISET2=Low). The maximum charging current is still

set by the resistor connected to ISET1 pin; however,

because of this current limiting feature, the actual

charging current is usually less than 450mA (or 90mA).

(3) Q2 design value is 40m.

Charge Current Setting

High

Yes AC Adapter ISET1, half charging rate by setting ISET2 to low

No Battery N/A

Nov. 2011 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

14

Page 15

×

×

×

Data Sheet

Single-cell Li-Ion Charger IC with System Power Management AUR9807

Charge Function Descriptions

Charge Flow

Maximum Charging Current Setting

MODE=High ISET2=High

MODE=High ISET2=Low

MODE=Low

ISET2=High/L

ow

I

I

I

CHG

CHG

CHG

Pre-charge and Charge Done

Current Setting

I

maxCHG,

I

KV

=

SETSET

R

SET

2.5V,

=

maxSET,

PRECHG

I

TERM

=

I

=

10

I

I

KV

=

SETSET

R

SET

1.25V,

=

maxSET,

PRECHG

I

TERM

=

I

=

20

I

I

KV

=

SETSET

R

SET

2.5V,

=

maxSET,

PRECHG

I

TERM

=

I

=

25

10

maxCHG,

20

maxCHG,

10

maxCHG,

;

ModeAC;

maxCHG,

ModeAC;

maxCHG,

ModeUSB;

Nov. 2011 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

15

Page 16

Data Sheet

Single-cell Li-Ion Charger IC with System Power Management AUR9807

Charge Function Descriptions (Continued)

The maximum charging current, the pre-charge

current and charge done current setting are given in

the above table. The charging process begins with a

pre-charge phase; when the battery voltage reaches

the pre-charge threshold V

, the charger enters

LOWV

the constant current mode. At this stage, the charger

tries to charge the battery with the maximum

charging current (a constant); however, the actual

charging current may be lower due to Active Power

Management activated by large system loading or

insufficient input current capability. The thermal

fold-back mechanism also reduces the actual

charging current when the junction temperature is

over 110°C. The battery voltage rises gradually with

the constant current entering the battery.

When the battery voltage reaches V

BAT(REG)

, the

charger enters the constant voltage mode. At this

stage, the charger keeps the battery voltage at

V

BAT(REG)

with a decreasing charging current. When

the charging current drops below the charge done

current setting, nominally the charging process is

complete (this can be observed from the external

indicator). Depending on different versions, after the

charge done status indicated, the charger will stop

providing charging current completely or stay in

constant voltage mode till time out. When the battery

voltage drops below the recharge threshold, a new

charge cycle begins.

Example:

With a R

=1k, the maximum charging current is

SET

about 1A for ISET2=High and 0.5A for ISET2=Low.

The pre-charge current I

is 100mA. The charge

PRECHG

done current setting is 100mA for AC mode and

40mA for USB mode. Note the absolute values of

pre-charge current and charge done current setting do

not vary with ISET2.

Power Source Selecting

OUT

REF

i. V

ii. V

iii. V

IN<VBAT

BAT<VIN<VOUT(REG)

OUT(REG) +VDO(IN-OUT)<VIN

iv. 6V<V

: V

OUT=VBAT–VDO(BAT-OUT)

: V

: V

IN

OUT =VBAT–VDO(BAT-OUT)

OUT=VIN–VDO(IN-OUT)

<6V: V

OUT=VOUT(REG)

The AUR9807 selects power source automatically

depending on the voltage present at the input. When

V

is lower than V

IN

power the system. The output voltage V

V

DO(BAT-OUT)

than V

. When the input voltage V

and lower than 6V, the input source is used

BAT

, the battery is responsible to

BAT

is V

OUT

is higher

IN

BAT

to supply the system power; the output voltage

depends on V

Nov. 2011 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

. When V

IN

is lower than V

IN

OUT(REG)

the output voltage V

is high enough, which means that VIN>(V

–

V

DO(IN-OUT)

V

OUT(REG)

), the output voltage is regulated at

. When the input voltage V

6V, the current path between IN and OUT is cut off to

protect the chip; AUR9807 therefore selects the

Battery as the power source; the output voltage V

,

is then V

16

BAT–VDO(BAT-OUT)

OUT

is VIN–V

.

