Page 1

AP2161/ AP2171

1A SINGLE CHANNEL CURRENT-LIMITED POWER SWITCH

Description

The AP2161 and AP2171 are integrated high-side power switches

optimized for Universal Serial Bus (USB) and other hot-swap

applications. The family of devices complies with USB 2.0 and

available with both polarities of Enable input. They offer current and

thermal limiting and short circuit protection as well as controlled rise

time and under-voltage lockout functionality. A 7ms deglitch capability

on the open-drain Flag output prevents false over-current reporting

and does not require any external components.

All devices are available in SO-8, MSOP-8EP, SOT25, and

U-DFN2018-6 packages

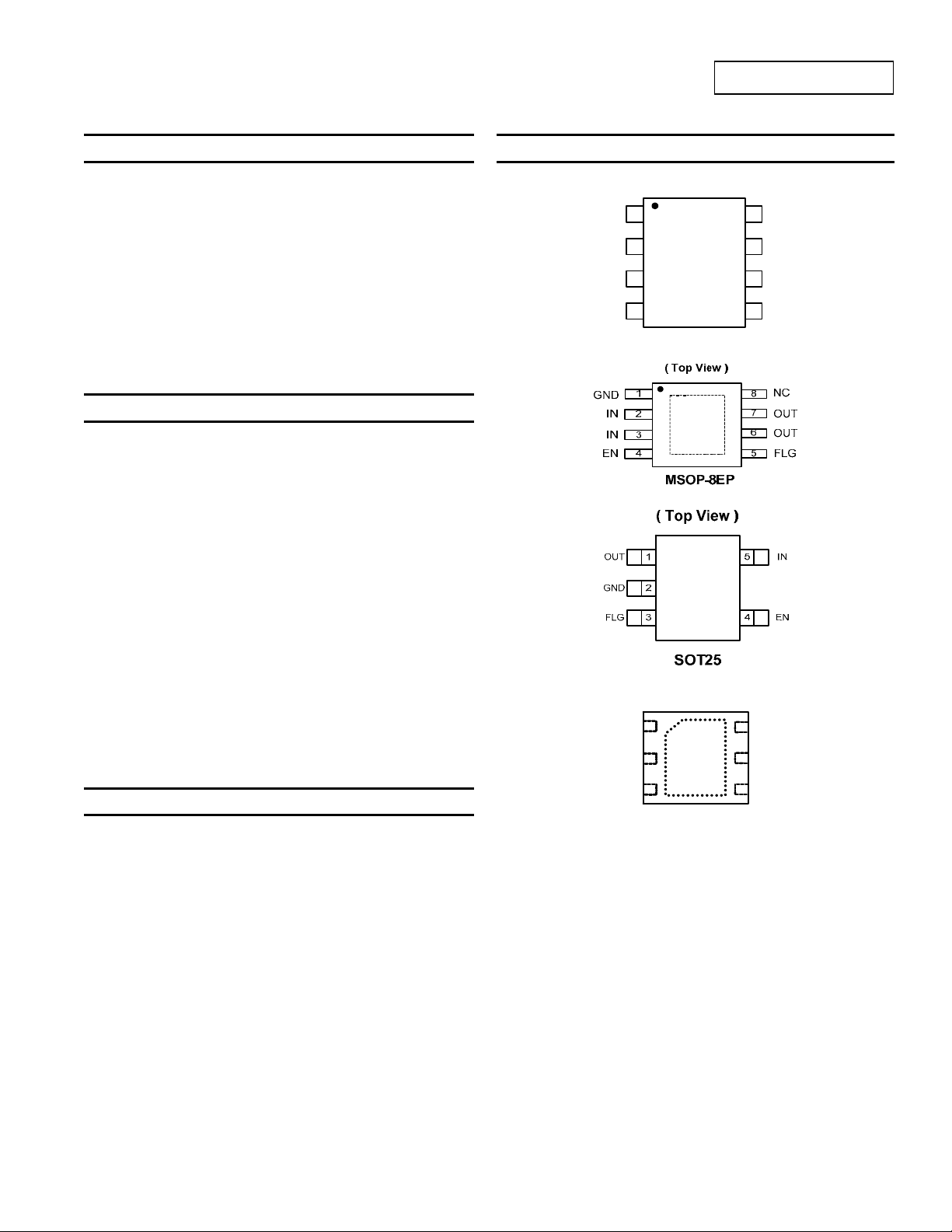

Pin Assignments

GND

IN

EN

( Top View )

1

2

3

IN

4

SO-8

8

NC

7

OUT

6

OUT

5

FLG

Features

Single USB Port Power Switches

Over-Current and Thermal Protection

1.5A Accurate Current Limiting

Reverse Current Blocking

95m On-Resistance

Input Voltage Range: 2.7V – 5.5V

0.6ms Typical Rise Time

Very Low Shutdown Current: 1µA (max)

Fault Report (FLG) with Blanking Time (7ms typ)

ESD Protection: 4kV HBM, 300V MM

Active Low (AP2161) or Active High (AP2171) Enable

Ambient Temperature Range: -40°C to +85°C

SOT25, SO-8, MSOP-8EP (Exposed Pad), and U-DFN2018-6:

Available in “Green” Molding Compound (No Br, Sb)

Totally Lead-Free & Fully RoHS Compliant (Notes 1 & 2)

Halogen and Antimony Free. “Green” Device (Note 3)

UL Recognized, File Number E322375

IEC60950-1 CB Scheme Certified

GND

IN

( Top View )

1

2

3

6

5

4

OUT

OUT

FLGEN

Applications

Consumer electronics – LCD TV & Monitor, Game Machines

Communications – Set-Top-Box, GPS, Smartphone

Computing – Laptop, Desktop, Servers, Printers, Docking

Station, HUB

Notes: 1. No purposely added lead. Fully EU Directive 2002/95/EC (RoHS) & 2011/65/EU (RoHS 2) compliant.

2. See http://www.diodes.com/quality/lead_free.html for more information about Diodes Incorporated’s definitions of Halogen- and Antimony-free, "Green"

and Lead-free.

3. Halogen- and Antimony-free "Green” products are defined as those which contain <900ppm bromine, <900ppm chlorine (<1500ppm total Br + Cl) and

<1000ppm antimony compounds.

AP2161/ AP2171

Document number: DS31564 Rev. 7 - 2

www.diodes.com

1 of 18

U-DFN2018-6

March 2013

© Diodes Incorporated

Page 2

AP2161/ AP2171

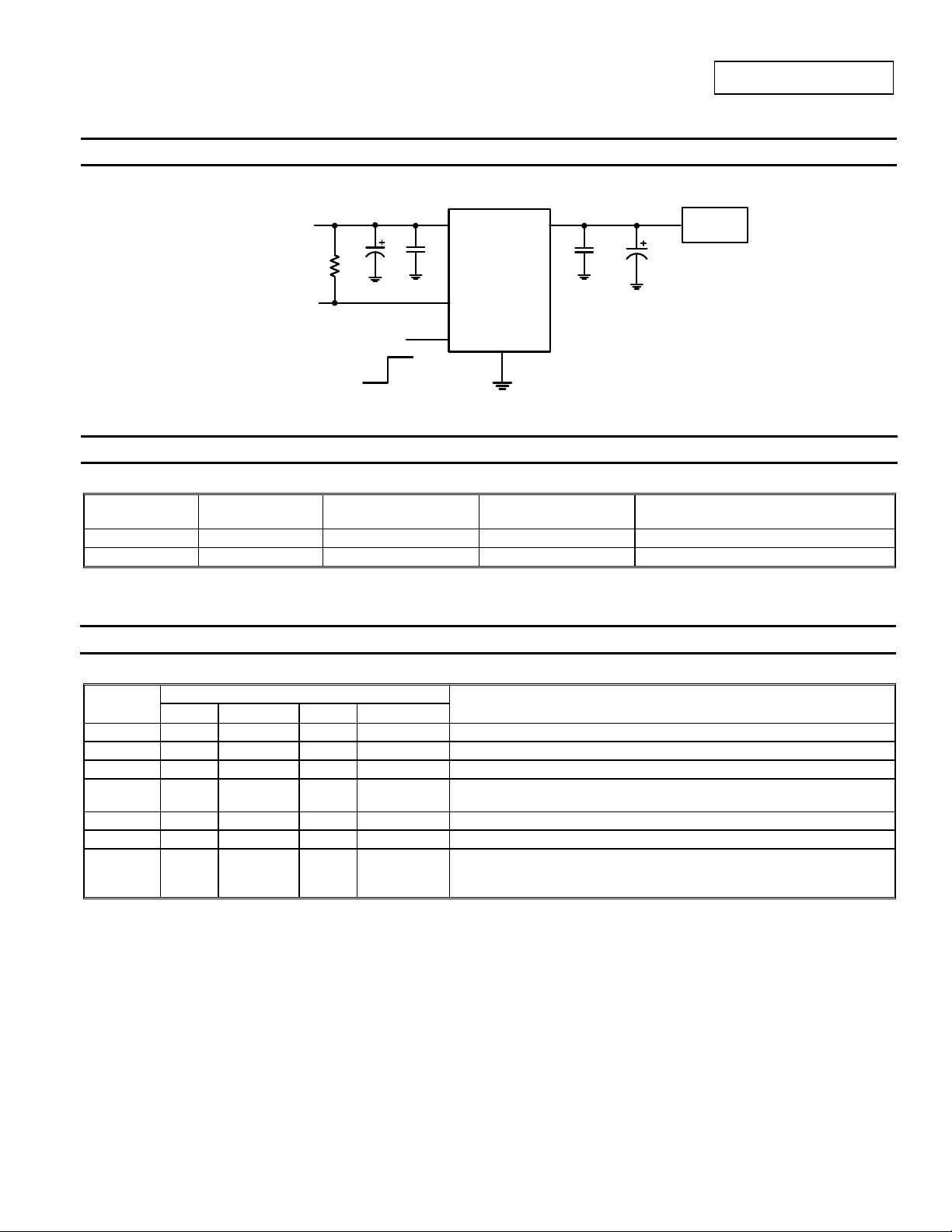

Typical Applications Circuit

AP2171 Enable Active High

Power Supply

2.7V to 5.5V

10uF

10k

ON

OFF

IN

0.1uF

FLG

EN

GND

OUT

0.1uF

120uF

Load

Available Options

Part Number Channel Enable Pin (EN)

AP2161 1 Active Low 1.5A 1.0A

AP2171 1 Active High 1.5A 1.0A

Current Limit

(typ)

Recommended Maximum Continuous

Load Current

Pin Descriptions

Pin

Name

GND 1 1 2 1 Ground

IN

EN 4 4 4 3 Enable input, active low (AP2161) or active high (AP2171)

FLG 5 5 3 4

OUT

NC

Exposed tab - Exposed tab - Exposed tab

SO-8 MSOP-8EP SOT25 U-DFN2018-6

2, 3 2, 3 5 2 Voltage input pin (all IN pins must be tied together externally )

6, 7 6, 7 1 5, 6 Voltage output pin (all OUT pins must be tied together externally )

8 8 N/A N/A No internal connection; recommend tie to OUT pins

AP2161/ AP2171

Document number: DS31564 Rev. 7 - 2

Pin Number

Function

Over-current and over-temperature fault report; open-drain flag is active low w hen

triggered

Exposed pad.

It should be connected to GND and thermal mass for enhanced thermal

impedance. It sho u l d n ot be u s e d as elec t r i cal g r o u nd co n d ucti o n p a t h.