DO(IN-OUT)

is higher than

IN

; when V

OUT(REG)

IN

+

OUT

Page 17

Data Sheet

Single-cell Li-Ion Charger IC with System Power Management AUR9807

Charge Function Descriptions (Continued)

Active Power Management (APM)

AC MODE (MODE=HIGH)

i. V

APM-REG<VOUT

by R

SET

ii. V

BAT<VOUT<VAPM-REG

–I

OUT

max

iii. V

OUT<VBAT

USB 500 MODE (MODE=LOW ,

ISET2=HIGH)

i. V

APM-REG<VOUT

by R

SET

ii. V

BAT<VOUT<VAPM-REG

450mA – I

iii. V

OUT

OUT<VBAT

USB 100 MODE (MODE=LOW ,

ISET2=LOW)

i. V

APM-REG<VOUT

by R

SET

ii. V

BAT<VOUT<VAPM-REG

90mA–I

iii. V

OUT

OUT<VBAT

The active power management feature adjusts the

charging current to resist the output voltage drop due to

heavy system loading or insufficient input driving

capability. In the extreme situation, the charging current

flow would be reversed (the battery helps to supply the

system power). The active power management

regulation voltage V

APM-REG

= I

APM-SET×RAPM

V

: Normal Mode; I

: APM mode ; I

: BAT supply mode

: Normal Mode; I

: APM mode; I

: BAT supply mode

: Normal Mode; I

: APM mode; I

: BAT supply mode

is given by:

APM-REG

× SF

AUR9807

(4)

determined

CHG

CHG

determined

CHG

CHG

determined

CHG

CHG

=

=

= I

supply

When the output voltage is higher than V

input source is capable of providing the charging

current (set by R

) and output current (determined by

SET

system loading) simultaneously. When the output

voltage goes down and reaches V

APM-REG

increasing loading, AUR9807 starts to reduce the

charging current and tries to keep the output voltage at

V

. Because AUR9807 uses the remaining

APM-REG

available current to charge the battery, the charging

current can be estimated as I

the I

supply max

is determined by the driving capability of

supply max

– I

OUT

the AC adapter and AUR9807 itself (usually the

limiting factor is the AUR9807, and I

2A). The I

USB mode (I

and I

supply max

is determined by the ISET2 setting in

supply max

is about 450mA with ISET2 high,

supply max

is about 90mA with ISET2 low).

supply max

When the loading current keeps increasing and exceeds

I

supply max

voltage dropping below V

, the AUR9807 can not prevent the output

even the charging

APM-REG

current is reduced to zero. When the output voltage

drops below the battery voltage, the battery helps to

supply the loading current and keeps the output voltage

roughly at V

I

= I

OUT

supply max+IBAT

(4) R

APM

R

APM

. At this situation, we have:

BAT

(5)

<38k: V

>41k: The V

APM-REG=IAPM-SET×RAPM

APM-REG

is set to a

predetermined fixed value (4.26V)

(5) I

BAT

=(V

BAT–VOUT

) / (40m Power Path

Resistance)

Battery Temperature Protection

BAT

1µF

Li Battery

APM-REG

due to an

. In AC mode,

is about

×SF

, the

100µA

LOGIC UNIT

V

HTF

NTC

TS

V

LTF

Nov. 2011 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

17

Page 18

Data Sheet

Single-cell Li-Ion Charger IC with System Power Management AUR9807

Charge Function Descriptions (Continued)

The AUR9807 interrupts the charging process when the

battery temperature is out of normal range. It provides a

100µA sensing current to the negative-temperature

coefficient resistor (on the battery side) through the TS

pin. The battery protection is achieved by constantly

monitoring the voltage at the TS pin. When this voltage

is higher than V

V

(nominally 0.5V), an under-temperature or

HTF

(nominally 2.5V) or lower than

LTF

over-temperature condition is detected. For an usual

103AT-type NTC resistor, the corresponding

temperature range is between 0°C and 45°C. The

normal battery temperature range can be modified by

adjusting the NTC resistor or by adding extra resistor

network between the TS pin and the

negative-temperature coefficient resistor. The charging

process would resume after the battery temperature

goes back within the normal range.