2 of 18

www.diodes.com

March 2013

© Diodes Incorporated

Page 3

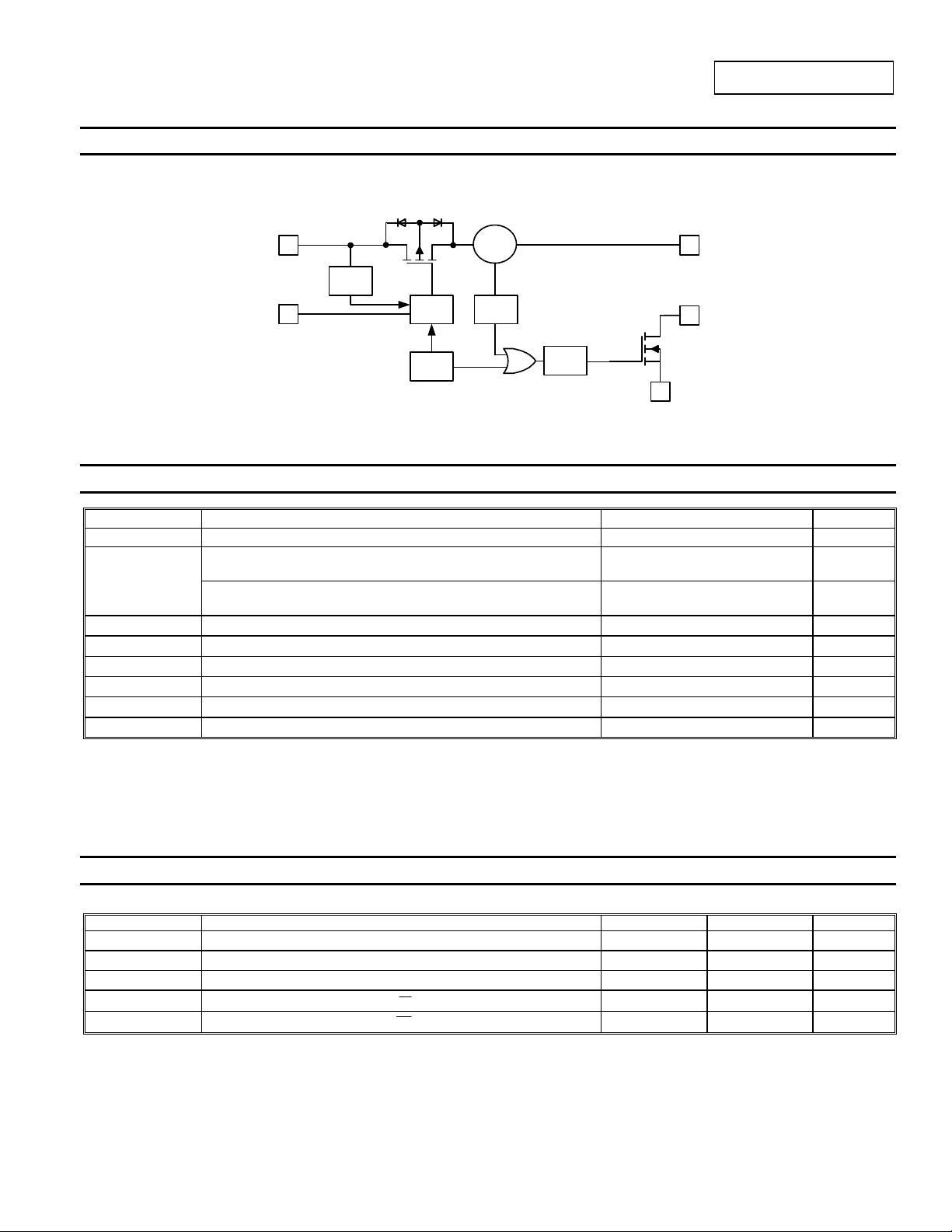

Functional Block Diagram

AP2161/ AP2171

AP2161, AP2171

IN

UVLO

EN

Driver

Thermal

Sense

Current

Sense

Current

Limit

Deglitch

GND

OUT

FLG

Absolute Maximum Ratings (@T

= +25°C, unless otherwise specified.)

A

Symbol Parameter Ratings Units

ESD HBM Human Body Model ESD Protection 4 kV

Machine Model ESD Protection

ESD MM

for MSOP-8EP, SOT25 packages

Machine Model ESD Protection

for U-DFN2018-6, SO-8 packages

VIN

V

OUT

V

EN , VFLG

I

LOAD

T

J(MAX)

TST

Caution: Stresses greater than the 'Absolute Maximum Ratings' specified above, may cause permanent damage to the device. These are stress ratings only;

functional operation of the device at these or any other conditions exceeding those indicated in this specification is not implied. Device reliability may be

affected by exposure to absolute maximum rating conditions for extended periods of time.

Semiconductor devices are ESD sensitive and may be damaged by exposure to ESD events. Suitable ESD precautions should be taken when handling

and transporting these devices

Note: 4. UL Recognized Rating from -30°C to +70°C (Diodes qualified

Input Voltage 6.5 V

Output Voltage

Enable Voltage 6.5 V

Maximum Continuous Load Current Internal Limited A

Maximum Junction Temperature 150 °C

Storage Temperature Range (Note 4) -65 to +150 °C

T

from -65°C to +150°C)

ST

400 V

300 V

VIN +0.3

V

Recommended Operating Conditions (@T

= +25°C, unless otherwise specified.)