Charge Timeout Setting

The charge timeout setting is programmed by the

resistor R

pin. The timeout setting is given by:

t

= K

CHG

A suggested 36k R

because the nominal value of K

actual charging process, the charging duration is

elongated if the charging current can not reach the

maximum current setting (again this relates to system

loading and environment temperature); therefore, it is

possible that the charging process is still on progress

while the 3.6 hrs timeout limit has been reached. To

circumvent this problem, the actual charging current is

monitored and the clock rate of the timer counter is

halved if the charging current is less than 50% of the

maximum fast charging current. This is equivalent to

modify the timeout setting temporarily by the following

equation:

t

= K

CHG

If the actual charging current is less than one fourth the

maximum fast charging current, the time out counter

rate is reduced to 25%. The temporary timeout setting

is given by:

t

= K

CHG

Nov. 2011 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

connected between the TMR and ground

TMR

× R

x K

TMR

TMR

gives a 3.6 hrs timeout setting

TMR

is 0.36 sec/. In the

TMR

× R

, where K

TMR

EXT1

=2

TMR

EXT1

EXT2

x K

TMR

× R

, where K

TMR

EXT2

=4

Once the abnormal condition is removed (high

temperature or heavy loading), the charging current

resumes the maximum values (set by R

), and the

SET

time out counter will operate in normal rate.

Charge Status Indicator

Status STAT1 STAT2

Pre-charge ON ON

Constant current and constant

voltage charge

ON OFF

Charge done OFF ON

Fault condition (time out,

sleep mode, or OTP)

OFF OFF

The open drain pins STAT1 and STAT2 provides the

information about the charger status when the CE pin

(chip enable) is set to high. The various charger status

and the corresponding STAT1 and STAT2 levels are

given in the above Table. Connect these pins to the host

processor or LEDS to indicate the charger status.

Short Circuit Protection

AUR9807 provides short circuit protection for both the

input and the battery. When V

is larger than V

IN

BAT

, AC

adapter (or USB port) is chosen as the power source. If

the output voltage is lower than 1V (V

than t

, a short circuit condition is detected; the

DGL(SC)

OUT(SC1)

) for more

power path between the input and the output will be cut

off. The charging process will be interrupted. A 500

resistor is used to pull up the output voltage; if the load

at the output is removed, the output voltage can be

pulled up and the short circuit condition is dissolved.

Similarly, when the battery is chosen as the power

source, an output voltage lower than the battery voltage

by 200mV (V

OUT(SC2)

) longer than t

DGL(SC)

will trigger

the short circuit protection mechanism (this

corresponds to a 5A loading current). A 10mA current

source is used to pull up the output and detect the

removal of the short condition. The power consumption

is less than 5µA under the battery supply mode;

however, AUR9807 is still able to monitor the output

voltage and detect a short circuit condition with this

limiting current budget.

SYSOFF Function

The SYSOFF function is used to cut off the power path

between the battery and the output. This means the

18

Page 19

Data Sheet

Single-cell Li-Ion Charger IC with System Power Management AUR9807

Charge Function Descriptions (Continued)

charger function can be disabled by pulling up the

SYSOFF pin; in this mode, the AUR9807 is almost a

regulator to power the system. Because the power path

is cut off, the output voltage will drop to zero when the

input source is removed, the battery will not be used to

power the system. The SYSOFF pin is pulled high

internally; therefore, this pin should be pulled to ground

for normal operation.

Recharge Process and Timer Fault

Elimination

If timeout occurs and the battery voltage is higher

than the recharge threshold, the charger will stay in

the charge done mode until the battery voltage drops

below the recharge threshold. Once the battery

voltage drops below the recharge threshold, a new

charge cycle starts.

If timeout occurs and the battery voltage is lower

than the recharge threshold, the charger will indicate

a fault condition and an internal resistor between

output and battery will try to pull up the battery

voltage. If the internal resistor is unable to pull up the

battery voltage to the recharge threshold, the charger

will stay in fault condition. Once the battery voltage

is higher than the recharge threshold, the charger

removes the pull-up resistor, leaves the fault

condition and stay in the charge done mode

temporarily. The charger then waits the battery

voltage to drop below the recharge threshold and

starts a new charge cycle.

Nov. 2011 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

19

Page 20

Data Sheet

Single-cell Li-Ion Charger IC with System Power Management AUR9807

PC Board Layout Considerations

It is important to pay special attention to the PCB

layout. The following provides some guidelines.

1. To obtain optimal performance, the decoupling

capacitor from the input terminal to GND and the

output filter capacitor from OUT to GND should be

placed as close as possible to the AUR9807, with

short trace runs to both signal and GND pins.

2. All low-current GND connections should be kept

V

OUT

H

V

+5V

OUT

JP5

3

2

1

separate from the high-current charge or discharge

paths from the battery. Use a single-point ground

technique incorporating both the small signal

ground path and the power ground path.

3. The high-current charge paths into IN and from the

BAT and OUT pins must be sized appropriately for

the maximum charge current in order to avoid

voltage drops in these traces.

STAT1

LED1 - Green

STAT2

LED2 - Red

R1 1k

R2 1k

H

TP4

TP3

R3 1k

C4

10µF/16V

R13

/opt

R14

30k

R11

27k

R8

1k

R10

10k

C5

/opt

R15

50k

R12

20k

R9

10k

V

OUT

/PG

R16

1k

V

V

IN

V

BAT

IN

C6

/opt

C7

/opt

R4

100k

D1

5.1V ZENER

L

3

2

ISET2

1

H

JP1

C2

10µF/35V

C3

1µF

R5

100k

3

2

1

JP2

L

MODE

H

1

2

3

4

5

6

7

8

10

TP1

ISET1

R6

100k

C1

0.1µF

U1

VREF

STAT1

STAT2

IN

BAT

BAT

ISET2

MODE

ISET1

AUR9807

3

L

2

CE

1

H

JP3

GND

GND

/PG

OUT

OUT

OUT

TMR

APM

SYSOFF

L

SYS_OFF

H

LED3 - Green

20

19

18

17

16

15

14

13

129

TSCE

11

3

2

1

JP4

TP2

R7

100k

TMR

APM

TS

H

Figure 13. The Evaluation Board Schematic

Nov. 2011 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

20

Page 21

Data Sheet

Single-cell Li-Ion Charger IC with System Power Management AUR9807

PC Board Layout Considerations (Continued)

Figure 14. Top Side View of The Evaluation Board

Figure 15. Bottom Side View of The Evaluation Board

Nov. 2011 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

21

Page 22

Data Sheet

Single-cell Li-Ion Charger IC with System Power Management AUR9807

Typical Application

Figure 16. Typical Application of AUR9807

Nov. 2011 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

22

Page 23

Data Sheet

Single-cell Li-Ion Charger IC with System Power Management AUR9807

Mechanical Dimensions

QFN-4.5

×3.5-20

Unit: mm(inch)

Nov. 2011 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

23

Page 24

BCD Semiconductor Manufacturing Limited

IMPORTANT NOTICE

http://www.bcdsemi.com

BCD Semiconductor Manufacturing Limited reserves the right to make changes without further notice to any products or specifications herein. BCD Semiconductor Manufacturing Limited does not assume any responsibility for use of any its products for any

IMPORTANT NOTICE

IMPORTANT NOTICE

particular purpose, nor does BCD Semiconductor Manufacturing Limited assume any liability arising out of the application or use

of any its products or circuits. BCD Semiconductor Manufacturing Limited does not convey any license under its patent rights or

BCD Semiconductor Manufacturing Limited reserves the right to make changes without further notice to any products or specifi-

BCD Semiconductor Manufacturing Limited reserves the right to make changes without further notice to any products or specifi-

other rights nor the rights of others.

cations herein. BCD Semiconductor Manufacturing Limited does not assume any responsibility for use of any its products for any

cations herein. BCD Semiconductor Manufacturing Limited does not assume any responsibility for use of any its products for any

particular purpose, nor does BCD Semiconductor Manufacturing Limited assume any liability arising out of the application or use

particular purpose, nor does BCD Semiconductor Manufacturing Limited assume any liability arising out of the application or use

MAIN SITE

of any its products or circuits. BCD Semiconductor Manufacturing Limited does not convey any license under its patent rights or

of any its products or circuits. BCD Semiconductor Manufacturing Limited does not convey any license under its patent rights or

- Headquarters

BCD (Shanghai) Micro-electronics Limited

other rights nor the rights of others.

other rights nor the rights of others.

No. 1600, Zi Xing Road, Shanghai ZiZhu Science-based Industrial Park, 200241, P. R.C.