A

Symbol Parameter Min Max Units

V

IN

I

OUT

T

A

VIH High-Level Input Voltage on EN or EN

VIL Low-Level Input Voltage on EN or EN

Input voltage 2.7 5.5 V

Output Current 0 1.0 A

Operating Ambient Temperature -40 +85

2.0

VIN

C

0 0.8 V

V

AP2161/ AP2171

Document number: DS31564 Rev. 7 - 2

3 of 18

www.diodes.com

March 2013

© Diodes Incorporated

Page 4

AP2161/ AP2171

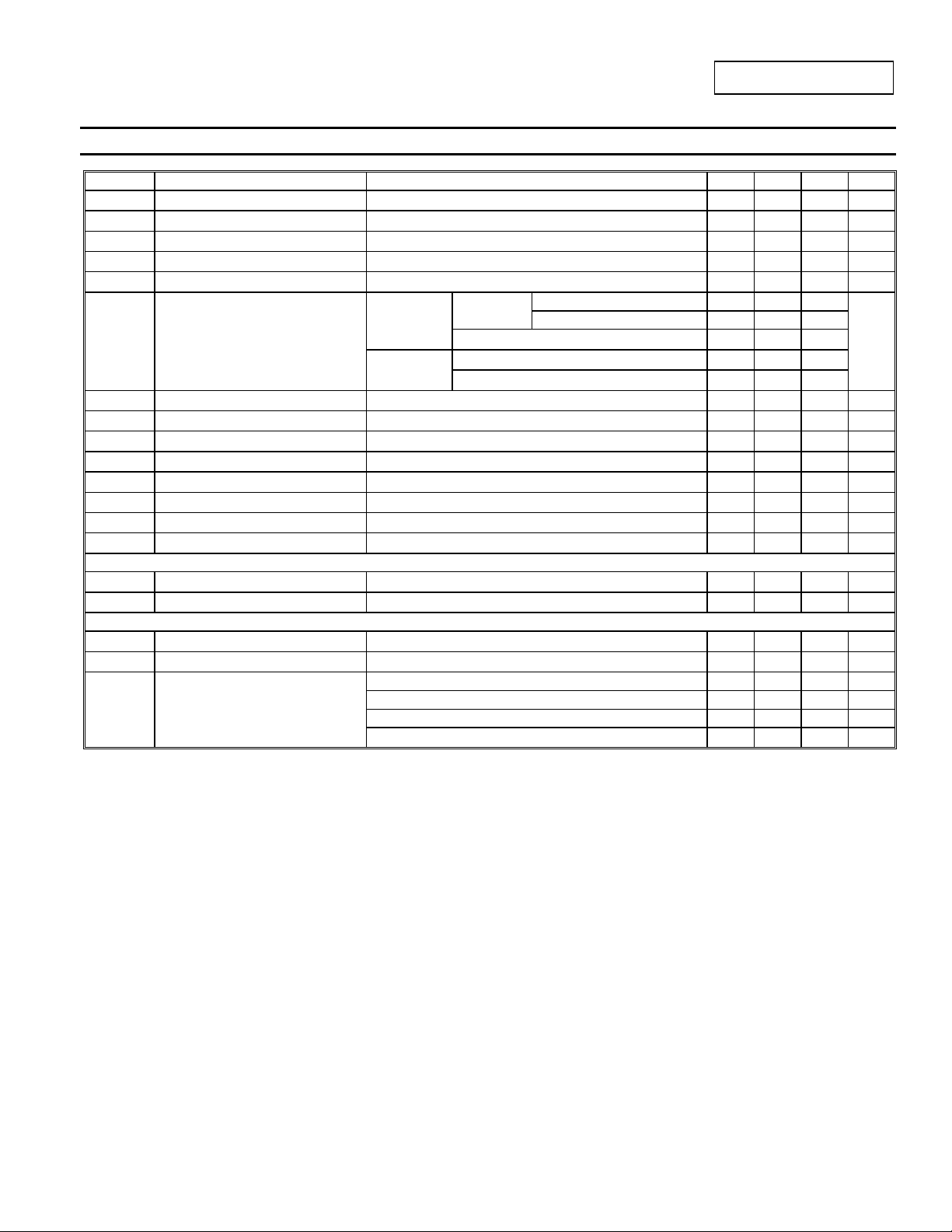

Electrical Characteristics (@T

= +25°C, VIN = +5V, unless otherwise specified.)

A

Symbol Parameter Test Conditions Min Typ Max Unit

V

UVLO

I

SHDN

I

LEAK

I

REV

R

DS(ON)

I

SHORT

I

LIMIT

I

I

SINK

t

D(ON)

t

D(OFF)

Input UVLO

Input Shutdown Current

Input Quiescent Current

I

Q

R

= 1k

LOAD

Disabled, I

Enabled, I

OUT

OUT

= 0

= 0

Input Leakage Current Disabled, OUT grounded 1 µA

Reverse Leakage Current

Switch on-resistance

Short-Circuit Current Limit

Over-Load Current Limit

Current limiting trigger threshold

Trig

EN Input leakage

Output turn-on delay time

Output turn-on rise time

tR

Output turn-off delay time

Output turn-off fall time

tF

Disabled, V

V

= 5V,

IN

I

= 1A

OUT

VIN = 3.3V,

= 1A

I

OUT

= 0V, V

IN

T

= +25°C

A

OUT

-40°C TA +85°C

T

= +25°C

A

-40°C TA +85°C

= 5V, I

REV

at VIN

SOT25, MSOP-8EP, SO-8 95 115

U-DFN2018-6 90 110

Enabled into short circuit, CL = 68µF

V

= 5V, V

IN

= 4.6V, CL = 68µF, -40°C TA +85°C

OUT

Output Current Slew rate (<100A/s) , CL=68µF

V

= 5V

EN

CL = 1µF, R

CL = 1µF, R

CL = 1µF, R

CL = 1µF, R

LOAD

LOAD

LOAD

LOAD

= 10

= 10

= 10

= 10

1.6 1.9 2.5 V

0.5 1 A

45 70 µA

1 µA

140

m

120 140

170

1.2 A

1.1 1.5 1.9 A

2.0 A

1 µA

0.05 ms

0.6 1.5 ms

0.01 ms

0.05 0.1 ms

Fault Flag

R

t

Blank

FLG output FET on-resistance

FLG

FLG blanking time

I

= 10mA

FLG

C

= 10µF, CL = 68µF

IN

20 40

4 7 15 ms

Over-Temperature Protection

T

SHDN

T

Thermal Shutdown Threshold

Thermal Shutdown Hysteresis 25

HYS

Enabled, R

LOAD

= 1k

140

C

C

SO-8 (Note 5) 110 °C/W

Thermal Resistance Junction-to-

JA

Ambient

MSOP-8EP (Note 6) 60 °C/W

SOT25 (Note 7) 157 °C/W

U-DFN2018-6 (Note 8) 70 °C/W

Notes: 5. Test condition for SO-8: Device mounted on FR-4, 2oz copper, with minimum recommended pad layout.

6. Test condition for MSOP-8EP: Device mounted on 2” x 2” FR-4 substrate PC board, 2oz copper, with minimum recommended pad on top layer and

thermal vias to bottom layer ground plane.

7. Test condition for SOT25: Device mounted on FR-4, 2oz copper, with minimum recommended pad layout.

8. Test condition for U-DFN2018-6: Device mounted on FR-4 2-layer board, 2oz copper, with minimum recommended pad on top layer and 3 vias to bottom

layer 1.0”x1.4” ground plane.