Tel: +86-021-2416-2266, Fax: +86-021-2416-2277

MAIN SITE

MAIN SITE

REGIONAL SALES OFFICE

- Headquarters

BCD Semiconductor Manufacturing Limited

BCD Semiconductor Manufactur ing Limited

Shenzhen Office

- Wafer Fab

No. 1600, Zi Xing Road, Shanghai ZiZhu Science-based Industrial Park, 200241, China

Shanghai SIM-BCD Semiconductor Manufacturing Co., Ltd., Shenzhen Office

Shanghai SIM-BCD Semiconductor Manufacturing Limited

Tel: +86-21-24162266, Fax: +86-21-24162277

Unit A Room 1203,Skyworth Bldg., Gaoxin Ave.1.S., Nanshan District

800, Yi Shan Road, Shanghai 200233, China

Shenzhen 518057, China

Tel: +86-21-6485 1491, Fax: +86-21-5450 0008

REGIONAL SALES OFFICE

Tel: +86-0755-8660-4900, Fax: +86-0755-8660-4958

Shenzhen Office

REGIONAL SALES OFFICE

Shanghai SIM-BCD Semiconductor Manufacturing Co., Ltd., Shenzhen Office

Taiwan Office (Hsinchu)

Shenzhen Office

Unit A Room 1203, Skyworth Bldg., Gaoxin Ave.1.S., Nanshan District, Shenzhen,

BCD Semiconductor (Taiwan) Company Limited

Shanghai SIM-BCD Semiconductor Manufacturing Co., Ltd. Shenzhen Office

China

8F, No.176, Sec. 2, Gong-Dao 5th Road, East District

Advanced Analog Circuits (Shanghai) Corporation Shenzhen Office

Tel: +86-755-8826 7951

HsinChu City 300, Taiwan, R.O.C

Room E, 5F, Noble Center, No.1006, 3rd Fuzhong Road, Futian District, Shenzhen 518026, China

Fax: +86-755-8826 7865

Tel: +886-3-5160181, Fax: +886-3-5160181

Tel: +86-755-8826 7951

Fax: +86-755-8826 7865

- Wafer Fab

Shanghai SIM-BCD Semiconductor Manufacturing Co., Ltd.

800 Yishan Road, Shanghai 200233, China

Tel: +021-6485-1491, Fax: +86-021-5450-0008

- Wafer Fab

BCD Semiconductor Manufacturing Limited

Shanghai SIM-BCD Semiconductor Manufacturing Co., Ltd.

Taiwan Office (Taipei)

- IC Design Group

800 Yi Shan Road, Shanghai 200233, China

BCD Semiconductor (Taiwan) Company Limited

Advanced Analog Circuits (Shanghai) Corporation

Tel: +86-21-6485 1491, Fax: +86-21-5450 0008

3F, No.17, Lane 171, Sec. 2, Jiu-Zong Rd., Nei-Hu Dist., Taipei(114), Taiwan, R.O.C

8F, Zone B, 900, Yi Shan Road, Shanghai 200233, China

Tel: +886-2-2656 2808

Tel: +86-21-6495 9539, Fax: +86-21-6485 9673

Fax: +886-2-2656-2806/26562950

Taiwan Office

BCD Semiconductor (Taiwan) Company Limited

USA Office

Taiwan Office

4F, 298-1, Rui Guang Road, Nei-Hu District, Taipei,

BCD Semiconductor Corp.

BCD Semiconductor (Taiwan) Company Limited

Tai wan

48460 Kato Road, Fremont, CA 94538, USA

4F, 298-1, Rui Guang Road, Nei-Hu District, Taipei,

Tel: +886-2-2656 2808

Tel: +1-510-668-1950

Taiwan

Fax: +886-2-2656 2806

Fax: +1-510-668-1990

Tel: +886-2-2656 2808

Fax: +886-2-2656 2806

USA Office

Korea Office

BCD Semiconductor Limited Korea office.

Room 101-1112, Digital-Empire II, 486 Sin-dong,

Yeongtong-Gu, Suwon-city, Gyeonggi-do, Korea

Tel: +82-31-695-8430

BCD Semiconductor Corp.

USA Office

30920 Huntwood Ave. Hayward,

BCD Semiconductor Corporation

CA 94544, USA

30920 Huntwood Ave. Hayward,

Tel : +1-510-324-2988

CA 94544, U.S.A

Fax: +1-510-324-2788

Tel : +1-510-324-2988

Fax: +1-510-324-2788

Loading...

Loading...