AP2161/ AP2171

Document number: DS31564 Rev. 7 - 2

4 of 18

www.diodes.com

March 2013

© Diodes Incorporated

Page 5

Typical Performance Characteristics

AP2161/ AP2171

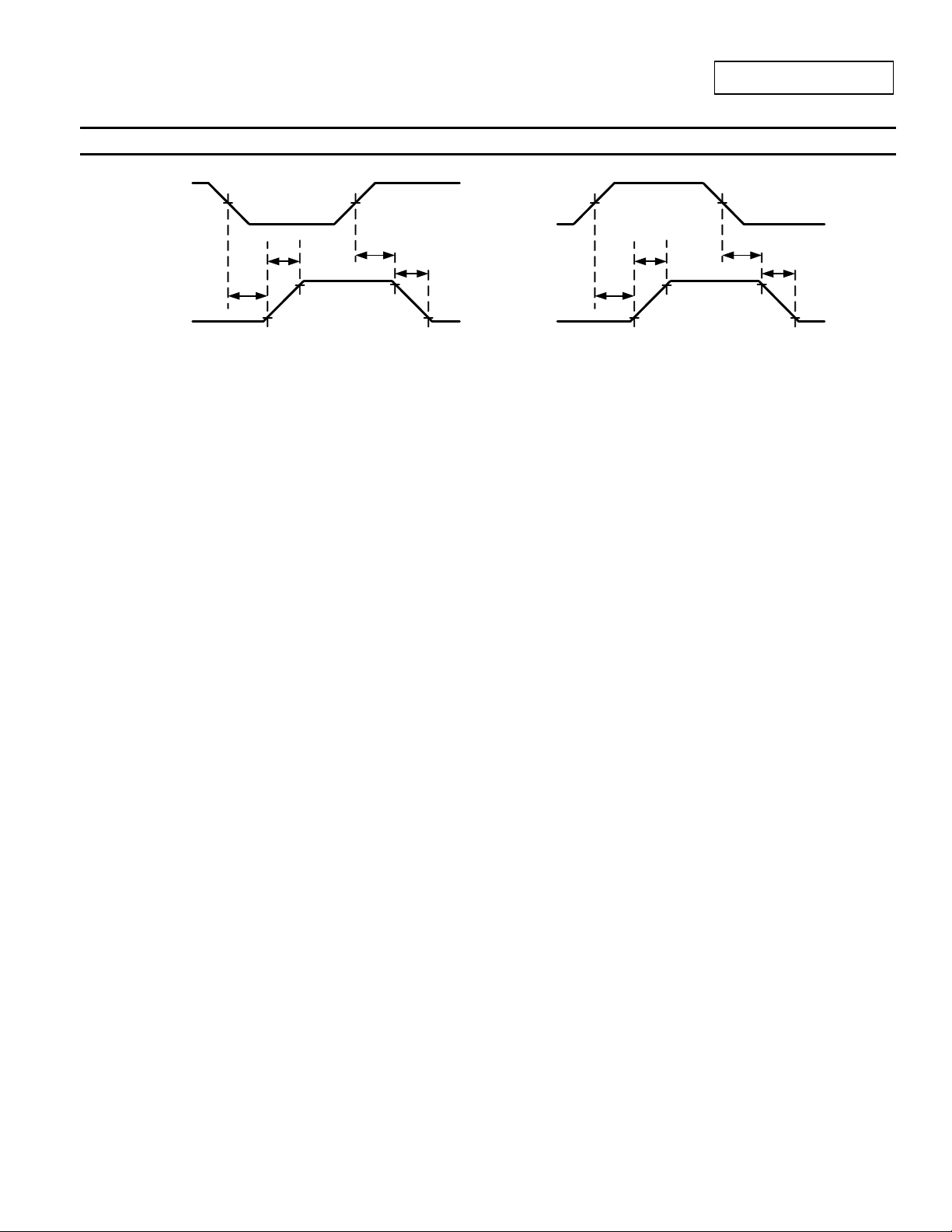

Ven

5V/div

Vout

2V/div

V

EN

V

OUT

50%

T

D(ON)

T

10%

50%

T

R

90%

D(OFF)

90%

10%

T

F

V

EN

50%

T

T

D(ON)

V

OUT

10%

50%

T

R

90%

D(OFF)

90%

10%

T

F

Figure 1 Voltage Waveforms: AP2161 (left), AP2171 (right)

All Enable Plots are for AP2171 Active High

Turn-On Delay and Rise Time

500µs/div

CL = 1µF

TA = +25°C

RL = 10

Ven

5V/div

Vout

2V/div

Turn-Off Delay and Fall Time

CL = 1µF

TA = +25°C

RL = 10

500µs/div

Turn-On Delay and Rise Time

Ven

5V/div

Vout

2V/div

AP2161/ AP2171

Document number: DS31564 Rev. 7 - 2

500µs/div

Ven

5V/div

Vout

2V/div

CL = 100µF

TA = +25°C

RL = 10

5 of 18

www.diodes.com

Turn-Off Delay and Fall Time

500µs/div

CL = 100µF

TA = +25°C

RL = 10

March 2013

© Diodes Incorporated

Page 6

Typical Performance Characteristics (cont.)

Short Circuit Current,

Device Enabled Into Short

AP2161/ AP2171

Inrush Current

Ven

5V/div

Iout

500mA/div

Vflag

2V/div

Iout

1A/div

V

IN

TA = +25°C

CL = 68µF

500µs/div

1 Ω Load Connected to Enabled Device

= 5V

V

IN

TA = +25°C

CL = 68µF

= 5V

Ven

5V/div

Iout

200mA/div

=100µF

C

L

C

=220µF

L

CL=470µF

V

= 5V

IN

TA = +25°C

RL = 5

1ms/div

2Ω Load Connected to Enabled Device

V

= 5V

IN

Vflag

2V/div

Iout

1A/div

TA = +25°C

=

Short Circuit with Blanking Time and Recovery

Vout

5V/div

Vflag

5V/div

Iout

1A/div

AP2161/ AP2171

Document number: DS31564 Rev. 7 - 2

2ms/div

20ms/div

V

= 5V

IN

TA = +25°C

CL = 68µF

6 of 18

www.diodes.com

Vflag

5V/div

Iout

500mA/di

v

Ven

5V/div

Vin

5V/div

2ms/div

Power On

1ms/div

TA = +25°C

CL = 68µF

RL = 5

March 2013

© Diodes Incorporated

Page 7

Typical Performance Characteristics (cont.)

UVLO Increasing

Vin

2V/div

TA = +25°C

CL = 68µF

RL = 5

Vin

2V/div

AP2161/ AP2171

UVLO Decreasing

TA = +25°C

CL = 68µF

RL = 5

Iout

500mA/div

1ms/div

Turn-On Time vs Input Voltage

750

700

650

600

550

500

450

400

Turn-On Time (us)

350

300

250

1.522.533.544.555.56

Input V o ltage (V)

CL = 1µF

RL = 10

=+

°

Rise Time vs I nput Vol t age

650

600

550

500

450

400

Rise Time (us)

350

300

250

22.533.544.555.56

Input V o ltage (V)

CL = 1µF

RL = 10

TA = +25°C

Iout

500mA/div

10ms/div

Turn-O f f Time vs I nput Vol tage

30

29

29

28

28

27

27

Turn-Off Time (us)

26

26

25

1.5 2 2.5 3 3.5 4 4.5 5 5.5 6

Input Voltage (V)

Fall Time vs Input Voltage

22

22

21

21

Fall Time (us )

20

20

19

22.533.544.555.56

Input Voltage (V)

CL = 1µF

RL = 10

=+

CL = 1µF

RL = 10

=+

°

°

AP2161/ AP2171

Document number: DS31564 Rev. 7 - 2

7 of 18

www.diodes.com

March 2013

© Diodes Incorporated

Page 8

Typical Performance Characteristics (cont.)

Supply Current , Out put Enabled vs Am bi e nt Tem per a t ur e

68

63

58

53

48

43

38

33

Supply Current, Output Enab led (uA)

28

Vin=5.5V

-60 -40 -20 0 20 40 60 80 100

Vin=5.0V

Vin=3.3V

Ambient Tem perature (°C)

Vin=2.7V

AP2161/ AP2171

Supply Current, Out put Disabl ed vs A m bi ent Temperat ur e

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

Supply Current, Output Disabled (uA)

0.0

-60 -40 -20 0 20 40 60 80 100

Vin=3.3V

Vin=5.0V

Vin=2.7V

Ambient Temperature (°C)

Vin=5.5V

Static Drain- Source O n-St ate Resi stance vs A m bi ent

170

160

150

140

130

120

110

Resistance (mΩ)

100

Static Drain-Source On-State

90

80

-60 -40 -20 0 20 40 60 80 100

Undervoltage Lockout vs Am bi ent Tem perat ur e

2.20

2.10

2.00

1.90

1.80

Undervoltage Lockout (V)

1.70

1.60

-60 -40 -20 0 20 40 60 80 100

Temperature

Vin=2.7V

Vin=3.3V

Vin=5V

Amb ient Tem peratu re (°C)

UVLO Rising

UVLO Falling

Amb ient Temp erature (°C)

Short-Circ ui t O ut put Current vs A m bi ent Tem perature

1.56

CL=100µF

1.55

1.54

1.53

1.52

1.51

1.50

1.49

1.48

1.47

Short-Circuit Output Current (A)

1.46

1.45

-60 -40 -20 0 20 40 60 80 100

1.99

1.98

1.97

1.96

1.95

1.94

1.93

1.92

1.91

Threshold Trip Current (A)

1.90

1.89

1.88

2.8 3.3 3.8 4.3 4.8 5.3

Vin=2.7V

Ambient Temperature (°C)

Threshold Tri p Curr ent v s I nput Vol t age

Vin=3.3V

Input Voltage (V)

Vin=5.0V

Vin=5.5V

TA = +25°C

CL= 68µF

AP2161/ AP2171

Document number: DS31564 Rev. 7 - 2

8 of 18

www.diodes.com

March 2013

© Diodes Incorporated

Page 9

Typical Performance Characteristics (cont.)

Curr e n t Li m it Re s p on s e v s Pe a k Cu rre nt

120

100

80

V

= 5V

60

40

Current Limit Response (us)

20

0

024681012

Peak Current (A)

IN

TA = +25°C

AP2161/ AP2171

Document number: DS31564 Rev. 7 - 2

9 of 18

www.diodes.com

AP2161/ AP2171

March 2013

© Diodes Incorporated

Page 10

AP2161/ AP2171

Application Information

Power Supply Considerations

A 0.01-F to 0.1-F X7R or X5R ceramic bypass capacitor between IN and GND, close to the device, is recommended. Placing a high-value

electrolytic capacitor on the input (10-F minimum) and output pin(s) is recommended when the output load is heavy. This precaution reduces

power-supply transients that may cause ringing on the input. Additionally, bypassing the output with a 0.01-F to 0.1-F ceramic capacitor improves

the immunity of the device to short-circuit transients.

Over-current and Short Circuit Protection

An internal sensing FET is employed to check for over-current conditions. Unlike current-sense resistors, sense FETs do not increase the series

resistance of the current path. When an over-current condition is detected, the device maintains a constant output current and reduc es the output

voltage accordingly. Complete shutdown occurs only if the fault stays long enough to activate thermal limiting.

Three possible overload conditions can occur. In the first condition, the output has been shorted to GND before the device is enabled or before VIN

has been applied. The AP2161/AP2171 senses the short circuit and immediately clamps output current to a certain safe level namely I

LIMIT

.

In the second condition, an output short or an overload occurs while the device is enabled. At the instance the overload occurs, highe r curr ent m ay

flow for a very short period of time before the current limit function can react. After the current limit function has tripped (reached the over-current

trip threshold), the device switches into current limiting mode and the current is clamped at I

LIMIT

.

In the third condition, the load has been gradually increased beyond the recommended operating current. The current is permitted to rise until the

current-limit threshold (I

) is reached or until the thermal limit of the device is exceeded. The AP2161/AP2171 is capable of delivering current up

TRIG

to the current-limit threshold without damaging the device. Once the threshold has been reached, the device switches into its current limiting mode

and is set at I

LIMIT

.

Note that when the output has been shorted to GND at extremely low temperature (< -30°C), a minimum 120-F electrolytic capacitor on the output

pin is recommended. A correct capacitor type with capacitor voltage rating and temperature characteristics must be properly chosen so that

capacitance value does not drop too low at the extremely low temperature operation. A recommended capacitor should have temperature

characteristics of less than 10% variation of capacitance change when operated at extremely low temp. Our recommended aluminum electrolytic

capacitor type is Panasonic FC series.

FLG Response

When an over-current or over-temperature shutdown condition is encountered, the FLG open-drain output goes a ctive low after a nominal 7-ms

deglitch timeout. The FLG output remains low until both over-current and over-temperature conditions are removed. Connecting a heavy capacitive

load to the output of the device can cause a momentary over-current condition, which does not trigger the FLG due to the 7-ms deglitch timeout.

The AP2161/AP2171 is designed to eliminate false over-current reporting without the need of external components to remove unwanted pulses.

Power Dissipation and Junction Temperature

The low on-resistance of the internal MOSFET allows the small surface-mount packages to pass large current. Using the maximum operating

ambient temperature (T

= R

P

D

DS(ON)

× I2

) and R

A

, the power dissipation can be calculated by:

DS(ON)

Finally, calculate the junction temperature:

T

= PD x R

J

JA

+ TA

Where:

T

= Ambient temperature °C

A

R

= Thermal resistance

JA

= Total power dissipation

P

D

Thermal Protection

Thermal protection prevents the IC from damage when heavy-overload or short-circuit faults are present for extended periods of time. The

AP2161/AP2171 implements a thermal sensing to monitor the operating junction temperature of the power distribution switch. Once the die

temperature rises to approximately 145°C due to excessive power dissipation in an over-current or short-circuit condition, the internal thermal

sense circuitry turns the power switch off, thus preventing the power switch from damage. H ysteresis is built into the thermal sense circuit allowing

the device to cool down approximately 25°C before the switch turns back on. The switch continues to cycle in this manner until the load fault or

input power is removed. The FLG open-drain output is asserted when an over-temperature shutdown or over-current occurs with 7-ms deglitch.

AP2161/ AP2171

Document number: DS31564 Rev. 7 - 2

10 of 18

www.diodes.com

March 2013

© Diodes Incorporated

Page 11

AP2161/ AP2171

Application Information (cont.)

Under-Voltage Lockout (UVLO)

Under-voltage lockout function (UVLO) keeps the internal power switch from being turned on until the power supply has reached at least 1.9V, even

if the switch is enabled. Whenever the input voltage falls below approximately 1.9V, the power switch is quickly turned off. This facilitates the design

of hot-insertion systems where it is not possible to turn off the power switch before input power is removed.

Host/Self-Powered And Bus-Powered HUBs

Hosts and self-powered hubs have a local power supply that powers the embedded functions and the downstream ports (see Figure 2). This power

supply must provide from 5.25V to 4.75V to the board side of the downstream connection under full-load and no-load conditions. Hosts and SPHs

are required to have current-limit protection and must report over-current conditions to the USB controller. Typical SPHs are desktop PCs, monitors,

printers, and stand-alone hubs.

Figure 2 Typical One-Port USB Host / Self-Powered Hub

Generic Hot-Plug Applications

In many applications it may be necessary to remove modules or pc boards while the main unit is still operating. These are considered hot-plug

applications. Such implementations require the control of current surges seen by the main power supply and the card being inserted. The most

effective way to control these surges is to limit and slowly ramp the current and voltage being applied to the card, similar to the way in which a

power supply normally turns on. Due to the controlled rise times and fall times of the AP2161/AP2171, these devices can be used to provide a

softer start-up to devices being hot-plugged into a powered system. The UVLO feature of the AP2161/AP2171 als o ensures that the switch is off

after the card has been removed, and that the switch is off during the next insertion.

By placing the AP2161/AP2171 between the VCC input and the rest of the circuitry, the input power reaches these devices first after insertion. The

typical rise time of the switch is approximately 1ms, providing a slow voltage ramp at the output of the device. This implementation controls system

surge current and provides a hot-plugging mechanism for any device.

AP2161/ AP2171

Document number: DS31564 Rev. 7 - 2

11 of 18

www.diodes.com

March 2013

© Diodes Incorporated

Page 12

Ordering Information

AP2161/ AP2171

Part Number Package Code Packaging

AP21X1WG-7 W SOT25 3000/Tape & Reel -7

AP21X1SG-13 S SO-8 2500/Tape & Reel -13

AP21X1MPG-13 MP MSOP-8EP 2500/Tape & Reel -13

AP21X1FMG-7 FM U-DFN2018-6 3000/Tape & Reel -7

Quantity Part Number Suffix

7”/13” Tape and Reel

Marking Information

(1) SO-8

( Top view )

8765

Logo

Part Number

8 : Active Low

9 : Active High

AP21X X

YY WW X X

1 : 1 Channel

G : Green

YY

: Year : 08, 09,10~

WW

: Week : 01~52; 52

represents 52 and 53 week

: Internal Code

X

2

1

(2) MSOP-8EP

34

( Top view )

87 65

Logo

Part Number

8 : Active Low

9 : Active High

AP21X X

234

1

YWXE

A~ Z : Green

MSOP-8EP

Y : Year : 0~9

W : Week : A~Z : 1~26 week;

a~z : 27~52 week; z represents

52 and 53 w eek

1 : 1 Channel

AP2161/ AP2171

Document number: DS31564 Rev. 7 - 2

12 of 18

www.diodes.com

March 2013

© Diodes Incorporated

Page 13

Marking Information (cont.)

(3) SOT25

AP2161/ AP2171

( Top View )

(4) U-DFN2018-6

AP2161/ AP2171

Document number: DS31564 Rev. 7 - 2

5

7

4

XX : Identification code

Y

: Year 0~9

W X

XX

Y

: Week : A~Z : 1~26 week;

W

a~z : 27~52 week; z represents

52 and 53 week

X

1 2 3

: A~Z : Green

Device Package type Identification Code

AP2161W SOT25 HT

AP2171W SOT25 HU

Device Package type Identification Code

AP2161FM U-DFN2018-6 HT

AP2171FM U-DFN2018-6 HU

13 of 18

www.diodes.com

March 2013

© Diodes Incorporated

Page 14

Package Outline Dimensions (All dimensions in mm.)

Please see AP02002 at http://www.diodes.com/datasheets/ap02002.pdf for latest version.

(1) Package Type: SO-8

E1

E

A1

Detail ‘A’

L

0.254

Gaug e Plane

Seating Plane

7°~9

°

Detail ‘A’

A3

h

°

45

A2

e

b

D

A

(2) Package Type: MSOP-8EP

D

x

y

E

E2

1

e

8Xb

A1

A

D

AP2161/ AP2171

Document number: DS31564 Rev. 7 - 2

A3

A2

D1

E3

E1

Gauge Plane

Seating Plane

See Detail C

0.25

4

X

1

c

4

X

1

0

°

a

0

°

L

Detail C

14 of 18

www.diodes.com

AP2161/ AP2171

Dim Min Max

Dim Min Max Typ

SO-8

A - 1.75

A1 0.10 0.20

A2 1.30 1.50

A3 0.15 0.25

b 0.3 0.5

D 4.85 4.95

E 5.90 6.10

E1 3.85 3.95

e 1.27 Typ

h - 0.35

L 0.62 0.82

0 8

All Dimensions in mm

MSOP-8EP

A - 1.10 A1 0.05 0.15 0.10

A2 0.75 0.95 0.86

A3 0.29 0.49 0.39

b 0.22 0.38 0.30

c 0.08 0.23 0.15

D 2.90 3.10 3.00

D1 1.60 2.00 1.80

E 4.70 5.10 4.90

E1 2.90 3.10 3.00

E2 1.30 1.70 1.50

E3 2.85 3.05 2.95

e - - 0.65

L 0.40 0.80 0.60

a 0° 8° 4°

x - - 0.750

y - - 0.750

All Dimensions in mm

March 2013

© Diodes Incorporated

Page 15

Package Outline Dimensions (All dimensions in mm.)

Please see AP02002 at http://www.diodes.com/datasheets/ap02002.pdf for latest version.

(3) Package Type: SOT25

A

H

K

J

(4) Package Type: U-DFN2018-6

A

A1

Pin#1 ID

E

AP2161/ AP2171

Document number: DS31564 Rev. 7 - 2

B C

N

D

e

L

A3

D

D2

L

E2

z

b

M

SEATING PLANE

15 of 18

www.diodes.com

AP2161/ AP2171

Dim Min Max Typ

SOT25

A 0.35 0.50 0.38

B 1.50 1.70 1.60

C 2.70 3.00 2.80

D

0.95

H 2.90 3.10 3.00

J 0.013 0.10 0.05

K 1.00 1.30 1.10

L 0.35 0.55 0.40

M 0.10 0.20 0.15

N 0.70 0.80 0.75

0° 8°

All Dimensions in mm

U-DFN2018-6

Dim Min Max Typ

A 0.545 0.605 0.575

A1 0 0.05 0.02

A3

0.13

b 0.15 0.25 0.20

D 1.750 1.875 1.80

D2 1.30 1.50 1.40

e

0.50

E 1.95 2.075 2.00

E2 0.90 1.10 1.00

L 0.20 0.30 0.25

z

0.30

All Dimensions in mm

March 2013

© Diodes Incorporated

Page 16

Suggested Pad Layout

Please see AP02001 at http://www.diodes.com/datasheets/ap02001.pdf for the latest version.

(1) Package Type: SO-8

(2) Package Type: MSOP-8EP

(3) Package Type: SOT25

AP2161/ AP2171

Document number: DS31564 Rev. 7 - 2

Y2

X

Dimensions Value (in mm)

X 0.60

C1

C2

Y

X C

G

X1

C2C2

G

Z

Y

X

Y

Y1

C1

16 of 18

www.diodes.com

Y 1.55

C1 5.4

C2 1.27

Dimensions

C 0.650

G 0.450

X 0.450

X1 2.000

Y 1.350

Y1 1.700

Y2 5.300

Dimensions Value (in mm)

Z

G

X

Y

C1 2.40

C2

Value

(in mm)

3.20

1.60

0.55

0.80

0.95

AP2161/ AP2171

March 2013

© Diodes Incorporated

Page 17

Suggested Pad Layout (cont.)

Please see AP02001 at http://www.diodes.com/datasheets/ap02001.pdf for the latest version.

(4) Package Type: U-DFN2018-6

XC

Taping Orientation (Note 9)

For U-DFN2018-6

Y1

Y

Dimensions Value (in mm)

C 0.50

G 0.20

X 0.25

X1 1.60

Y 0.35

G

X1

Y1 1.20

AP2161/ AP2171

Notes: 9. The taping orientation of the other package type can be found on our website at http://www.diodes.com/datasheets/ap02007.pdf

AP2161/ AP2171

Document number: DS31564 Rev. 7 - 2

17 of 18

www.diodes.com

March 2013

© Diodes Incorporated

Page 18

AP2161/ AP2171

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS DOCUMENT,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

(AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes

without further notice to this document and any product described herein. Diodes Incorporated does not assume any liability arising out of the

application or use of this document or any product described herein; neither does Diodes Incorporated convey any license under its patent or

trademark rights, nor the rights of others. Any Customer or user of this document or products described herein in such applications shall assume

all risks of such use and will agree to hold Diodes Incorporated and all the companies whose products are represented on Diodes Incorporated

website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized sales channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorize d application, Customers shall indemnify and

hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees arising out of, directly or

indirectly, any claim of personal injury or death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names and markings

noted herein may also be covered by one or more United States, international or foreign trademarks.

This document is written in English but may be translated into multiple languages for reference. Onl y the English version of this document is the

final and determinative format released by Diodes Incorporated.

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems without the express

written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided in the

labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected to cause the

failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices or systems, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any

use of Diodes Incorporated products in such safety-critical, life support devices or systems, notwithstanding any devices- or systems-related

information or support that may be provided by Diodes Incorporated. Further, Customers must fully indemnify Diodes Incorporated and its

representatives against any damages arising out of the use of Diodes Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2013, Diodes Incorporated

www.diodes.com

IMPORTANT NOTICE

LIFE SUPPORT

AP2161/ AP2171

Document number: DS31564 Rev. 7 - 2

18 of 18

www.diodes.com

March 2013

© Diodes Incorporated

Loading...

Loading...